Base-less clamping jaw type main shaft device for lamp inspection machine

A main shaft device, no base technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of product inspection influence, difficult to clean, complex mechanical structure of base structure, etc., to achieve compact structure, easy control, easy maintenance and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

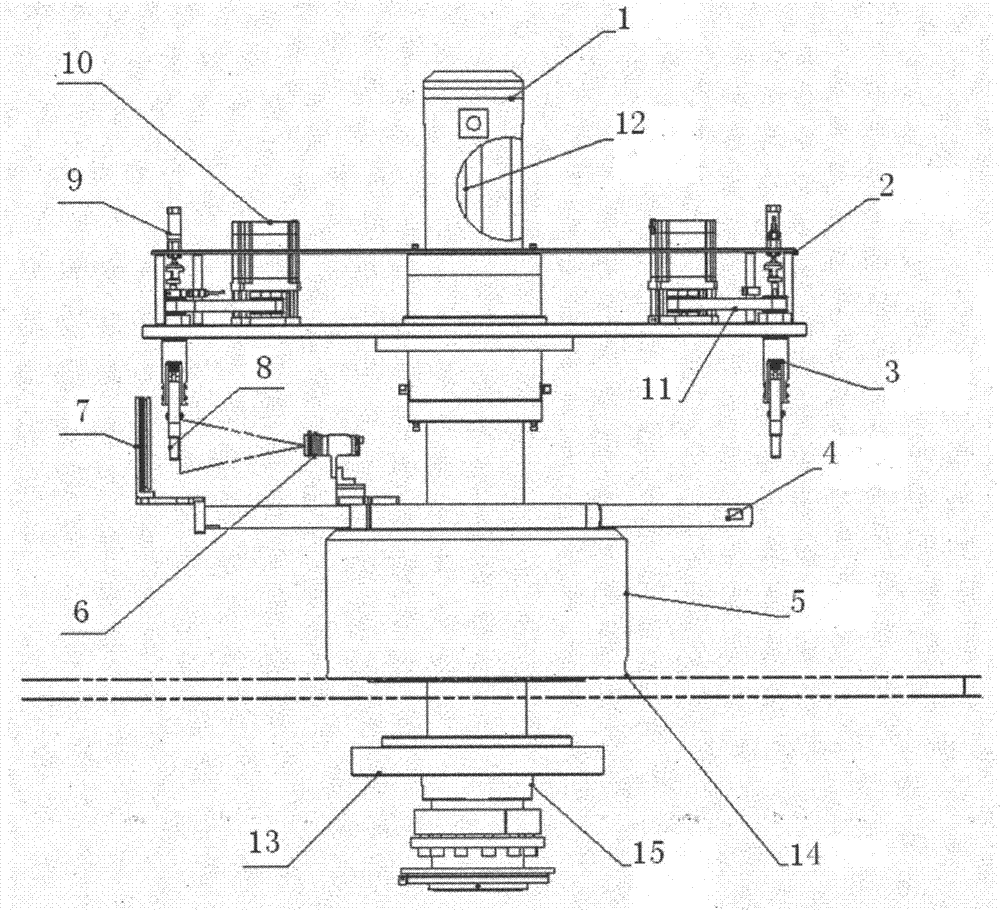

[0018] Such as figure 1 As shown, the present invention provides a baseless jaw-type spindle device for a light inspection machine, which is composed of three major parts: a spindle rotation system, a vision system and its driving device, and a mechanical gripper. The main shaft 1 of hollow structure is directly mounted on the main shaft support base plate 14 through the main shaft device supporting bearing 13 , and the main shaft 1 is driven to rotate around its own axis by the main shaft driving device 15 . The jaw mounting flange 2 is installed on the main shaft 1 through the connecting flange, and is connected with the driving screw 12 pierced in the main shaft 1 through the connecting piece, and the jaw mounting flange 2 is driven by the driving screw 12 to be positioned at different positions. high. The gripper mounting fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com