Positioning support mechanism of fuel tank product

A technology for positioning support and fuel tank, which is applied to hollow objects, household containers, auxiliary devices, etc., can solve the problems of insufficient internal space of positioning support mechanism, increased labor intensity of operators, inaccurate positioning of welding products, etc., so as to solve the problem of insufficient placement space. , The effect of high positioning accuracy and accurate debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

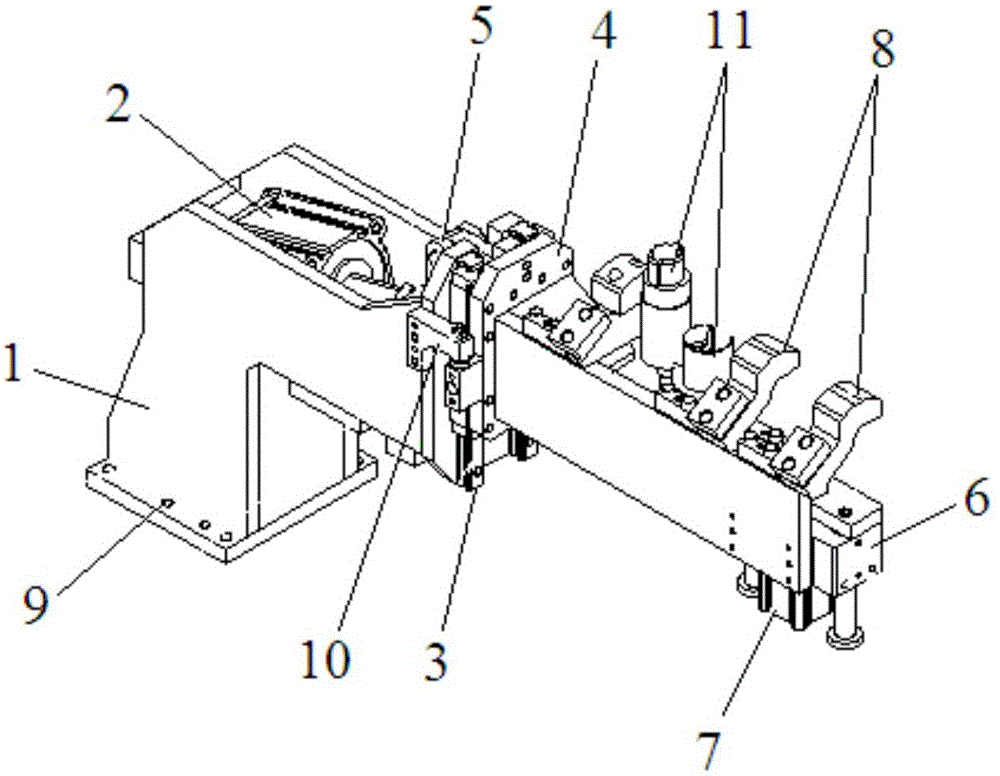

[0011] see figure 1 , a positioning support mechanism for fuel tank products, including a welding seat 1, the welding seat 1 is provided with a concave cavity and is rotatably installed with a first cylinder 2 arranged horizontally, and the front side of the welding seat 1 is fixedly connected with a vertically arranged guide rail 3. A slider 4 that can slide up and down along the guide rail 3 is installed. An adapter block 5 is rotatably connected between the rear side of the slider 4 and the end of the piston rod of the first cylinder 2, and the front side of the slider 4 is fixed. A crossbeam 6 is connected; the upper part of the crossbeam 6 is respectively fixedly connected with a plurality of supporting blocks 8 for supporting the fuel tank body, the crossbeam 6 is provided with a vertical through hole, and the bottom of the crossbeam 6 is equipped with a vertically arranged second cylinder 7, The piston rod of the second cylinder 7 passes through the vertical through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com