Assembling tool and method for magnetic suspension bearing rotor

A technology of magnetic suspension bearing and assembling tooling, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of scratches, high operation requirements and retention, and achieves simple process, high rotor coaxiality and position accuracy, and convenient removal of parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

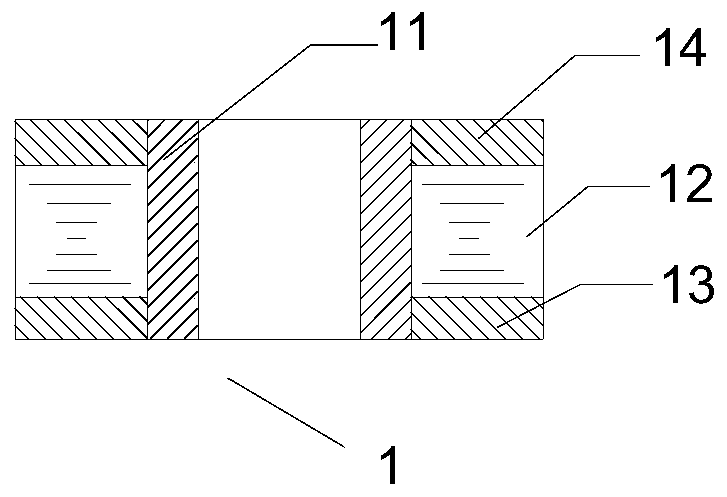

[0039] Such as figure 1 As shown, the rotor 1 to be assembled in the present invention includes: a sleeve 11 and a plurality of annular magnetic conductive sheets 12, and a plurality of annular magnetic conductive sheets 12 are stacked together and sleeved outside the sleeve 11; A first annular baffle 13 and a second annular baffle 14 at both ends of the pipe 11 , wherein a plurality of annular magnetic conductive sheets 12 are sandwiched between the first annular baffle 13 and the second annular baffle 14 .

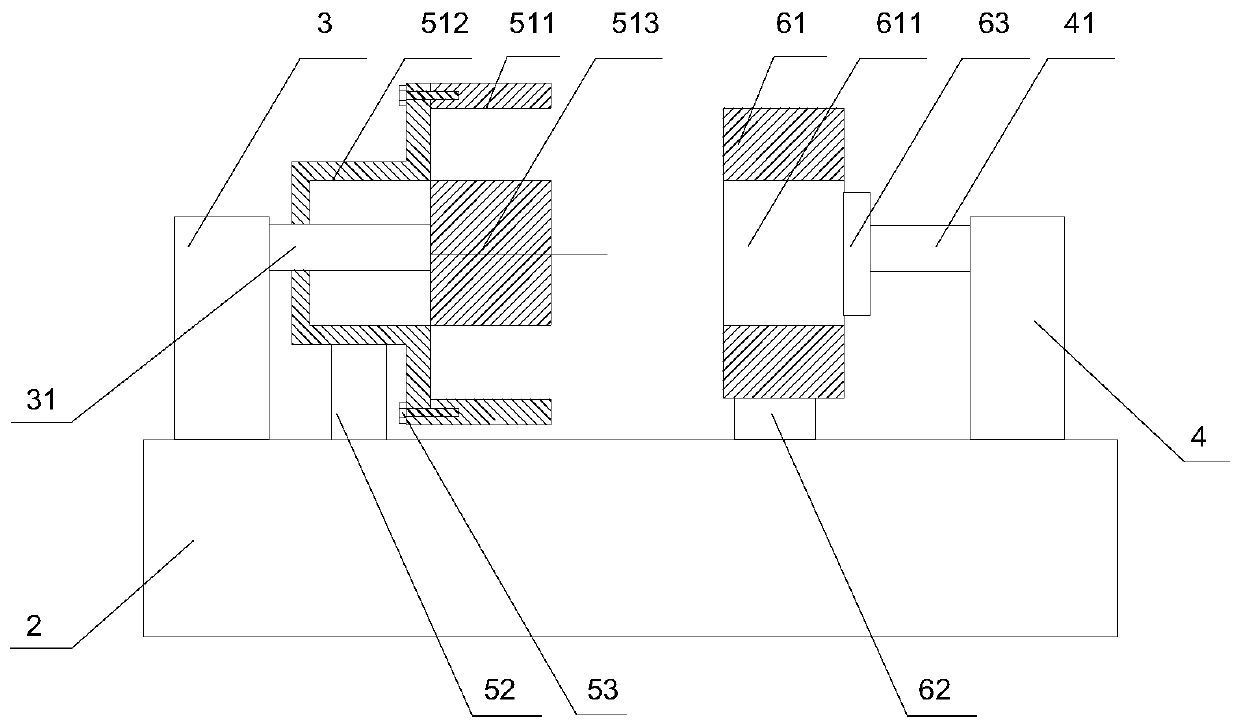

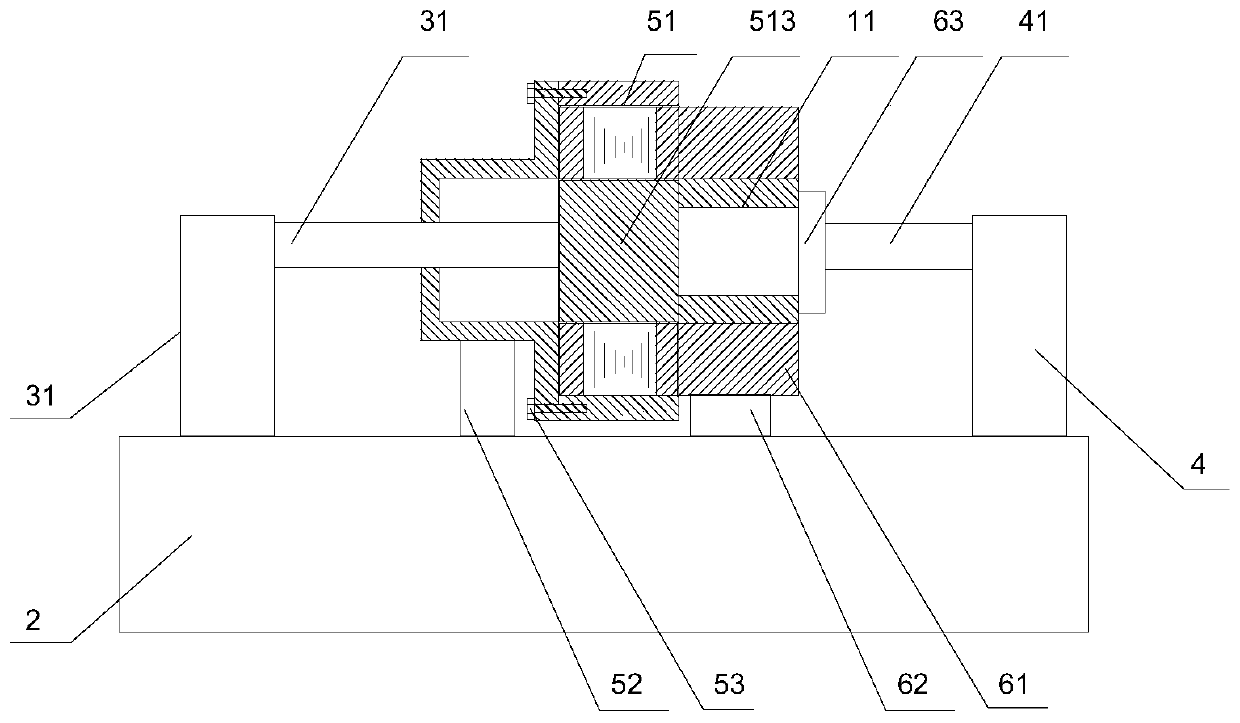

[0040] Such as Figure 2 to Figure 6 As shown, the present invention discloses an assembly tool for the magnetic suspension bearing rotor 1 for the rotor 1 of this structure. A rotor assembly structure 5 is connected; the cylinder two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com