Patents

Literature

73results about How to "Precise positioning and fixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

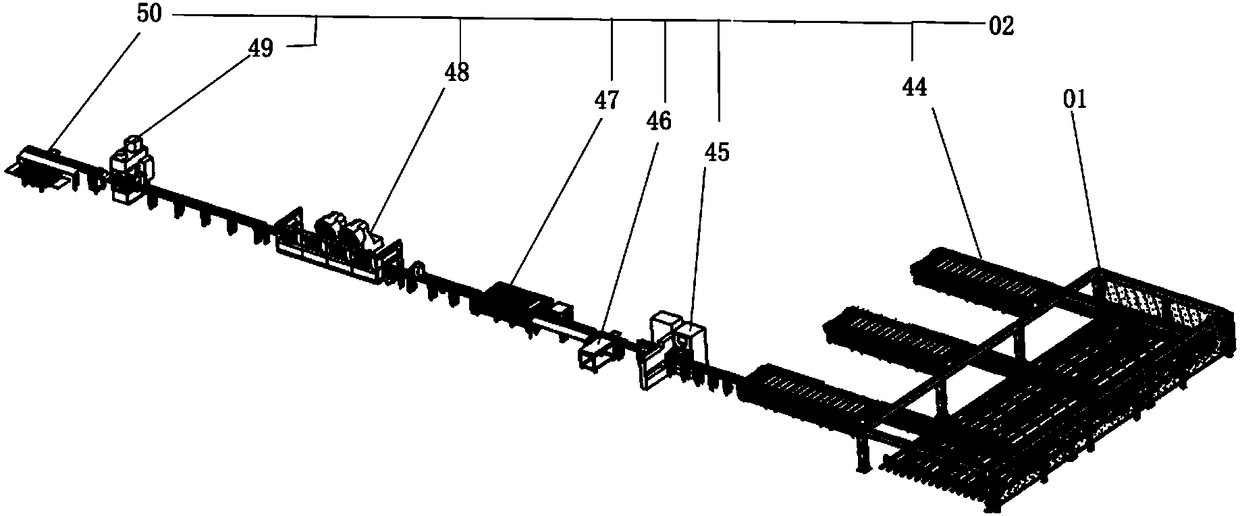

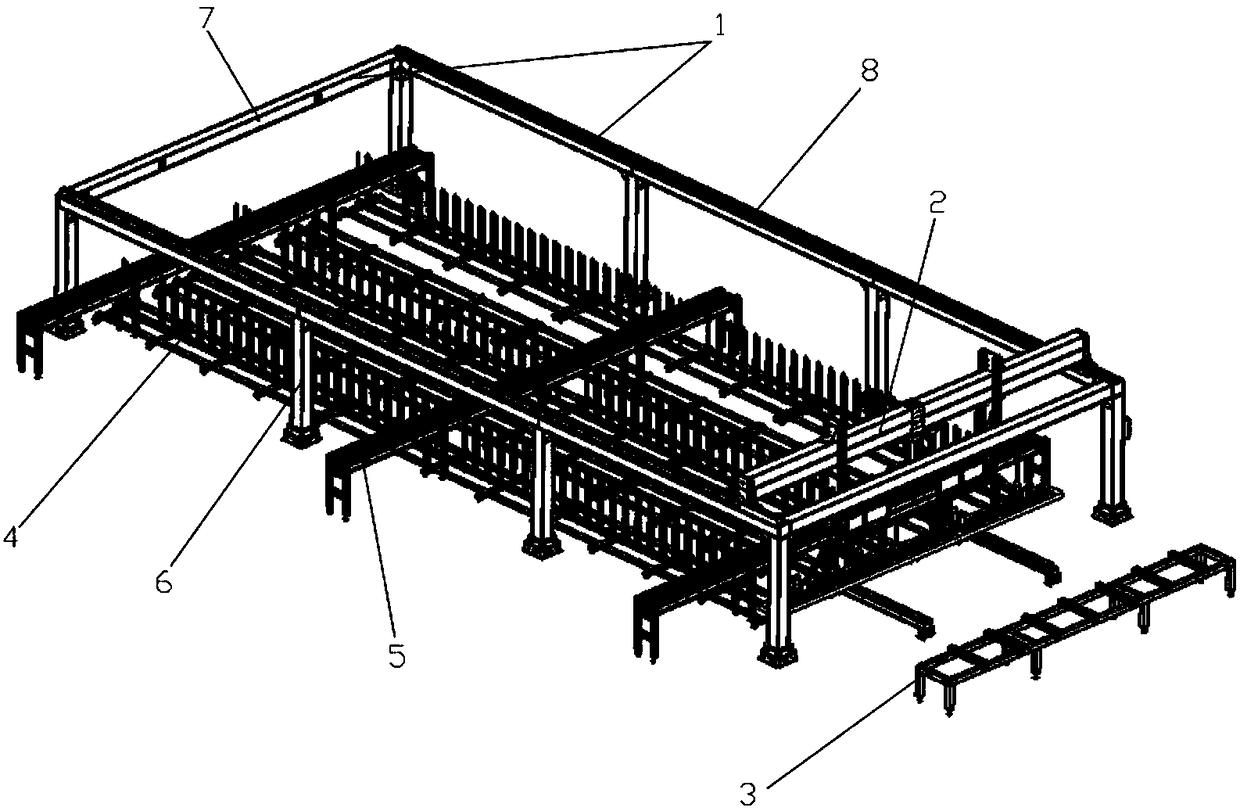

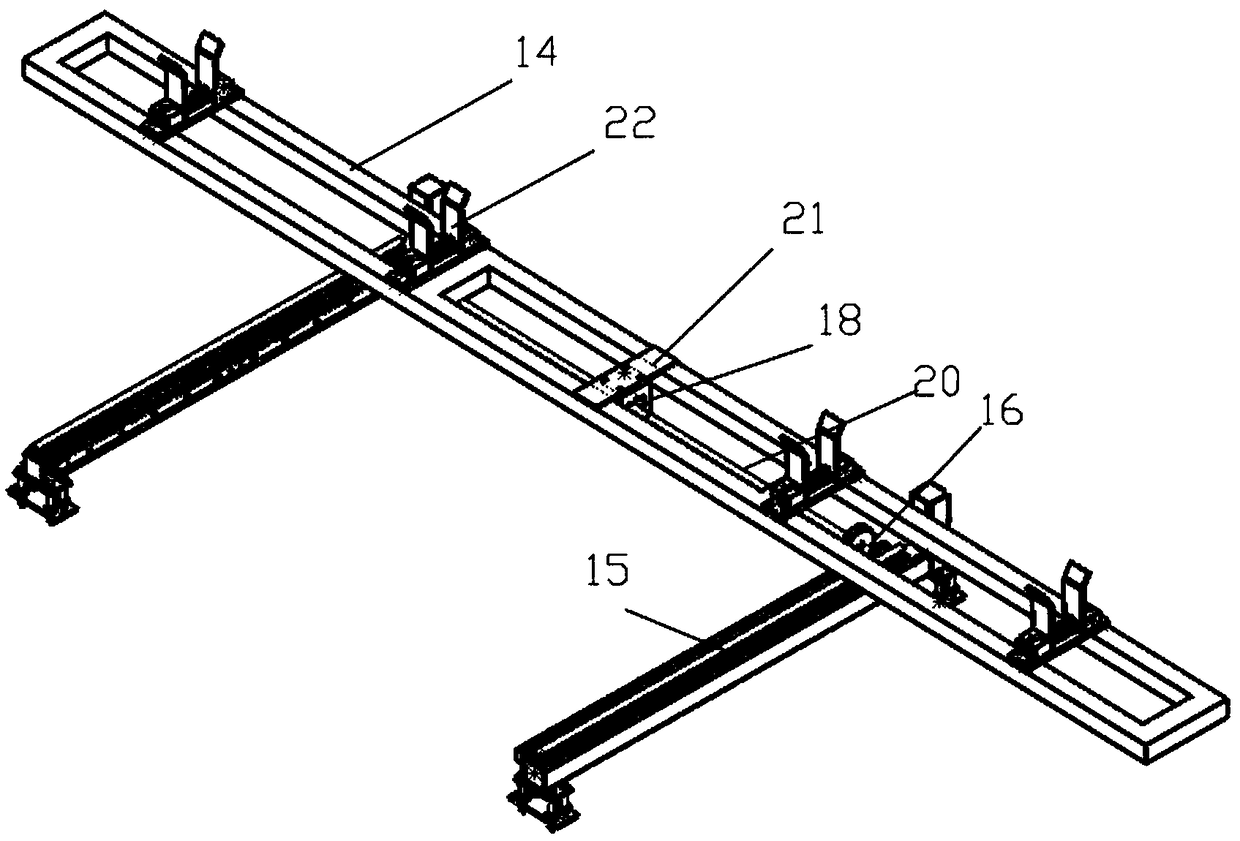

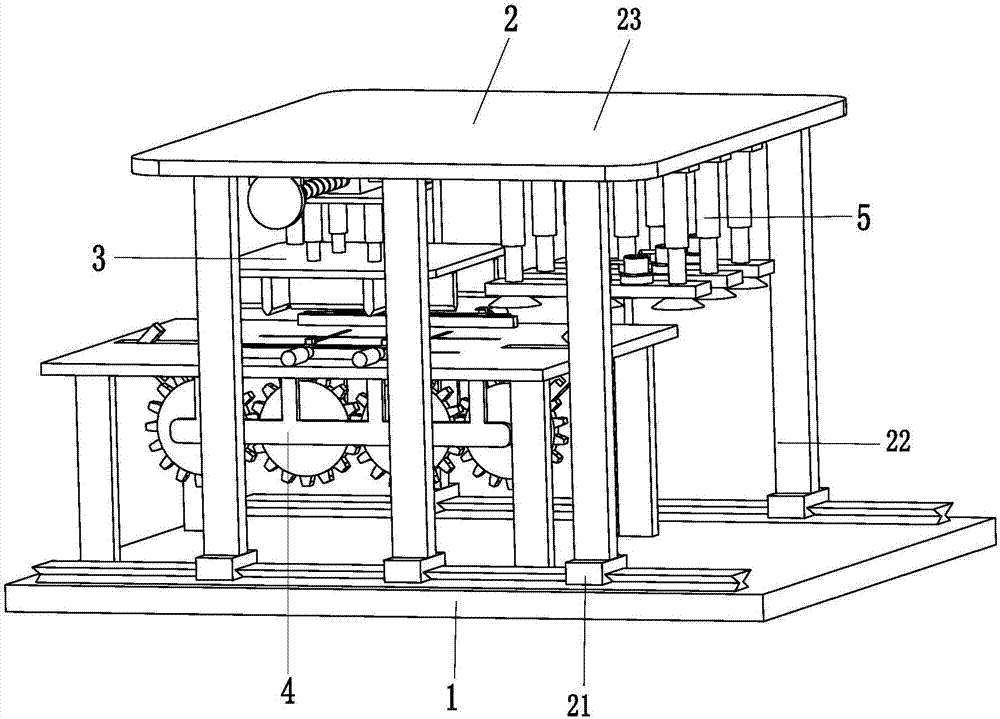

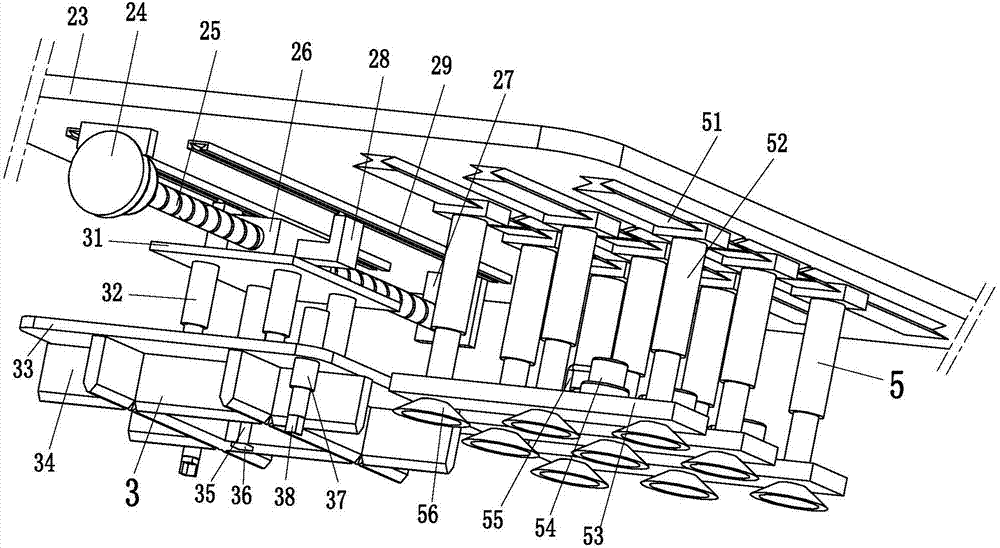

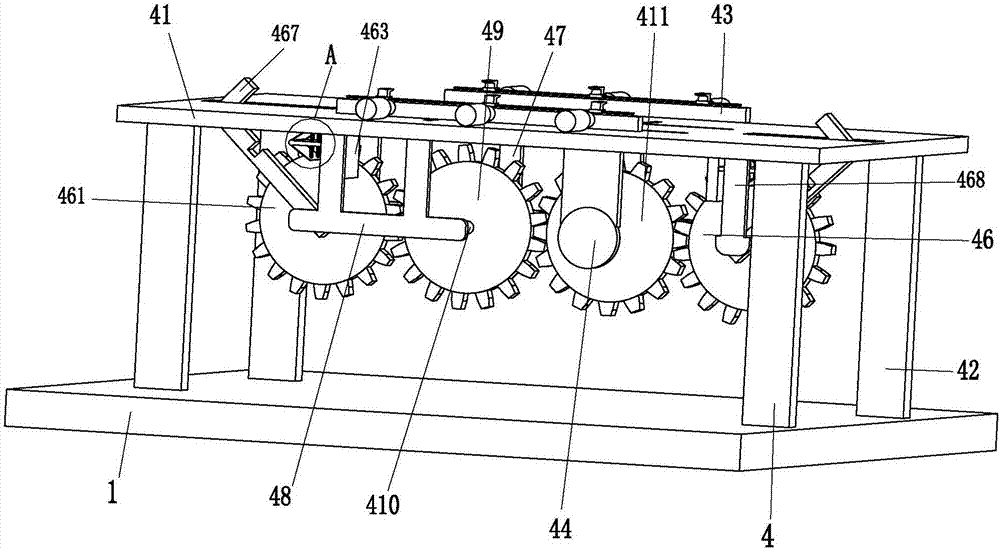

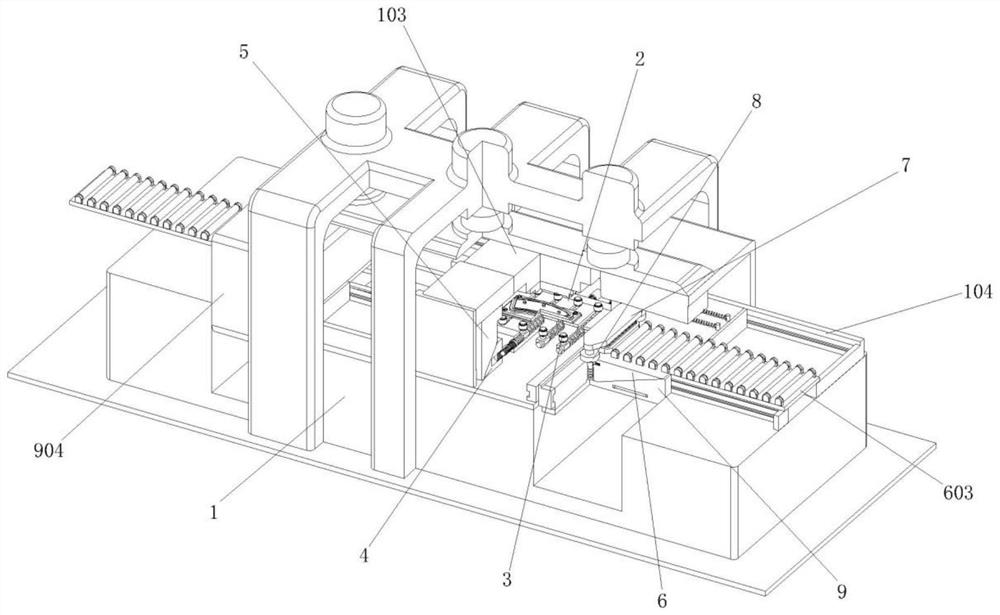

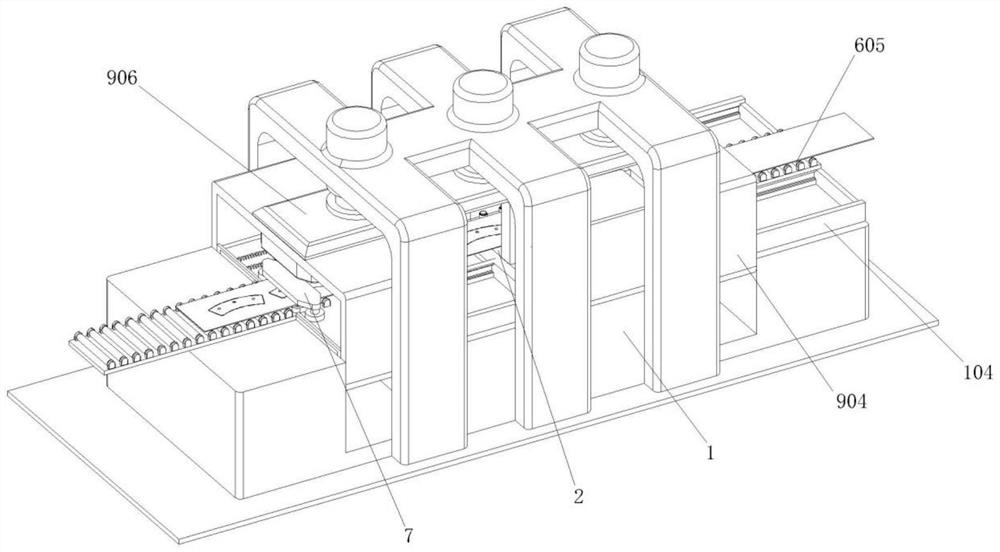

Copper bar automatic plane warehouse and copper bar integrated production line

PendingCN108249119ASmooth transferRealize automatic loading and unloading functionOther manufacturing equipments/toolsMechanical conveyorsProduction lineEngineering

The invention relates to a copper bar production technology, in particular to copper bar automatic plane warehouse and copper bar integrated production line which achieves automatic storage, automaticfeeding, automatic production and automatic discharge for copper bars. The production line comprises a copper bar automatic plane warehouse and a copper bar automatic production line. A copper bar warehouse outer frame comprises stand columns, a beam and a linear guide rail, the stand columns are installed on the ground, the beam is connected with the stand columns on the two sides, the linear guide rail is installed on the stand column, each copper bar warehouse location comprises a copper bar warehouse location frame and multiple limiting columns, the copper bar warehouse location is arranged inside the copper bar warehouse outer frame, the multiple limiting columns are installed on the copper bar warehouse location frame, a copper bar discharge conveying line is also arranged in the copper bar warehouse outer frame and penetrates through multiple copper bar warehouse locations, the copper bar discharge conveying line comprises a copper bar discharge conveying frame, a copper bar discharge motor and a conveying belt wheel, and the copper bar discharge motor is installed on the copper bar discharge conveying frame and is in linkage with the conveying belt wheel.

Owner:JIANGSU SENLAN INTELLIGENCE SYST CO LTD

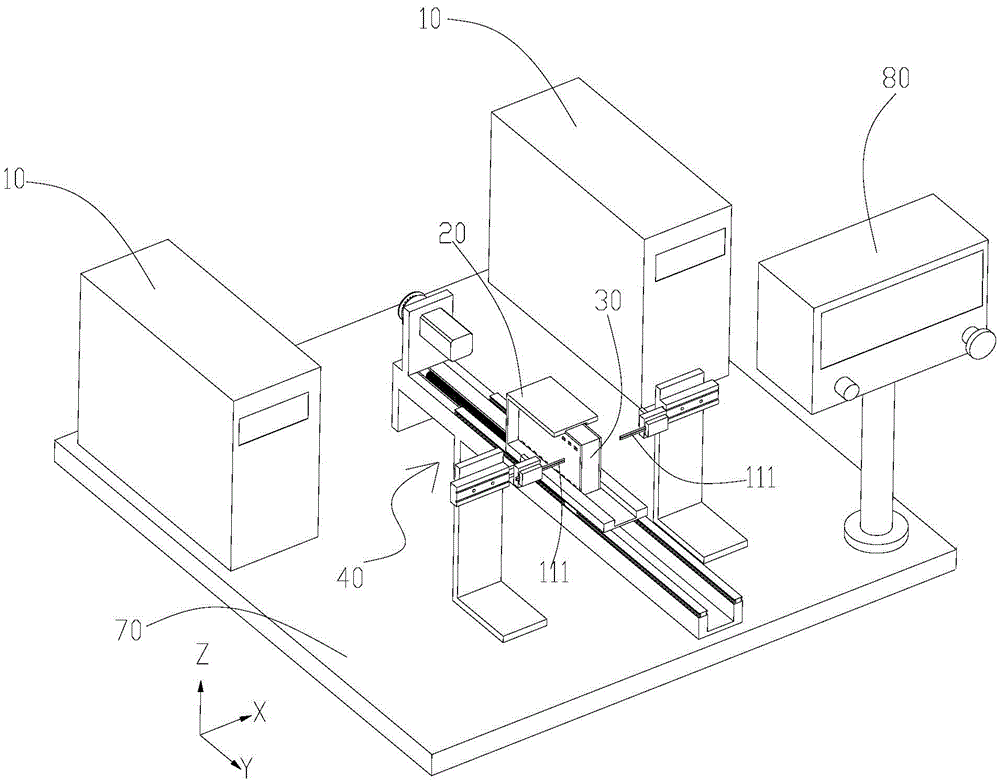

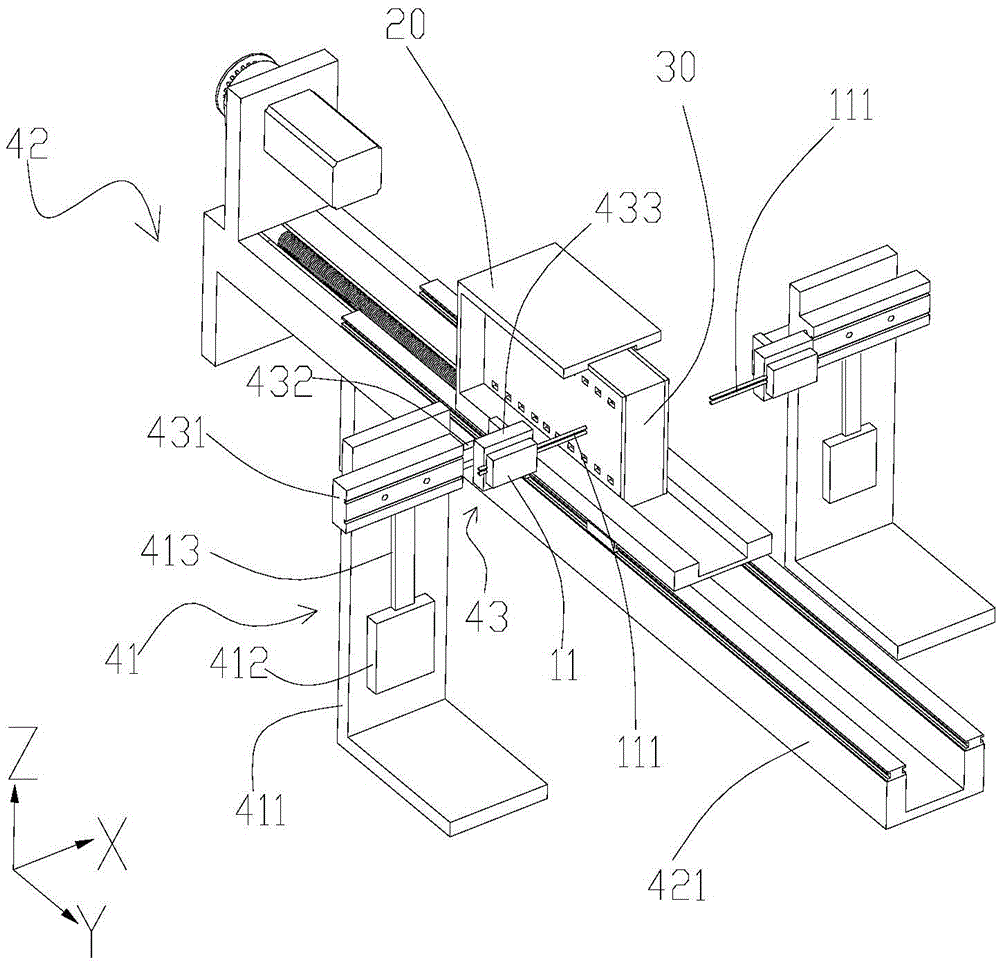

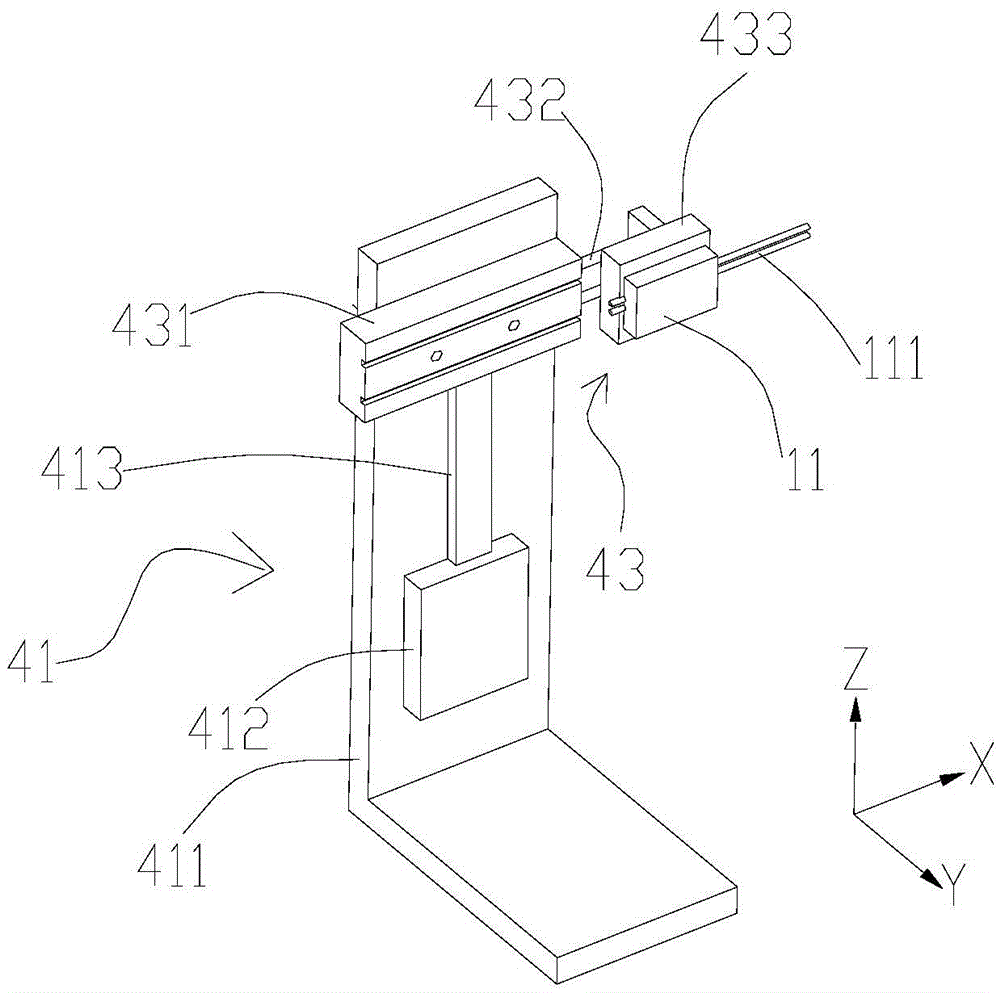

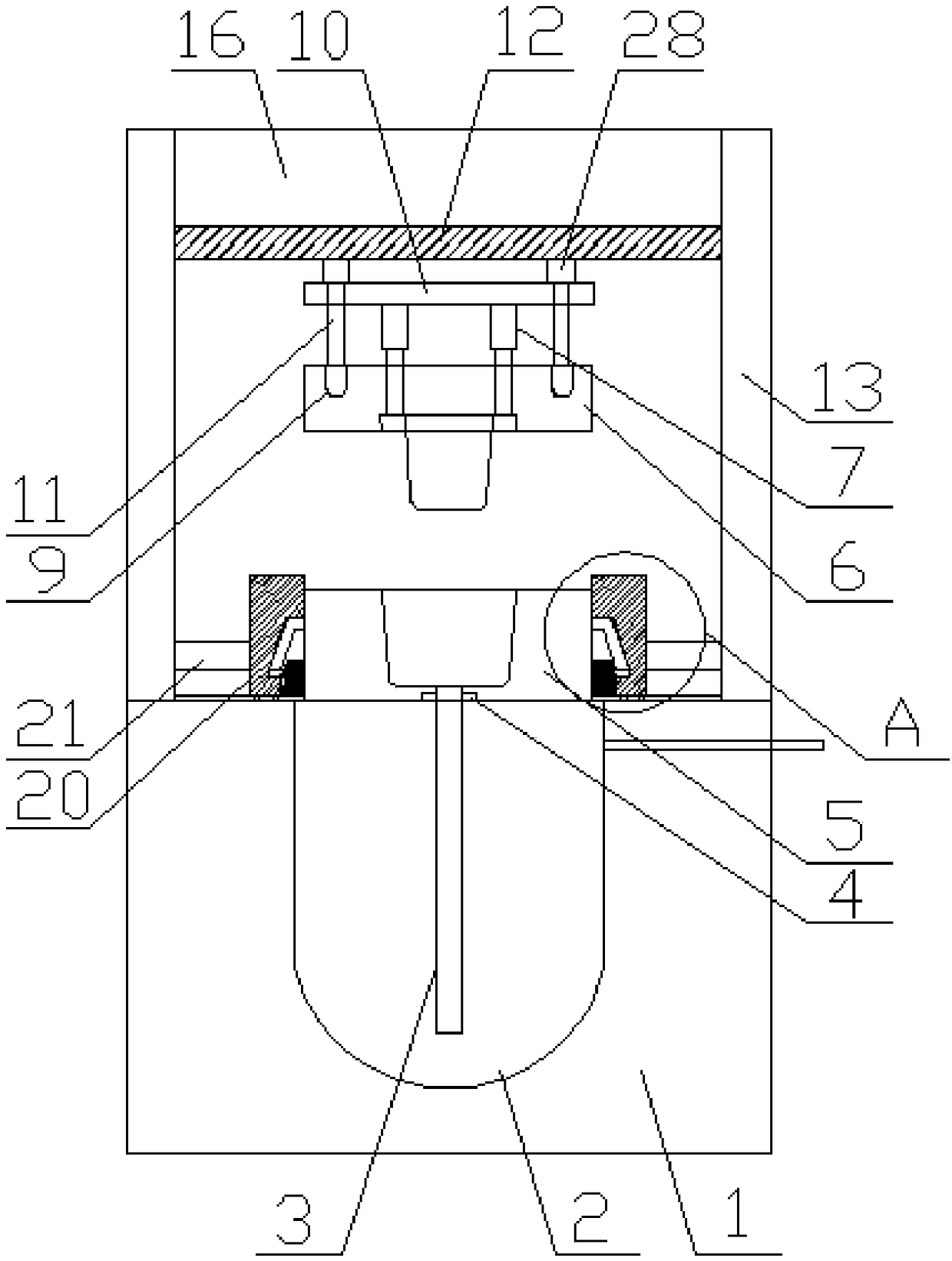

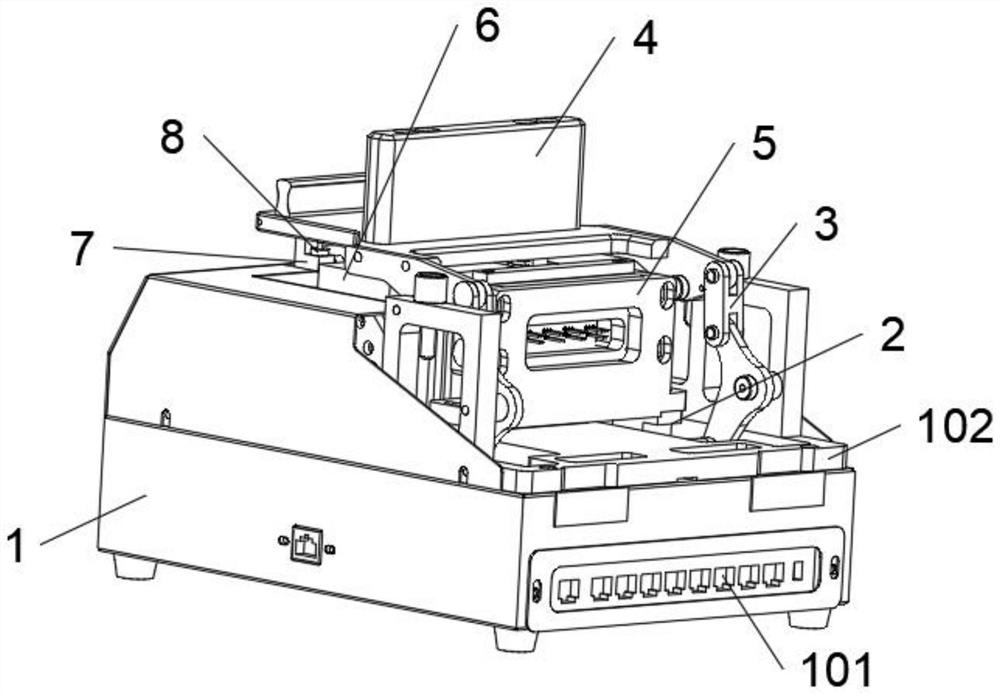

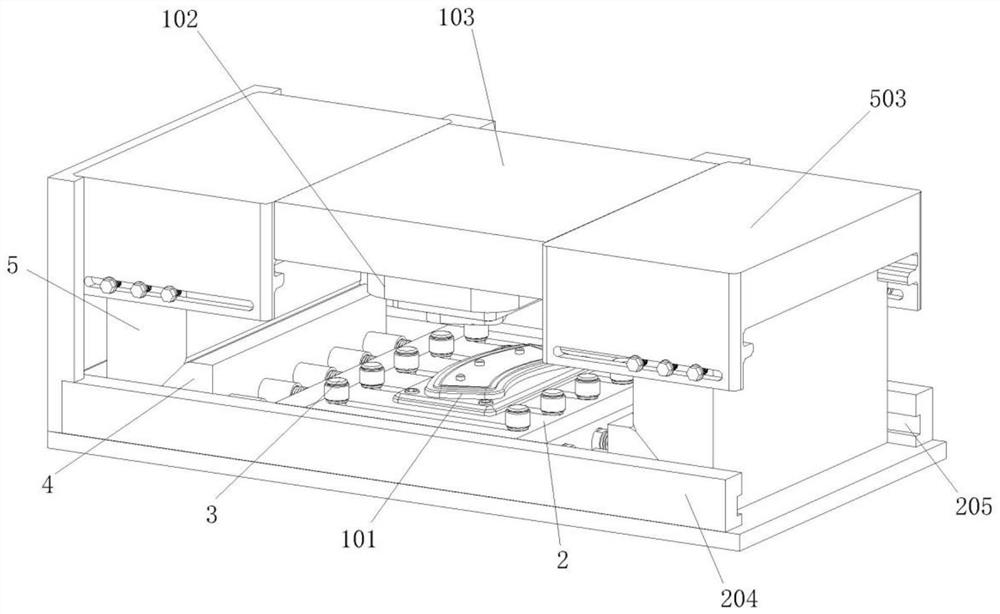

Automatic battery core spot welding device and automatic spot welding method thereof

ActiveCN105537835APrecise positioning and fixingFit tightlyWelding/cutting auxillary devicesAuxillary welding devicesControl systemMetal sheet

The invention discloses an automatic battery core spot welding device and an automatic spot welding method thereof. The automatic battery core spot welding device comprises two spot welding devices, a spot welding fixture, a fixture clamping seat, a displacement device and a PLC control system; welding heads of the spot welding devices are symmetrically arranged, the spot welding fixture is used for containing a battery core monomer to be welded, the fixture clamping seat is used for fixing the spot welding fixture, and the displacement device is arranged between the two welding heads and can drive the fixture clamping seat and the welding heads to do relative three-dimensional movement to enable the welding heads to correspond to spot welding holes formed in the spot welding fixture to perform welding in the spot welding process; the PLC control system can enable the spot welding devices and the displacement device to coordinately work; the spot welding fixture can accurately position and fix different numbers of the battery cores to ensure that electrodes and metal sheets of the battery cores to be closely attached; through the displacement which moves in the X, Y and Z three-dimensional directions to enable the welding heads to correspond to the spot welding holes formed in the spot welding fixture to perform welding, automation is completely achieved in the whole spot welding process, manpower is saved, the efficiency is improved, and it is guaranteed the quality of the products processed through spot welding is good without being influenced by individual level of operators.

Owner:DONGGUAN AOHAI TECH CO LTD

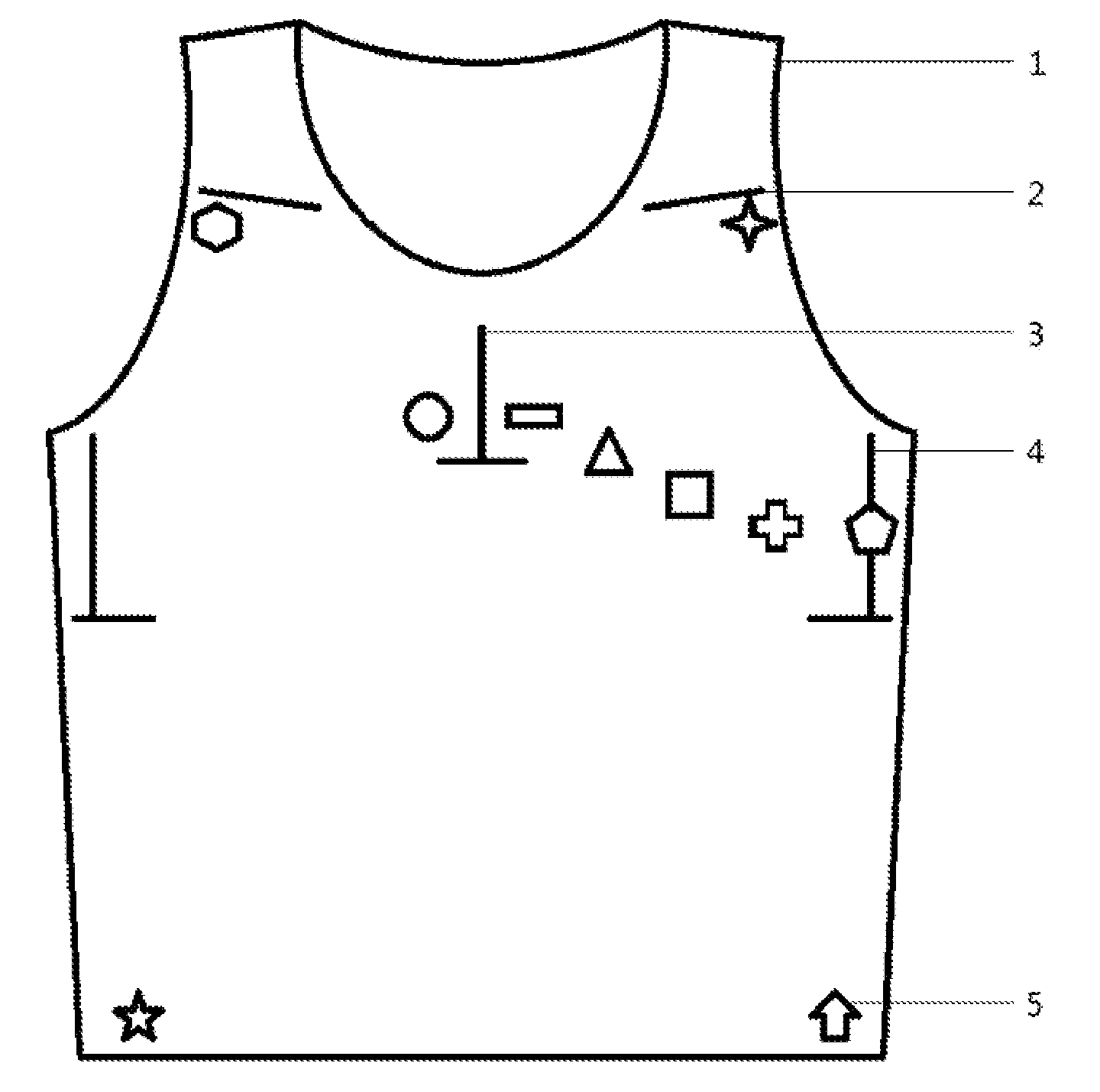

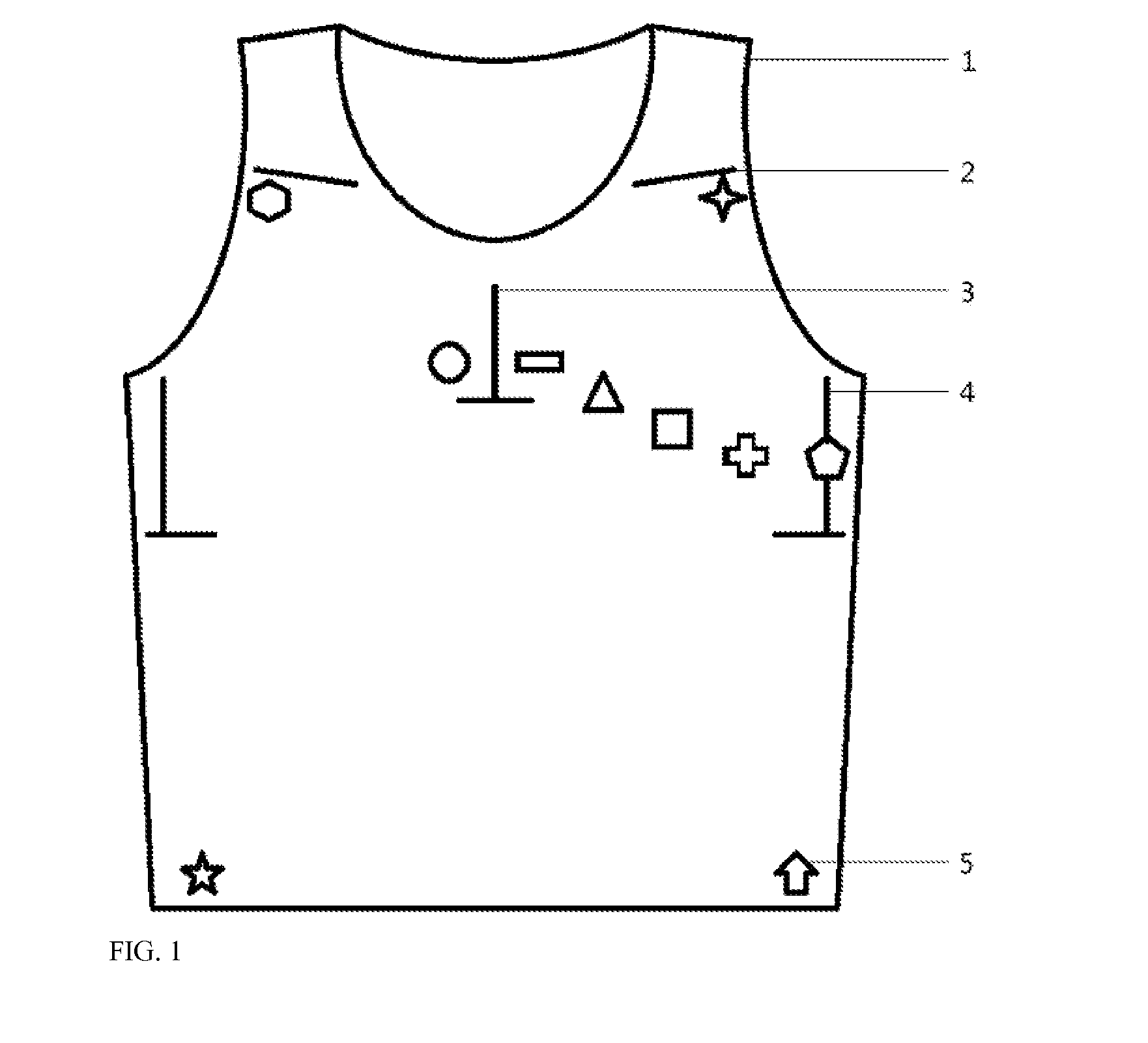

Elastic garment for positioning and fixing ECG electrodes

InactiveUS20160066809A1Precise positioningProperly fixedElectrocardiographySensorsBody shapeEngineering

An elastic garment provides an easy, quick, user-friendly way of positioning and fixing ECG electrodes. The elastic textile can offset the impact of body shape on the position of ECG electrodes. The elasticity ensures good electrode abutment and prevent electrode dislocation. The garment has labels indicating the significant bony landmarks, which help user wear the garment correctly thus ensuring the position of the electrodes. Optional features include: labels to indicate the position of electrodes; embedded wires, electrodes and connectors to external ECG device. The garment makes it possible for non-professionals to perform ECG examination including the standard 12-lead ECG. It also minimizes electrode dislocation and uncomfortable feelings of wearing ECG device, especially for those under long-term ECG monitoring. It can also help avoid the inconvenient procedure of undressing a patient during ECG examination.

Owner:LUO ZHIYUAN +1

Image Correction Design System and Method for Oral and Maxillofacial Surgery

ActiveUS20180147015A1Shorten the timePrecise positioningMedical simulationImage enhancementMaxillofacial oral surgeryDisplay device

An image correction design system for an oral and maxillofacial surgery. The image correction design system comprises: a first image data scanning module for scanning to obtain image data of relative coordinate positions of maxillofacial bones, teeth, and soft tissues; a second image data scanning module for scanning image data of a plaster dental impression of a patient; a scanning image correction and comparison module for correcting and comparing the image data from the first image data scanning module and the image data from the second image data scanning module and performing archiving to obtain first archives; an image block calculation module for performing an image layer management and block cutting display of the first archives to obtain second archives; a surgery simulation image design module for inputting a surgery data parameter for the second archives after the image layer management and cut block display, so as to design and establish surgery simulation image files; and an output module for outputting the surgery simulation image files by using a display device.

Owner:SHE CHENG XIN

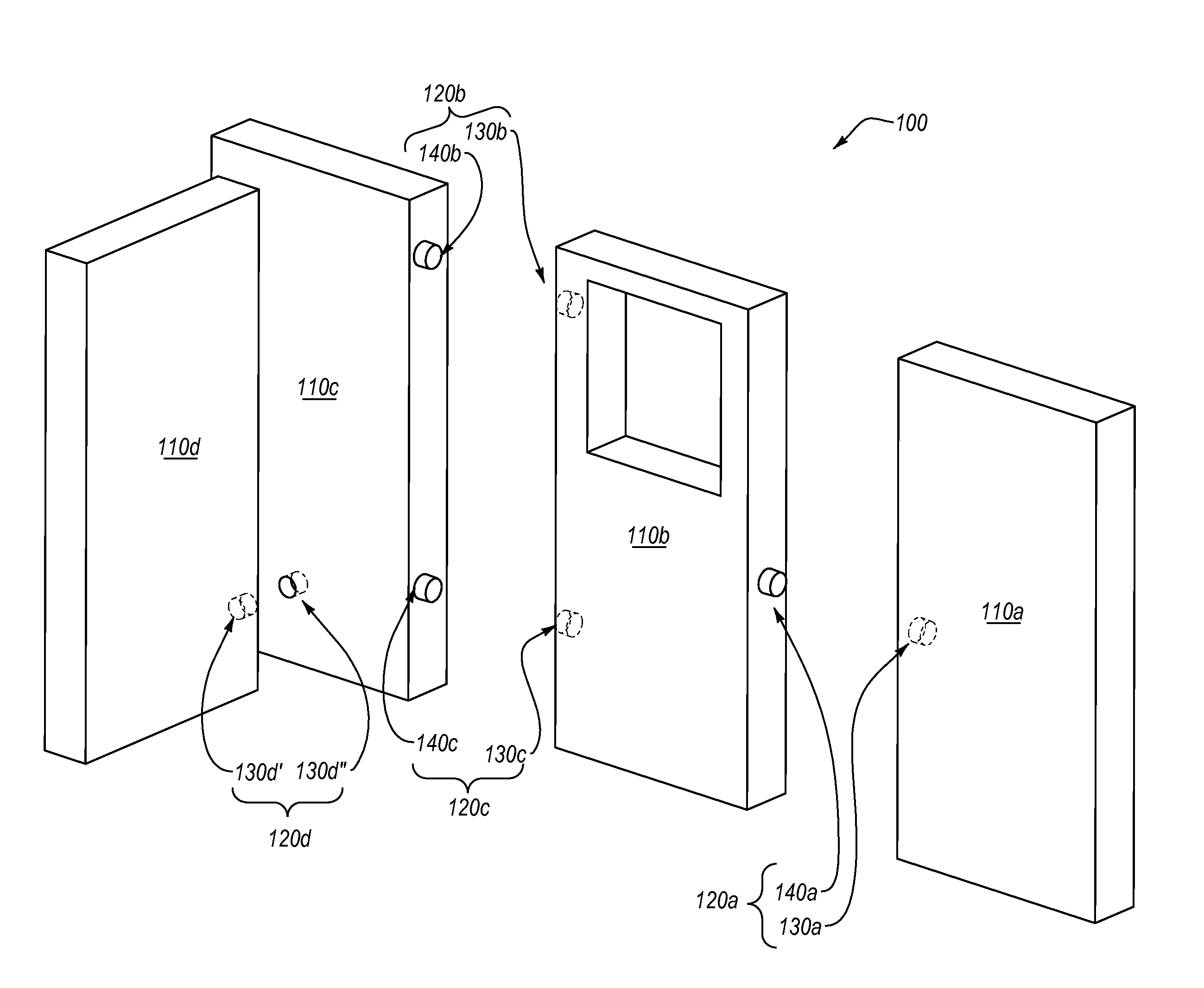

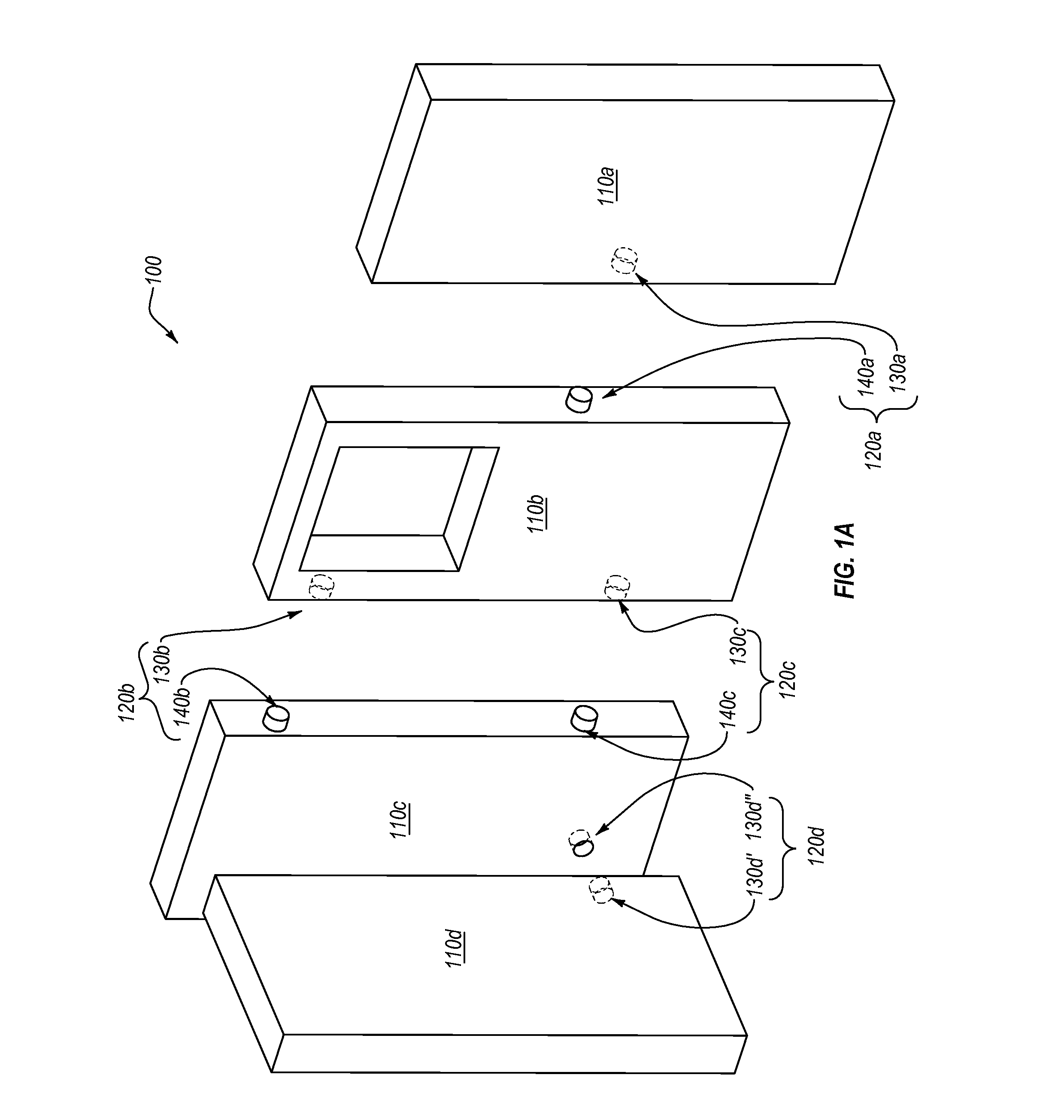

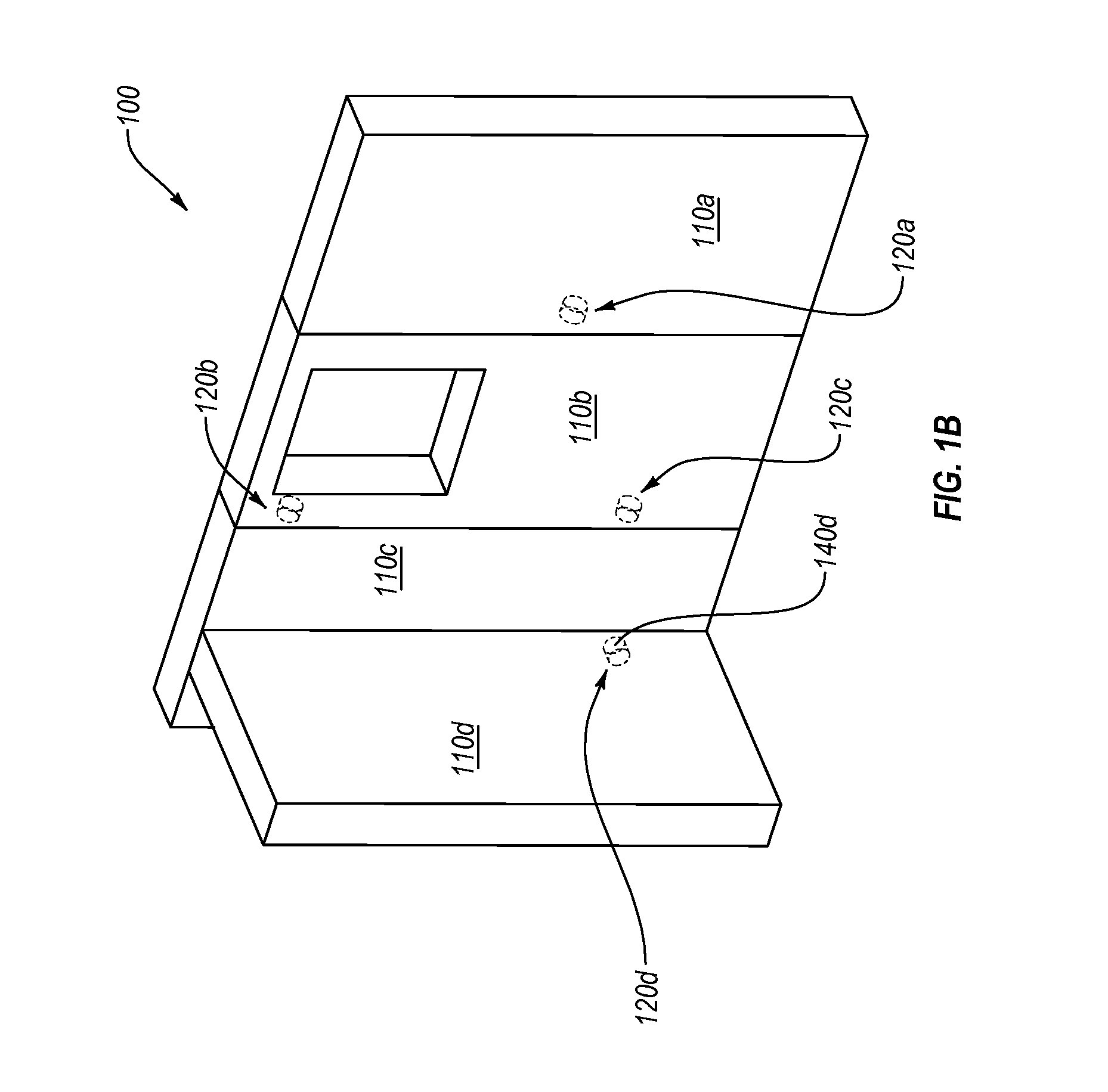

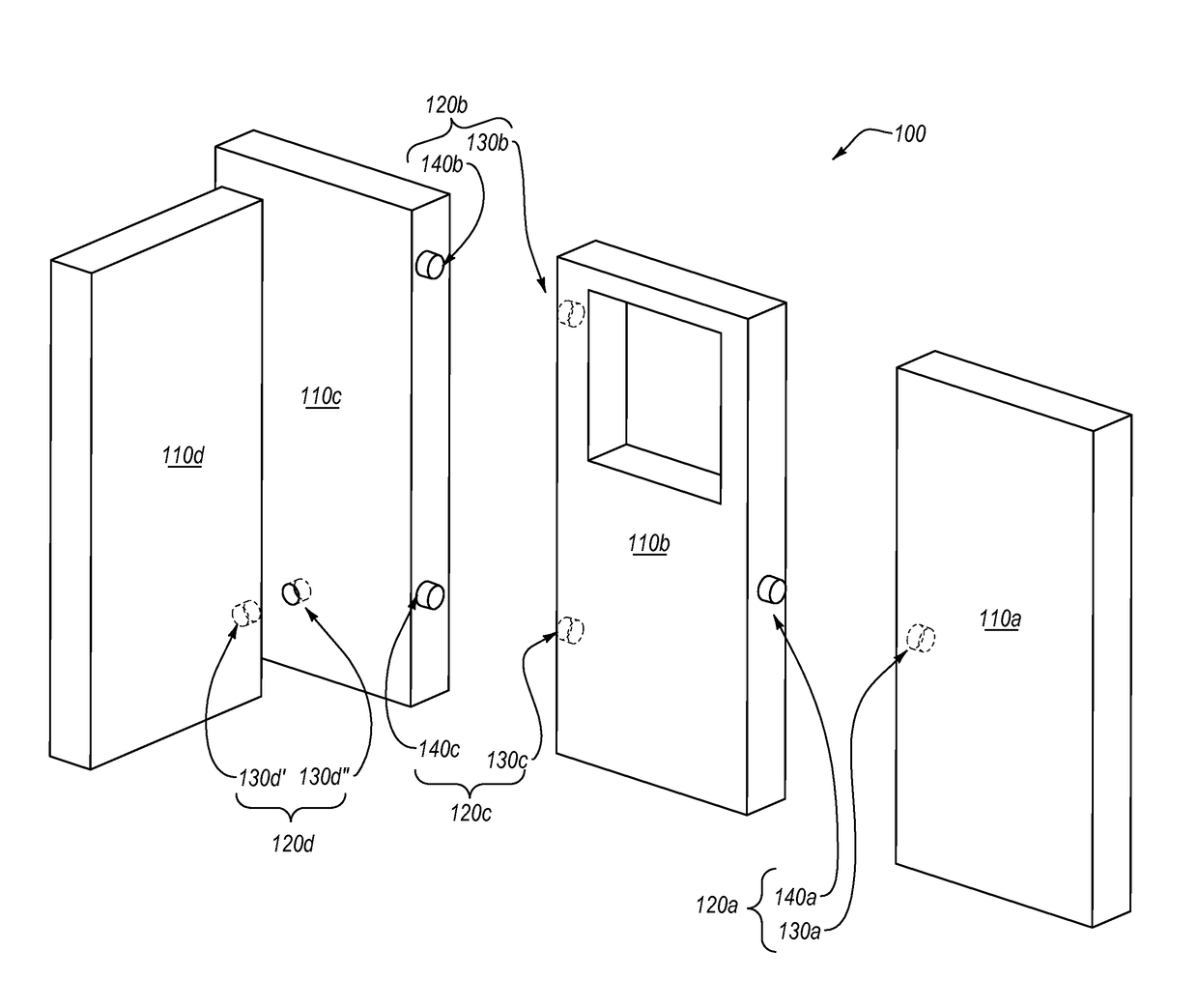

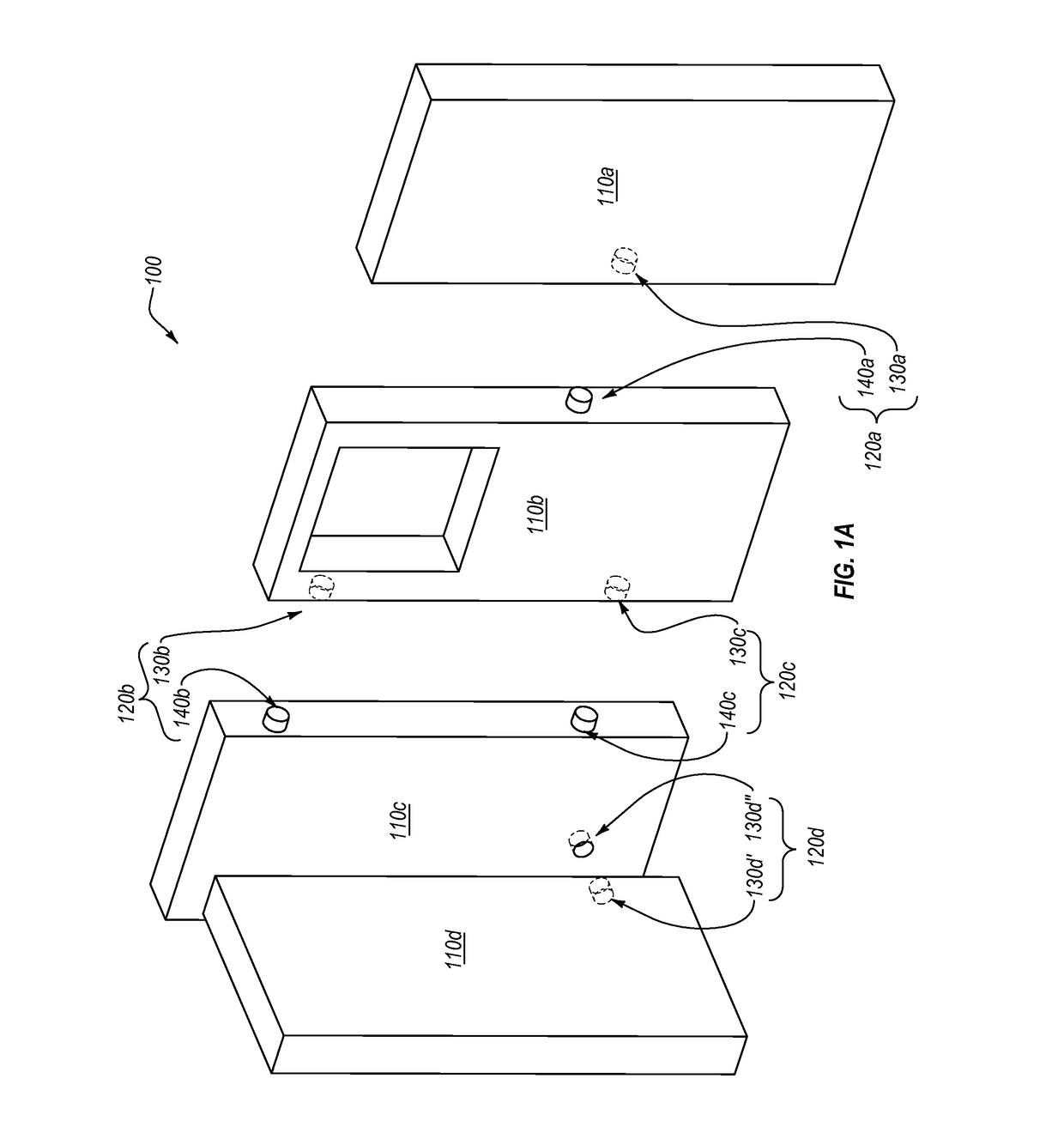

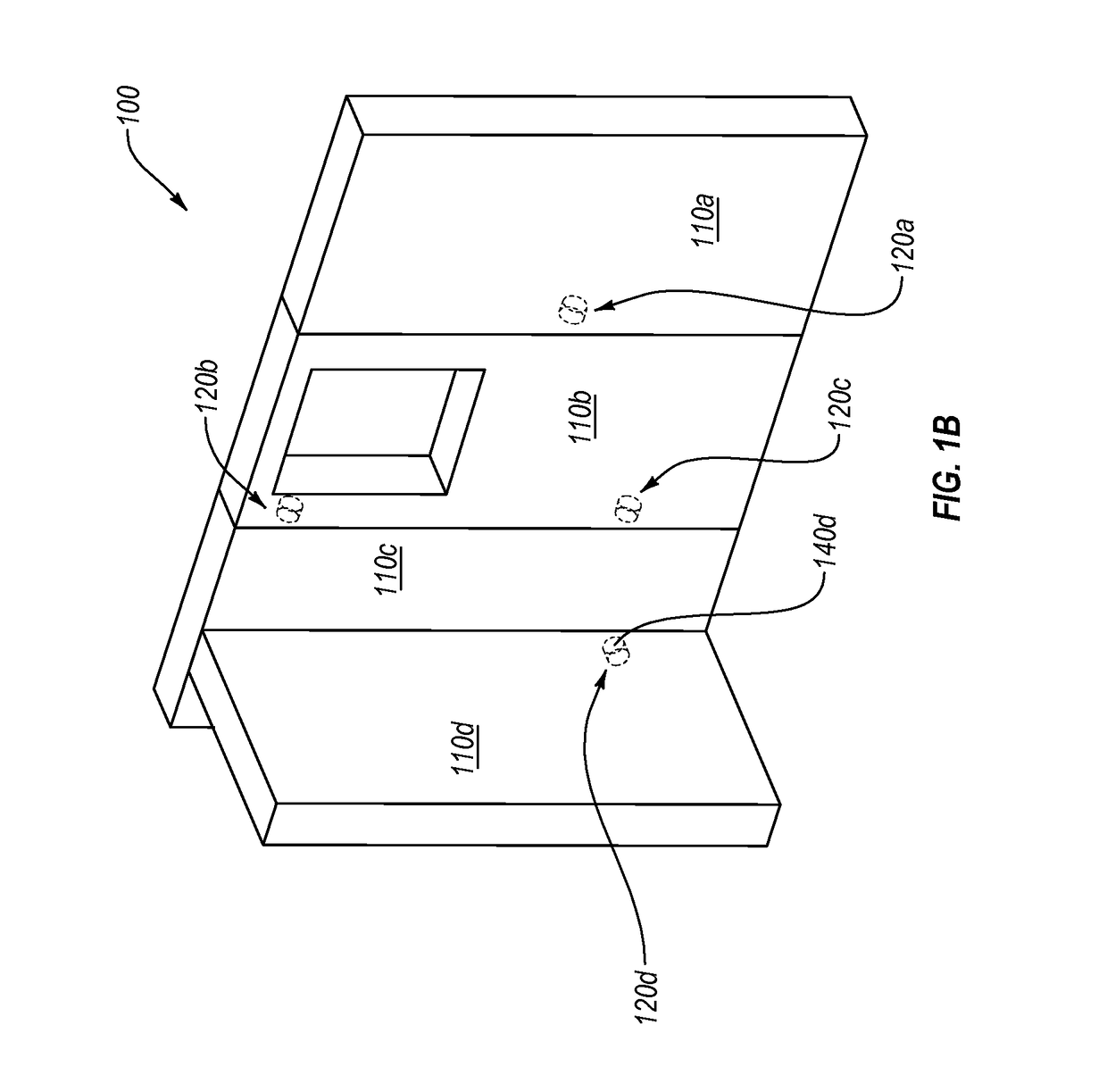

Modular building construction systems and methods

ActiveUS20150300008A1Precise positioningAccurately secureCeilingsCovering/liningsModularityEngineering

Implementations of the present invention relate to systems, methods, and apparatus for constructing a building. More specifically, the present disclosure provides an interlocking wall system that can allow a builder to accurately position, orient, and / or secure various structural wall modules. Additionally, this disclosure provides systems and methods for securing one or more cladding layers to the building's envelope. Furthermore, implementations of the present disclosure can allow for quick and modifiable installation of utility and communication lines within the building.

Owner:DIRTT ENVIRONMENTAL SOLUTIONS

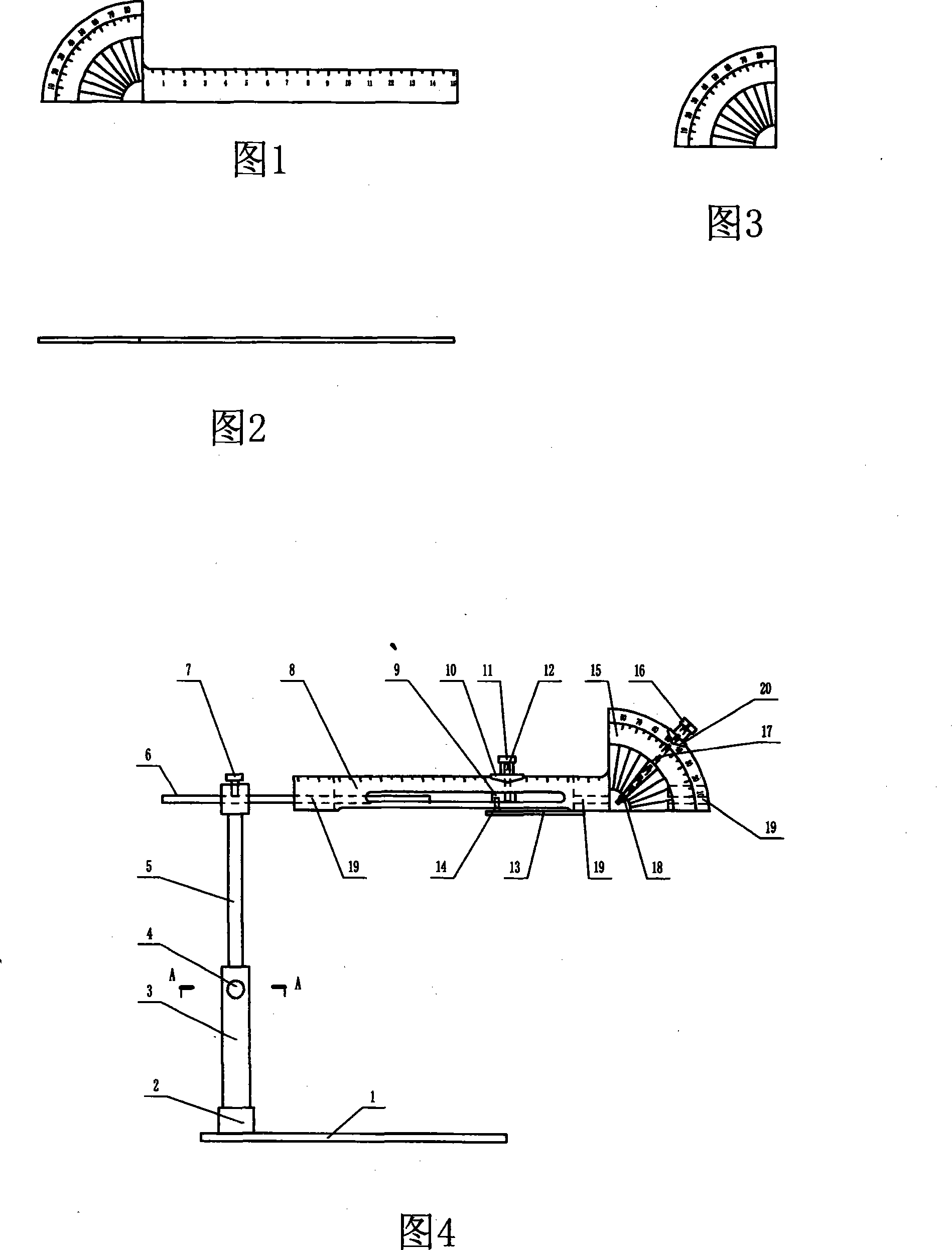

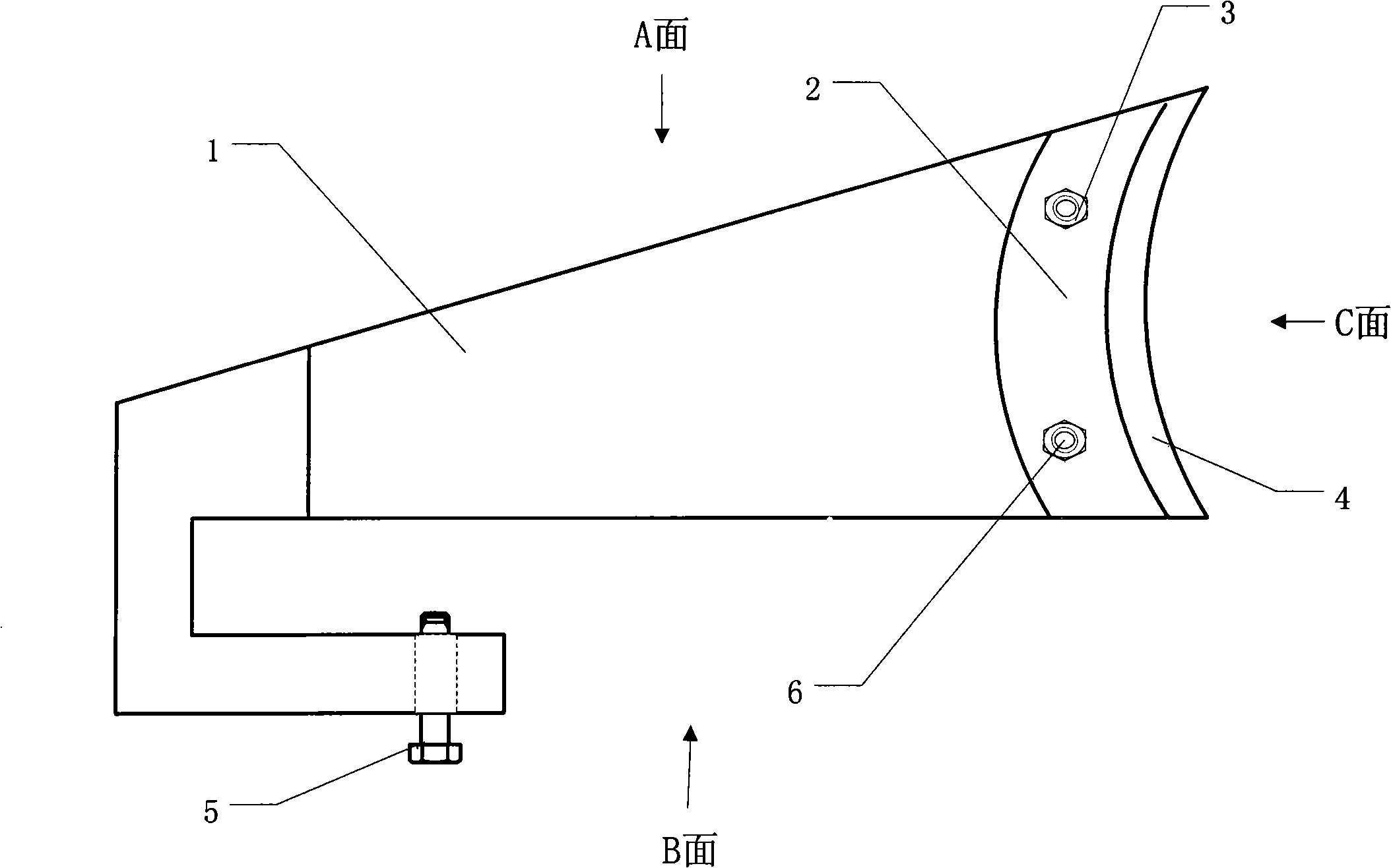

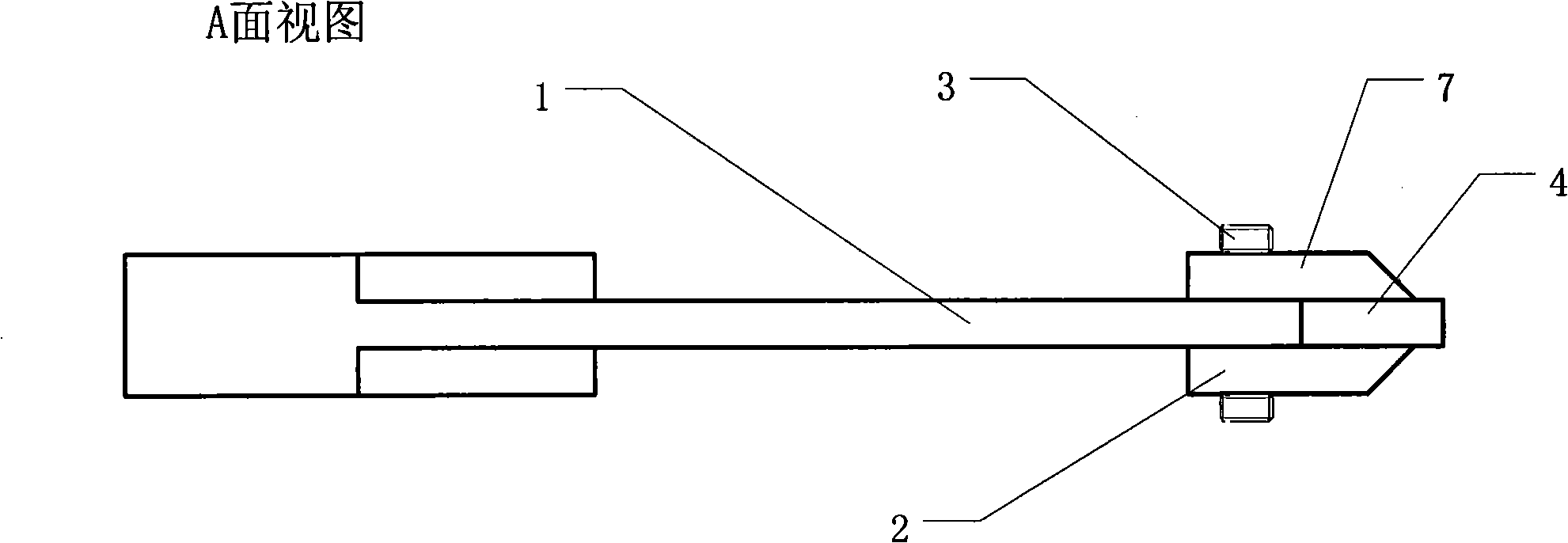

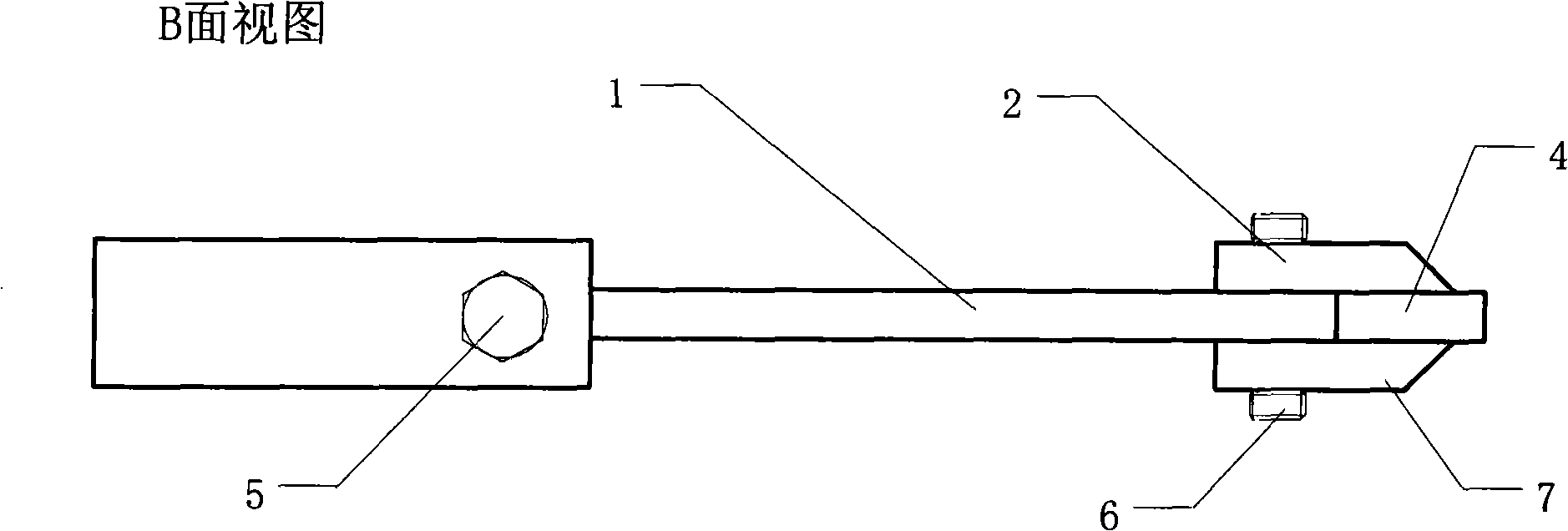

Intervertebral disk puncture locator

InactiveCN101239006APrecise positioning and fixingPrecise positioningDiagnosticsSurgical needlesLength scaleIntervertebral disk

The invention provides an intervertebral puncture positioning instrument, comprising: an angle locator which is provided with a fan-shaped positioning angle ruler and a positioning ruler. The surface of the positioning angle ruler is marked with angle scale and the surface of the positioning ruler is provided with length scale. For a doctor with familiar skill, accurate position is realized when having the intervertebral puncture by using the intervertebral puncture positioning instrument.

Owner:房风锁

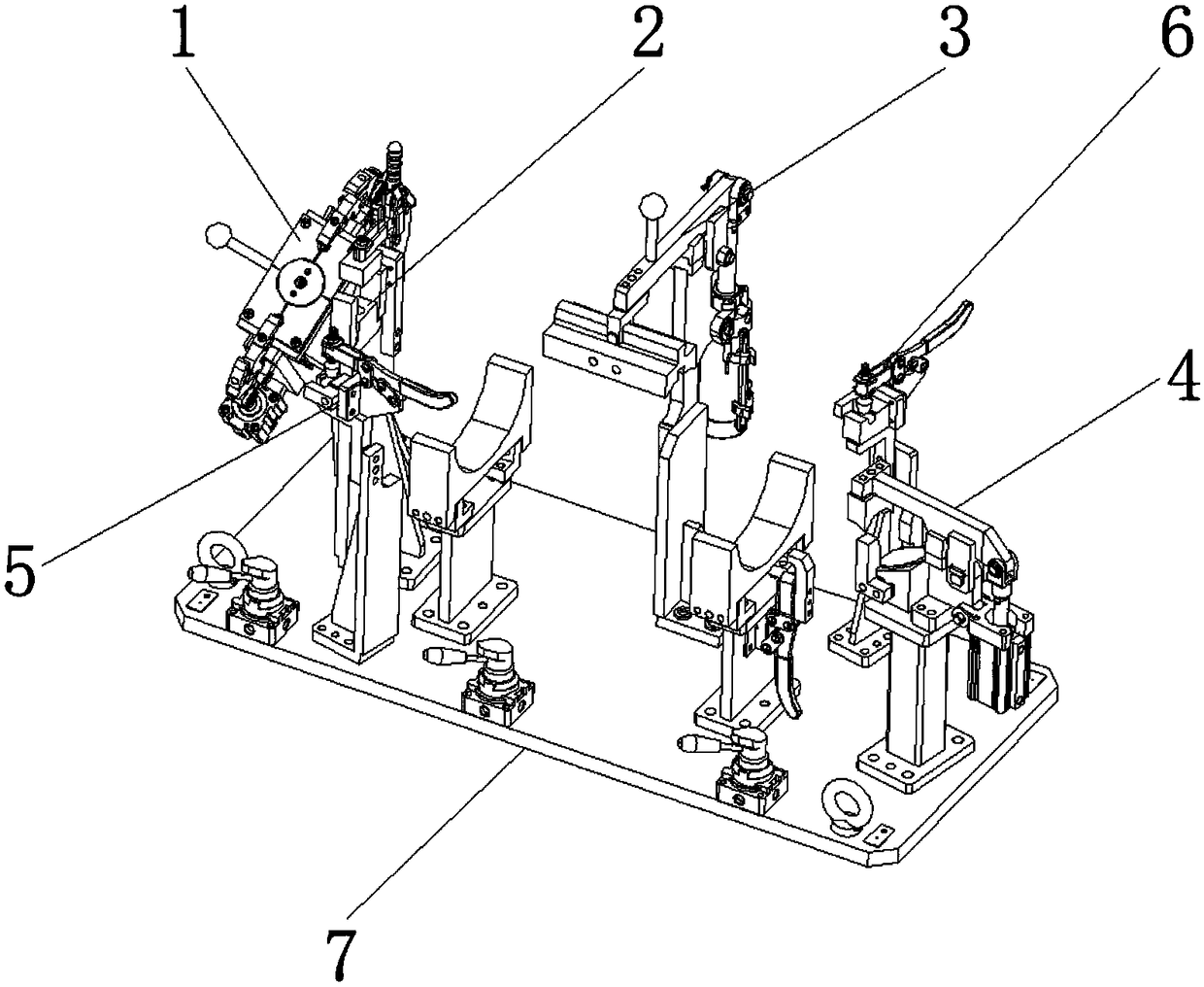

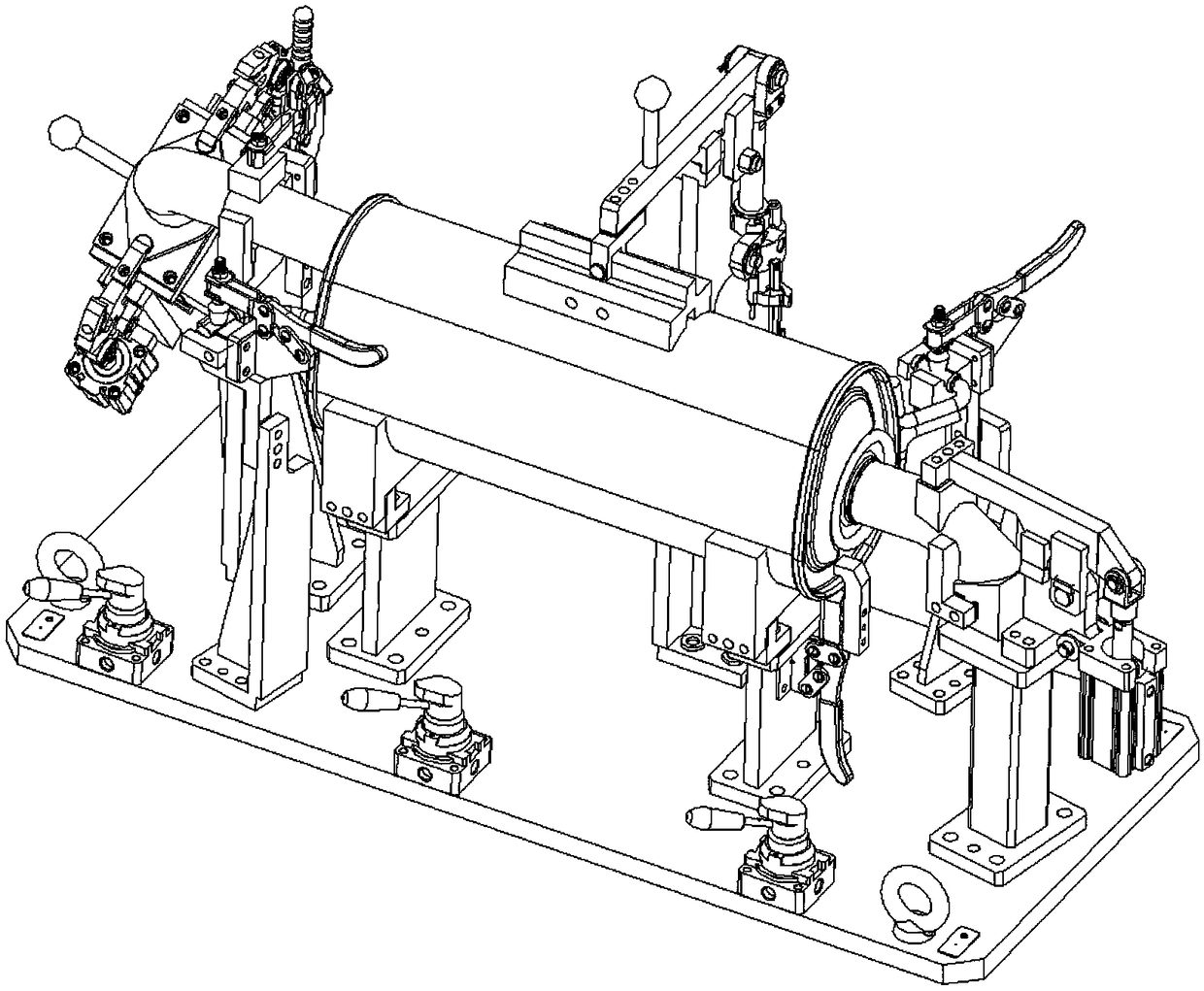

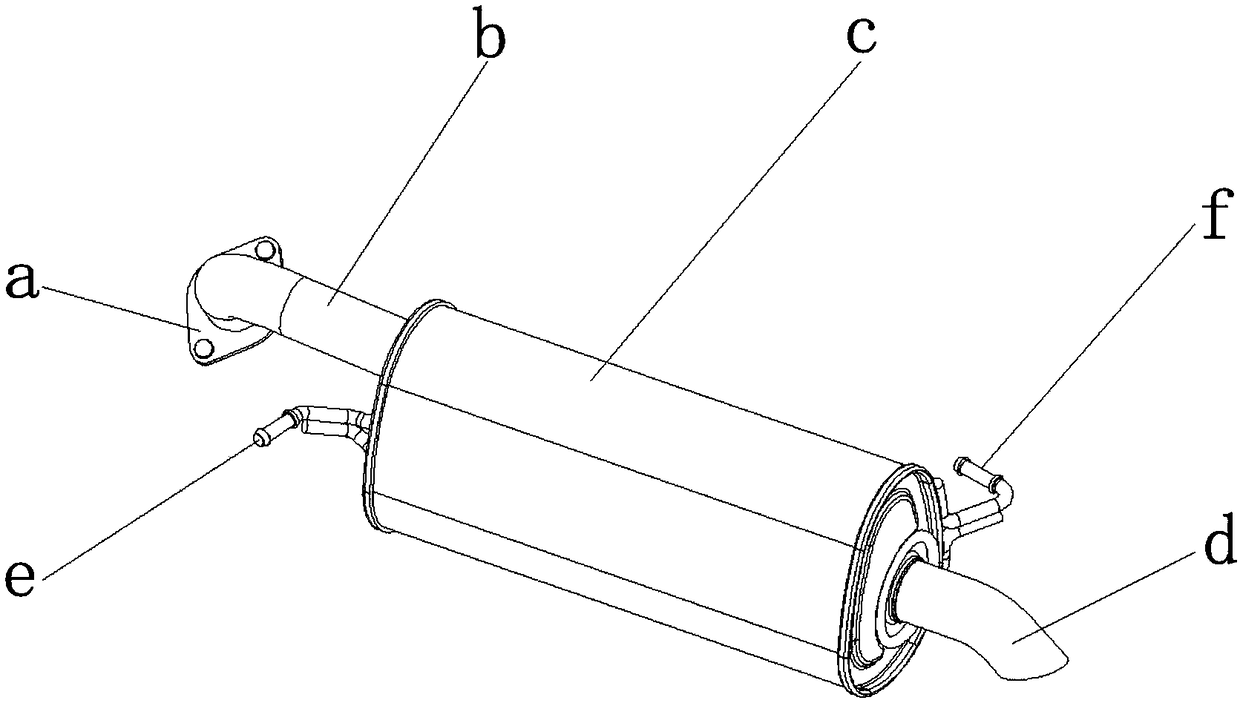

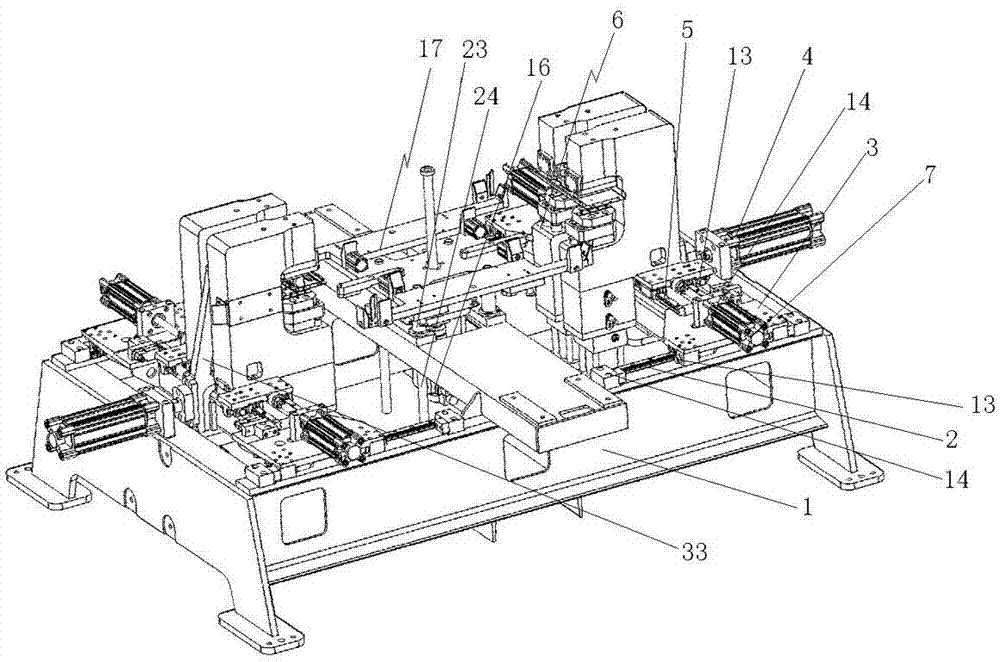

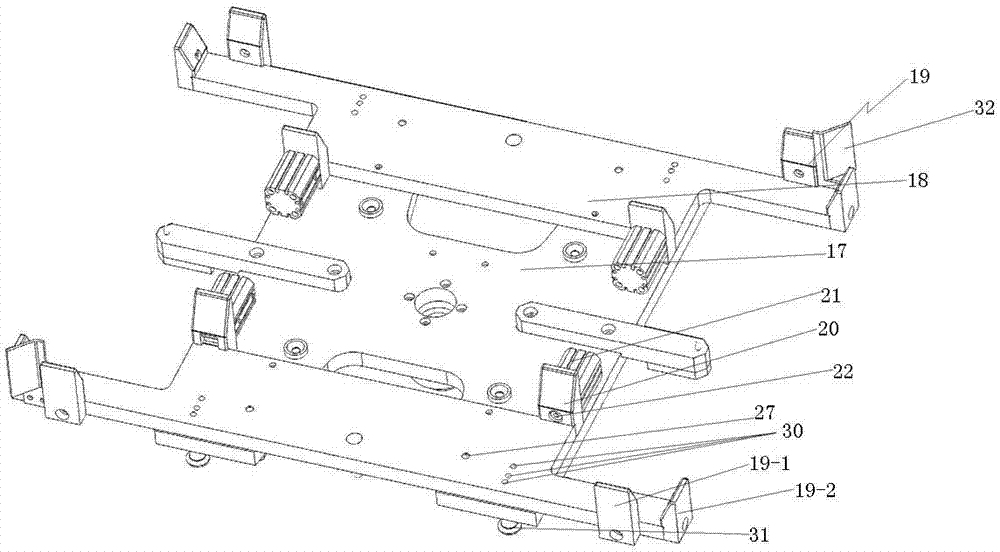

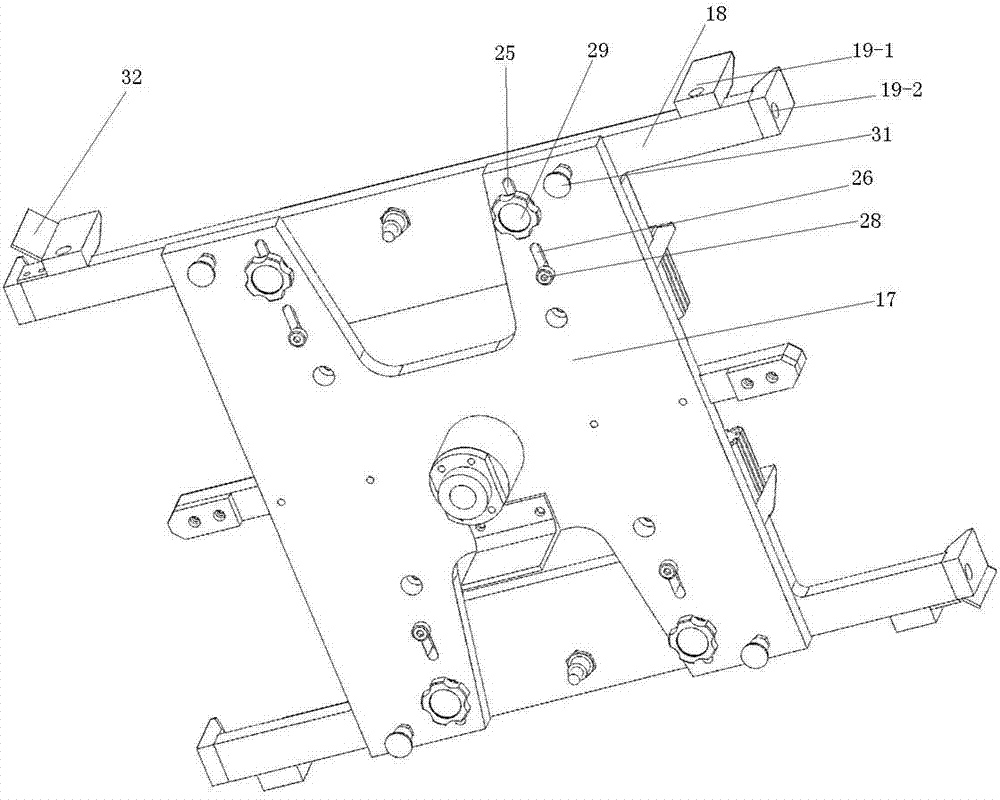

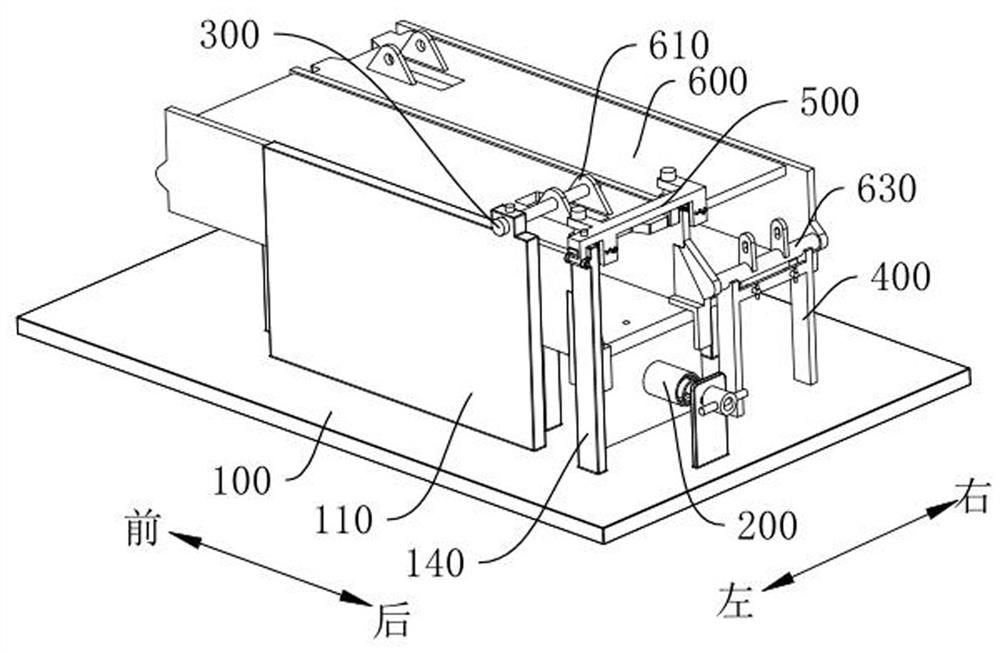

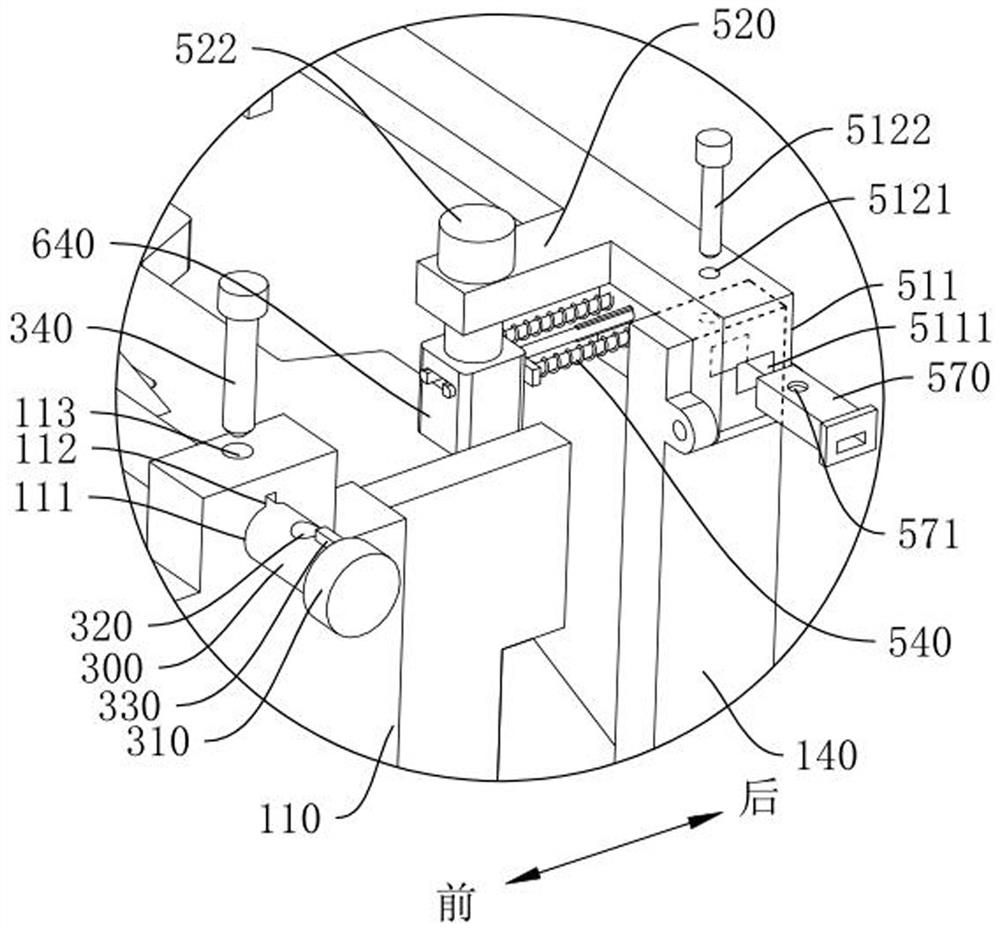

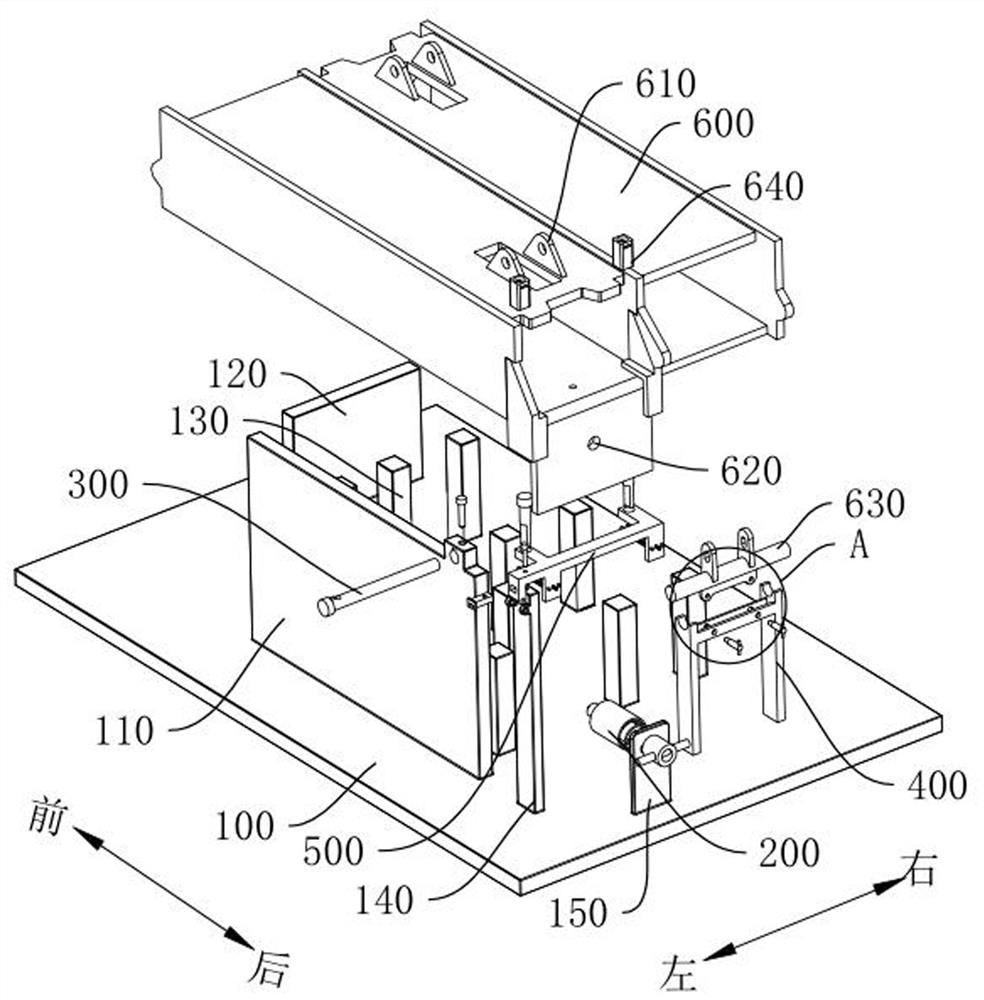

Rear silencer assembly welding fixture of automobile exhaust system

InactiveCN108326495APrecise positioningPrecise positioning and fixingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringExhaust pipe

The invention discloses a rear silencer assembly welding fixture of an automobile exhaust system. The welding fixture comprises a flange positioning device, a gas inlet pipe positioning device, a silencer positioning device, an exhaust pipe positioning device, a first hook positioning device and a second hook positioning device that are used for accurately positioning and effectively fixing a flange, a gas inlet pipe, a silencer, an exhaust pipe, a first rear silencer hook and a second rear silencer hook respectively, wherein the flange positioning device, the gas inlet pipe positioning device, the silencer positioning device, the exhaust pipe positioning device, the first hook positioning device and the second hook positioning device correspond to positions of the flange, the gas inlet pipe, the silencer, the exhaust pipe, the first rear silencer hook and the second rear silencer hook respectively and are arranged above a mounting substrate with the smooth upper surface; the fixture is used for welding assembly of a silencer assembly; spare parts are precise in positioning and convenient to mount and fetch; and the fixture guarantees production efficiency and can meet large-scaleproduction requirements.

Owner:SHANDONG VOCATIONAL COLLEGE OF SCI & TECH

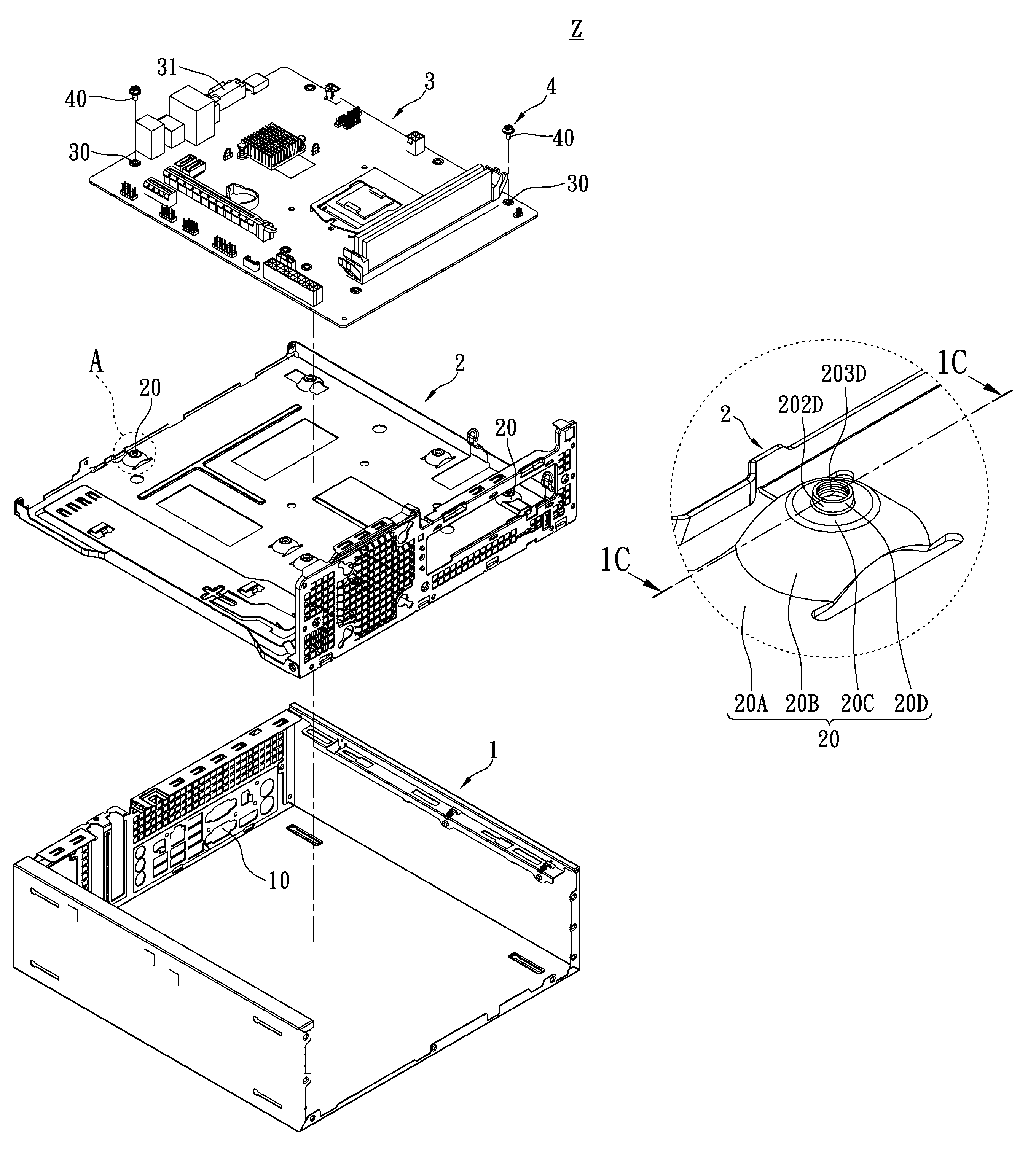

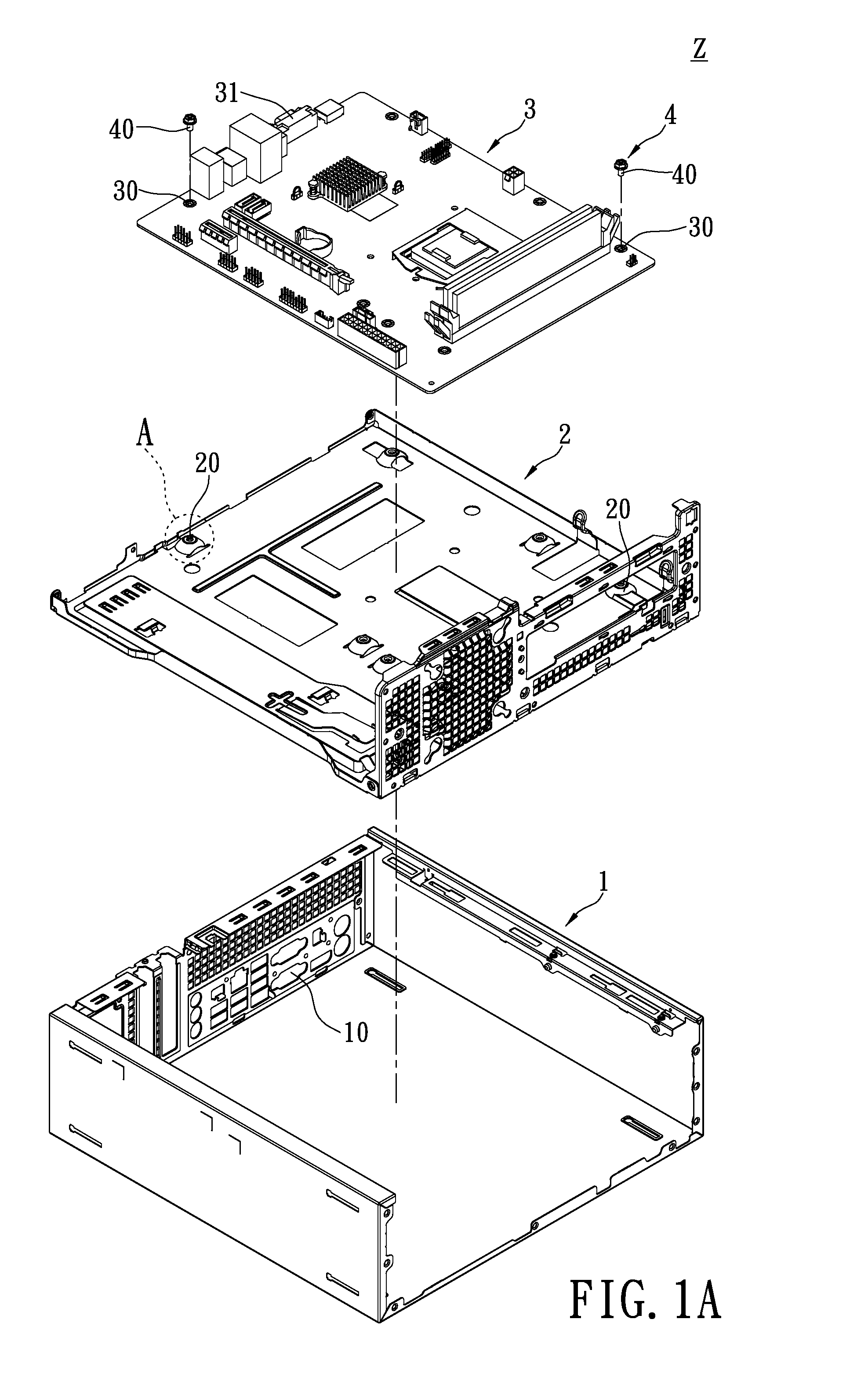

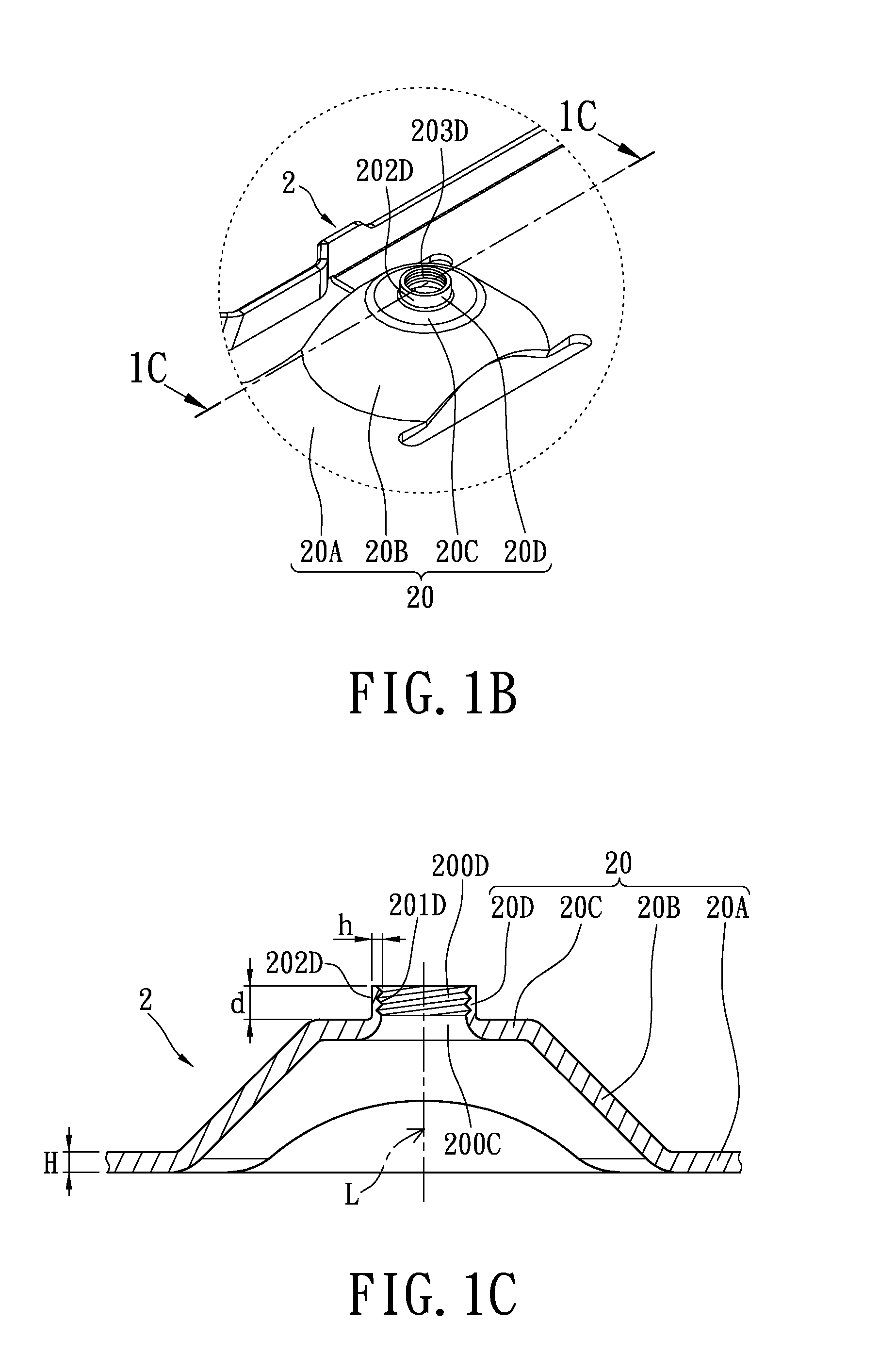

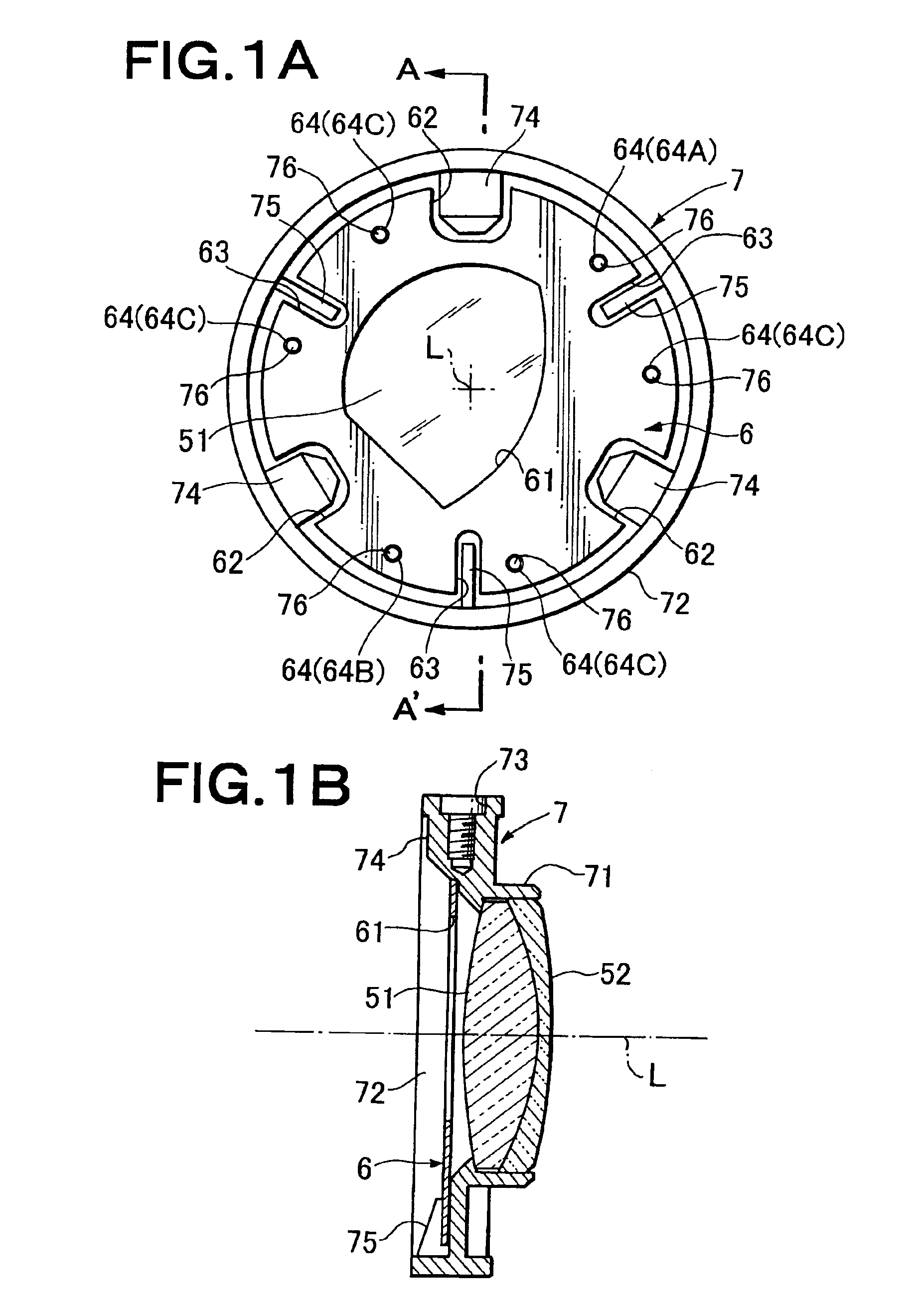

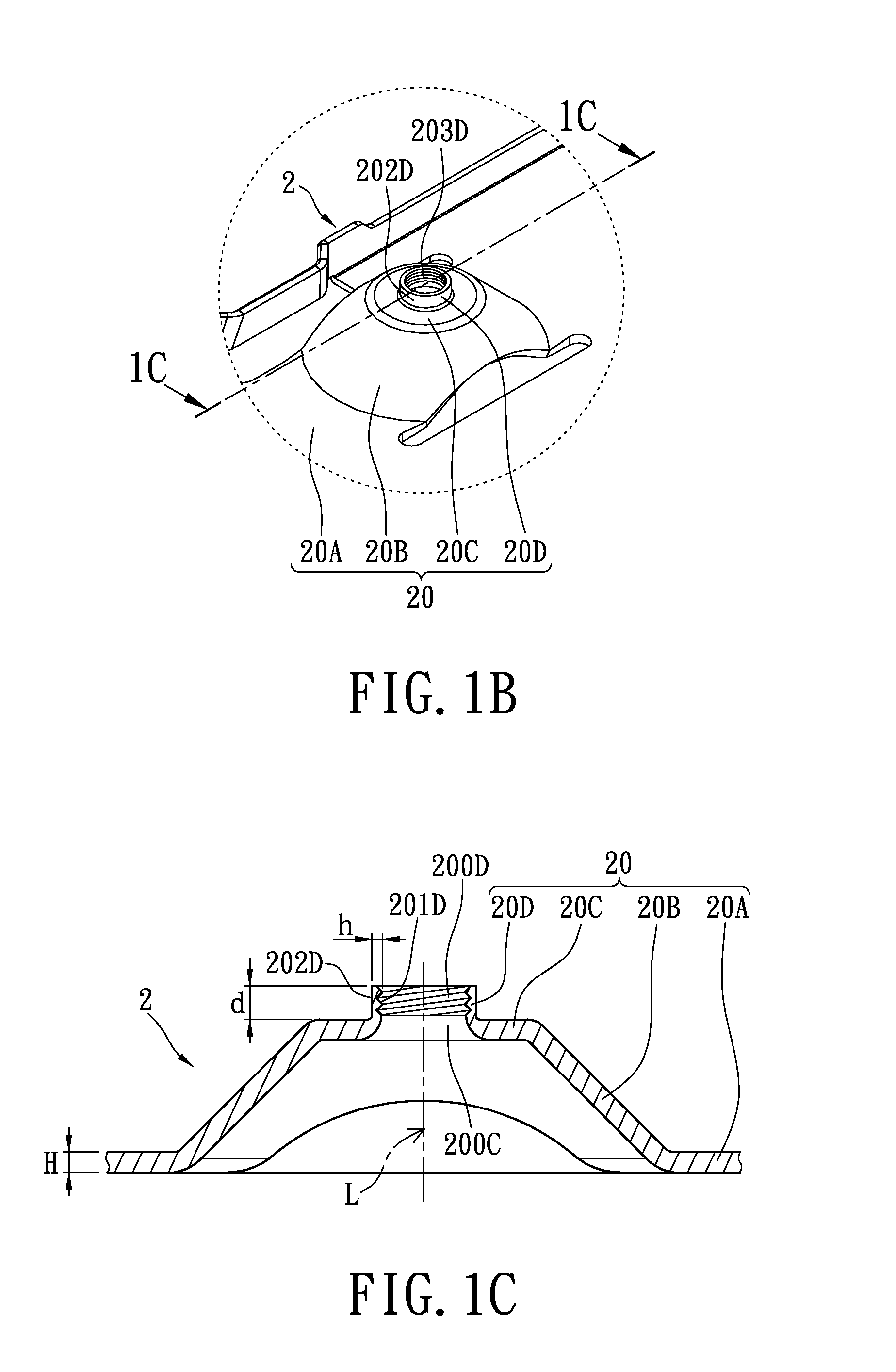

Positioning structure, positioning securing structure and electronic device

InactiveUS8937814B2Precise positioning and fixingDigital data processing detailsNutsEngineeringHollow cylinder

Owner:LITE ON TECH CORP +1

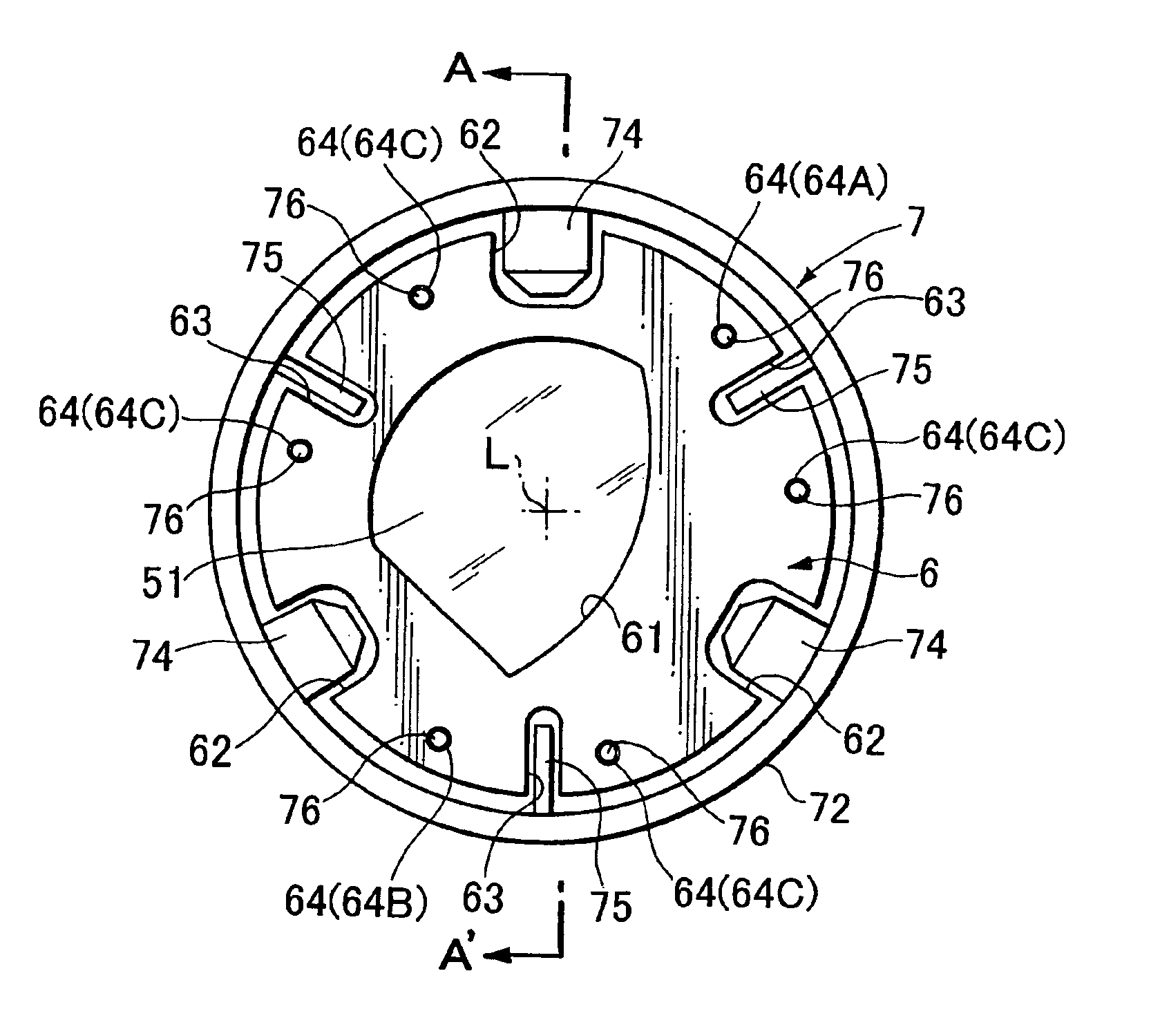

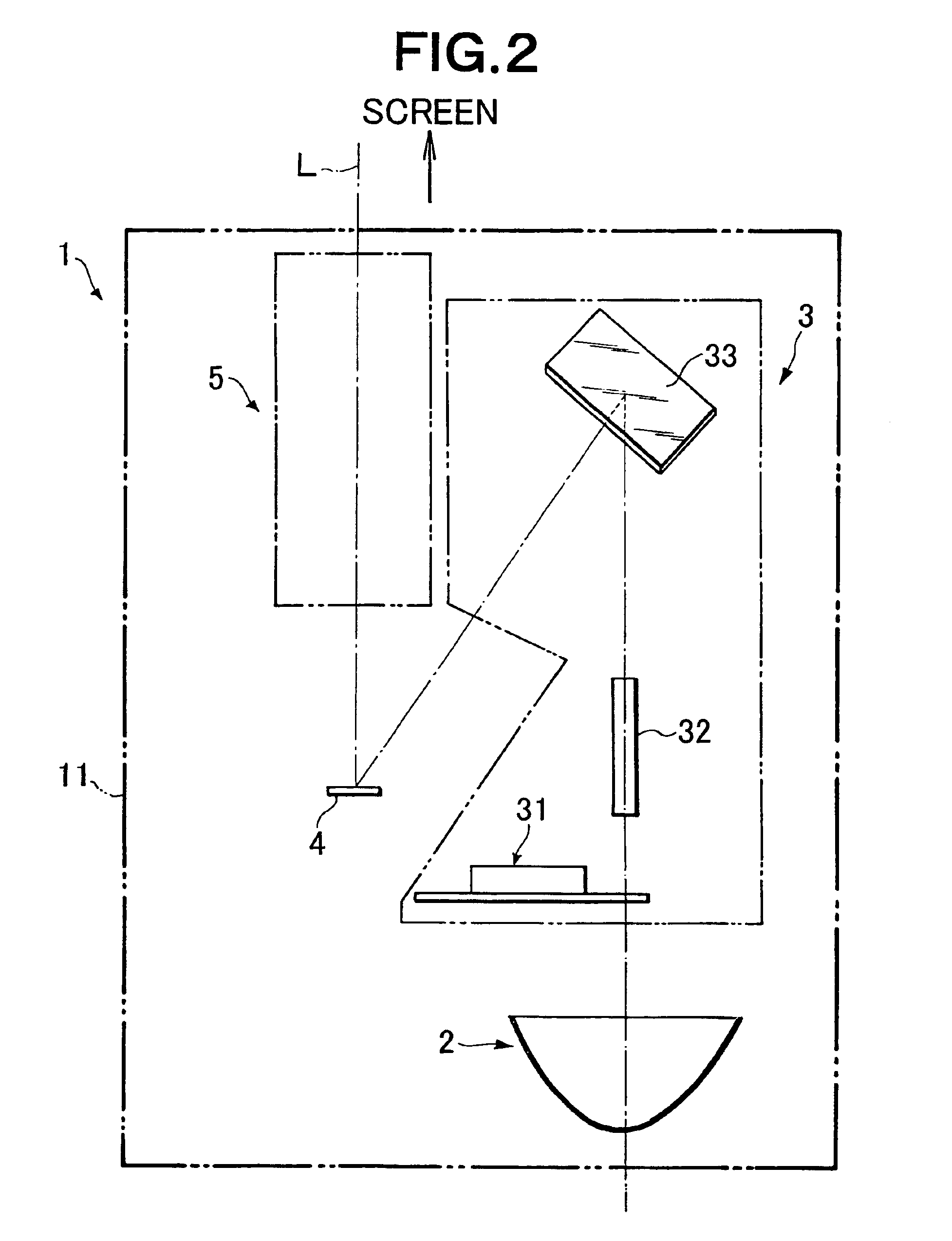

Asymmetric aperture diaphragm placing structure for projection lens and projection type image display apparatus using the same

InactiveUS6942349B2Precise positioningPrecise positioning and fixingTelevision system detailsProjectorsOptical axisProjection lens

An asymmetric aperture diaphragm placing structure for a projection lens is provided for securing an asymmetric aperture diaphragm to a lens holder. The asymmetric aperture diaphragm includes a positioning part formed asymmetrical about the optical axis. The lens holder has a mating part adapted to engage the positioning part only in a state where the asymmetric aperture diaphragm is in a predetermined direction with respect to the optical axis. The asymmetric aperture diaphragm is secured to the lens holder in a state where the positioning part and the mating part engage each other.

Owner:FUJI PHOTO OPTICAL CO LTD

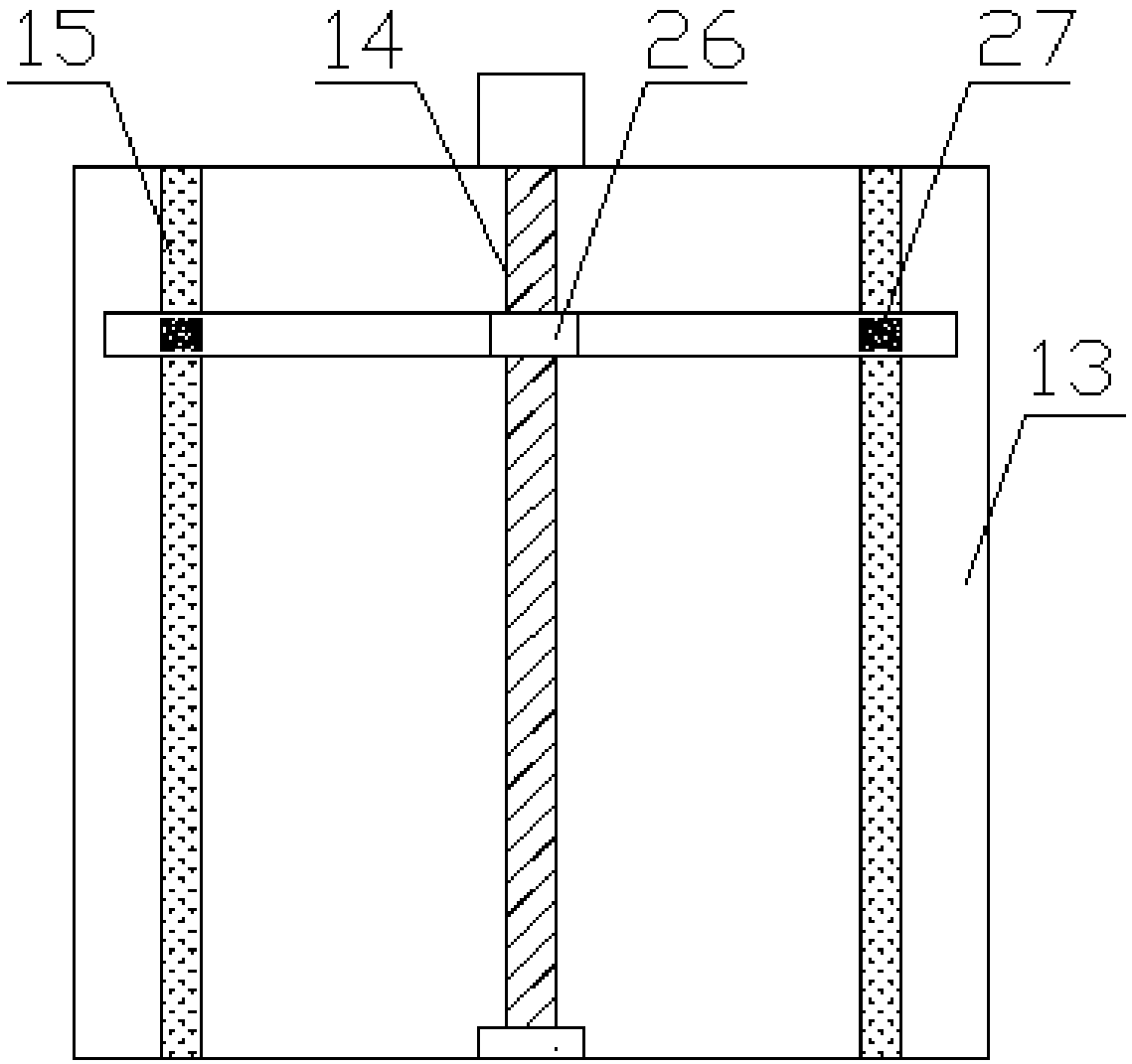

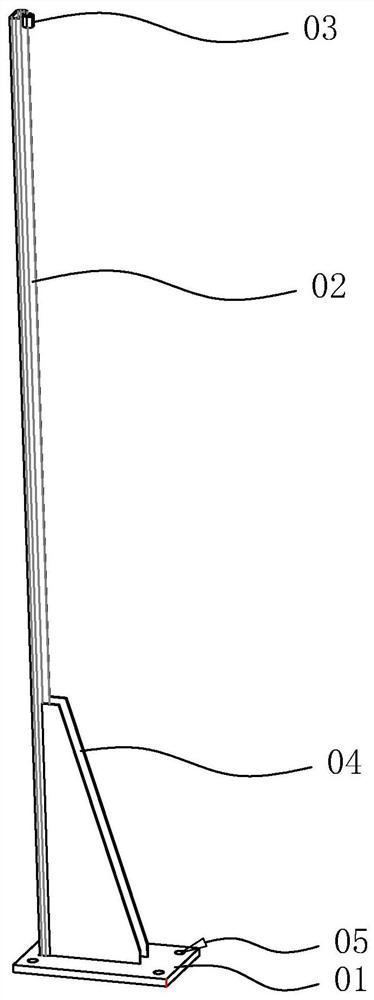

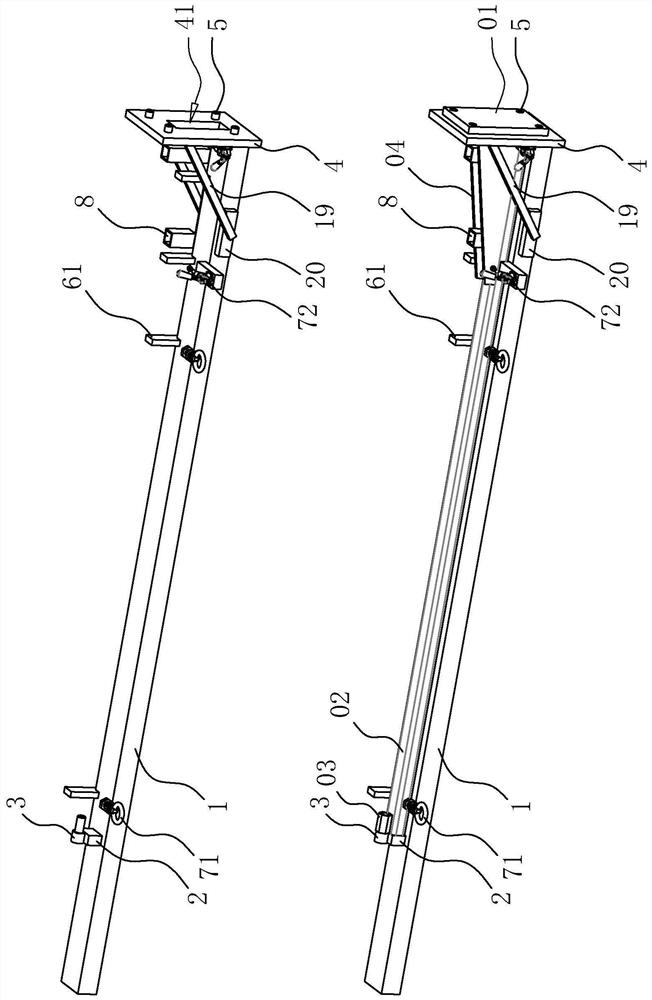

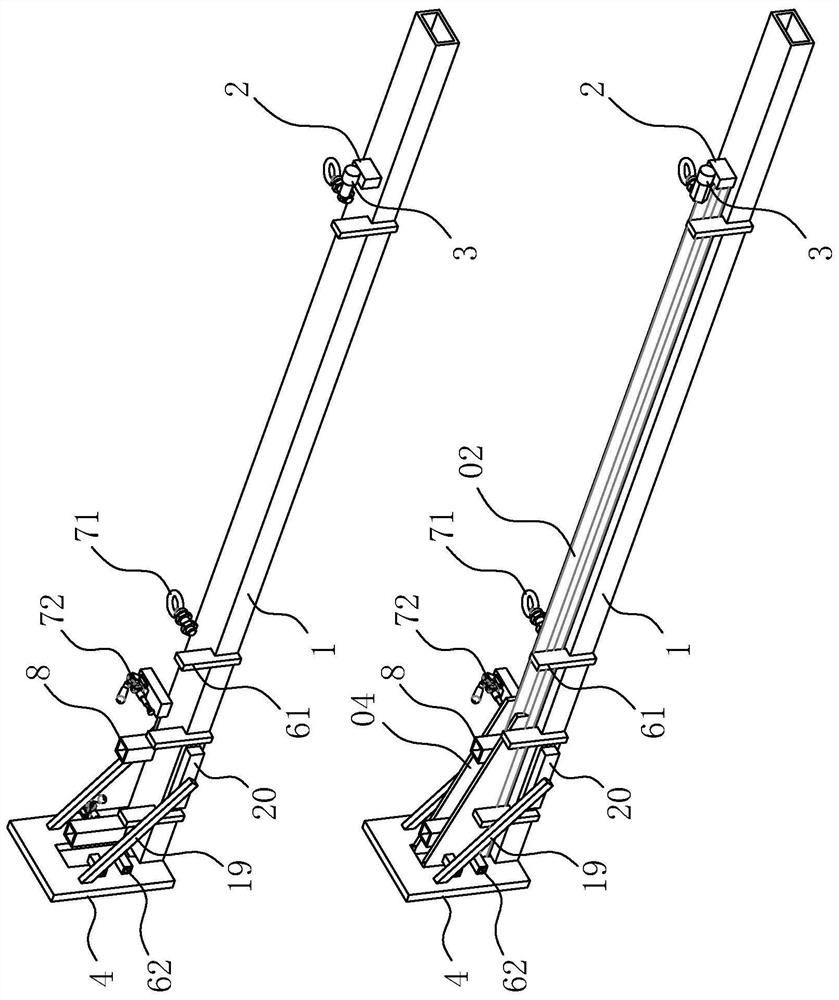

Automatic cutting robot for polystyrene foam plates for building wall thermal insulation

InactiveCN107571302AImprove work efficiencyReduce labor intensityMetal working apparatusThermal insulationPolystyrene

The invention relates to an automatic cutting robot for polystyrene foam plates for building wall thermal insulation. The automatic cutting robot comprises a support bottom plate, a lifting frame device, a cutting device, a fixing device and sucking devices, wherein the lifting frame device is mounted on the support bottom plate, the cutting device and the sucking devices are mounted on the lifting frame device, the sucking devices are uniformly distributed on the lifting frame device, and the fixing device is mounted on the support bottom plate. The automatic cutting robot can solve the problems that when the foam plates are cut at present, the foam plates cannot be located or fixed, cut foam blocks are easily clamped in cutters, some foam plates cannot be fully cut off, the cut foam blocks need to be manually collected, and the like. The automatic cutting robot has the advantages that the functions of automatically precisely fixing the foam plates and automatically locating and cutting the foam plates can be realized, the cut foam blocks cannot be clamped in the cutters, the phenomena of non-thorough cutting cannot occur when the foam plates are cut, the cut foam blocks are automatically sucked and placed, and the like.

Owner:宋当建

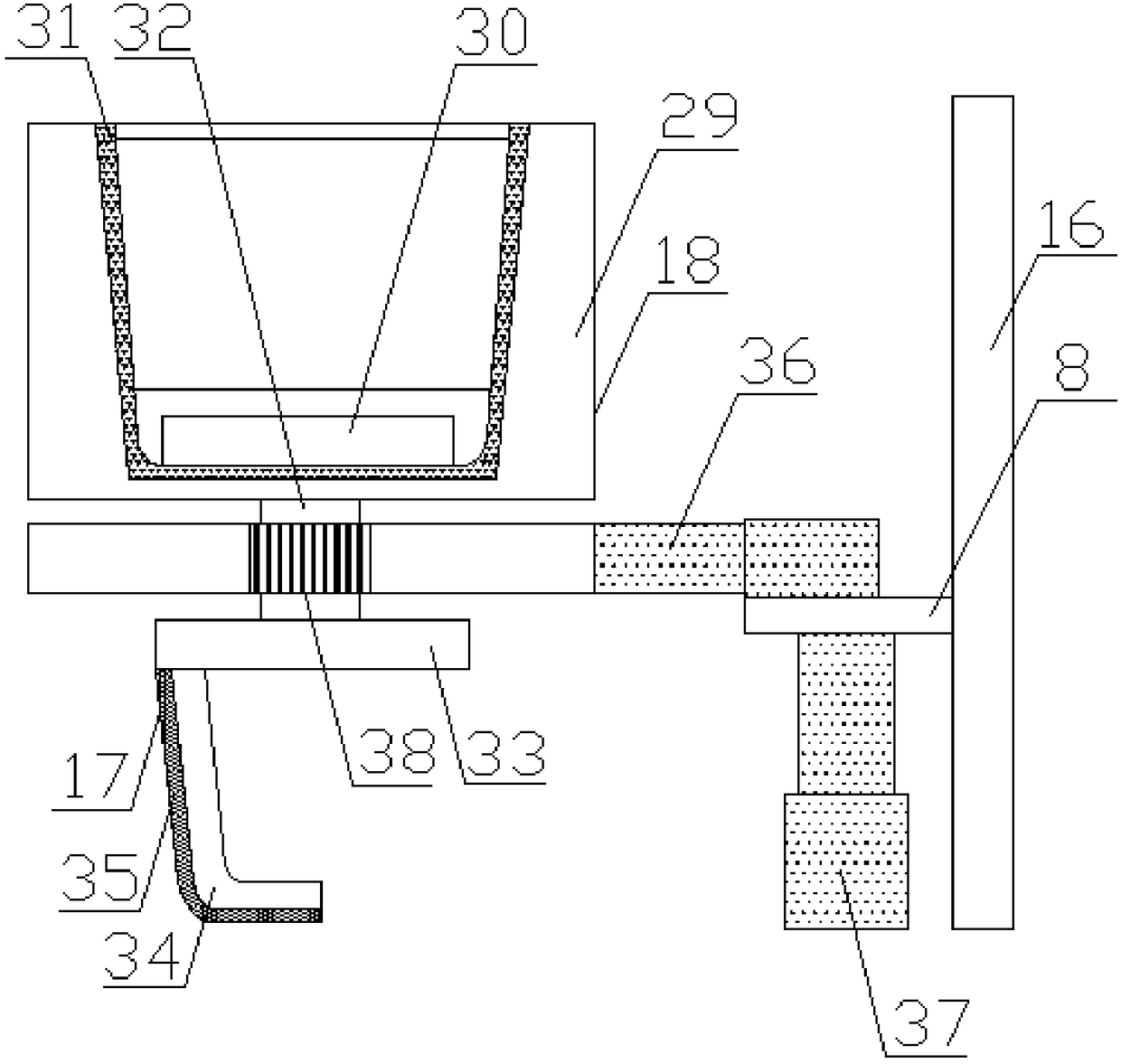

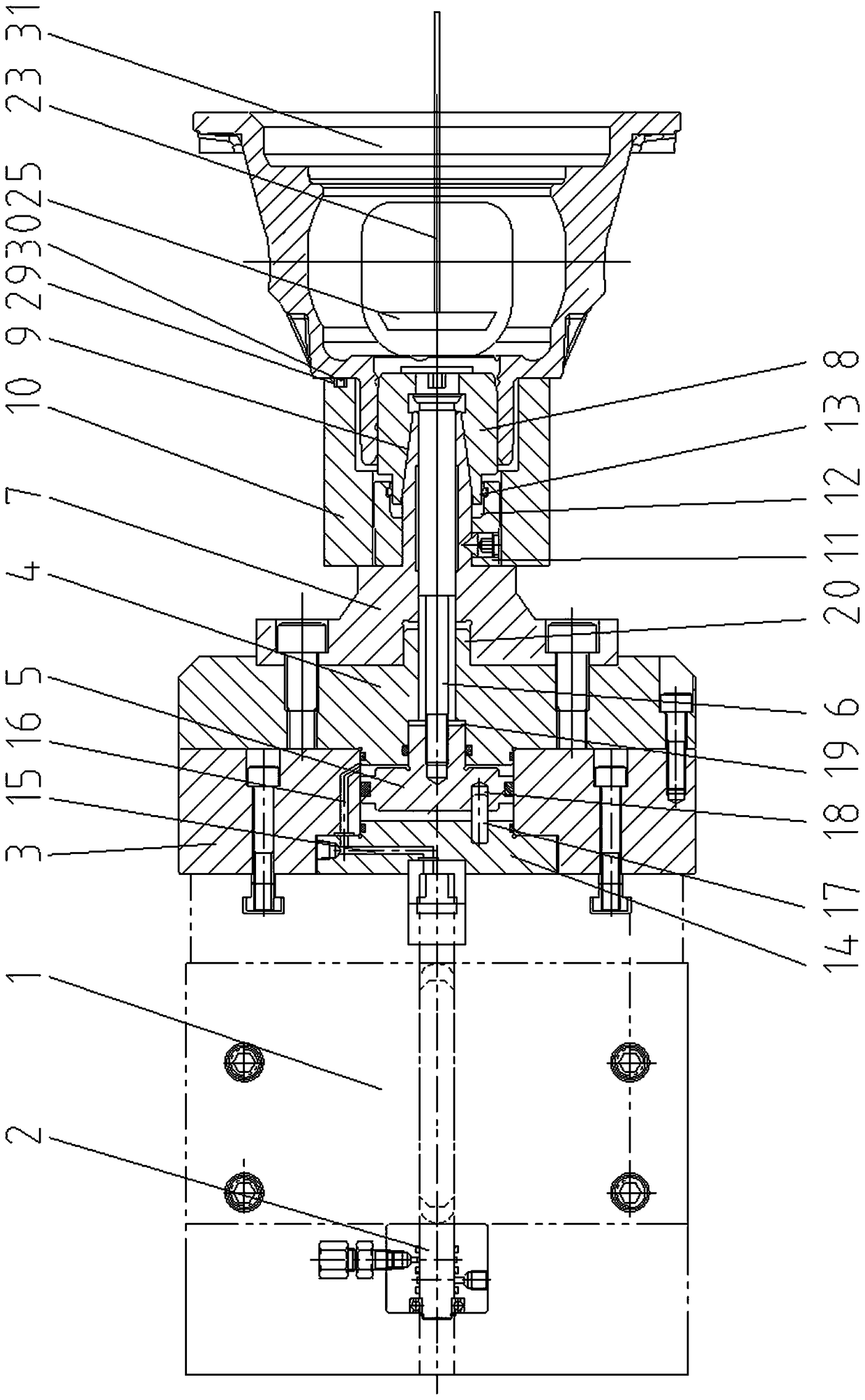

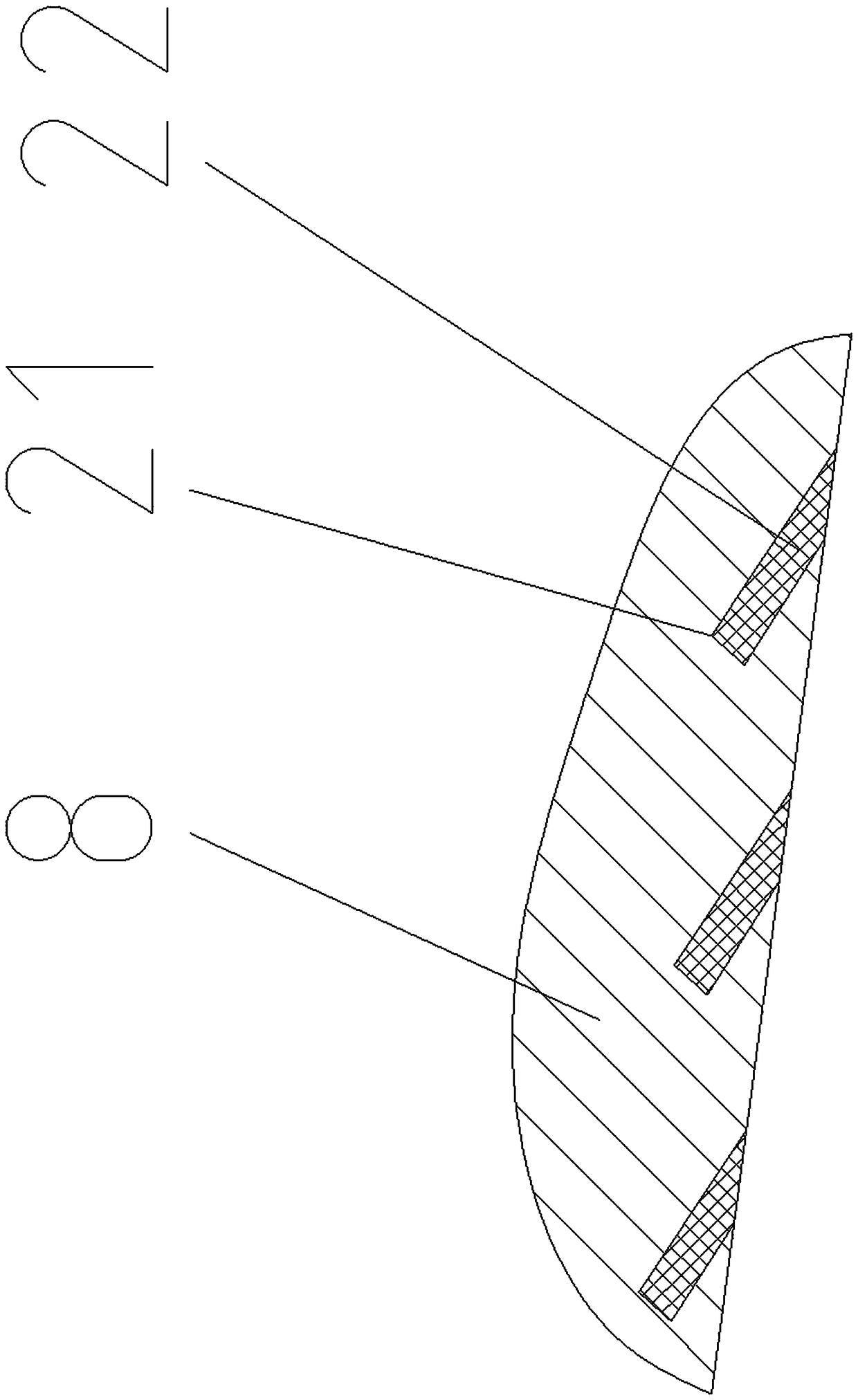

Low pressure casting machine

The invention discloses a low pressure casting machine. The low pressure casting machine comprises a worktable, wherein an insulating furnace is arranged in the worktable; a riser tube is arranged inthe insulating furnace; a calibrating block is arranged on the top of the insulating furnace and is arranged on the outer side of the riser tube; a lower mold is arranged on the top of the worktable;an upper mold is arranged on the top of the lower mold; mounting holes are formed in the four corners of the top of the upper mold; and a mold jacking plate is arranged on the top of the upper mold. Alead screw drives a bushing to move upward so as to drive a pressure plate, the upper mold, the mold jacking plate and a finished product to move upward, a roller and a slide rail are movably locked,and a lug slides in a guide rail, so that the low pressure casting machine is stable to demold and does not damage the finished product. A double-shaft motor drives a carrying barrel and a connectingrod to rotate, and the carrying barrel rotates, so that heat of the finished product is dissipated more quickly; the connecting rod drives cleaning cotton to rotate to clean a lower cavity; and the low pressure casting machine is accurate to fix the position, convenient to use and high in casting quality if being used for loading and loading a mold.

Owner:繁昌县琪鑫铸造有限公司

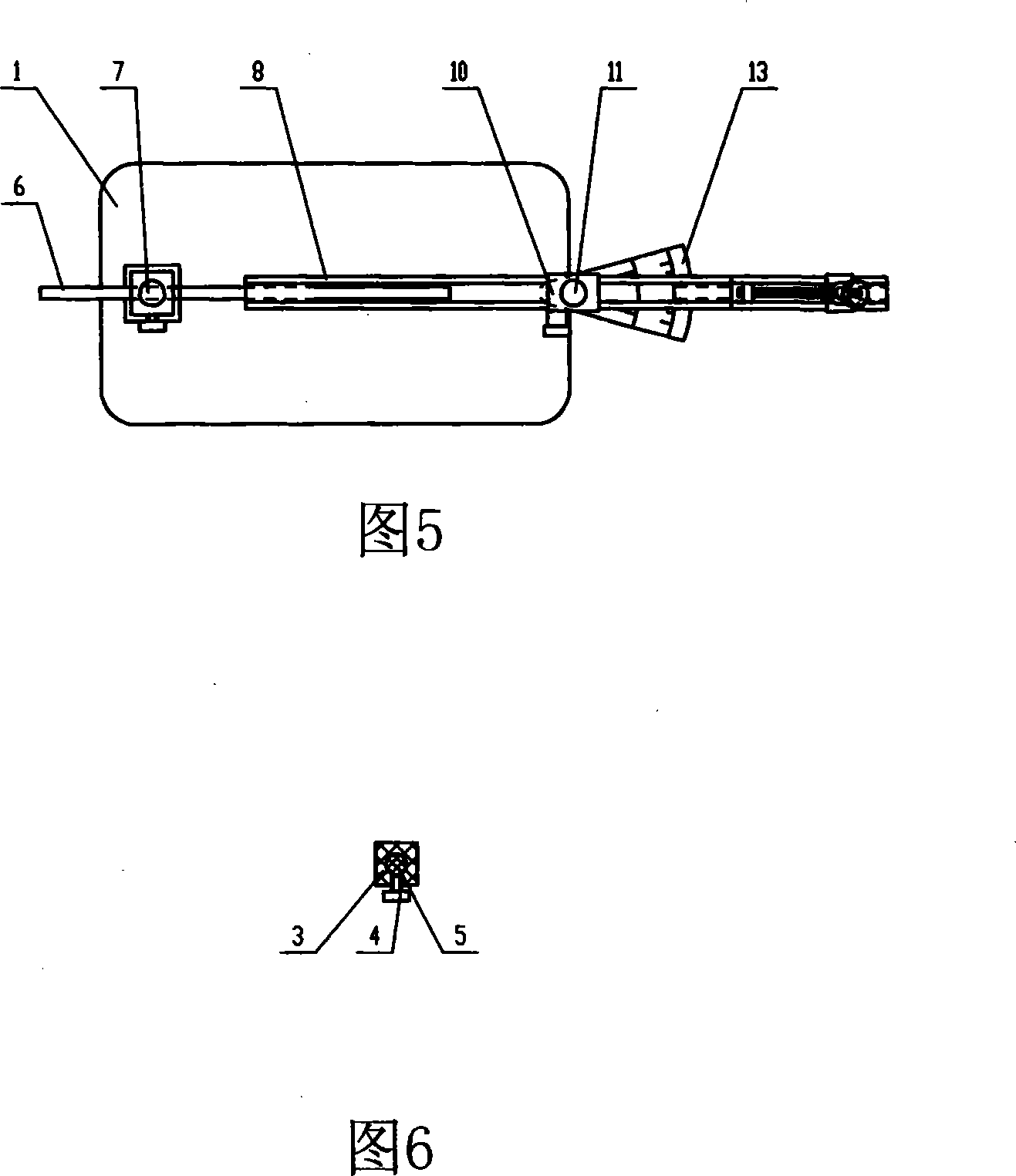

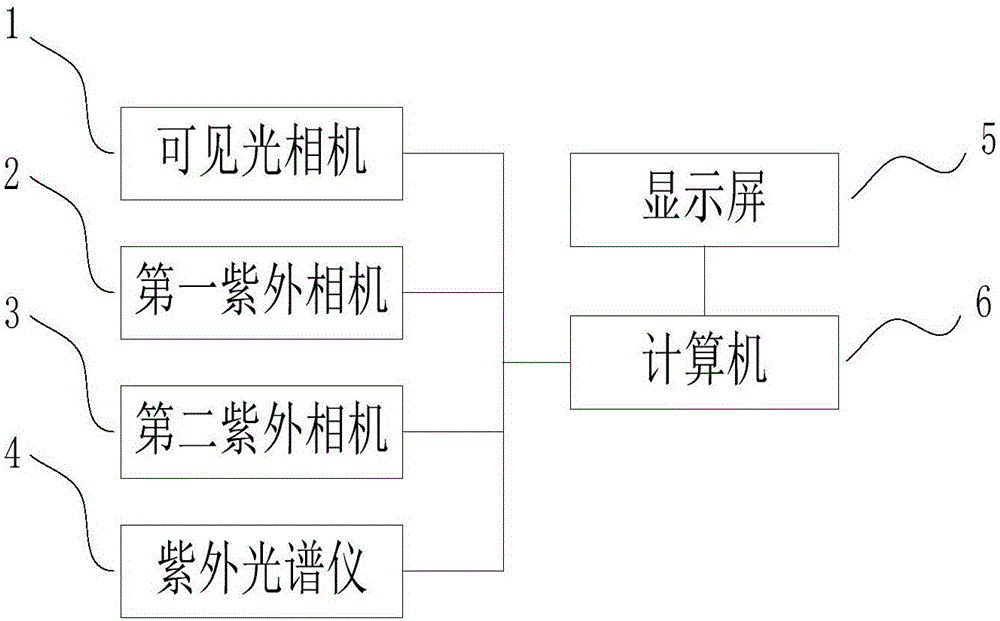

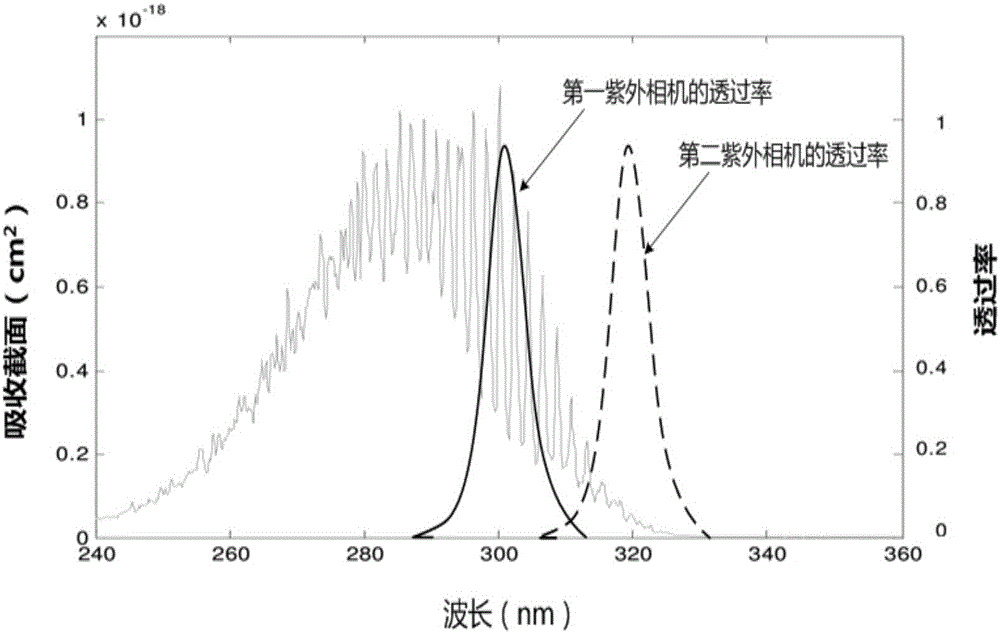

Sulfur dioxide gas imaging remote-measuring method and device

ActiveCN105044110APrecise positioning and fixingUndisturbedColor/spectral properties measurementsWater vaporSpectrograph

The invention discloses a sulfur dioxide gas imaging remote-measuring method and device. The sulfur dioxide gas imaging remote-measuring device comprises an ultraviolet-visible multi-spectrum camera, an ultraviolet spectrograph, a displayer and a computer. The sulfur dioxide gas imaging remote-measuring method comprises the following steps: imaging a target area by using the ultraviolet-visible multispectral camera, performing the continuous spectrum acquisition on a view field central area by using the ultraviolet spectrograph, processing the collected images and spectrum data by using the computer, and displaying the processing result on a display screen in a real-time manner. According to the device, the ultraviolet-visible multi-spectrum imaging and the ultraviolet differential absorption spectrum detection are combined to realize the visible dynamic sulfur dioxide gas emission remote measurement, and the positions and concentration distribution of sulfur dioxide smoke plume discharged by stationary pollution sources can be accurately determined; in addition, through the adoption of the ultraviolet detection method, the interference from water-vapor is avoided, and the cost is relatively low.

Owner:青岛中科智富光电科技有限公司

Modular building construction system

ActiveUS9670669B2Precise positioning and fixingPrevent and reduce incidenceCovering/liningsWallsModularityEngineering

Owner:DIRTT ENVIRONMENTAL SOLUTIONS

Ink color-separation device used for printing and using method thereof

InactiveCN101259781AOvercoming Mobile's Technical ShortcomingsPrecise positioning and fixingPrinting press partsEngineeringFastener

The invention relates to a color-separating device for printing, which comprises a fastener-type ink separating plate, an arc guard sheet, a fixing-connecting mechanism and a mounting-positioning mechanism; wherein, the arc guard plate is connected with the fastener-type ink separating plate through the fixing-connecting mechanism and the mounting-positioning mechanism is used for arranging the fastener-type ink separating plate at the proper position on the bottom plate of an ink groove.

Owner:SHENZHEN XINHUAYI PRINTING

Rear box board riveting device of dishwasher box

The invention relates to the technical field of dishwasher box machining, in particular to a rear box board riveting device of a dishwasher box. The rear box board riveting device comprises a base. A jacking air cylinder is mounted in the middle of the base. A support seat is mounted on the piston rod of the jacking air cylinder. Positioning plates are respectively mounted at two ends of the support seat. Outer positioning blocks are respectively mounted on two sides of the outer end of each positioning plate. Inner positioning blocks matched with the outer positioning blocks are respectively mounted on two sides of the inner end of each positioning plate. A positioning air cylinder is mounted on each inner positioning block. Slidable riveting moving seats are respectively symmetrically mounted on the base parts on two sides on the support seat. The cylinder block of a transverse drive air cylinder is fixed on the base. Slidable riveting seats are symmetrically mounted on the riveting moving seats. The piston rod of a longitudinal drive air cylinder is connected with the riveting seats. A sucker rack is mounted on each riveting moving seat between the two corresponding riveting seats, and a rear box board sucker is mounted on the sucker rack. By the rear box board riveting device, positioning and fixing of the dishwasher box can be achieved conveniently and accurately, two ends of the rear box board of the dishwasher box can be riveted at the same time, and riveting efficiency is increased.

Owner:WUXI AMTEX AUTOMATION TECH

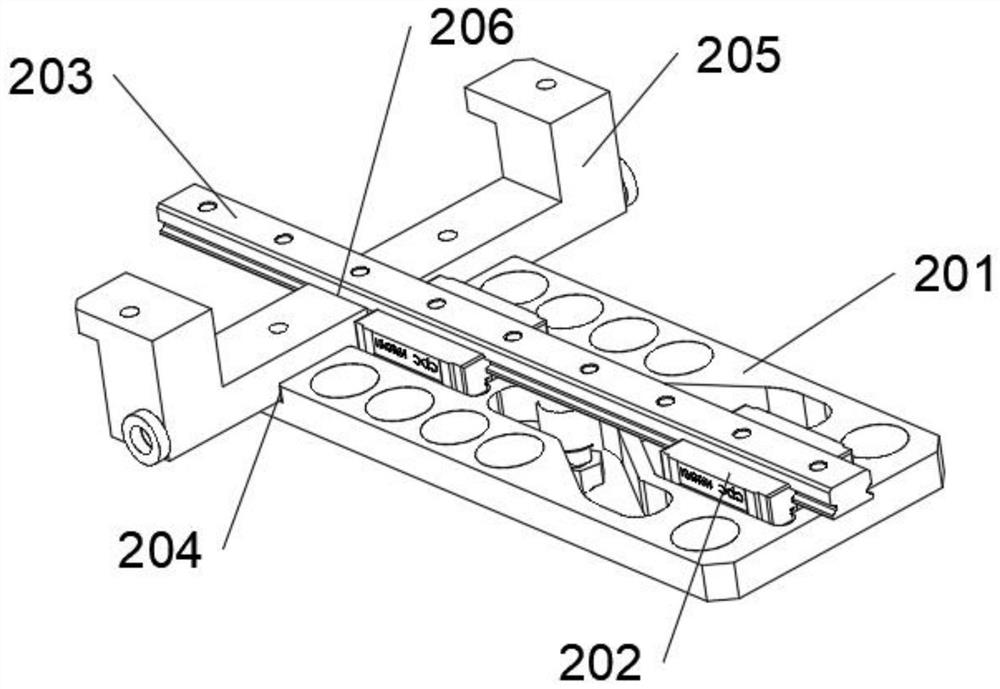

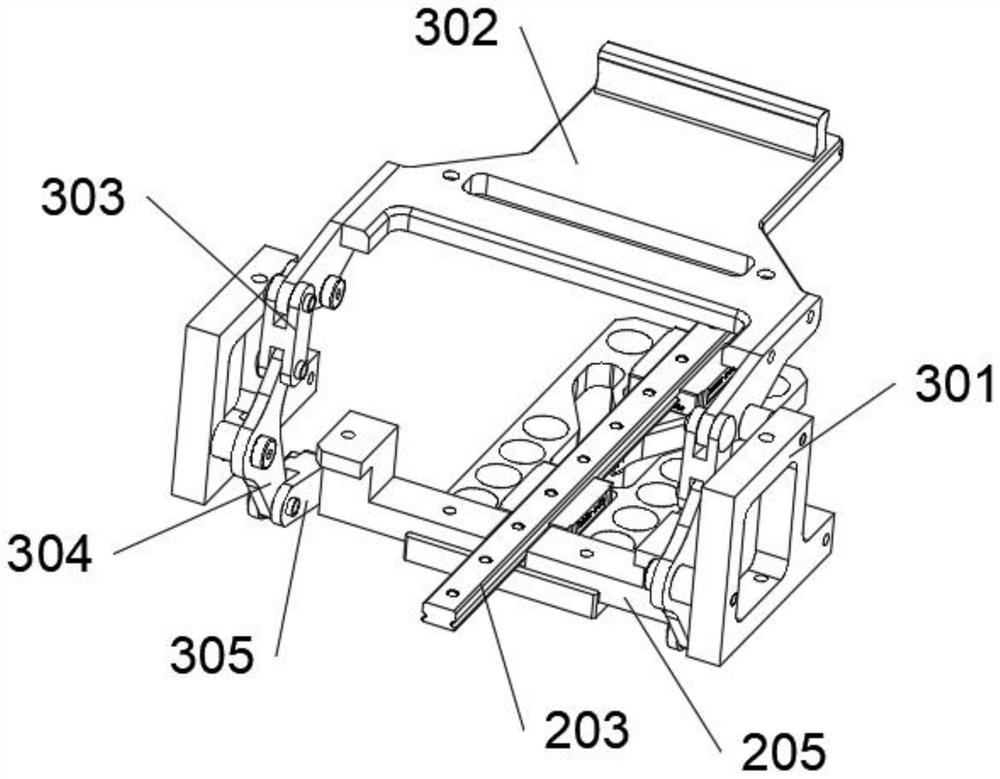

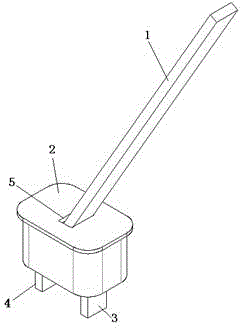

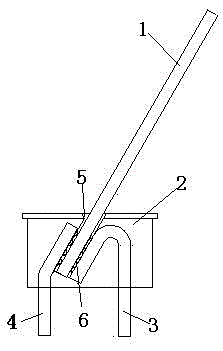

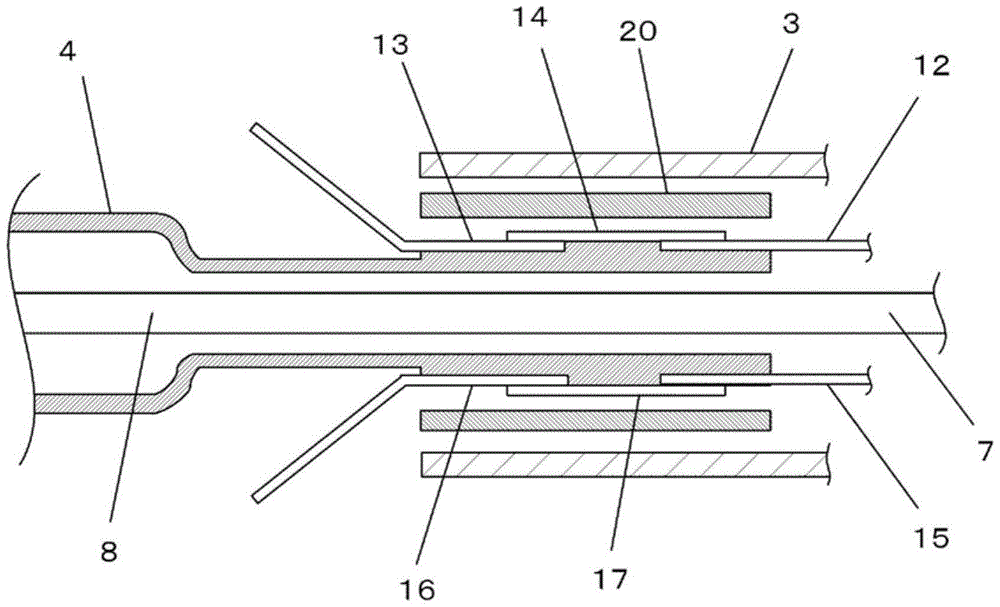

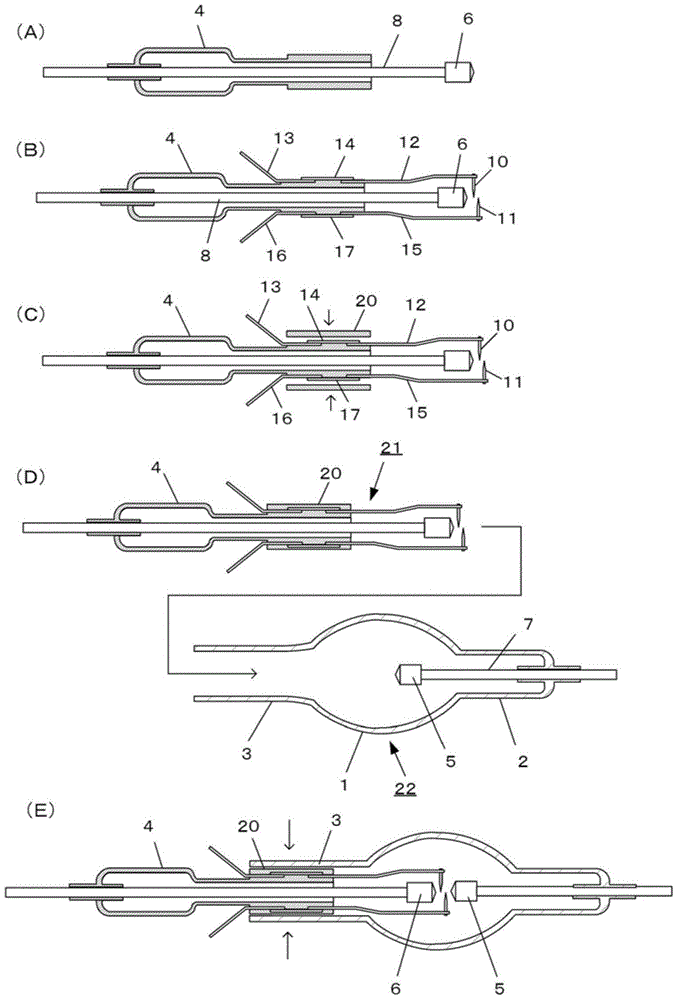

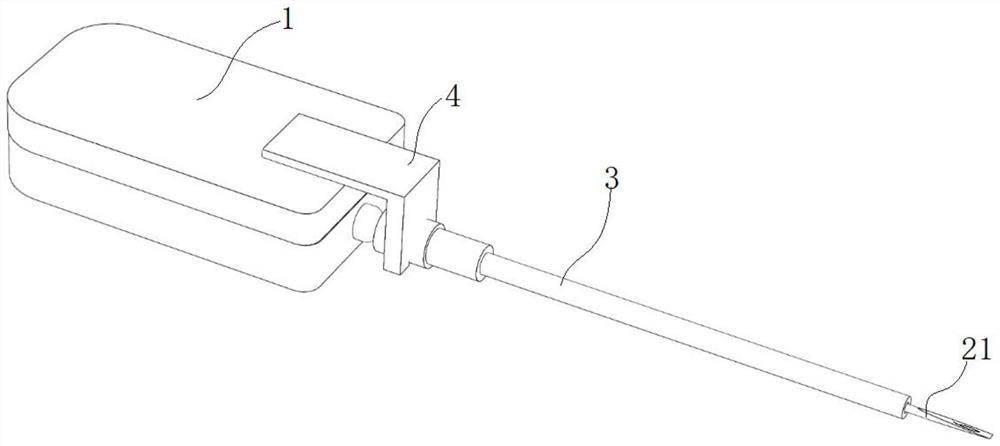

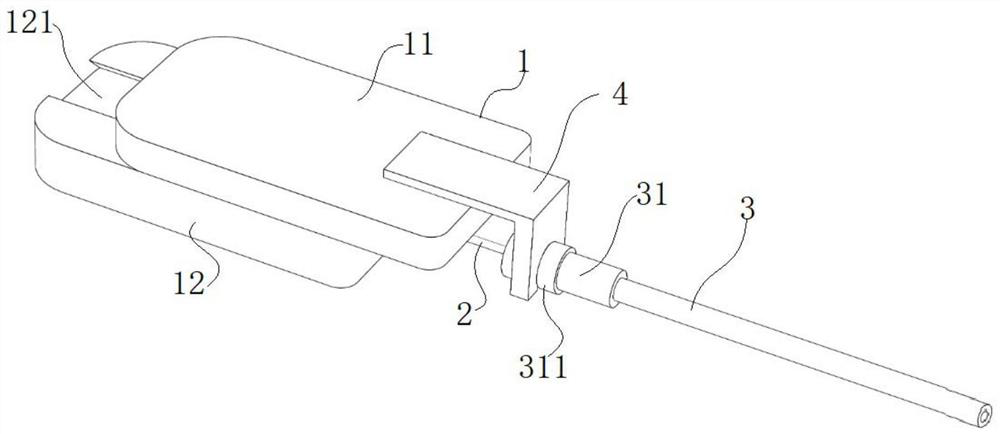

Ink box chip upgrading tool

ActiveCN113071221AEasy to insertRealize linkage effectPrintingStructural engineeringElectrical and Electronics engineering

The invention relates to the technical field of tools, in particular to an ink box chip upgrading tool which comprises a base, signal transmission connectors are installed on the side face of the base at equal intervals, a base plate is arranged in the base and located above the bottom face in parallel, and a sliding assembly is arranged in the base and located below the base plate. Linkage assemblies are symmetrically arranged on the two sides of the upper portion of the base plate, the linkage assemblies are matched with the sliding assembly in structure, a plugging assembly is arranged between the linkage assemblies, an elastic pressing assembly is arranged at the position, located on one side of the plugging assembly, in the linkage assemblies, and a clamping assembly is arranged at the position, located below the elastic pressing assembly, in the base. According to the ink box chip upgrading tool, through a pressing contact assembly, the device can conveniently send out a signal indicating that the whole tool is assembled to the outside, and through combination with the plugging assembly in the tool, an external signal can be stably and effectively guided into the ink box through a chip module and is upgraded, so that the rejection rate of a chip is greatly reduced, the repeated utilization rate of the chip is increased, and processing resources and cost are saved to a certain extent.

Owner:ZHUHAI CHUANGFEI AUTOMATION CO LTD

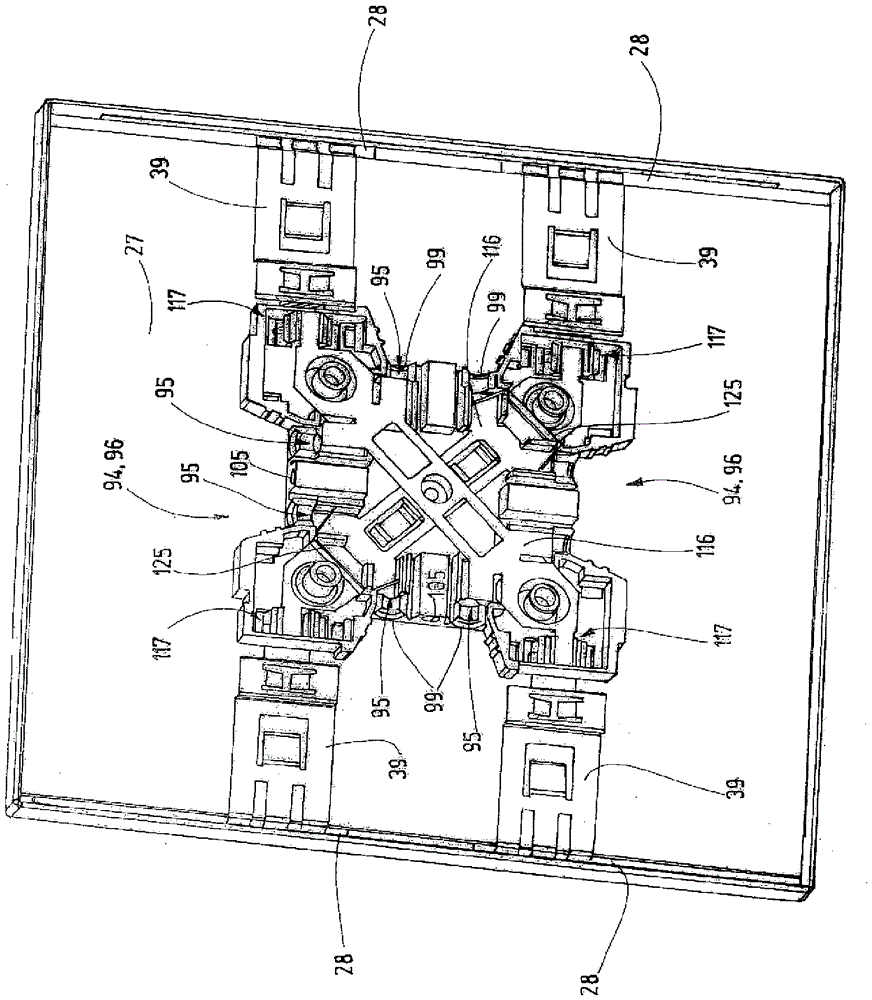

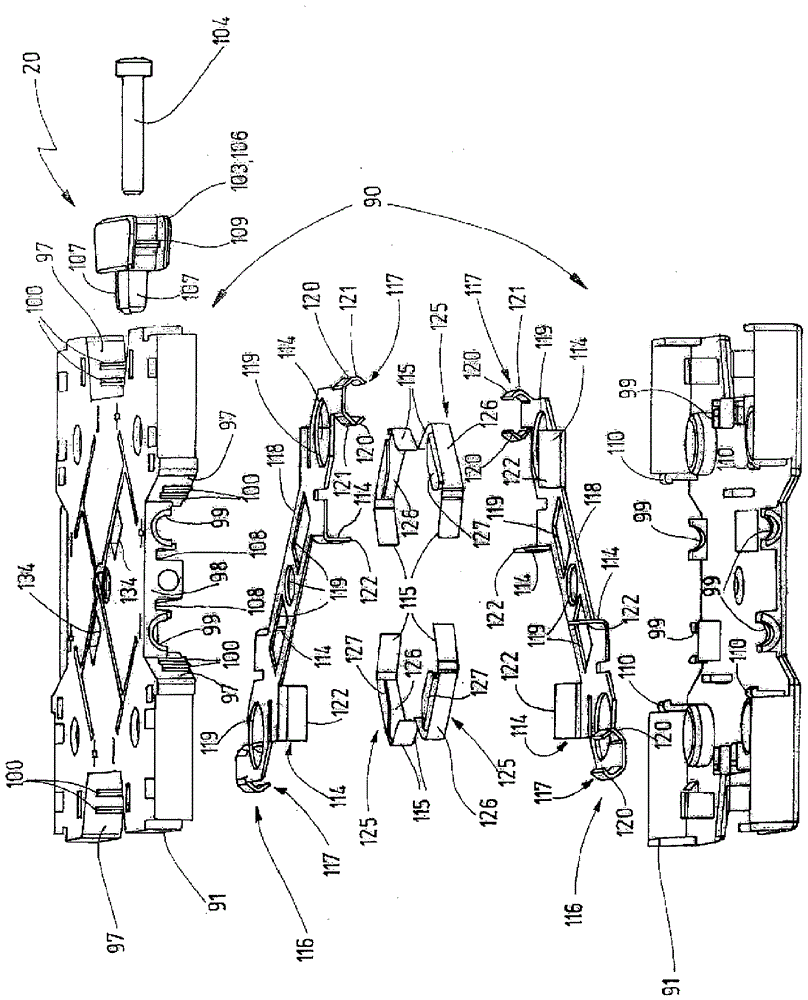

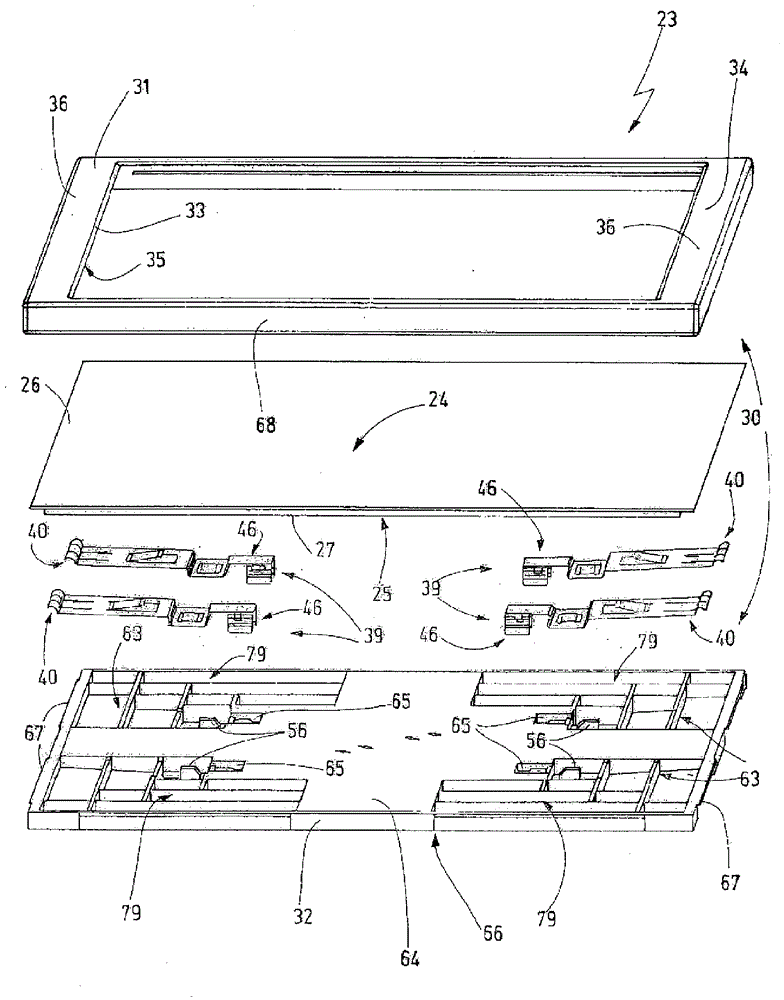

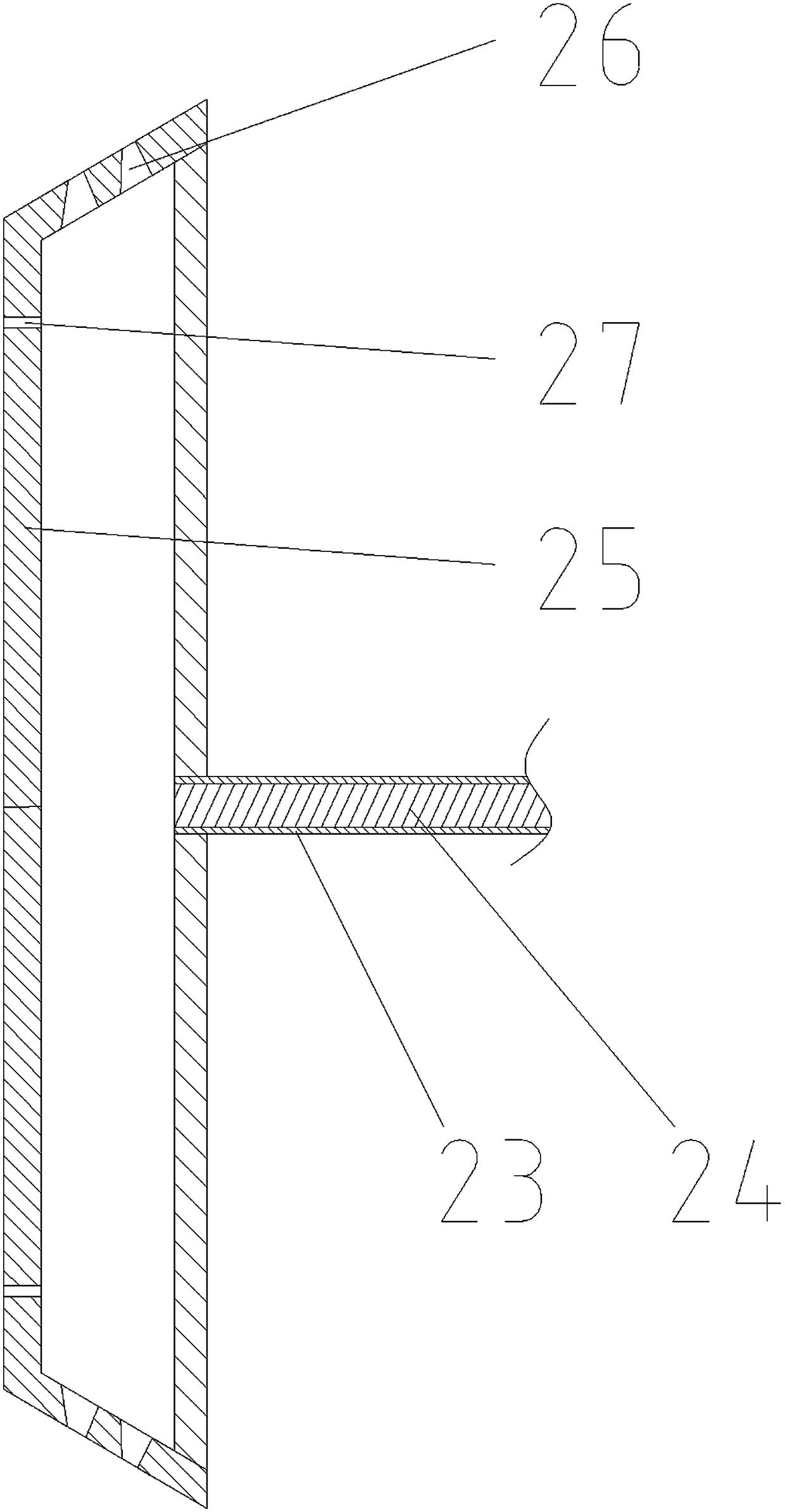

oled illuminants for lamps

InactiveCN103415740BPrecise positioning and fixingSimplifies electrical wiringPlanar light sourcesLighting support devicesElectrical connectionSemiconductor

The invention relates to a luminaire (23) and a lamp holder (20) for a lamp (15). The features of the lamp holder ( 20 ) can also be implemented independently of the features of the light ( 23 ). The illuminant ( 23 ) has a preferably planar luminous surface ( 24 ). One or more semiconductor light emitting elements are arranged in the light housing (30). The illuminant connection ( 70 ) required for the mechanical and electrical connection to the lampholder ( 20 ) is arranged on the rear side ( 66 ) of the illuminant ( 23 ) opposite the luminous area ( 24 ). The dimensions of the illuminant ( 23 ) are preferably larger than the dimensions of the lampholder ( 20 ), so that the illuminant ( 23 ) completely covers the lampholder ( 20 ) when viewed in a direction perpendicular to the luminous surface ( 24 ) of the illuminant. A particularly aesthetically pleasing impression can thereby be achieved. A large total luminous area of the luminaire ( 15 ) with an aesthetically pleasing overall image can be realized particularly easily in a modular manner by means of the lampholder ( 20 ) and the illuminant ( 23 ).

Owner:PANASONIC CORP +2

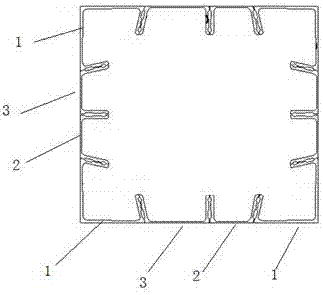

Smoke flue template mold

InactiveCN107100362AEasy to install and disassembleQuick installation and removalForms/shuttering/falseworksEngineeringPosition fixing

The invention discloses a smoke flue template mold. The smoke flue template mold comprises four corner templates. The two sides of each corner template are connected with a left template body and a right template body correspondingly, and the adjacent left template bodies and right template bodies are sequentially connected to be of a quadrangular structure; and the corner templates, the left template bodies and the right template bodies are each provided with a bent connecting part, and the connecting parts of adjacent components are connected through bolts. Installation and dismantling are easy, quick, light and convenient, position fixing is accurate, reusing is achieved, the left template bodies and right template bodies can be used in a refitting mode in other projects, and cost of the templates in smoke flues of kitchens and bathrooms is remarkably reduced.

Owner:CHINA MCC5 GROUP CORP

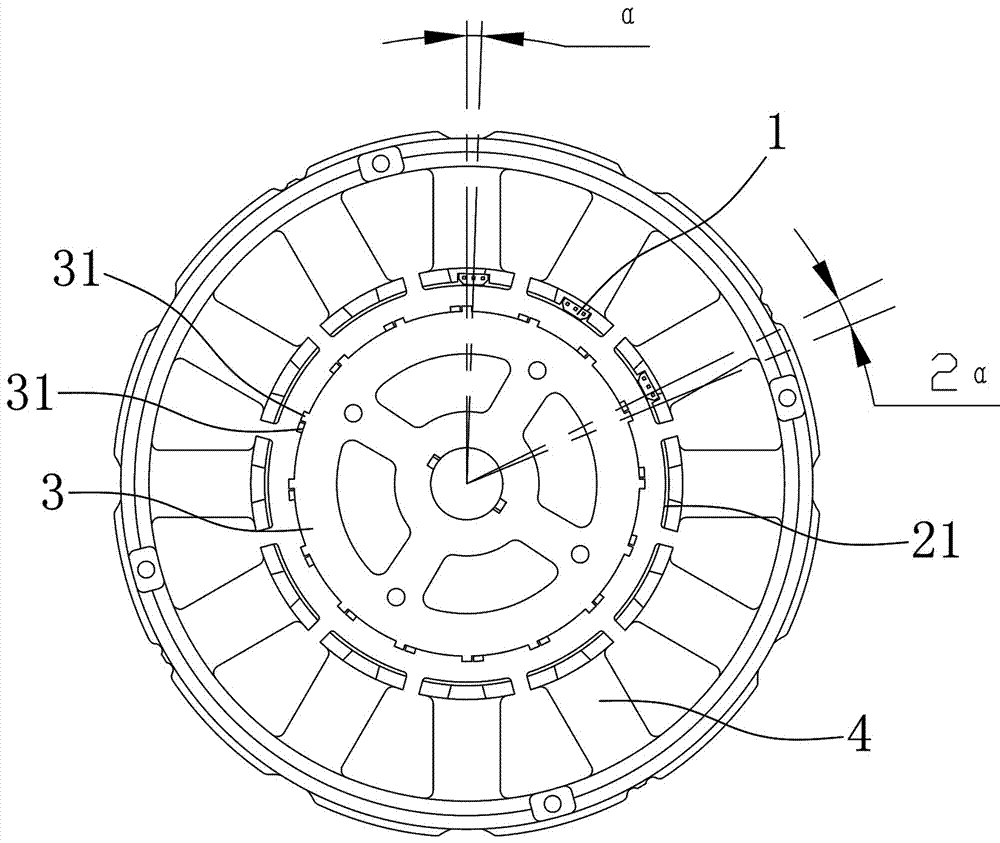

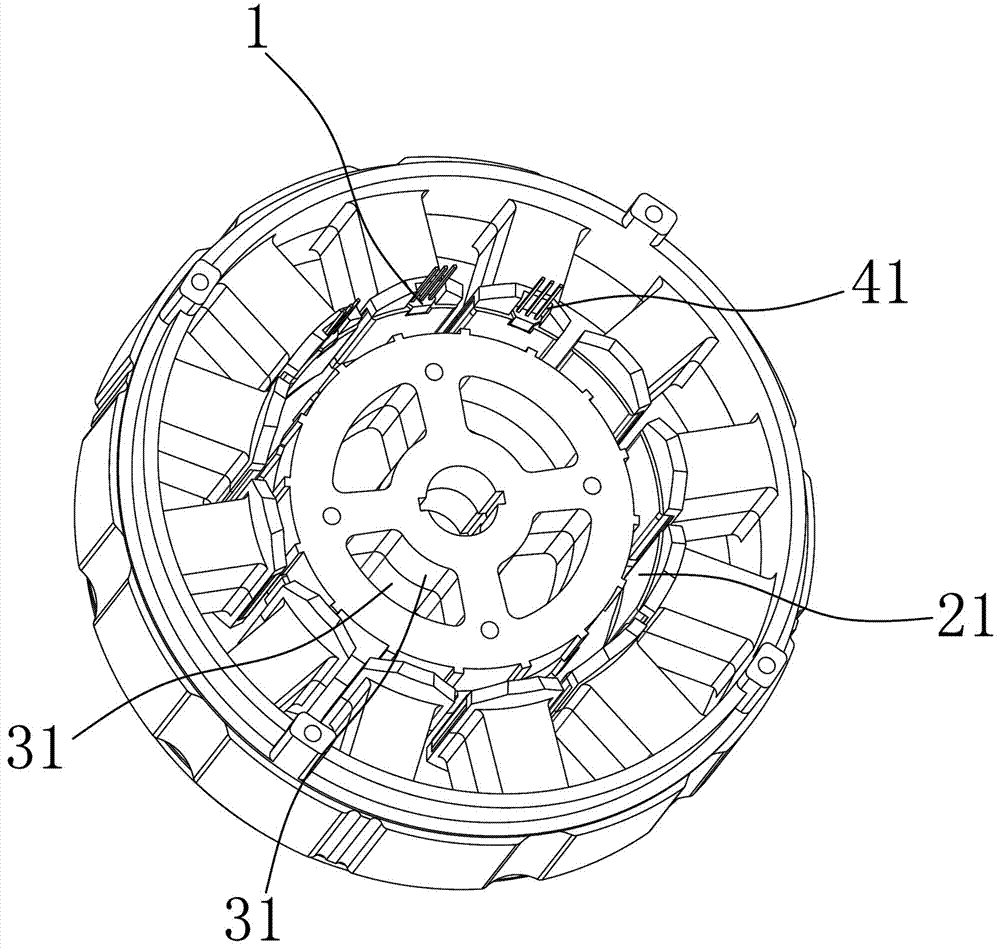

Oblique pole type motor Hall installation structure

PendingCN107979240APrecise positioning and fixingImprove motion stabilityStructural associationEngineeringL-shell

The invention aims to provide an oblique pole type motor Hall installation structure which can be used for achieving a built-in Hall and more accurate installation position of the Hall and reducing unbalancing quantity. In order to achieve the purpose, the oblique pole type motor Hall installation structure employs the following technical scheme that the Hall is fixed on a stator, a rotor is arranged in the stator and comprises multiple segments of single rotors, adjacent single rotors deviate relative to each other, an accommodating groove is formed in an inner edge of a tooth part of the stator and is used for accommodating the Hall, a Hall shell of the Hall is arranged in the accommodating groove, a Hall pin of the Hall extends along a parallel line of a rotor shaft, and a center of theaccommodating groove deviates from the center of the tooth part of the stator wherein the accommodating groove is located.

Owner:HENGDIAN GRP INNUOVO ELECTRIC

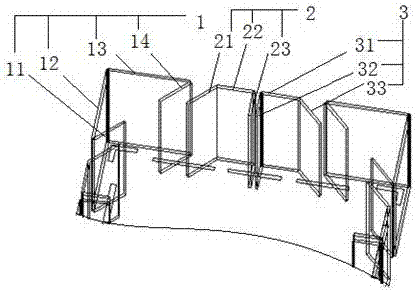

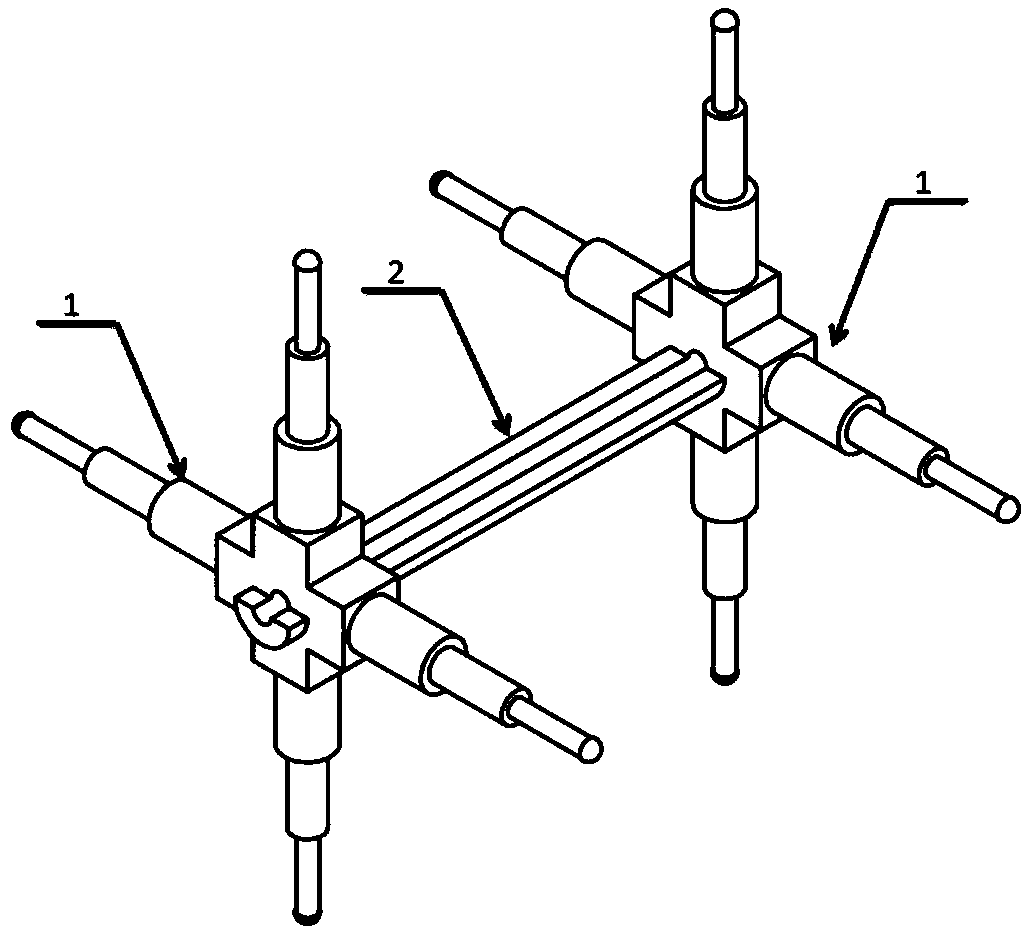

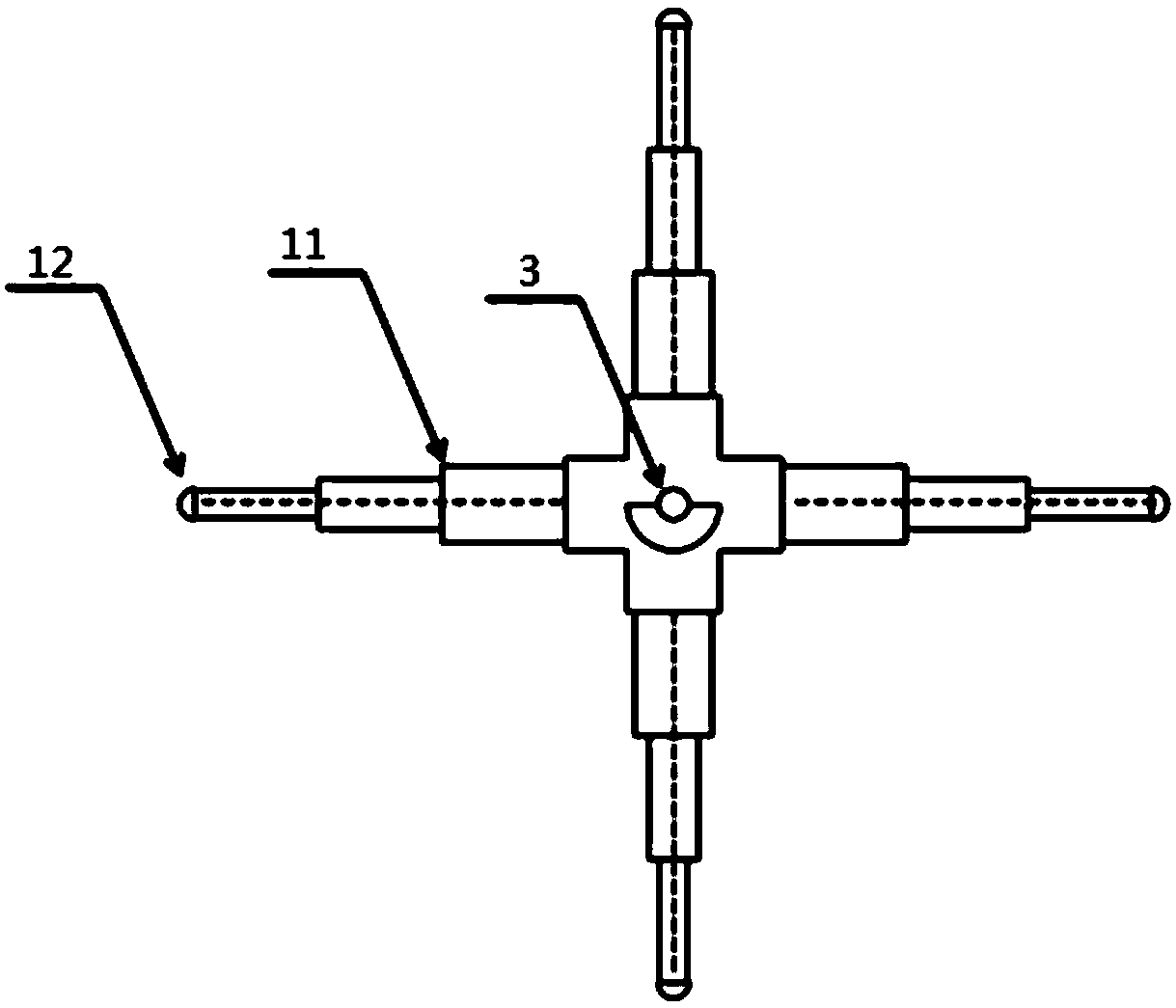

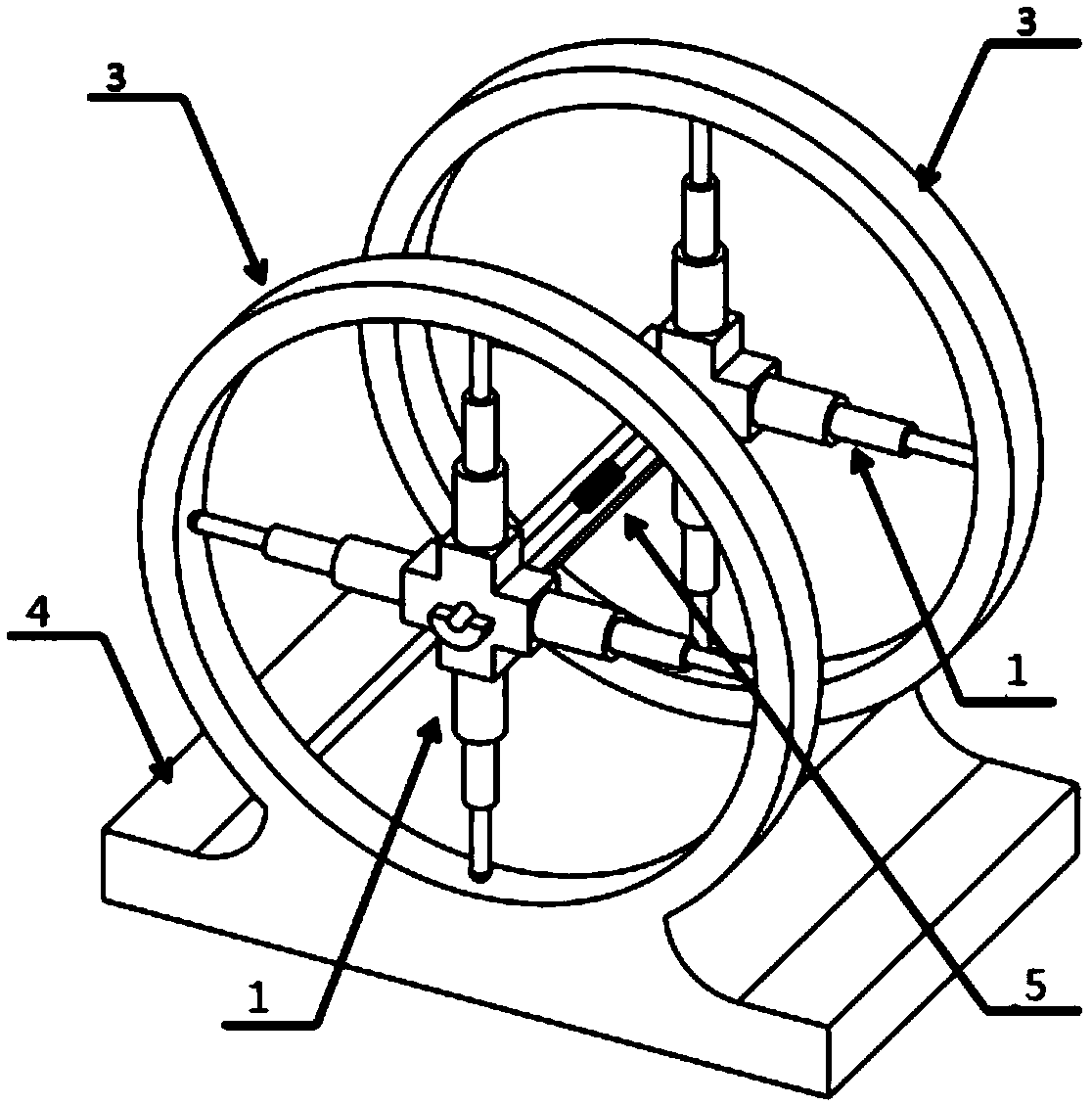

Test piece fixture for Helmholtz coil testing

ActiveCN109596863APrecise positioning and fixingReasonable designMeasurement instrument housingHelmholtz coilHomogeneous magnetic field

The invention provides a test piece fixture for Helmholtz coil testing, which consists of a central shaft lever and two connecting rods sleeving the central shaft lever, wherein the positions of the two connecting rods on the central shaft lever are adjustable; each connecting rod is composed of a supporting block and 3 to 4 telescopic struts uniformly distributed in radial circumference on the supporting block; the telescopic struts have the same length; the connecting rods are installed in a Helmholtz coil by the acting force and the counter-acting force when the tail ends of the telescopicstruts are in contact with the inner side of the Helmholtz coil; the middle parts of the support blocks are provided with through holes for allowing the central shaft lever to pass through; a groove for containing an experimental test piece is arranged at the center of the central shaft lever; and the central shaft lever is arranged coaxial with the Helmholtz coil. The fixture can quickly and accurately locate the test piece in the uniform magnetic field area in the middle of the Helmholtz coil, and can be applied to Helmholtz coils of different sizes.

Owner:TSINGHUA UNIV +1

Socket for LED lamp filament

InactiveCN102983257AFast and accurate electrical accessPrecise positioning and fixingLighting support devicesLight fasteningsElectricityEngineering

The invention relates to a socket for an LED (light-emitting diode) lamp filament, which comprises a socket body and elastic electrode plates, wherein at least one tilted trough is formed in the socket body and internally provided with at least one elastic electrode plate. The tilted trough is internally provided with the two elastic electrode plates, namely an elastic positive electrode plate connected with positive electricity and an elastic negative electrode plate connected with negative electricity; the elastic positive electrode plate and the elastic negative electrode plate are positioned on the two sides of the tilted trough; the elastic electrode plates are wrapped with plastic which is used for fixing the elastic electrode plates; a plurality of irregular small bumps are formed on contact surfaces of the elastic electrode plates, contacted with a positive electrode and a negative electrode of the LED lamp filament and used for clamping the positive electrode and the negative electrode of the LED lamp filament; the tilted trough is square, rectangular or polygonal; and the elastic positive electrode plate and the elastic negative electrode plate are arranged in the socket body in an injection molding manner. The socket has the advantages that the lamp filament can be connected electrically quickly and accurately; a position of the lamp filament can be fixed; and an angle of the lamp filament can be controlled.

Owner:SHANGHAI DANGOO ELECTRONICS TARDING

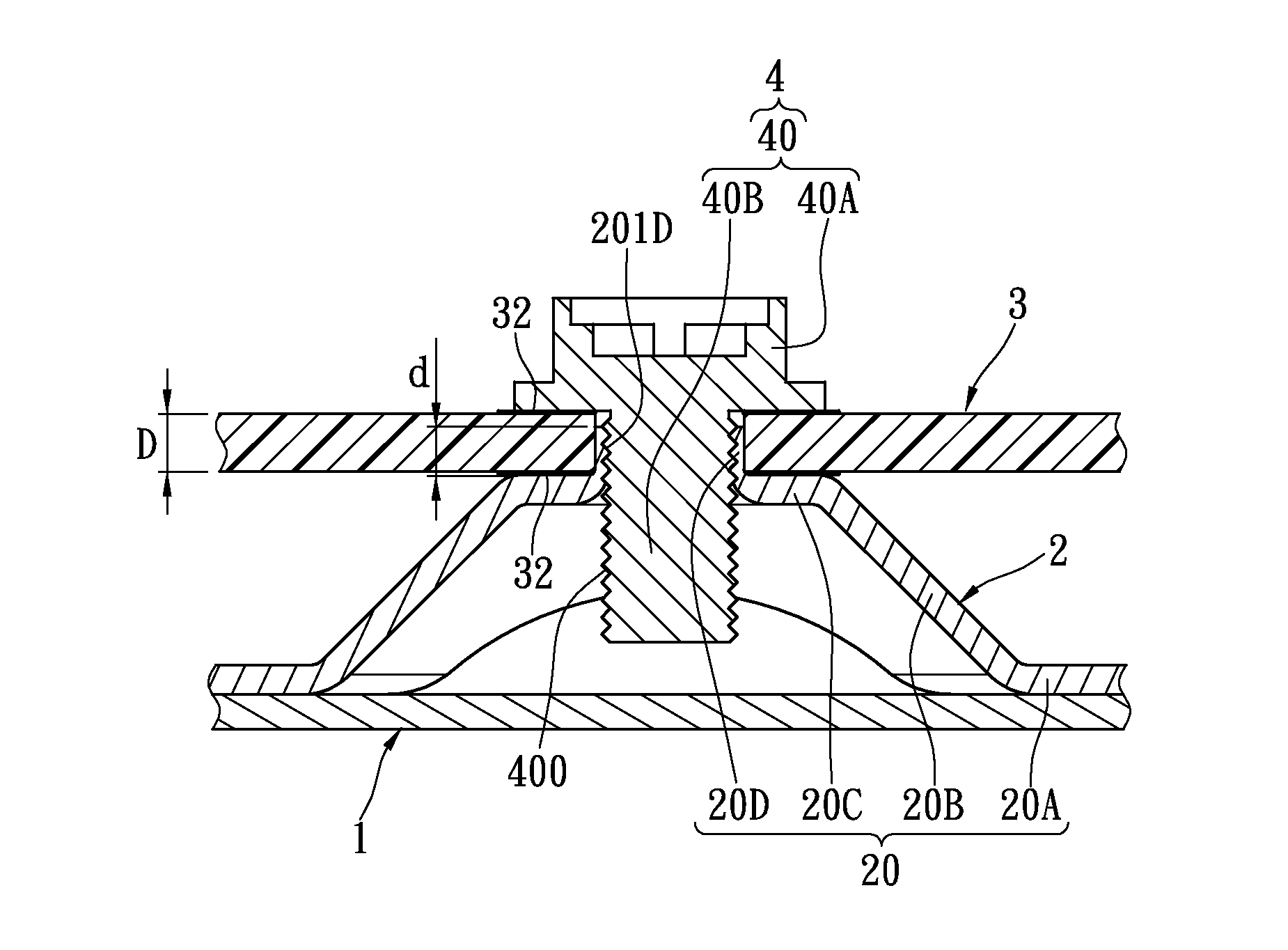

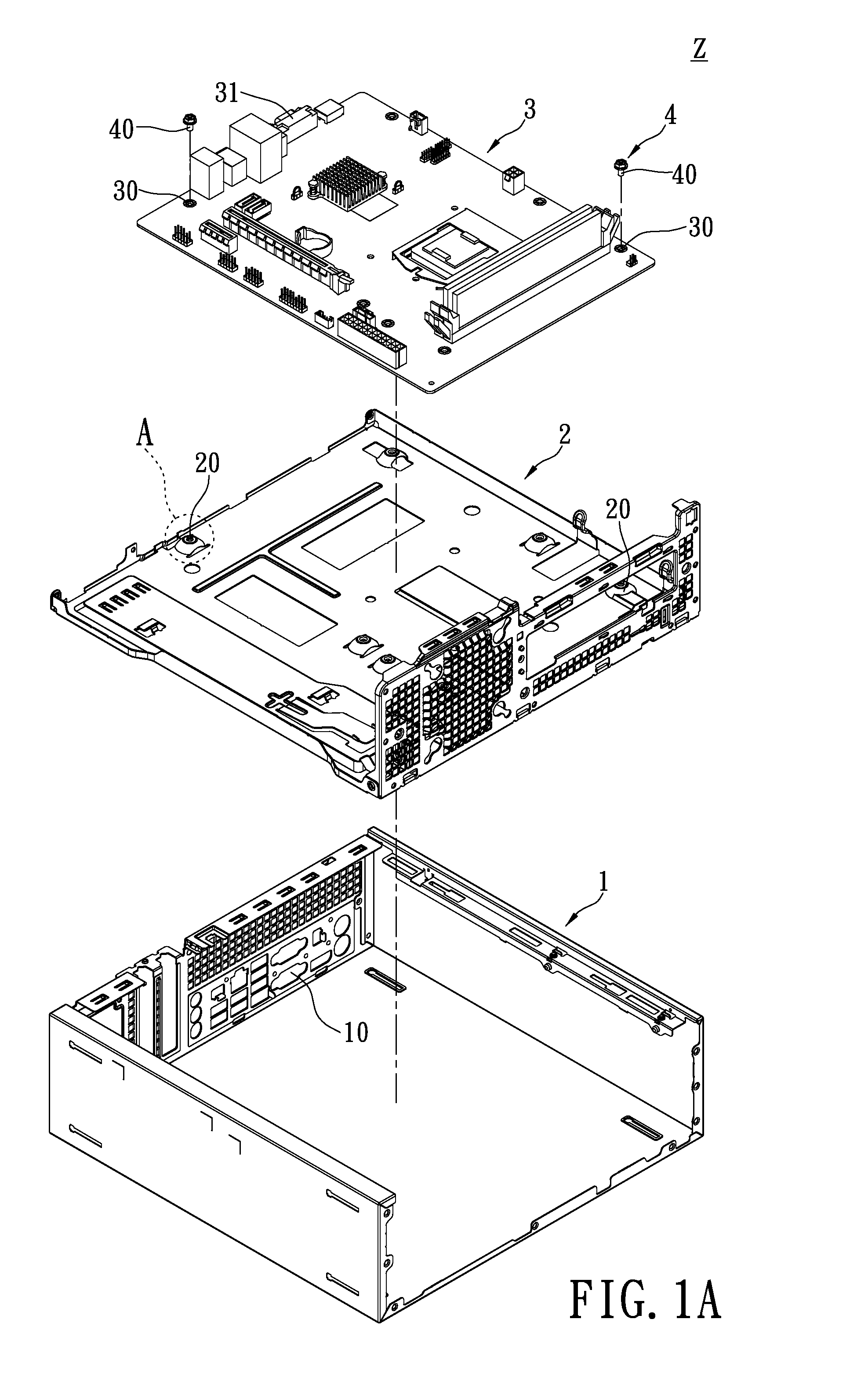

Positioning structure, positioning securing structure and electronic device

InactiveUS20130308285A1Precise positioning and fixingDigital data processing detailsNutsEngineeringHollow cylinder

A positioning structure for positioning a plate-shaped structure having at least one positioning hole is disclosed. The positioning structure includes at least one positioning element corresponding to the positioning hole, and the positioning element includes a placement portion for supporting the plate-shaped structure and a positioning portion extending toward a direction far away from the placement portion to form a hollow cylinder shape, and the positioning portion has an outer surrounding surface and a plurality of inner threads. Hence, when the outer surrounding surface of the positioning portion of the positioning element is inserted into the positioning hole to contact with the inner surface of the positioning hole, the positioning portion of the position element can be positioned in the positioning hole, thus the instant disclosure can be used to accurately position and secure the plate-shaped structure.

Owner:LITE ON TECH CORP +1

Stamped part quick locating device

ActiveCN111633092AAvoid affecting the deliveryPrecise positioning and fixingMetal-working feeding devicesStripping-off devicesStructural engineeringMechanical engineering

The one or more embodiments of the invention provides a stamped part quick locating device. The stamped part quick locating device comprises a fixed base. A lower die base is arranged in the middle position. An upper die base is arranged above the lower die base. A stamping sliding block is arranged above the upper die base. The left and right sides of the fixed base are symmetrically provided with transverse conveying racks. The inner sides of the transverse conveying racks are provided with transverse guide grooves. Vertical locating clamping rods of the stamped part quick locating device can be driven through trapezoidal clamping pressing blocks to synchronously and horizontally move to clamp raw materials to conduct locating. The trapezoidal clamping pressing blocks are pressed throughtrapezoidal hold-down pressing blocks synchronous with the stamping sliding block to do translational motion, so that stamping and fixing locating are synchronized. An upper clamping plate and a lower clamping plate of the stamped part quick locating device can do synchronous and horizontal movement with a progressive trapezoidal sliding block to quantitatively and progressively convey the raw materials. The progressive trapezoidal sliding block is driven through a lifting trapezoidal sliding block linked to the stamping sliding block to do translational motion, and then fixing locating and quantitative feeding operation of the raw materials can be completely synchronously.

Owner:安徽安路驰汽车部件有限公司

Split differential shell internal expansion machining method

ActiveCN108296725APrecise positioningPrecise positioning and fixingExpansion mandrelsMaintainance and safety accessoriesGear wheelMachining

The invention relates to a differential shell machining method, in particular to a split differential shell internal expansion machining method, and solves the technical problems of inconvenience to operate during clamping in machining of a differential shell in the prior art, incorrect positioning, easy shaking of workpieces during machining, weaker machining precision, weaker coaxiality of an internal spherical surface, lower machining efficiency and the like. The method comprises the following steps: an inner end of a split differential shell blank is inserted in a positioning block of an internal expansion positioning fixture for fixation; the split differential shell is cut by a feed bearing mounting position cutter, so that outer circles of bearing mounting positions at the two endsof the split differential shell are formed at the same time; the split differential shell is cut again by a feed molding cutter, so that an inner gear mounting spherical arc surface of the split differential shell is machined; and a split differential shell finished product is deviated from the positioning block to finish machining.

Owner:HANGZHOU JILI MACHINERY

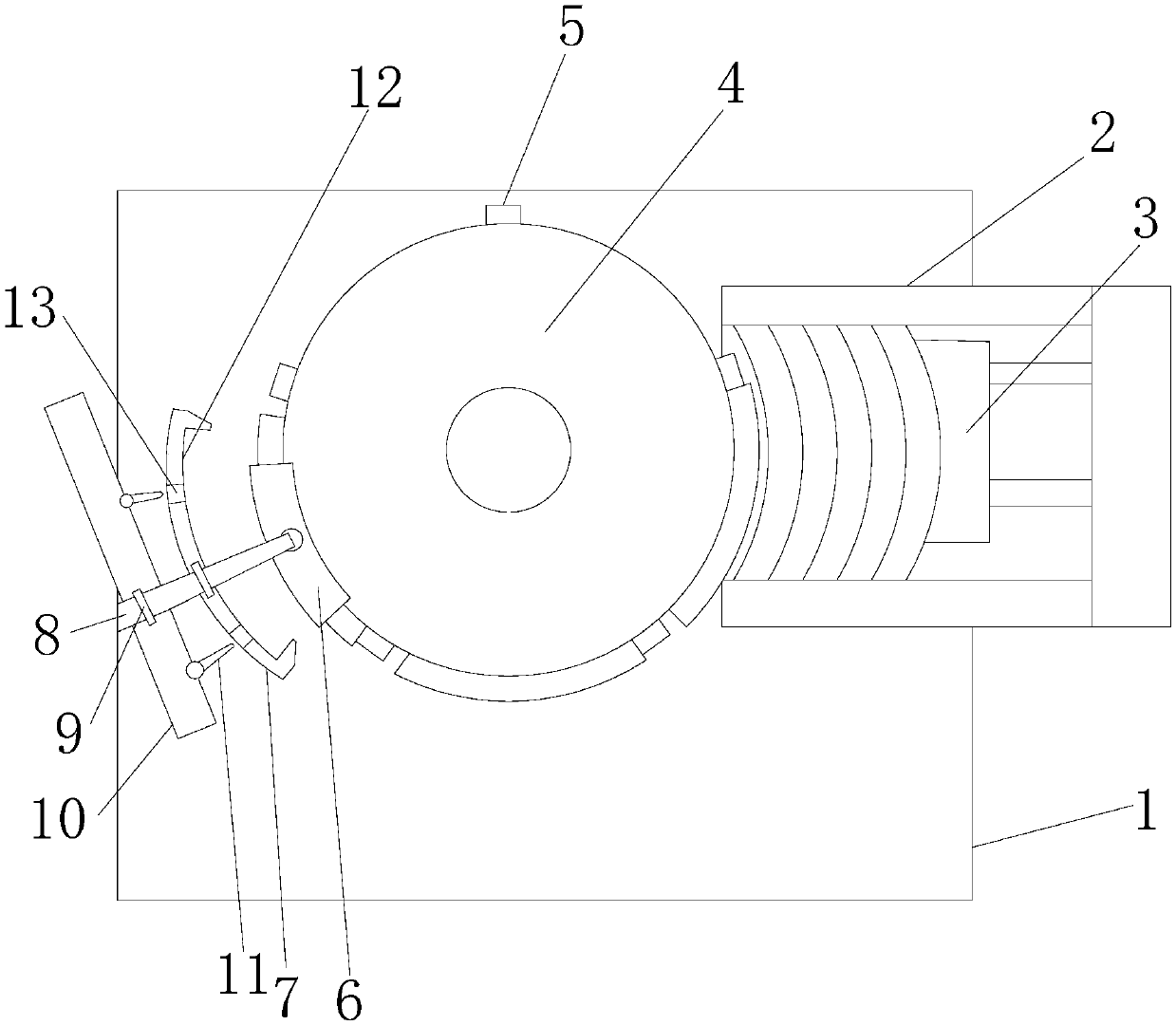

Brake pad drilling mold

InactiveCN107838480APrecise positioning and fixingReduce displacement phenomenonMetal working apparatusDrill jigsPunchingEngineering

The invention discloses a brake pad drilling mold, which comprises a base, a feeding trough, a pusher, a feeding turntable, a pushing protrusion, a pressing block, a limit card slot, a guide rail, an electric slider, a movable base plate, and a drilling hole. motor. The invention enables precise positioning and fixing of the brake pad during drilling, effectively reduces the displacement of the brake pad during the drilling process, improves the drilling precision, and facilitates the subsequent installation and use of the brake pad.

Owner:杨利人

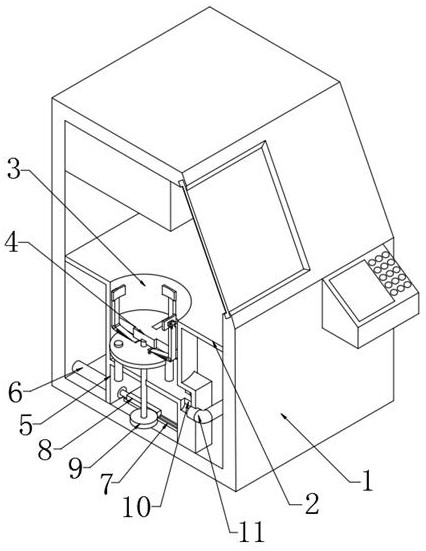

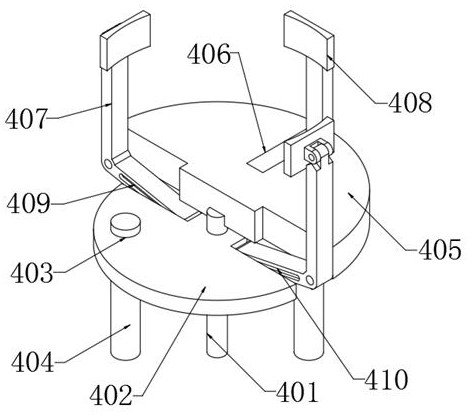

Environment-friendly intelligent graphite numerical control vertical lathe based on precise positioning system

PendingCN114683418APrecise positioning and fixingRapid positioningWorking accessoriesStone-like material working toolsPhysicsEngineering

The environment-friendly intelligent graphite numerical control vertical lathe based on the precise positioning system comprises a vertical lathe body, a supporting transverse plate is fixedly connected to the middle of the interior of the vertical lathe body, a positioning cylinder is fixedly connected to the middle of the top of the supporting transverse plate in an inserted mode, and a positioning fixing mechanism is arranged in the positioning cylinder; a supporting base is fixedly connected to the bottom of the positioning cylinder, and a hydraulic telescopic rod is fixedly inserted into the bottom of the rear side of the inner wall of the supporting base. According to the graphite raw material positioning device, graphite raw materials can be accurately stirred to the middle of the interior of the positioning cylinder and clamped and fixed, rapid positioning and fixing of the graphite raw materials are achieved, a lathe can conveniently and accurately machine the graphite raw materials, the machining efficiency is improved, and the machining cost is reduced. And graphite powder splashed to a supporting transverse plate and graphite powder falling into a positioning barrel can be uniformly absorbed into a powder collecting box, the recovery rate of the graphite powder is increased, recycling and reusing are convenient, resource waste is avoided, and the production cost is saved.

Owner:南通冠坤数控机床有限公司

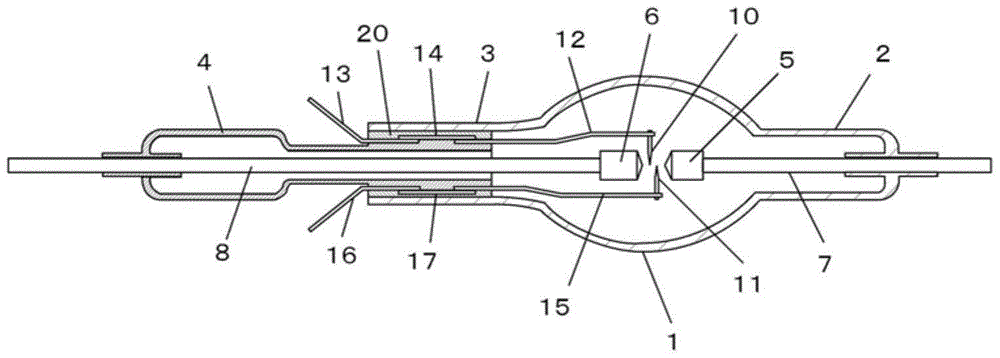

Short arc type flash lamp with both ends sealed

ActiveCN105914127APrecise positioning and fixingSimplified welding workGas discharge lamp detailsMetal foilAuxiliary electrode

The invention provides a short arc type flash lamp with both ends sealed. A light emitting tube is internally provided with a starting auxiliary electrode and a pair of main electrodes. In a first sealed tube of the light emitting tube, the core wire of a first main electrode is sealed and is leaded out of the light emitting electrode. A sealing glass tube is fused on a second sealed tube, and the core wire of a second main electrode is sealed in the sealing glass tube and is introduced out of the light emitting tube. In fusion operation of the second sealed tube and the sealing glass tube, correct fixing positions of an inner lead, an outer lead, a metal foil and the like of the starting auxiliary electrode can be obtained, thereby greatly simplifying packaging operation. On the outer peripheral surface of a fusion area between the sealing glass tube and the second sealed tube, a one-time sealing glass component is fused in a manner of covering the inner lead, the outer lead and the metal foil.

Owner:USHIO DENKI KK

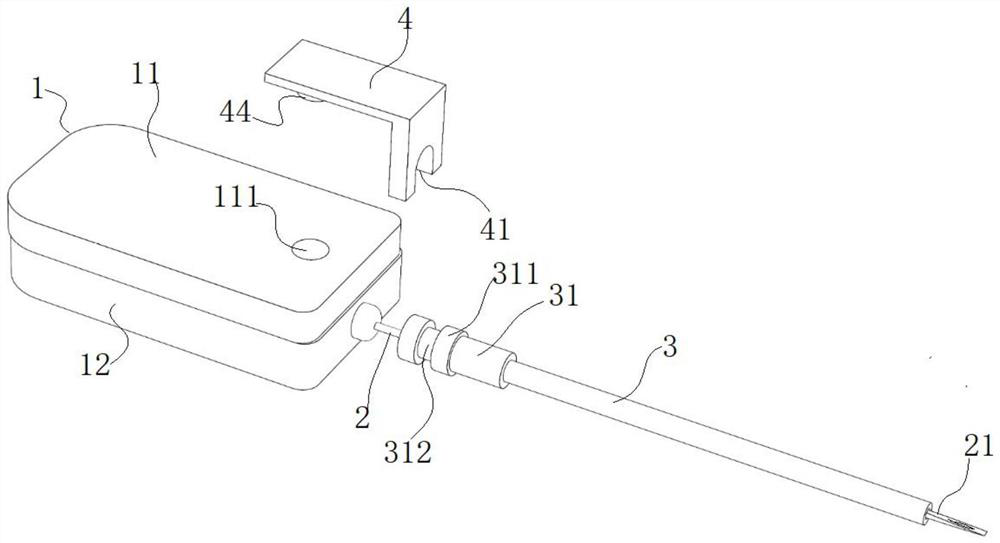

Hollow needle knife and application method thereof

PendingCN113288343ABoth damageConvenience to stayCannulasSurgical needlesAfter treatmentApparatus instruments

The invention discloses a hollow needle knife and an application method thereof, and belongs to the field of medical instruments. The hollow needle knife comprises a needle knife handle, a hollow needle knife body, a soft sleeve and a positioning and fixing mechanism, wherein the hollow needle knife body is fixedly connected to the front end face of the needle knife handle; and the positioning and fixing mechanism sleeves the hollow needle knife body with the soft sleeve in a positioning mode, the cutting capacity of the needle knife is fully utilized, the position and positioning relation of the soft sleeve and the needle knife are adjusted through the positioning and fixing mechanism, and during sweeping and scattering actions, the soft sleeve shields and protects a knife edge and is embedded into a focus at the same time. Therefore, it is guaranteed that the soft tissue is not damaged during sweeping and stripping treatment, after stripping and sweeping treatment, the soft sleeve can be conveniently left in the focus of a patient, the adhesion position is separated, and the rapid and accurate medical effect is achieved. The problems that in the prior art, a needle point only has a penetrating function, and the sweeping action cutting capacity is poor are solved. In addition, the hollow needle knife body has a precise medicine feeding function.

Owner:南京喜乐德科技有限公司

Workpiece welding positioning work fixture

ActiveCN112091504AReduce operating proceduresImprove workpiece assembly efficiencyWelding/cutting auxillary devicesAuxillary welding devicesPhysicsMechanical engineering

The invention relates to a workpiece welding positioning work fixture, and relates to the field of welding auxiliary devices. The work fixture comprises a work table for placing a supporting rod, a rod positioning piece fixed to one end of the work table, a positioning pin fixed to an abutting piece, a positioning plate fixed to the end, away from the positioning piece, of the work table, at leasttwo positioning cylinders fixed to the positioning plate, a fixed clamping piece fixed to one side of the work table a movable clamping piece fixed to one side, away from the fixed clamping piece, ofthe work table, and a movable positioning piece movably arranged on the work table. An avoiding groove is formed in the positioning plate. Aiming at the problem that the quality stability of the prior welding workpieces is poor, the workpiece welding positioning work fixture has the beneficial effect of improving the quality stability of batch welding workpieces.

Owner:SHANGHAI KONGBO IND

A welding tool for outrigger box assembly

ActiveCN113634977BPrecise positioning and fixingRealize tack weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPhysics

The invention discloses a welding tool for an outrigger box assembly, comprising: a base having an abutment structure for positioning two adjacent sides of the outrigger box and a supporting structure for supporting the outrigger box; a first positioning component, Elastically mounted on the base, the first positioning component is used to be elastically inserted into the positioning hole on the outrigger box; the second positioning component is passed through the base and used to insert into the ear plate hole on the outrigger box, and the ear The axes of the plate hole and the positioning hole are not parallel; the cylinder seat positioning component is used for positioning and clamping the oil cylinder support; the outrigger adjustment seat positioning component is used for positioning and clamping the outrigger adjustment seat. The present invention utilizes the positioning assembly of the oil cylinder seat and the positioning assembly of the outrigger adjusting seat to position the outrigger adjusting seat and the oil cylinder support to be welded, improves the accuracy of subsequent pair welding, and realizes the positioning welding of two important parts, ensuring the important Dimensional welding accuracy.

Owner:长沙孟德机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com