Method for cooling inner wall of waste heat boiler during adjustment of blowpipe of fuel-steam unit

A waste heat boiler and steam unit technology, which is applied in the steam generation method, the steam generation method using heat carrier, the steam generation and other directions, can solve the problem of lack of safe operation, shorten the construction period, improve the commissioning efficiency, and avoid the waste heat boiler equipment. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings. It should be emphasized that the following embodiments are illustrative, not restrictive, and should not be used as limitations of the present invention.

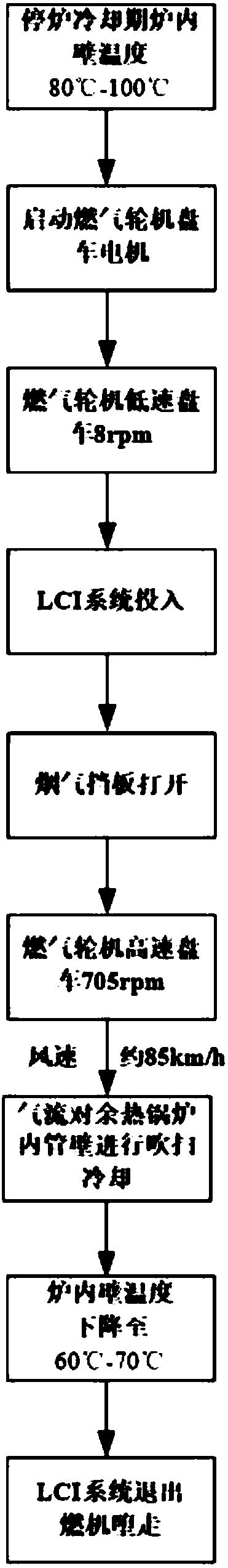

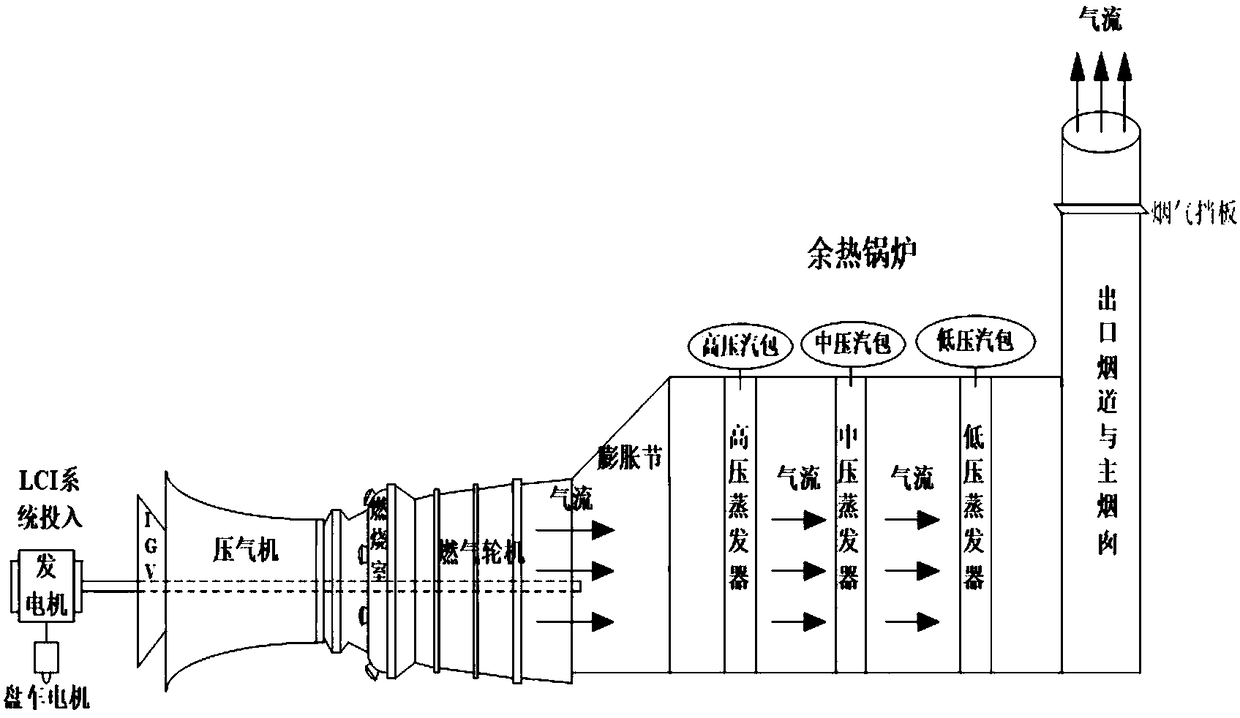

[0025] A cooling method for the inner wall of the waste heat boiler during the debugging and blowing of the gas-steam unit, such as figure 2 As shown, the equipment system used in this method includes: gas turbine, gas turbine cranking system, waste heat boiler, temperature measurement point on the inner wall of waste heat boiler, and the server of the operating unit control system, wherein the gas turbine cranking system includes gas turbine cranking motor and LCI system (Load Commutated Inverter, a speed-adjustable AC drive system specially designed to start gas turbines), such as figure 1 As shown, the method includes the following steps:

[0026] (1) Start the gas turbine cranking mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com