Self-meshing coupling and using method thereof

A technology of couplings and semi-couplings, applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of increasing moment of inertia, cumbersome installation, cumbersome and time-consuming, etc., to ensure coaxiality Precision, reasonable structure design, simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

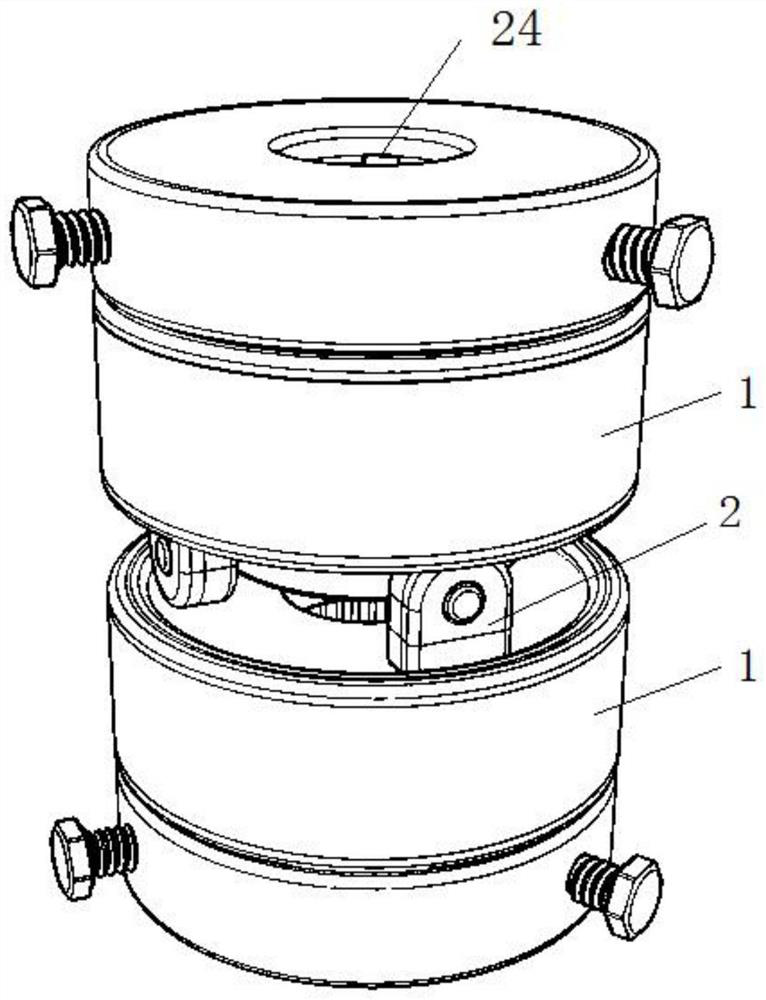

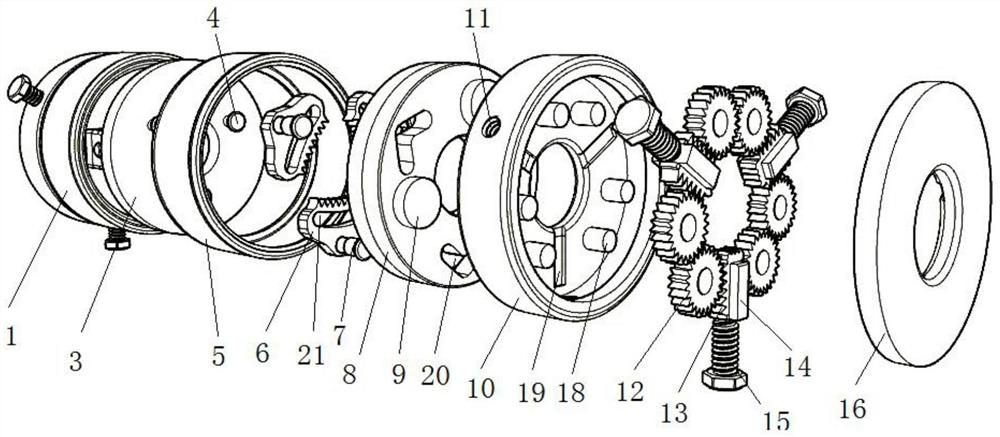

[0036] like Figure 1-7 As shown, the present embodiment proposes a self-engaging coupling, including two half-couplings 1, which are connected by a universal fork 2; The installation channel 24 of the rotating shaft 23; the half coupling 1 includes a snap shaft assembly and a positioning shaft assembly connected with the bite shaft assembly.

[0037] Elaborate above and below:

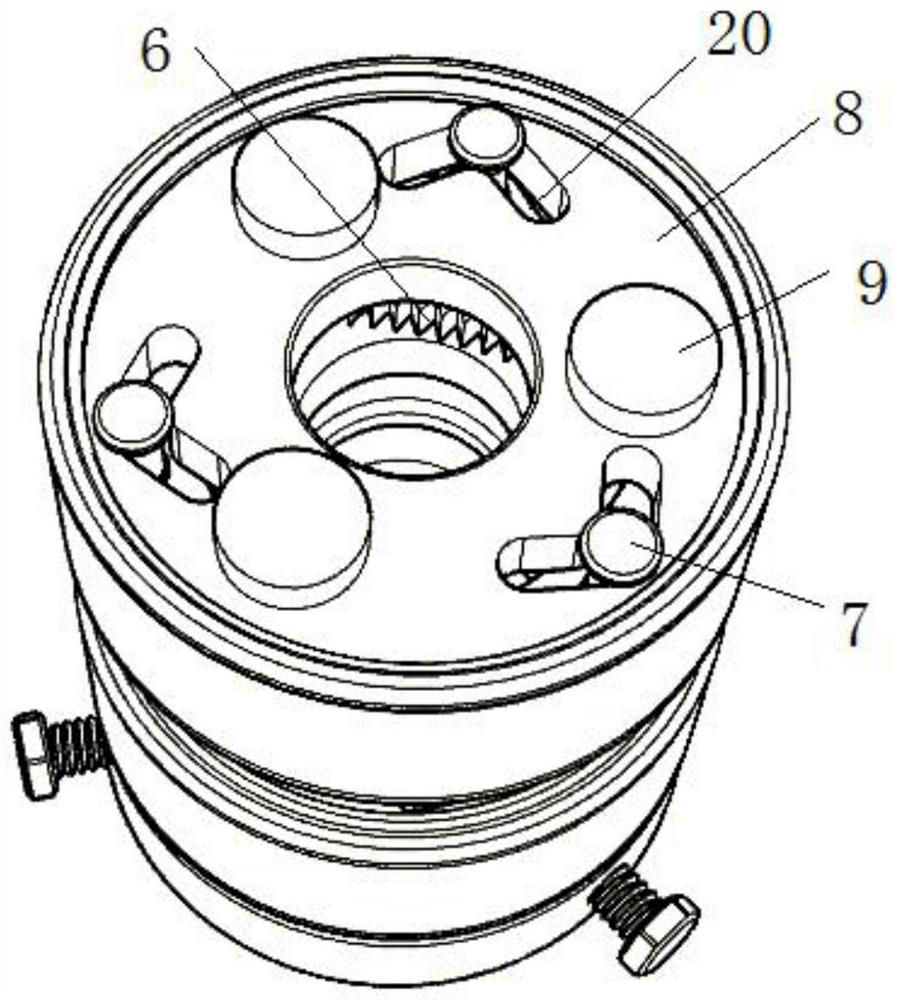

[0038] The bite shaft assembly includes a drive plate 3 connected with the universal fork 2, and the drive plate 3 is connected with a rotating shell 5; the drive plate 3 is connected with three evenly distributed lever shafts 4; the rotating shell 5 is provided with three arc teeth 6, The three cambered teeth 6 are evenly arranged in the circumferential direction, and the three cambered teeth 6 enclose an engagement cavity for engaging the rotating shaft 23 ; each cambered tooth 6 is provided with an arcuate groove 21 corresponding to the lever shaft 4 Each lever shaft 4 is movably placed in the co...

Embodiment 2

[0051] Reference attached Figure 8 , the self-engaging coupling proposed in this embodiment also includes a connecting shaft placed between the two half-couplings 1, and the two ends of the connecting shaft are respectively connected with the two half-couplings 1 through the universal fork 2 . In the present invention, a connecting shaft is also provided, and the connecting shaft is respectively connected with the two half-couplings 1 through the two universal fork heads 2, so that the difference of the compensation is larger, which is convenient for installation.

[0052] It can be seen from the above two embodiments that the cooperating use of the positioning shaft assembly and the bite shaft assembly in the present invention can not only ensure the coaxiality accuracy, but also quickly realize the quick connection between the coupling and the rotating shaft 23; the present invention It can be used in some emergency situations to achieve quick installation, reduce maintena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com