Patents

Literature

65results about How to "High concentricity precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

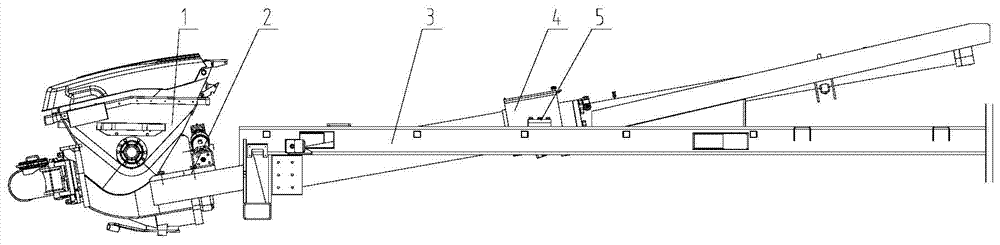

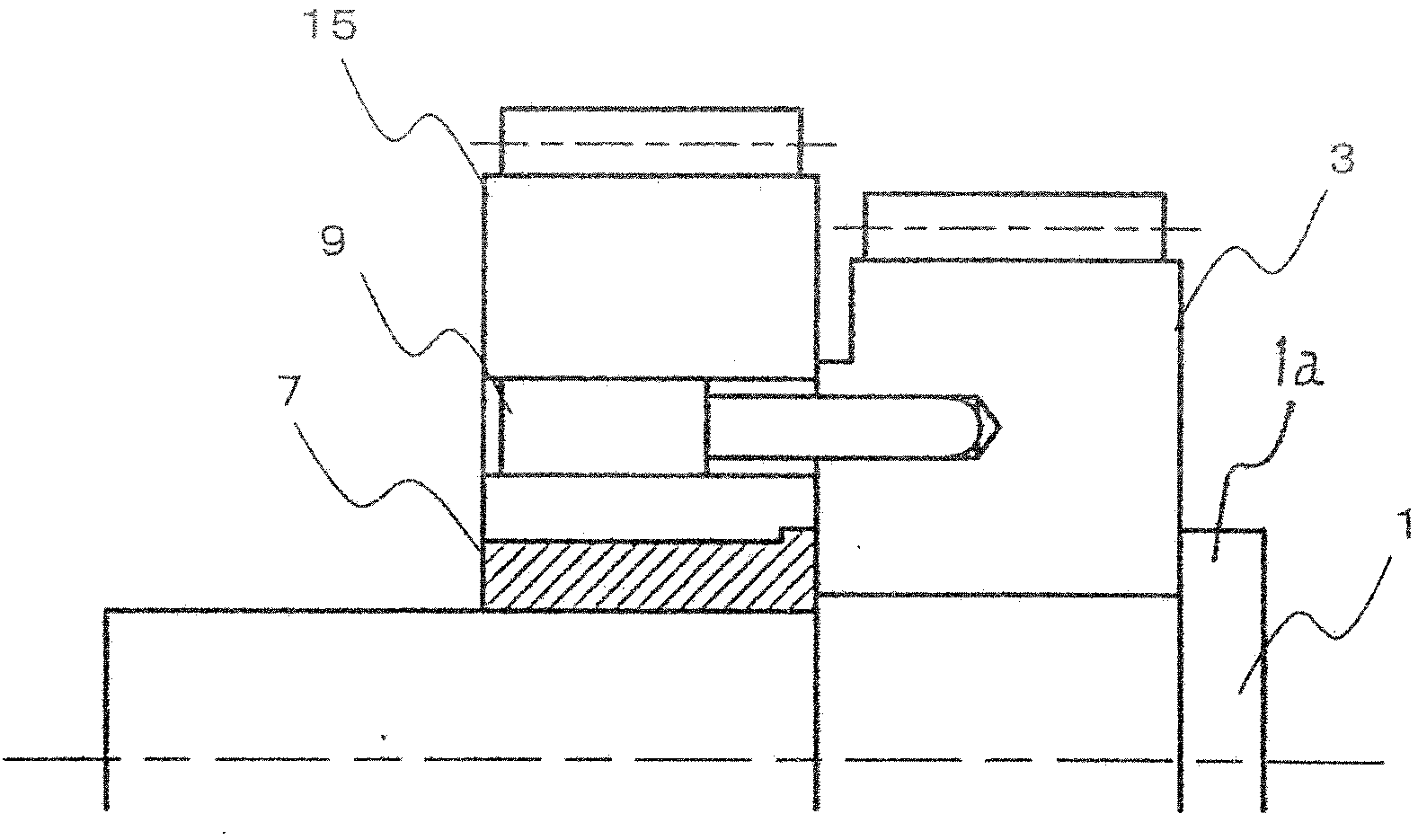

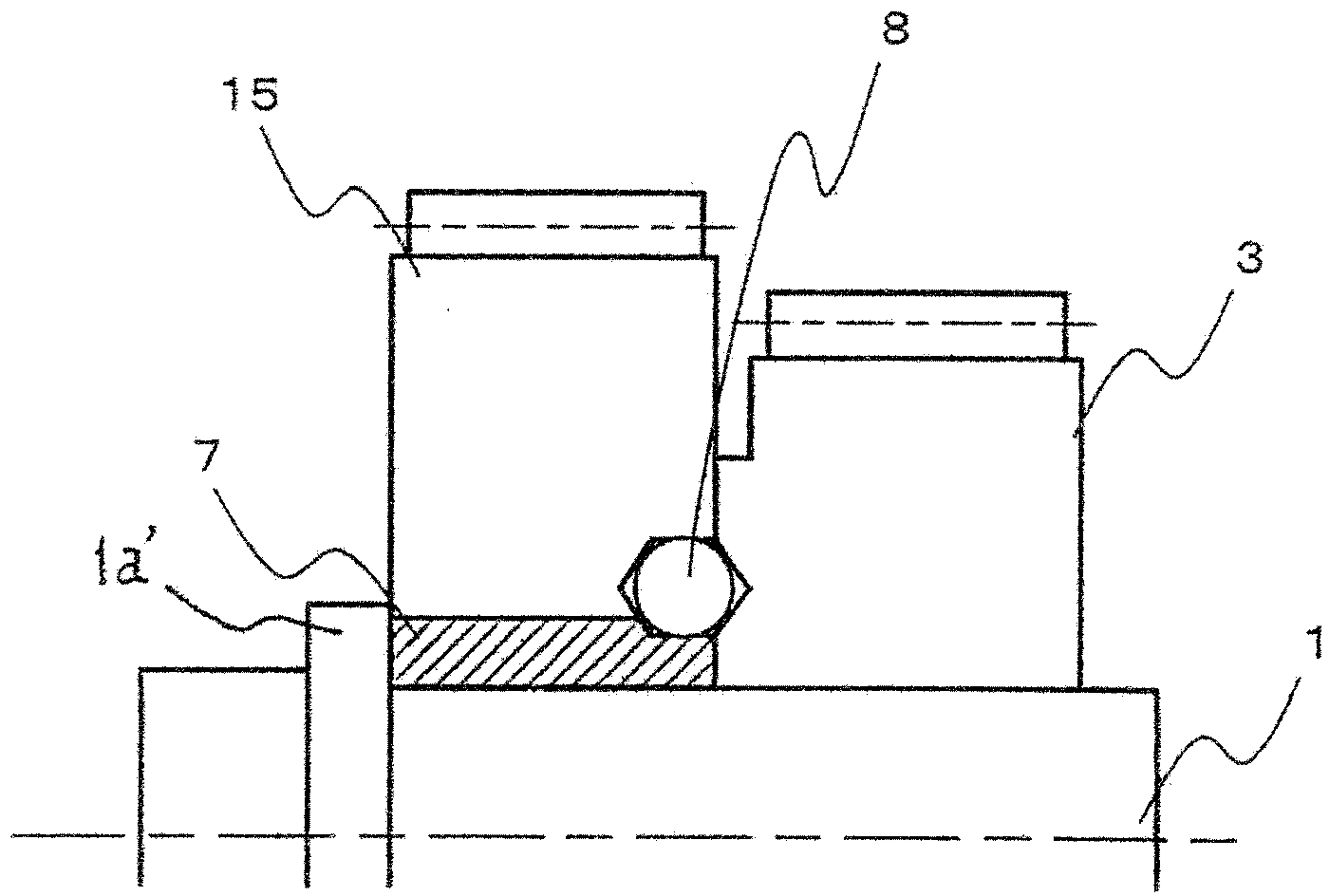

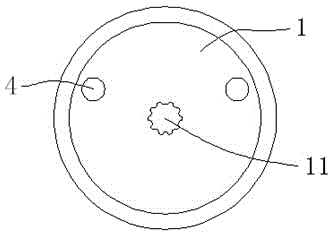

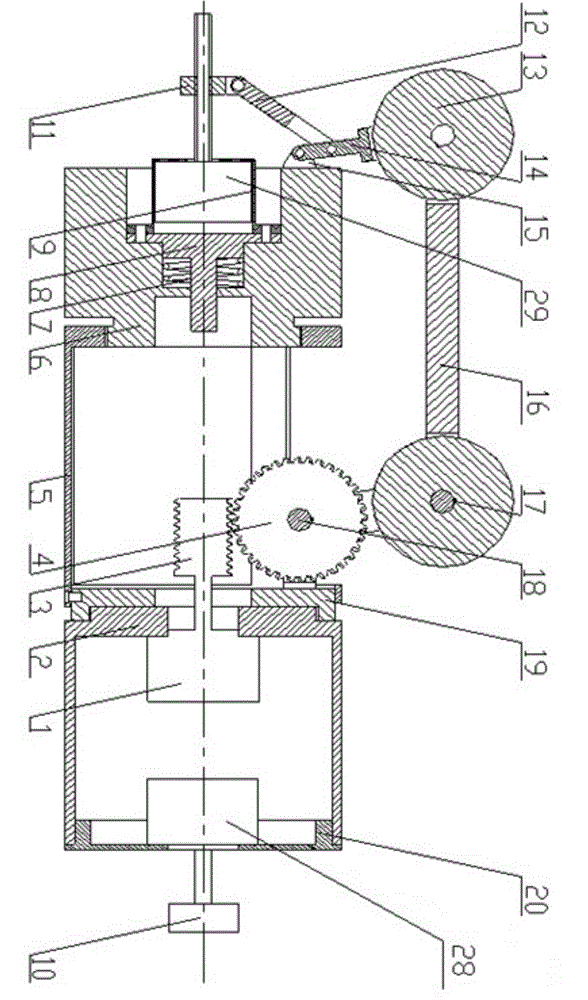

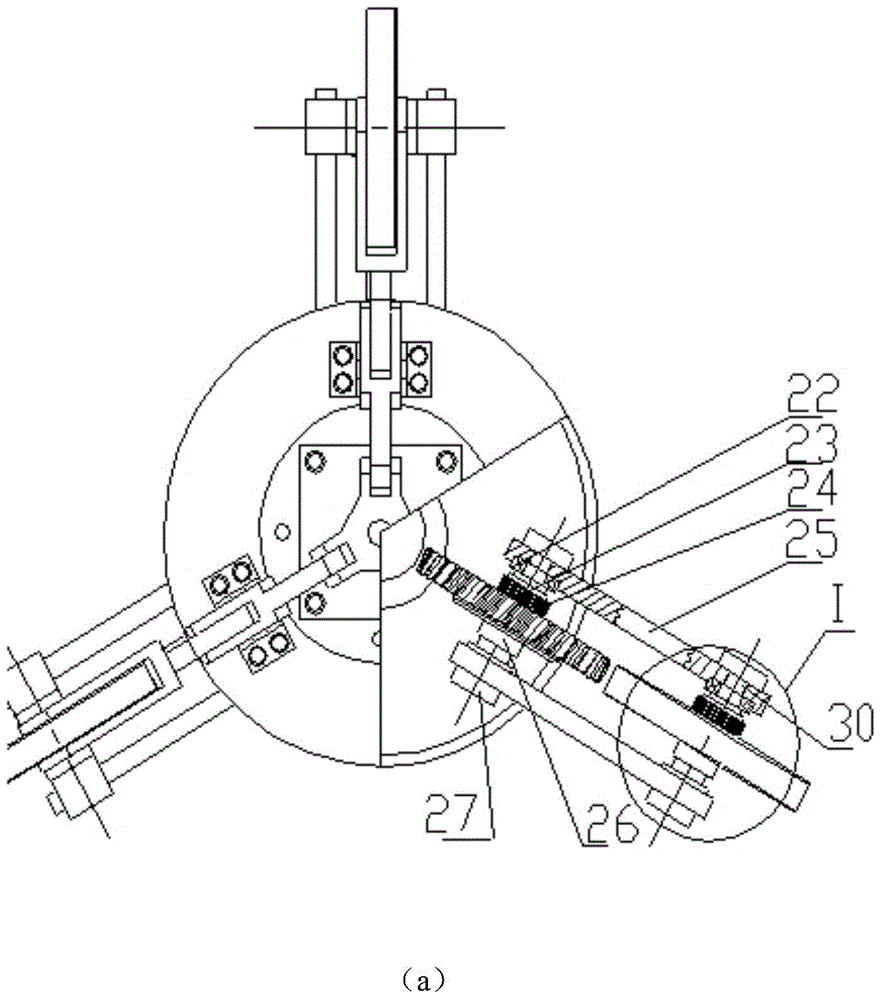

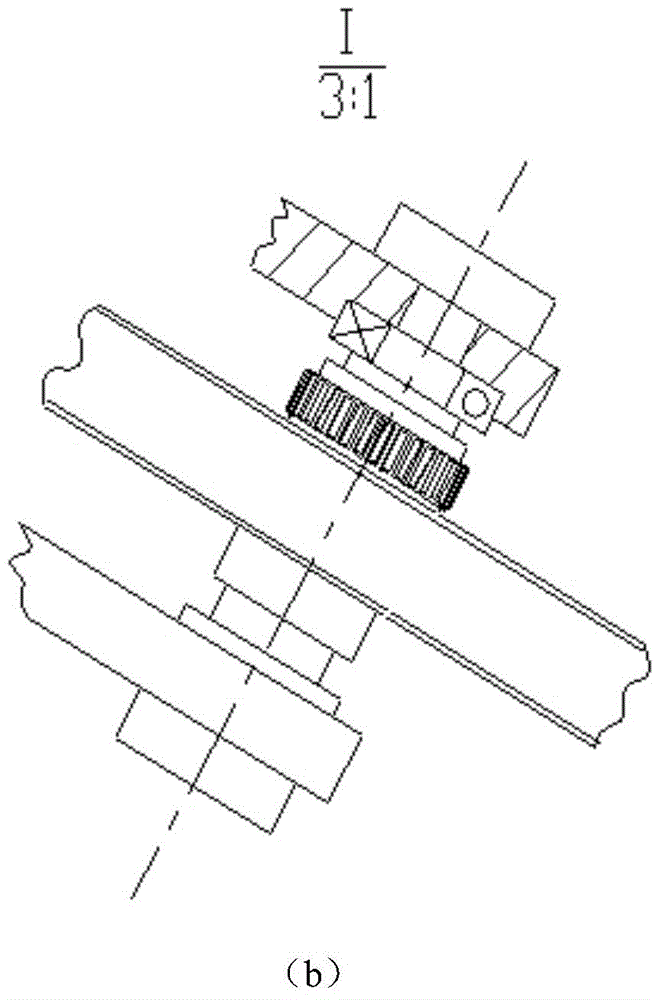

Processing device for double-center hole punching of common lathe

InactiveCN102784946APerformance is not affectedDoes not interfere with normal operationAttachable boring/drilling devicesNeedle roller bearingBall bearing

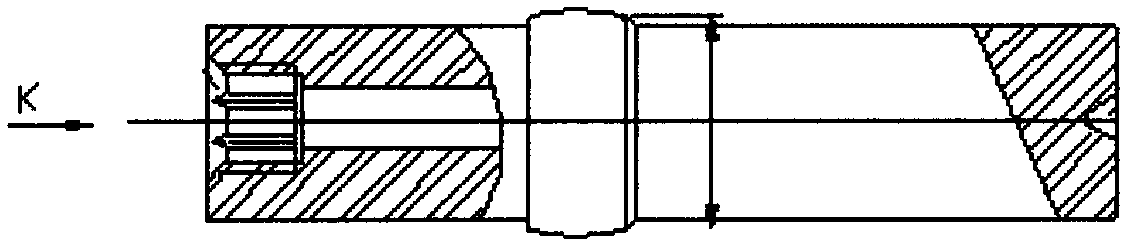

The invention discloses a processing device for double-centre hole punching of a common lathe. The processing device comprises a proportional reversing feeding device, two groups of shaft hole feeding devices arranged in main shaft holes, a drill chuck connecting rod, a drill chuck and a central drill, wherein the central drill is arranged at a front end of the drill chuck connecting rod through the drill chuck; two groups of shaft hole feeding devices are respectively arranged at front and back parts of the drill chuck connecting rod; each group of the shaft hole feeding devices structurally comprises a liner sleeve, needle rolling bearings, an shaft sleeve and a linear ball bearing which are arranged in the main shaft holes, wherein the linear ball bearing is tightly sleeved on the drill chuck connecting rod; the shaft sleeve is tightly sleeved on the linear ball bearing; the needle rolling bearings are respectively arranged at two ends of the shaft sleeve; and the liner sleeve tightly arranged in the main shaft hole is sleeved on the needle rolling bearing; and one end of the proportional reversing feeding device is connected with a rear end of the drill chuck connecting rod, and the other end of the proportional reversing feeding device is connected with a tail seat of a lathe main body for arranging the drill chuck. By adopting the processing device to punch centre holes at two ends of parts, such as shafts, clamping time can be reduced, efficiency can be improved, precision can be improved, the precision of coaxiality of processing workpieces can be ensured, and meanwhile, workpieces with central holes with different depth and different types at a left end and a right end can be processed through a left central drill and a right central drill with different-ratio feeding rate and feeding volume.

Owner:GUANGXI UNIV

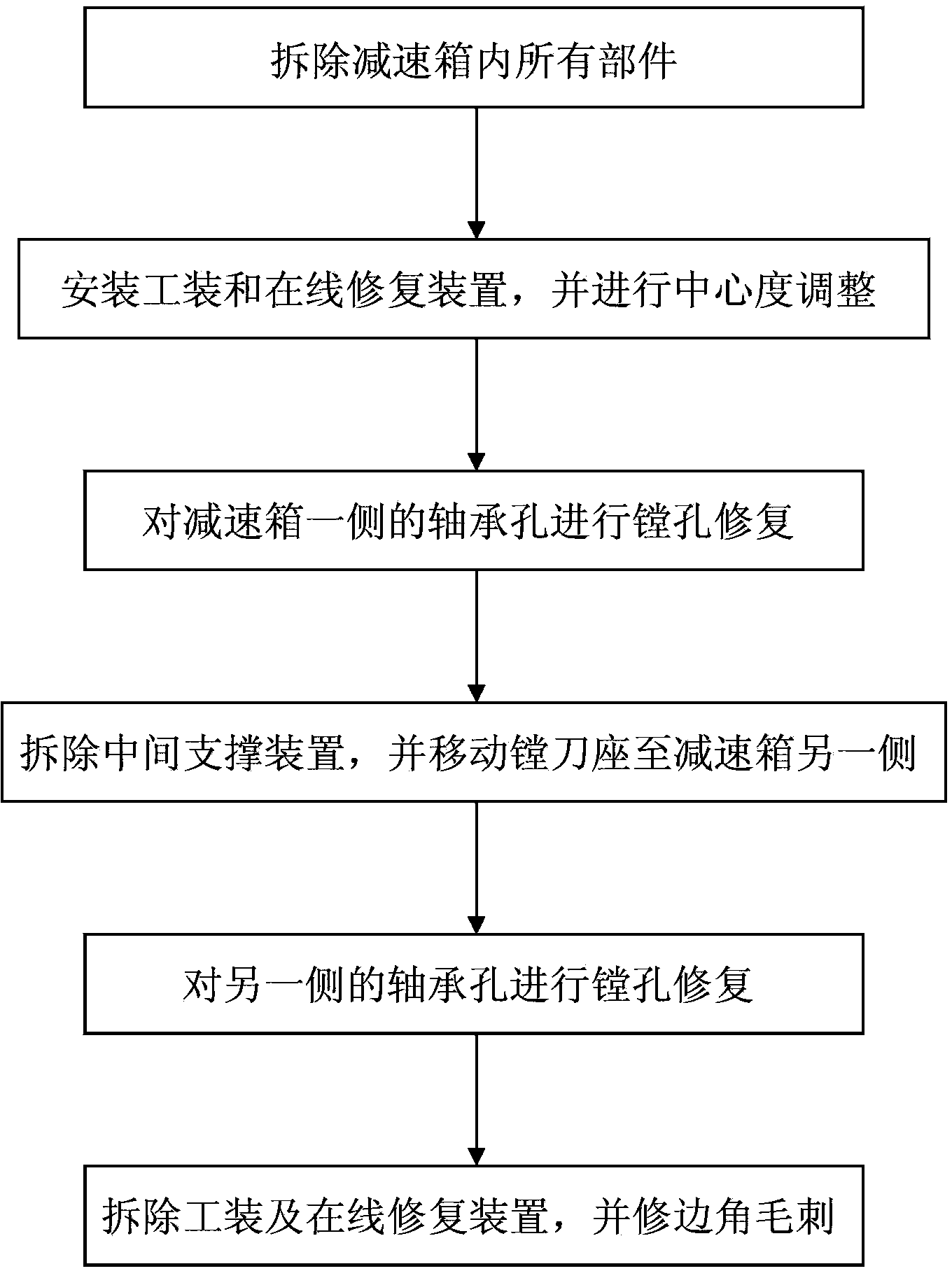

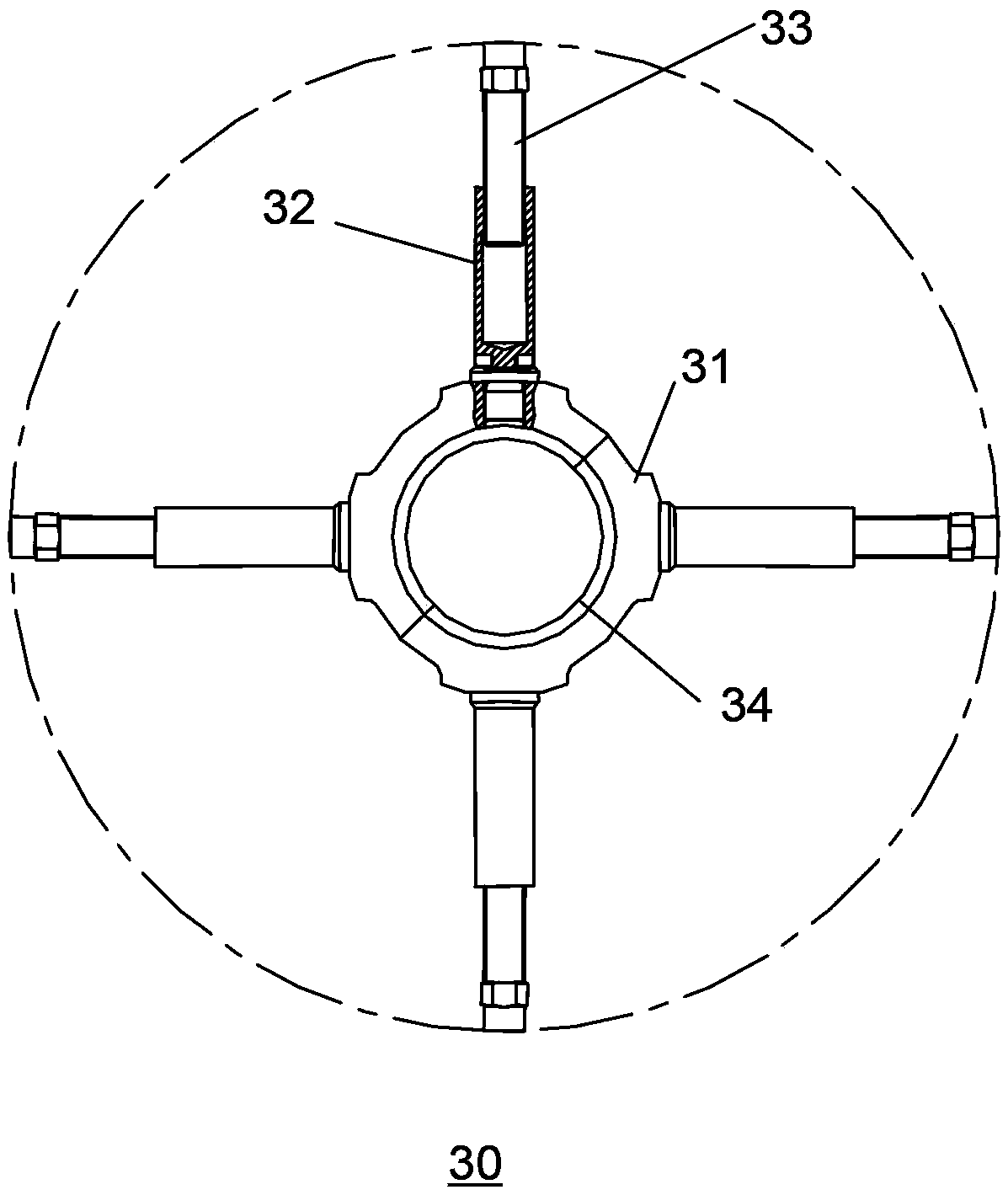

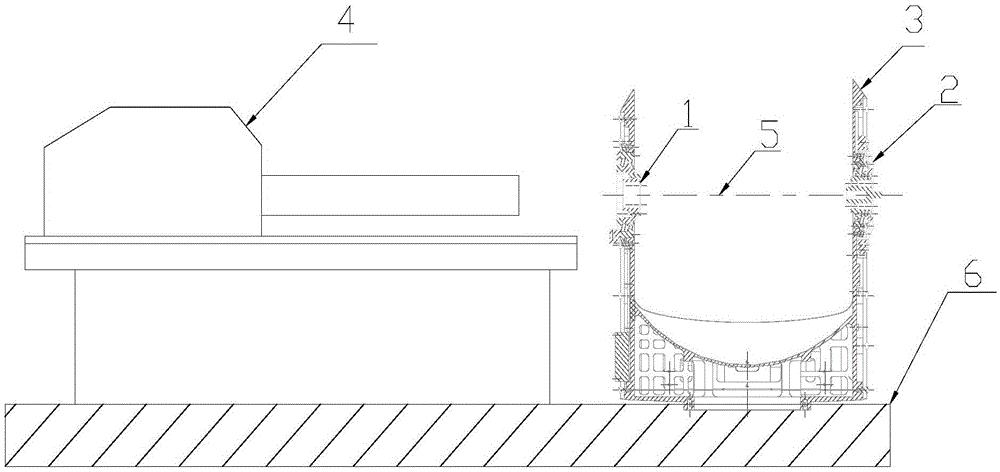

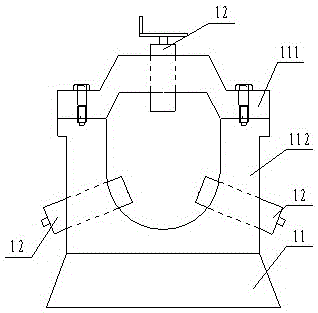

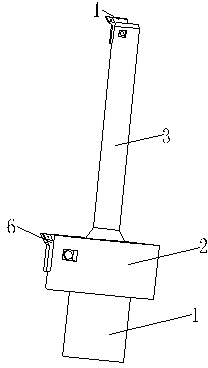

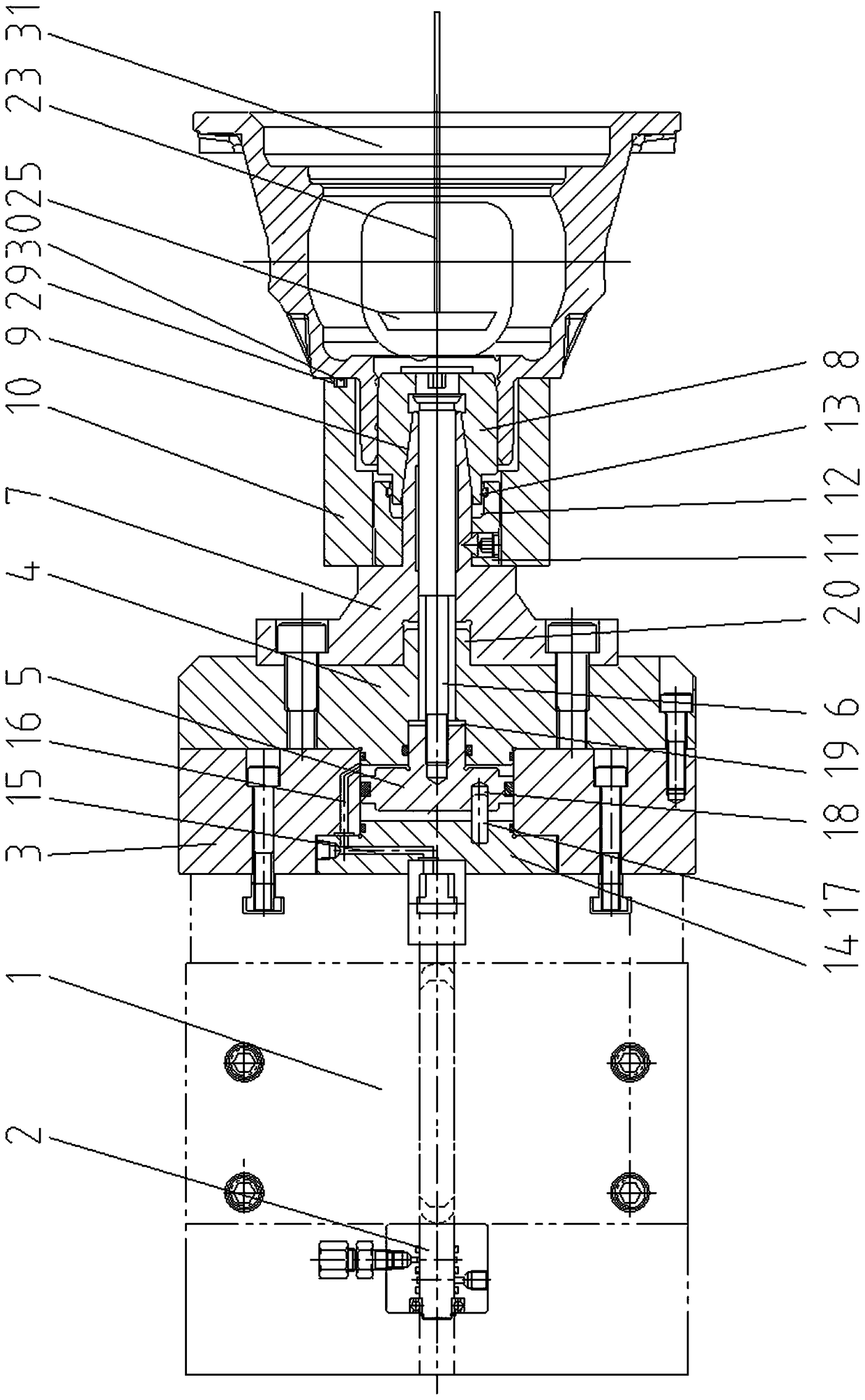

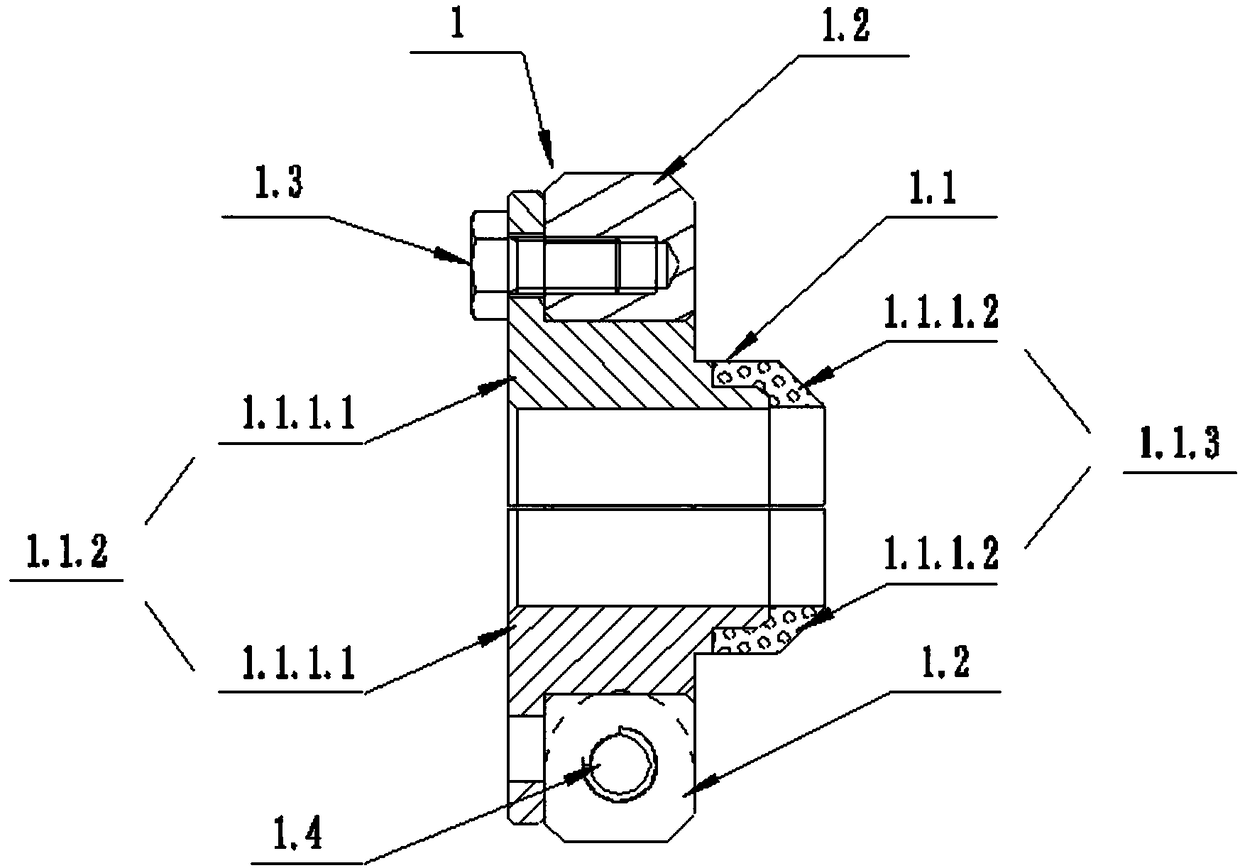

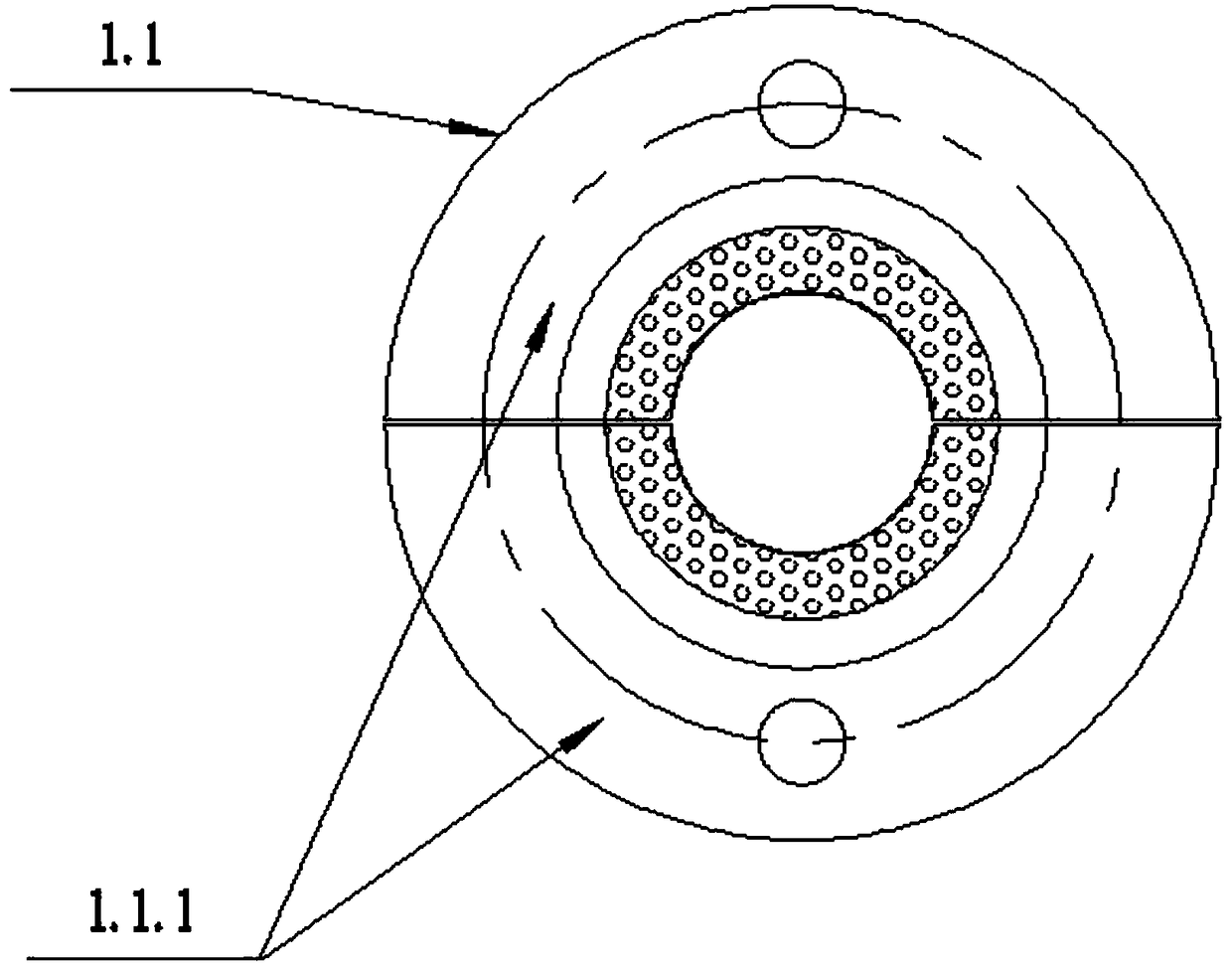

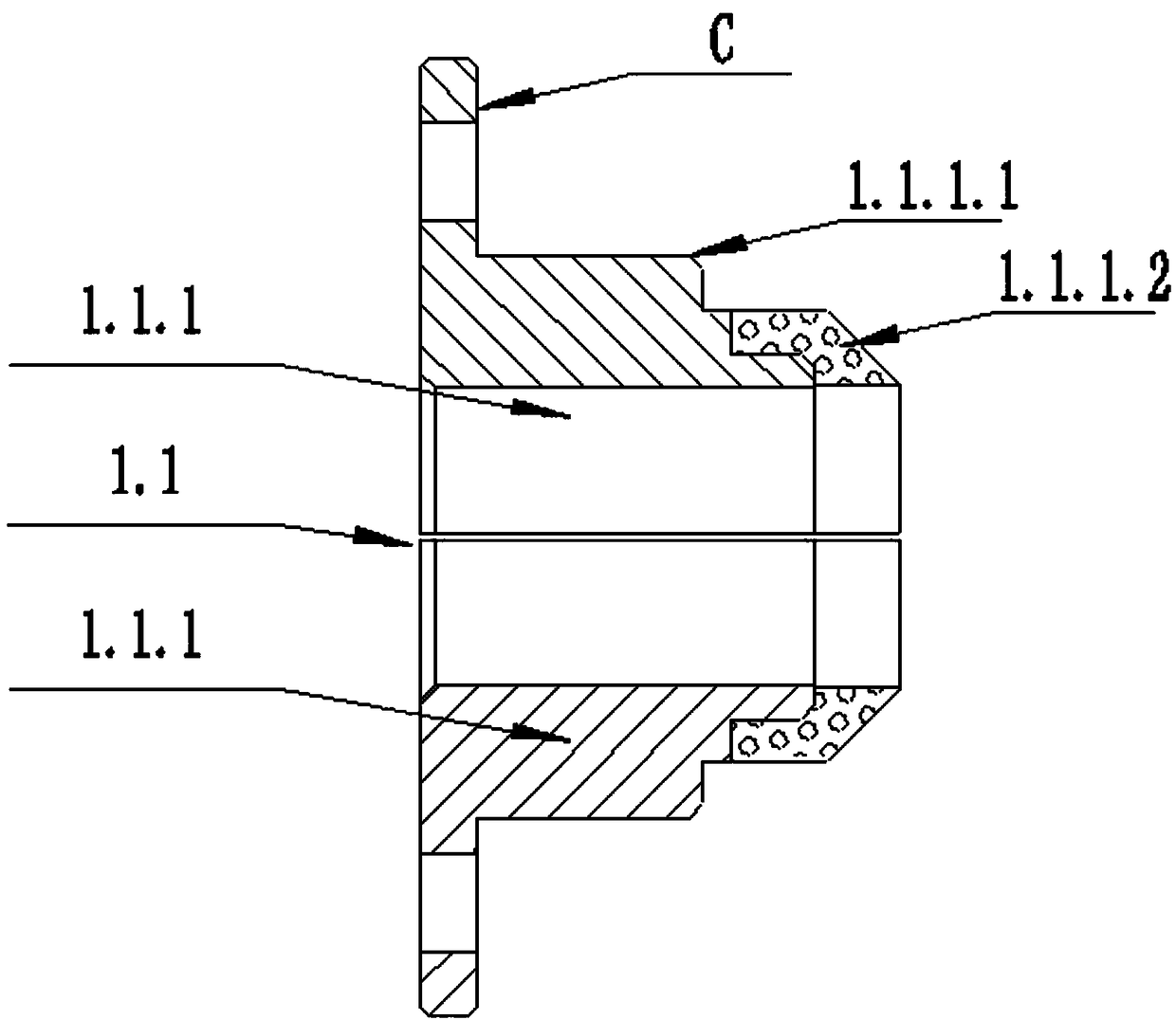

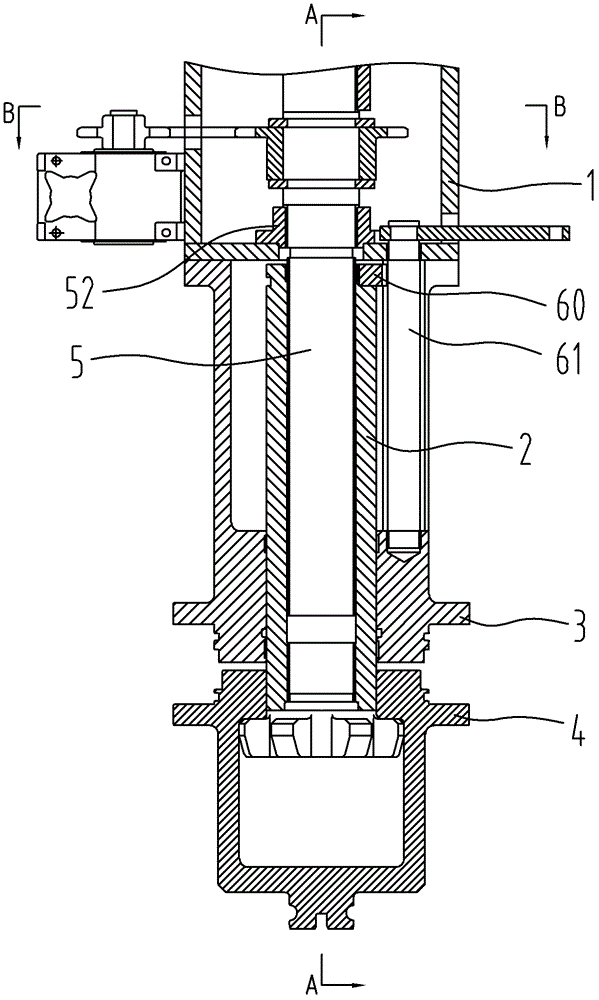

Device for online repairing of large reduction gearbox bearing hole abrasion and method thereof

ActiveCN103659146ARealize online repairHigh concentricity precisionMetal working apparatusPortable drilling machinesEngineeringStructural engineering

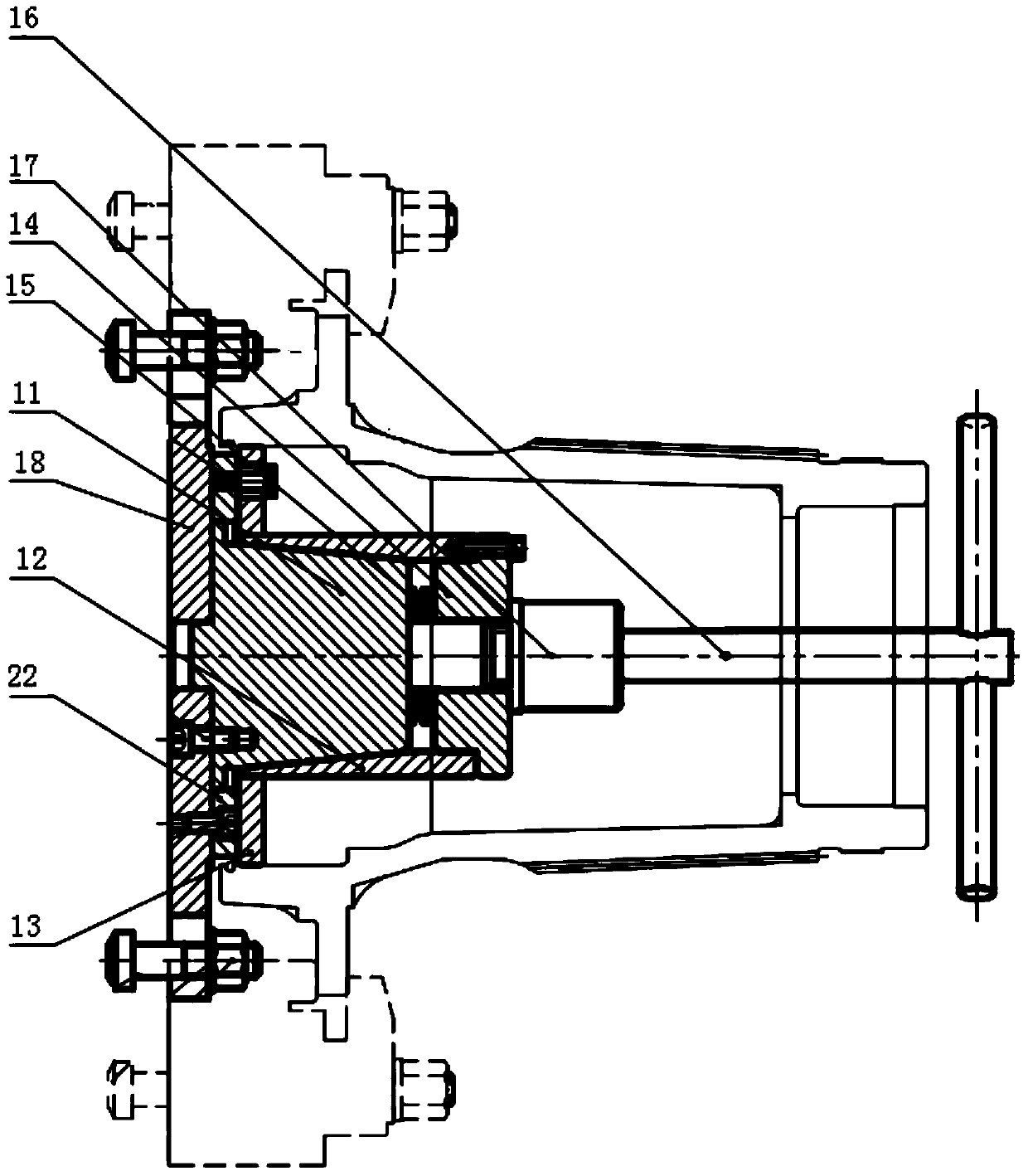

The invention discloses a device for online repairing of large reduction gearbox bearing hole abrasion and a method thereof. The device comprises a portable boring machine, a positioning device and a middle supporting device. By means of positioning of the positioning device, the middle supporting device and a reduction gearbox, the portable boring machine sequentially bores bearing holes in the two sides of the reduction gearbox, so that online repairing of the bearing holes is achieved, and size precision, geometric tolerance and roughness of the repaired bearing holes can fully meet the requirements of a drawing. Besides, the bearing holes in the two sides are bored through one cutter, coaxiality precision is high, and the device is convenient to use.

Owner:BAOSHAN IRON & STEEL CO LTD

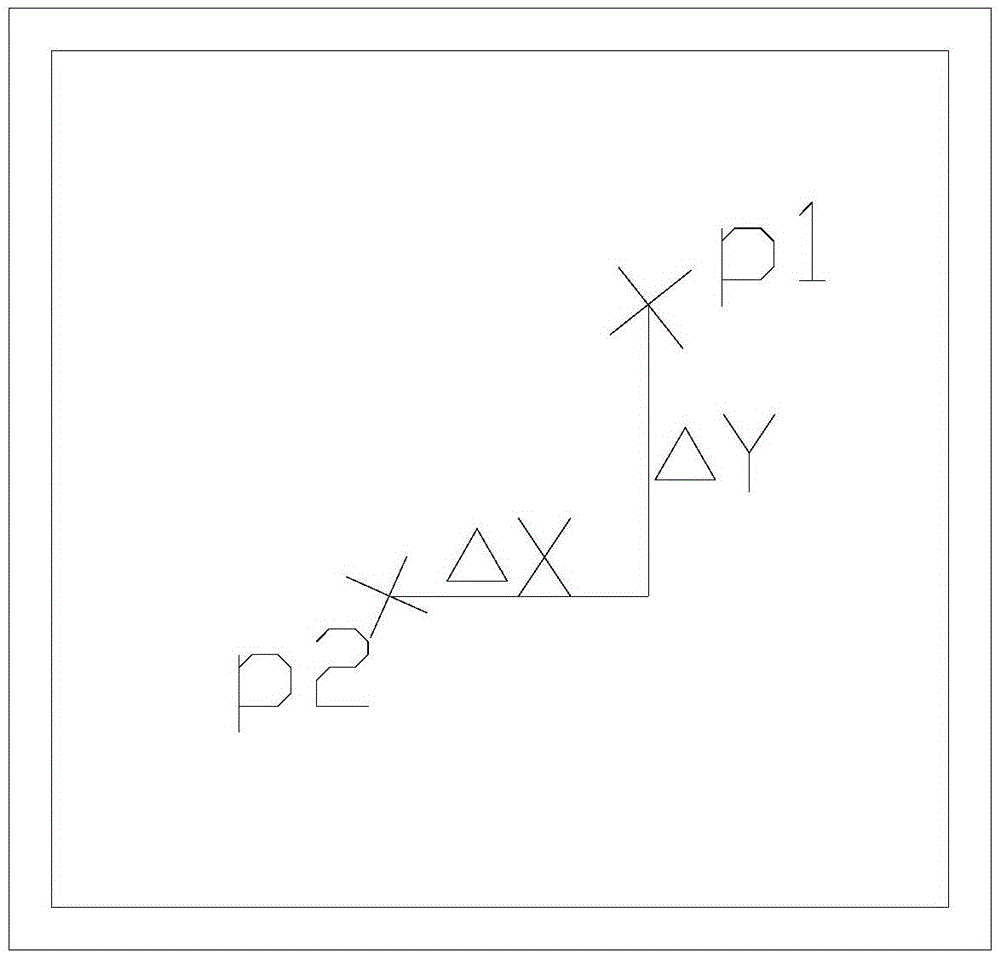

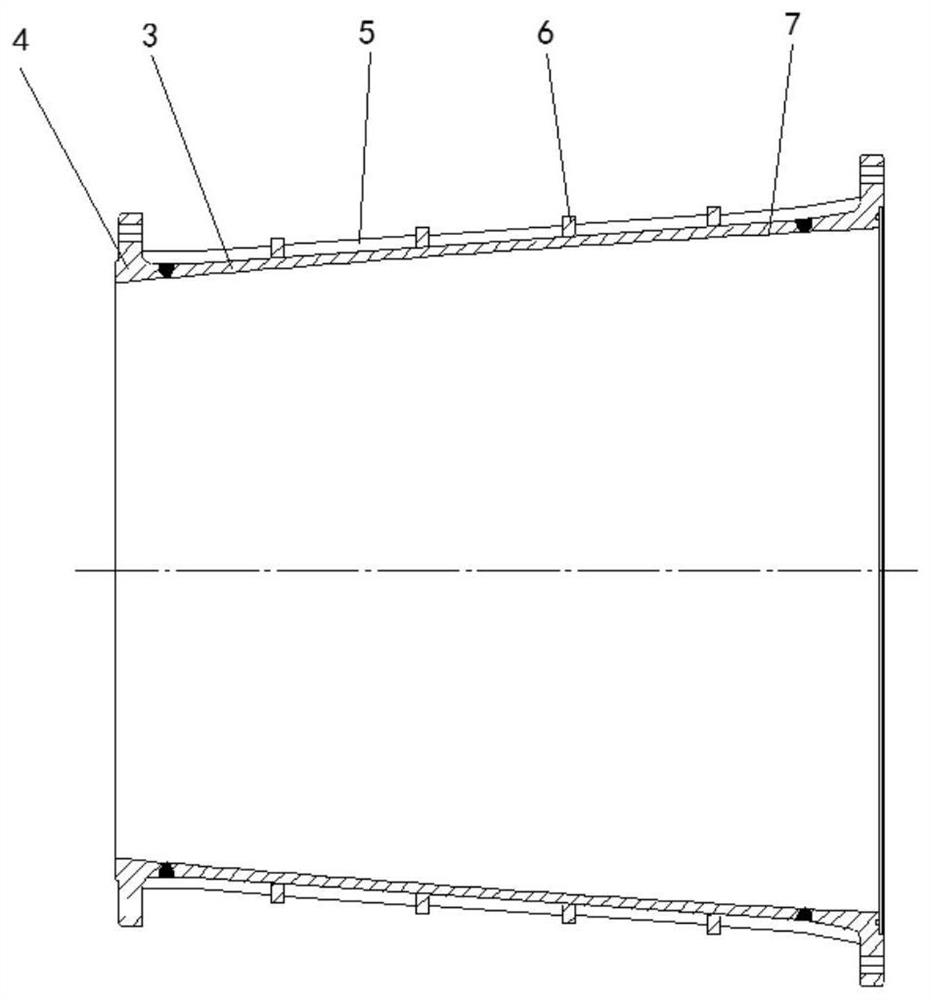

Coaxial assembly method for shaft components and coaxiality detection method for shaft components

ActiveCN105414957AQuick assemblyRealize the assemblyAssembly machinesUsing optical meansEngineeringTelescope

The invention discloses a coaxial assembly method for shaft components and a coaxiality detection method for the shaft components. The assembly method includes the steps that a reticle is assembled into a process hole in one shaft component, and the shaft component and an internal focusing telescope are adjusted to establish a benchmark, so that the self-collimating image circle drawing amount received by the internal focusing telescope is minimum when the shaft component rotates, the position P1 of a reticle image is recorded, and the shaft component and the internal focusing telescope are fixed; and the reticle is assembled into a process hole of another shaft component, and the shaft component is adjusted, so that the self-collimating image circle drawing amount received by the internal focusing telescope is minimum when the shaft component rotates, the position P2 of a reticle image and the position P1 of the reticle image coincide with each other, and the shaft component is fixed and assembled. According to the coaxial assembly method and the coaxiality detection method, the shaft component assembly and coaxiality detection are achieved through an optical method, assembly precision is high, efficiency is high, the detection error is small, the speed is high, operation is simple, the application range is wide, and the methods are suitable for being applied and popularized.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

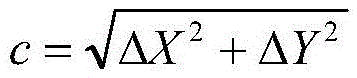

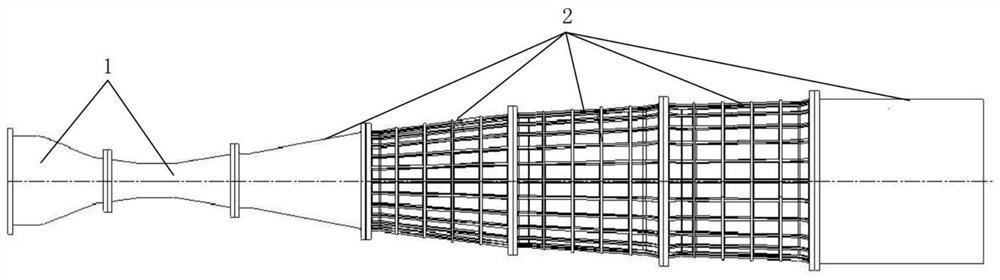

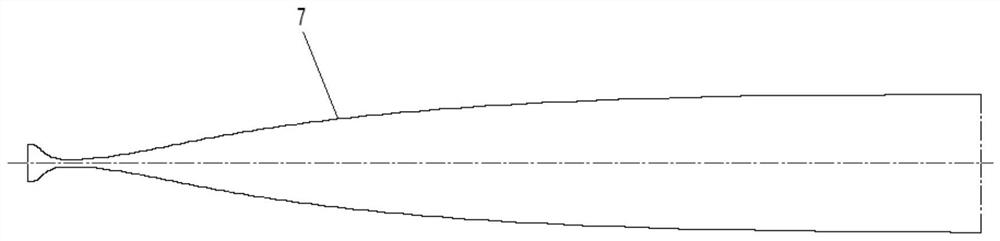

Manufacturing technology for axisymmetric nozzle of conventional hypersonic wind tunnel

The invention discloses a manufacturing technology of an axisymmetric nozzle of a conventional hypersonic wind tunnel. The manufacturing technology comprises the processes of manufacturing of a nozzle blank piece, machining of a part section, detecting and assembling of the nozzle, through control on the important links of controlling nozzle product manufacturing residual stress elimination, inner molded surface machining precision, inner molded surface roughness, nozzle coaxiality, nozzle assembling clearance, connection difference treatment and the like, the deviation between the inner molded surface of the manufactured nozzle and the theoretical molded surface meets the precision requirement, it is ensured that the nozzle obtains the velocity field quality meeting the national military standard requirement, and the manufacturing risk and the repetition of the machining process in the machining process are reduced. The manufacturing technology has already been applied to manufacturing of axisymmetric molded surface nozzles of phi 0.5 m magnitude, phi 1 m magnitude and phi 2 m magnitude, and the maximum Mach number deviation in a uniform area of a velocity field of the nozzle is smaller than 1% of the national military standard requirement.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

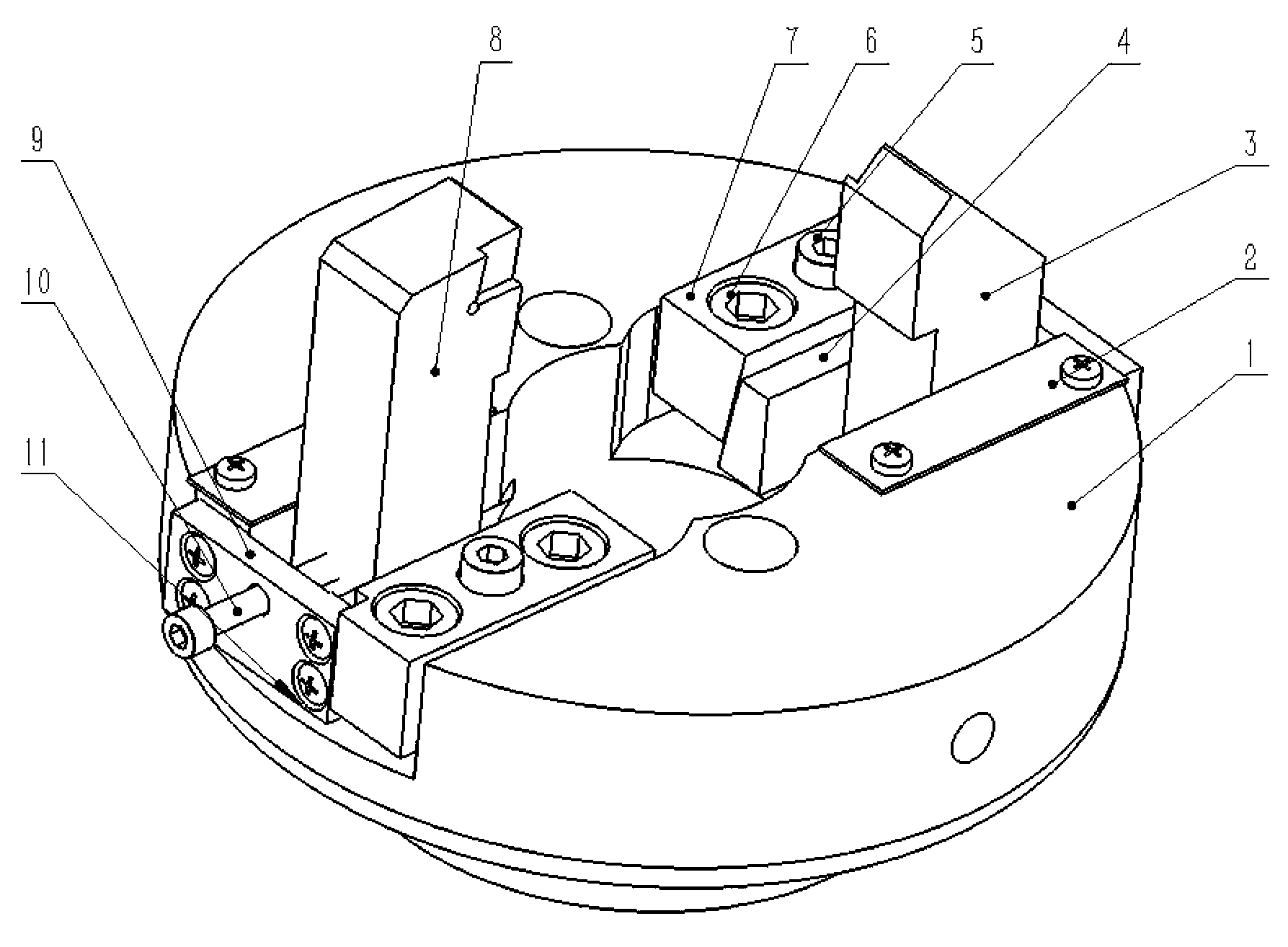

Combined type excircle and chamfering turning mechanism

ActiveCN103302533ACompact structureReasonable structurePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a combined type excircle and chamfering turning mechanism which comprises a cutterhead, an excircle turning tool, a chamfering turning tool, a fixed wedge, a movable wedge, a ruler, an inner hexagon screw, a dismantling screw, a backing plate, an adjusting fixing plate and an adjusting screw, wherein the cutterhead is mounted on a flange surface of a machine tool spindle; the excircle turning tool and the backing plate are connected and fixed together through a cross recess countersunk head screw; the backing plate is directly clamped in a groove of the cutterhead; the bottom surface of the fixed wedge is connected with the cutterhead by a flat key; one side surface of the fixed wedge is in contact with the excircle turning tool, and the other side surface is in contact with the movable wedge; one side surface of the external turning tool is in contact with one side surface of the groove of the cutterhead, and the other side surface is in contact with the fixed wedge; the adjusting fixing plate is respectively connected with the cutterhead and the fixed wedge; the inner hexagon screw is fixed on the cutterhead; the dismantling screw is mounted on the movable wedge; and the adjusting screw is mounted on the adjusting fixing plate. The chamfering turning tool and the excircle turning tool are symmetrically arranged on the cutterhead, and the mounting manners of the chamfering turning tool and the external turning tool are identical. The whole set of mechanism has the advantages of reasonable structure, and convenience for operation and use, and the external turning tool and the chamfering turning tool are easy to adjust in the radial direction.

Owner:ANHUI LICHENG MACHINERY EQUIP

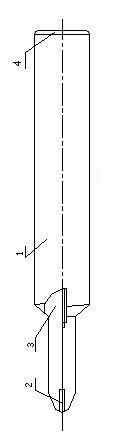

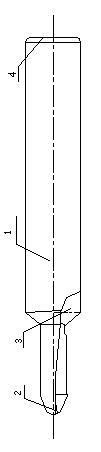

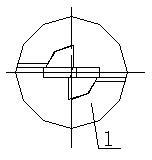

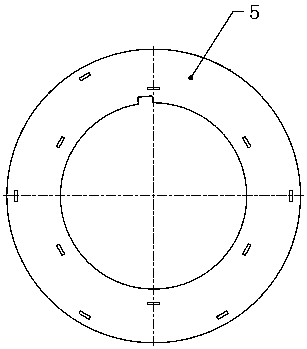

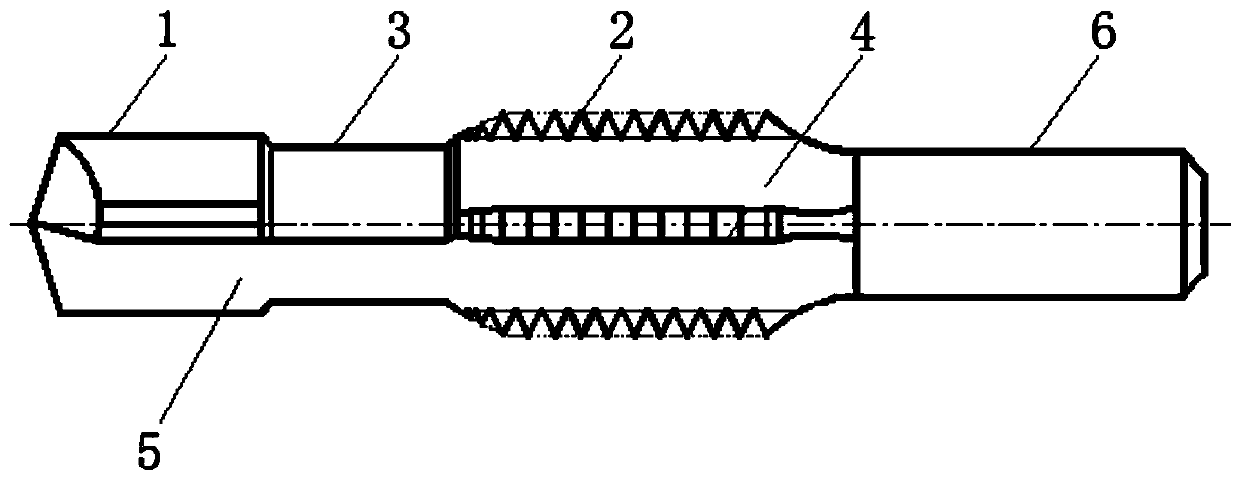

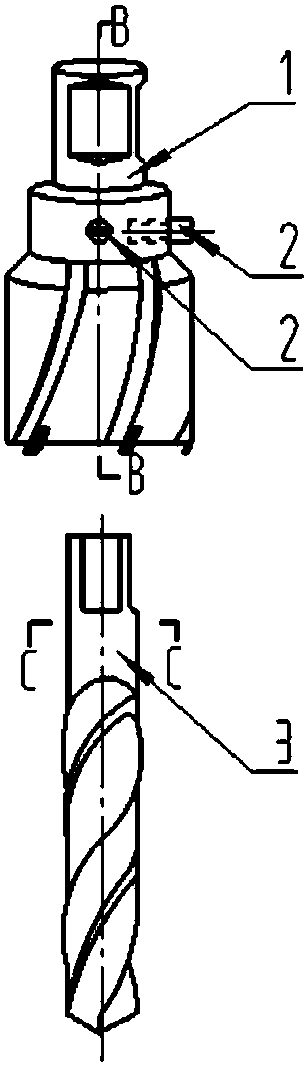

Polycrystalline diamond drilling and reaming integrated cutter and machining method

InactiveCN102145394ASimple structureEasy to manufactureTurning toolsPolycrystalline diamondComposite blade

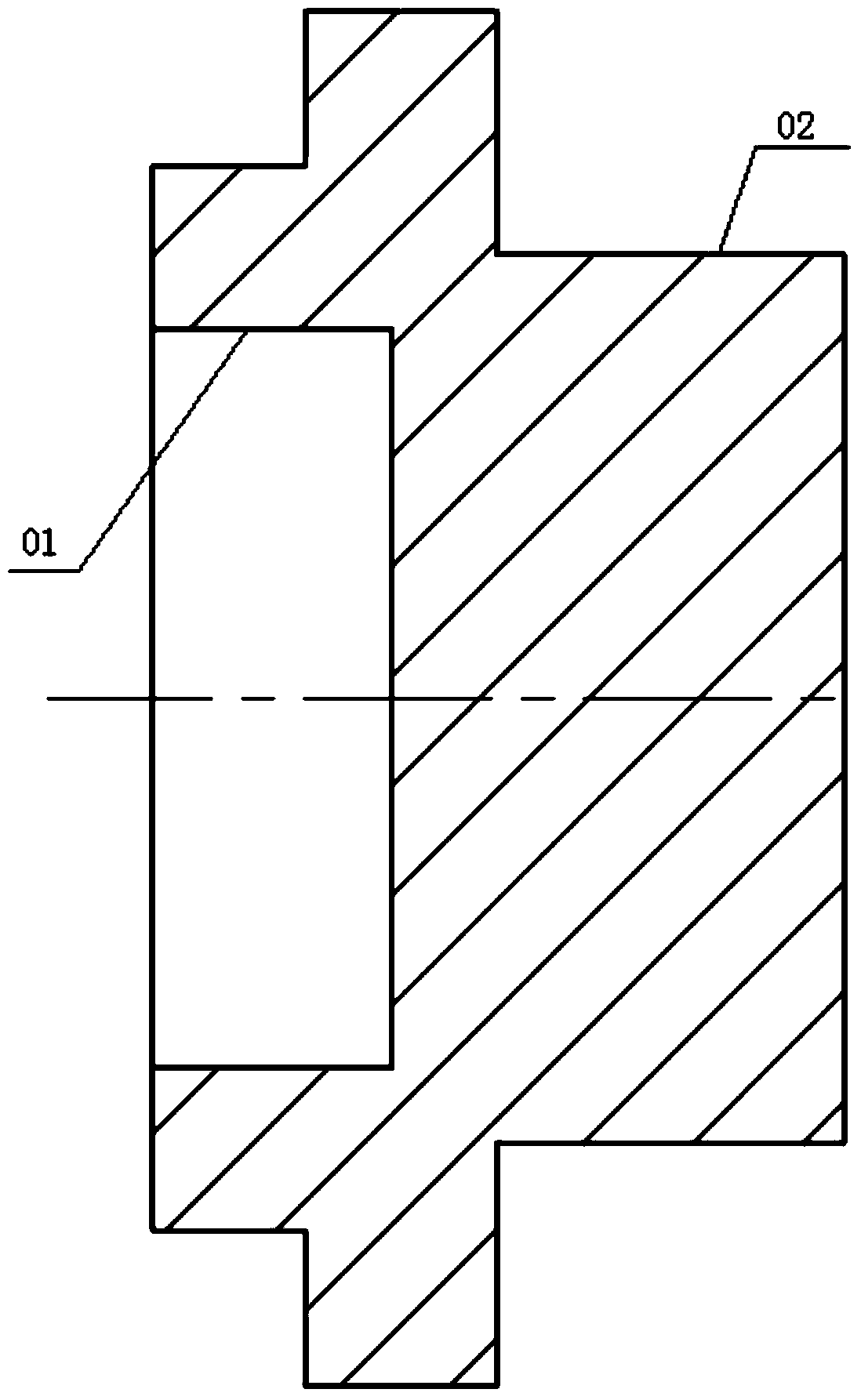

The invention discloses a polycrystalline diamond drilling and reaming integrated cutter and a machining method. Carbon fiber composite materials are widely applied to the aerospace and are almost machined by adopting a hole machining method. The polycrystalline diamond drilling and reaming integrated cutter comprises a cutter substrate (1) which is sequentially provided with a drilling end (2), a reaming end (3) and a clamping end (4) to form a stepped straight flute structure, wherein the drilling end is welded with a group of polycrystalline diamond (PCD) drilling end composite blades (5), and the reaming end is welded with a group of PCD reaming end composite blades (6). The polycrystalline diamond drilling and reaming integrated cutter is used for drilling carbon fiber composite materials.

Owner:HARBIN UNIV OF SCI & TECH

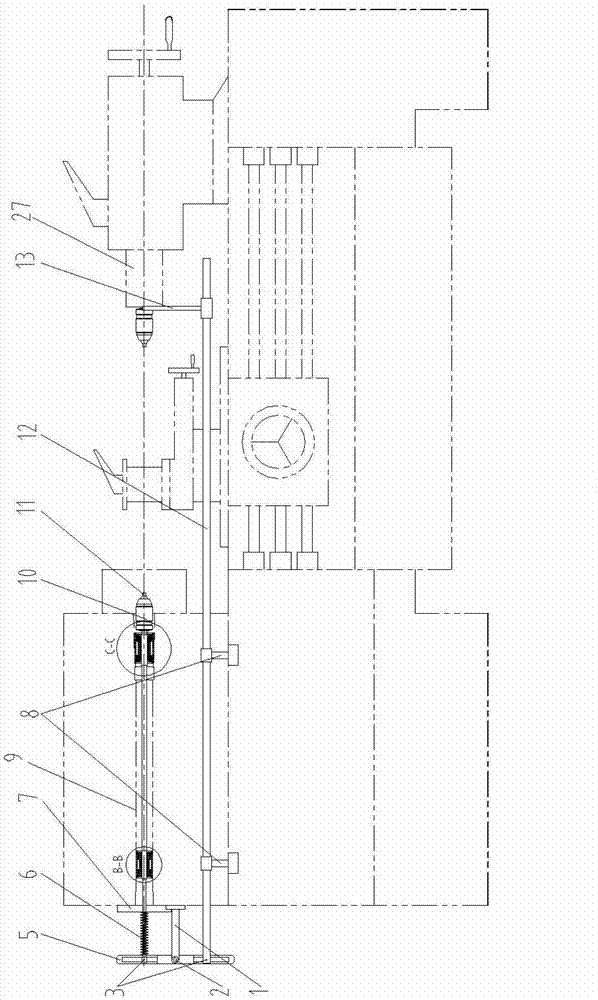

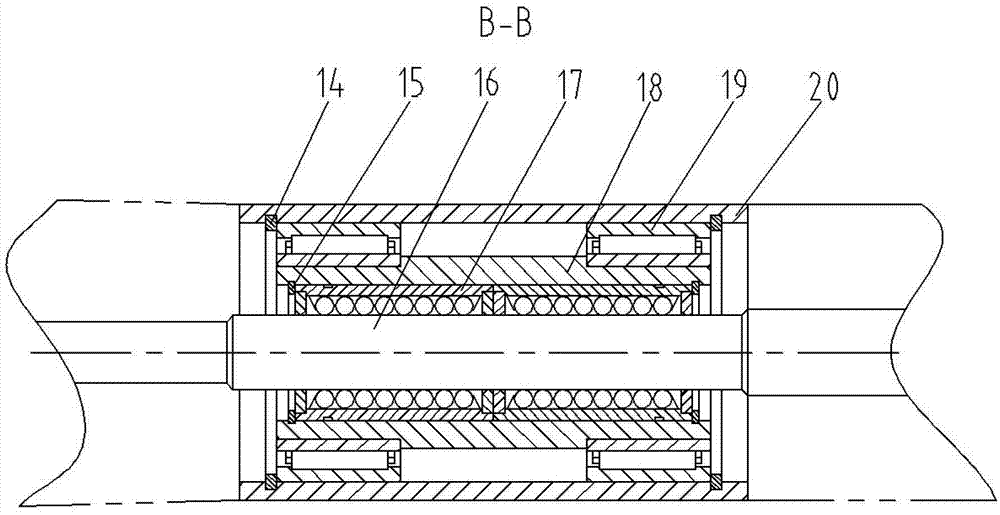

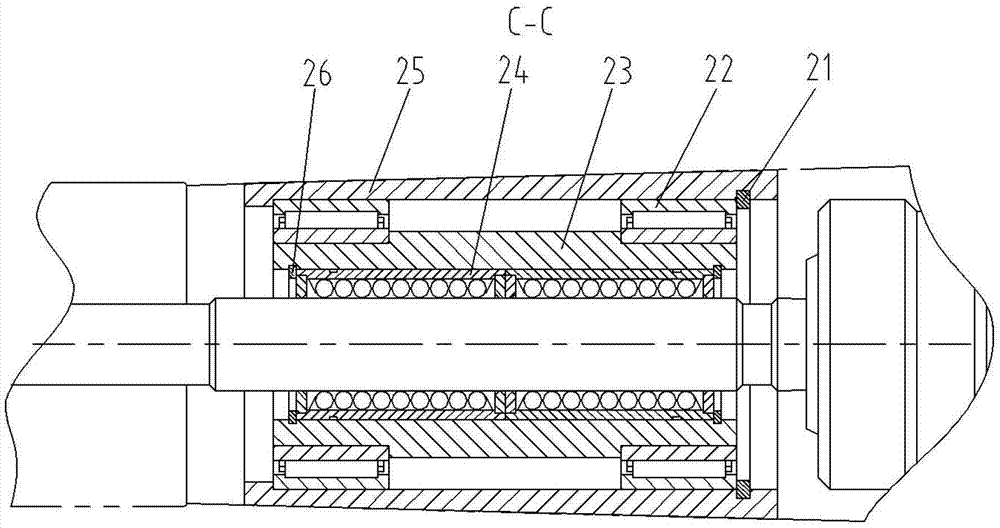

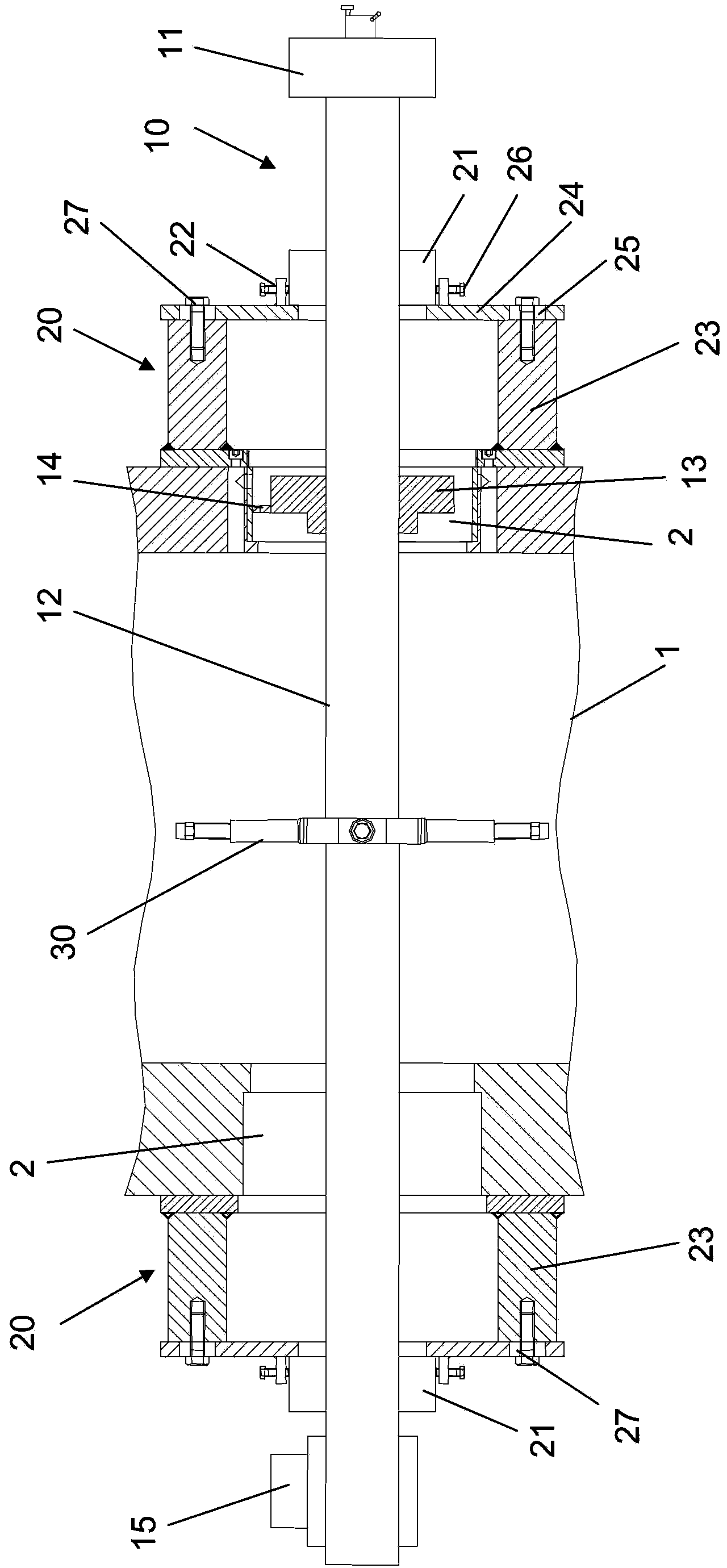

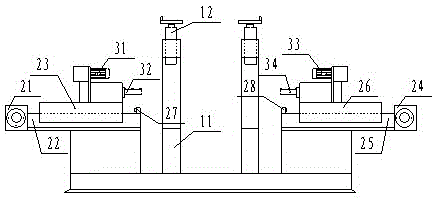

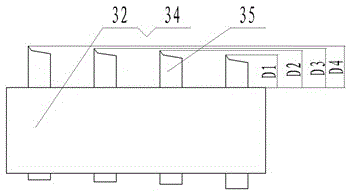

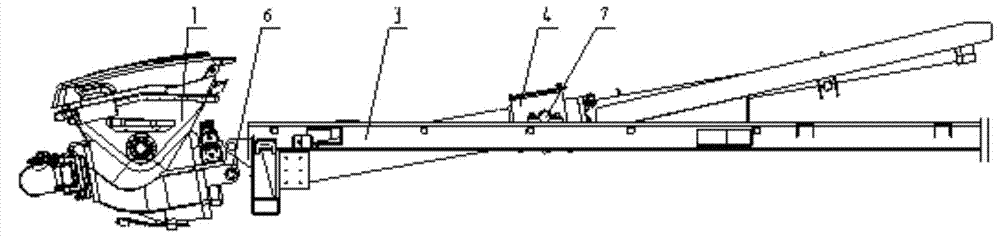

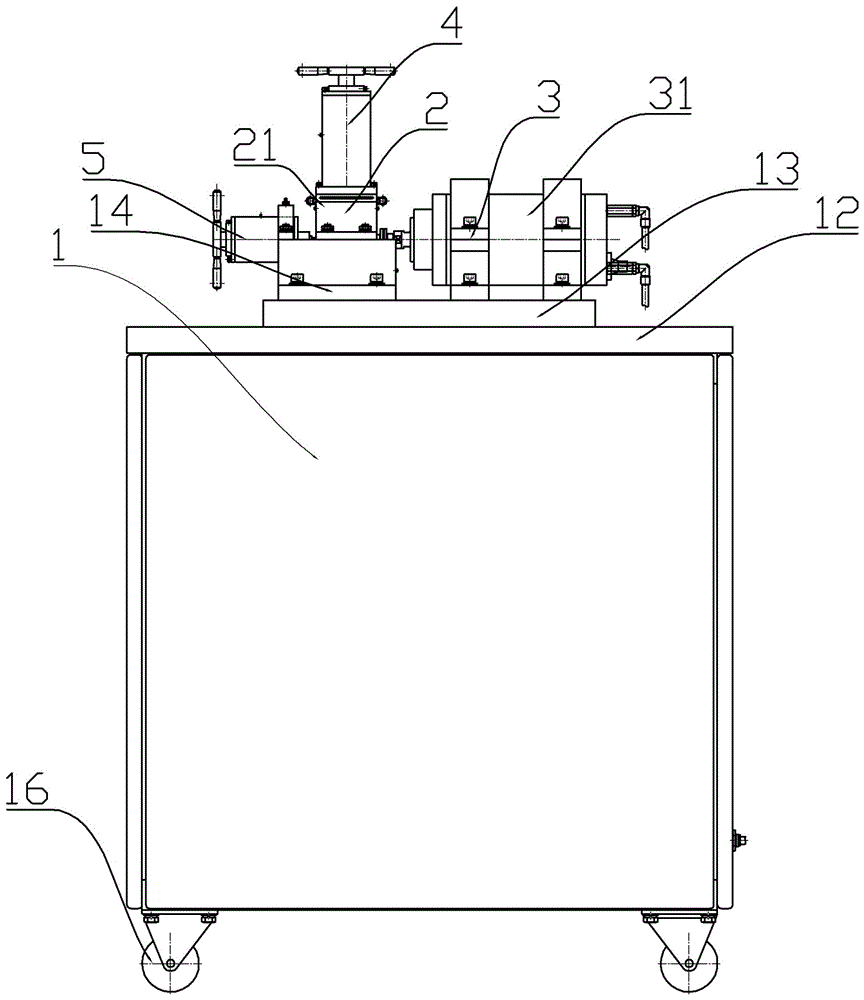

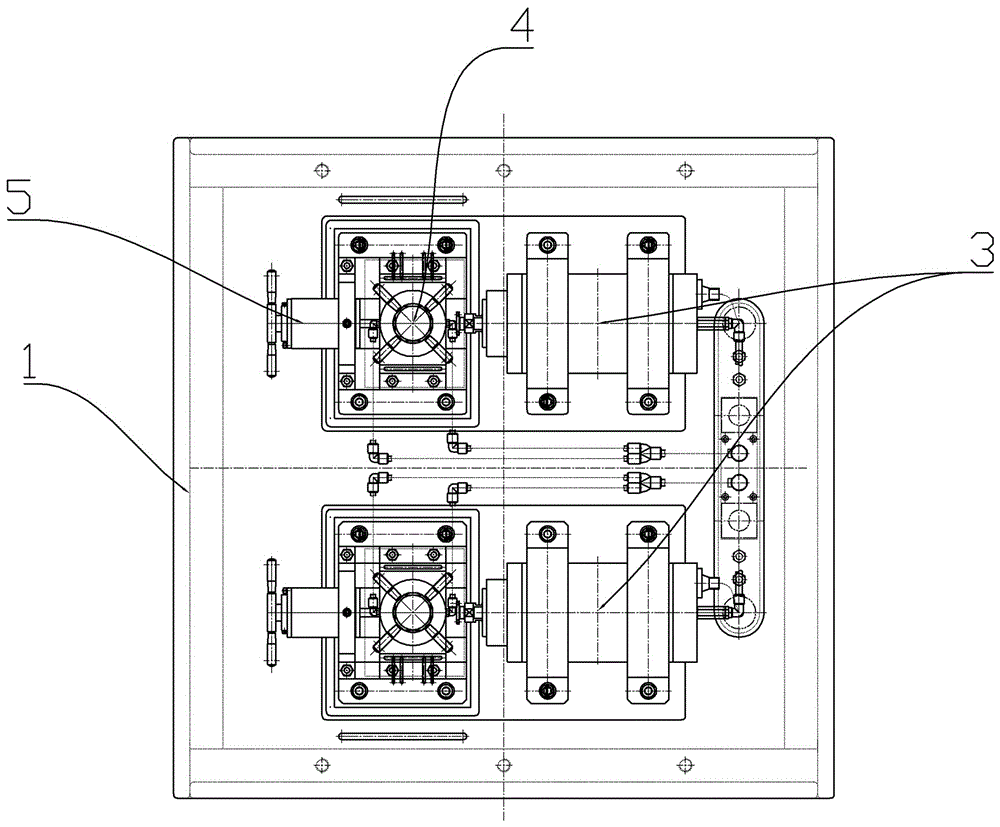

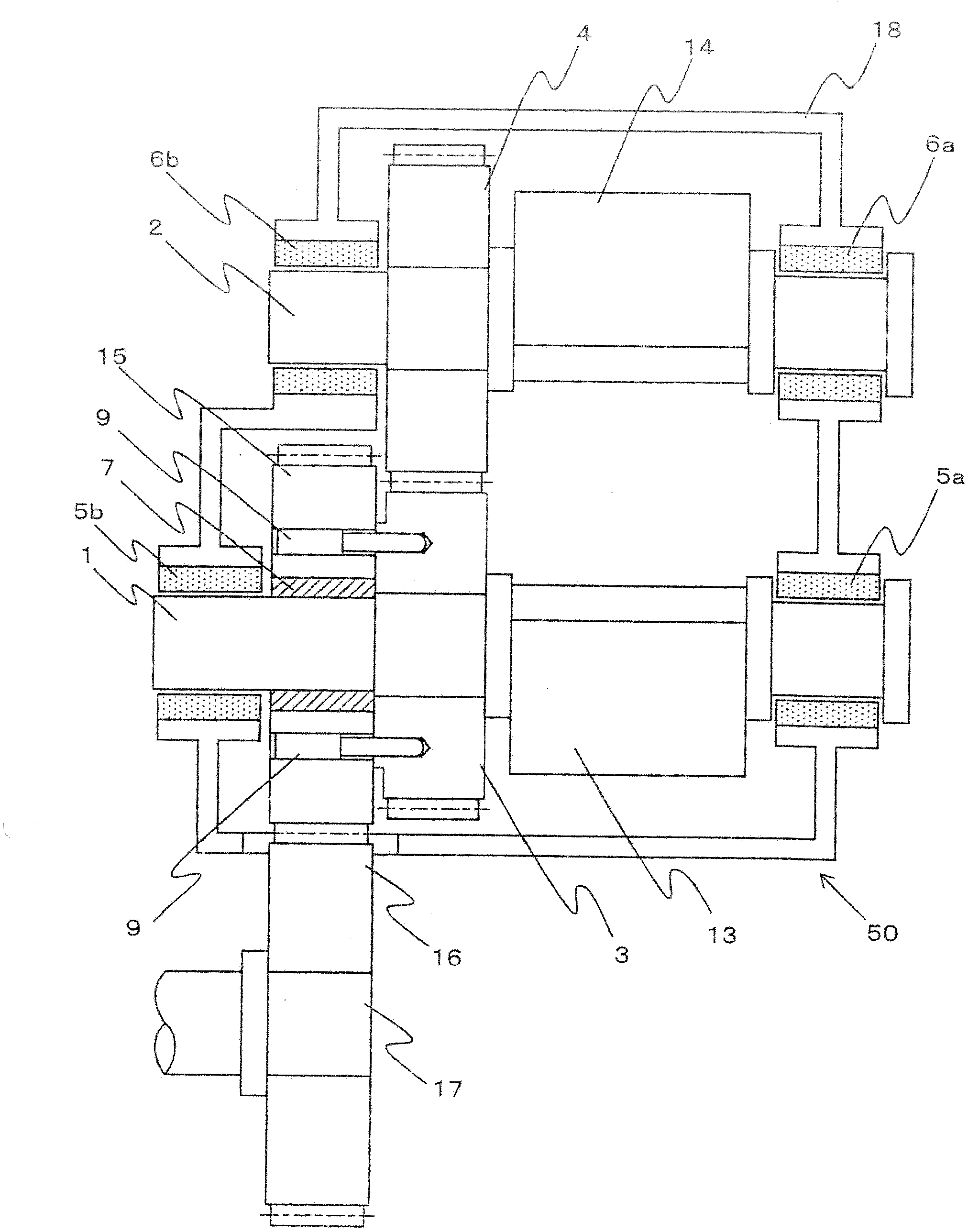

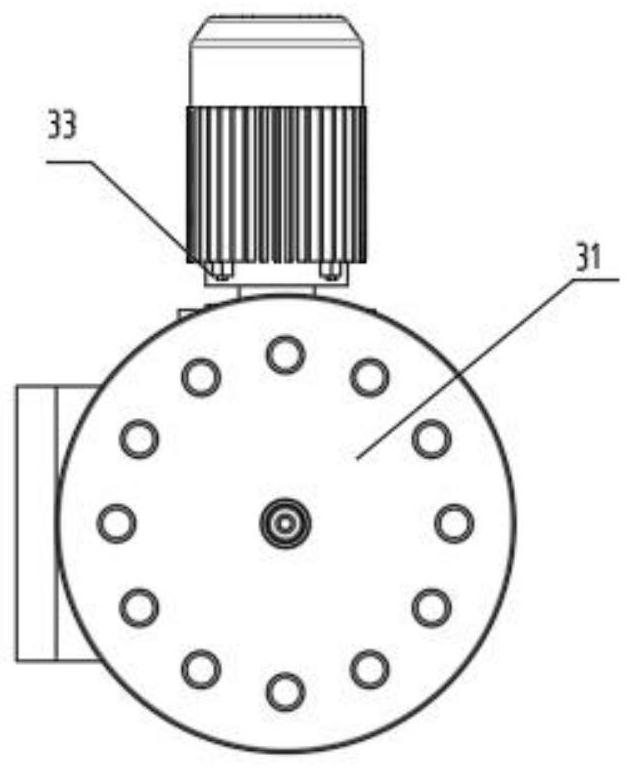

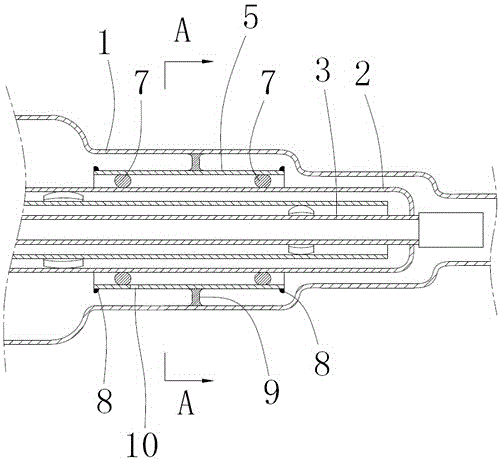

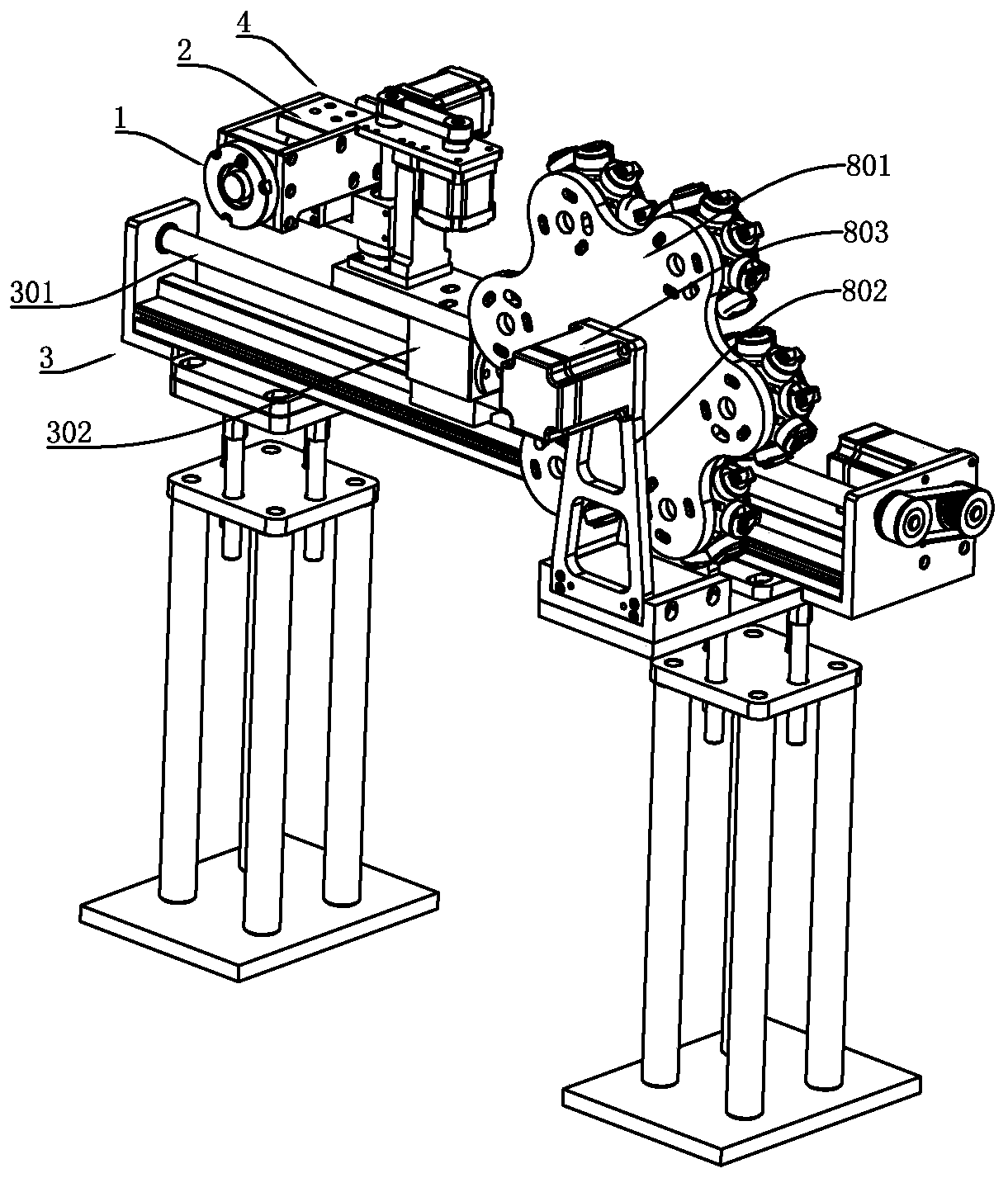

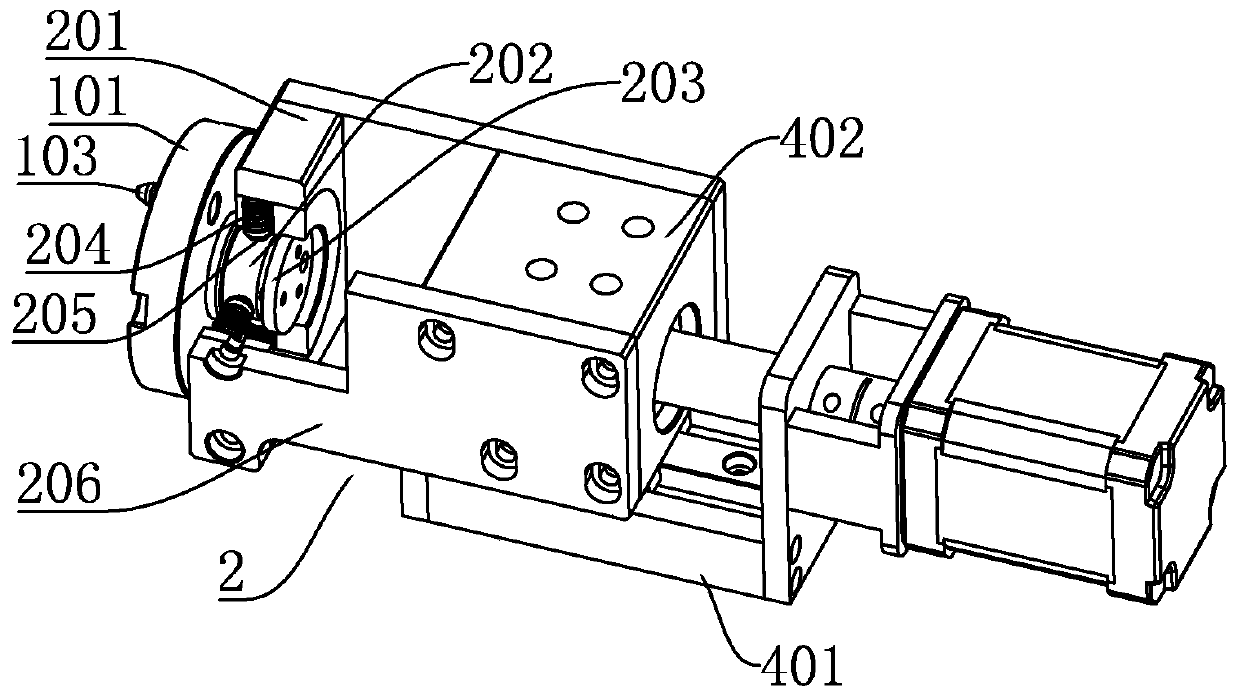

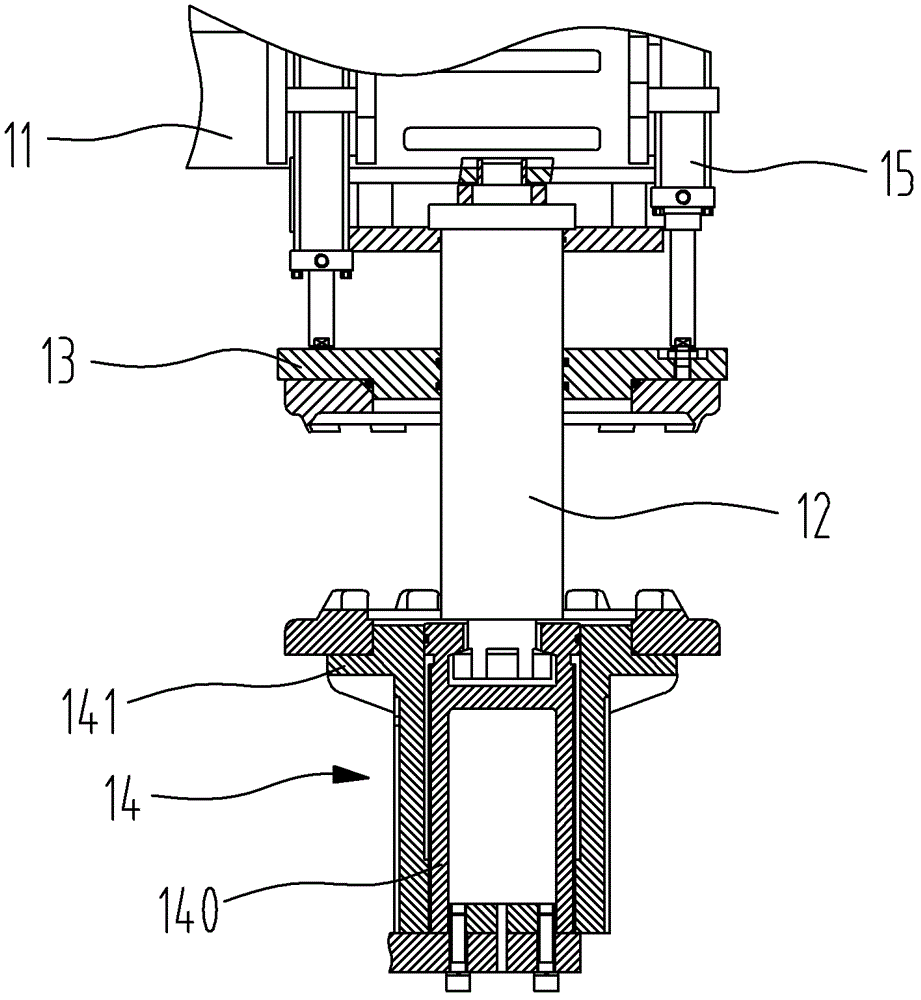

High-precision double-power-head boring device for gypsy boring

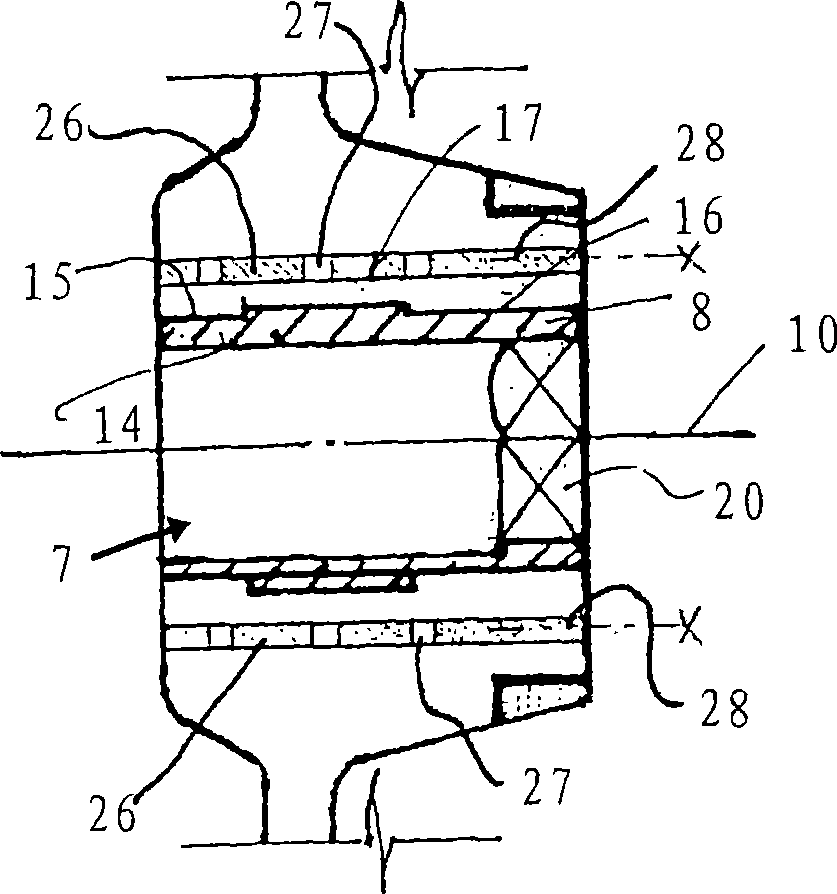

InactiveCN105127467AGuaranteed smoothnessGuaranteed stabilityTurning machine accessoriesWorkpiecesMechanical engineeringEngineering

The invention discloses a high-precision double-power-head boring device for gypsy boring. The device comprises a clamping mechanism, a feeding mechanism and a machining mechanism, wherein a gypsy is clamped by the clamping mechanism, the feeding mechanism drives the machining mechanism to move leftwards and rightwards, rotation of a boring cutter is achieved through the machining mechanism, and then boring of the gypsy is achieved. In this way, the two ends of the gypsy can be bored in a one-take mode, the coaxial precision of holes in the two ends of the obtained gypsy is improved greatly, and then the using smoothness and stability of the gypsy are guaranteed, abrasion of the gypsy is reduced greatly and service life is prolonged.

Owner:常熟中德重机有限公司

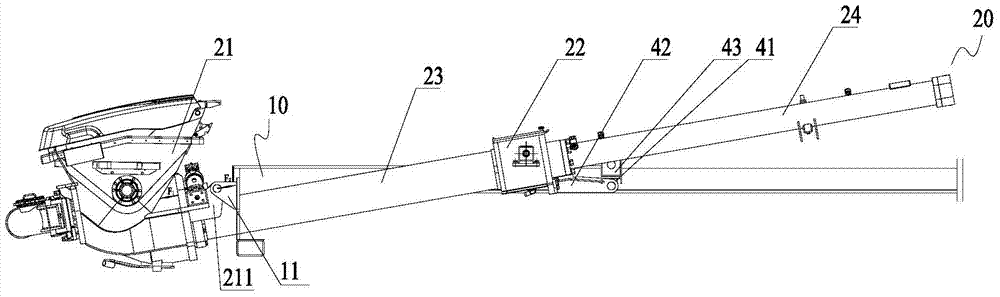

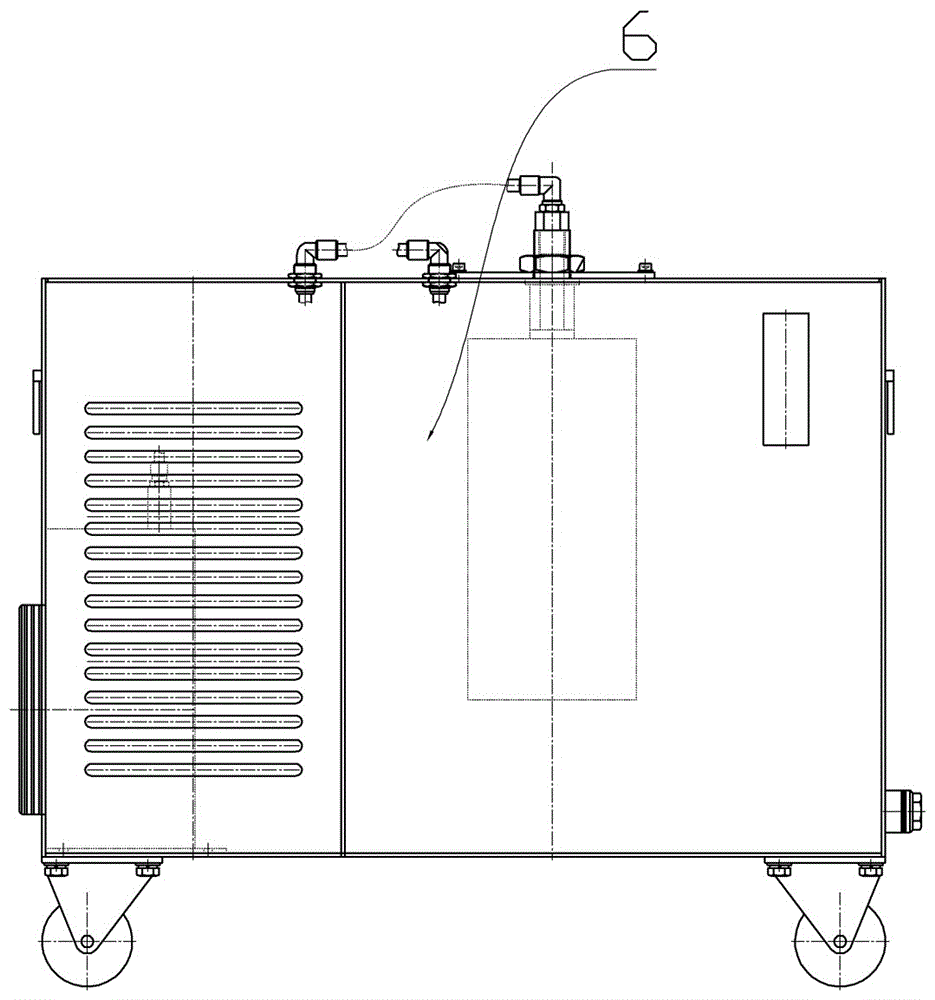

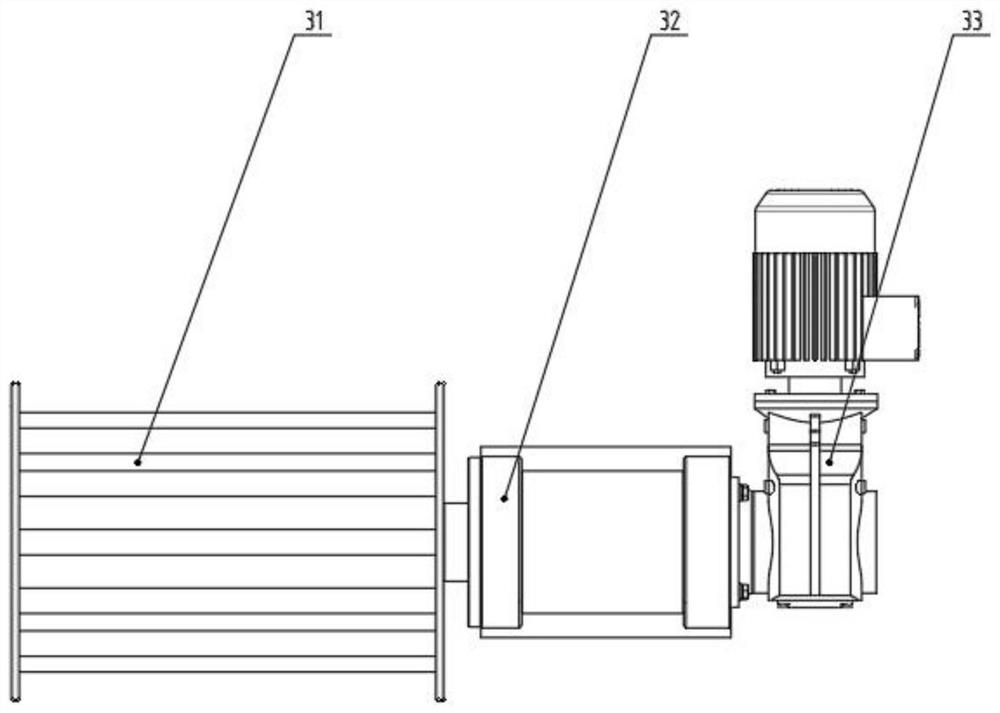

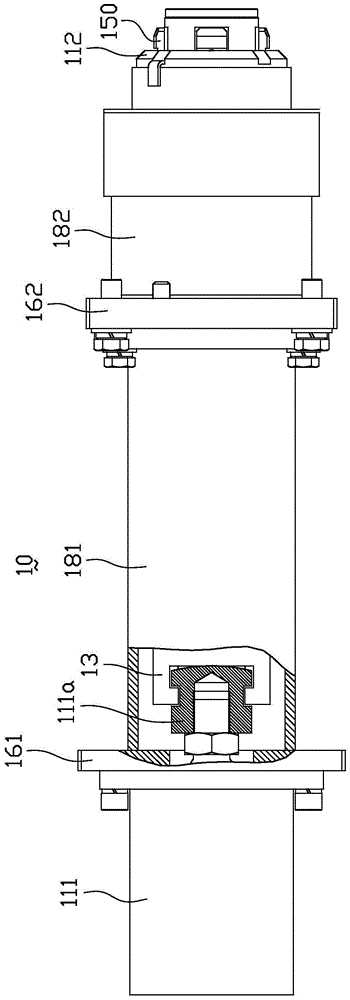

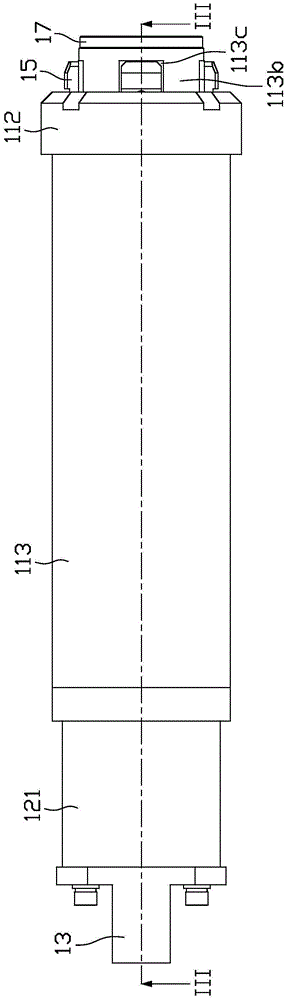

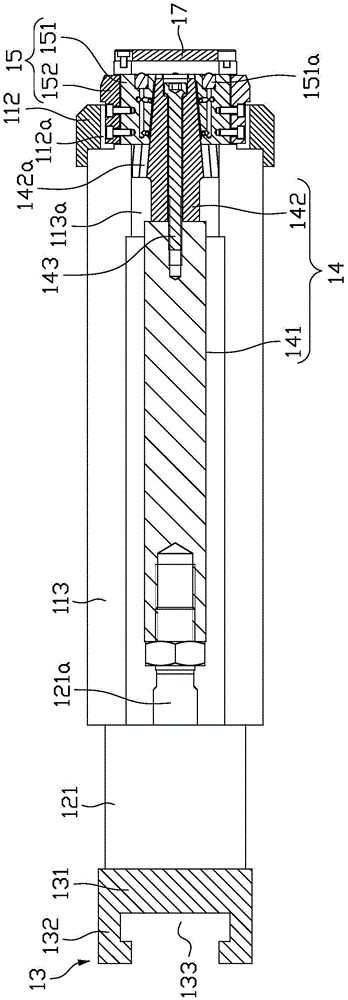

Pumping equipment

ActiveCN103790816AHigh concentricity precisionImprove reliabilityPositive displacement pump componentsLiquid fuel engine componentsShake upEngineering

The invention provides a set of pumping equipment. The pumping equipment comprises a rack and a pumping unit arranged on the rack. The pumping equipment further comprises elastic supports arranged on the rack, wherein the elastic supports comprise at least two first elastic supports and a second elastic support, the at least two first elastic supports are arranged on the two sides of the pumping unit so as to prevent the pumping unit from shaking laterally, and the second elastic support is arranged on the rack and elastically supports the lower portion of the pumping unit so as to prevent the pumping unit from shaking up and down. According to the pumping equipment, the elastic supports are arranged and comprise the at least two first elastic supports for preventing the pumping unit from shaking laterally and the second elastic support for preventing the pumping unit from shaking up and down, namely, the first elastic supports and the second elastic support are matched for use, buffering is formed for shaking and deformation in the vertical direction and the lateral direction, and therefore shaking and deformation of a frame are prevented from being directly transmitted to the pumping unit, the coaxiality accuracy of the pumping unit is improved, the service life of a piston, an oil cylinder, a concrete cylinder and other key parts is prolonged, and the reliability of the pumping unit is improved.

Owner:ZOOMLION HEAVY IND CO LTD

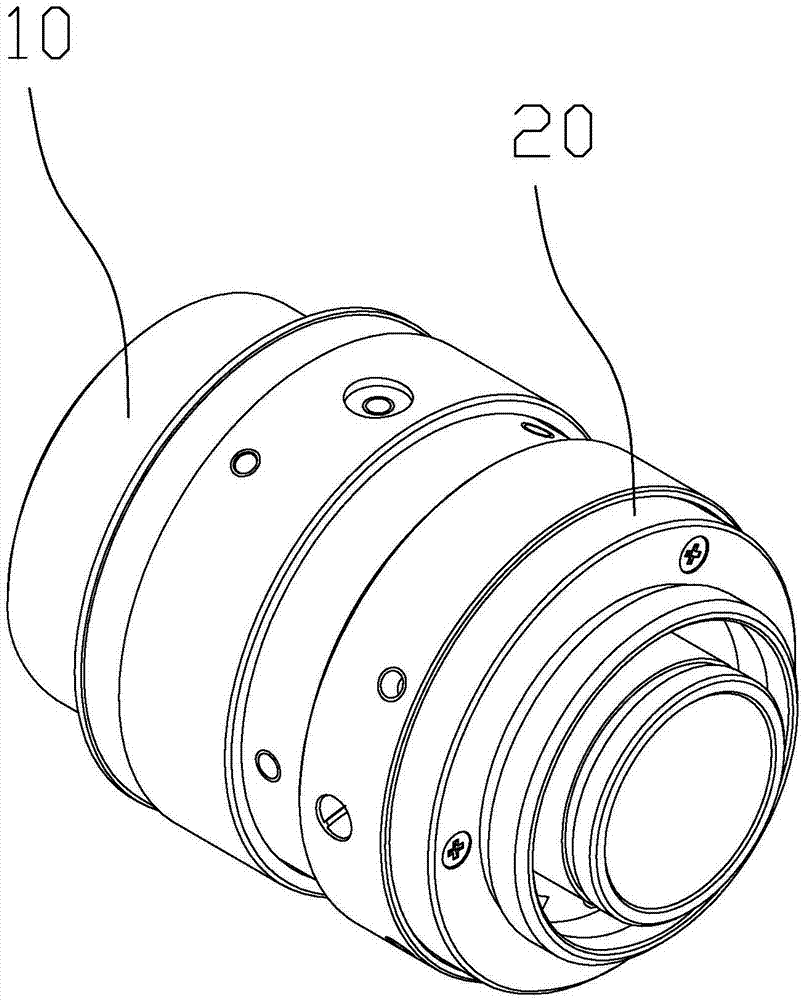

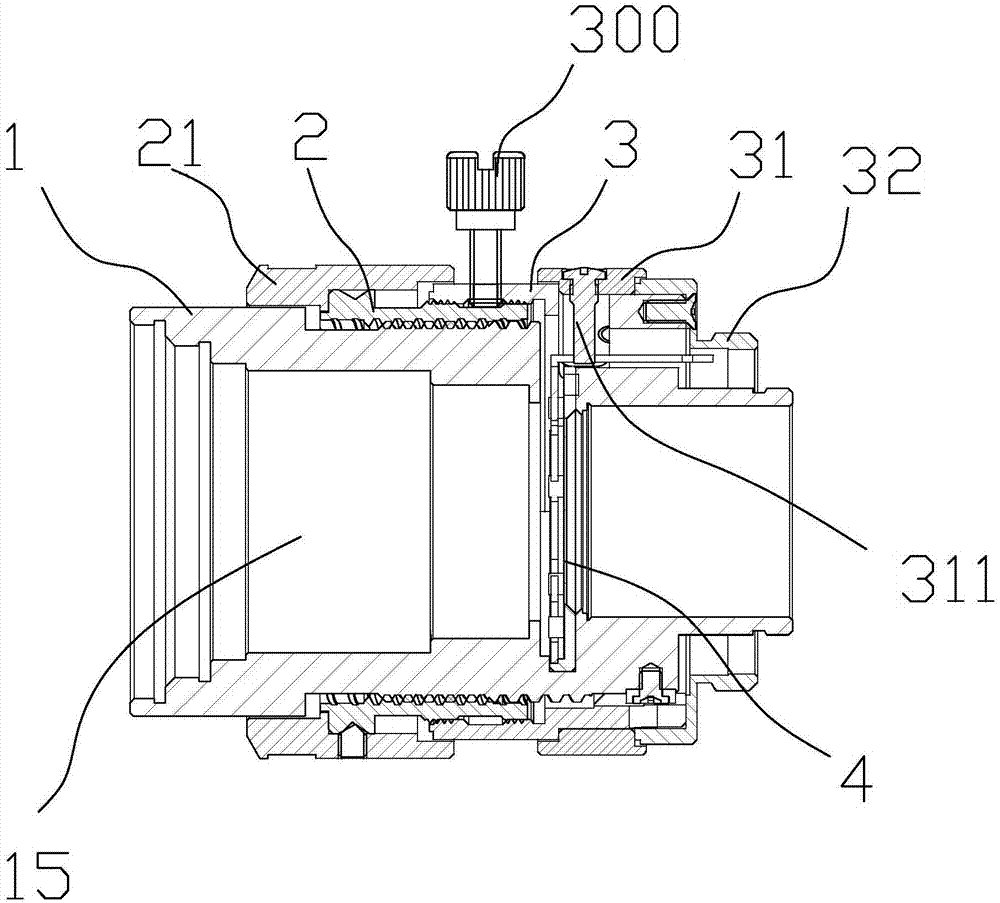

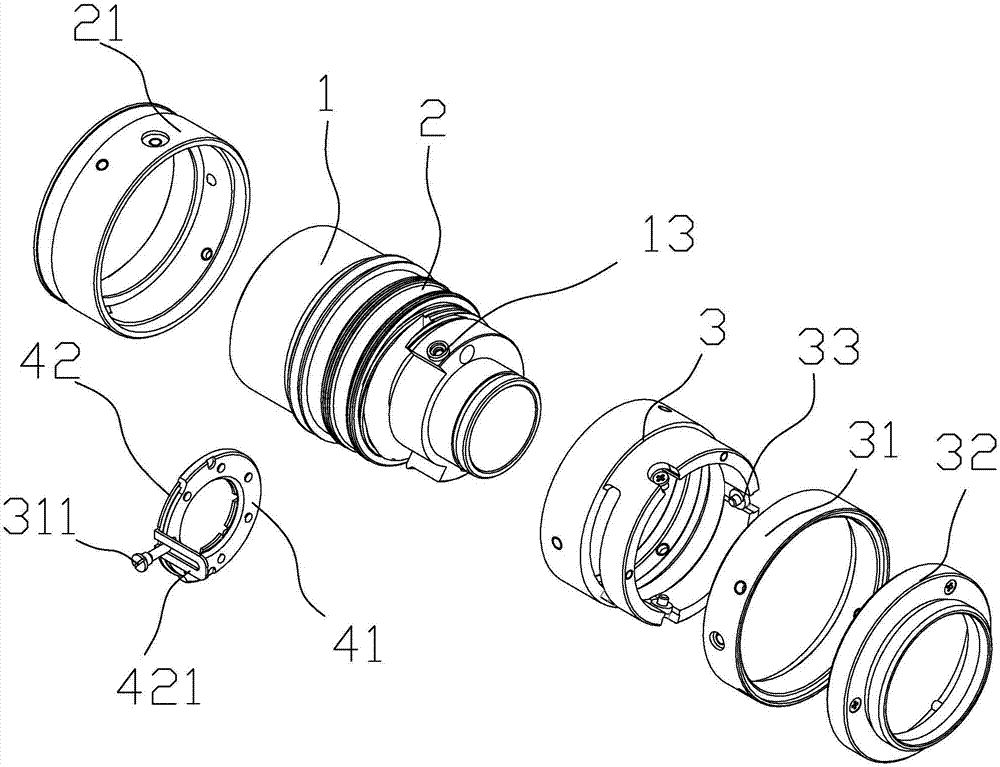

Machine vision lens

The invention relates to a machine vision lens; a single diaphragm module and a diaphragm seat are fastened; the diaphragm needs not to be split into a front lens frame and a rear lens frame; a diaphragm sheet of the diaphragm module and a movable ring can be directly assembled into the lens frame side face, and a lens frame diaphragm groove and screws can fasten the diaphragm seat; the front and rear lenses of the diaphragm can be directly assembled into the same lens frame, thus improving the coaxiality precision of the assembled lenses, and greatly improving the lens yield rate and stability.

Owner:XIAMEN LEADING OPTICS

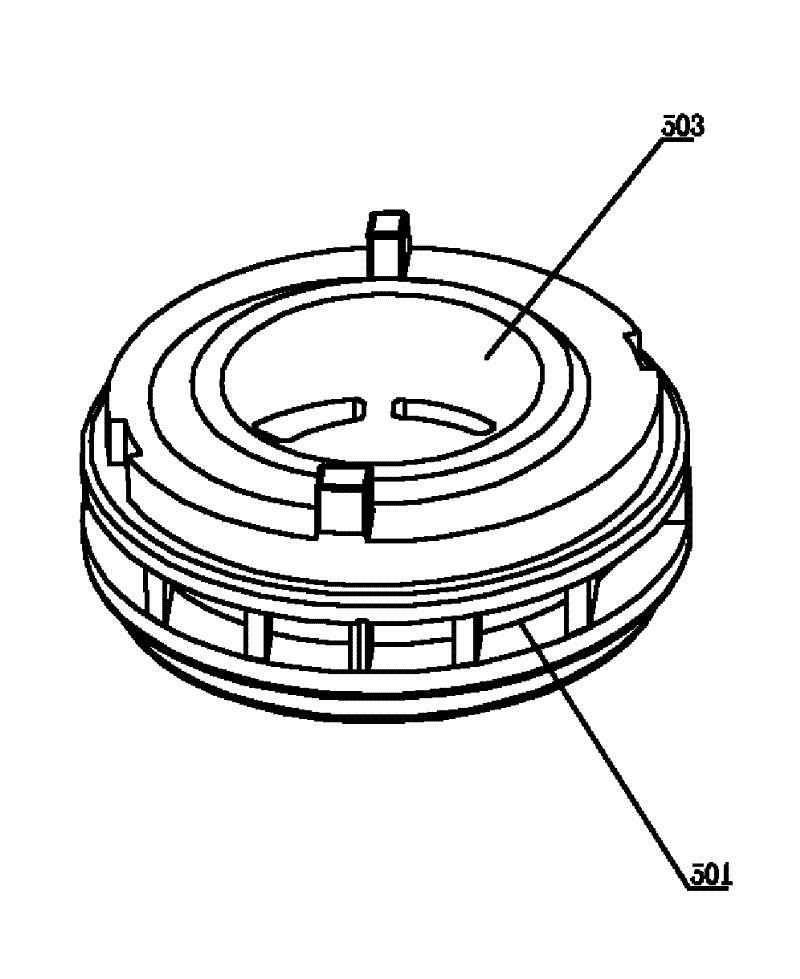

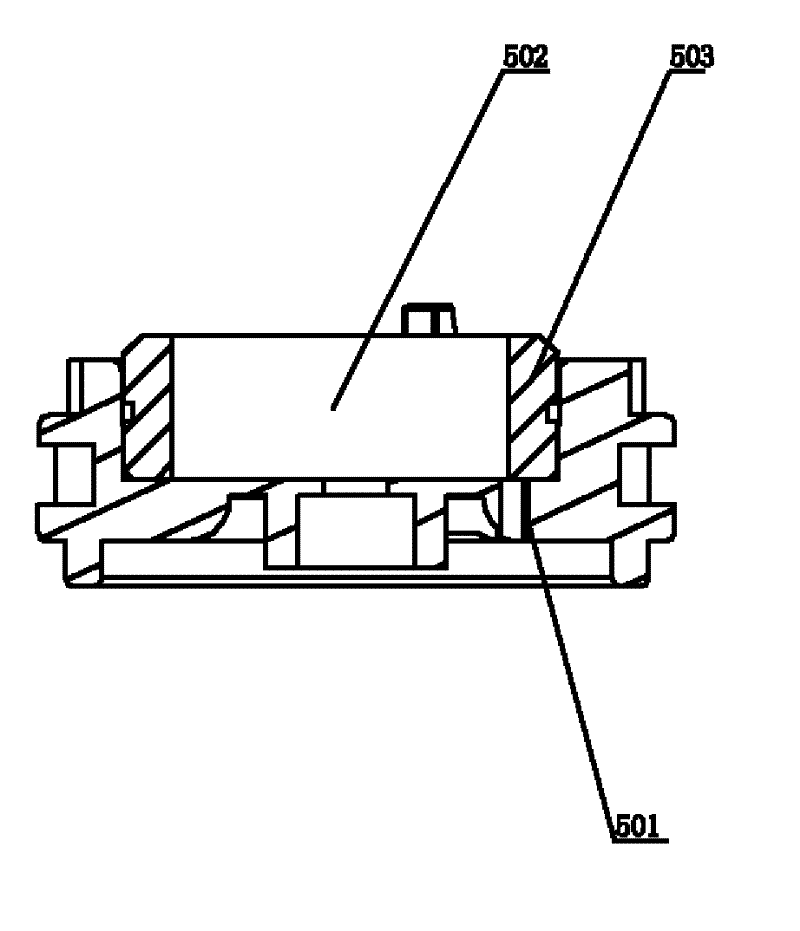

Bearing test device

InactiveCN106404395ASolve problems that cannot be applied to miniature bearingsGuaranteed coaxialityMachine bearings testingEngineeringTest fixture

The invention relates to the field of bearing test devices, and particularly relates to a bearing test device. The bearing test device comprises a test head component which comprises left and right bushings. The test head component also comprises a positioning bushing. The positioning bushing and the left and right bushings are coaxially fixed. Centering and positioning of the left and right bushings are performed through the positioning bushing in assembling so that the coaxiality of the left and right bushings can be guaranteed, then the coaxiality of left and right test bearings can be guaranteed and the coaxiality error of the left and right test bearings can be reduced. Compared with the present bearing test device that the left and right bushings are fixed on a base, the coaxiality of the left and right bushings can be guaranteed by the positioning bushing of the bearing test device so that the coaxiality precision of the left and right test bearings can be enhanced, and the problem that the present bearing test device cannot be suitable for miniature bearings can be solved.

Owner:LUOYANG BEARING RES INST CO LTD

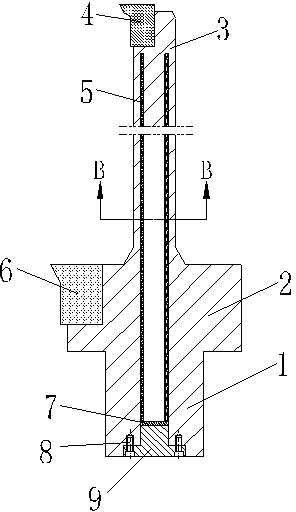

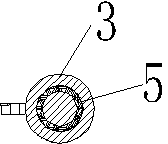

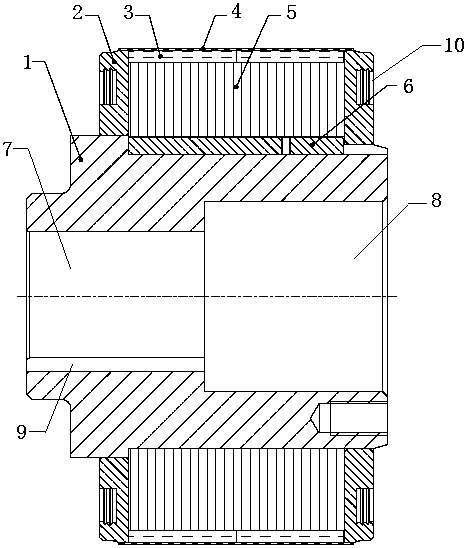

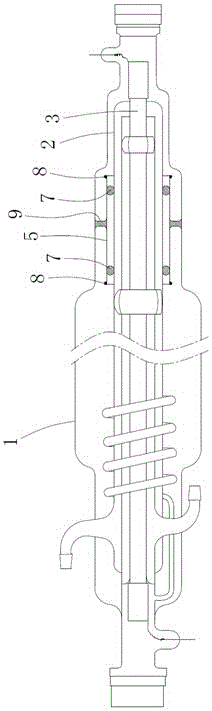

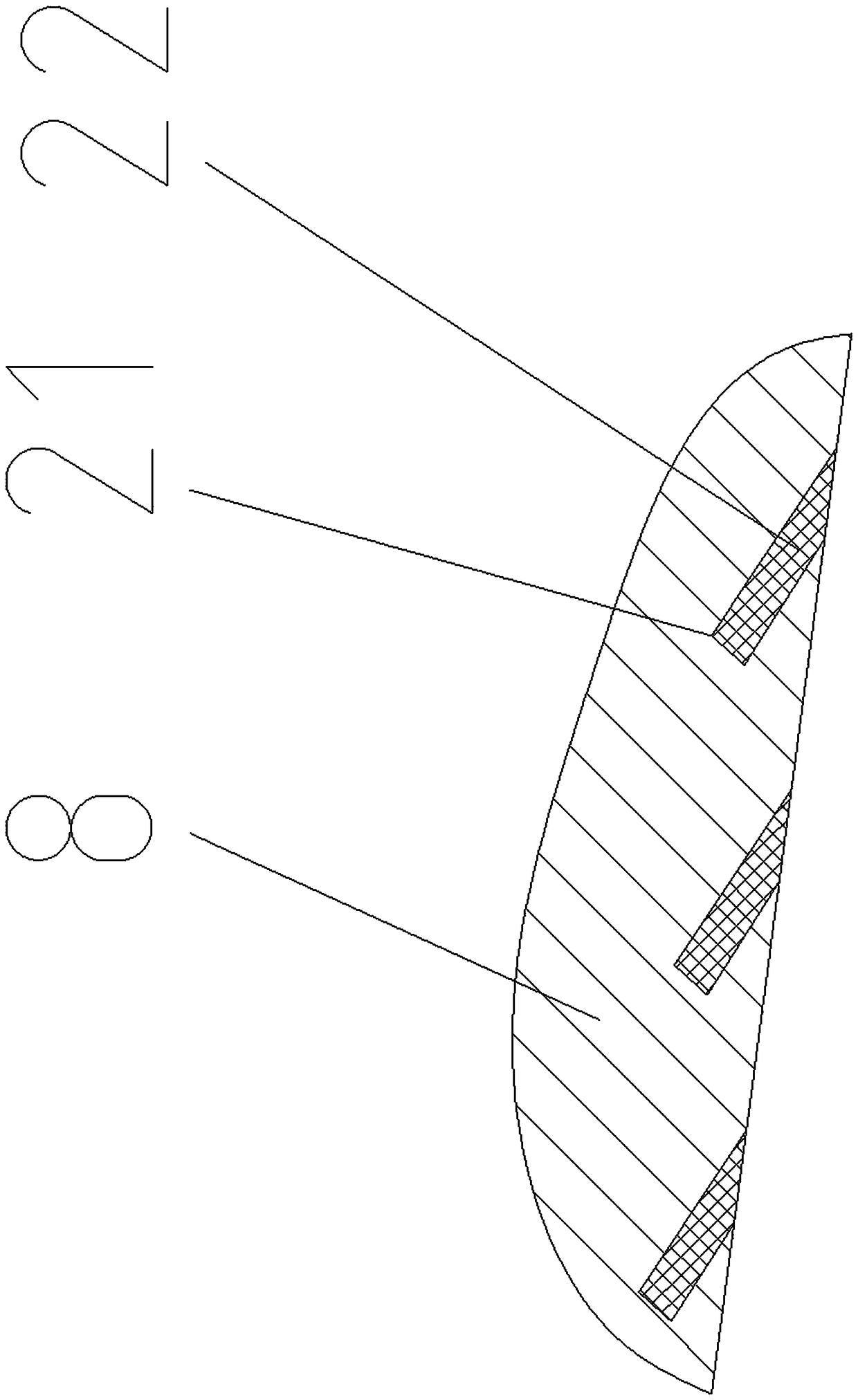

Shock-absorbing boring cutter capable of machining slender stepped hole

InactiveCN102837014AHigh concentricity precisionStrong absorption capacityTurning toolsPrecessionEngineering

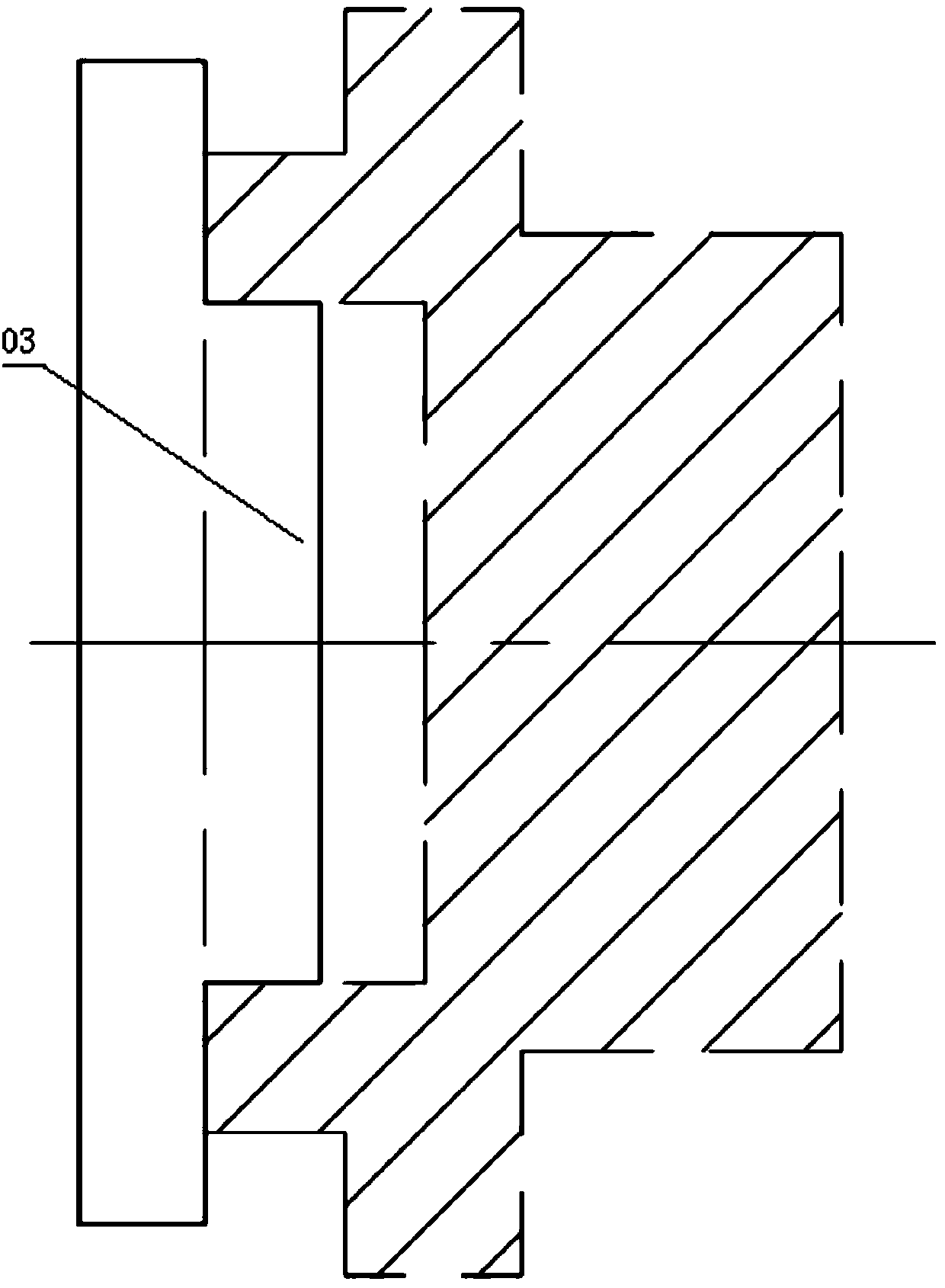

The invention discloses a shock-absorbing boring cutter capable of machining a slender stepped hole. The shock-absorbing boring cutter comprises a clamping part, a large boring cutter bar, a small boring cutter bar, a small boring cutter, a shock-absorbing material, a large boring cutter, a sealing ring, a connecting bolt and a rear end cover, wherein the clamping part is arranged on the rear end of the large boring cutter bar; the small boring cutter bar is arranged on the front end of the large boring cutter bar; the small boring cutter is arranged on the front end of the small boring cutter bar; the large boring cutter is arranged on the large boring cutter bar; an annular slot is arranged inside the cutter bar for filling the shock-absorbing material; the sealing ring is arranged on the rear end of a shock-absorbing slot for sealing; the rear end cover is fixed by the connecting bolt; the large boring cutter and the small boring cutter can designed to be detachable. According to the scheme of the invention, the shock-absorbing material is arranged inside the cutter bar, so as to prevent shock of the cutter bar from affecting machining precession while a slender hole is machined; two boring cutters are arranged, so that the cutters are not needed to be changed while the stepped hole is machined, thereby avoiding an influence of cutter changing to coaxiality and precision of a workpiece.

Owner:SUZHOU MAIDER MACHINERY

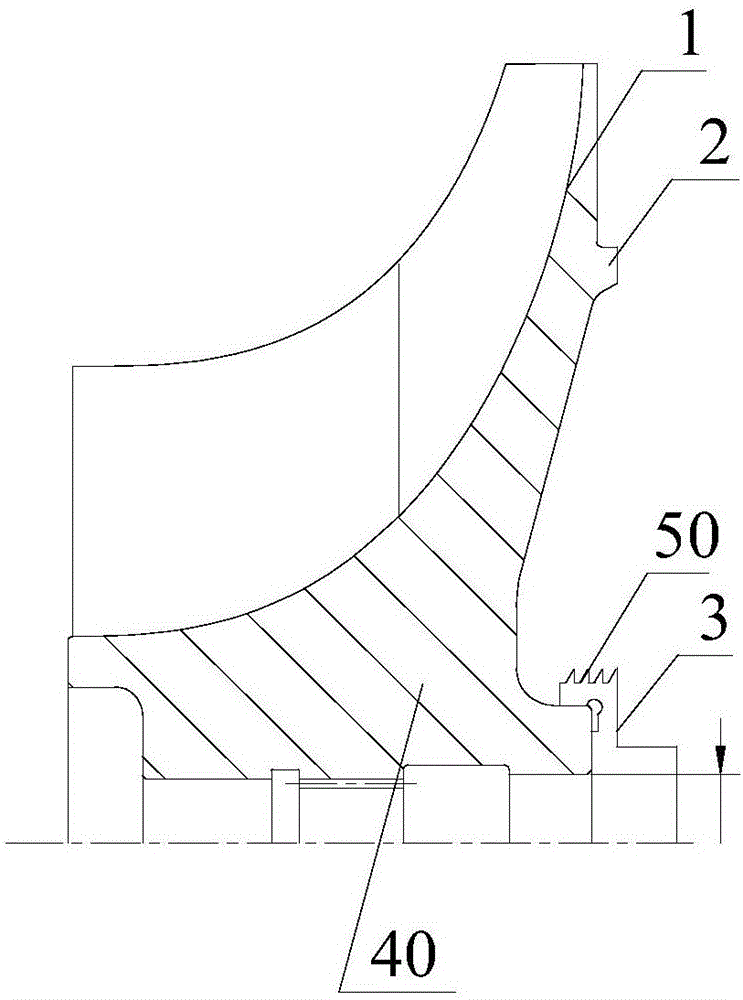

Manufacturing process of oil outlet tray of gasoline pump and structure of oil outlet tray

The invention discloses a manufacturing process of an oil outlet tray of a gasoline pump and the oil outlet tray of the gasoline pump. The process comprises the following steps of: (1) opening a mould, wherein a mould-opening pressure is 15 to 45 N and a mould-opening speed is 10 to 28 m / s; (2) putting a lining into the mould; (3) assembling the mould, wherein a mould assembly pressure is 15 to 80 N and a mould assembly speed is 5 to 45 m / s; (4) injecting, wherein injecting time is 18 to 23 S; (5) maintaining pressure, wherein a maintaining pressure is 14 to 17 N and pressure-maintaining timeis 18 to 25 S; (6) after finishing pressure maintaining, carrying out the steps (1) and (7) at the same time; (7) ejecting a moulded product, wherein an ejection pressure is 0 to 3 N and an ejection speed is 11 to 12 m / s; and (8) rejecting, wherein a rejecting pressure is 0 to 5 N and a rejecting speed is 12 to 15 m / s. By the process, the accuracy of the oil outlet tray is improved, and manufacturing cost is low.

Owner:GUANGZHOU CAMPIU AUTOMOTIVE PARTS

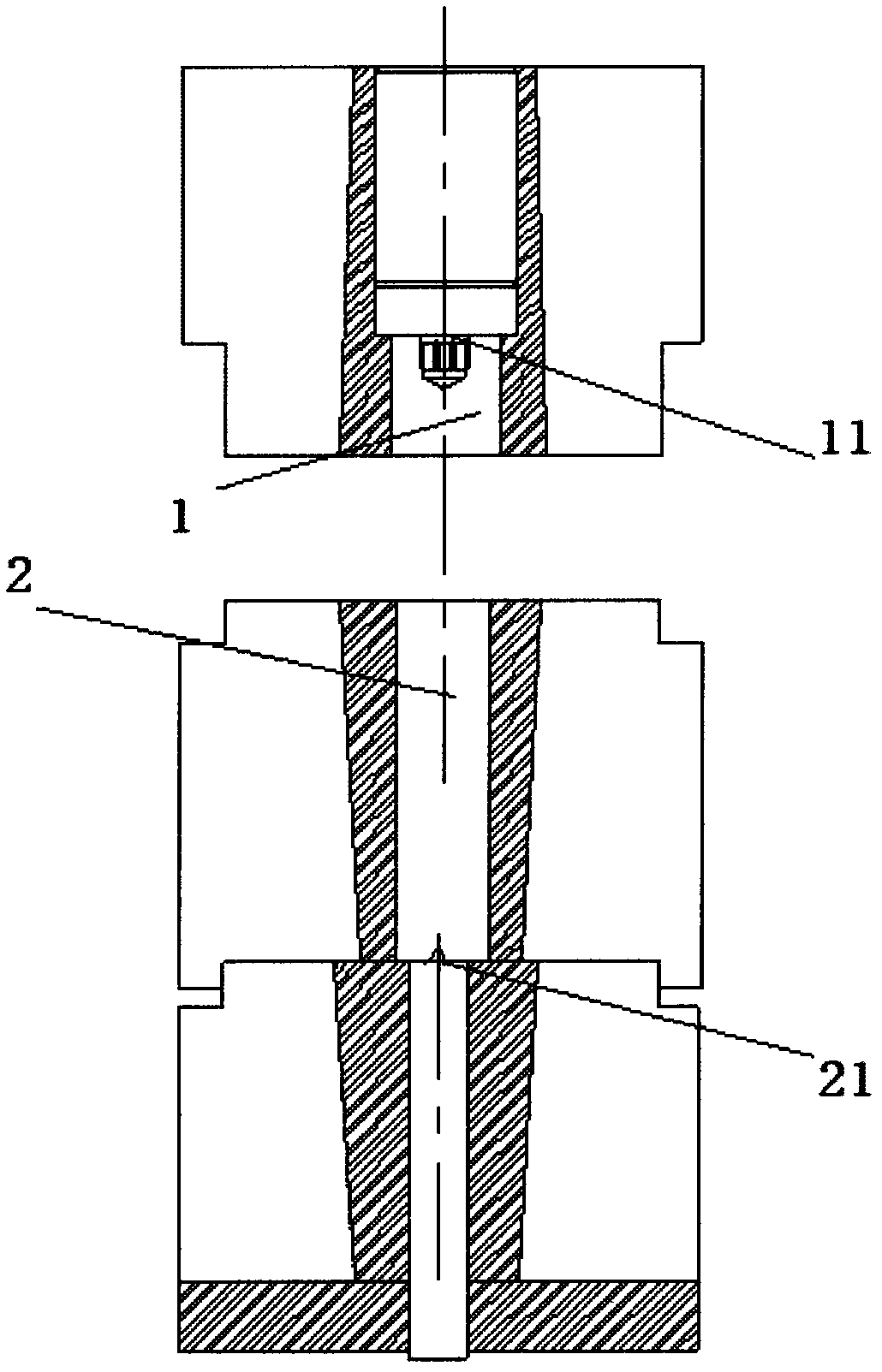

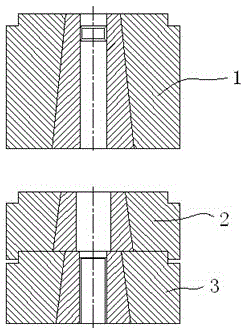

Cold extruding process

InactiveCN103071689AHigh concentricity precisionImprove product qualityExtrusion diesEngineeringMachining

The invention provides a cold extruding process. Fabrication of center holes at two ends of a shaft is completed through cooperation between an oil hydraulic press and a die, wherein the die is composed of an upper die and a lower die, the upper die is installed on an upper working platform of the oil hydraulic press, the lower die is installed on a lower working platform of the oil hydraulic press, and the upper die and the lower die are respectively provided with a die cavity matching with the shaft; a to-be-fabricated shaft is put in the die cavity of the lower die, then the upper working platform drives the upper die to press downwardly, and the upper die and the lower die cooperate with each other to finish fabrication of center holes at two ends of the shaft. According to the process provided in the invention, fabrication of the center holes at two ends of the shaft is finished through one extrusion, so precision of coaxiality of the two center holes is substantially improved, processing in a subsequent procedure is facilitated, product quality is greatly improved, and raw materials are saved by 19%; meanwhile, frequency of mechanical cutting is reduced, which enables time for subsequent lathe machining to be saved, two-stage fabrication in conventional methods is changed into one formation, and thus, working hours are saved by about 25% as a whole.

Owner:常熟市金华机械股份有限公司

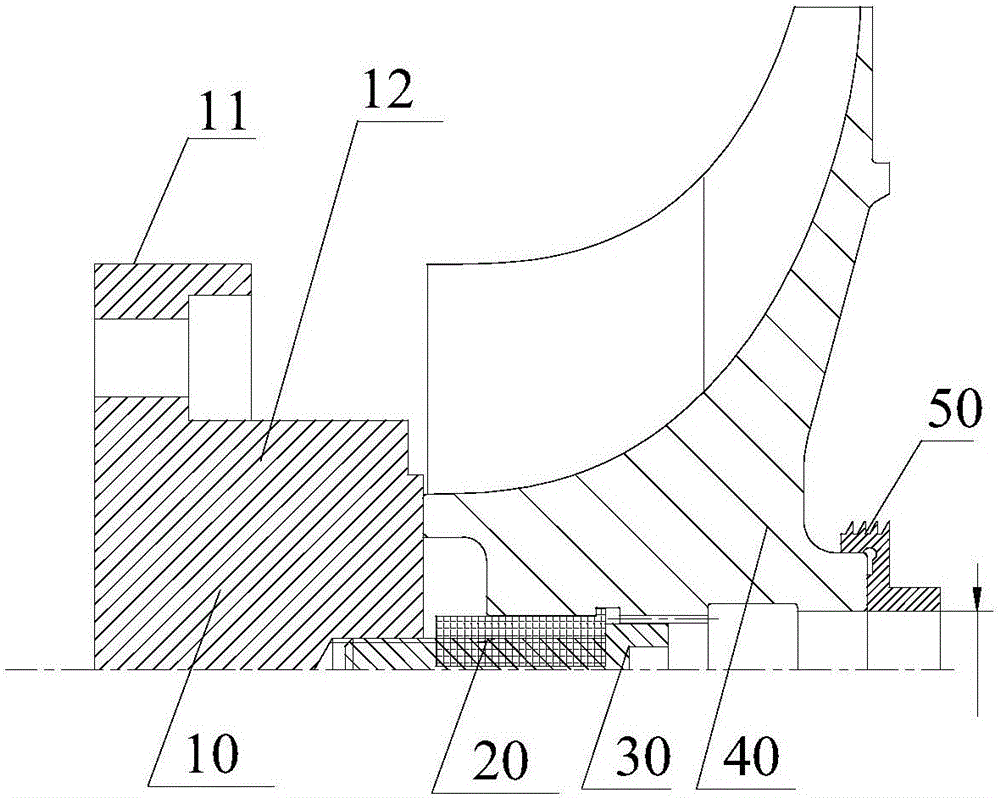

Workpiece positioning tool for machine tool

The invention discloses a workpiece positioning tool for a machine tool. The workpiece positioning tool for the machine tool comprises a cone, an inner cone sleeve, an elastic positioning ring, a gland, an elastic part, a rotation handle and a base. The cone comprises a first end face and a second end face, and the cross section area of the cone is gradually enlarged in the direction from the first end face to the second end face. The inner cone sleeve is arranged on the periphery of the cone in a sleeved mode. The elastic positioning ring is arranged on the periphery of the inner cone sleeve in a sleeved mode. The gland abuts against the end, close to the first end face of the cone, of the inner cone sleeve. The elastic part is connected between the gland and the cone in an abutted mode. The base is connected with the machine tool and connected with the second end face of the cone. With the arrangement, the high coaxiality of round faces at different positions can be ensured when the round faces at the different positions are machined with the workpiece positioning tool for the machine tool.

Owner:SHANTUI CONSTR MASCH CO LTD

Permanent magnet synchronous motor rotor component and manufacturing method thereof

PendingCN107863830ASimple structureSimple processing technologyMagnetic circuit rotating partsMechanical energy handlingFiberCarbon fibers

The invention discloses a permanent magnet synchronous motor rotor component and a manufacturing method thereof. The permanent magnet synchronous motor rotor component comprises a rotating shaft, a balance ring, a magnetic steel, a carbon fiber sleeve, a rotor core and a flat key, a first U-shaped groove is formed in the outer circle surface of the rotating shaft, the flat key is arranged in the first U-shaped groove, the rotor core is arranged on the outer surface of the rotating shaft in a sleeved manner and in interference fit with the rotating shaft, the balance ring is arranged at the endof the rotating shaft in a sleeved manner and in interference fit with the rotating shaft and the rotor core, the magnetic steel is pasted on the outer surface of the rotor core, the carbon fiber sleeve is arranged on the outer surfaces of the magnetic steel and the balance ring in a sleeved manner, a first cylindrical shaft hole and a second cylindrical shaft hole are mutually communicated and formed in the rotating shaft, and the first cylindrical shaft hole is larger than the second cylindrical shaft hole. The component is simple in structure, convenient to assemble, disassemble and maintain, high in qualification rate, small in size and less in consuming material and not easy to break and generates less heat in operation.

Owner:NINGBO PHASE MOTION CONTROL

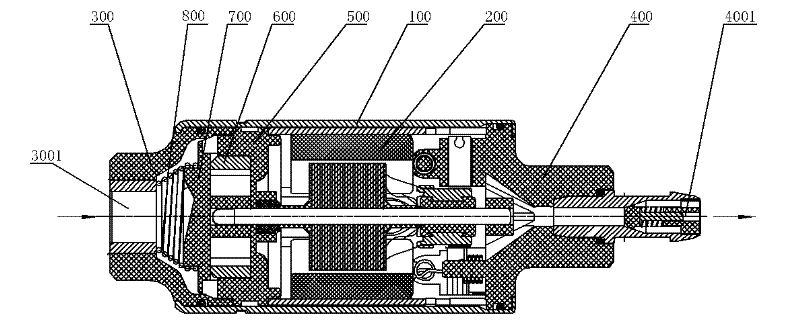

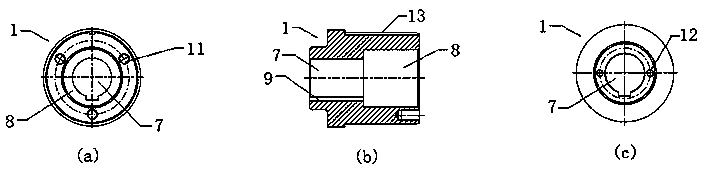

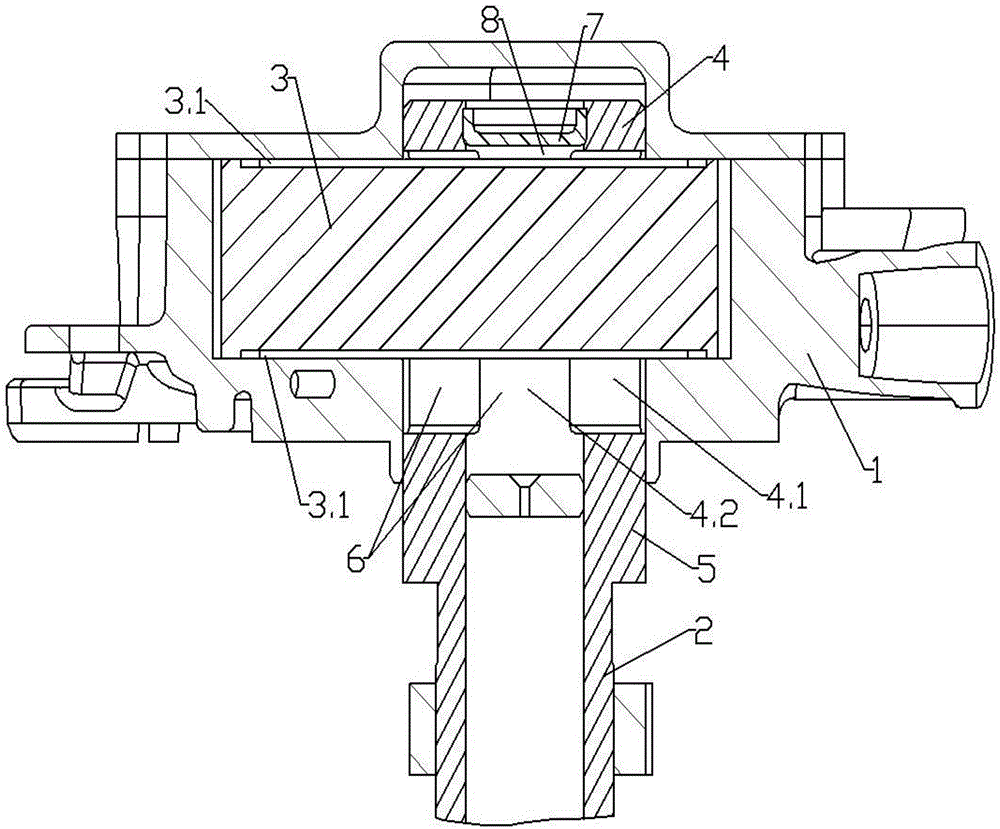

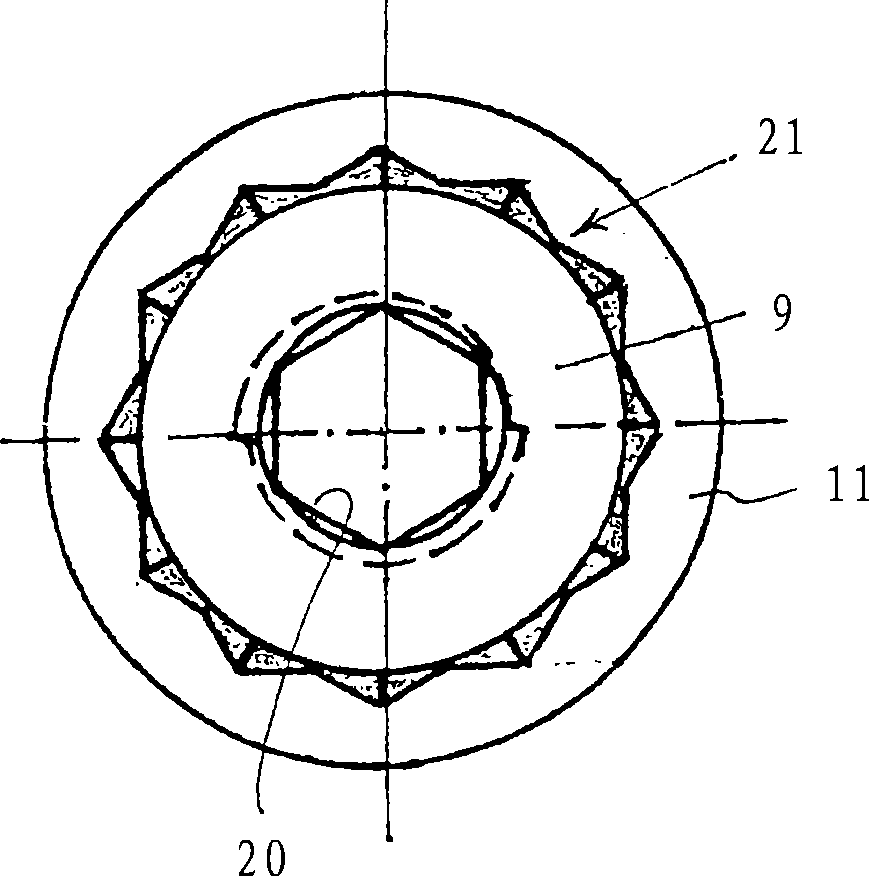

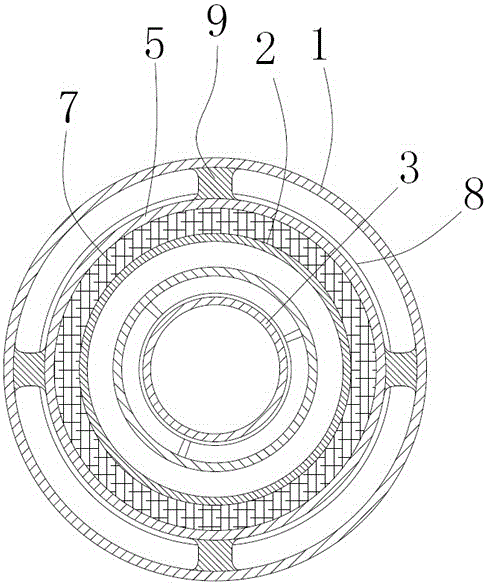

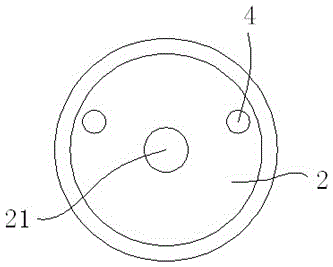

Vacuum pump with integrated cam shaft

ActiveCN104481876AReduce assemblyHigh concentricity precisionRotary piston pumpsRotary piston liquid enginesEngineeringCam

The invention provides a vacuum pump with an integrated cam shaft. The vacuum pump comprises a pump body (1), a cam shaft (2), a blade (3) and a rotor (4) installed in an inner cavity of the pump body (1), wherein a connecting segment (5) is formed at the lower end of the rotor (4), the rotor (4) is of an integral structure with the cam shaft (2) through the connecting segment (5), the rotor (4) is provided with a radial mounting hole (4.1), the blade (3) is mounted in the mounting hole (4.1) in a suspension manner, the mounting hole (4.1) below the blade (3) forms a lower oil inlet cavity (6) for enabling lubricating oil to enter, oil grooves (4.2) communicated with the lower oil inlet cavity (6) are symmetrically formed in the two side walls of the mounting hole (4.1) along the axial direction, a sealing cover (7) used for covering the oil grooves (4.2) is arranged at the top of the rotor (4), and a second oil inlet cavity (8) for enabling the lubricating oil to enter is formed between the sealing cover (7) and the top of the blade (3). The vacuum pump with integrated cam shaft is simple in structure and does not need to be assembled, can be used for effectively guaranteeing the coaxiality, and can be used for effectively avoiding the abrasion of the blade, so that the service life of the blade is prolonged.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

Engine balancer

InactiveCN103671705ALow percussionNo damageInertia force compensationYielding couplingDrive shaftEngineering

Owner:HITACHI AUTOMOTIVE SYST LTD

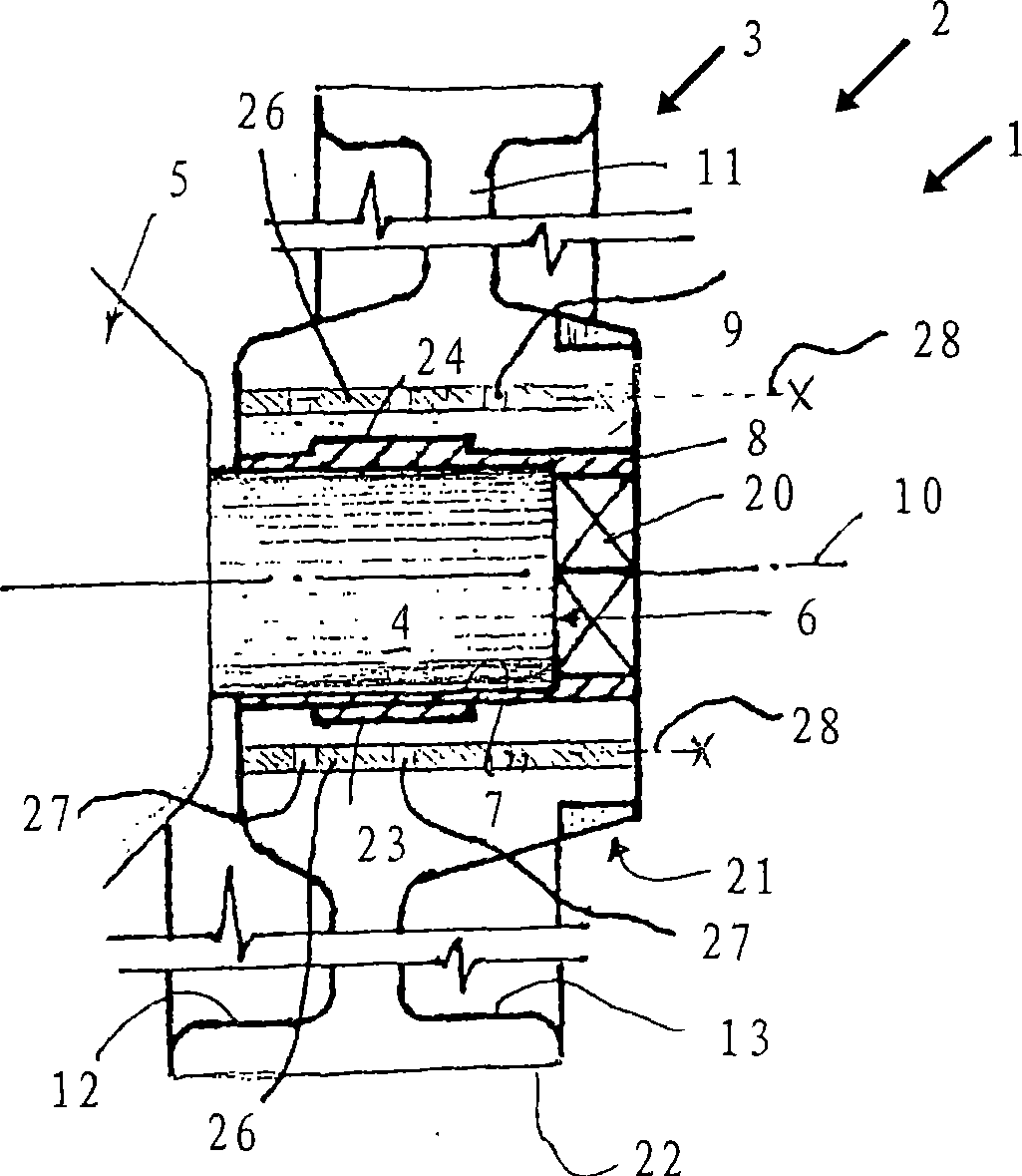

Machine element for a shaft-to-hub connection and production method for a shaft-to-hub connection

InactiveCN101387318AReduce clampingDon't worry about failureCouplings for rigid shaftsConnectionsEngineeringMechanical engineering

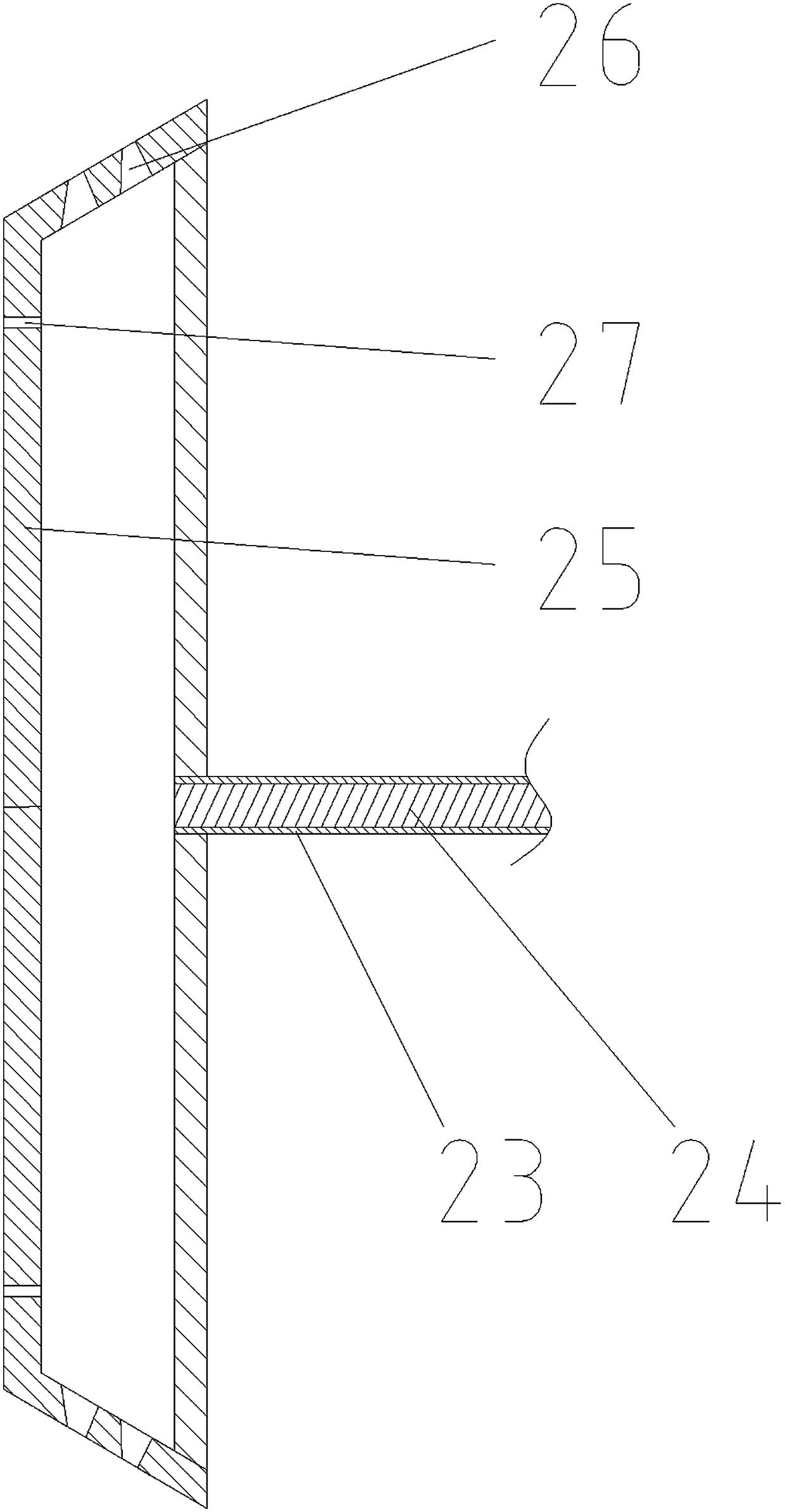

The invention relates to a machine element (2) used for a shaft-to-hub connection (1), containing an un-notched tensioning / clamping element (8), which is inserted into a receptacle space of the machine element (2). The tensioning / clamping element (8) has an opening (7) for receiving a shaft (4) twistable relative to the machine element (2), a supporting sleeve (26) arranged radially external to the tensioning / clamping element (8). Therefore, the machine element (2) has the advantages of easy manufacture, excellent use and bearing large force.

Owner:GM GLOBAL TECH OPERATIONS LLC

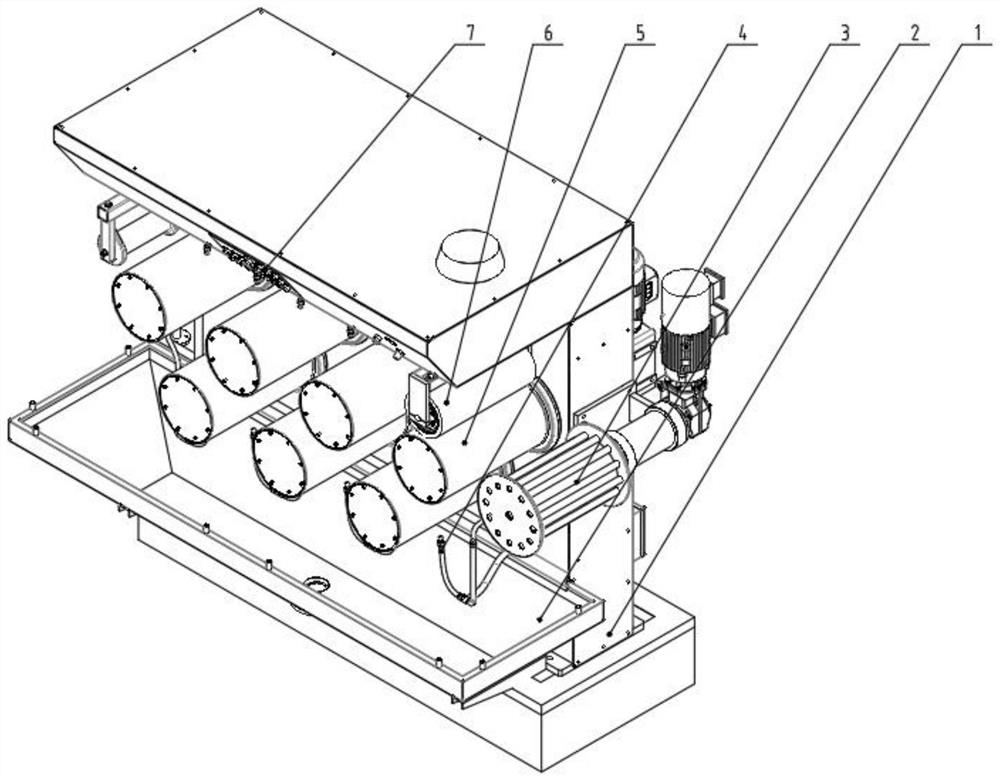

Lyocell fiber winding machine winding roller connecting structure convenient to inspect and maintain

PendingCN114852781AEasy assembly againHigh concentricity precisionFilament handlingWinding machineLyocell

The invention discloses a lyocell fiber winding machine winding roller connecting structure convenient to inspect and maintain, which comprises a box body part, a liquid receiving tank part is arranged on the side surface of the box body part, a waste silk leading-out roller part is fixedly mounted in the middle of the end surface of the box body part, and a spraying part is arranged on the side surface of the box body part. A plurality of winding roller parts are fixedly installed on the side face of the box body part, the liquid receiving groove part is located under the spraying part and the winding roller parts, the length of the liquid receiving groove part is 1.1 times larger than that of the box body part, a pressing roller part is fixedly installed at the bottom of a top plate of the box body part, and an operation panel is fixedly installed at one end of the top of the box body part; according to the lyocell fiber winding machine winding roller connecting structure convenient to inspect and maintain, it is guaranteed that broken filaments cannot adhere to the surface of a godet, waste filaments can be relatively reduced, the waste filaments cannot be wound around the winding roller to cause unnecessary shutdown, the tensioning sleeve connecting mode is adopted, disassembly is convenient, the coaxiality precision is high, and the service life of the winding roller is prolonged. And the maintenance time can be greatly shortened.

Owner:江苏金斗重工有限公司

Positioning device for assembly

ActiveCN106625195AHigh concentricity precisionSolve technical issues that reduce accuracyHoning machinesGrinding work supportsInterference fitMachine parts

The invention discloses a positioning device for an assembly. The device is used for positioning during machining of the assembly; the assembly comprises a reference piece and a to-be-machined piece in interference fit with the reference piece; the positioning device comprises a body for fixing the assembly, two semi-circular open bushings in clearance fit with the central hole of the reference piece and a fixing piece for fixing the central hole of the reference piece; and the fixing piece penetrates through the central hole of the reference piece to expand the two semi-circular open bushings to be a full ring, so that the assembly is pressed against the body. The stressed part of the positioning device is far away from the machined part of the to-be-machined piece, so that the machined part of the to-be-machined piece is located in a non-stressed area and is affected by grinding resistance only, and the coaxial accuracy of the positioning device is improved; and the technical problem that the coaxial accuracy is reduced due to deformation of machined parts due to the fact that stressed parts are close to the machined parts during machining positioning of existing starter type assemblies is solved.

Owner:CHINA HANGFA SOUTH IND CO LTD

Structure laser with support barrel

ActiveCN106207719AImprove reliabilityExtended service lifeLaser constructional detailsEngineeringRelative slip

The invention relates to the field of lasers, in particular to a structure laser with a support barrel. The laser comprises a reservoir pipe, a water-cooling pipe and a discharge tube, wherein a reflecting lens is arranged at one end of the reservoir pipe and an output lens is arranged at the other end of the reservoir pipe; the water-cooling pipe is sleeved with the reservoir pipe; the discharge tube is sleeved with the water-cooling pipe; two ends of the water-cooling pipe and the discharge tube are in closed connection separately; and a support barrel structure sleeves outside the water-cooling pipe and elastically supports the water-cooling pipe in the water-cooling pipe. By the laser, on one hand, the direct alignment accuracy of the reflecting lens and the output lens is ensured to improve the output quality of a laser beam; and on the other hand, the risk of relative slippage between a support part and the water-cooling pipe and the discharge tube is reduced to reduce the risk that the reservoir pipe and the water-cooling pipe are scratched by the support part is reduced. Therefore, the reliability of the laser is improved and the service lifetime is prolonged.

Owner:CHENGDU WEESON TECH

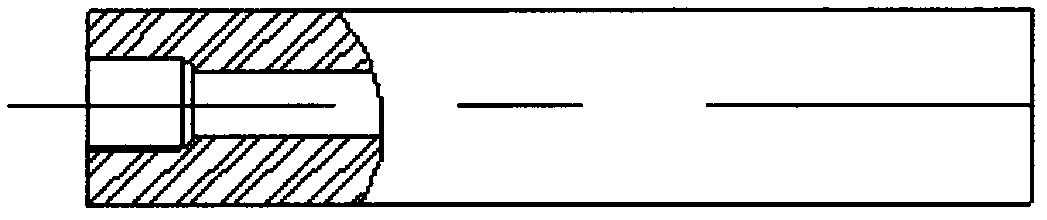

External spline shaft cold extrusion mold

InactiveCN105013851AHigh concentricity precisionReduce the number of mechanical cutsExtrusion diesPolymer chemistryExtrusion

The invention discloses an external spline shaft cold extrusion mold which comprises an upper mold, a middle mold and a lower mold which are coaxial. The upper mold is installed on an upper working platform of an oil press. The middle mold and the lower mold are installed on a lower working platform of the oil press. A positioning pin is installed in the middle mold and the lower mold in a penetrating manner. The center of the upper mold is an upper mold cavity. The center of the middle mold is a middle mold cavity. The center of the lower mold is a lower mold cavity. The central points of the upper mold cavity, the middle mold cavity and the lower mold cavity are located on the same central axis. By applying the external spline shaft cold extrusion mold, the problem of material flow uniformity caused by extrusion of a special-shaped irregular spline can be solved.

Owner:常熟市金华机械股份有限公司

Drilling and tapping combined tool for threaded through hole

PendingCN111014786ASave materialLow costThread cutting toolsTransportation and packagingDrill holeGeotechnical engineering

The invention discloses a drilling and tapping combined tool for a threaded through hole. The tool comprises a drill bit body, and a drill bit and a screw tap are arranged at the front end of the drill bit body; and a narrowed transition part is arranged on the position, between the drill bit and the screw tap, of the drill bit body, a plurality of screw tap chip removal grooves are formed in thescrew tap, drill bit chip removal grooves corresponding to the screw tap chip removal grooves on the screw tap are formed in the drill bit and the transition part, and a knife handle is arranged at the rear end of the drill bit body. The drilling and tapping combined tool for the threaded through hole is reasonable in structural design, and belongs to the technical field of machining tools; the tool has the functions of drilling and tapping, and a drilling and tapping screw hole has high coaxiality precision; and the split drill bit and the screw tap are manufactured as the drilling and tapping combined tool, the drill bit and the screw tap are combined into one whole of the drilling and tapping combined tool, and the through hole threaded hole is machined through the buffering transitionof the transition part, so that the drilling and tapping combined tool has the functions of drilling and tapping.

Owner:GUANGXI YUCHAI MASCH CO LTD

Split differential shell internal expansion machining method

ActiveCN108296725APrecise positioningPrecise positioning and fixingExpansion mandrelsMaintainance and safety accessoriesGear wheelMachining

The invention relates to a differential shell machining method, in particular to a split differential shell internal expansion machining method, and solves the technical problems of inconvenience to operate during clamping in machining of a differential shell in the prior art, incorrect positioning, easy shaking of workpieces during machining, weaker machining precision, weaker coaxiality of an internal spherical surface, lower machining efficiency and the like. The method comprises the following steps: an inner end of a split differential shell blank is inserted in a positioning block of an internal expansion positioning fixture for fixation; the split differential shell is cut by a feed bearing mounting position cutter, so that outer circles of bearing mounting positions at the two endsof the split differential shell are formed at the same time; the split differential shell is cut again by a feed molding cutter, so that an inner gear mounting spherical arc surface of the split differential shell is machined; and a split differential shell finished product is deviated from the positioning block to finish machining.

Owner:HANGZHOU JILI MACHINERY

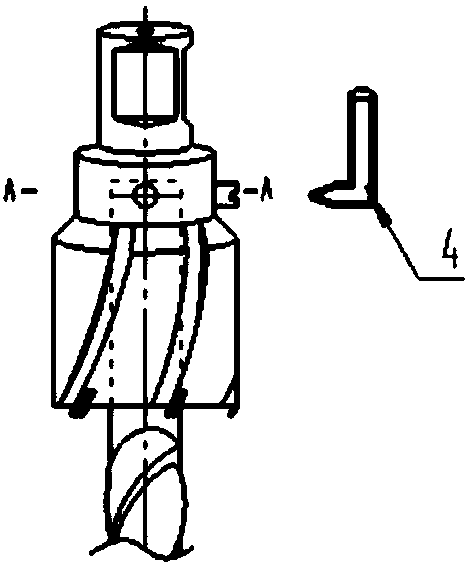

Spliced chamfering cover, assembly method and chamfering drill bit

PendingCN108544664ASimple and easy assemblySimple and easy to operateStone-like material working toolsPetroleum engineeringDrill bit

The invention relates to a spliced chamfering cover, an assembly method and a chamfering drill bit. The spliced chamfering cover comprises two or more circular-arc-shaped chamfering pieces and a hoop,and the circular-arc-shaped chamfering pieces form an annular chamfering ring; and a drill stem is sleeved with the chamfering ring, the chamfering ring is sleeved with the hoop, and the chamfering ring is fastened on the drill stem. Compared with the prior art, the spliced chamfering cover is easy to assemble and adjust, the fit clearance between the chamfering ring and the drill stem can be reduced through the fastening function of the hoop, runout of a working surface is reduced, and it is ensured that an inner chamfer of a machined glass hole is accurate in shape and free of edge breakage.

Owner:GUILIN CHAMPION UNION DIAMOND CO LTD

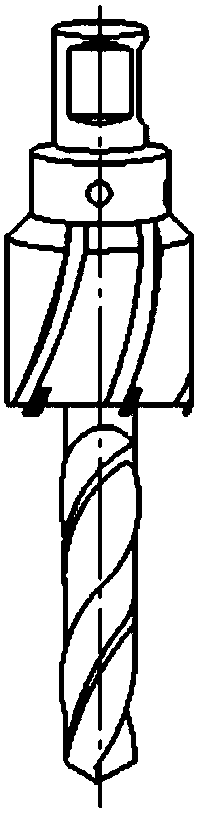

Counter bore once drilling device and assembly method

InactiveCN107671334AHigh concentricity precisionEasy to assemble and disassembleTransportation and packagingMetal-working hand toolsPresent methodCooling effect

The invention provides a countersunk hole one-time drilling forming device and assembly method, which adopts the combination of the countersunk drill bushing and the side groove straight shank drill bit, one-time drilling forming, and solves the countersink drilling and forming process safely, quickly and easily . According to the type of countersunk hole in the engineering plate, the corresponding countersunk drill sleeve and side groove straight shank drill are selected to match the standard part specifications of countersunk head bolts. By adopting the method, the processing procedure can be reduced, the processing precision can be improved, the loss of the drill bit can be reduced, the construction cost can be saved, the processing efficiency can be greatly improved, the method is safe and reliable, and it is easy to popularize and use in production. In addition, diversion holes and diversion grooves are respectively opened on the countersunk drill bushing and side groove straight shank drill bit, without external cooling device, the cooling effect is remarkable, and the construction cost is greatly reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

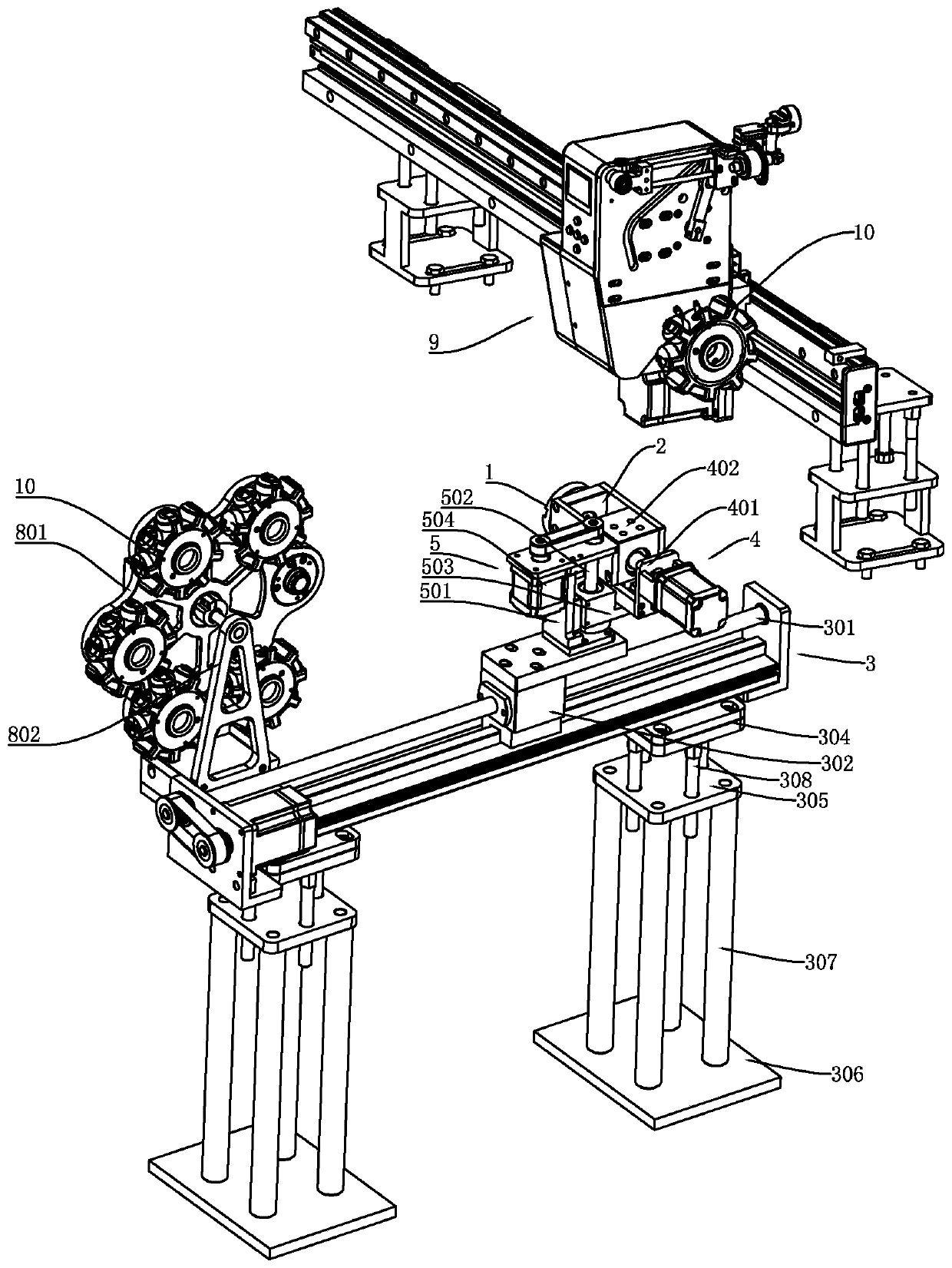

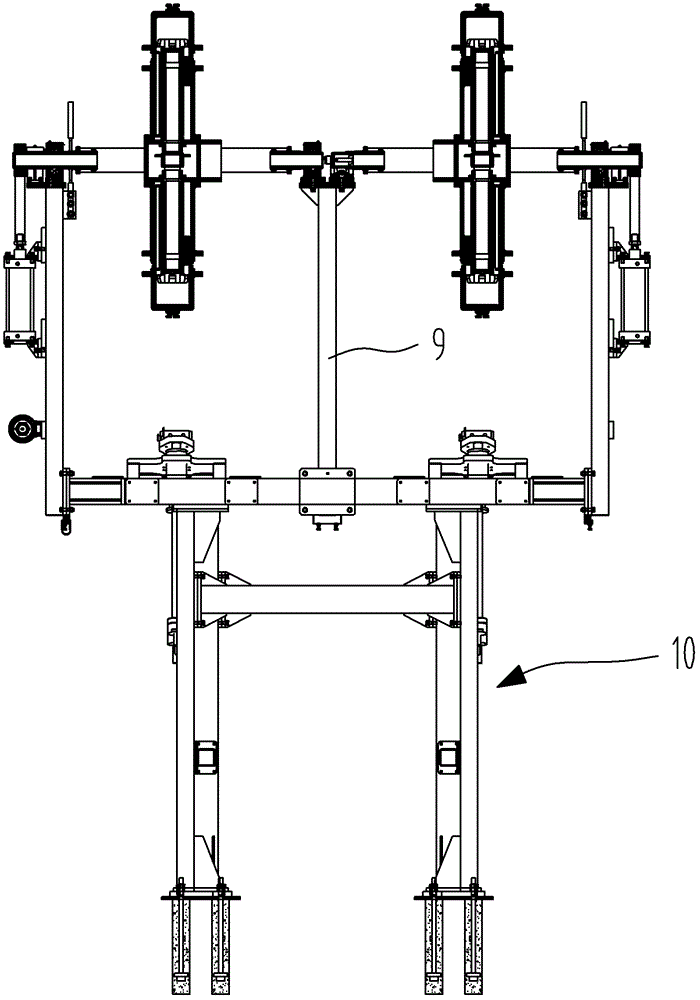

Automatic material change device for bobbin case storage tray

InactiveCN110359196AIncreased rotational freedomEasy to installBobbin-winding devicesAuxillary devicesBobbinDrive shaft

The invention discloses a change device for a bobbin case storage tray. The device structurally comprises a material taking head, a floating mechanism, an adjusting manipulator and a conveying mechanism, a plurality of adjusting arms are sequentially connected to form the adjusting manipulator which at least comprises a horizontal movement adjusting arm of a horizontal movement material taking mechanism and a height adjusting arm for adjusting heights and directions, the material taking head is movably connected with the horizontal movement adjusting arm through the floating mechanism and candeflect relative to the horizontal movement direction of the height adjusting arm under the action of external force, the adjusting manipulator is slidably connected with the conveying mechanism, andthe adjusting manipulator and the conveying mechanism are used for adjusting the spatial position of the material taking head. The bobbin case storage tray on an automatic embroidery machine bobbin case change device can be automatically replaced, butt joint errors in butt joint of the bobbin case storage tray and a drive shaft assembly can be adaptively compensated, and the storage tray can be accurately mounted on the drive shaft assembly for the bobbin case storage tray.

Owner:ZHUJI LIGHT IND TIMES ROBOT TECH CO LTD

Automatic photographing robot

ActiveCN105269566AHigh concentricity precisionReduce gapProgramme-controlled manipulatorOptically investigating flaws/contaminationAutomatic controlEngineering

The invention discloses an automatic photographing robot, comprising a rack, a drive mechanism, a variable diameter adjusting mechanism, a photographing mechanism, a transmission mechanism, a running gear, and an automatic control system. Three stepping motors can be used to drive the robot and control size of expanded pipe diameters and rotation of a camera. The robot realizes tasks of walking, going back, stopping, and taking pictures in different diameter pipes. The drive mechanism uses a worm and gear mechanism and a synchronous pulley mechanism, and can realize constant transmission ratio and stable motion transmission. The running gear uses three-jaw form centring, and uses a parallelogram mechanism to realize same-degree diameter variation at the same time of walking wheels in three groups of walking devices. A variable diameter adjusting device uses a screw-nut mechanism to adjust expanded diameter sizes. In addition, a built-in flexible regulation device can overcome stuck phenomenon in a walking process. The robot is simple in structure and convenient in manufacturing, and the robot can ensure very high coaxiality precision.

Owner:NANJING UNIV OF SCI & TECH

positioning tensioner

ActiveCN104014832BHigh concentricity precisionFacilitate automated productionExpansion mandrelsEngineeringExpansion joint

Owner:ZOOMLION HEAVY IND CO LTD

Back air filling device of tire

ActiveCN102357958BAvoid deformationHigh concentricity precisionTyresVehicle servicing/repairingPetroleum engineering

Owner:SINO ARP TIRES EQUIP TECH (SUZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com