Division board used for debugging large-multiplying power continuous zooming camera system

A camera system and high magnification technology, applied in the field of optical instruments, can solve problems such as thick engraved lines, inability to align with the reference electric "cross" line, and affect debugging accuracy, so as to achieve accurate debugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

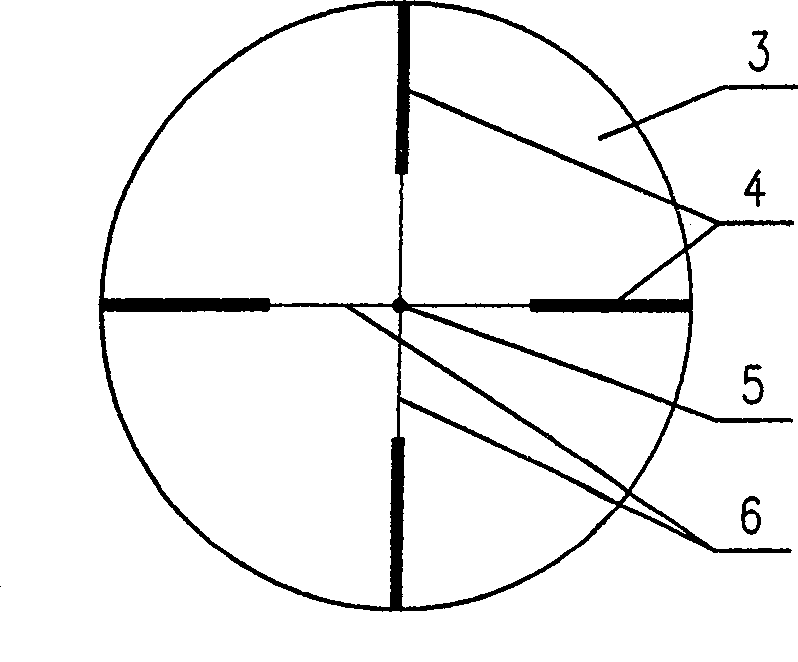

[0016] The invention according to figure 2 The graphic structure shown is implemented, and the manufacturing method is the same as that of a common reticle, that is, black graphics are engraved on the glass substrate 3, and the common methods for making a reticle can be adopted: plate-making photography, wax engraving and acid etching, etc. The width of the fine engraved line 6 is generally 0.1 mm, the width of the thick engraved line 4 is ten times the width of the fine engraved line 6, which is 1 mm, the diameter of the central point 5 is the same as the width of the thick engraved line 4, and the depth of the engraved line is the same as that of ordinary The reticle is the same, and there is no requirement here. The glass substrate 3 is made of K9 glass, and its size can be made according to needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com