Push type electromagnetic relay automatic debugging machine

An electromagnetic relay and automatic debugging technology, which is applied to relays, circuits, electric switches, etc., can solve the problems of low debugging efficiency and many program steps, and achieve the effect of improving debugging work efficiency and reducing working procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

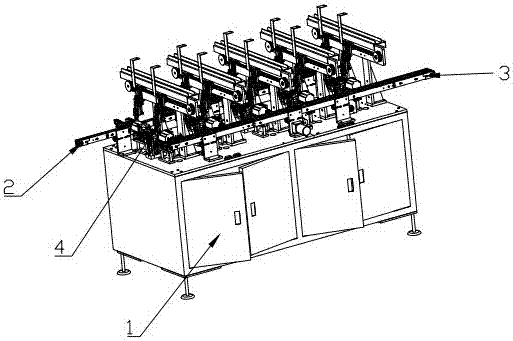

[0019] As shown in the figure, a push-type electromagnetic relay automatic debugging machine includes a frame 1, and the frame 1 is provided with a feeding device 2 and a discharging device 3 arranged in parallel, and the feeding device 2 and the discharging device An automatic debugging device 4 is provided between the devices 3 .

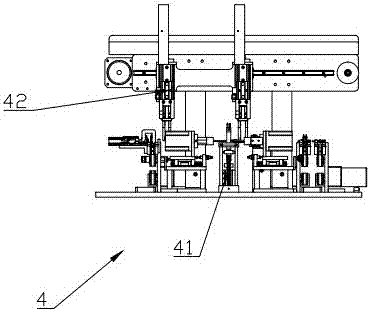

[0020] The automatic debugging device includes a debugging mechanism 41 and a grabbing mechanism 42; the automatic debugging device 4 is controlled by a controller.

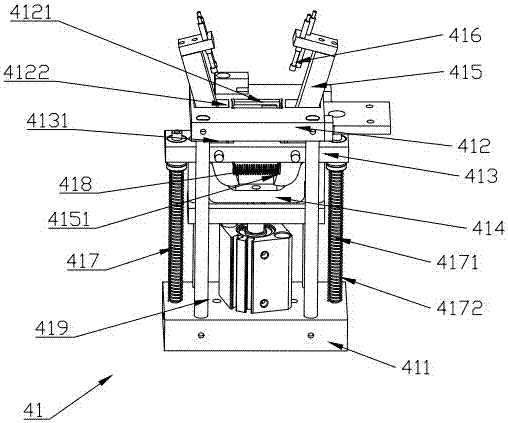

[0021] The debugging mechanism 41 includes a fixed bottom plate 411 , a debugging panel 412 , an action plate 413 , a pushing block 414 , a pull rod 415 , a testing cap 416 , a first elastic component 417 , and a second elastic component 418 .

[0022] The debugging panel 412 is fixed above the fixed bottom plate 411 through the support column 419, and the center ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com