Travel shell of blind-hole rod of control rod drive mechanism in pressurized water reactor and method of machining travel shell

A processing method and a technology of a driving mechanism, applied to mechanical equipment, connecting rods, shafts, bearings, etc., can solve problems such as failure to meet drawings and process requirements, and failure to correct the deviation of the inner and outer circles and coaxiality, so as to reduce the unit The effect of secondary processing cutting amount, improvement of pass rate, and control of processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation of the blind hole rod travel housing and processing method of the PWR control rod drive mechanism of the present invention will be described in detail below in conjunction with the accompanying drawings.

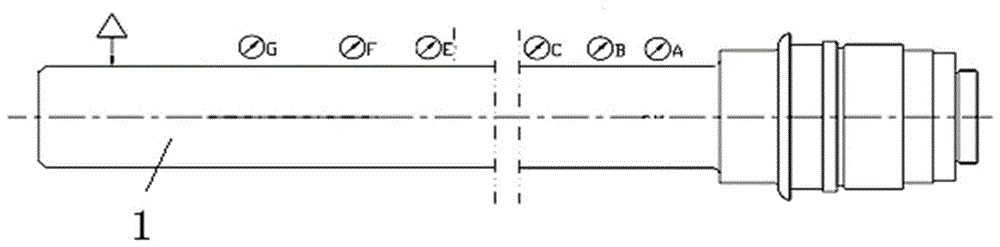

[0037] The method for processing the blind-hole rod travel shell of the drive mechanism of the pressurized water reactor control rod, wherein the outer diameter of the blind-hole rod is less than 100mm, and the length-to-diameter ratio is greater than 54, is characterized in that it includes the following steps:

[0038] (1) Rough machining the outer circle of the small end blank of the slender rod;

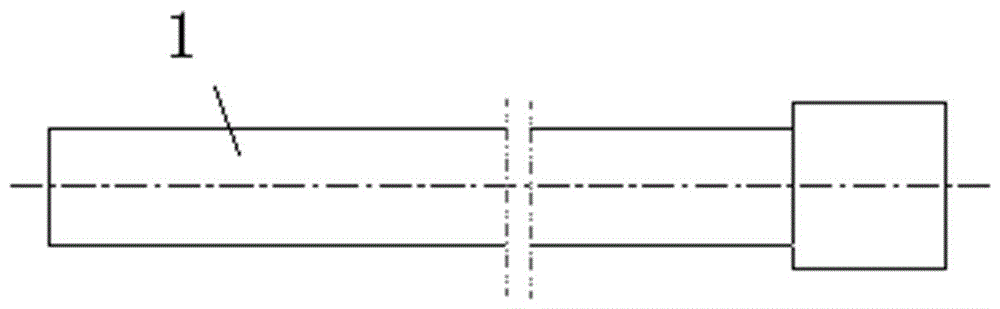

[0039] See attached figure 1 The outer circle of the slender rod at the small end of rough turning requires φ110~φ109.

[0040] (2) One deep hole processing;

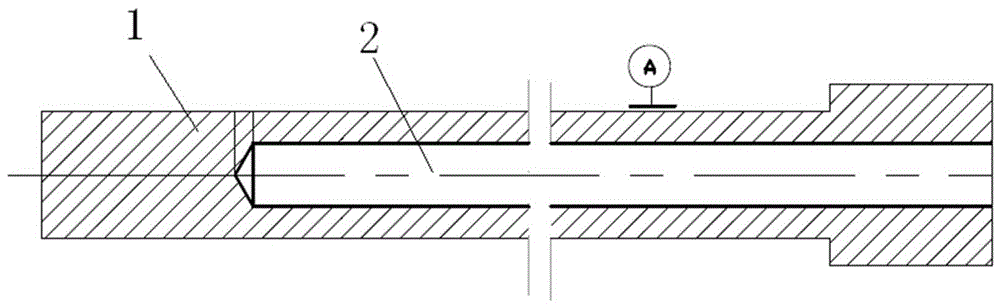

[0041] See attached figure 2 ,The first blind hole processing: It is required to drill and expand the inner hole φ60, and carry out stabilization heat treatment.

[0042] Measureme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com