Diesel oil tank antifreezing device

An antifreeze device and fuel tank technology, applied in the automotive field, can solve the problems of affecting the atomization effect of diesel oil, increasing driving costs, increasing fuel consumption, etc., achieve high use value and promotion value, reduce fuel consumption and operating costs, and prevent diesel from solidifying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

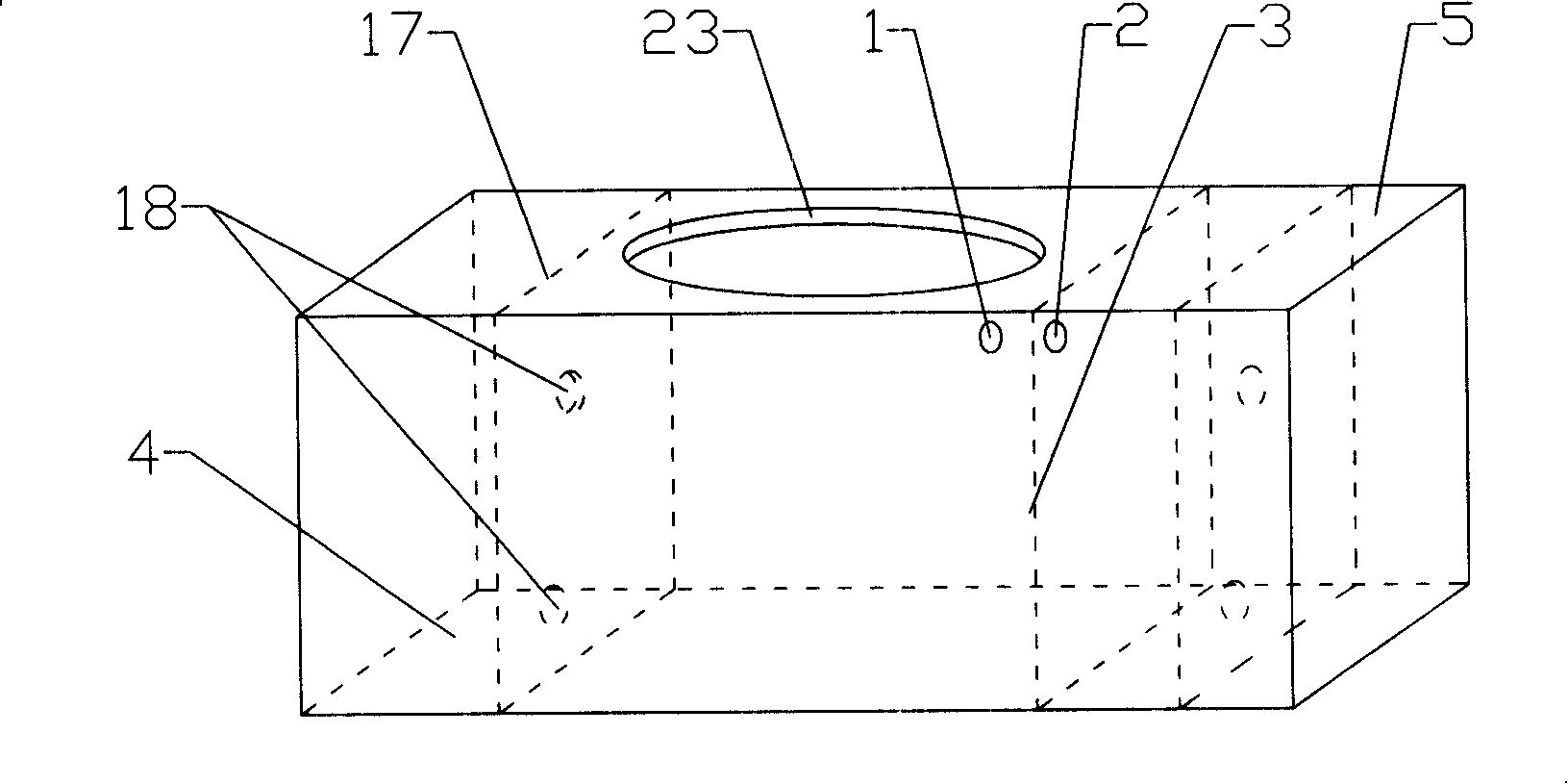

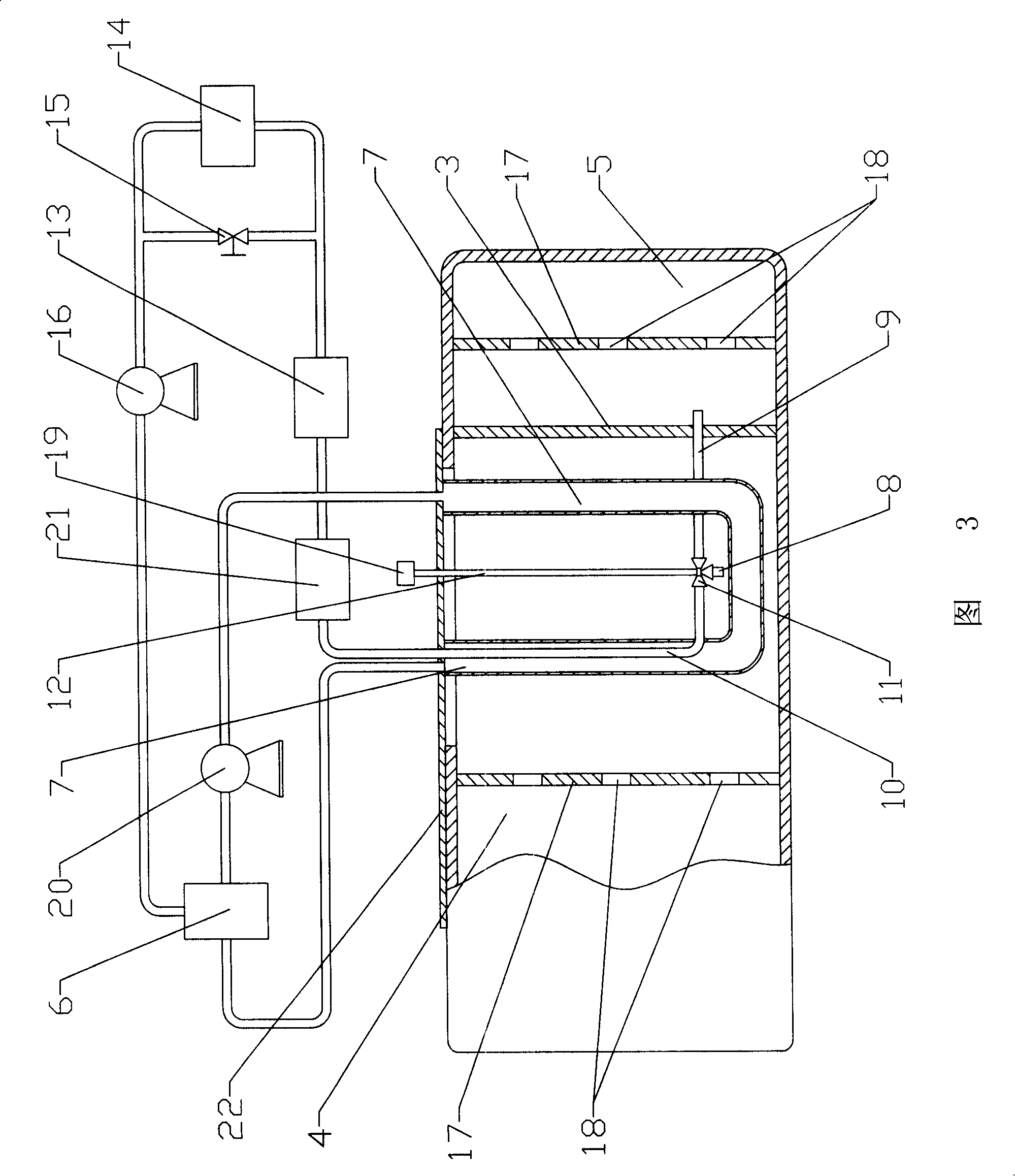

[0022] best practice, such as figure 1 As shown, a diesel fuel tank antifreeze device includes a fuel tank and a fuel delivery pipe. A partition 3 is arranged in the cavity of the fuel tank. There is an oil inlet 1, an oil inlet 2 is provided on the auxiliary fuel tank 5, No. 0 diesel oil is placed in the main fuel tank 4, and No. One partition 17 is provided with two through holes 18 on the partition 17 , and one partition 17 is provided in the auxiliary fuel tank 5 with two through holes 18 on the partition 17 .

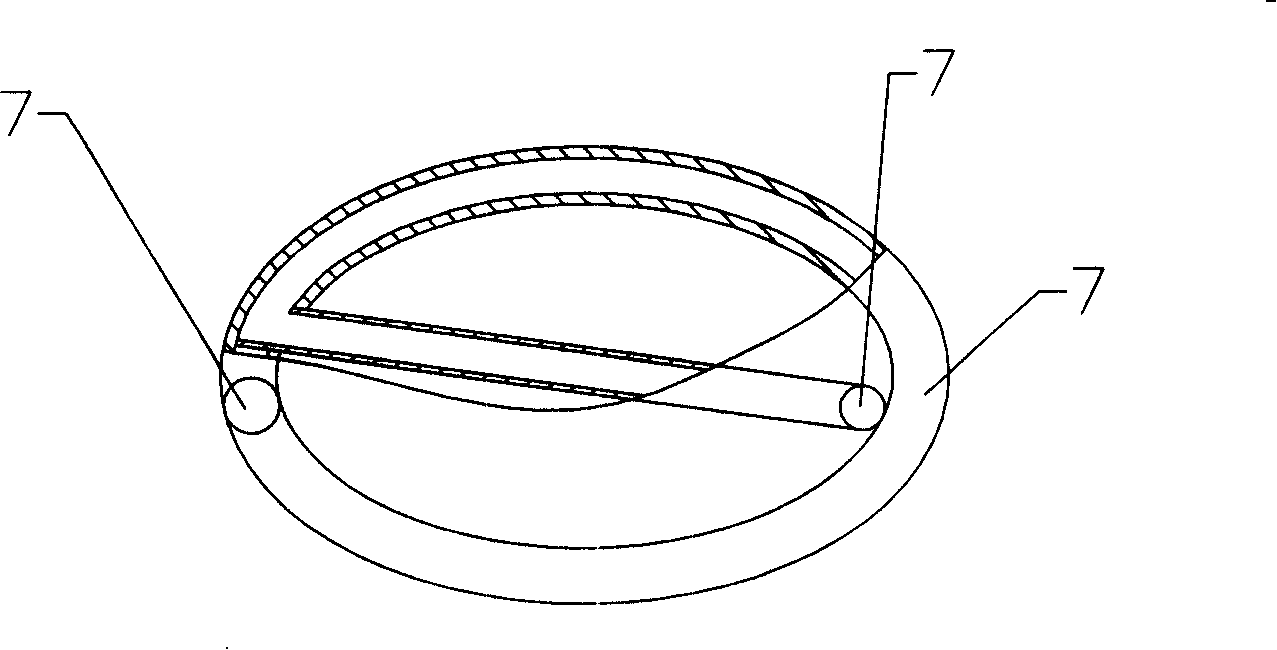

[0023] Such as figure 2 , shown in Fig. 3, be provided with heating water pipe 7 in main oil tank 4, the two ends of heating water pipe 7 extend outside main oil tank 4 and communicate with the circulating cooling water pipeline of engine 6, the water pipe at the bottom of heating water pipe 7 is made spiral , the oil delivery pipe includes a main oil pipe 8 communicated with the main oil tank 4, an auxiliary oil pipe 9 communicated with the auxiliary oil tank 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com