Ultrasonic auxiliary silicon carbide wafer grinding and polishing device

An ultrasonic-assisted silicon carbide technology, applied in the field of processing equipment, ultrasonic-assisted grinding and polishing of silicon carbide wafers, can solve the problems of large surface damage and low material removal rate of silicon carbide wafer grinding and polishing, and improve processing efficiency and quality , economic precision is not high, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

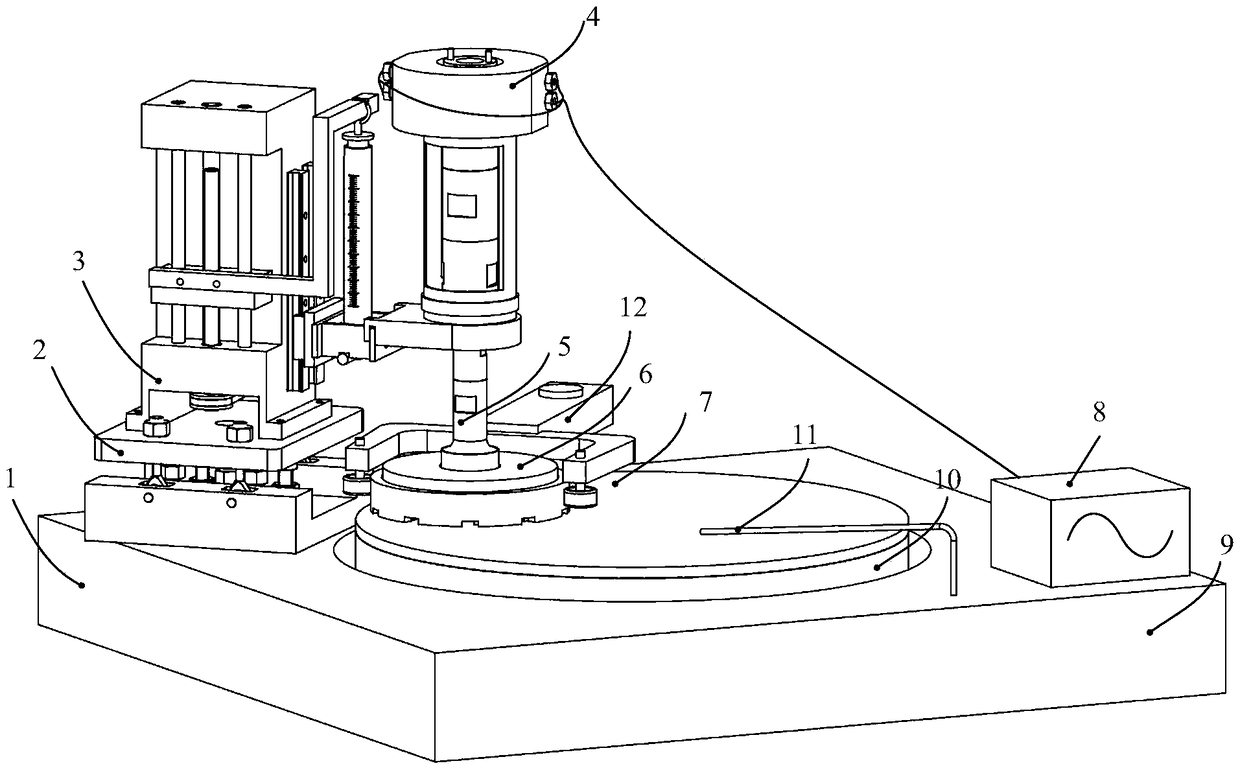

[0045] The present invention is described in detail below in conjunction with accompanying drawing:

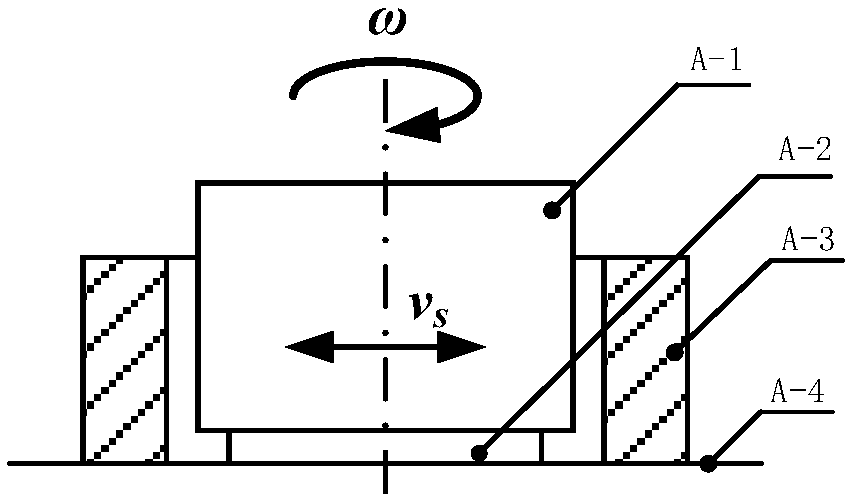

[0046] Referring to Fig. 1, the power part of described conventional grinding and polishing device comprises counterweight A-1, No. 1 retaining ring A-3, No. 1 grinding disc or polishing pad A-4; No. 1 test piece A-2 is placed on Between counterweight A-1 and No. 1 grinding disc or polishing pad A-4, counterweight A-1, No. 1 specimen A-2 and No. 1 grinding disc or polishing pad A-4 are stacked from top to bottom Placed and connected with each other, the counterweight A-1 provides the polishing pressure for the No. 1 specimen A-2, and the friction of the No. 1 specimen A-2 on the No. 1 grinding disc or polishing pad A-4 Rotate down (rotating speed is ω), the clearance fit between No. 1 retaining ring A-3 and counterweight A-1 is limited to limit the horizontal movement of No. 1 specimen A-2 (rotating speed is v s ) without impeding rotation.

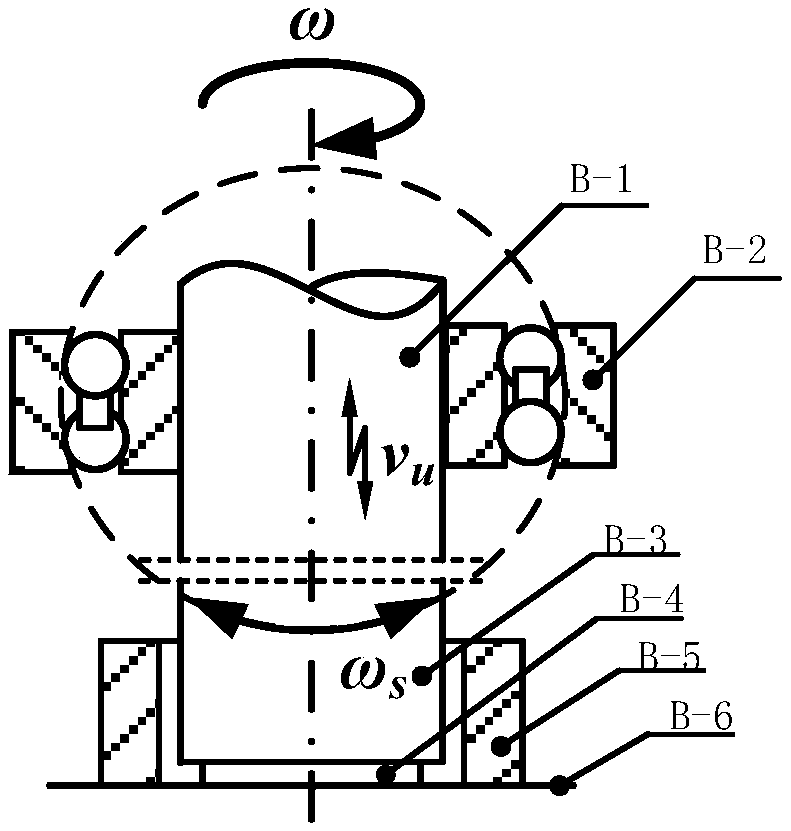

[0047] A kind of ultrasonic assi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com