Support device for stable debugging of electrically operated valve

A technology of electric valve and support device, applied in the direction of engine frame, supporting machine, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

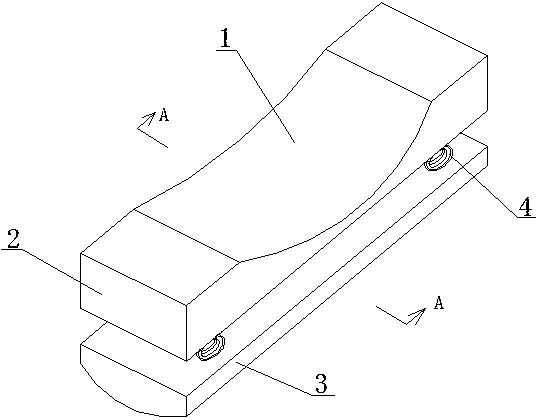

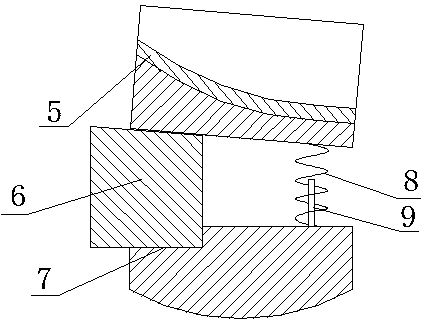

[0022] Such as Figure 1-Figure 4 The stable debugging support device for the electric valve shown includes the electric device pad and the valve pad 11, the electric device pad includes the upper support seat 2 and the lower base 3, and there is a space for height adjustment between the upper support seat 2 and the lower base 3 , the upper support seat 2 and the lower base 3 are provided with conical springs 8 at the four corners of the height adjustment space, and the upper and lower ends of the conical spring 8 are fixedly connected to the upper support seat 2 and the lower base respectively. 3. The height of the lower base 3 is higher than the height of the valve pad 11, and an installation groove 1 is provided in the middle of the upper end of the upper support seat 2. The installation groove 1 has an arc-shaped structure, and the arc-shaped structure gap of the installation groove 1 The horizontal two ends are arranged with one end high and the other end low, a layer of ...

Embodiment 2

[0027] In this embodiment, the following structure is optimized on the basis of Embodiment 1: the inclined surface at the upper end of the support block 6 is at an angle of 8°-15° to the horizontal plane.

[0028] This embodiment considers that the angle of the electric valve is generally suitable within a certain range when the electric valve is tilted, that is, in order to reduce the problem of poor valve operation and deviation of the debugging data caused by the angle discomfort. It is concluded that when the inclination angle of the electric valve is 8°-15°, it is optimal, not only can it be convenient to debug and read data, but after the electric valve is debugged, it can be used basically without secondary debugging on site, and the debugging effect is the best, so In this embodiment, the inclined surface of the upper end of the support block 6 is set at 8°-15° to the horizontal plane, so that when the support block 6 supports the upper support seat 2, the inclination a...

Embodiment 3

[0030] In this embodiment, on the basis of Embodiment 1, the following structure is added: a vertical limit post 9 is arranged inside the conical spring 8 .

[0031] In this embodiment, in order to prevent the pad of the electric device from being tilted and overturned due to uneven force, and to prevent accidents during debugging, a vertical limit post 9 is also provided inside the conical spring 8. The vertical limit post 9 On the one hand, it can limit the maximum compression of the conical spring 8 to prevent elastic failure caused by excessive compression of the conical spring 8. On the other hand, it can limit the spring when it is compressed and tilted, preventing the electric device pad from overturning due to excessive spring tilt Inverted, to ensure the smooth progress of debugging, strong practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com