Copper bar automatic plane warehouse and copper bar integrated production line

A production line and warehouse technology, applied to other manufacturing equipment/tools, conveyors, manufacturing tools, etc., can solve problems such as few automated production lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

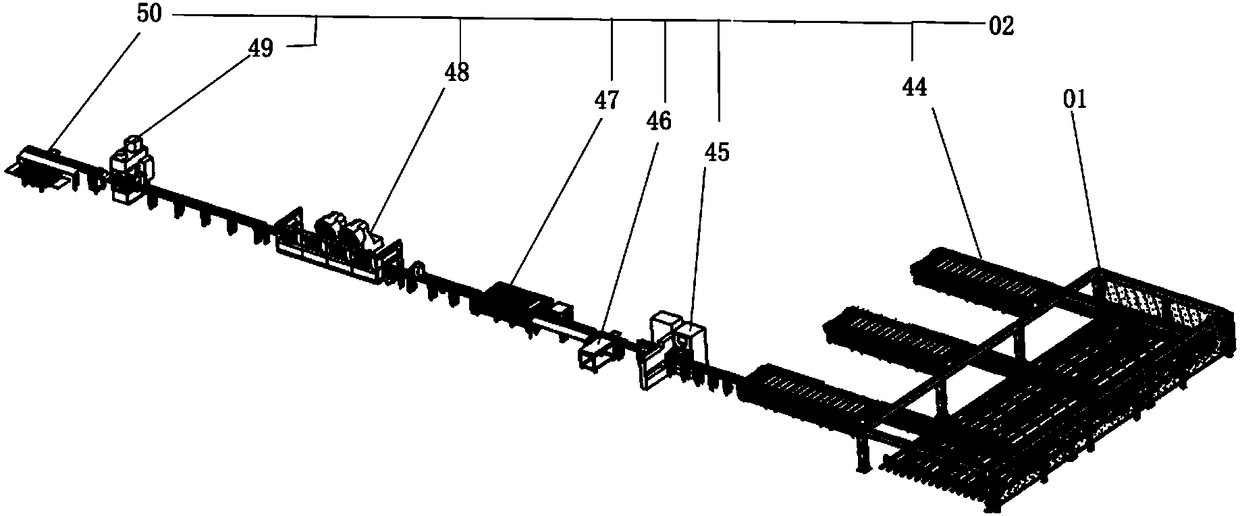

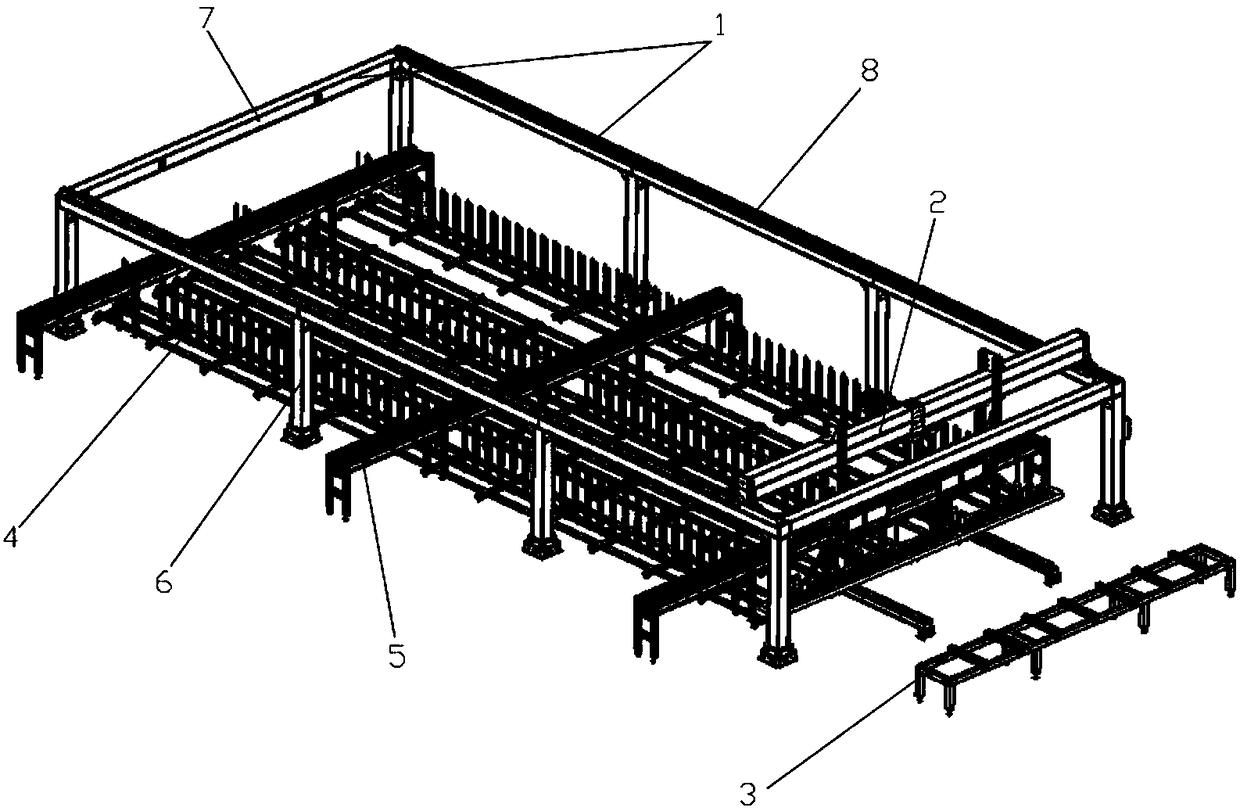

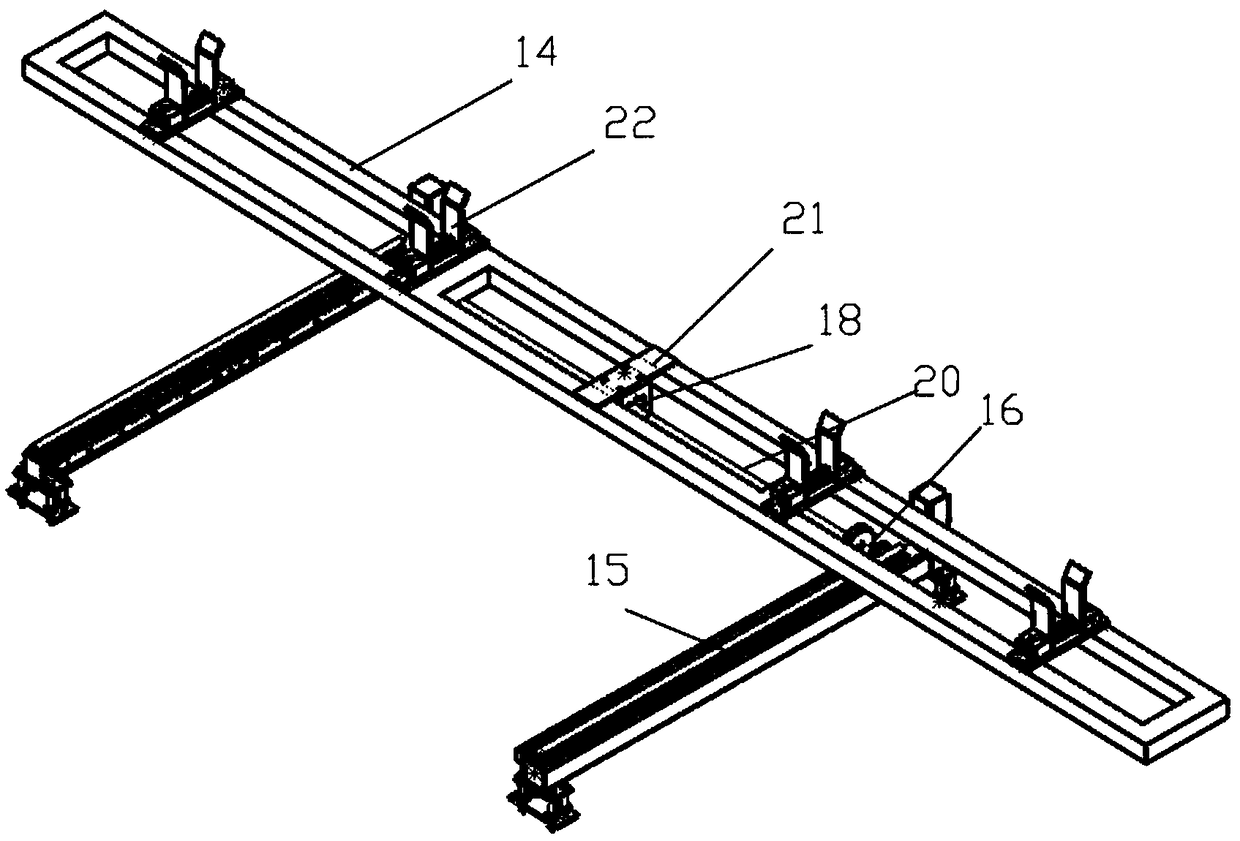

[0076] As shown in the figure, an automated flat warehouse for copper bars and an integrated production line for copper bars, including an automated flat warehouse for copper bars 01 and an automated production line for copper bars 02;

[0077] The copper busbar automated flat warehouse 01 includes a copper busbar warehouse outer frame 1, a copper busbar storage transfer machine 2, a copper busbar loading and transferring machine 3, a copper busbar storage location 4 and a copper busbar discharge conveying line 5;

[0078] The outer frame 1 of the copper bar warehouse includes a column 6, a beam 7 and a linear guide rail 8, the column 6 is installed on the ground, the beam 7 is connected with the columns 6 on both sides respectively, and the linear guide rail 8 is installed on the column 6;

[0079] The copper bar storage position 4 includes a copper bar storage position frame 9 and a limiting column 10, the copper bar storage position frame 9 is arranged in the outer frame 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com