Simulation design method based on industrial robot sorting workstation

An industrial robot, simulation design technology, applied in the direction of instruments, simulators, control/regulation systems, etc., to shorten the implementation cycle, improve reliability, and improve debugging efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

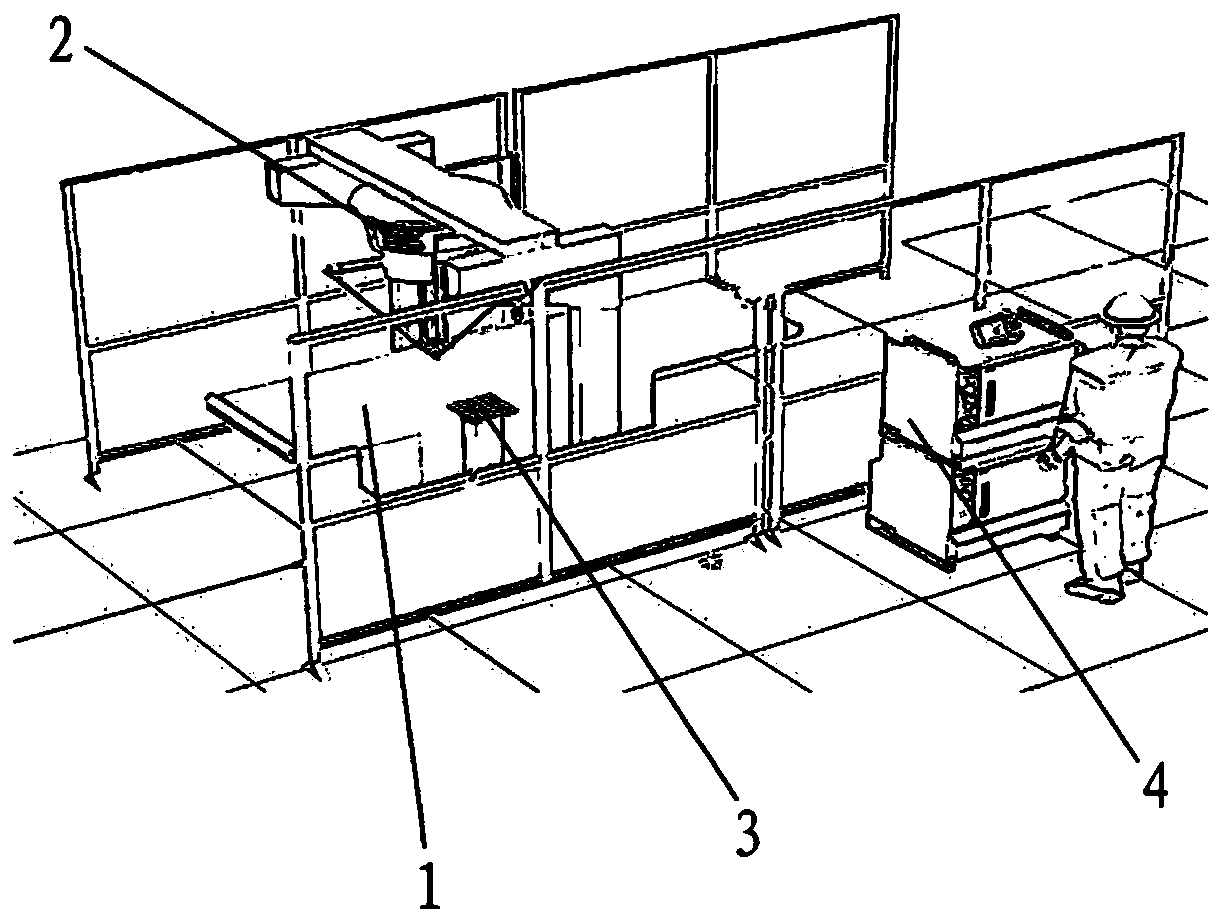

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

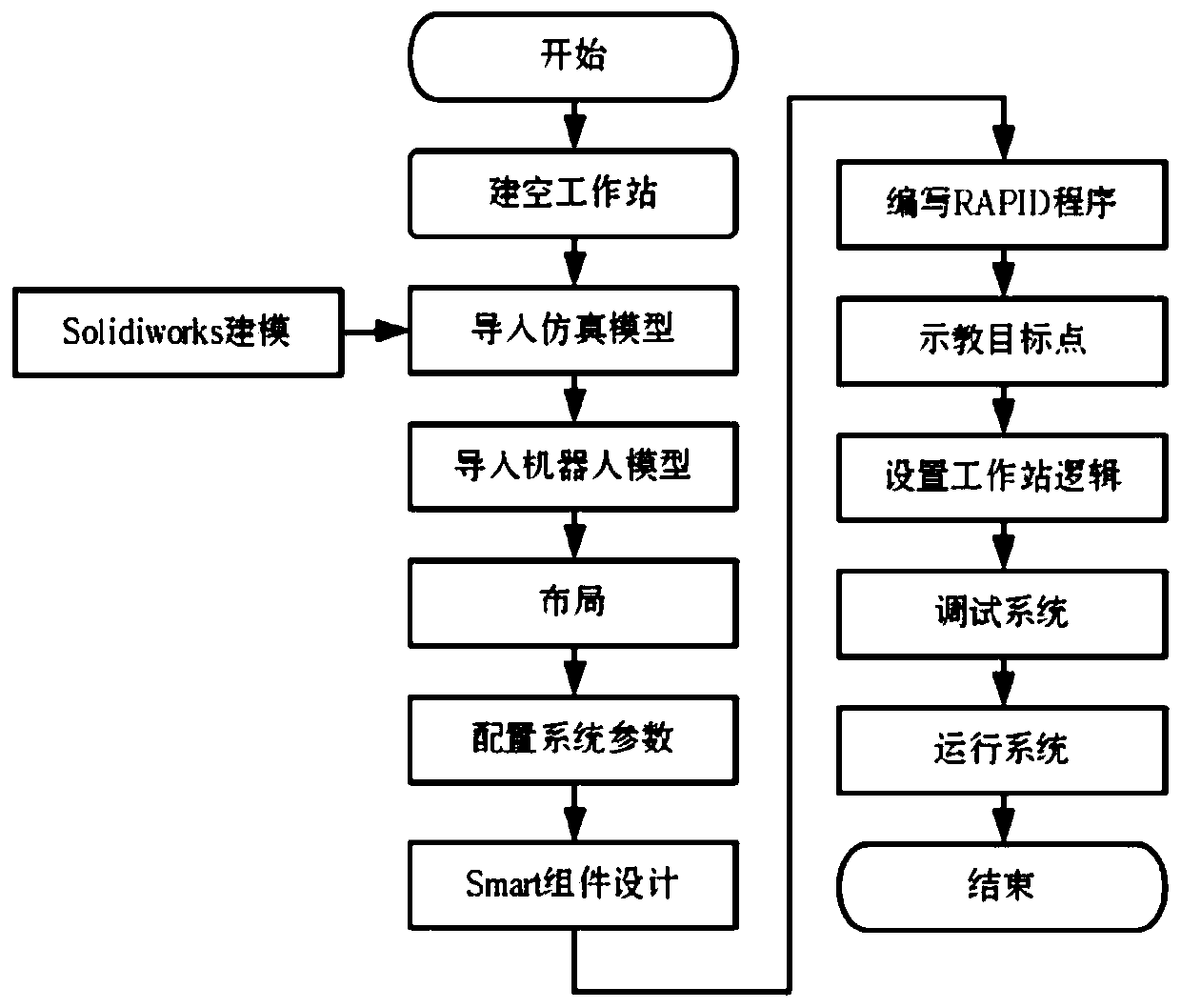

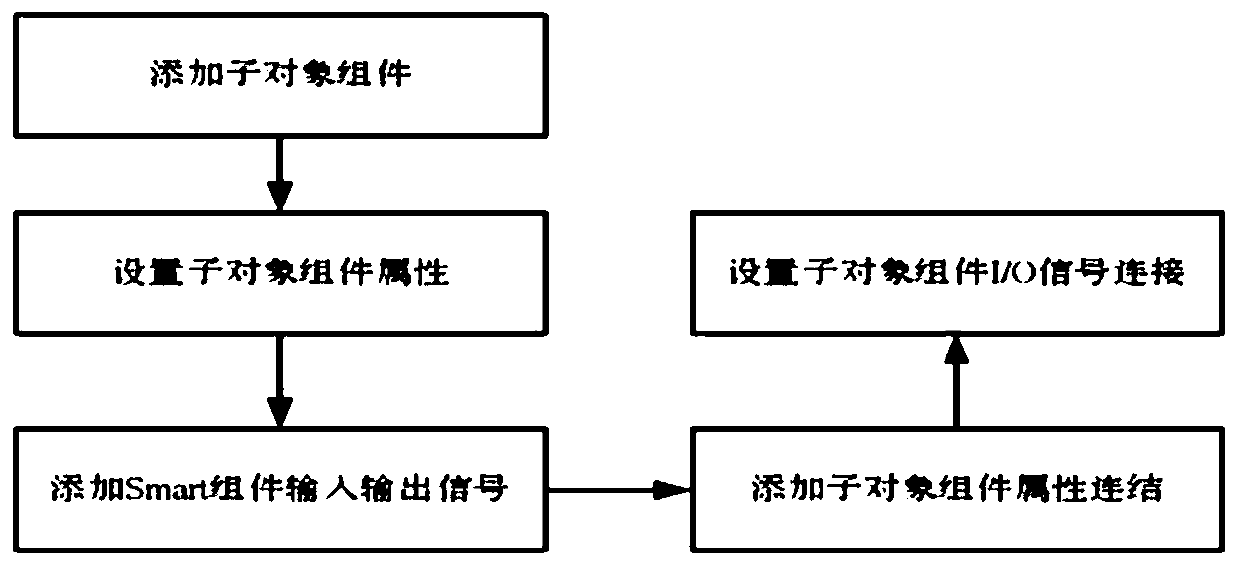

[0023] The specific embodiment of the simulation design method based on industrial robot sorting workstation of the present invention, as figure 1 , figure 2 shown, including the following steps:

[0024] S1: Use Solidworks 3D software to build conveyor belt models, industrial robot models, and object storage device models, and import the model files into RobotStudio software;

[0025] S2: Determine control parameters based on the industrial robot model, and determine an industrial robot simulation model according to the control parameters;

[0026] S3: The objects appear on the conveying mechanism according to the law of random distribution function, and different typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com