A light beam directivity debugging system and method

A technology of beam pointing and debugging system, which is applied in the direction of optical instrument testing, machine/structural component testing, measuring devices, etc. It can solve the problems of large fluctuations in debugging quality, unsuitable for batch debugging of workpieces, and low debugging accuracy. Good consistency of results, high debugging efficiency, and standardized debugging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

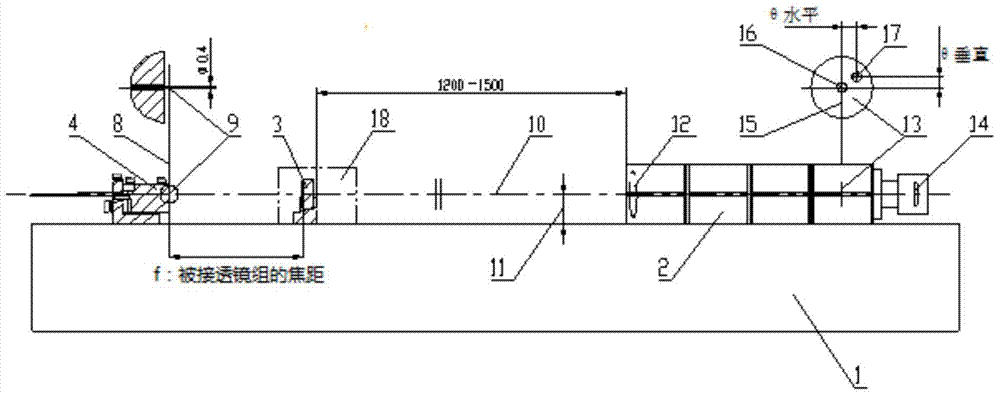

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

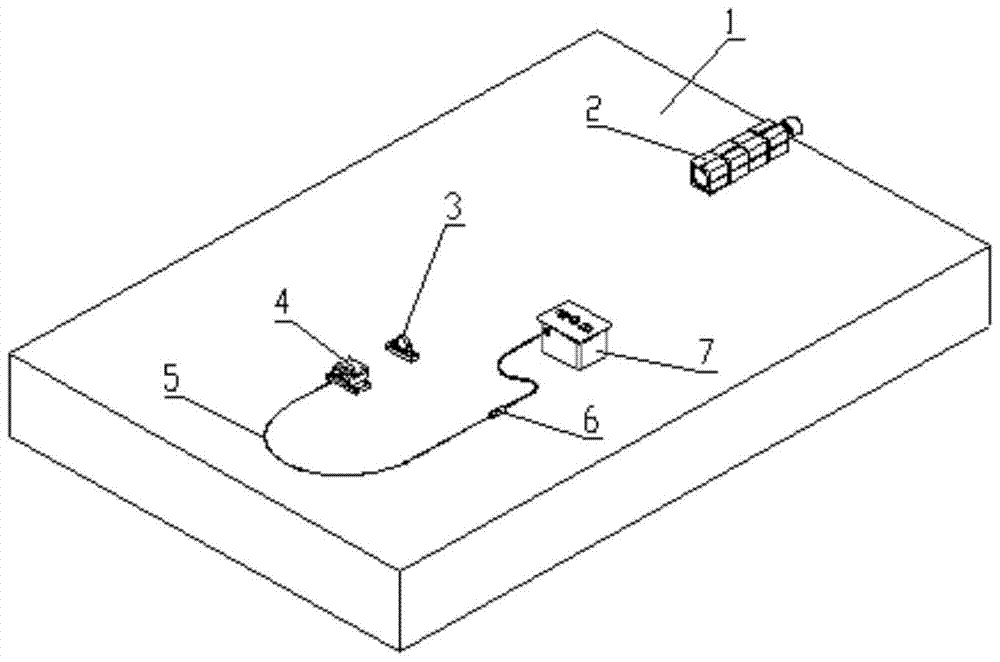

[0034] In one embodiment, the present invention provides a light beam directivity adjustment system, including a reference platform, a square tube front mirror, an adjusted lens group, a standard cursor group, a conductive optical fiber, a red light source, and a light source control box.

[0035] The square tube front mirror, adjusted lens group and standard cursor group are set on the reference platform and arranged in sequence along the optical path.

[0036] The red light source and the light source control box constitute a controllable light source and are transmitted to the indicating end face of the standard cursor group through the conducting fiber; the conducting fiber, the red light source and the light source control box are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com