A robot control method, system, device and storage medium

A control method and control system technology, which is applied in the field of intelligent manufacturing, can solve problems affecting debugging work efficiency, inconvenient debugging work, contact, collision, etc., and achieve the effects of improving debugging work efficiency, shortening time cost, reducing losses and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

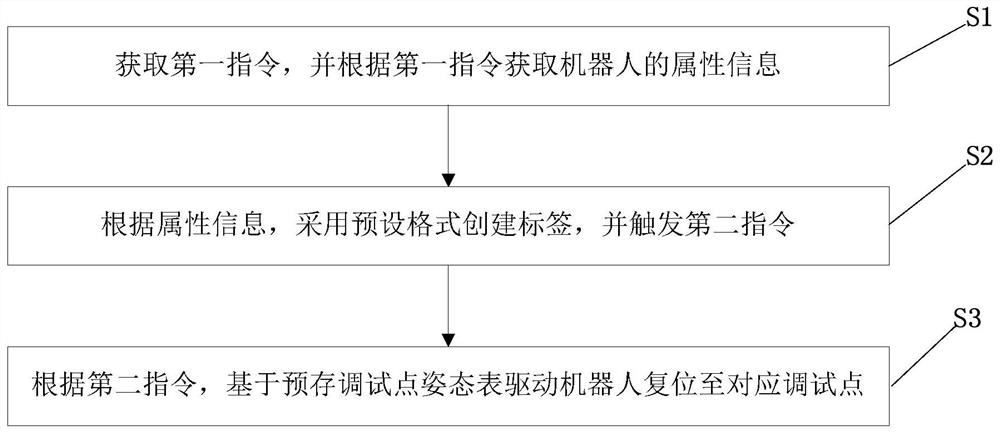

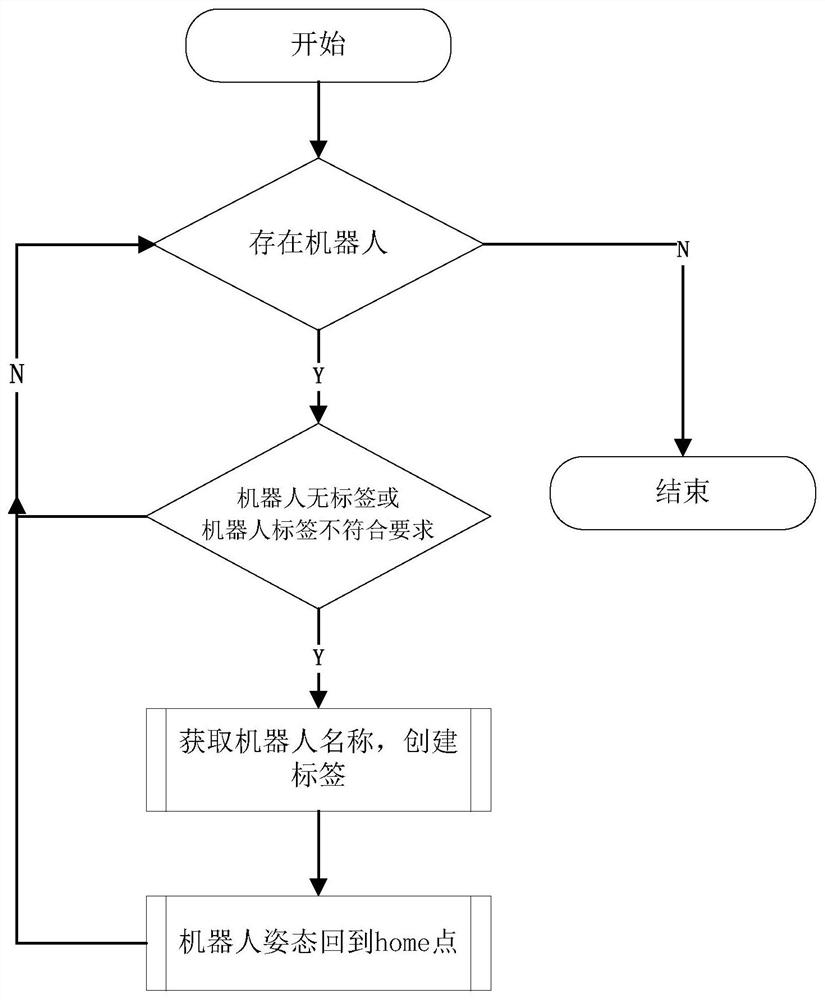

[0048] like figure 1 Shown, is a kind of robot control method provided by the present invention, comprises the following steps:

[0049] S1. Obtain the first instruction, and obtain the attribute information of the robot according to the first instruction;

[0050] S2. Create a label in a preset format according to the attribute information, and trigger a second instruction;

[0051] S3. Drive the robot to reset to the corresponding debugging point based on the pre-stored debugging point posture table according to the second instruction.

[0052] In this embodiment, any software in Process Simulate, Process Design, and Teamcenter under the Tecnomatix platform can be used to carry out debugging work such as production linkage debugging, motion trajectory creation, and signal addition to carry out digital transformation, simulation, and debugging, wherein the attributes Information refers to the information indicating the characteristics and essence of the robot itself, such a...

Embodiment 2

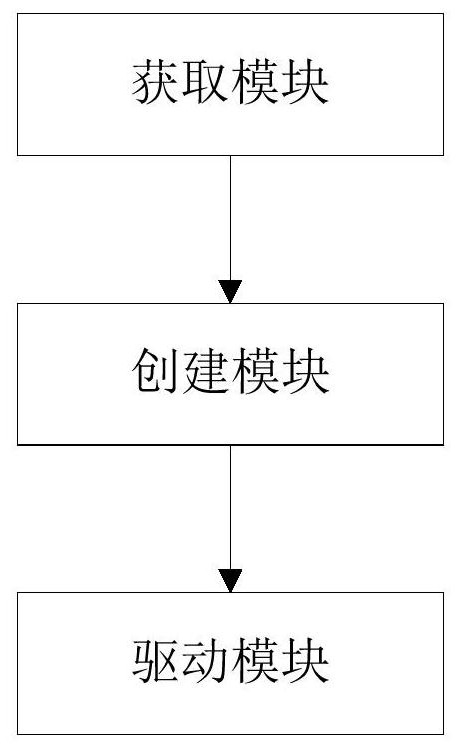

[0068] like figure 2 Shown is a structural block diagram of a robot control system provided by the present invention, including:

[0069] An acquisition module, configured to acquire the first instruction, and acquire the attribute information of the robot according to the first instruction;

[0070] creating a module, configured to create a label in a preset format according to the attribute information, and trigger a second instruction;

[0071] The driving module is configured to drive the robot to reset to the corresponding debugging point based on the pre-stored debugging point posture table according to the second instruction.

[0072] Optionally, the acquisition unit includes:

[0073] A collection unit, configured to obtain a third instruction, and collect robot model data according to the third instruction;

[0074] The trigger unit is configured to trigger the first instruction after the collected robot model data is successfully matched according to the pre-stor...

Embodiment 3

[0083] In an apparatus, the memory is used to store at least one program, and the processor is used to load the at least one program to execute the method described in the method embodiment.

[0084] A device in this embodiment can execute a robot control method provided in Embodiment 1 of the method of the present invention, can execute any combination of implementation steps of the method embodiments, and has the corresponding functions and beneficial effects of the method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com