Split differential shell internal expansion machining method

A processing method and differential gear technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of inconvenient processing of differential gear housing, poor coaxiality of inner spherical surface, poor machining accuracy, etc. Problems, to achieve the effect of not easy to shake, good coaxiality, and compact fixture structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: The method for processing the inner expansion of the split differential case of this example, the steps are:

[0027] a. Insert the inner end of the split differential housing 31 blank into the positioning block of the internal expansion positioning fixture, insert the spring sleeve into the inner hole of the inner end of the split differential housing blank, and the hydraulic device drives the piston When moving backward, the pull rod is driven to move backward, the spring sleeve at the end of the pull rod moves backward along the tapered surface of the card core, the spring sleeve expands, and the spring sleeve fixes the split differential housing blank;

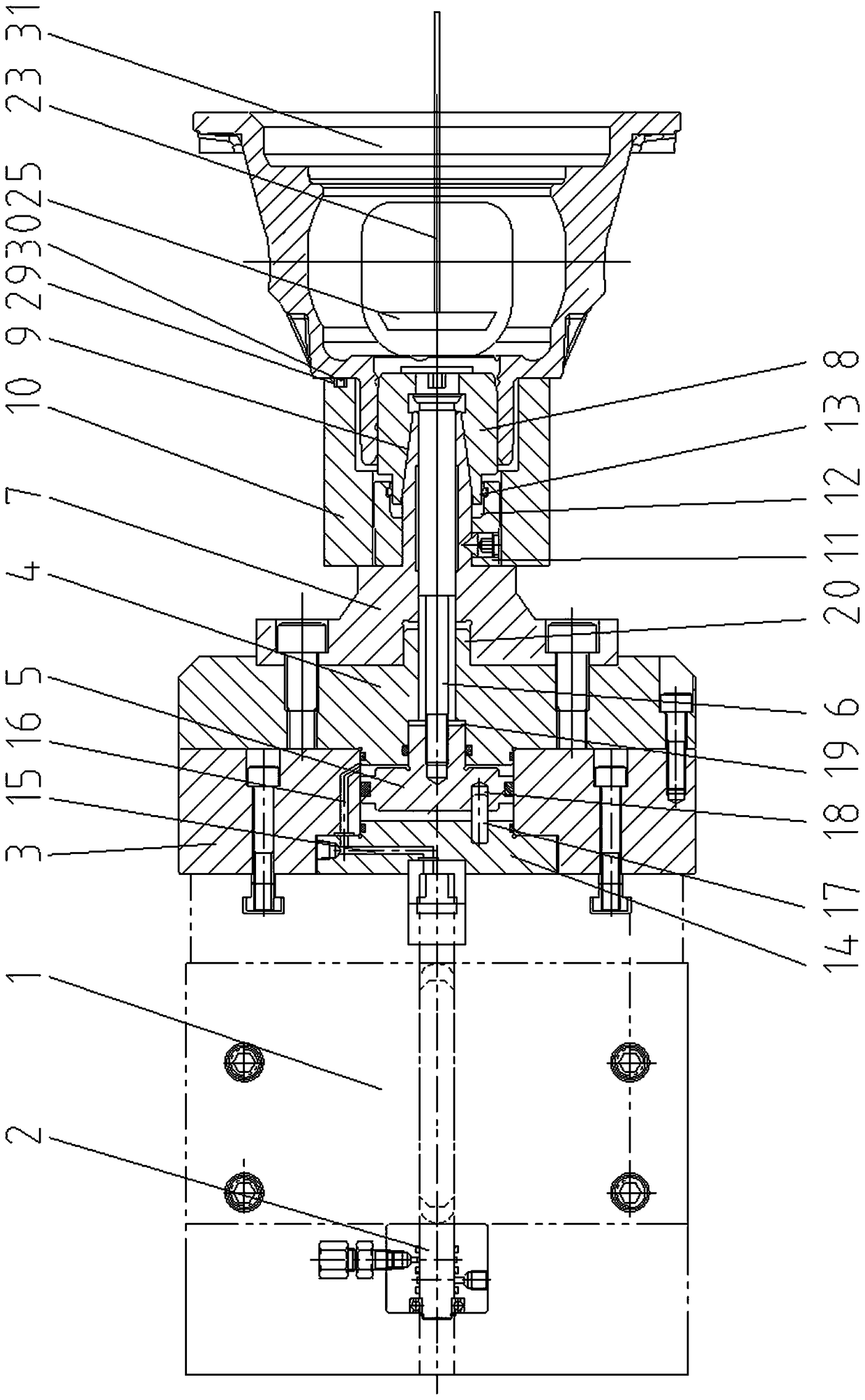

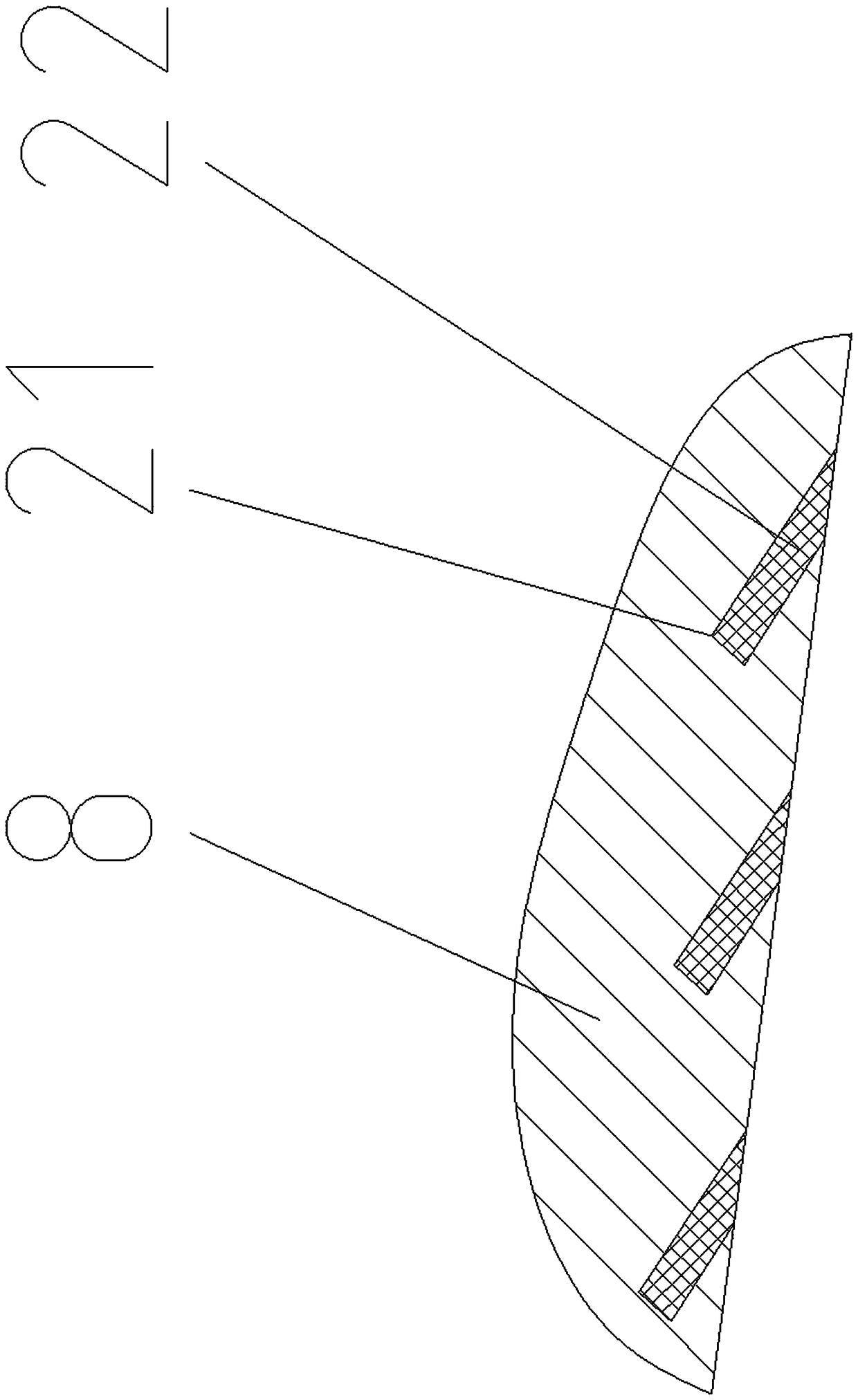

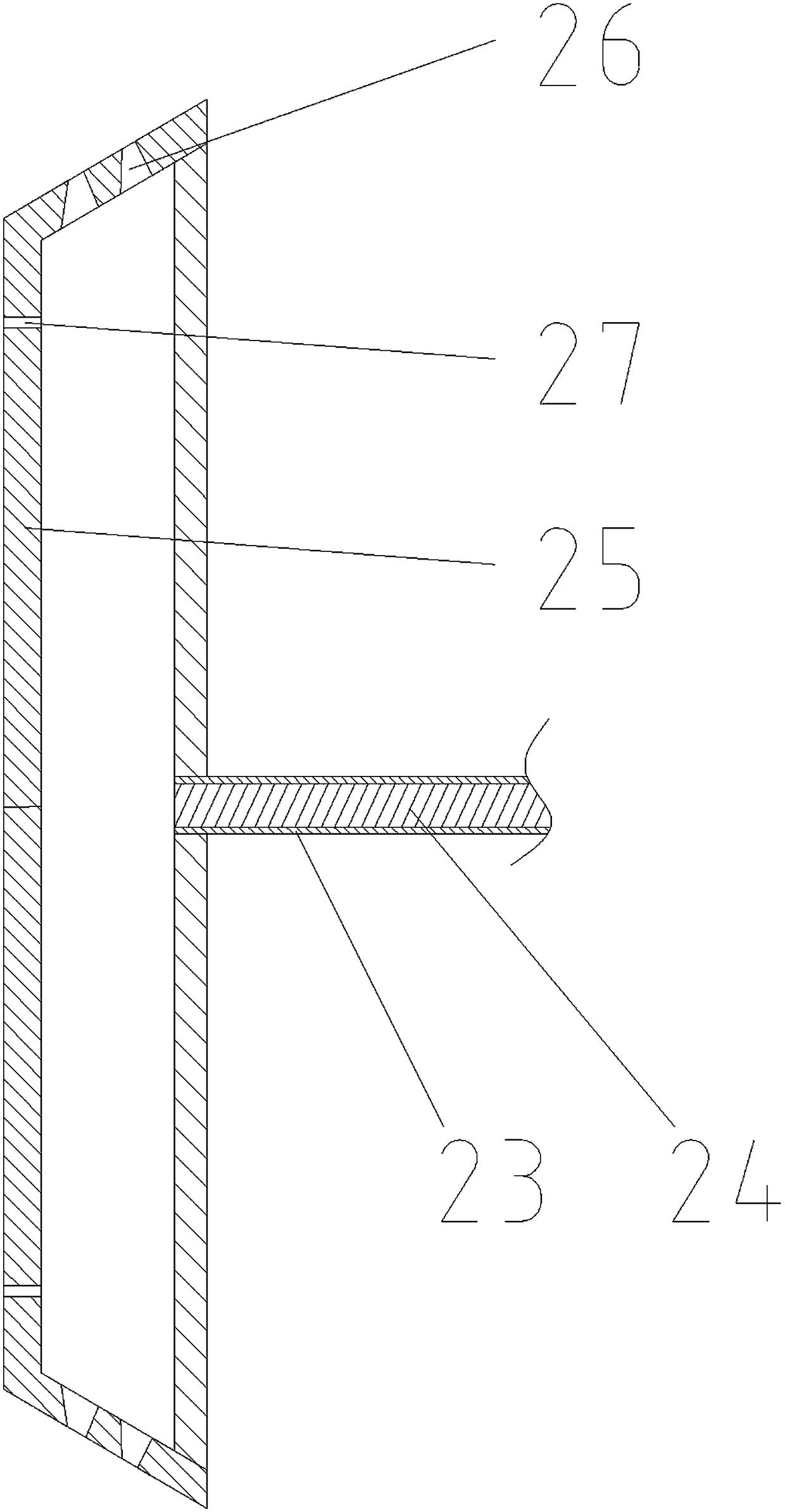

[0028] like figure 1 , the internal expansion positioning fixture includes a frame 1, the frame is provided with an oil pressure device 2, the front end of the frame is provided with a valve body 3 and a valve cover 4, the valve cavity of the valve body is provided with a piston 5, and the oil pressure d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com