Patents

Literature

41results about How to "Improve debugging work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

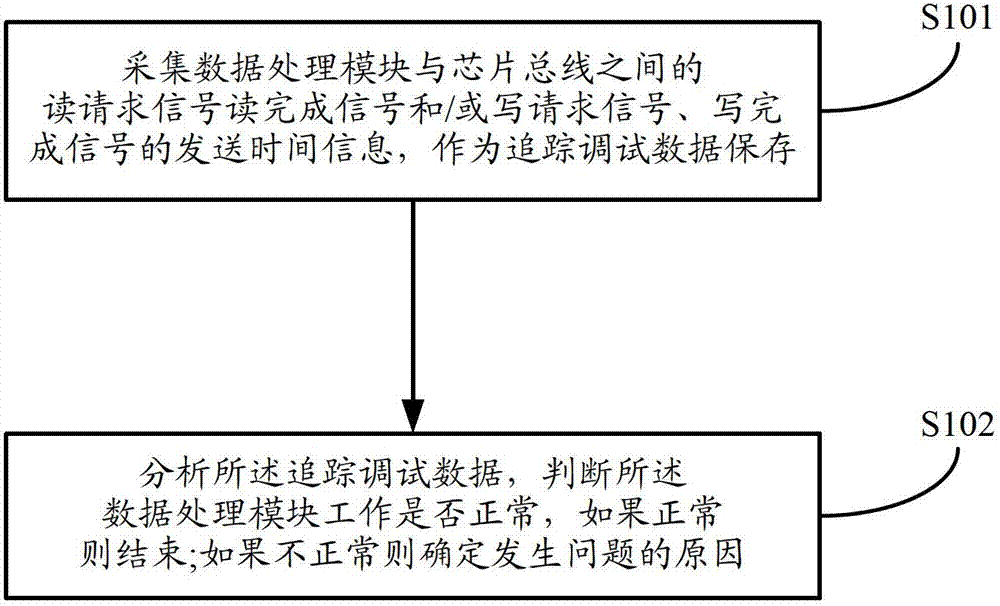

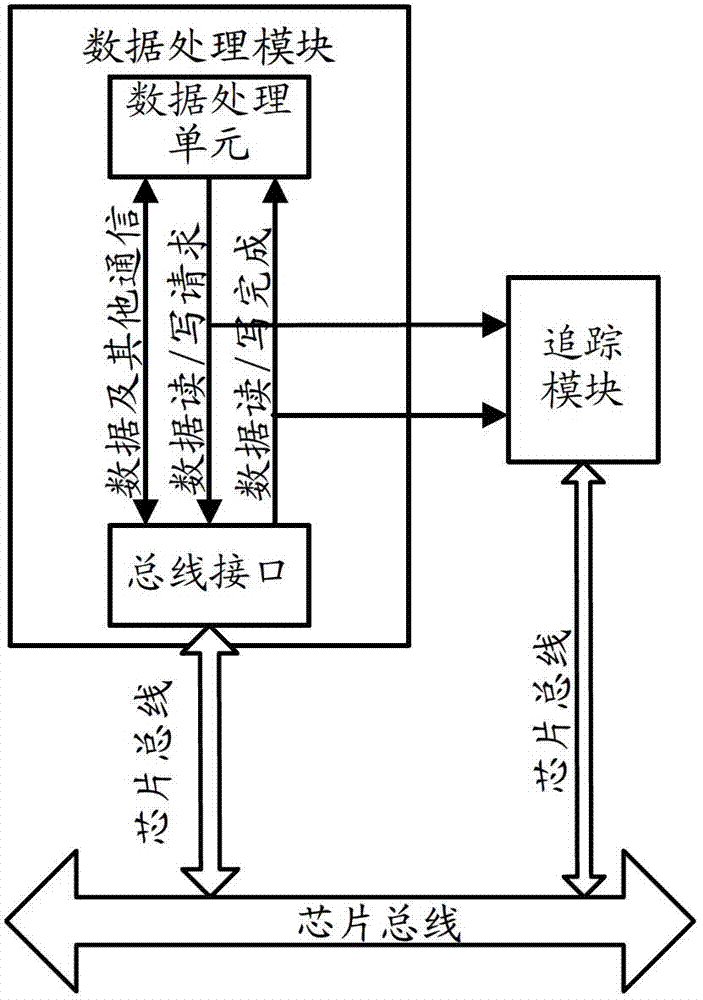

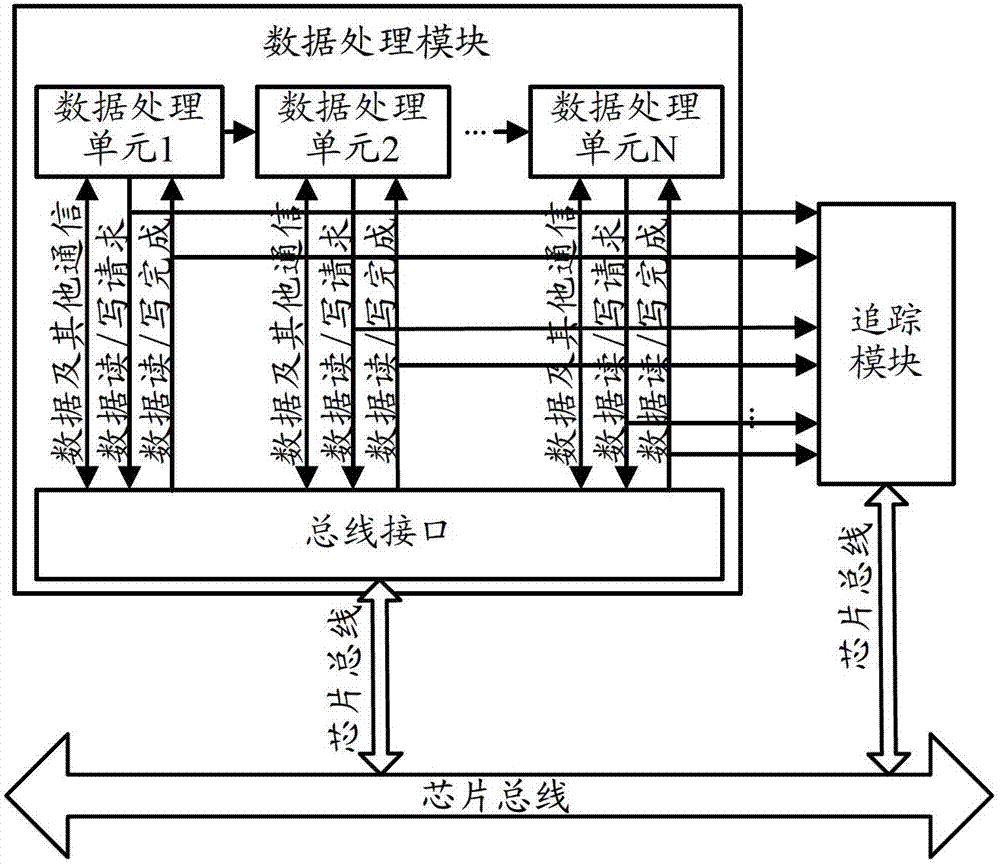

Method and device for chip tracking debugging of system on chip

InactiveCN103593271AAccurately locate the problemReduce workloadFunctional testingEmbedded systemReal time tracking

Disclosed are a method and device for tracing and debugging a chip of a system on chip (SOC), the method comprising: collecting the send time information of read request signals and read completion signals between a data processing module and a chip bus, and / or the send time of write request signals and write completion signals between the data processing module and the chip bus; the send time information as tracing and debugging data is stored; analyzing the tracing and debugging data to judge whether the data processing module works normally, and if so, stopping tracing and debugging the chip of the SOC, if not, determining the cause of occurring problem. By recording related reading and writing operation time of the data processing module, real-time tracing the whole data process procedure, the present invention can understand not only the running status of a module internal logic, but also the congestion situation of a SOC chip internal bus; almost not increasing any cost of original system processing; by analyzing the whole data process procedure, the present invention can locate the problem accurately and rapidly, reduce the workload of the designer and tester, improve the efficiency of debugging.

Owner:ZTE CORP

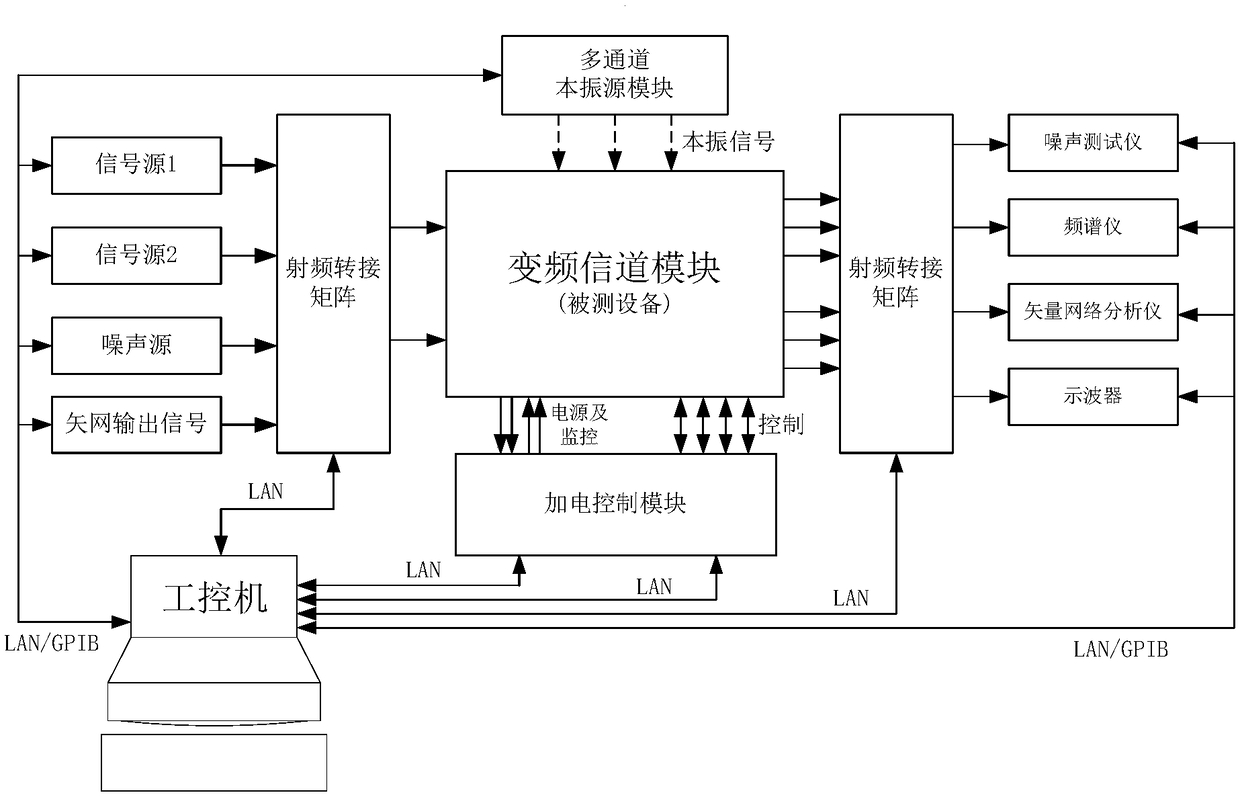

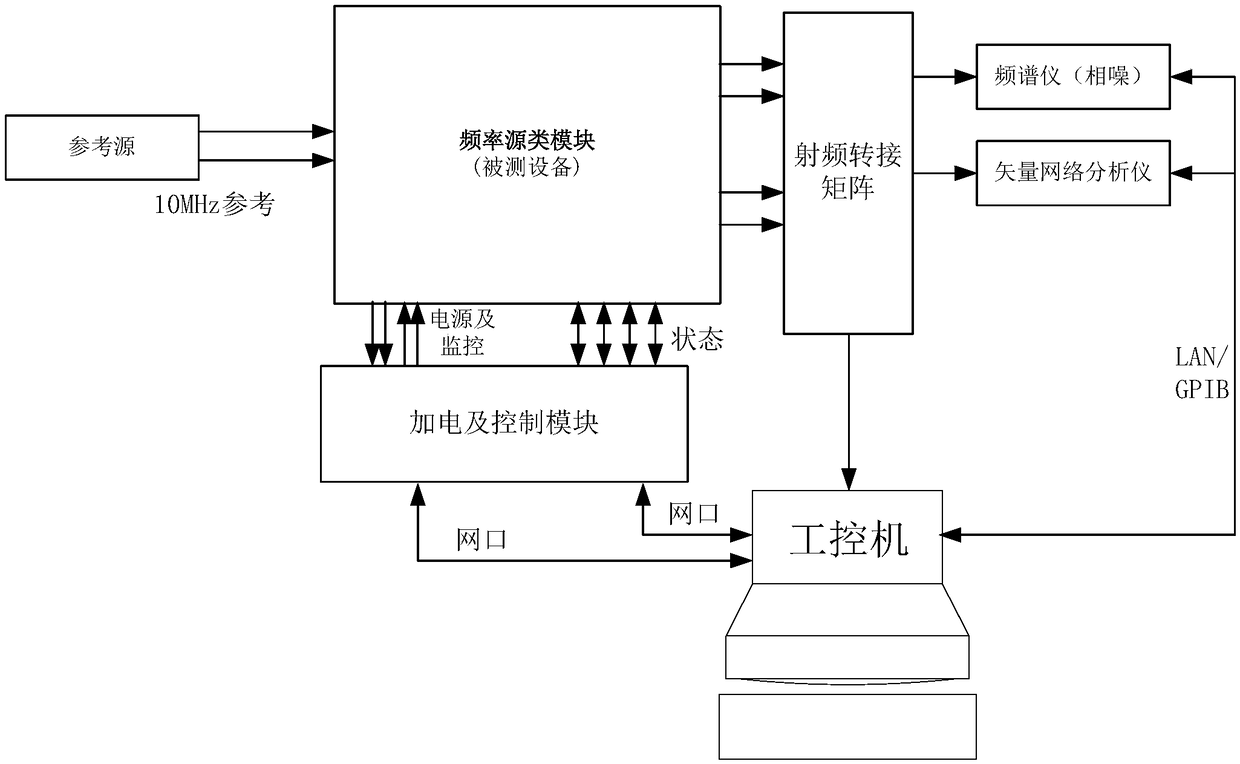

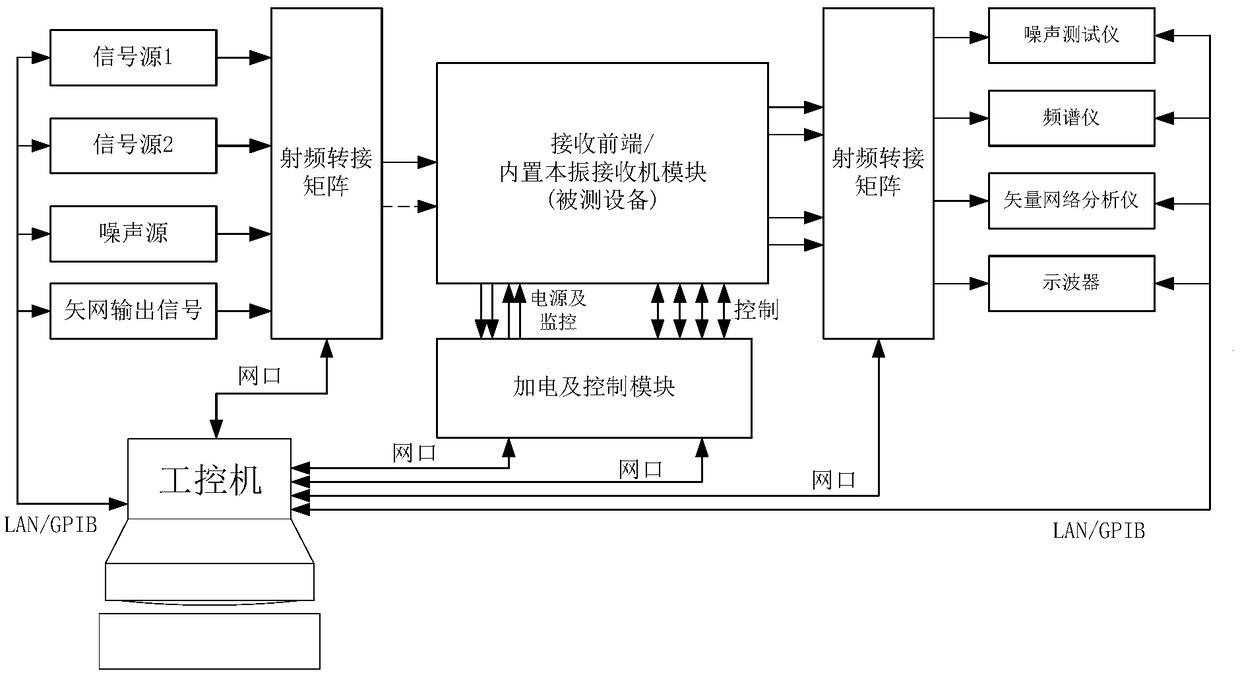

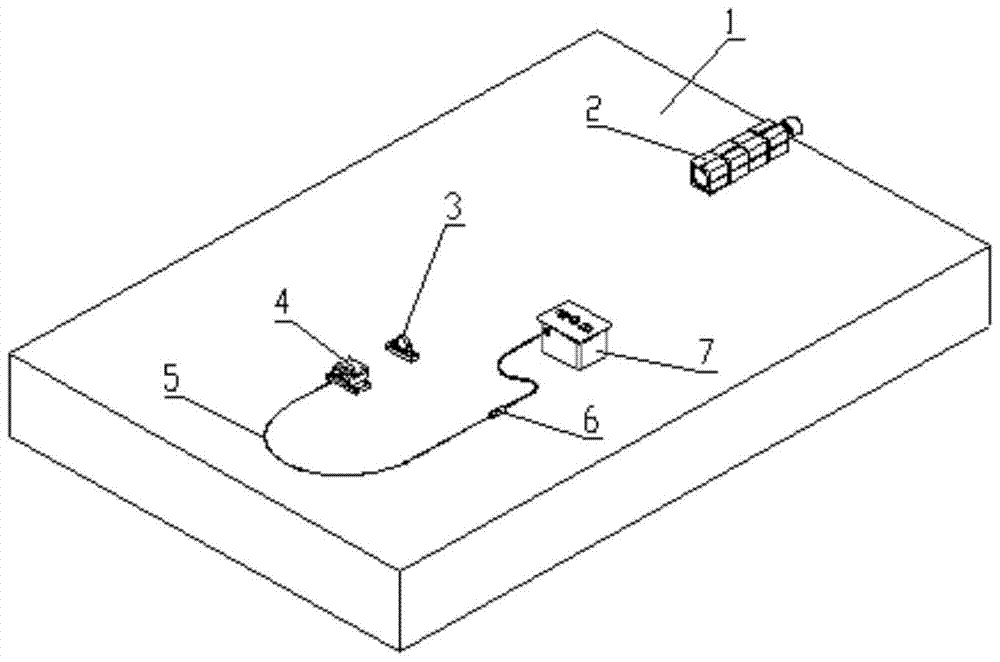

High-coverage automatic radio frequency index test device

InactiveCN109302713AQuick verificationReduce cost inputNetwork planningLocal oscillator signalPhase noise

The invention discloses a high-coverage automatic radio frequency index test device. By using the device provided by the invention, quick tests with high coverage can be performed on multi-channel radio frequency indexes of various types of equipment under test. The device provided by the invention is implemented via the technical scheme as follows: an input radio frequency interconnection matrixmodule receives multiple signal sources, a noise source and an output signal of a vector network, and provides source signals such as a microwave vector signal source, the noise source and the vectornetwork output signal to the equipment under test; the equipment under test receives a low-phase noise local oscillator signal and a reference clock signal from a multi-channel local oscillator sourcemodule; the equipment under test completes automatic switching of multiple channels via an output radio frequency interconnection matrix module, and transmits a test signal to an universal measurement instrument; an industrial control computer calls control parameters of the universal measurement instrument and the equipment under test to complete automatic test of the multiple indexes, reads a test result of the universal measurement instrument and automatically generates a test report in a standard format; the artificial configuration test and automatic test on the main indexes of the equipment under test are achieved by using a visual manual control interface.

Owner:10TH RES INST OF CETC

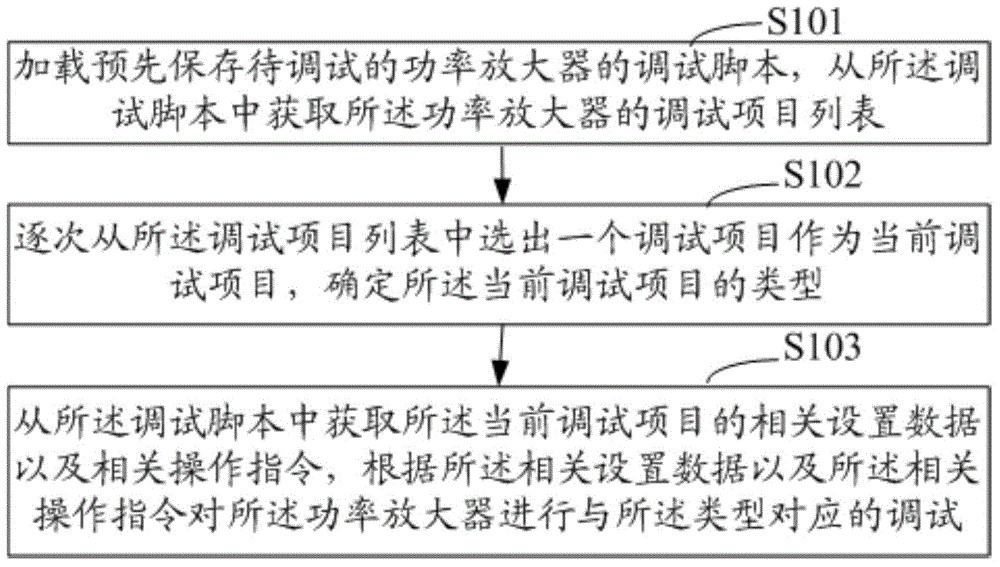

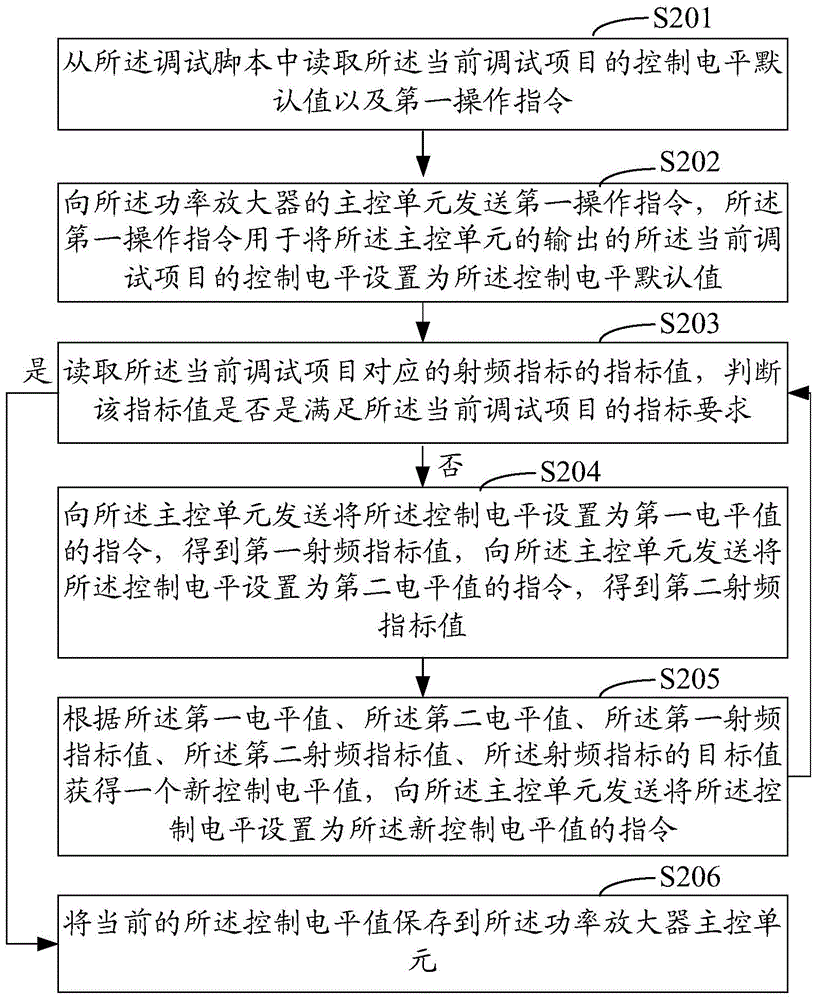

Debugging method, device and system of power amplifier

ActiveCN104539250AImprove debugging work efficiencyAvoid lack of versatilityPower amplifiersSoftware testing/debuggingAudio power amplifierComputer engineering

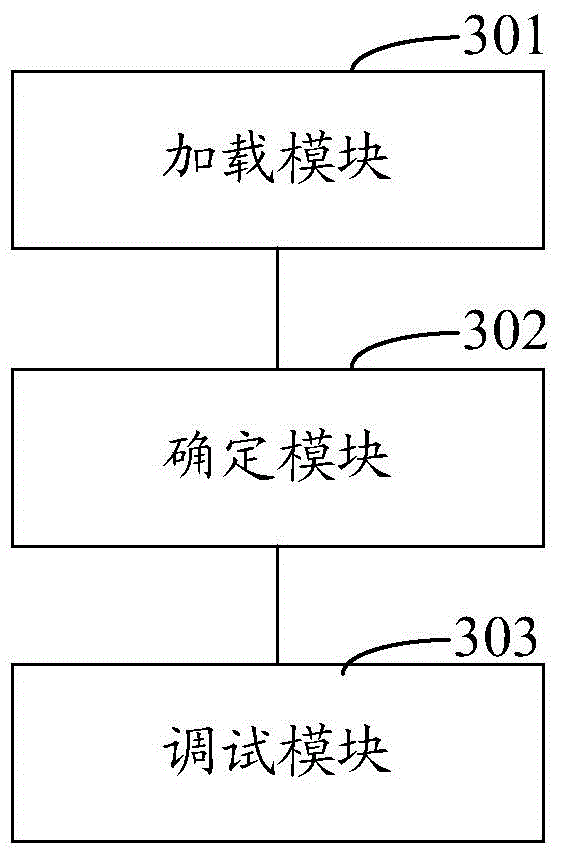

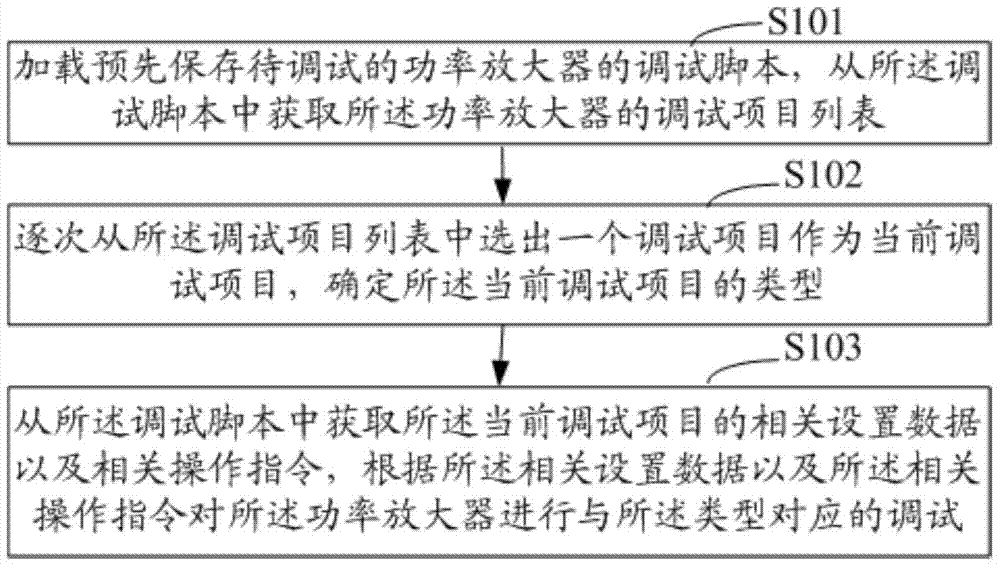

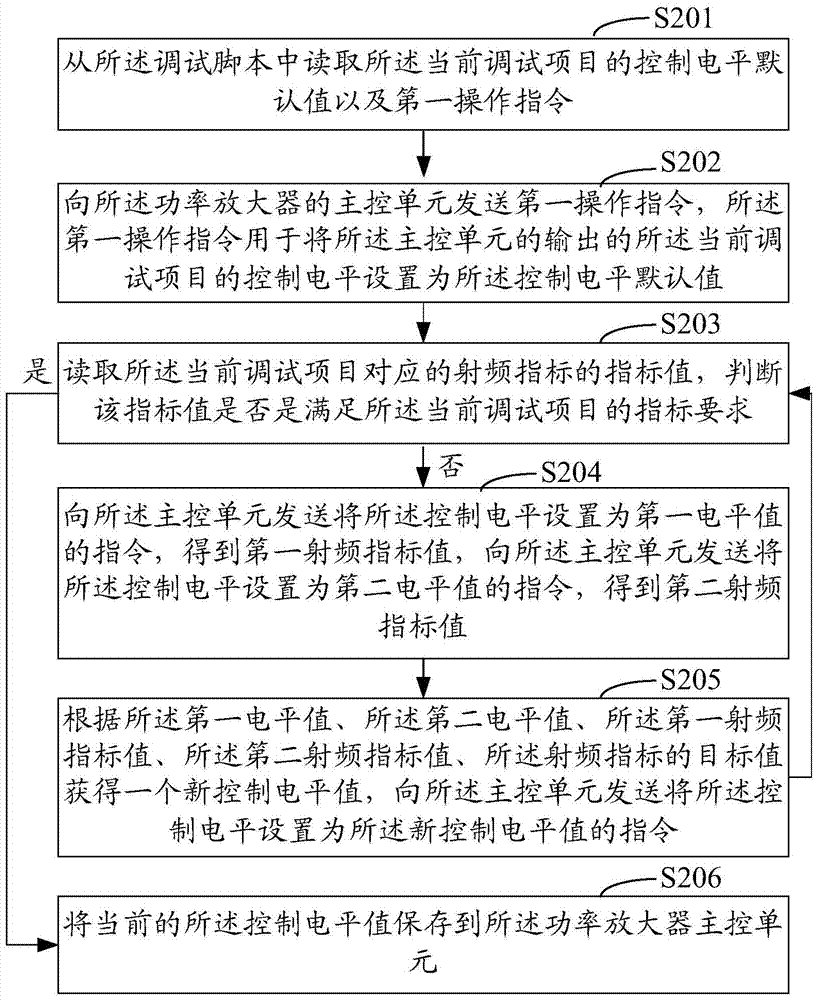

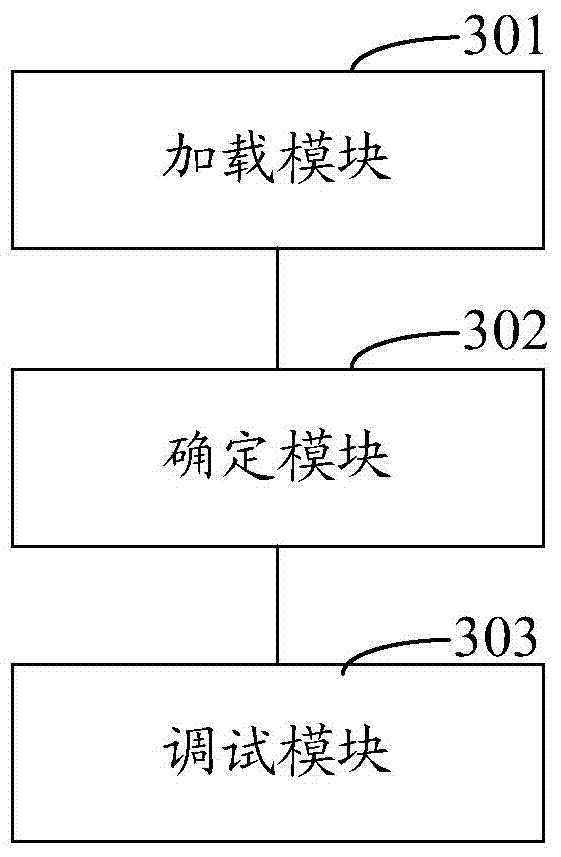

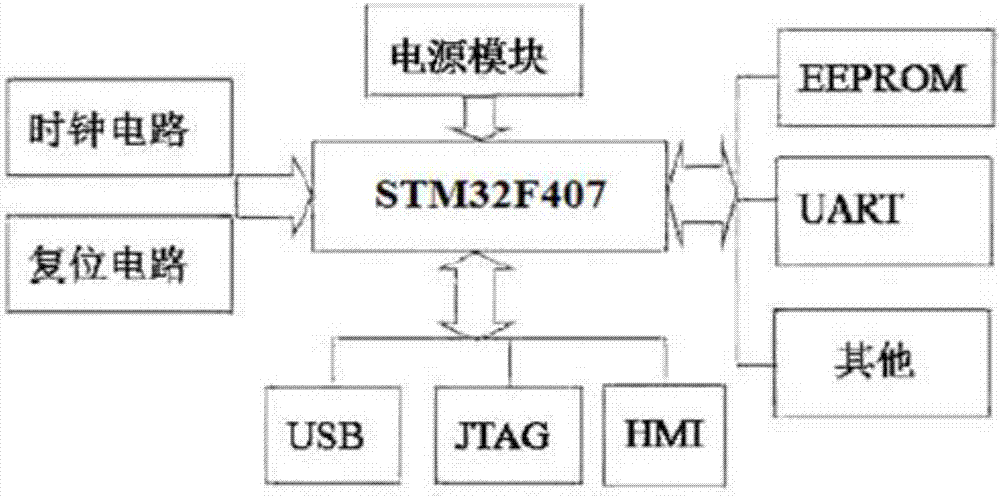

The invention provides a debugging method, device and system of a power amplifier. The method comprises the following steps: loading a debugging script of the power amplifier, which is pre-stored and needs to be debugged, and obtaining a debugging item list of the power amplifier from the debugging script; gradually selecting one debugging item from the debugging item list as a current debugging item; determining the type of the current debugging item; obtaining relative set data and relative operation instructions of the current debugging item from the debugging script; and carrying out debugging corresponding to the type on the power amplifier according to the relative set data and the relative operation instructions. With the adoption of the debugging method, device and system of the power amplifier, the consistency of debugging results can be guaranteed and the debugging efficiency is improved.

Owner:COMBA TELECOM SYST CHINA LTD

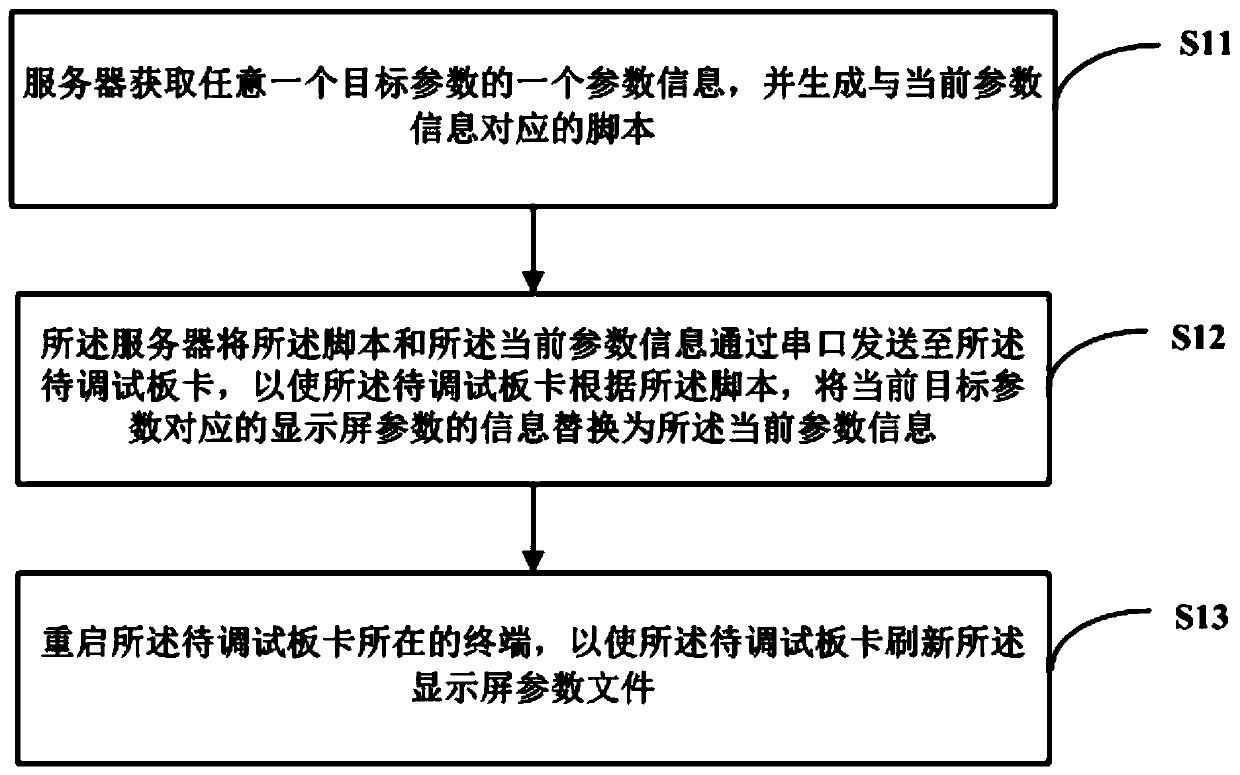

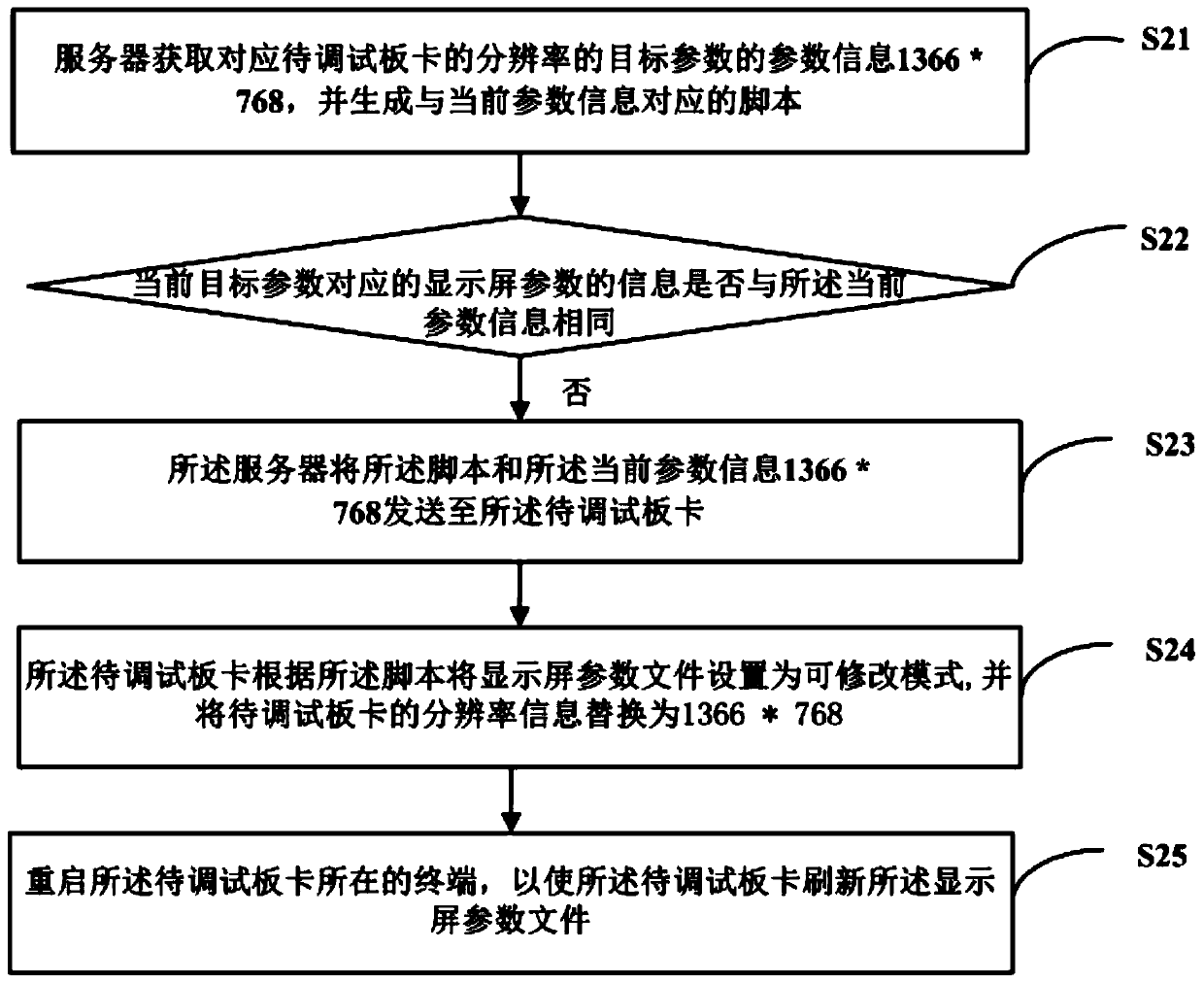

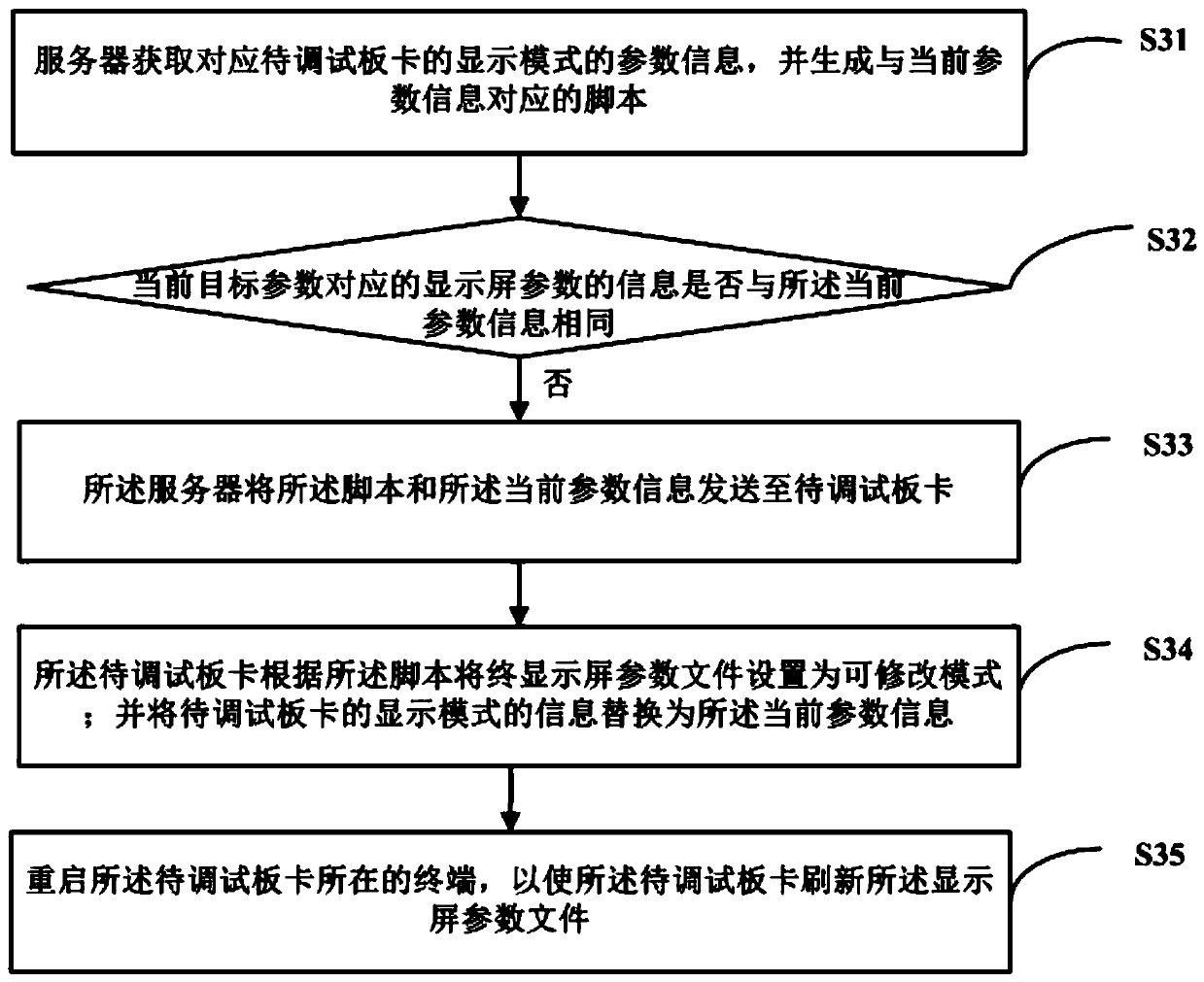

Display parameter debugging method and server

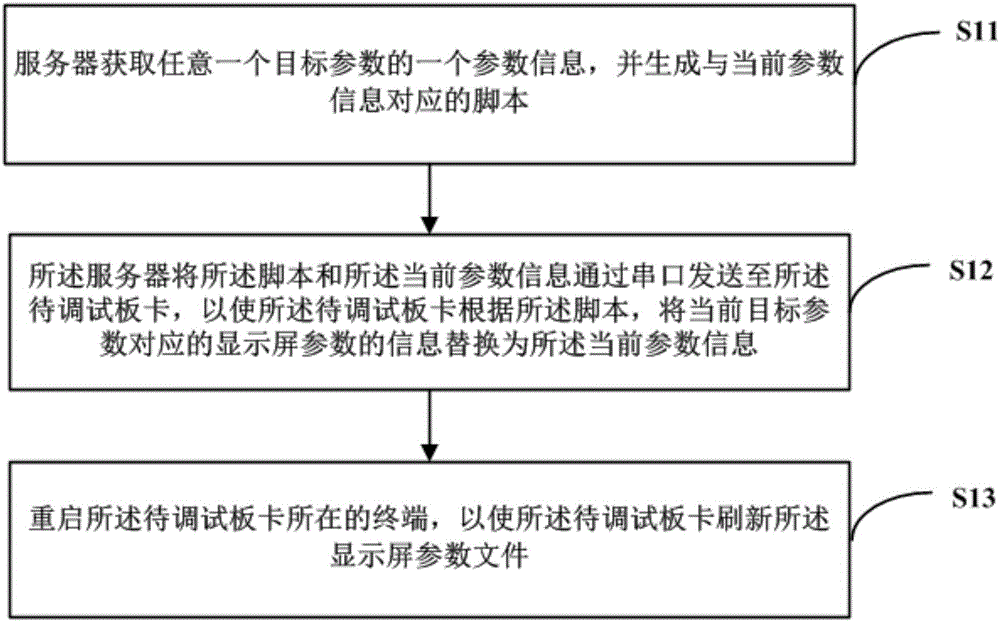

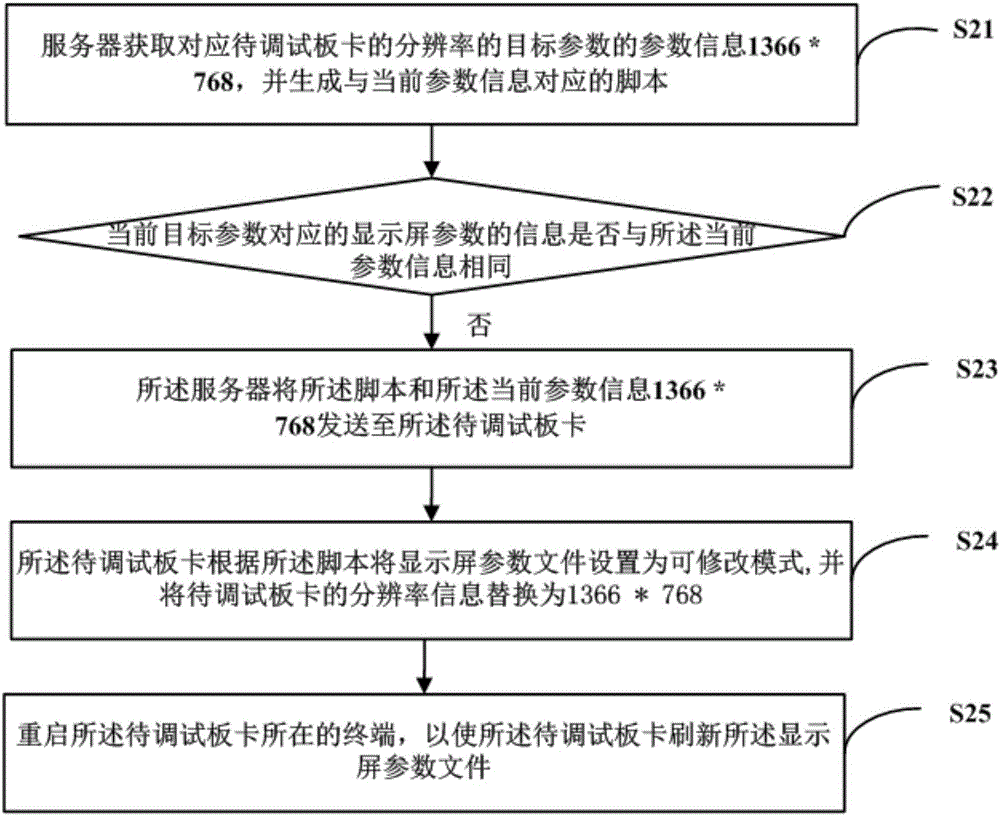

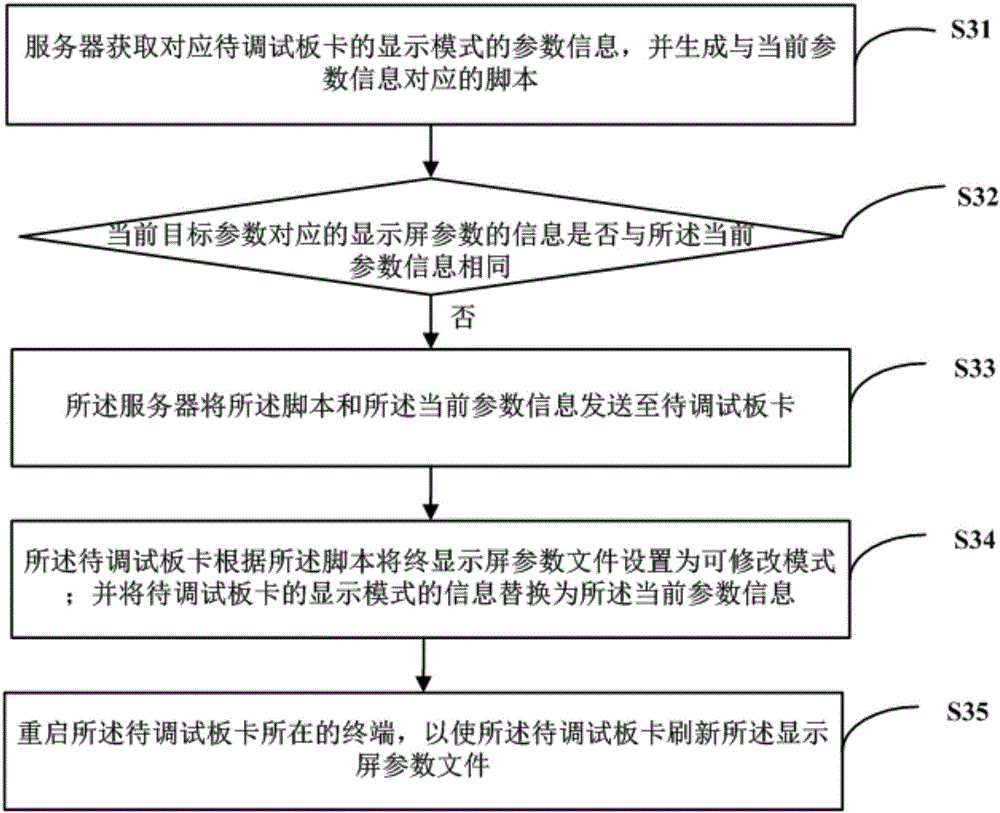

ActiveCN106776174ASolve the problem of low debugging efficiencySimplified commissioning stepsDetecting faulty computer hardwareSoftware testing/debuggingComputer engineeringSingle parameter

A display parameter debugging method and a server are provided; the method comprises: when the server acquires single parameter information of any target parameter, generating a script corresponding to current parameter information, wherein the server includes multiple target parameters in one-to-one correspondence with multiple display parameters of a board to be debugged, and each target parameter is pre-provided with single or multiple parameter information; allowing the server to transmit the script and the current parameter information to the board to be debugged through a serial port so that the board to be debugged replaces, according to the script, the display parameter information corresponding to the current target parameter with the current parameter information. The problem that a complex process for correcting and debugging a display in the prior art results in low debugging efficiency is solved, display screen debugging steps are simplified, and debugging efficiency is improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

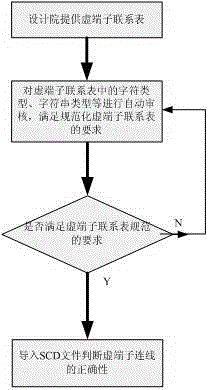

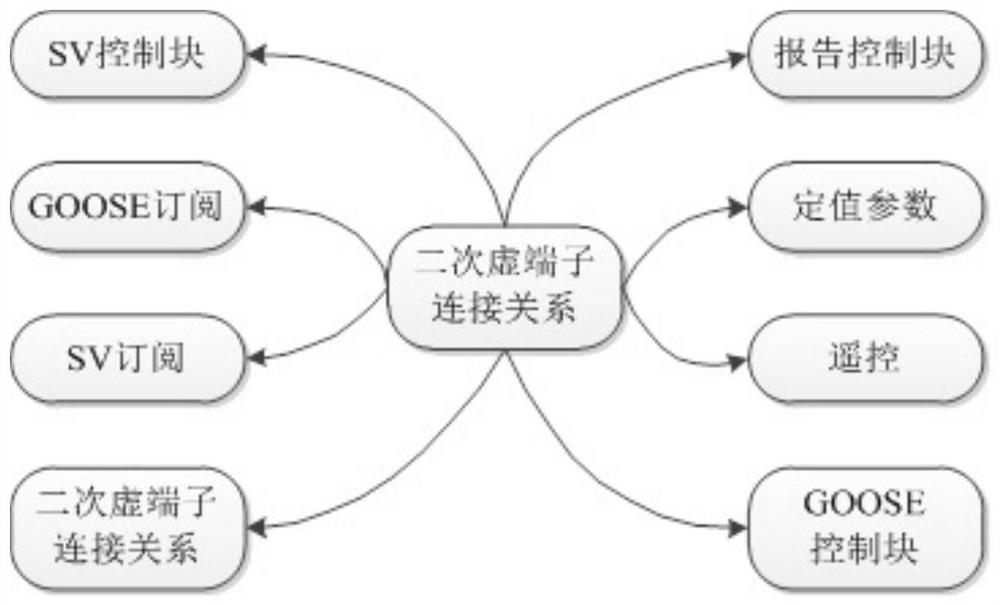

Method for determining connection correctness of virtual terminals of intelligent transformer station

InactiveCN106199323AImprove debugging work efficiencyRealize automatic comparisonElectric connection testingVirtual terminalSmart substation

The invention relates to a method for determining the connection correctness of virtual terminals of an intelligent transformer station. The method forms two virtual terminal relation tables by using a standard virtual terminal relation table format and importing a virtual terminal relation table into a SCD model file, and compares the input correctness of external short addresses by means of a character comparison way. The method may realize automatic comparison of the information in a SCD file, effectively avoids erroneous manual virtual terminal connection, and remarkably improves the debugging efficiency of the intelligent transformer station.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

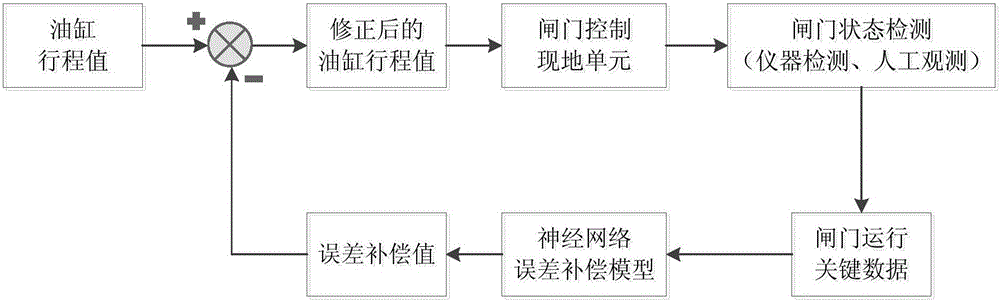

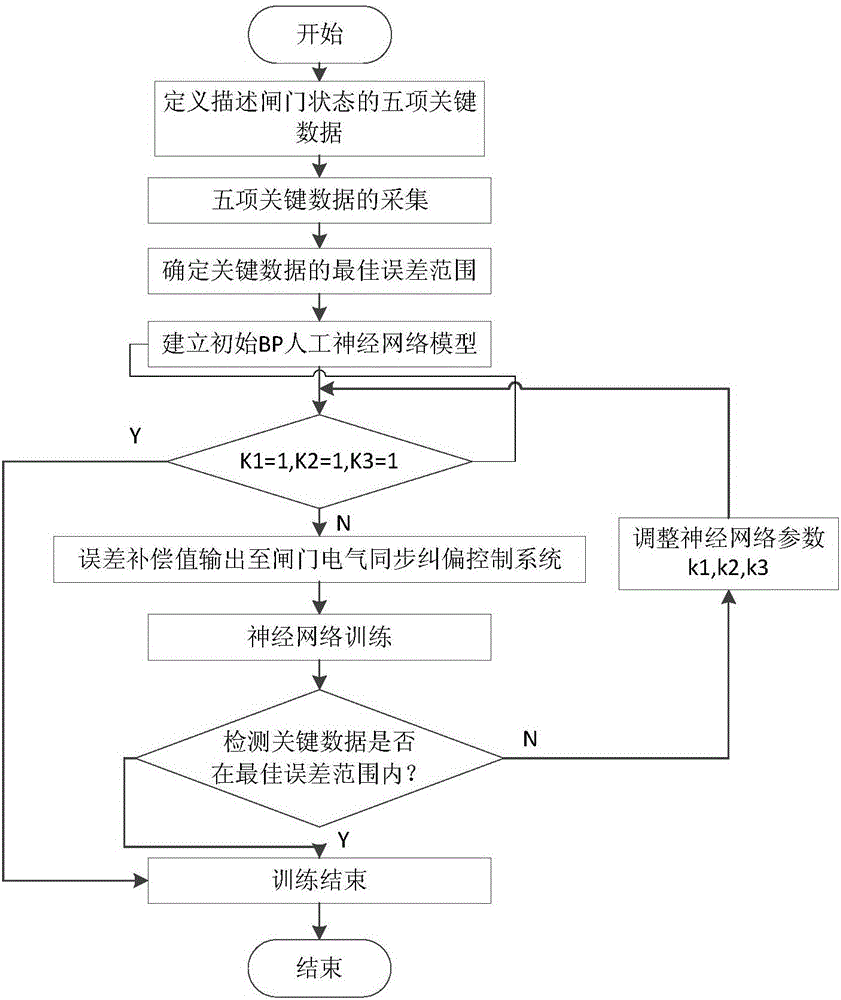

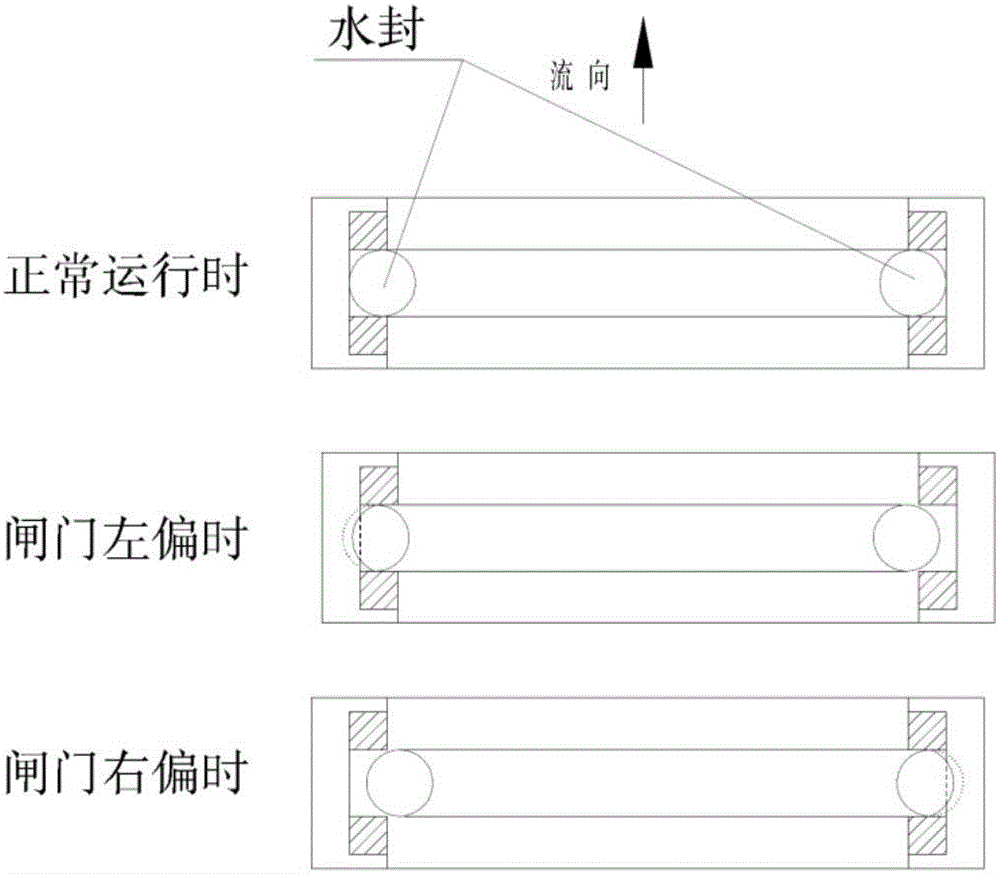

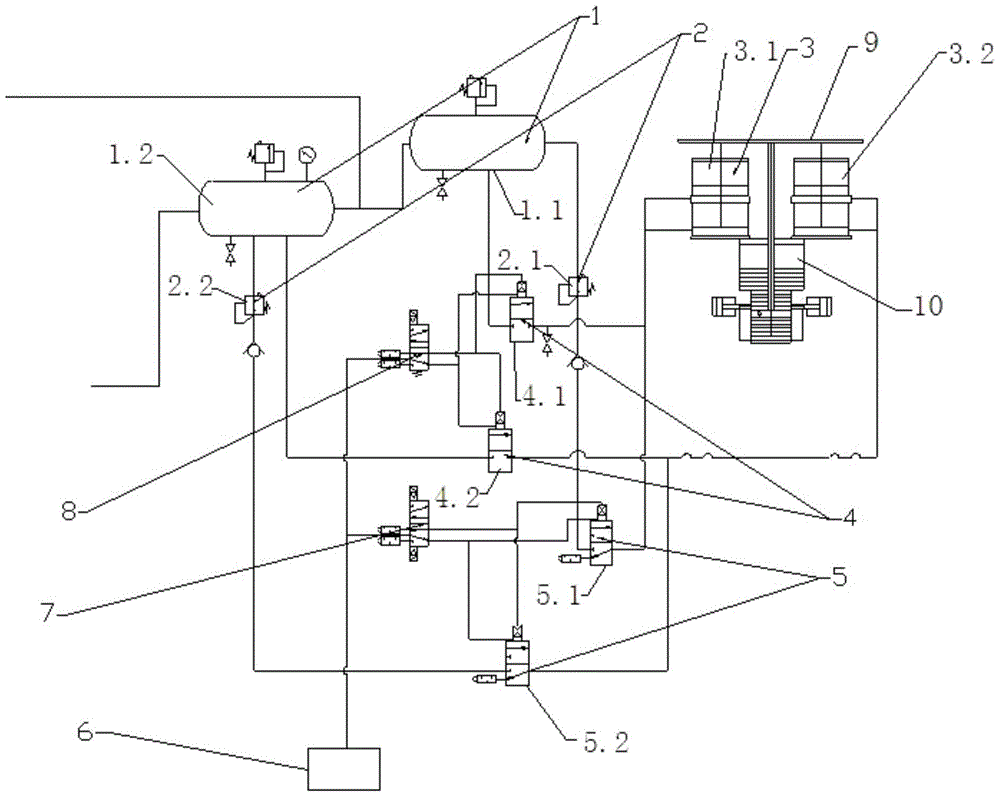

Double-cylinder hydraulic gate oil cylinder stroke error compensation method based on artificial neural network

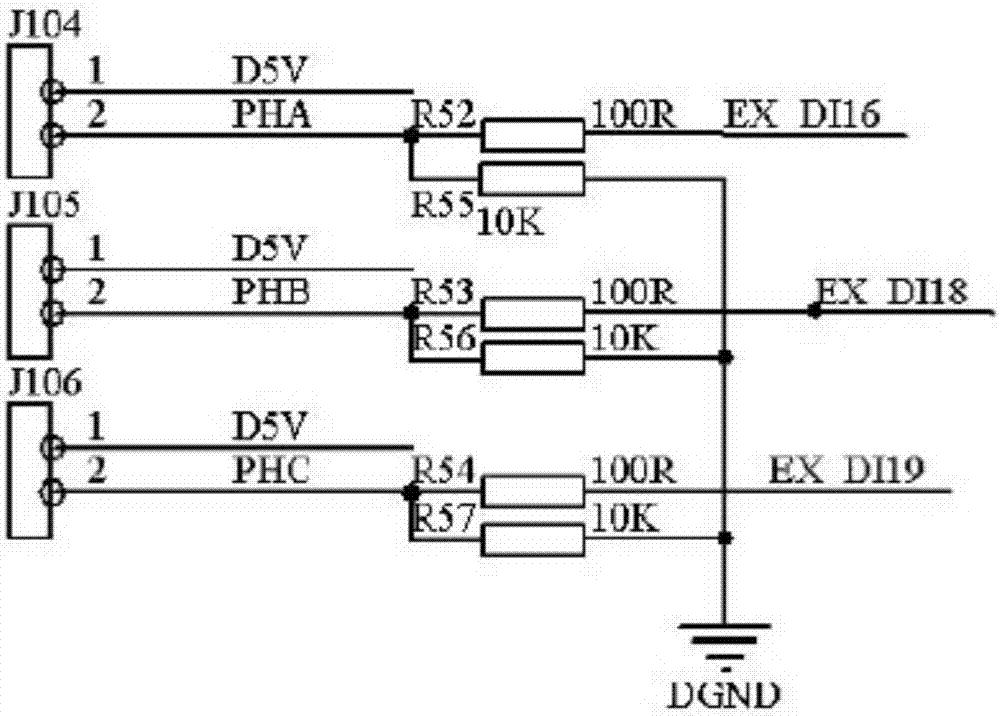

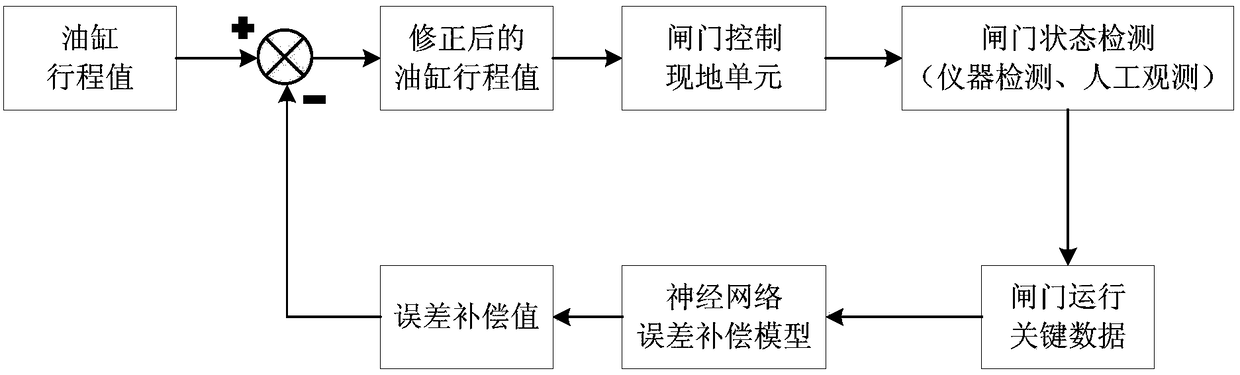

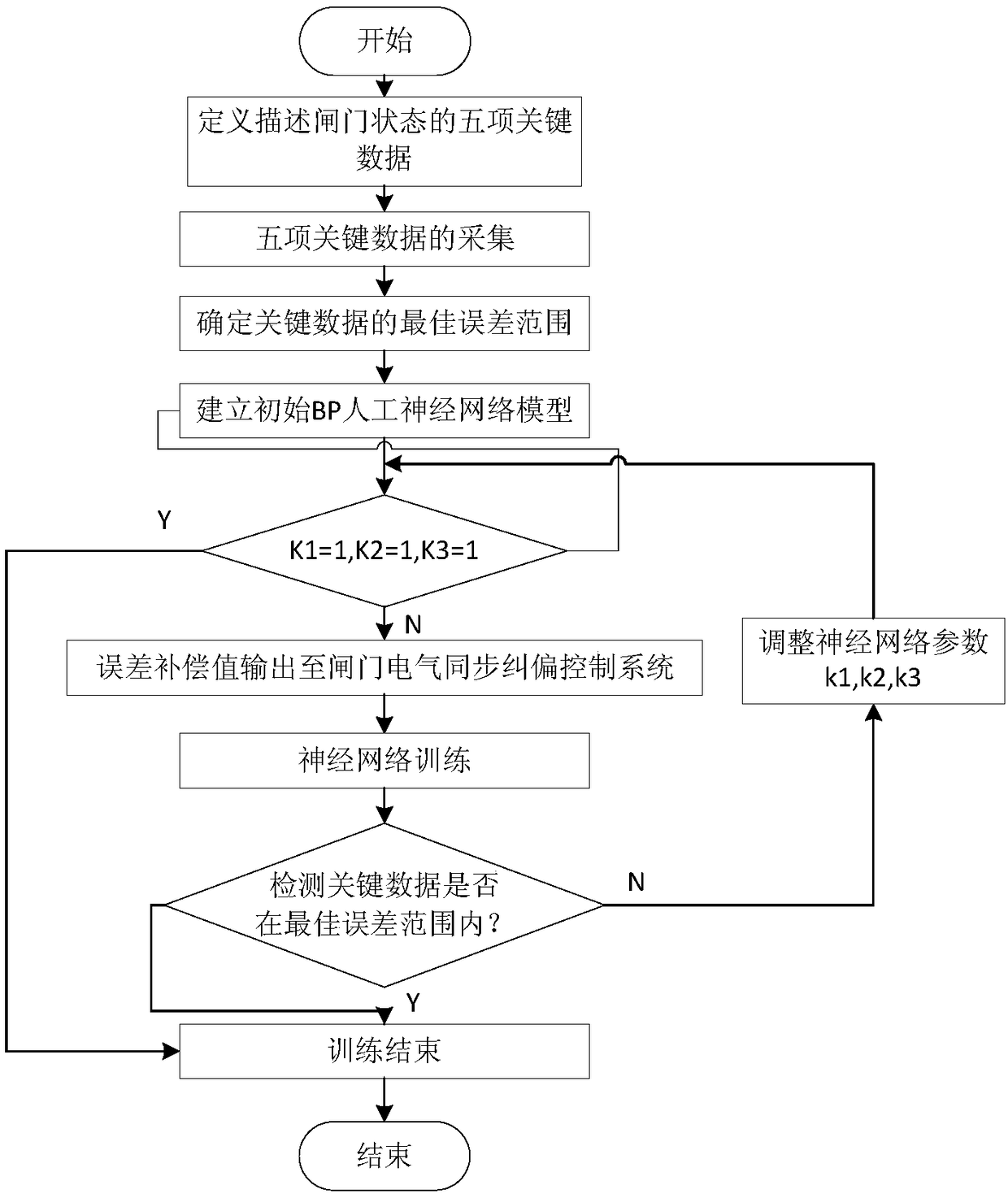

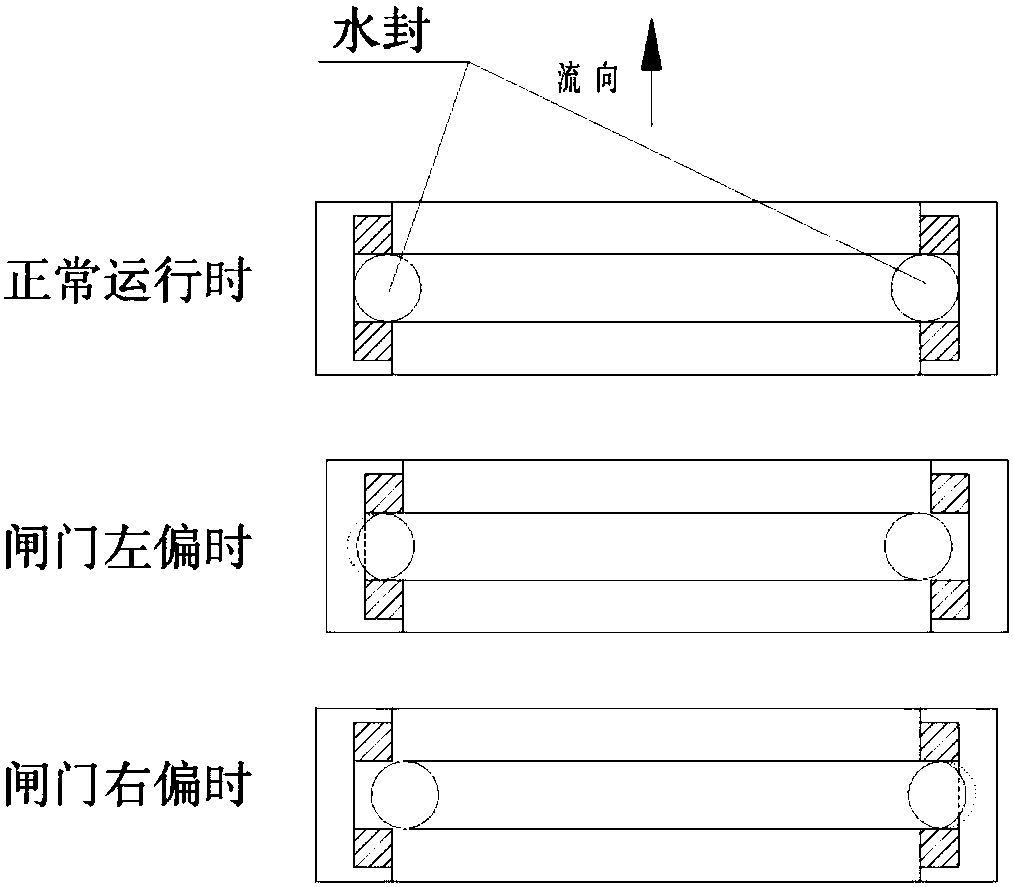

ActiveCN106759137AIncrease water seal extrusionReflect the actual operating statusBarrages/weirsAdaptive controlControl systemNoise level

The invention discloses a double-cylinder hydraulic gate oil cylinder stroke error compensation method based on an artificial neural network. The method includes the following steps that (1) key data of a gate state are defined and include a left-right oil cylinder stroke deviation value delta Hc, a gate left-right opening degree deviation value delta H, a gate water seal extrusion degree D, a gate noise level DB and a gate vibration level V; (2) the key data are collected, and an error grading standard is set; (3) the optimal error range is determined; (4) the mapping relation between the key data and an oil cylinder stroke compensation value h is established; (5) an initial BP artificial neural network model is established, and the oil cylinder stroke compensation value h is obtained; (6) the oil cylinder stroke compensation value h is output to a gate electrical synchronous deviation rectification control system; and (7) artificial neural network training is carried out, and the optimal gate running track is obtained. According to the double-cylinder hydraulic gate oil cylinder stroke error compensation method based on the artificial neural network, the practical running state of a gate is reflected comprehensively and accurately, the problem that the gate state reflected by an oil cylinder stroke detection value is inconsistent with the practical gate state is solved, and the running synchronization precision of the gate is remarkably improved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

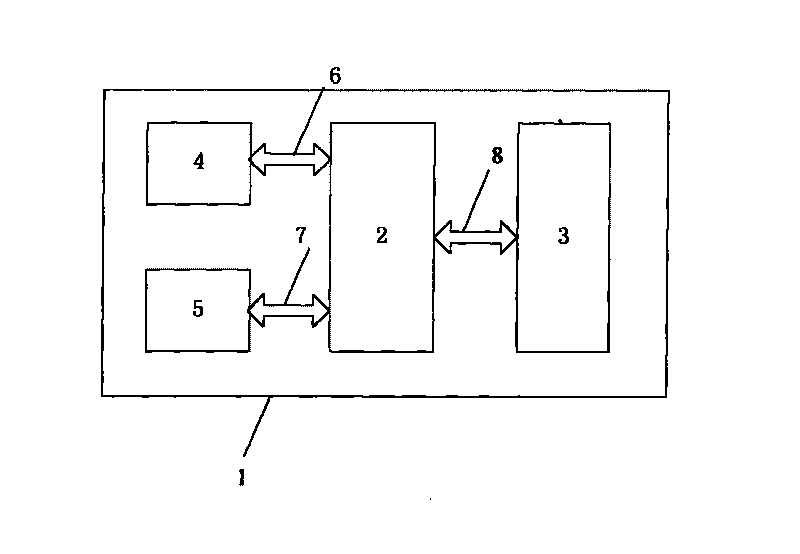

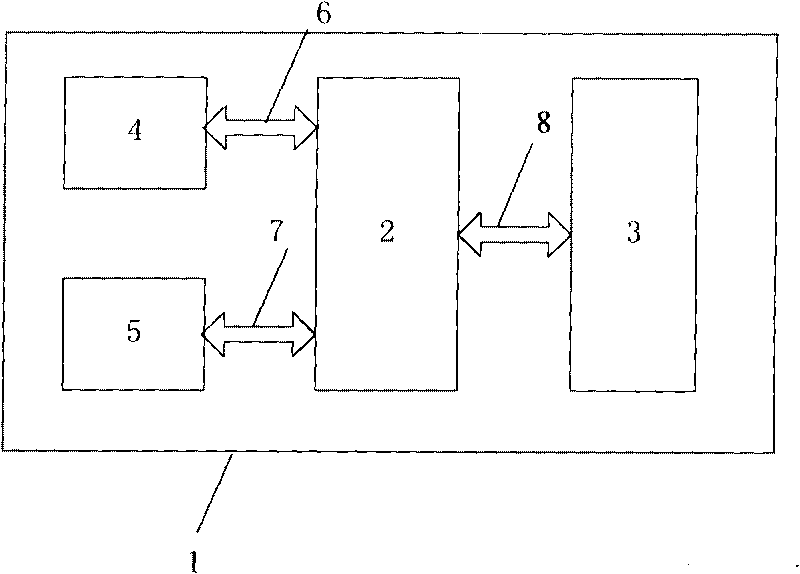

Microprocessor chip emulator and breakpoint setting method

InactiveCN101751323AImprove debugging work efficiencyImprove debugging efficiencySoftware testing/debuggingMode switchMode switching

The invention discloses a microprocessor chip emulator which comprises an emulation chip, an emulation management module, a user program memory and a monitoring program memory. The emulation management module controls the emulation chip to work in a monitoring mode or in a user mode through the emulation management interface. When the emulation chip works in the monitoring mode, the emulation management module can provides the breakpoint information to the emulation chip through the emulation management interface, and the emulation chip executes a monitoring program to set breakpoints. When controlling the emulation chip to be switched from the user mode to the monitoring mode, the emulation management module records a position at which the execution of the user program is stopped; and when the emulation chip is switched back to the user mode, the emulation management module controls the emulation chip to continue to execute the user program from the stop position. The invention also discloses a method for setting the breakpoints when the user program is operated at full speed. The method can still set the breakpoints when the user program is operated at full speed, thereby improving the debugging efficiency of the program.

Owner:SHANGHAI HUAHONG INTEGRATED CIRCUIT

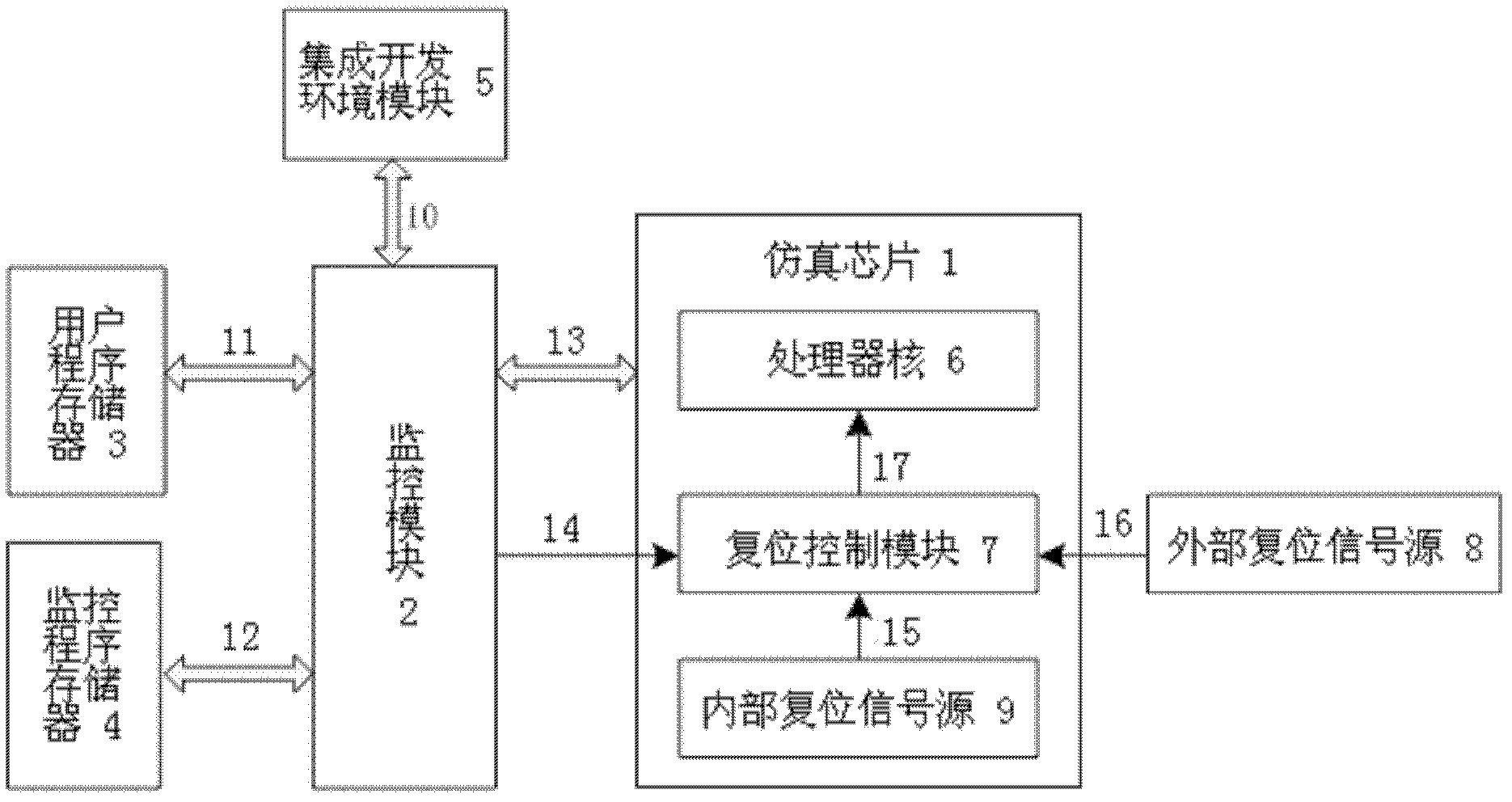

Simulator free from interference of resetting in monitor mode

InactiveCN103207824AImprove job stabilityImprove work efficiencyFunctional testingWork statusMonitoring program

The invention discloses a simulator free from the interference of resetting in a monitor mode. The simulator comprises a simulation chip, a monitoring module, a user program memory, a monitor program memory, an external resetting signal source and an integrated development environment module on a user computer, wherein the simulation chip comprises a processor core, a resetting control module and an internal resetting signal source; when the resetting control module outputs an effective resetting signal to the processor core, the processor core is in a reset state; when the resetting control module outputs an ineffective resetting signal, the processor core works normally; and in the monitor state, the monitoring module outputs an effective control signal to the resetting control module, and the resetting control module outputs an ineffective resetting signal to the processor core no matter whether the resetting control module receives the effective or ineffective external resetting signal or the effective or ineffective internal resetting signal. According to the simulator, not only can the working states of a processor chip of a product during various kinds of resetting be truly simulated in an operation mode, but also the abnormal influence of various kinds of resetting on the work of the simulator can be shielded in the monitor mode.

Owner:SHANGHAI HUAHONG INTEGRATED CIRCUIT

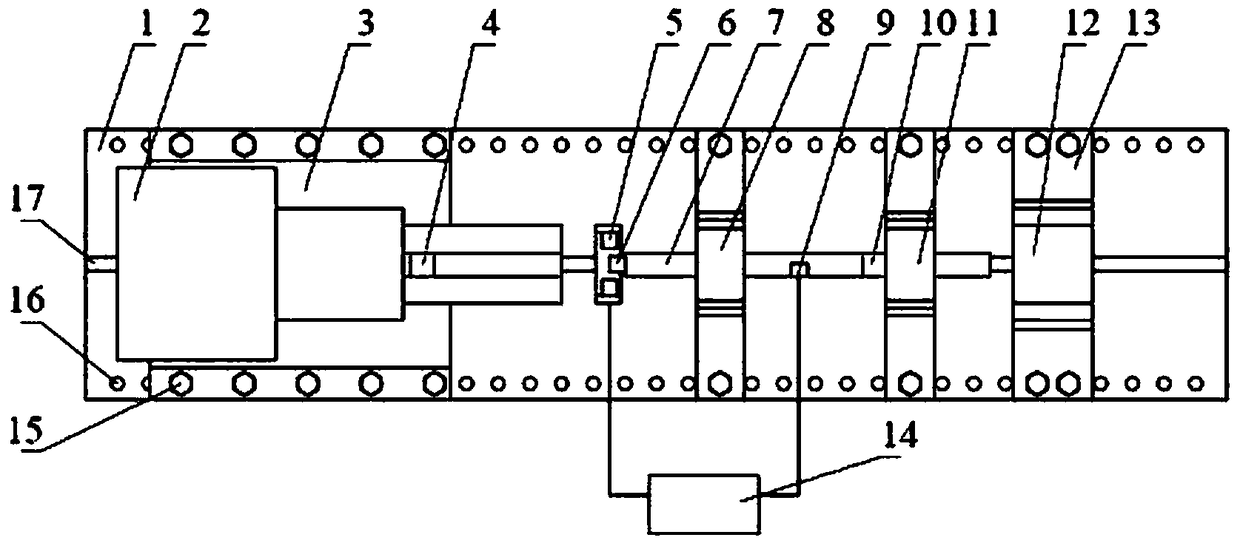

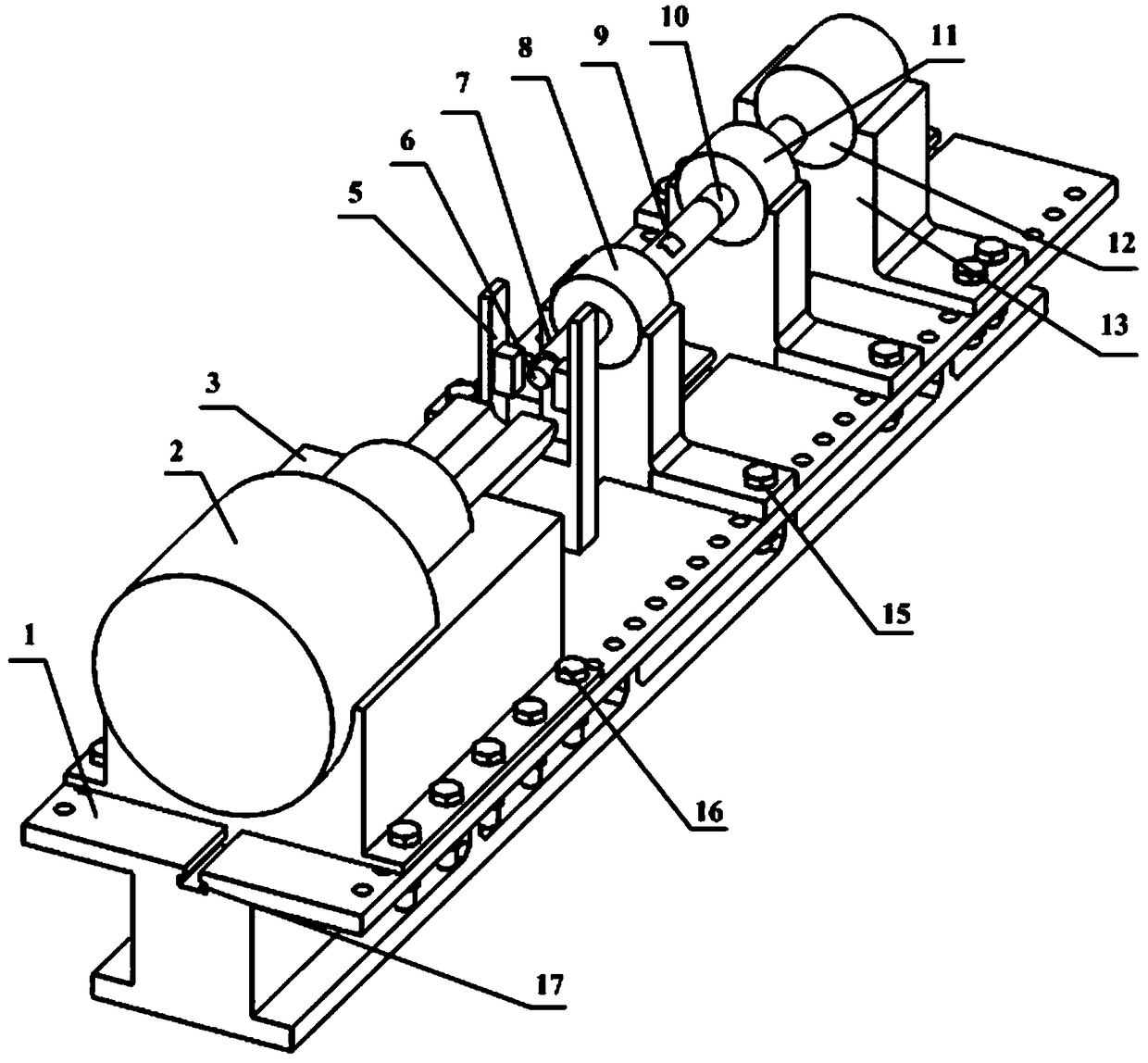

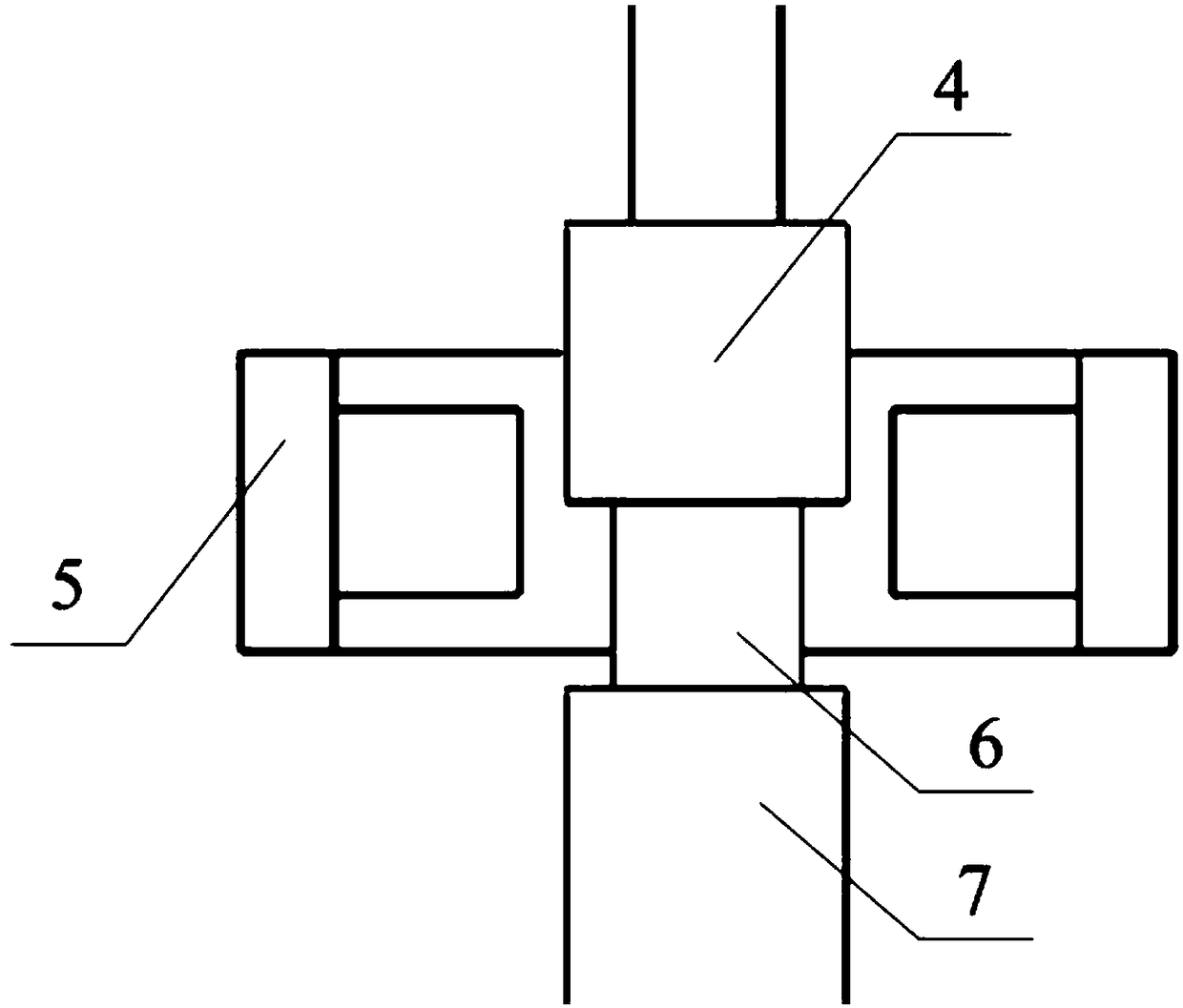

SHPB device and method for achieving ultra-high controllable strain rate impact

The invention discloses an SHPB device and method for achieving ultra-high controllable strain rate impact. The device comprises structures of a guiding rail with a T-shape groove, a light gas gun loading mechanism, a light gas gun base, a bullet, a magnetic electricity type particle velocity measuring device, a testing member, an output rod, an output rod fixing device, a strain piece, an absorbing rod, an absorbing rod fixing device, a damping device, a damping device fixing device, a data processing system and the like; the device is characterized in that the impacting on the testing memberof an incidence rod is replaced with the direct impacting on the testing member by the bullet, the particle velocity of the testing member at the incidence end is measured by the magnetic electricitytype particle velocity measuring device, the average stress, strain rate and strain of the testing member are obtained according to unidimensional stress wave assumption and uniform distribution assumption of the stress / strain of a short testing member along the length of the short testing member, and the coaxiality of the device is ensured by the T-shaped groove and bolt connection cooperative action. By means of the device and the method, controllable and ultra-high strain rate (107s<-1> scale) loading can be achieved within a larger range (104-107s<-1> scale), the debugging efficiency canbe improved, the structure is simple, and the dynamic mechanical performance of a material under the ultra-high strain rate is obtained conveniently and rapidly.

Owner:UNIV OF JINAN

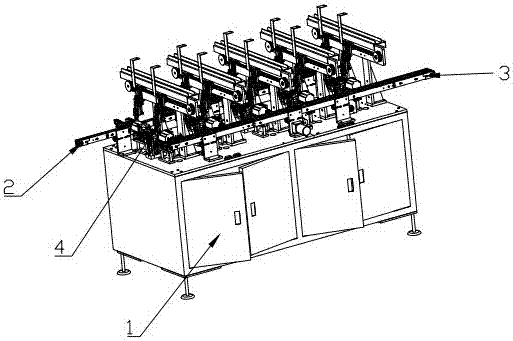

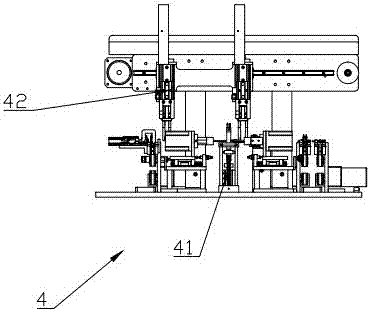

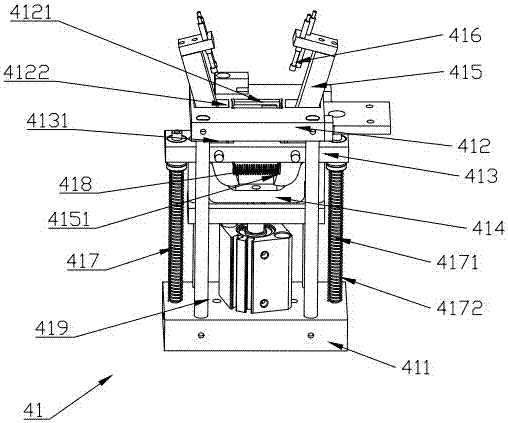

Push type electromagnetic relay automatic debugging machine

ActiveCN105938781BDebug accuratelyOmit positioning fixtureElectric switchesRelaysState of artEngineering

The invention provides an automatic debug machine of a push electromagnetic relay. The automatic debug machine comprises a fixed bottom plate, a debug panel, an action plate, a push block and draw bars, wherein a positioning and placing groove is arranged in the center of the debug panel; first movable slots are arranged in two sides of the positioning and placing groove; the action plate is arranged between the fixed bottom plate and the debug panel and is connected with first elastic assemblies for driving the action plate to move downwards; the push block is arranged at the lower part of the action plate; a trumpet-shaped open slot is arranged at the upper end of the push block and the lower end of the push block is connected with a power source; the draw bars are hinged with the action plate; one end of each draw bar is arranged in the open slot of the push block and is attached to the side wall of the open slot and the other end passes through the corresponding first movable slot and is provided with a test cap sleeve; and one end, arranged in the open slot, of each of the two draw bars is provided with a second elastic assembly for acting towards two sides. The automatic debug machine has the advantage that debugging of the relay can be quickly and accurately achieved only by up and down movement of a drive air cylinder. Compared with the prior art, two working steps of clamping and loosening a positioning clamp are omitted; the working procedures are reduced; and the debugging work efficiency is improved.

Owner:YUEQING MEISHUO ELECTRIC

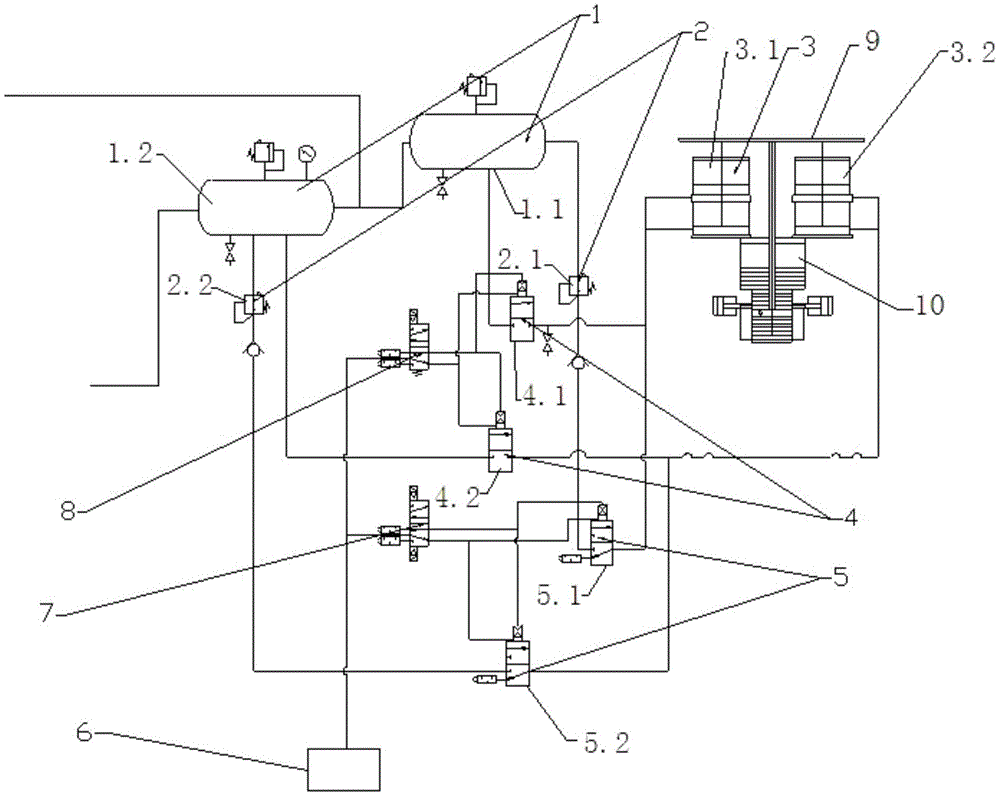

Press machine air pad ascending and descending control device and method based on power failure protection

The invention relates to a press machine air pad ascending and descending control device based on power failure protection, and belongs to the technical field of a plate material forming press machine. The press machine air pad ascending and descending control device comprises an air pad jacking cylinder, an air storage tank and a control air source, wherein a high-pressure air inlet air path and a low-pressure air inlet air path are connected between an air outlet of the air storage tank and a lower cavity of the air pad jacking cylinder; a high-pressure air inlet valve is arranged on the high-pressure air inlet air path; a low-pressure air inlet valve is arranged on the low-pressure air inlet air path; the control air source is respectively connected with the high-pressure air inlet valve and the low-pressure air inlet valve through a high-pressure air inlet control valve and a low-pressure air inlet control valve, and the low-pressure air inlet control valve is a two-position five-way double-electric-control self-maintaining electromagnetic valve. The invention also discloses a press machine air pad ascending and descending control method based on power failure protection. The device and the method have the advantages that an air pad is enabled to be always in an ascending jacking state in the mold debugging process, and the misoperation possibility of the air pad is reduced to minimum, and the potential safety hazards in the mold debugging process can be eliminated, and the safety of the mold debugging personnel is ensured.

Owner:DONGFENG MOTOR CORP HUBEI

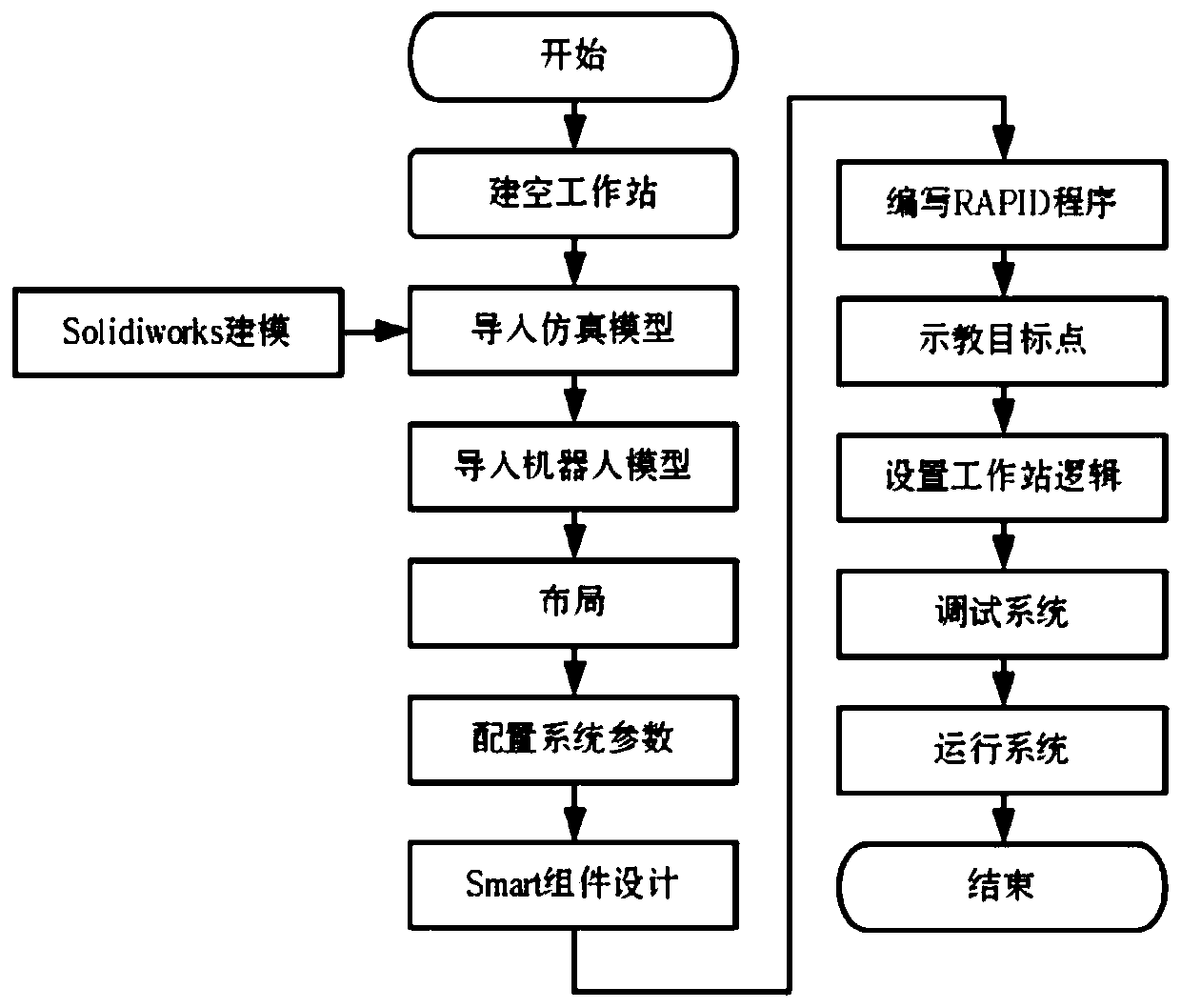

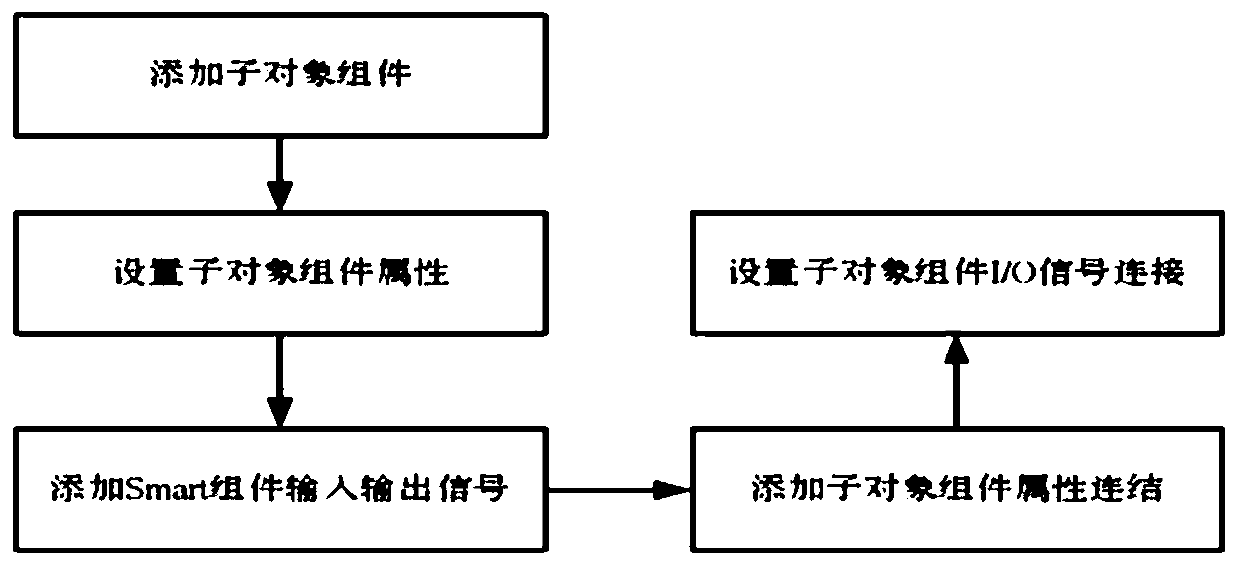

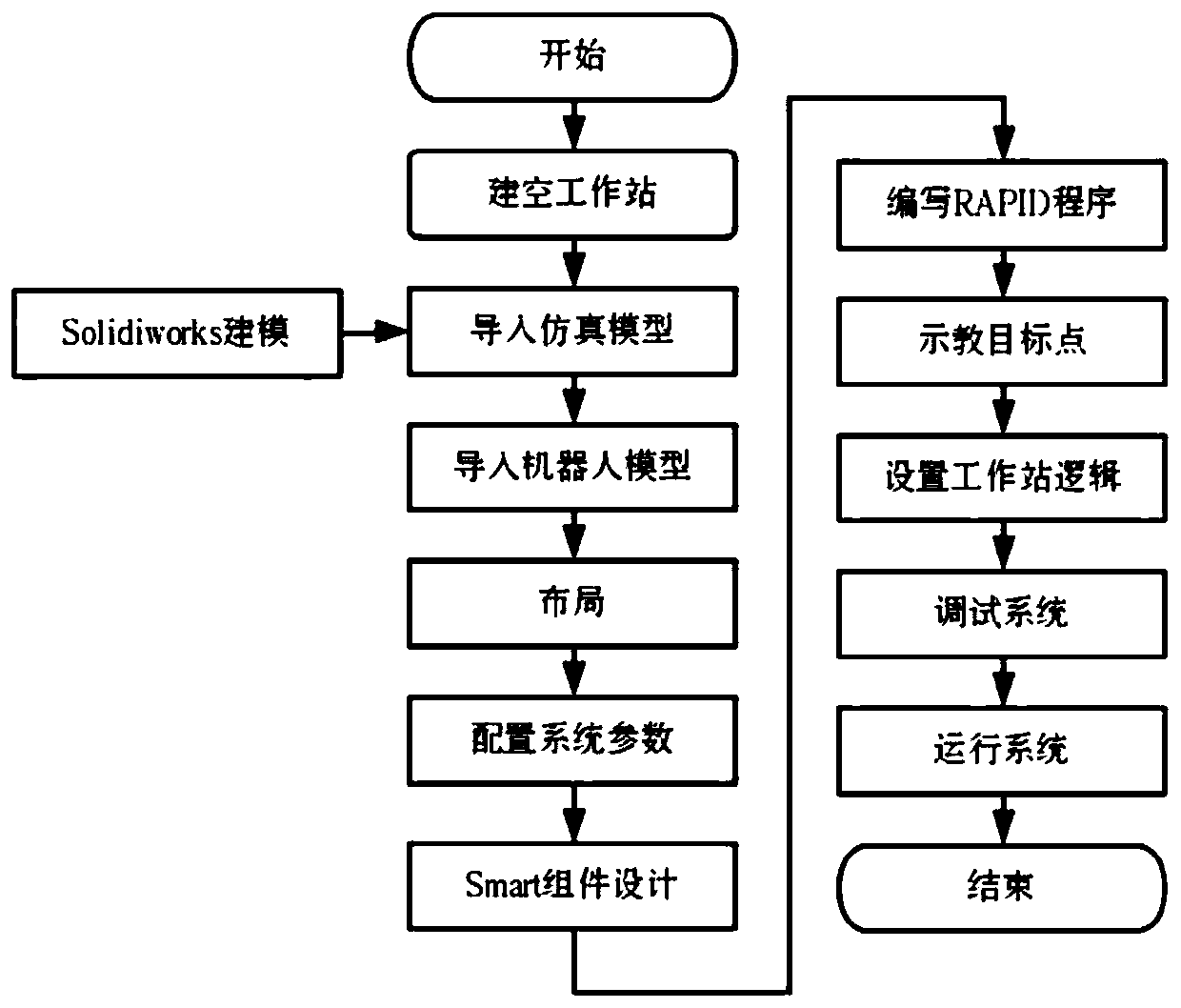

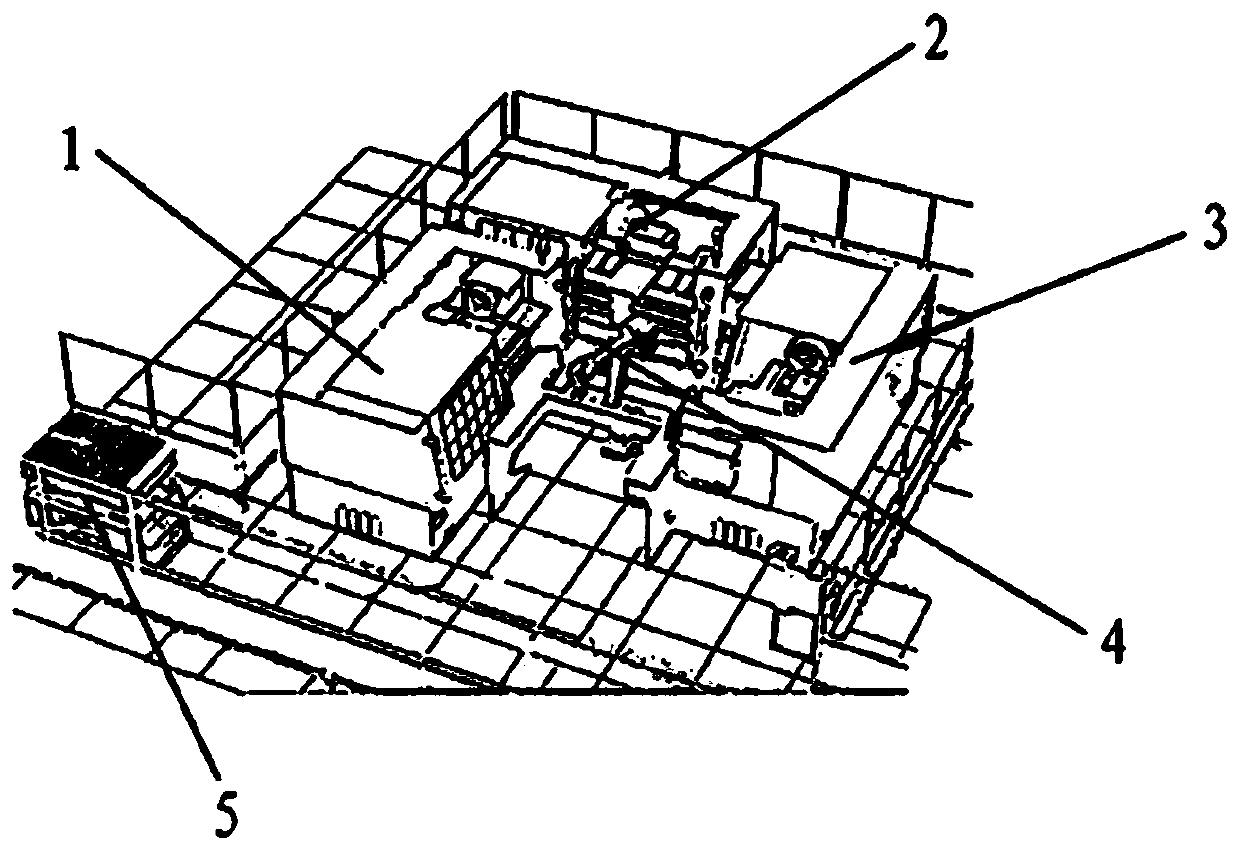

Simulation design method based on industrial robot sorting workstation

InactiveCN110737205AImprove debugging work efficiencyImprove reliabilitySimulator controlWorkstation designWorkstation

The invention relates to a simulation design method based on an industrial robot sorting workstation. The simulation design method comprises the following steps of: S1, establishing a conveying mechanism model, an industrial robot model and an object storage device model by adopting three-dimensional software, and importing a model file into RobotStudio software; S2, determining control parametersbased on the industrial robot model, and determining an industrial robot simulation model according to the control parameters; S3, enabling objects to appear on the conveying mechanism according to arandom distribution function rule, and distributing different features to different types of objects; and S4, designing parameters of a Smart component according to the operation logic of the industrial robot, and performing simulation control on the industrial robot simulation model, wherein the industrial robot recognizes the objects through a feature recognition mechanism and places differentobjects into corresponding storage areas in the object storage device according to the features of the objects. The simulation design method provides a theoretical basis and a test platform for the design of the industrial robot sorting workstation for designers and managers.

Owner:GUANGZHOU PANYU POLYTECHNIC

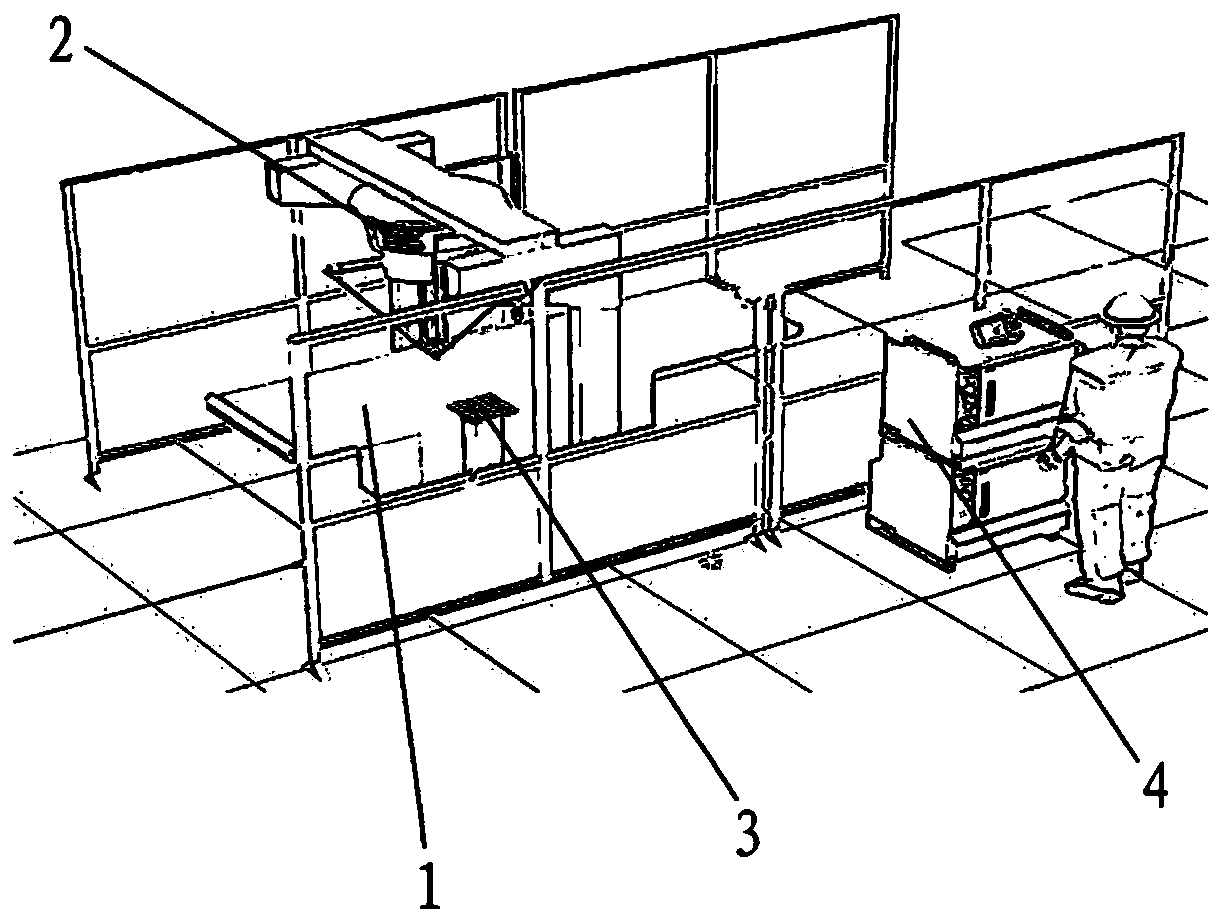

Simulation design method based on industrial robot loading-unloading workstation

PendingCN110456659AImprove debugging work efficiencyImprove reliabilitySimulator controlSimulationWorkstation design

The invention relates to a simulation design method based on an industrial robot loading-unloading workstation. The simulation design method comprises the following steps: S1, establishing a machine tool and industrial robot model by adopting three-dimensional software, and importing a model file into RobotStudio software; S2, determining control parameters based on the industrial robot model, anddetermining the industrial robot simulation model according to the control parameters; S3, designing parameters of Smart module according to industrial robot running logic, and performing simulationcontrol on the industrial robot simulation model. The simulation design of the industrial robot loading-unloading workstation is realized, the feasible evidence is provided for the design of the industrial robot loading-unloading workstation, the reliability of the design scheme can be improved by utilizing robot simulation technology, the project implementation cycle can be shortened, the field debugging time is reduced, and the debugging working efficiency of the industrial robot is improved. And meanwhile, the theoretic evidence of the workstation design is provided for a designer and a manager, the design and debugging cost of a production line are reduced.

Owner:GUANGZHOU PANYU POLYTECHNIC

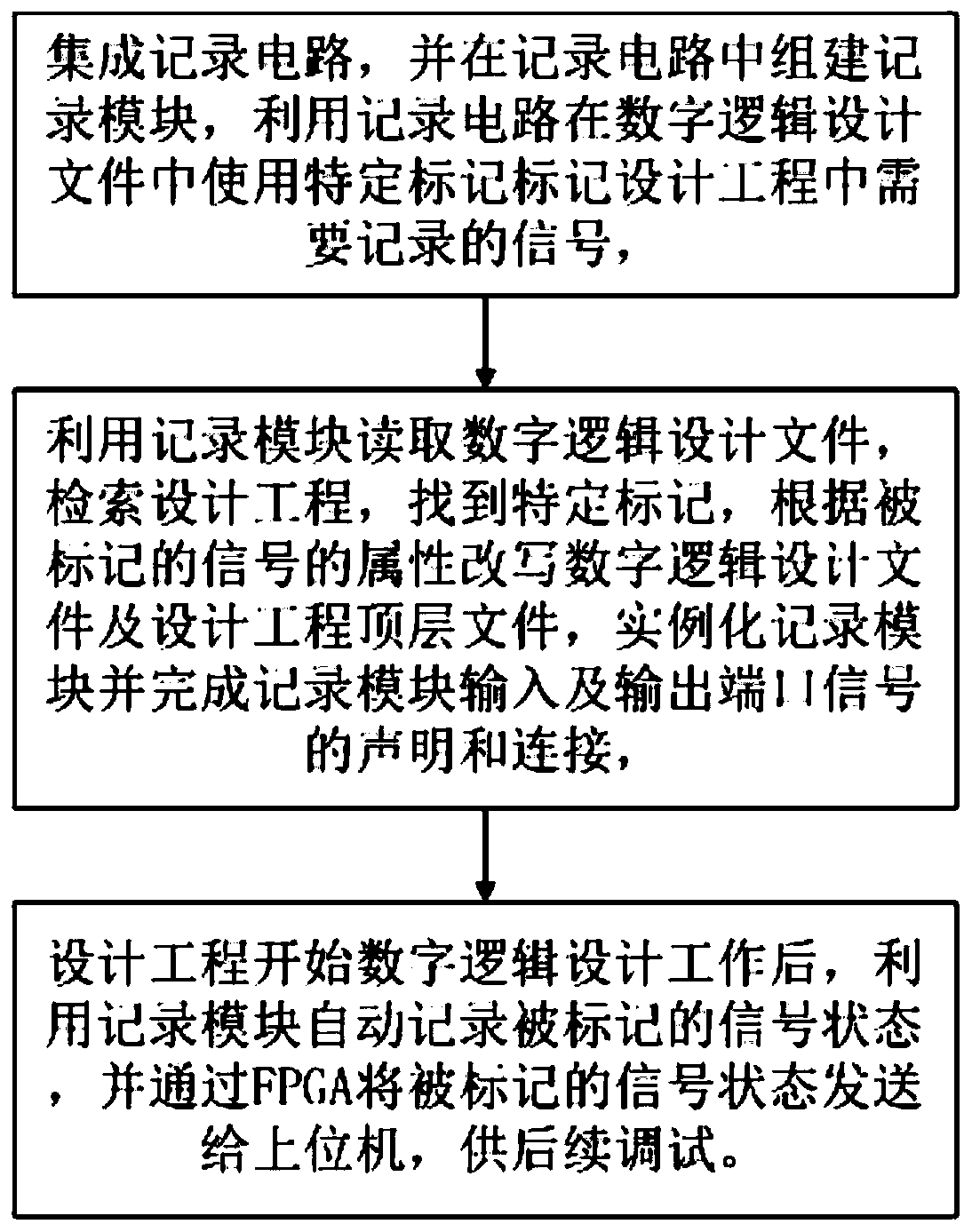

Method and system for recording working state of digital logic design engineering

PendingCN110471810ALong durationImprove work efficiencyFunctional testingFaulty hardware testing methodsDesign technologySoftware engineering

The invention discloses a method and system for recording the working state of a digital logic design project, and relates to the technical field of digital logic design. Signals needing to be recorded in a design project are marked by using specific marks in a digital logic design file by utilizing a recording circuit; a recording module is used for reading the digital logic design file, retrieving design engineering, finding specific markers, rewriting a digital logic design file and a design engineering top layer file according to the attribute of the marked signal; the recording module isinstantiated, declaration and connection of input and output port signals of the recording module are completed, after digital logic design work of a design project is started, the recording module isused for automatically recording the marked signal state, and the marked signal state is sent to the upper computer through the FPGA for subsequent debugging.

Owner:INSPUR ARTIFICIAL INTELLIGENCE RES INST CO LTD SHANDONG CHINA

A press air cushion lifting control device and method based on power failure protection

The invention relates to a press machine air pad ascending and descending control device based on power failure protection, and belongs to the technical field of a plate material forming press machine. The press machine air pad ascending and descending control device comprises an air pad jacking cylinder, an air storage tank and a control air source, wherein a high-pressure air inlet air path and a low-pressure air inlet air path are connected between an air outlet of the air storage tank and a lower cavity of the air pad jacking cylinder; a high-pressure air inlet valve is arranged on the high-pressure air inlet air path; a low-pressure air inlet valve is arranged on the low-pressure air inlet air path; the control air source is respectively connected with the high-pressure air inlet valve and the low-pressure air inlet valve through a high-pressure air inlet control valve and a low-pressure air inlet control valve, and the low-pressure air inlet control valve is a two-position five-way double-electric-control self-maintaining electromagnetic valve. The invention also discloses a press machine air pad ascending and descending control method based on power failure protection. The device and the method have the advantages that an air pad is enabled to be always in an ascending jacking state in the mold debugging process, and the misoperation possibility of the air pad is reduced to minimum, and the potential safety hazards in the mold debugging process can be eliminated, and the safety of the mold debugging personnel is ensured.

Owner:DONGFENG MOTOR CORP HUBEI

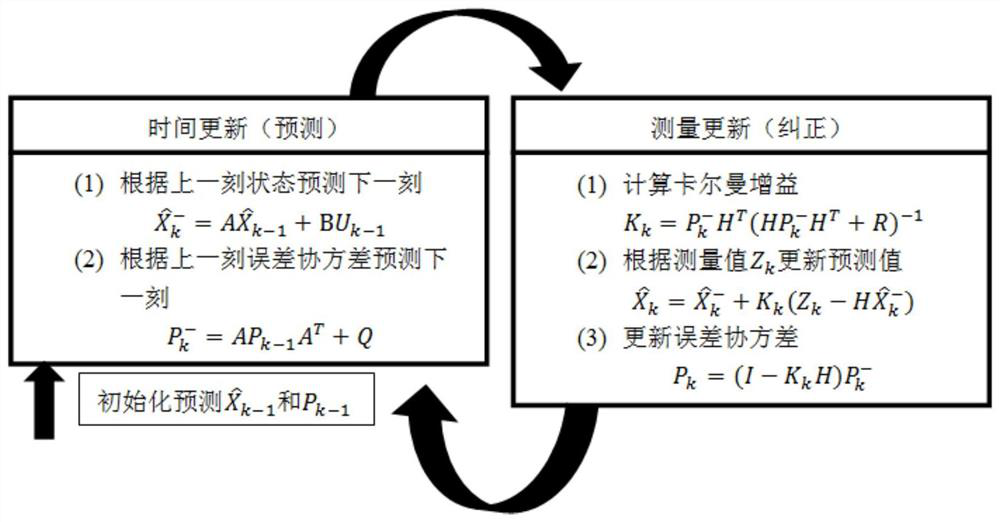

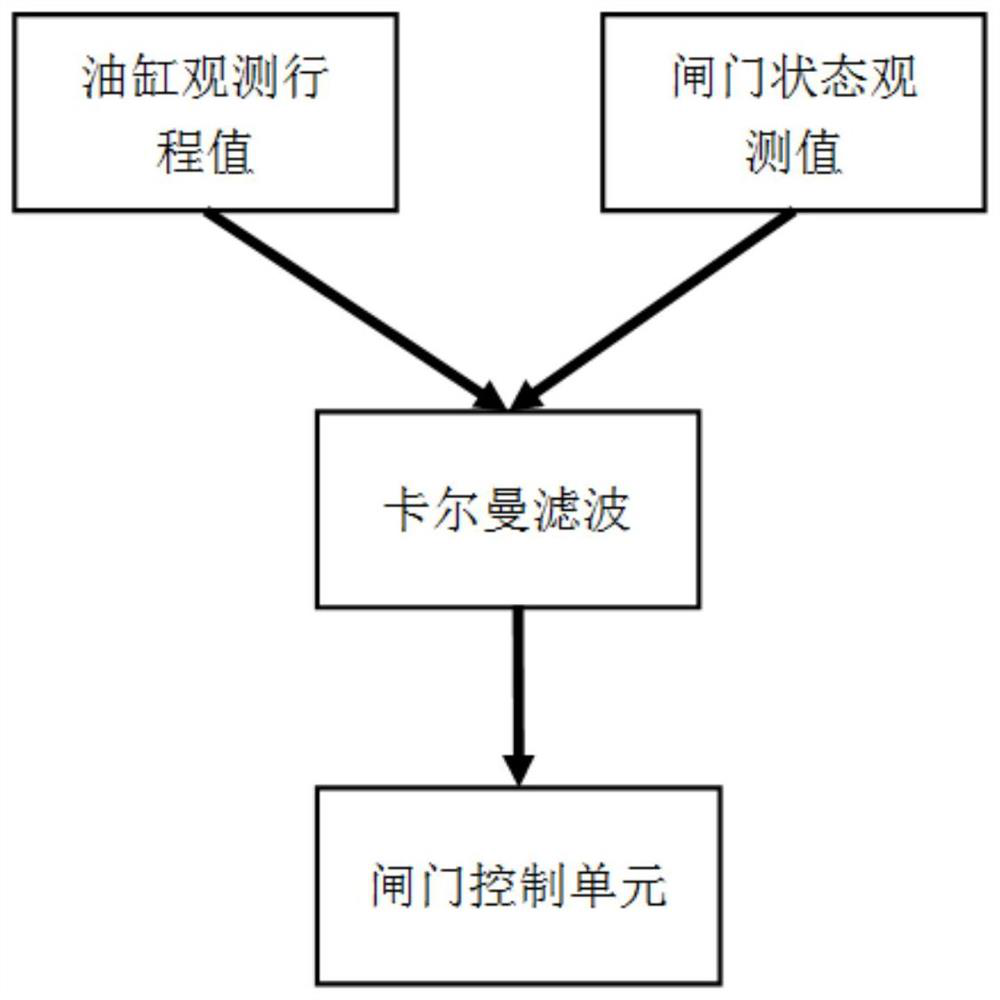

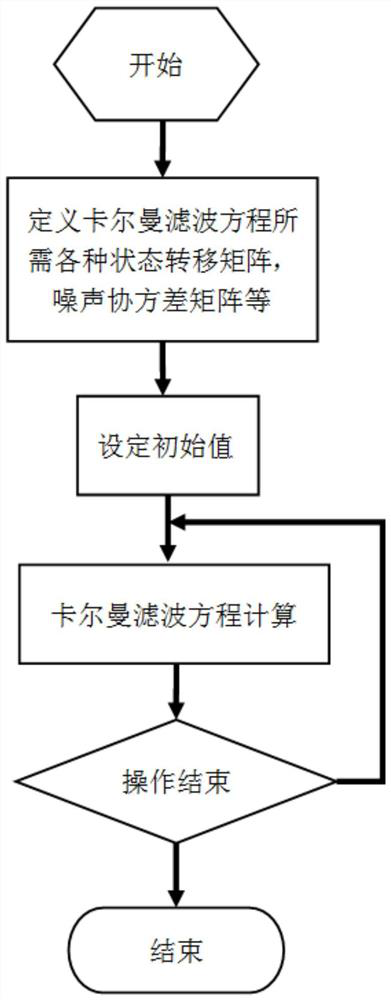

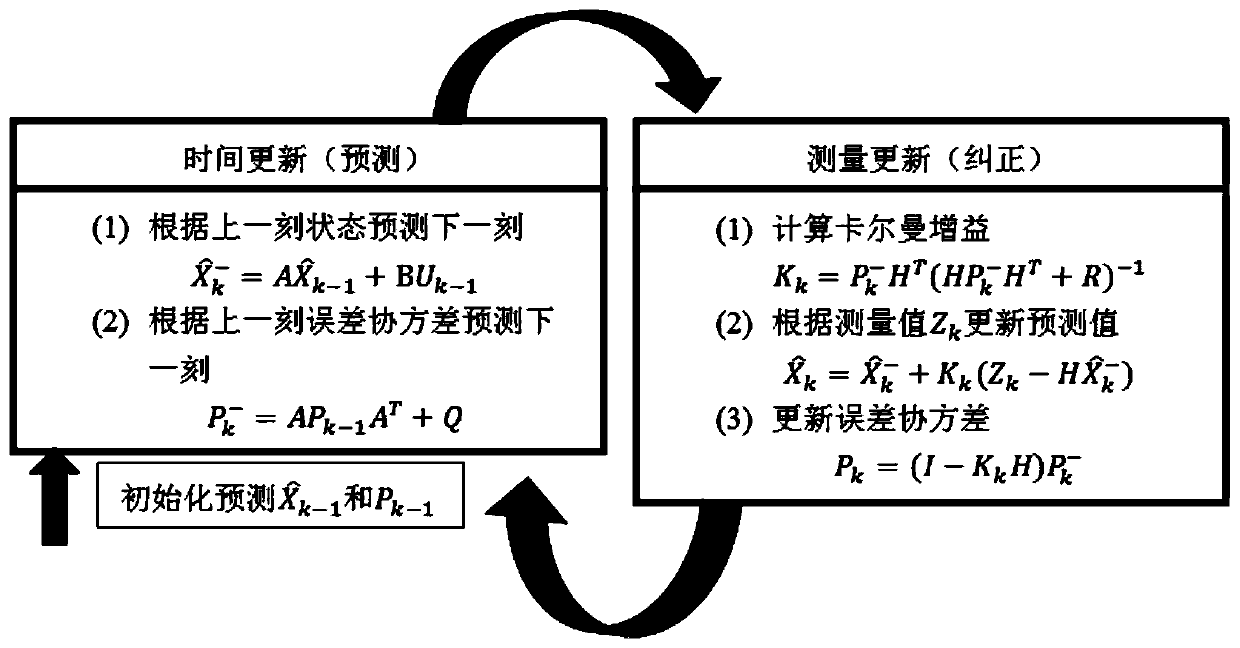

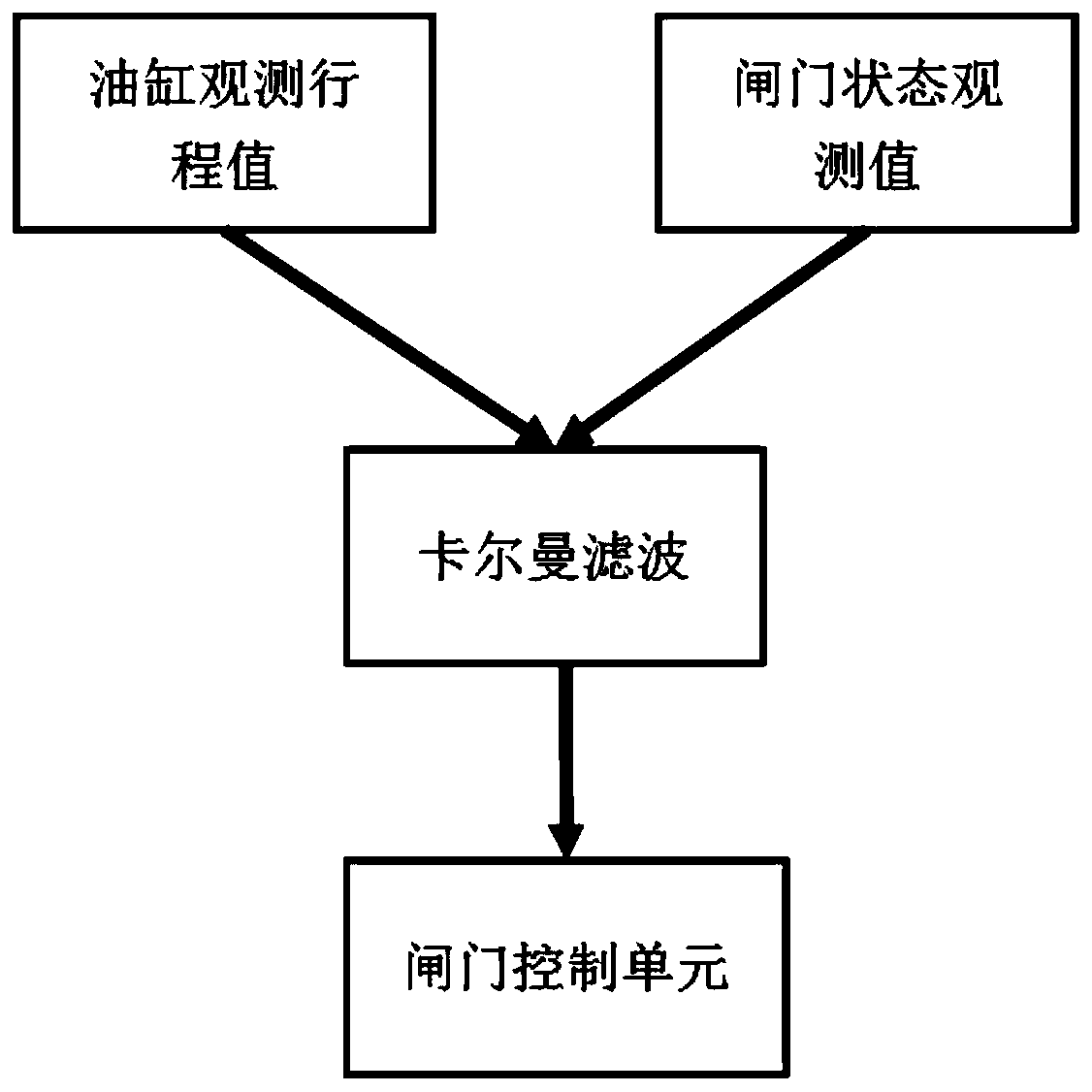

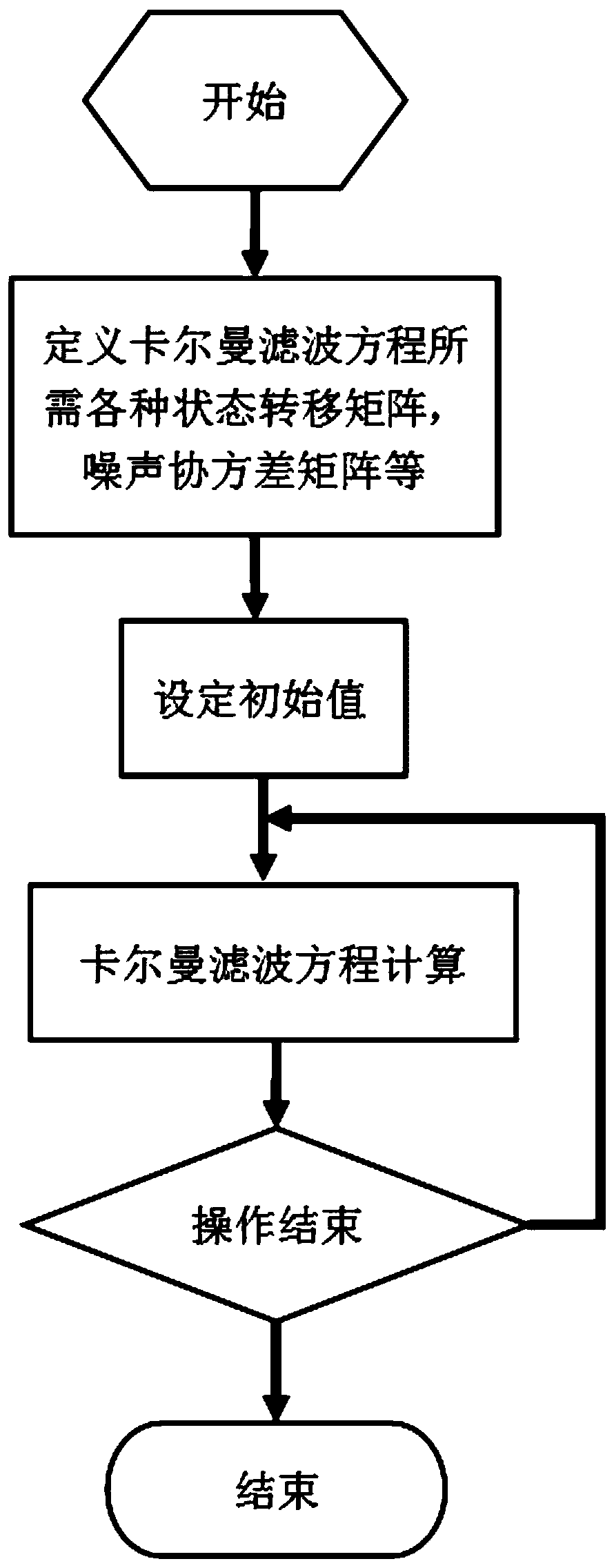

A Compensation Method for Double-cylinder Hydraulic Gate Cylinder Stroke Error Based on Kalman Filter

ActiveCN110245404BReduce consumptionReduce memory requirementsDesign optimisation/simulationSpecial data processing applicationsControl systemElectrical control

The invention provides a Kalman filter-based double-cylinder hydraulic gate oil cylinder stroke error compensation method, which is applied in the gate debugging operation process, and uses instruments to detect the stroke deviation value of the left and right oil cylinders and the water seal extrusion of the gate during the opening and closing operation process of the gate. Value, gate noise value, gate vibration value and other observation data of the gate operating state, and input into the Kalman filter equation, the updated predicted value is used as the cylinder stroke correction value, as the actual cylinder stroke value, the gate electrical control system according to According to the predicted stroke value of the cylinder, adjust the voltage value of the setting proportional control valve, so that the operating speed of the left and right cylinders changes, and the stroke difference between the two cylinders changes accordingly, and then adjust the state of the gate in the gate slot, and run with the best track to ensure the gate is efficient. Stable and reliable.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Debugging method, device and system of power amplifier

ActiveCN104539250BImprove debugging work efficiencyAvoid lack of versatilityPower amplifiersSoftware testing/debuggingAudio power amplifierDebugger

The present invention provides a debugging method, device and system of a power amplifier. The method comprises the steps of: loading a debugging script of a power amplifier to be debugged in advance, obtaining a debugging item list of the power amplifier from the debugging script; Select a debugging project from the debugging project list as the current debugging project, determine the type of the current debugging project; obtain the relevant setting data and related operation instructions of the current debugging project from the debugging script, and according to the relevant The setting data and the relevant operation instructions perform debugging corresponding to the type of the power amplifier. By adopting the scheme of the invention, the debugging efficiency can be improved while ensuring the consistency of the debugging results.

Owner:COMBA TELECOM SYST CHINA LTD

A control system that realizes one-screen multi-machine control on a touch screen by shorting ports

ActiveCN104460407BRealize the control methodReduce management costsProgramme controlComputer controlMulti machineControl system

The invention relates to one-screen multi-machine control over a touch screen, in particular to a control system for conducting one-screen multi-machine control over the touch screen by changing the short-circuit mode of an upper circuit port. The control system comprises the touch screen and a master control circuit. The master control circuit comprises a master control CPU. The touch screen is connected with the master control CPU through an RS-485 serial port. The control system is characterized in that a master control circuit IO interface comprises a plurality of short circuit terminals and a jumper cap, the short circuit terminals are connected to the master control CPU, and when the jumper cap is in short-circuit connection with different short circuit terminals, the master control CPU detects the level of each short circuit terminal; the master control CPU configures salve station addresses corresponding to equipment according to the detected level of the IO interface to control the different kinds of equipment. According to the control system, dial switches are arranged on the circuit, so that the current state is defined, the current state is recognized, the corresponding received and transmitted data are determined, and therefore the one-screen multi-machine control mode is achieved.

Owner:BEIJING IN POWER ELECTRIC +1

Stroke error compensation method for double cylinder hydraulic gate cylinder based on artificial neural network

ActiveCN106759137BIncrease water seal extrusionReflect the actual operating statusBarrages/weirsAdaptive controlControl systemNoise level

The invention discloses an artificial neural network-based method for compensating the cylinder stroke error of a double-cylinder hydraulic gate, including the steps of: 1) defining the key data of the gate state: left and right cylinder stroke deviation value ΔHc, gate left and right opening deviation value ΔH, gate water seal squeeze Pressure D, gate noise level DB, gate vibration level V; 2) Collect key data and set error classification standards; 3) Determine the best error range; 4) Establish a mapping relationship between key data and cylinder stroke compensation value h; 5 ) Establish the initial BP artificial neural network model to obtain the cylinder stroke compensation value h; 6) Output the cylinder stroke compensation value h to the electric synchronous correction control system of the gate; 7) Perform artificial neural network training to obtain the optimal trajectory of the gate operation. The invention comprehensively and accurately reflects the actual operating state of the gate, solves the problem that the gate state reflected by the stroke detection value of the oil cylinder is inconsistent with the actual gate state, and significantly improves the synchronization accuracy of the gate operation.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Kalman filtering-based double-cylinder hydraulic gate oil cylinder stroke error compensation method

ActiveCN110245404ASolve the problem of low efficiency and slow operation speedReduce the need for computing resourcesDesign optimisation/simulationSpecial data processing applicationsObservation dataControl system

The invention provides a Kalman filtering-based double-cylinder hydraulic gate oil cylinder stroke error compensation method. The method is applied to a gate debugging operation process, and comprises the steps of detecting the observation data of the gate operation states, such as the left and right oil cylinder stroke deviation values, a gate water seal extrusion value, a gate noise value, a gate vibration value, etc., during the gate opening and closing operation process through an instrument; inputting the observation data into a Kalman filtering equation; taking the updated predicted value as an oil cylinder stroke correction value and as an actual oil cylinder stroke value, enabling a gate electrical control system to adjust and set the voltage value of the proportional regulating valve according to the predicted oil cylinder stroke value, so that the operating rate of the left oil cylinder and the right oil cylinder is changed, the stroke difference of the left oil cylinder and the right oil cylinder is changed accordingly, and further the state of the gate in a gate groove is adjusted, the gate operates in an optimal track, and the gate is efficient, stable and reliable.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

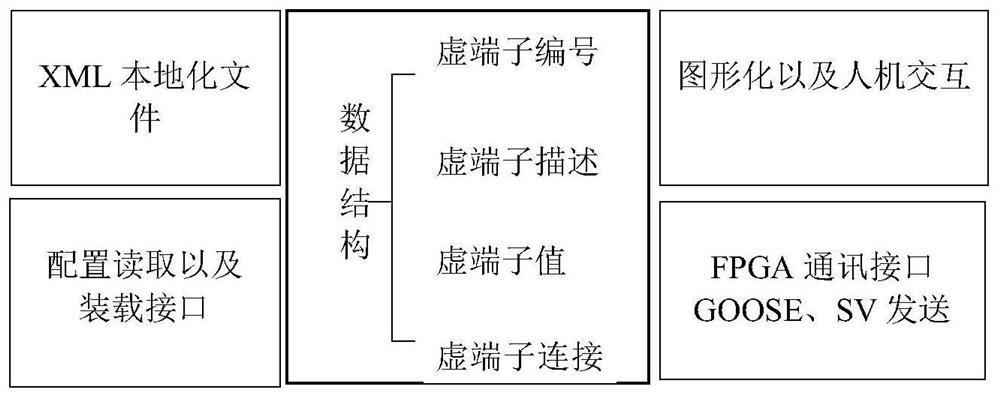

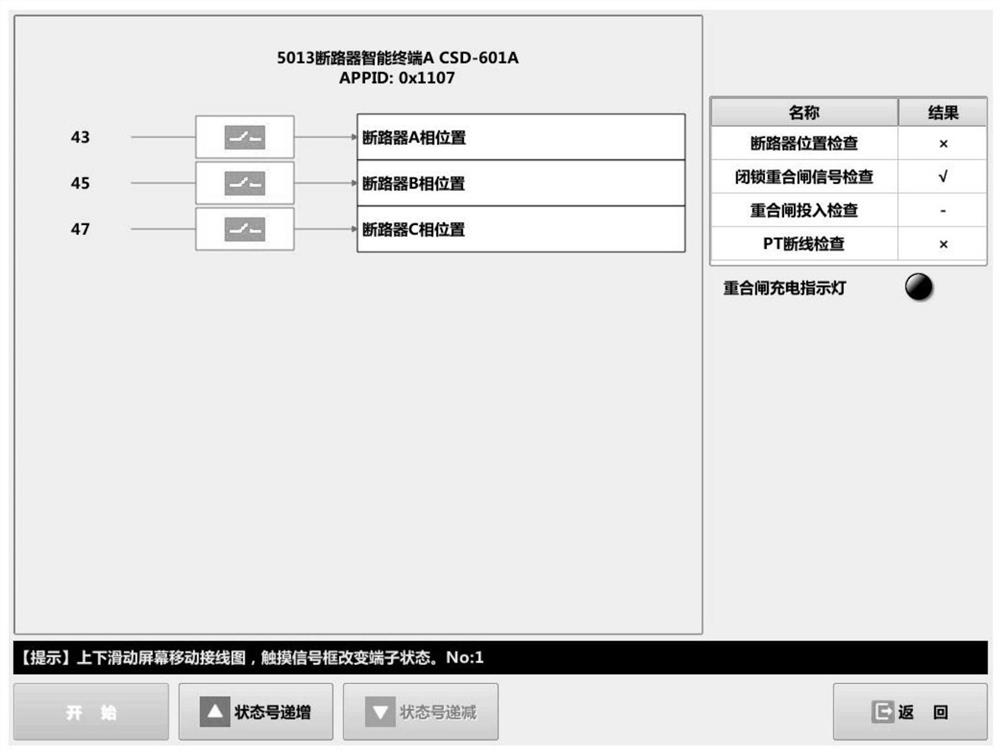

Intelligent station relay protection calibrator with line reclosing automatic judgment function

ActiveCN111474440BImprove debugging work efficiencyContinuity testingVirtual terminalSmart substation

The invention relates to an intelligent station relay protection calibrator with the function of automatically judging line reclosing. The intelligent station relay protection calibrator includes a programmable hardware platform, a reading and loading interface connected to the programmable hardware platform, and a graphical and human-computer interaction platform connected to the programmable hardware platform. The reading and loading interface is used to receive the SCD file and configuration parameters of the smart substation; the programmable hardware platform is used to parse the SCD file, build the line IDE linked list and virtual terminal list of the smart substation based on the result of parsing the SCD file, and obtain SV and GOOSE data , Based on the SV and GOOSE data, the logical judgment of the line reclosing condition is carried out to obtain the line reclosing judgment result; the graphical and human-computer interaction platform is used to graphically display the line reclosing judgment result. The invention can automatically and quickly judge and display the line reclosing of the intelligent substation, thereby improving the debugging work efficiency.

Owner:JIANGSU ELECTRIC POWER CO

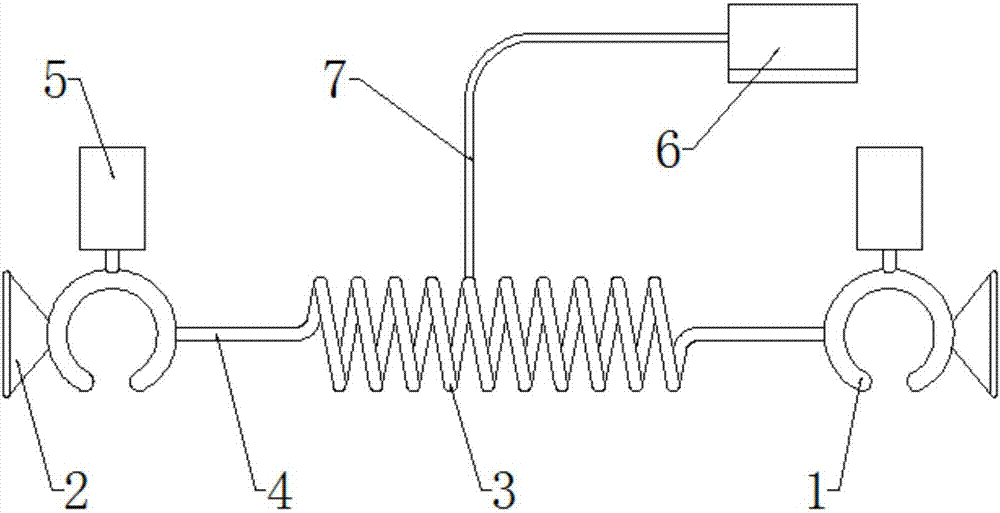

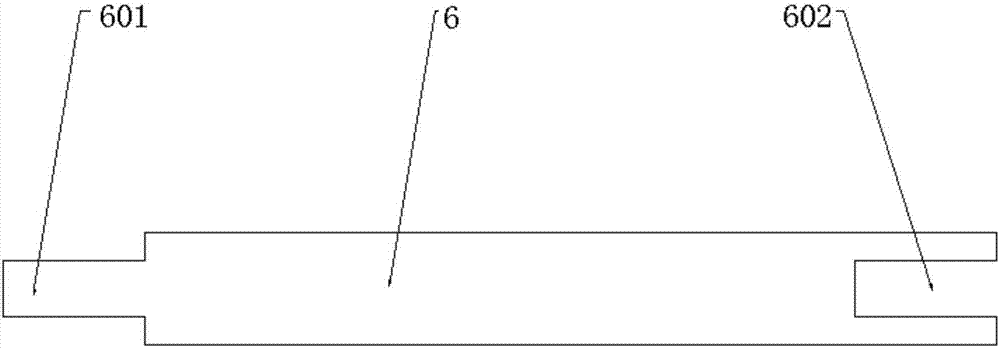

Terminal connection verifier

PendingCN107516789AImprove debugging work efficiencyEasy to markCouplings bases/casesElectrical controlEngineering

The invention discloses a terminal connection verifier. The verifier comprises two clamping rings (1) used for carrying out clamp connection on a same electric wire and a connection wire (4) used for connecting the two clamping rings (1). The clamping rings (1) are provided with connection components connected to a terminal and terminal nameplates (5). The terminal connection verifier can rapidly and accurately find the two terminals which are connected to each other, and can conveniently mark the terminals which are connected to each other and a wiring line so that efficiency of electrical control cabinet debugging work is increased.

Owner:ECONOMIC RES INST OF STATE GRID GANSU ELECTRIC POWER +2

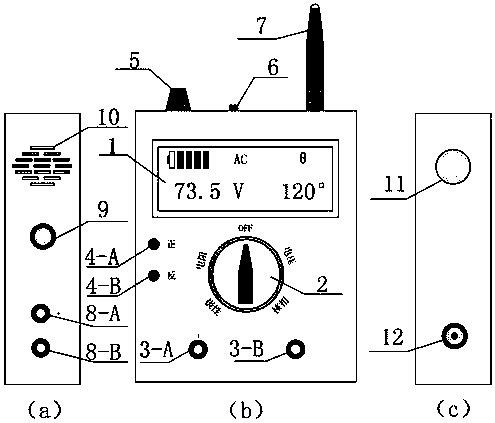

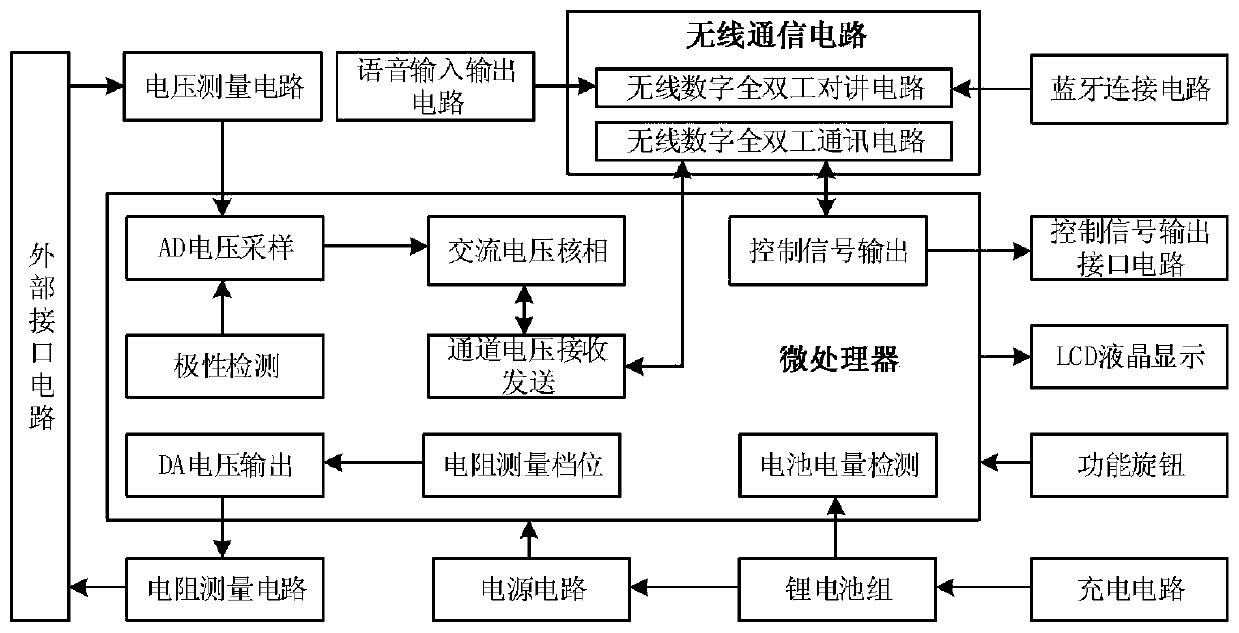

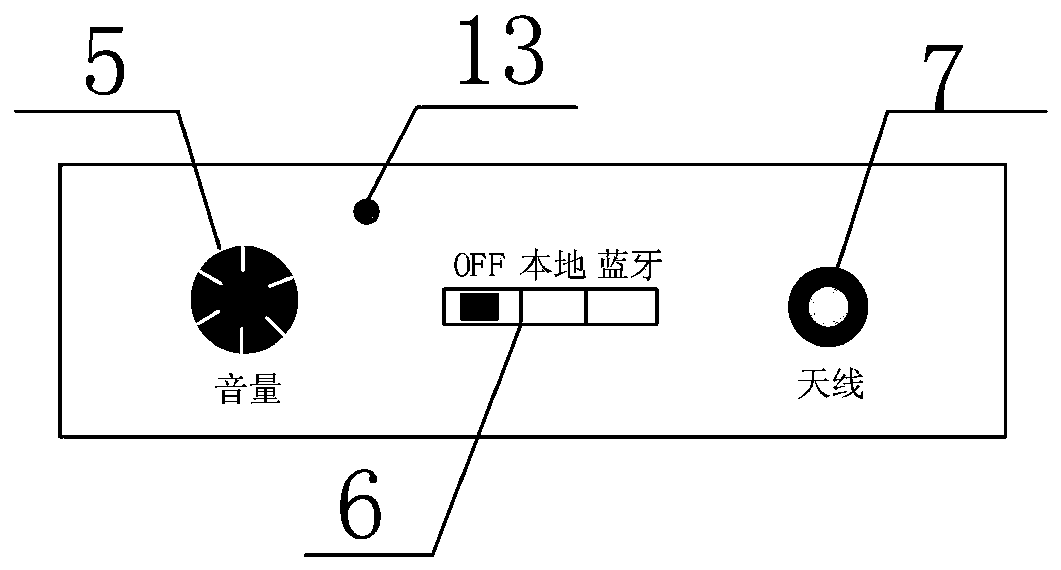

Multifunctional wireless relay protection debugging auxiliary instrument

PendingCN111025054AReduce volumeFlexible useElectrical testingRadio transmissionWireless controlTransformer

The invention relates to a multifunctional wireless relay protection debugging auxiliary instrument. The instrument is characterized in that a shell is provided with an LED liquid crystal display screen, a function knob, a positive electrode input terminal, a negative electrode input terminal, a talkback power switch, a wireless data communication antenna, a pulse positive electrode output terminal, a pulse negative electrode output terminal, a pulse output control button, an audio output port, a Bluetooth connection port and a charging interface; and a debugging circuit is arranged in the shell and comprises a voltage measurement module, a resistance measurement module, a power supply module, a voice module, a wireless communication module, a microprocessor and a battery electric quantitydetection module. The instrument is scientific and reasonable in design, is small in size, is complete in function, can realizes functions of a simple universal meter, full duplex intercom, PT phasechecking, polarity discrimination of a power transformer polarity test and wireless control of pulse output, and is flexible in use; and debugging is flexible, and the working efficiency is improved.

Owner:TIANJIN ELECTRIC POWER TRANSMISSION & TRANSFORMATION ENG CORP +2

Screen parameter debugging method and server

ActiveCN106776174BSolve the problem of low debugging efficiencySimplified commissioning stepsDetecting faulty computer hardwareSoftware testing/debuggingSoftware engineeringServer

A display parameter debugging method and a server are provided; the method comprises: when the server acquires single parameter information of any target parameter, generating a script corresponding to current parameter information, wherein the server includes multiple target parameters in one-to-one correspondence with multiple display parameters of a board to be debugged, and each target parameter is pre-provided with single or multiple parameter information; allowing the server to transmit the script and the current parameter information to the board to be debugged through a serial port so that the board to be debugged replaces, according to the script, the display parameter information corresponding to the current target parameter with the current parameter information. The problem that a complex process for correcting and debugging a display in the prior art results in low debugging efficiency is solved, display screen debugging steps are simplified, and debugging efficiency is improved.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

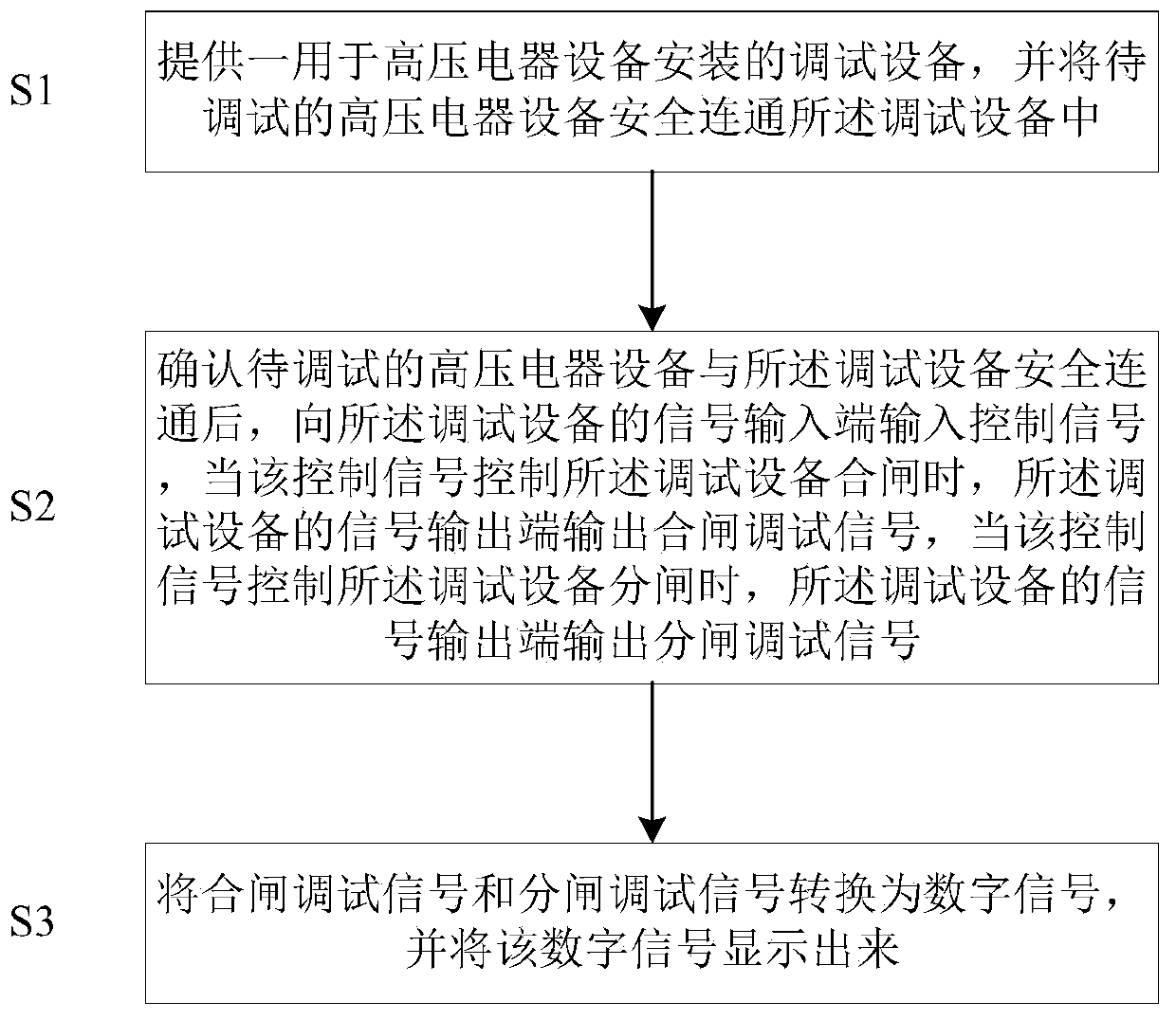

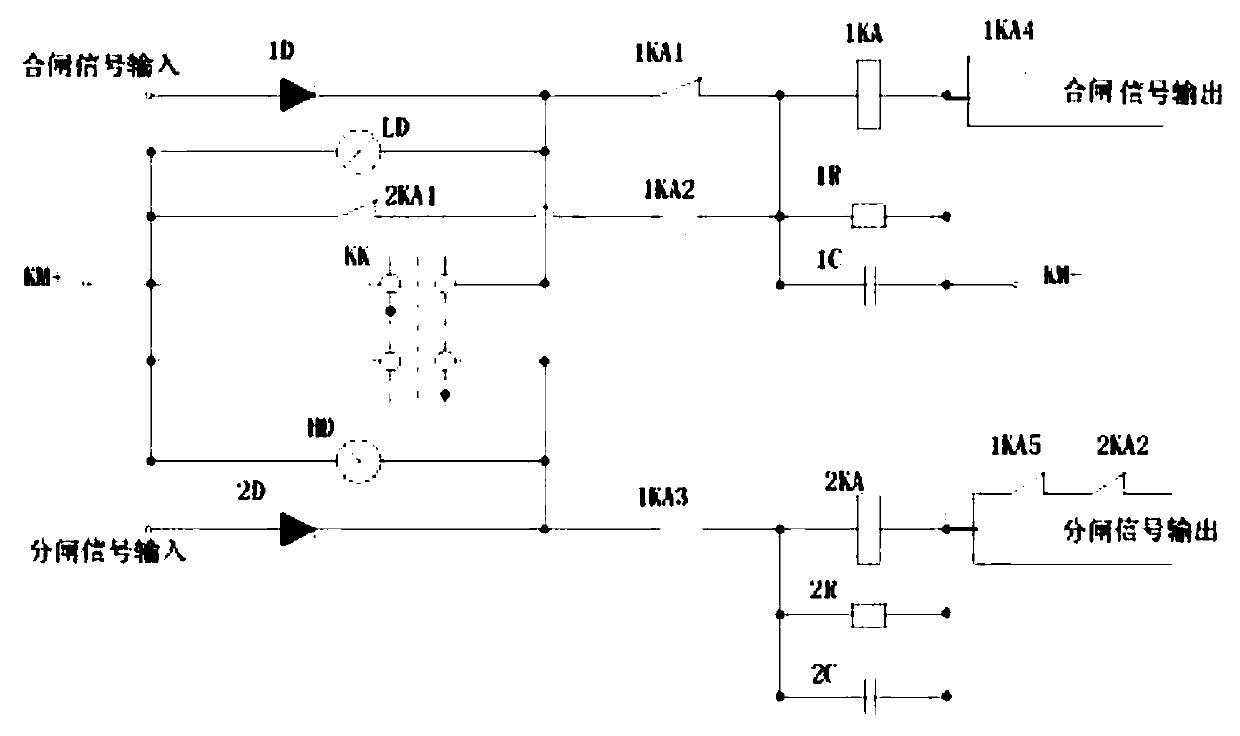

Method for installing and debugging high-voltage electrical equipment

InactiveCN110308356AReduce labor intensityImprove debugging work efficiencyElectric connection testingHigh pressureEquipment Safety

The invention discloses a method for installing and debugging high-voltage electrical equipment. The method includes the following steps of: providing debugging equipment for the installation of the high-voltage electrical equipment, and safely connecting the to-be-debugged high-voltage electrical equipment to the debugging equipment; after confirming that the to-be-debugged high-voltage electrical equipment is in safe connection with the debugging equipment, inputting a control signal to the signal input end of the debugging equipment, outputting a closing debugging signal by the signal output end of the debugging equipment when the control signal controls the debugging equipment to be closed, and outputting an opening debugging signal by the signal output end of the debugging equipment when the control signal controls the debugging equipment to be opened; and converting the closing debugging signal and the opening debugging signal into a digital signal, and displaying the digital signal. According to the scheme of the invention, the labor intensity of the debugging personnel in the debugging process of the high-voltage electrical equipment can be reduced, and the efficiency of debugging can be improved.

Owner:STATE GRID JIANGSU ELECTRIC POWER ENG CONSULTING CO LTD +1

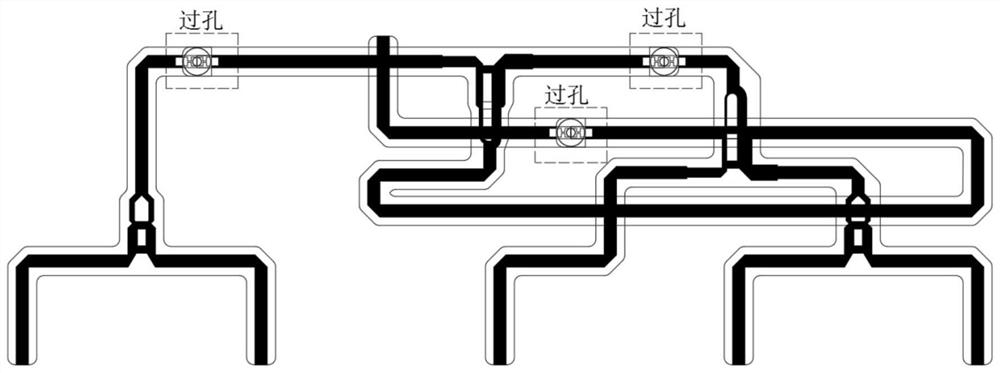

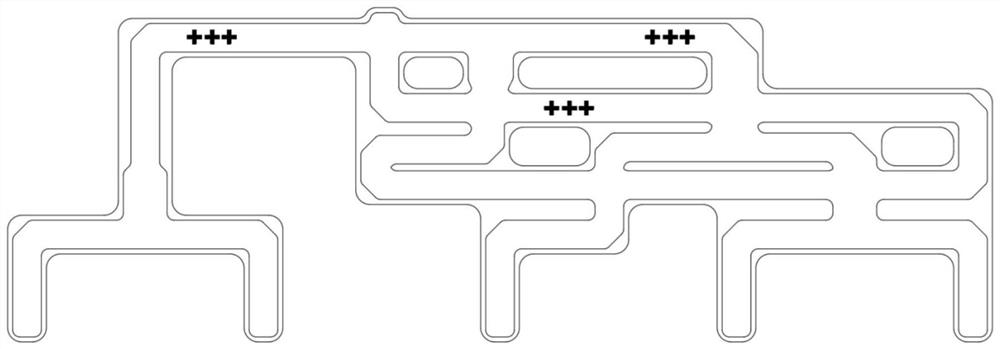

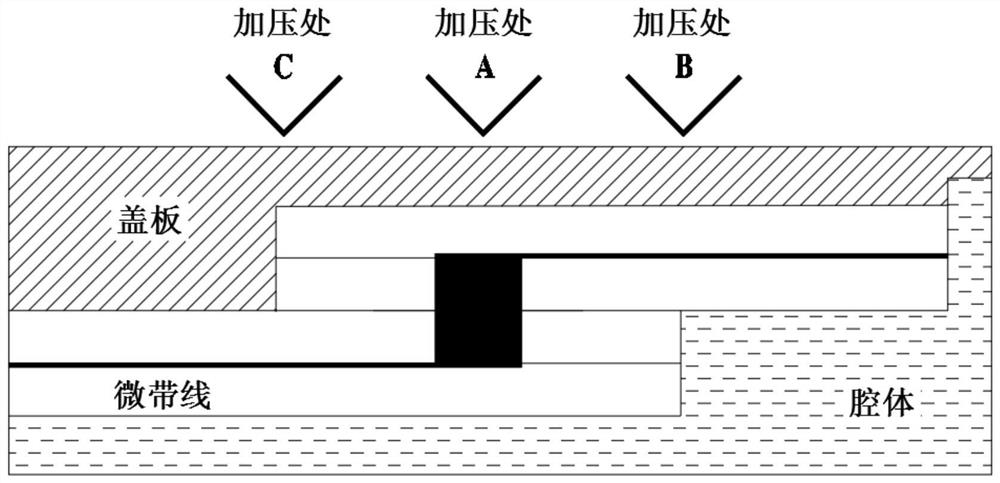

Debugging method for micro-strip power divider after laser welding and packaging

ActiveCN114256586AImprove pass rateImprove temperature stabilityCoupling devicesMicrowaveElectrical performance

The invention belongs to the technical field of microwave antennas, and relates to a debugging method for a micro-strip power divider after laser welding packaging. The microstrip power divider comprises a cavity, a cover plate, a microstrip line circuit board and a connector. The cavity and the cover plate are packaged in a laser welding mode. The microstrip line circuit board and the connector are mounted in the cavity; the debugging method of the micro-strip power divider after laser welding packaging comprises the following steps: applying force and / or impact to the outside of the cavity and / or the cover plate to enable the cover plate to generate elastic and / or plastic deformation, and debugging the micro-strip circuit board and / or the connector. The micro-strip power divider subjected to laser packaging can be debugged and repaired, the microwave electrical performance of the micro-strip power divider is guaranteed, and the high and low temperature stability of the micro-strip power divider is guaranteed.

Owner:LEIHUA ELECTRONICS TECH RES INST AVIATION IND OF CHINA

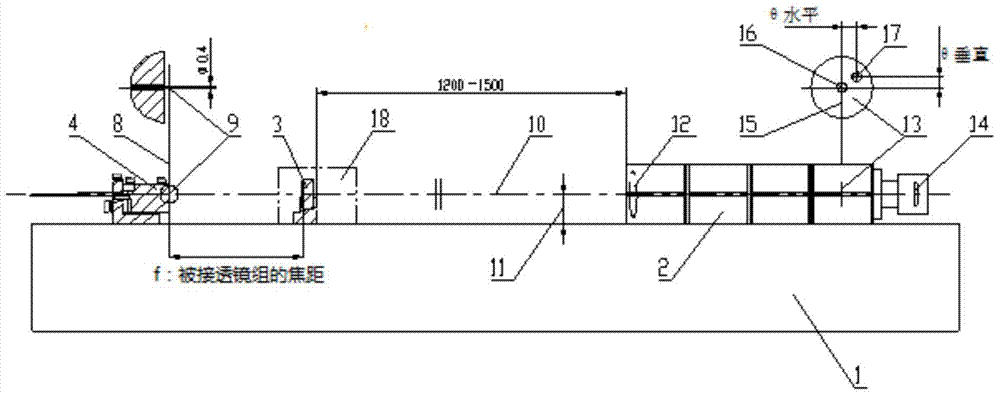

A light beam directivity debugging system and method

The invention provides a light beam directivity debugging system, which includes a reference platform, a square tube front mirror, an adjusted lens group, a standard cursor group, a conductive optical fiber, a red light source, and a light source control box; The lens group and the standard cursor group are sequentially arranged on the reference platform along the optical path; the red light source and the light source control box form a controllable light source and are transmitted to the indicating end face of the standard cursor group through the conduction fiber; the conduction fiber, the red light source and the light source control box are set On the reference platform; the collimation axis of the square tube front mirror and the standard cursor group are constructed as a reference axis, and the light-emitting end face of the standard cursor group is used as an indicator cursor to guide the adjusted lens group to indicate the light-emitting point of the lens for debugging. The light beam directivity debugging system of the present invention uses the collimation axis of the front mirror of the square tube and the standard cursor group to establish a reference axis, and uses the light-emitting end face of the standard cursor group as an indicator cursor to indicate the light output direction of the lens through the imaging position of the adjusted lens. , so that precise debugging can be performed.

Owner:BEIJING GK LASER TECH

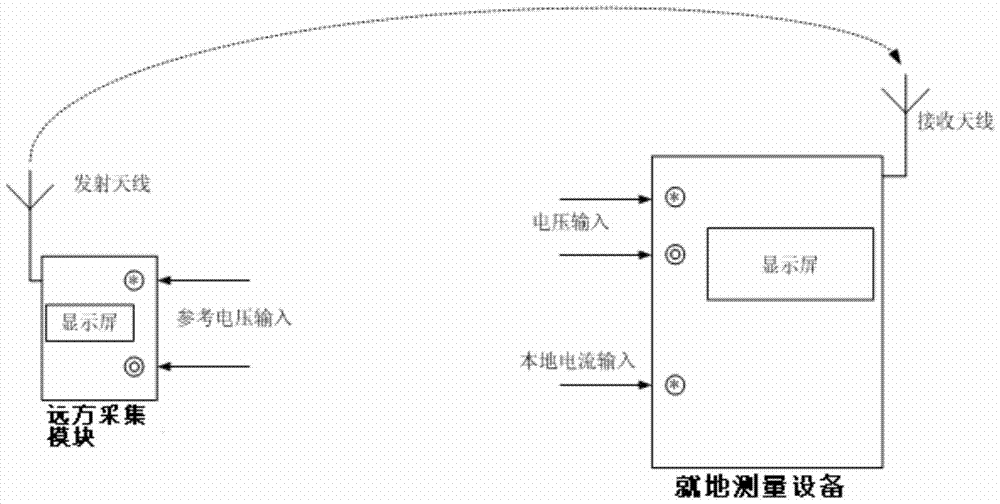

Method for wireless transmission of reference phasors in analog or phasor measurements

InactiveCN104155522BResolving dependencies on reference phasorsAvoid the risk of electric shockTransmission systemsCurrent/voltage measurementWireless transmissionMeasurement point

The invention relates to a method of wirelessly transmitting reference phasor in analog or phasor measurement. The method is characterized by comprsing the following steps: voltage reference phasor is acquired, the acquired voltage reference phasor is wirelessly transmitted in a wireless transmission mode, the above voltage reference phasor is received by adopting a wireless receiving mode in a measurement place, and the received voltage reference phasor is used to complele the phasor measurement work at the measurement place. The invneiton provides an analog phasor measurement method based on the wireless reference phasor transmission mode, a phasor measurement experiment can be carried out on a secondary current circuit in need of phasor measurement at any place, the problem that current phasor measurement can not be carried out when no reference voltage phasor place (such as an outdoor current transformer terminal box, a 2 / 3 connection mode bus protection screen and the like) exists can be solved, and the problem that a conventional phase meter, a volt ampere characteristic tester and other measurement mode depend on measurement place reference phasor can be solved.

Owner:STATE GRID CORP OF CHINA +2

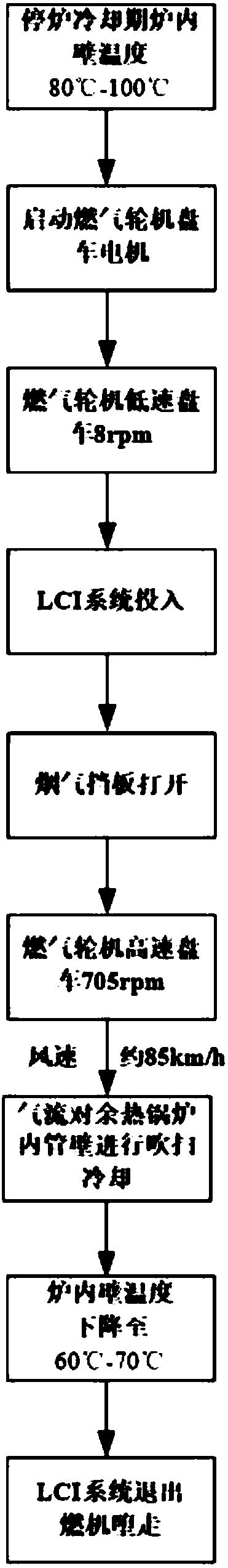

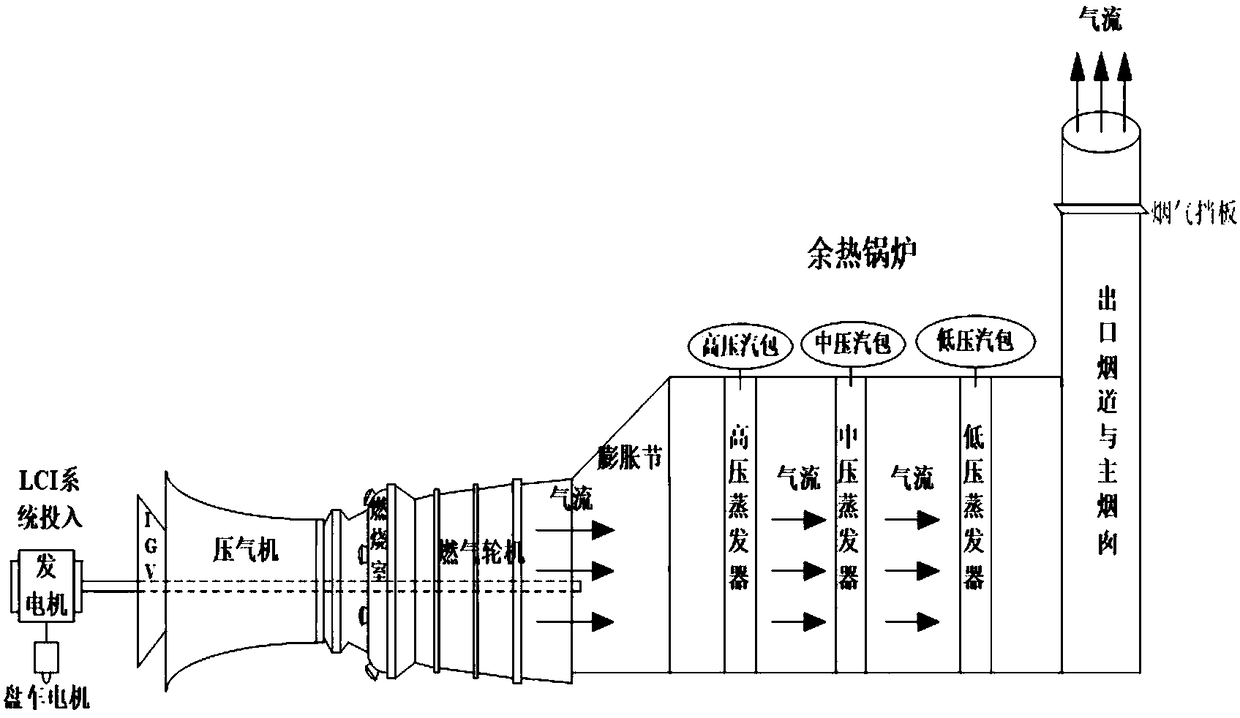

Method for cooling inner wall of waste heat boiler during adjustment of blowpipe of fuel-steam unit

ActiveCN108561868AReduce the phenomenon of high temperatureShorten the construction periodCleaning heat-transfer devicesSteam generation using hot heat carriersImpellerLow speed

The invention relates to a method for cooling the inner wall of a waste heat boiler during adjustment of a blowpipe of a fuel-steam unit. The method comprises the steps that (1) a gas turbine turningmotor is started, and a gas turbine is made to turn at a low speed, specifically, the rotation speed is 8 rpm, and duration is 30 min; (2) an LCI system is started, the turning motor disengages and exits, and the gas turbine is turned at a high speed; (3) a smoke baffle at an outlet flue of the waste heat boiler is opened; and (4) wind power generated by an impeller of a gas turbine is blown towards the inner pipe wall of the waste heat boiler for cooling, the LCI system exits when the temperature of the inner wall of the waste heat boiler is decreased to be about 60-70 DEG C, the idling rotation speed of the gas turbine is gradually decreased to 0 rpm, and the smoke baffle is closed. With adoption of the method, the gas turbine turning at a high speed is used as an electric fan, the generated strong airflow is blown towards the inner pipe wall of the waste heat boiler for cooling, and the phenomenon of high temperature of the inner pipe wall of the waste heat boiler caused by variousreasons can be quickly and effectively solved.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

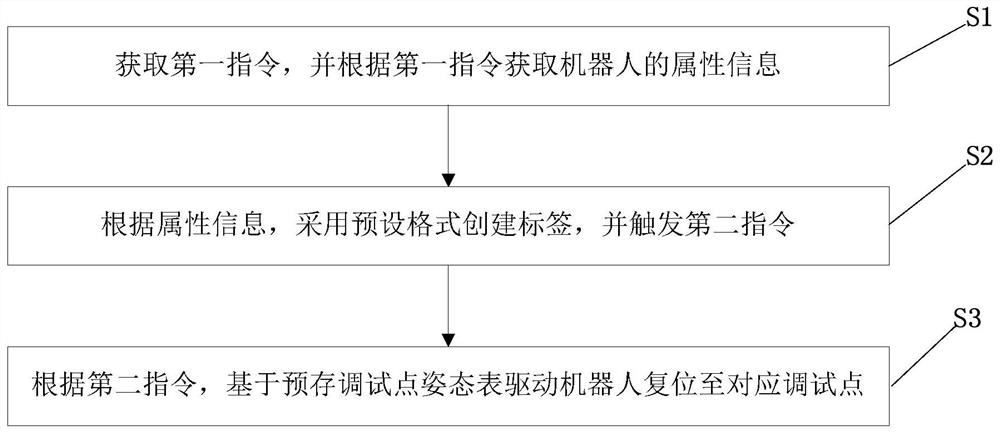

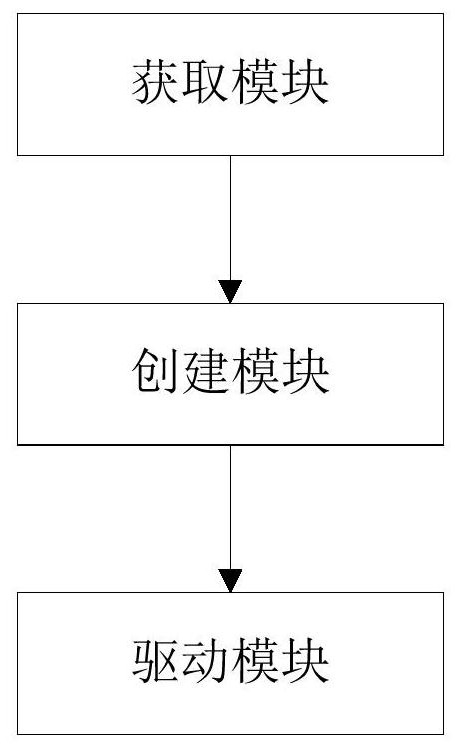

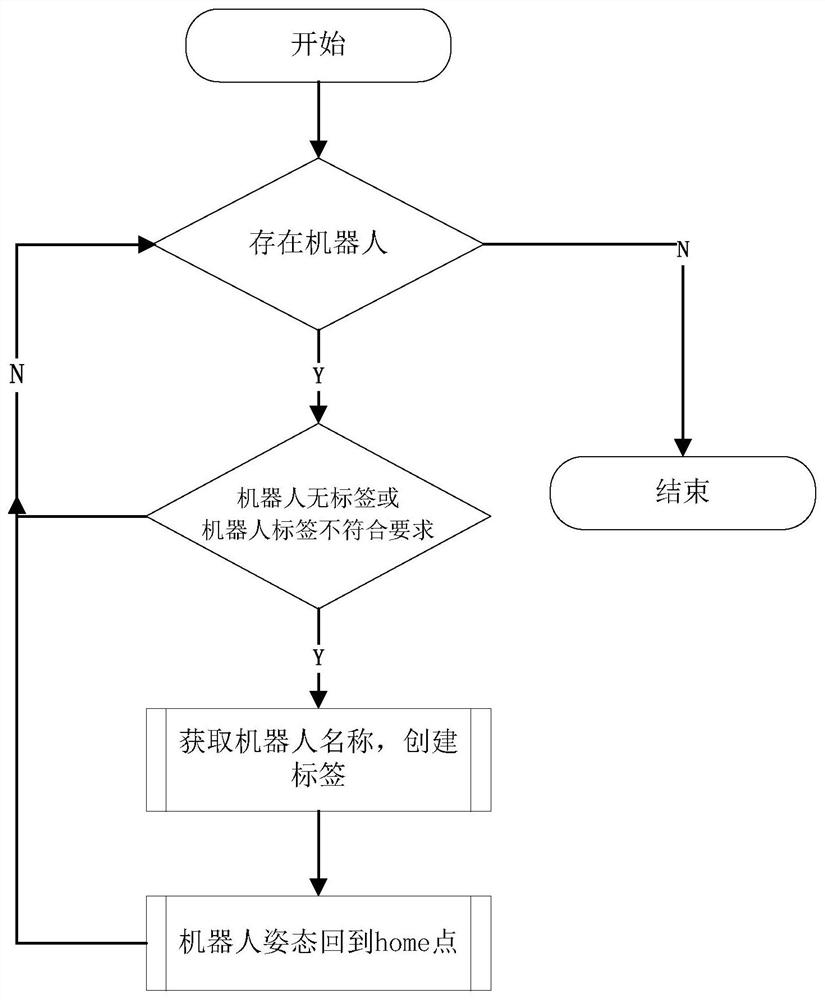

A robot control method, system, device and storage medium

ActiveCN111531540BEasy to operateSave time and costProgramme-controlled manipulatorSimulationControl engineering

The invention discloses a robot control method, system, device and storage medium, wherein the method includes: acquiring a first instruction, and acquiring attribute information of the robot according to the first instruction; creating a label in a preset format according to the attribute information, and triggering The second instruction: According to the second instruction, the robot is reset to the corresponding debugging point based on the pre-stored debugging point posture table; thus realizing the synchronous completion of creating labels and resetting operations, eliminating the need to manually create and edit labels for robots one by one , and saves the operation of manually resetting the robot to the debugging point one by one, simplifies the cumbersome operation process of the previous pre-commissioning, shortens the time and cost of the pre-commissioning, and greatly improves the efficiency of the debugging work, and avoids the robot During debugging such as resetting one by one, the confusion of robot labels will cause interference phenomena such as contact and collision between devices, reducing unnecessary losses and potential safety hazards.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com