Press machine air pad ascending and descending control device and method based on power failure protection

A technology of power loss protection and lifting control, applied in the direction of presses, manufacturing tools, etc., can solve the problems of injury of mold debugging personnel, accidental drop of air cushion, long preparation time, etc., to eliminate hidden safety hazards, reduce economic losses, and prevent mold damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

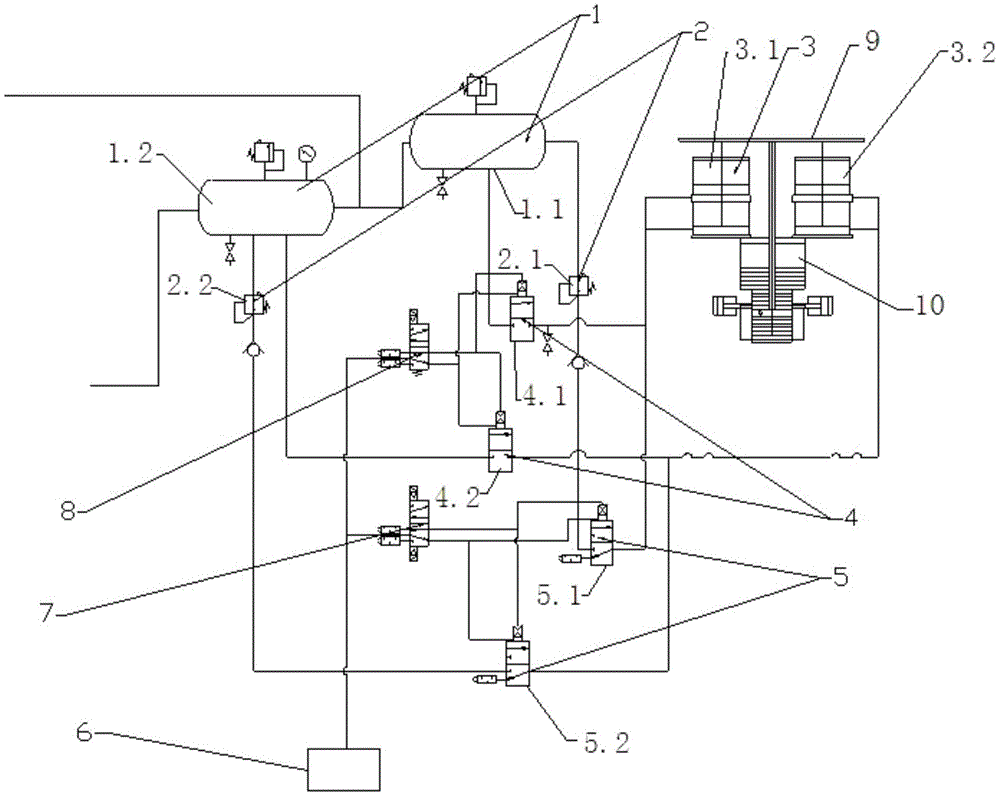

[0019] Such as figure 1 As shown, the present invention is based on a power failure protection press air cushion lifting control device, including an air cushion jacking cylinder 3, an air storage tank 1 and a control air source 6, and the gas outlet of the air storage tank 1 is connected to the air cushion jacking cylinder 3 The lower cavity is connected with a high-pressure intake air path and a low-pressure intake air path, the high-pressure intake air path is provided with a high-pressure intake valve 4, and the low-pressure intake air path is provided with a low-pressure intake valve 5 and a decompression valve. valve 2, the control air source 6 is connected to the high-pressure intake valve 4 and the low-pressure intake valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com