Patents

Literature

51results about How to "Inhibition of oxidative degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylic amide modified graft copolymer, preparation method and application thereof

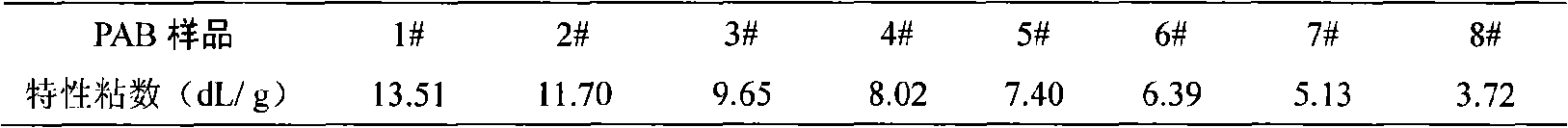

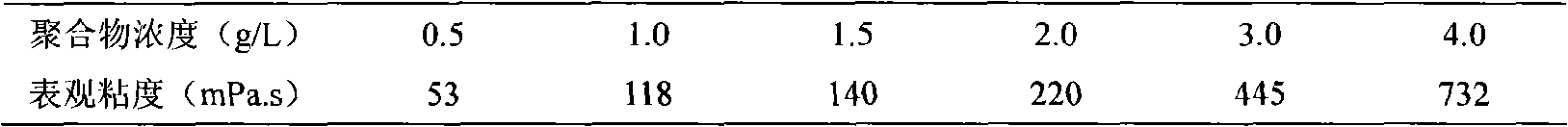

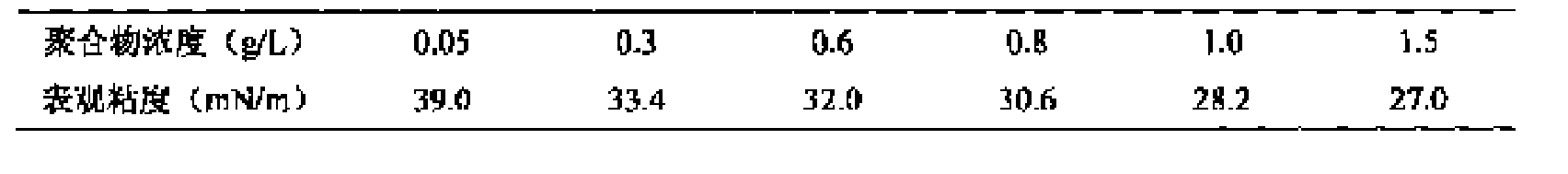

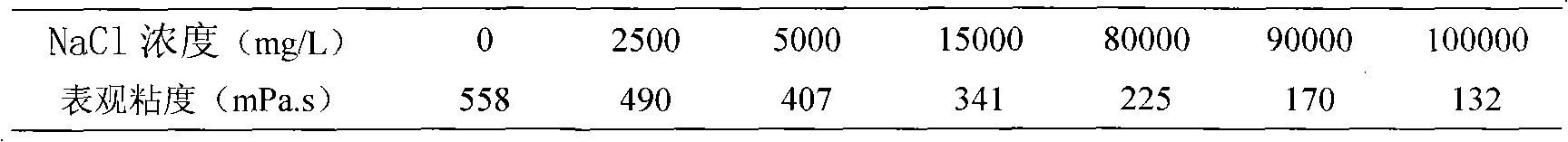

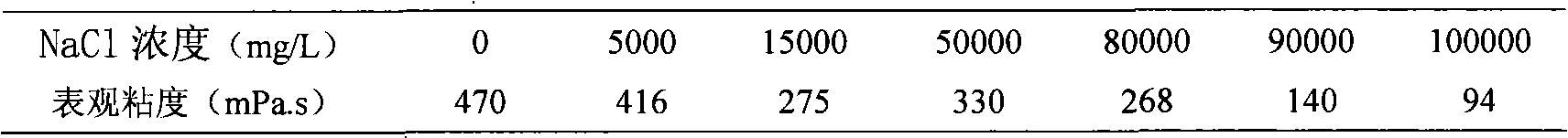

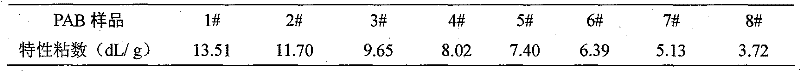

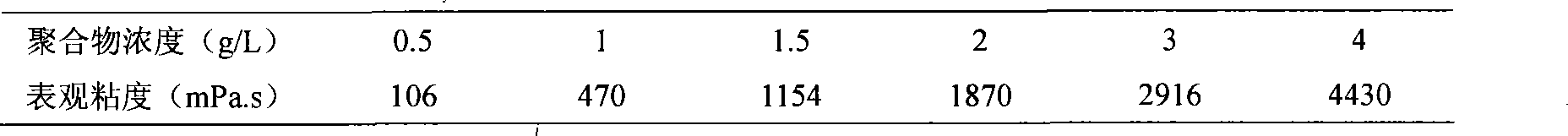

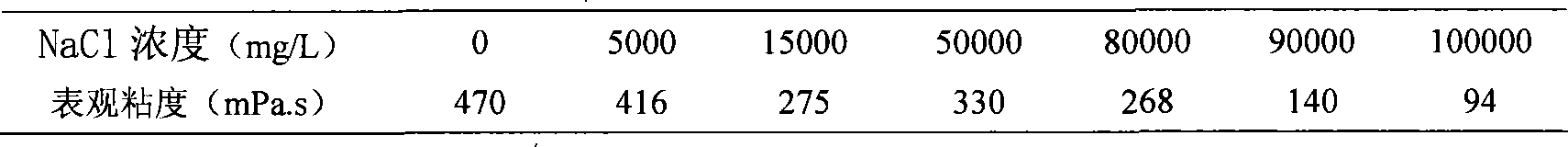

The invention discloses an acrylamide modified graft copolymer and a preparation method and usage thereof. The invention is characterized in that 20 parts of acrylamide, 1-20 anionic monomer and / or cationic monomer, 0.1-15 macromonomer, 0.05-10 ionic lyophobic monomer and 50-1000 deionized water are added into a three-necked reaction bottle, the pH value is adjusted to be 3-9, N2 is introduced for 30min, then 0.002-0.5 part of initiator persulfate is added at 30-75 DEG C, the reaction lasts 8-36h, then copolymer PAB is obtained, and finally water is used for dilution to obtain strong PAB solution. During polymerization, no surfactant is used, and the macromonomer with a long chain and the ionic lyophobic monomer with intermolecular association function are introduced into the copolymer PAB, so the capabilities of cooperative tackification and salt-resistance between the rigid conformation of a molecular chain and the intermolecular association can be played optimally, the PAB exhibits unique solution property and has higher colloidal viscosity in high saline solution than in fresh water, and the PAB obtains the capabilities of tackification, salt resistance, low surface tension and strong molecular association and can be used for the oil-displacing acrylamide modified graft copolymer. The copolymer is prepared into water solution with mass concentration of 0.2-3.0g / L and surfactant concentration of 0.01-2 mmol / L, then the water solution is added into a mixing vessel by a stirring device, and then a polymer oil-displacing agent with tackification, salt resistance and cutting resistance is obtained. The PAB has the functions of both a tackifier and a macromolecule surfactant. The copolymer PAB is prepared into water solution which has mass concentration of 0.05-7%, so the macromolecule surfactant with excellent surface activeness can be obtained and then applicable to an emulsifier, an emulsion splitter, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

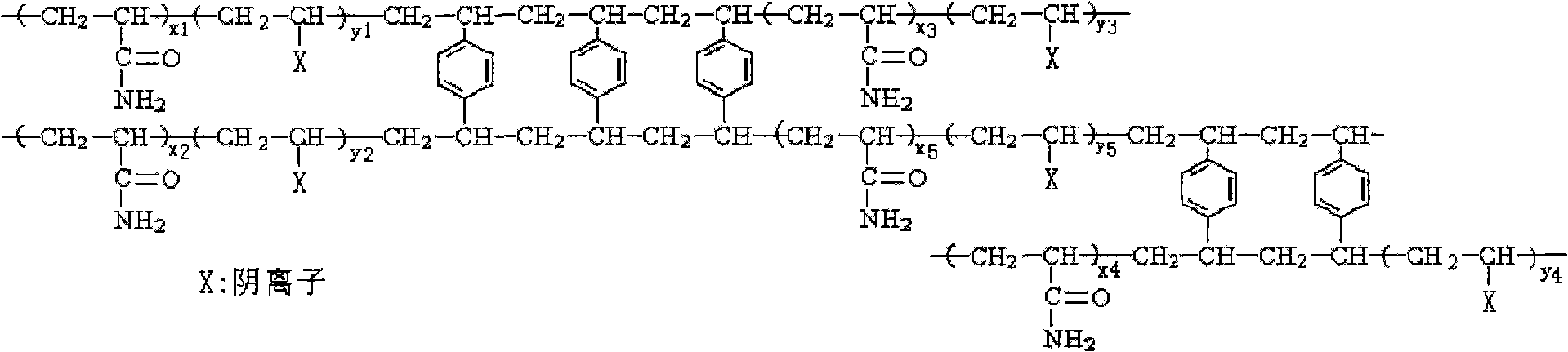

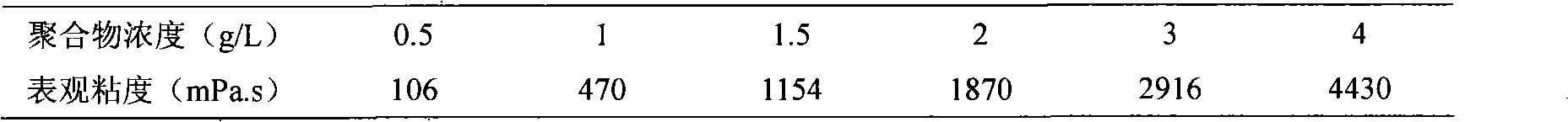

Non-linear associating water-soluble quadripolymer, and preparation and use thereof

InactiveCN101463116AImprove rigidityHigh temperature resistanceTransportation and packagingMixingIonChemistry

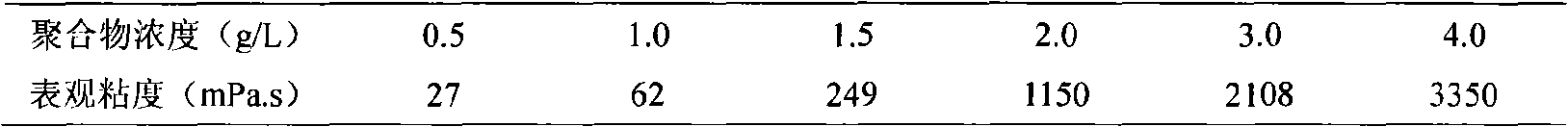

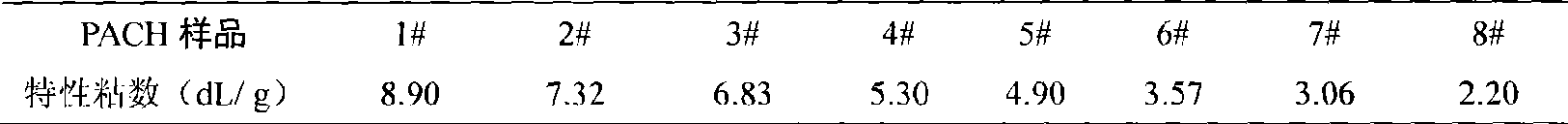

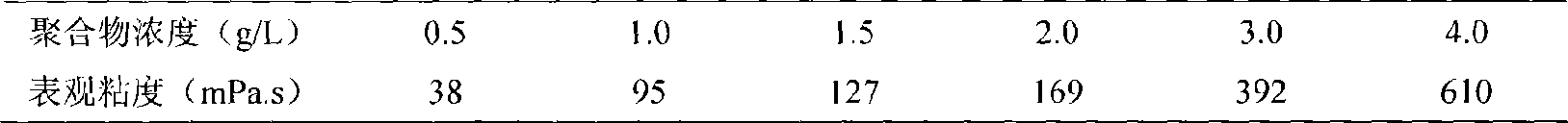

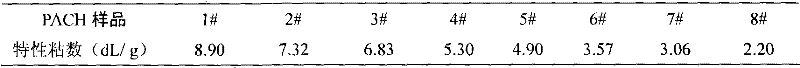

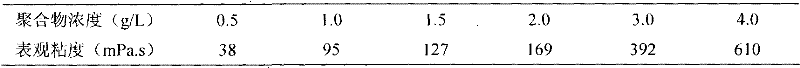

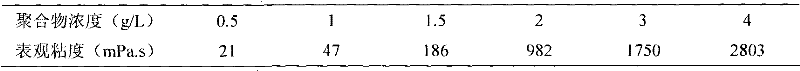

The invention discloses a non-linear associated water soluble quadripolymer as well as a preparation method and use thereof, comprising: adding 20 parts of acrylamide, 1-20 parts of nionic monomer or / and cationic monomer, 0.1-15 parts of macromonomer, 0.05-10 parts of hydrophobic monomer, 0.1-50 parts of surfactant and 60-1000 parts of deionized water to a three-necked reaction flask, adjusting the pH to be 3-9, adding 0.002-1 part of initiator (persulphate) at 30-75 DEG C after introducing N2 for 30min, reacting for 8-36h to obtain the quadripolymer PACH, diluting with water, and obtaining concentrated PACH solution. The macromonomer with a long chain and the hydrophobic monomer with a molecular association function are simultaneously introduced in a copolymer PACH, which can obtain the best synergistic viscosifying between rigid conformation of a molecular chain and molecular association and salt resistance. The non-linear associated water soluble quadripolymer is obtained. The copolymer is prepared into aqueous solution with the mass concentration of 0.2-3g / l and the surfactant concentration of 0.01-2mmol / l, added to a mixing vessel with a stirring device and evenly stirred at the room temperature to obtain a viscosified, salt-resistant and shear-resistant polymer oil displacement agent. The PACH has dual functions of a viscosifier and a high molecular surfactant; minute amount of a low molecular surfactant is added to the PACH solution, thus improving the apparent viscosity of the solution, reducing the surface tension of solution and the water-oil interfacial tension, and being beneficial to improving the crude oil recovery ratio. A copolymer PABE is prepared into the aqueous solution with the mass concentration of 0.05-7% to obtain high molecular surfactant with excellent surface activity, and the high molecular surfactant is used as an emulsifier, a demulsifier, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Comb-typed amphiphilic water-soluble co-polymer, method for preparing same and use

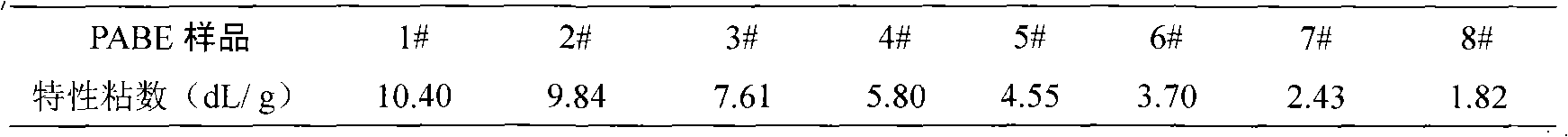

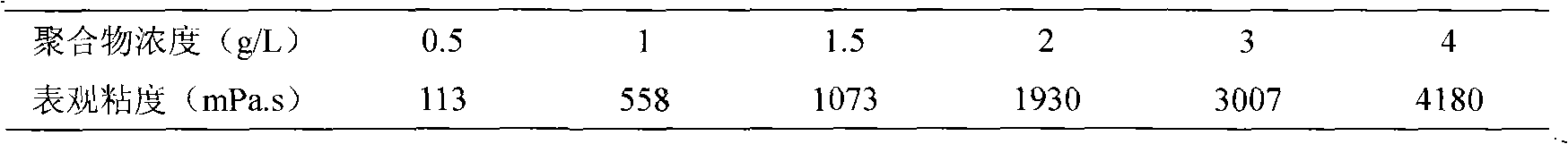

The invention discloses a comb-type amphipathicity water-solubility multipolymer and a method for making the same as well as an application. The method is characterized in that: 20 portions of acrylamide, 0.1 to 10 portions of negative ion monomer, 0.5 to 15 portions of at least one of the surface activity macromolecular monomer 4-vinyl benzyl alkylphenol polyoxyethylene ether or / and allyl alkylphenol polyoxyethylene ether and 30 to 600 portions of deionized water are added into a three-necked reaction bulb, the pH value of the solution is adjusted to between 4 and 9, N2 is introduced into the solution for 30 minutes, 0.002 to 0.3 portion of evocating agent sulphate is added at the temperature of between 30 and 70 DEG C to react 12 to 36 hours in order to prepare PABE which is diluted by water to obtain the PABE strong solution; the comb-type amphipathicity water-solubility multipolymer which can viscosify, has salt resistance and the low surface tension as well as the molecular association ability and can be used for the fuel scavenge. The multipolymer is prepared into a water solution with a mass concentration between 0.3 and 3g / L and a surface active agent concentration between 0.01 and 2mmol / L, the water solution is added into a blending container with a stirring device and is stirred evenly at room temperature so that the polymer oil-displacing agent which can viscosify and shear-resistant and has excellent anti-aging performance in a hyperhaline state and at the temperature of 70 DEG C. The PABE has the double function of a tackifier and a macromolecule surfactant. Infinitesimal low molecular surface active reagent is added into the PABE solution, thereby evidently increasing the apparent viscosity of the solution, reducing the surface tension and the oil-water boundary tension of the solution and contributing to improving the recovery ratio.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

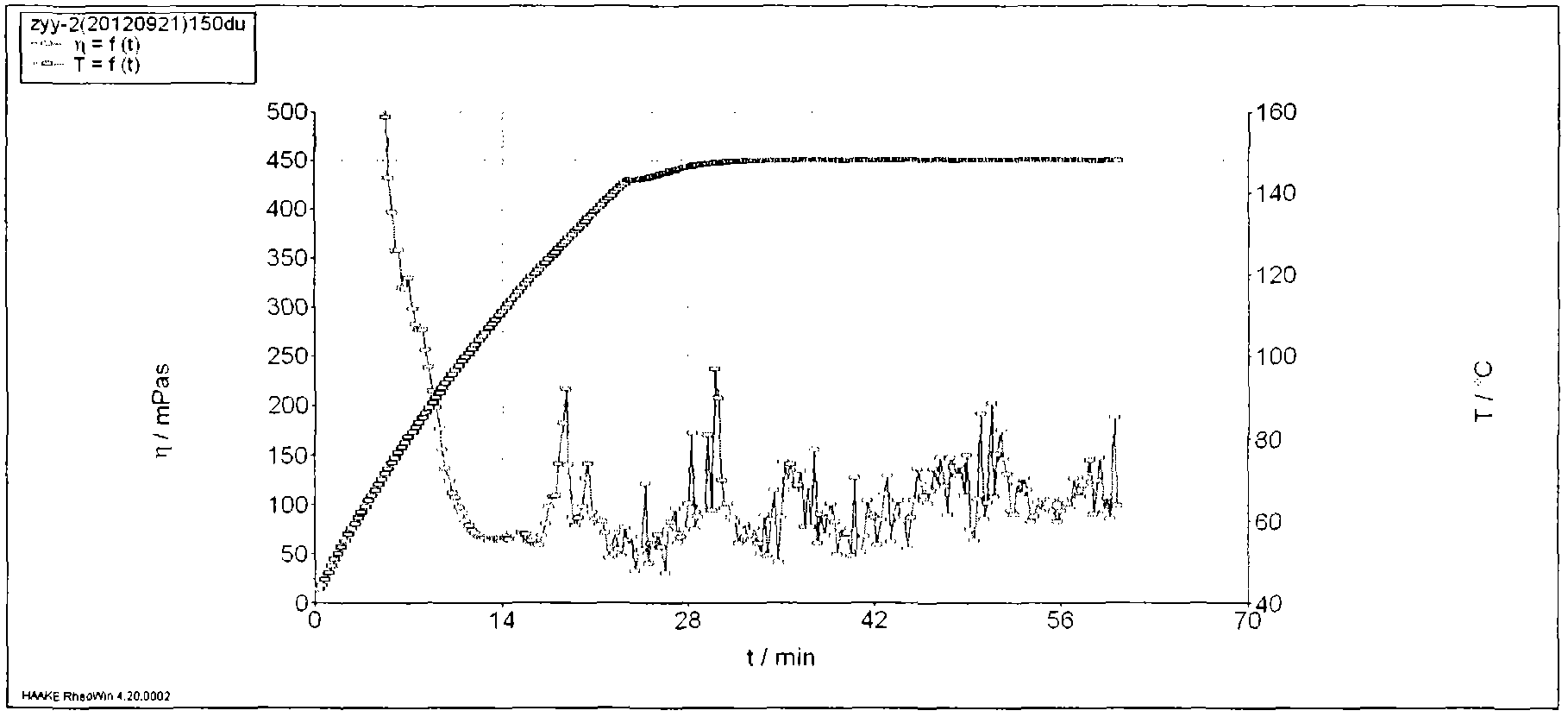

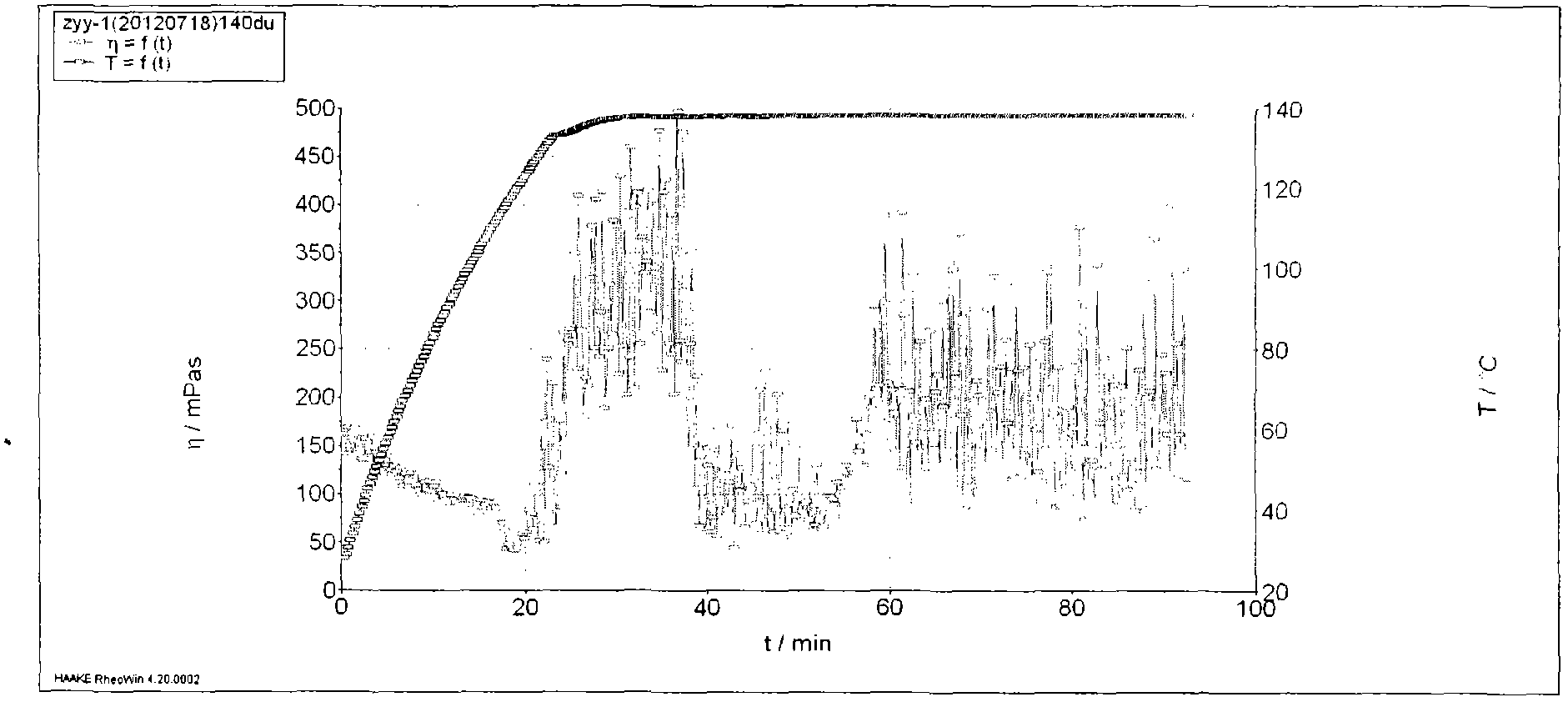

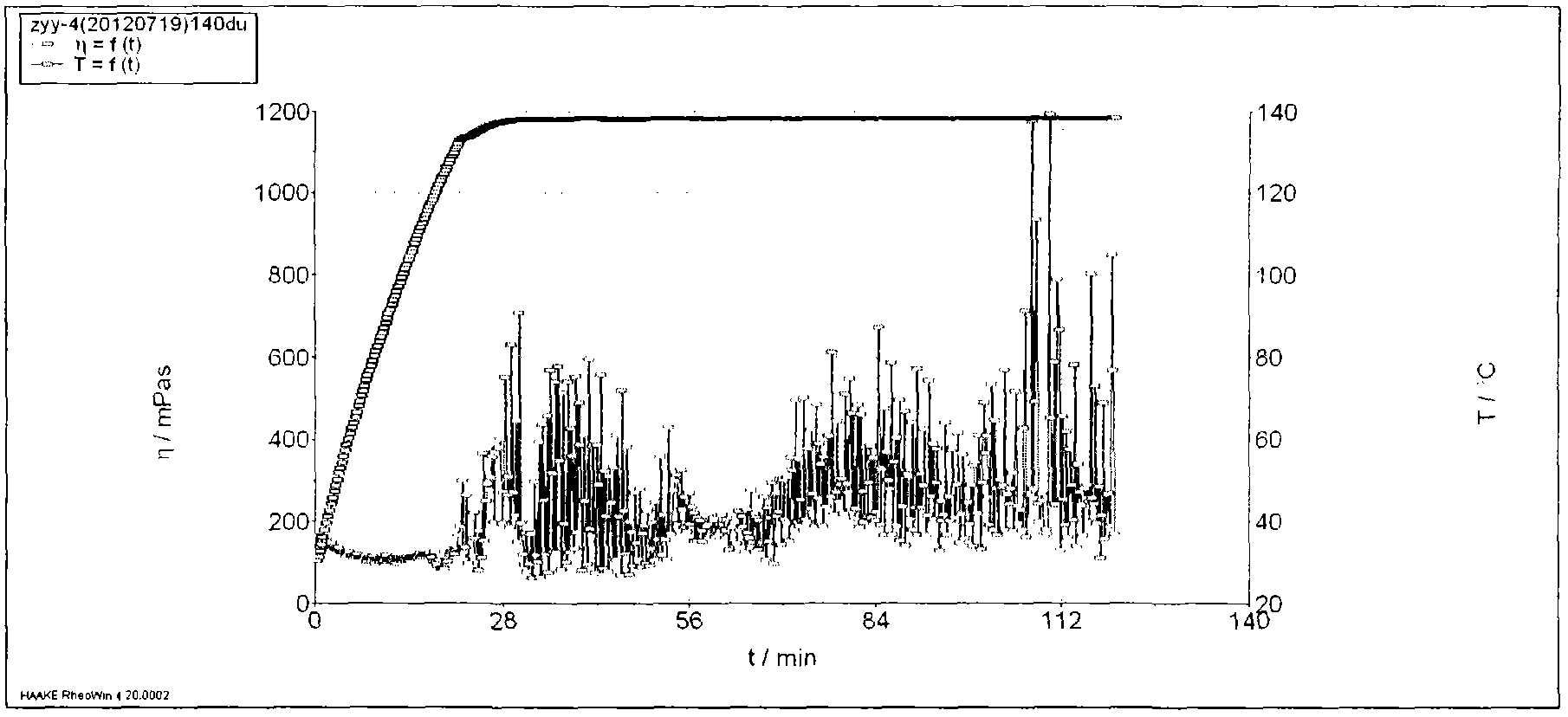

Preparation method of polyacrylamide nano composite fracturing fluid

ActiveCN104109525AHigh temperature resistantSalt resistantDrilling compositionIn situ polymerizationFracturing fluid

The invention adopts polyacrylamide and a nano inorganic phase to prepare a polyacrylamide nano composite material through an in-situ polymerization method and then forms a fracturing fluid thickening agent. The nano inorganic phase is prepared by mixing the products of intercalation reactions between an organic long-chain intercalator and layered silicate with magnesium nitrate and aluminum nitrate. The nano inorganic phase, acrylamide monomer, a coupling agent, a complexing agent, an initiator, an oxidant, a reductant, a cosolvent, an auxiliary agent, and deionized water form a suspension fluid reaction system, and the polyacrylamide nano composite material is formed after the polymerization-intercalation composite reactions. The polyacrylamide nano composite material with a mass percentage of 0.25% is taken as the thickening agent, and then is mixed with a crosslinking agent with a mass percentage of 0.20%, a gel breaker with a mass percentage of 0.20%, and other auxiliary agents to form a fracturing fluid system. The system is sheared for 70 minutes under a shearing speed of 170 s<-1> at a temperature of 150 DEG C so as to form a fracturing fluid with a viscosity larger than 50 mPa.s, and the fracturing fluid has the characteristics of high temperature resistance, shearing resistance, low frictional resistance, complete glue breaking effect, and good compatibility with the formation fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing allyl surface-active macromonomer

InactiveCN101543747AImprove surface activityGood viscosity increaseTransportation and packagingMixingChromatographic separationAlkylphenol

The invention discloses a method for preparing an allyl surface-active macromonomer, which is characterized by comprising the following steps: adding 20 portions of alkylphenol polyoxyethylene ether (CmH2m+1-C6H4-O-(CH2CH2O)nH, n is equal to 1 to 60, and m is equal to 1 to 20), 10 to 900 portions of solvent and 0.1 to 15 portions of catalyst into a three-mouth reaction flask with a reflux condensation device, and reacting the mixture for 1 hour under stirring at the room temperature; increasing temperature to 30 to 95 DEG C, adding 0.5 to 20 portions of allyl chloride into the reaction product, and continuously reacting for 6 to 48 hours; distilling the reaction product under reduced pressure to remove the solvent so as to obtain a crude product; and performing silica gel column chromatographic separation to obtain allyl alkylphenol polyoxyethylene ether with the yield of 70 to 95 percent. The allyl alkylphenol polyoxyethylene ether has excellent surface activity, and can be directly used as a surfactant. A water-soluble copolymer synthesized by taking the allyl alkylphenol polyoxyethylene ether as a surface-active macromonomer has the function of tackifying, or reducing solution surface tension and water-oil interfacial tension, and can be taken as a tackifying copolymer or a macromolecular surfactant for improving the oil recovery ratio.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

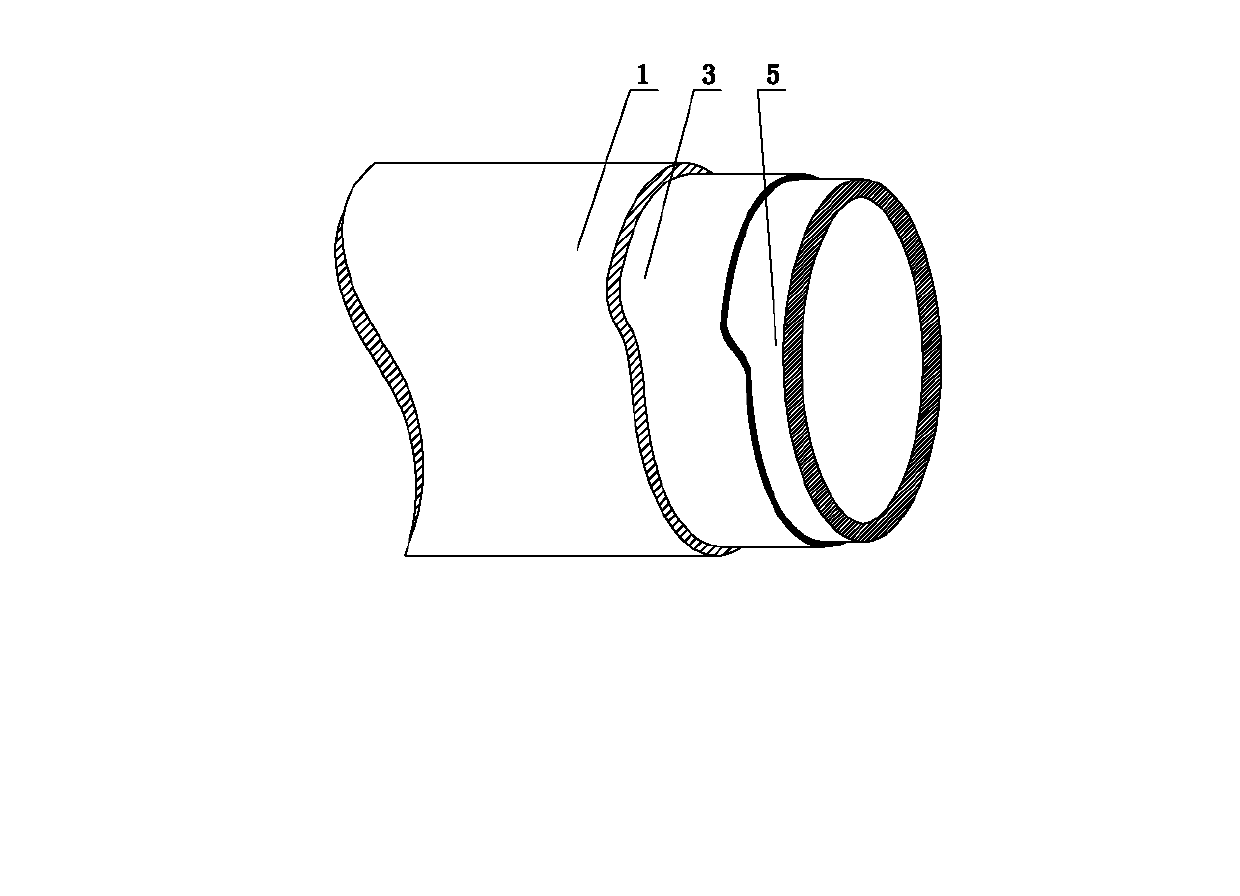

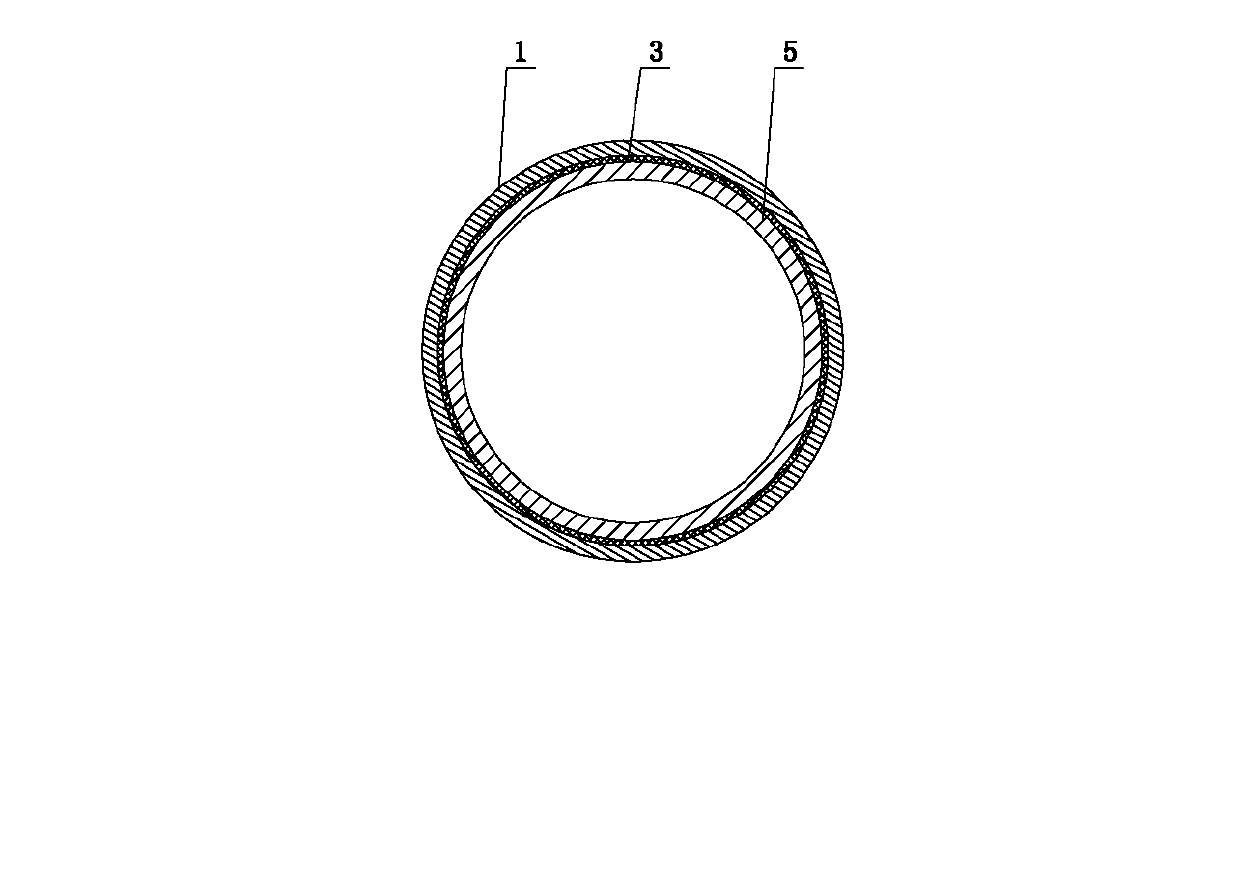

Novel high-strength HDPE (High-Density Polyethylene) composite tube and production method thereof

ActiveCN102996913AExtended service lifeInhibition of oxidative degradationRigid pipesCorrosion resistantOxidative degradation

The invention discloses a novel high-strength HDPE (High-Density Polyethylene) composite tube, which is obtained by composting an HDPE core tube, and a modified PE (Poly Ethylene) layer, wherein the innermost layer is the HDPE core tube which is enwrapped by a PE bonding layer, and the modified PE layer enwraps the PE bonding layer. The composite tube disclosed by the invention has the characteristics of good shock resistance, high compression strength, high wear resistance and the like. The HDPE core tube is corrosion resistant so that the composite tube is long in service life and capable of resisting the invasion by various corrosive media, such as an acid, an alkali and a salt, the modified PE layer is adopted so that plastic oxidative degradation is inhibited, tube ultra-violet resistance performance is improved, and tube service life is prolonged, and the PE bonding layer adopts a thermoplastic elastic body so that material performance is greatly improved, bonding capacity between the core tube and the modified PE layer is improved, and service life can reach 60 years.

Owner:HUBEI HUIFENG PLASTIC PIPE

Water-soluble micro-crosslinked copolymer, preparation and use thereof

InactiveCN101302266AGood water solubilityGood anti-aging performanceDrilling compositionIonChemistry

The invention discloses water-solubility micro-crosslinking copolymer, a method for making the same and an application of the same. The method is characterized in that: 20 portions of acrylamide, 0.5 to 15 portions of anion monomer, 0.1 to 6 portions of divinyl benzene, 0.5 to 50 portions of sodium laurylsulfate and 50 to 800 portions of deionized water are added in a three-necked reaction bottle, and the pH value of the solution is adjusted to between 4 and 9; after N2 is injected for 30 minutes, 0.001 to 0.2 portions of initiator persulphate is added in at a temperature of between 30 and 70 DEG C so as to carry out reaction for 6 to 36 hours, thereby obtaining PADM; then, the PADM is diluted by water to obtain a PADM solution, thereby obtaining the water-solubility micro-crosslinking copolymer which has ideal water solubility, copolymerization micro-crosslinking structure, difficult intramolecular crimp and molecular association capacity and can be used in oil expulsion. The copolymer is made into an aqueous solution with the mass concentration of between 0.3 and 3 g / L and the surfactant concentration of between 0.01 and 4 mmol / L, and then is added in a mixing vessel provided with a stirring device so as to be stirred evenly at room temperature, thereby obtaining a polymer oil displacement agent which is tackifying, salt resistant, thermotolerant and shear resistant and has excellent age resistance under the conditions of high salt and 110 DEG C. Moreover, the raw materials of PADM are easy to obtain; therefore, the water-solubility micro-crosslinking copolymer and the method have enormous application prospect in increasing crude oil recovery ratio.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method for preparing 4-vinyl benzyl surface-active macromonomer

InactiveCN101543748AImprove surface activityGood resistanceTransportation and packagingMixingChromatographic separationAlkylphenol

The invention discloses a method for preparing a 4-vinyl benzyl surface-active macromonomer, which is characterized by comprising the following steps: adding 20 portions of alkylphenol polyoxyethylene ether (CmH2m+1-C6H4-O-(CH2CH2O)nH, n is equal to 1 to 60, and m is equal to 1 to 20), 10 to 900 portions of solvent and 0.1 to 15 portions of catalyst into a three-mouth reaction flask with a reflux condensation device, and reacting for 1 hour under stirring at the room temperature; increasing temperature to 30 to 90 DEG C, adding 0.5 to 25 portions of 4-vinyl benzyl chloride into the reaction product, and continuously reacting for 6 to 48 hours; distilling the reaction product under reduced pressure to remove the solvent so as to obtain a crude product; and performing silica gel column chromatographic separation to obtain 4-vinyl benzyl alkylphenol polyoxyethylene ether with the yield of 62 to 94 percent. The 4-vinyl benzyl alkylphenol polyoxyethylene ether has excellent surface activity, and can be directly used as a surfactant. A water-soluble copolymer synthesized by taking the 4-vinyl benzyl alkylphenol polyoxyethylene ether as a surface-active macromonomer has the function of tackifying, or reducing solution surface tension and water-oil interfacial tension, and can be taken as a tackifying copolymer or a macromolecular surfactant for improving the oil recovery ratio.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Drug solution having reduced dissolved oxygen content, method of producing the same and drug solution containing unit having reduced dissolved oxygen content

ActiveUS20100092446A1Suppress oxidative degradationStable in timeBiocidePeptide/protein ingredientsChemistryDeoxidization

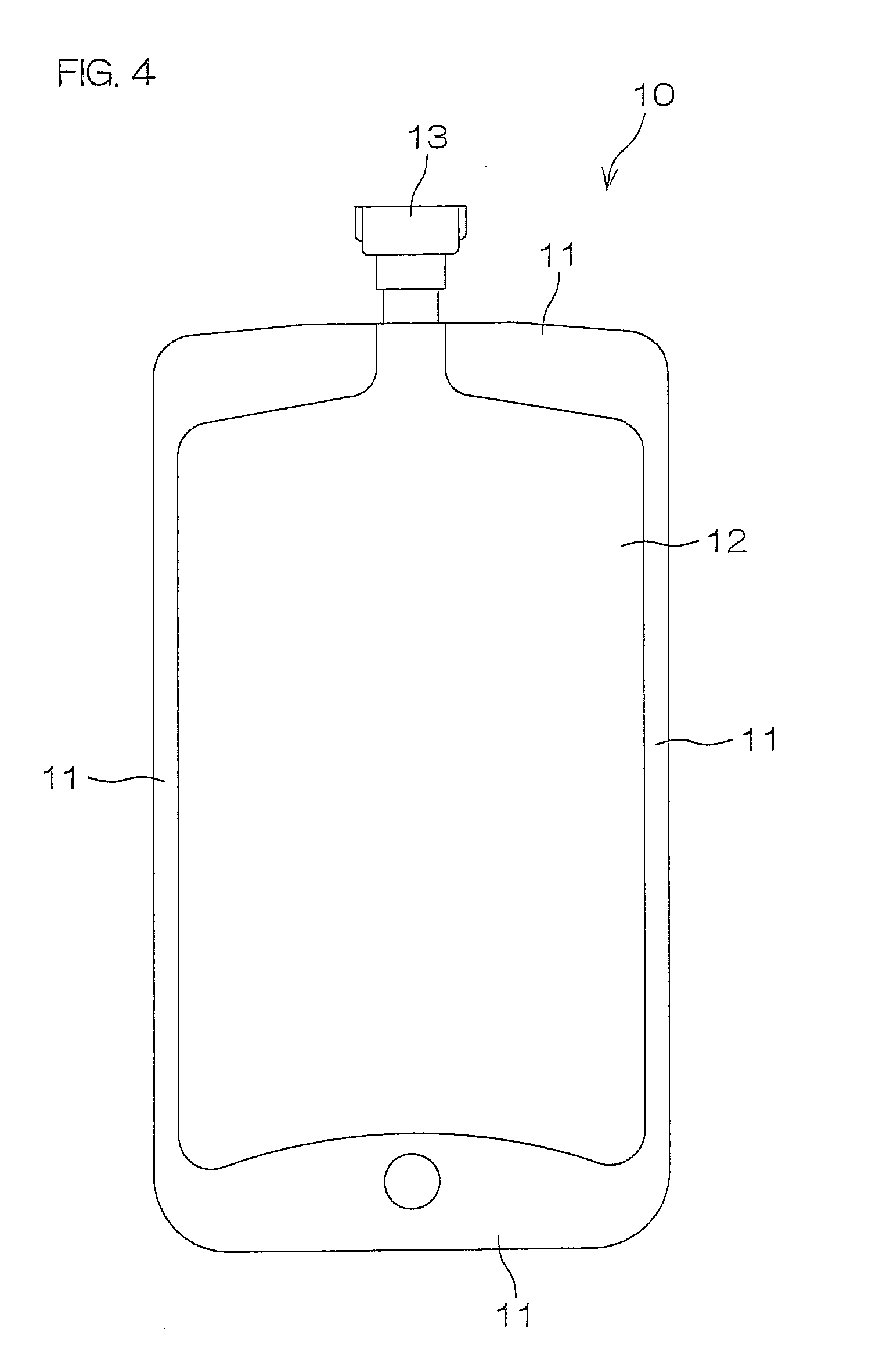

It is an object of the present invention to provide a drug solution which has a reduced dissolved oxygen content and is less susceptible to oxidative degradation and highly stable over time, a production method therefor, and a drug solution containing pack which is capable of maintaining the dissolved oxygen content of a drug solution at a reduced level, less susceptible to oxidative degradation of the drug solution and highly stable over time. To achieve the aforementioned object, the reduced-dissolved-oxygen-content drug solution is produced by filling and sealing the drug solution in a drug solution container (15) formed of a plastic material having an oxygen permeability of not lower than 200 cm3 / m2·24 h·atm at 25° C. at 60% RH within 12 hours after a steam sterilization process or a hot water sterilization process and having a steady-state oxygen permeability of not higher than 100 cm3 / m2·24 h·atm at 25° C. at 60% RH, subjecting the drug solution container to the steam sterilization process or the hot water sterilization process, and storing the drug solution container in an environment having deoxidization means for reducing the dissolved oxygen concentration of the drug solution to not higher than 2 ppm when the oxygen permeability of the plastic material reaches the steady-state level.

Owner:OTSUKA PHARM FAB INC

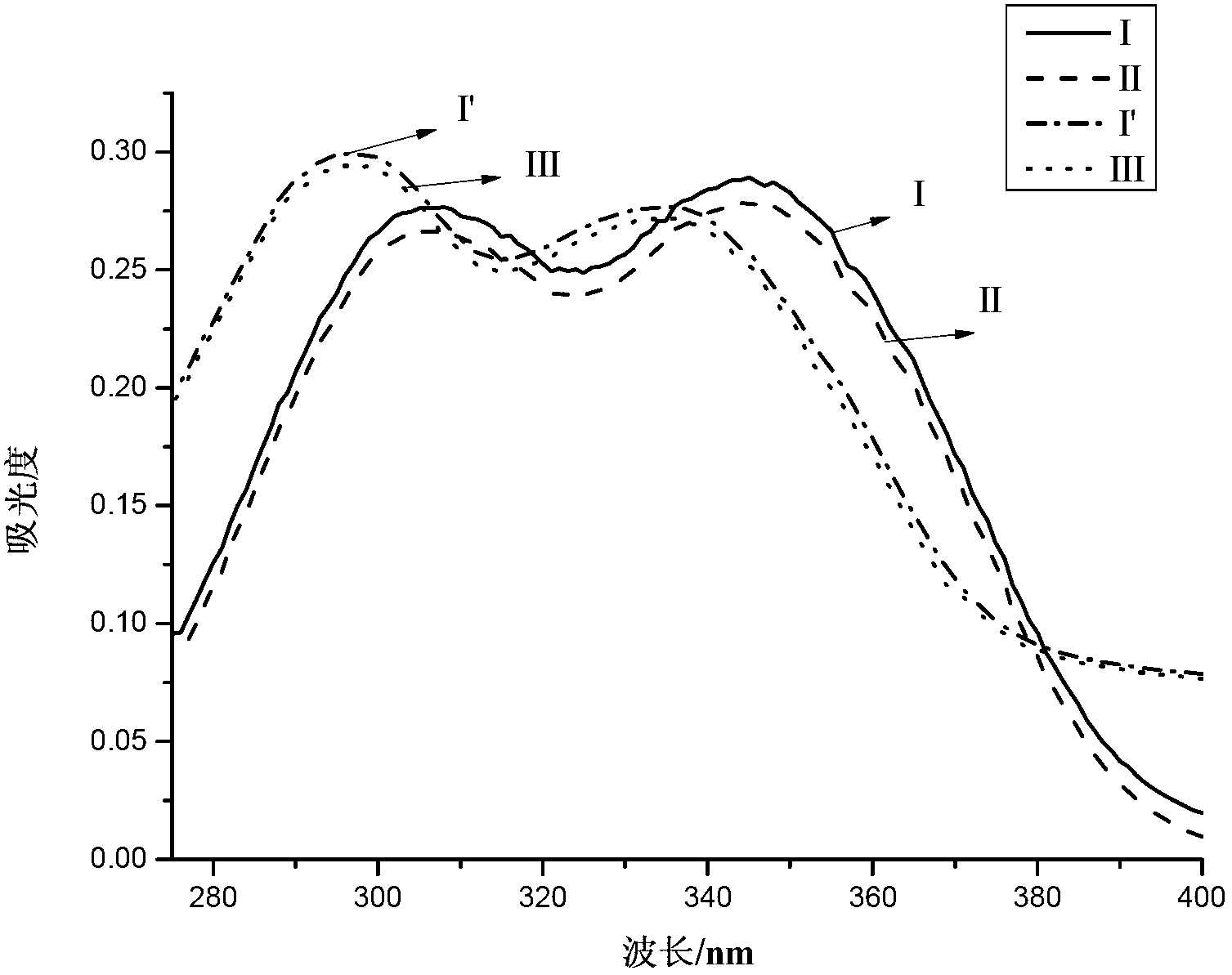

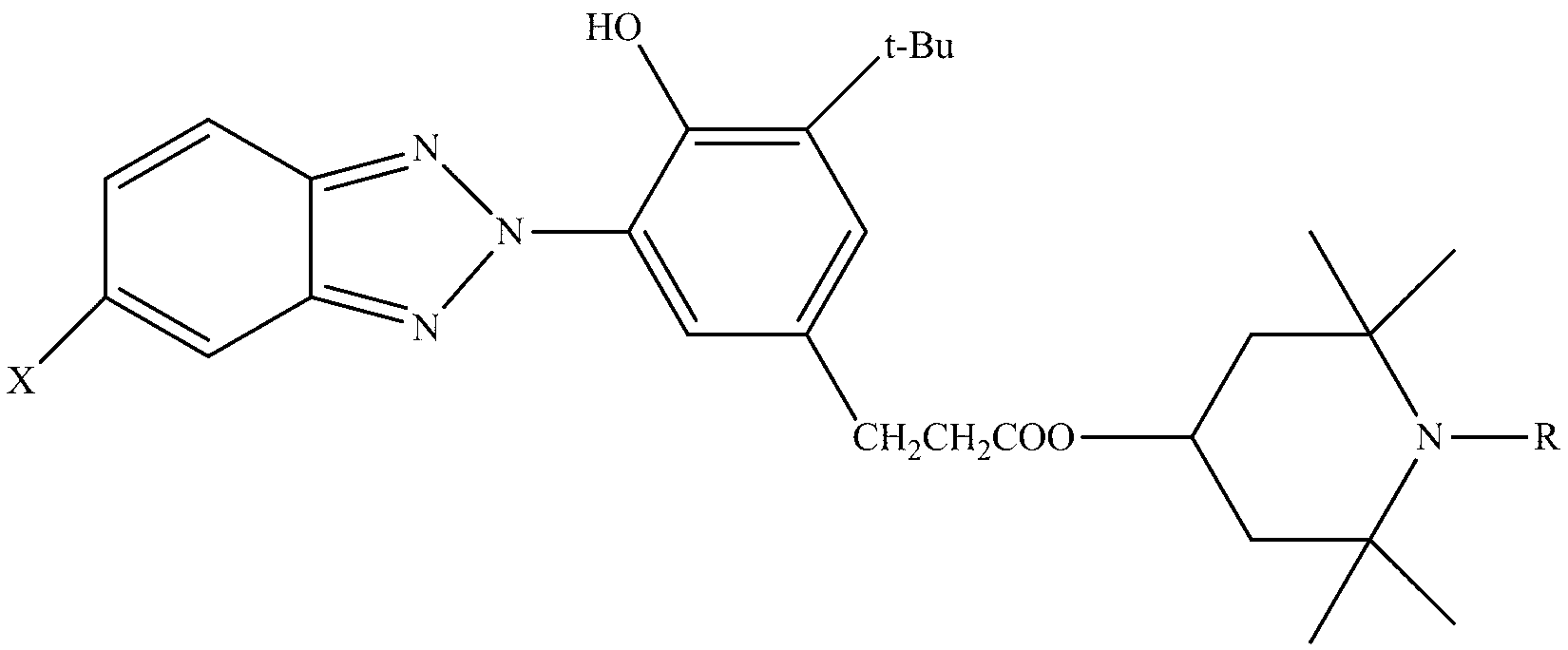

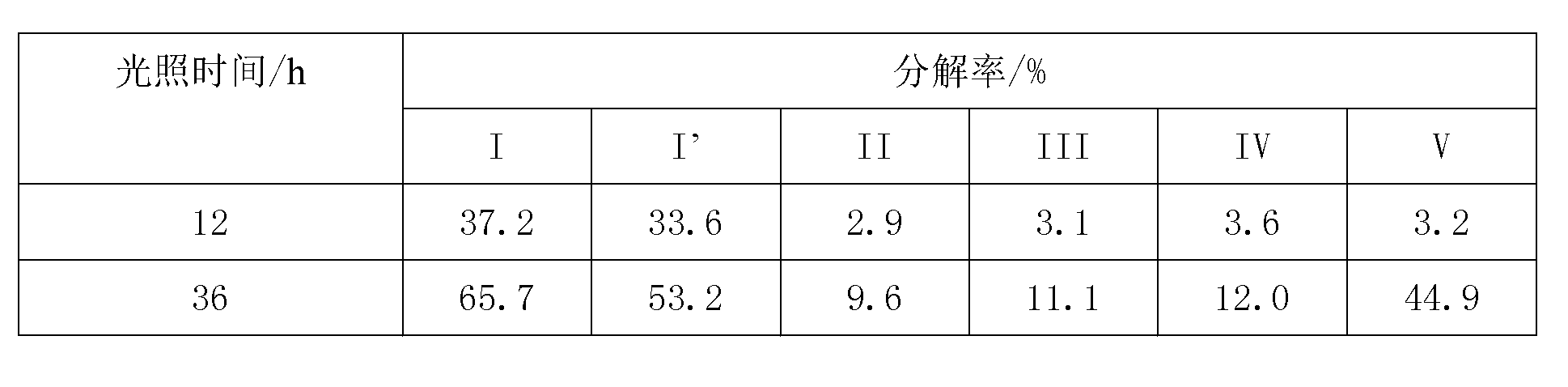

Benzotriazole-hindered amine composite photostabilizer and preparation method thereof

InactiveCN103012843AReduce lossLight stability and strong protection abilityOrganic chemistryBenzeneHindered amine light stabilizers

The invention discloses a benzotriazole-hindered amine composite photostabilizer of which the structural formula is disclosed in the specification, wherein R1 is H, CH3, C2H5, OCH3, OC2H5, Cl or Br, R2 is disclosed in the specification, R3 is alkyl group, alkoxy group or alkanoyl group, and R4 is H, alkyl group, alkoxy group or alkanoyl group. The invention also discloses a preparation method of the benzotriazole-hindered amine composite photostabilizer, which comprises diazo-coupling reaction, reduction ring-closing reaction, acyl-chlorination reaction, and alcoholization or ammonification reaction, thereby obtaining the benzotriazole-hindered amine composite photostabilizer.

Owner:ZHEJIANG SCI-TECH UNIV

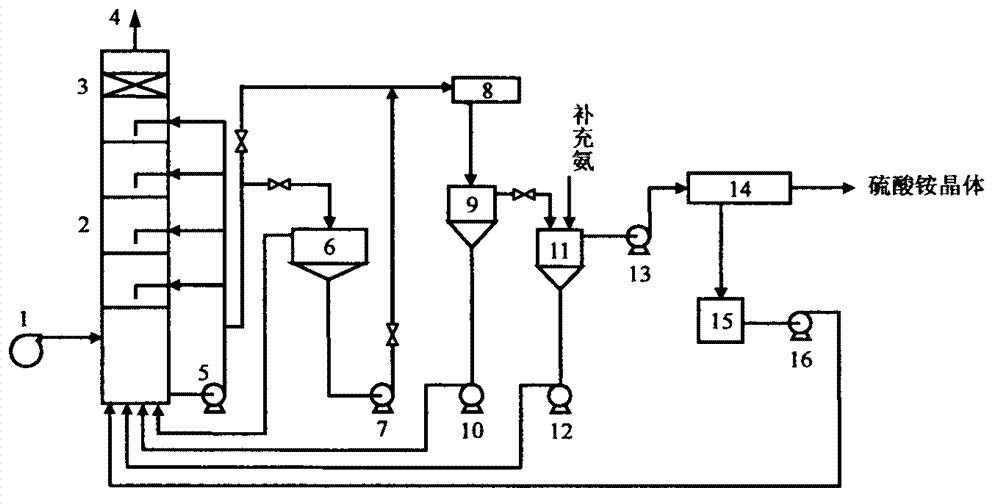

Method for desulfurization and denitrification of fume and coproduction of ammonium sulfate

ActiveCN103041688AInhibition of oxidative degradationReduce sulfur contentDispersed particle separationAmmonium sulfatesSulfate radicalsNitric oxide

The invention discloses a method for desulfurization and denitrification of fume and coproduction of ammonium sulfate. The method comprises the steps that slurry is prepared by a solution containing hydroxy carboxylic acid ligands and pyrite powder, the slurry is used for washing the fume containing sulfur dioxide and nitric oxide, sulfur dioxide and oxygen in the fume react with pyrite, sulfur dioxide and pyritic sulfur are oxidized into sulfate radicals, ferrous generated by leaching the pyrite is combined with aminocarboxylic acid ligands to generate a ferrous complexing agent, the ferrous complexing agent complexes and absorbs nitric oxide in the fume, a complexation product nitrosyl complex continues to react by the action of the pyritic to generate ammonium radicals, and the ammonium radicals are combined with the sulfate radicals to generate ammonium sulfate. According to the method, with the adoption of the pyrite, oxidation degradation of the ferrous complexing agent is inhibited, and the nitrosyl complex continues to react to generate the ammonium radicals. In addition, ferrous ions and the like leached from the pyrite have a catalyst effect in oxidizing sulfur dioxide.

Owner:青岛赛诺威尔工业水处理有限公司

Preparation method of novel polyphenols antioxidant

InactiveCN107827713AGood compatibilityInhibition of oxidative degradationOrganic chemistryOrganic compound preparationPolystyreneEthyl acetate

The invention relates to the field of preparation of antioxidants, in particular to a preparation method of a novel polyphenols antioxidant. The preparation method comprises the following steps: preparing an intermediate which adopts 3,5-di-tert-butyl-4-hydroxy-benzyl alcohol: adding 7.27 g of paraformaldehyde, 1.08 g of potassium tert-butoxide and 100 mL of tertiary butanol into a round-bottom flask with the volume of 500 mL, heating the flask under a condition of 70 DEG C till the paraformaldehyde is depolymerized; adding 20 g of 2,6-di-tert-butylphenol into the reaction liquid for reactionunder a normal temperature condition for 3 h, then adding 200 mL of deionized water into the reaction liquid, adding 100 mL of an ethyl acetate extraction organic phase, drying the mixture with a drying agent for 2 h, and carrying out suction filtering to remove the drying agent. The preparation method is simple in process and convenient to operate; a product is relatively high in heat stability and oxidization resistance, is high in compatibility with a polymer, can inhibit oxidative degradation of polypropylene, polyethylene, acrylonitrile-butadiene-styrene resin and polystyrene, and also can be used for synthesizing natural rubber, plastic and lubricating oil.

Owner:SHAANXI QIYUAN TECH DEV

Flame-retardant high-temperature-resistant radiation-resistant silicone rubber and preparation method thereof

ActiveCN111019358AImprove high temperature resistanceImprove radiation resistanceSiloxanePolymer chemistry

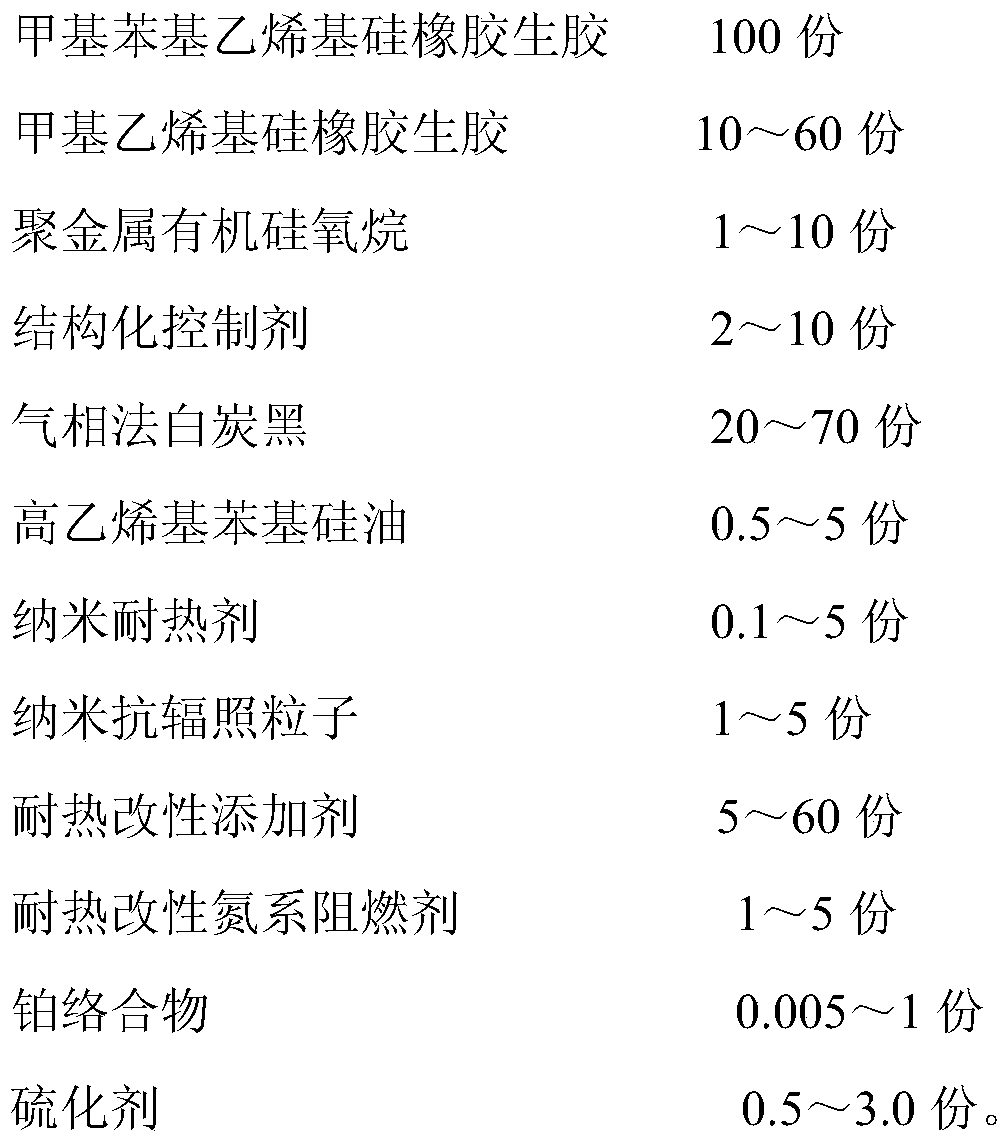

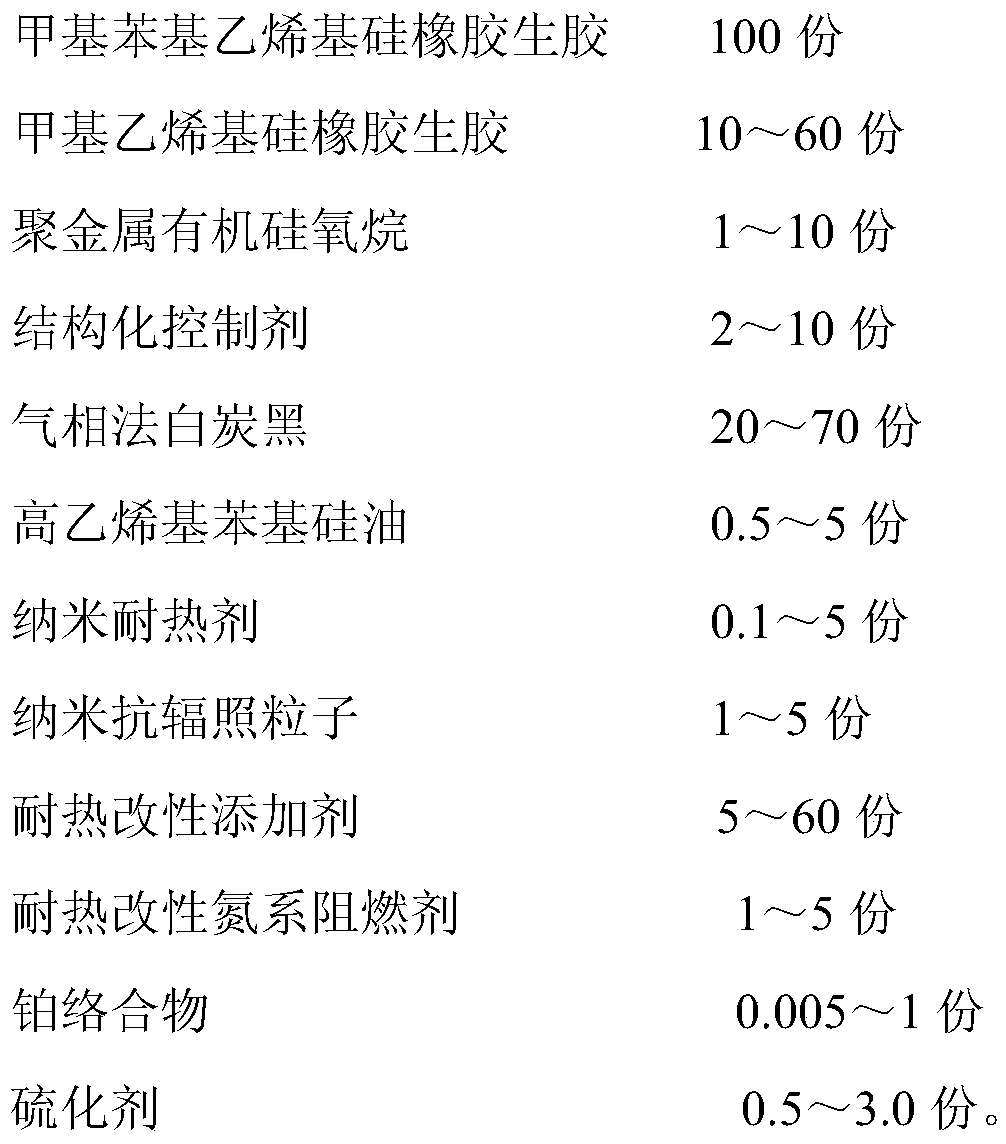

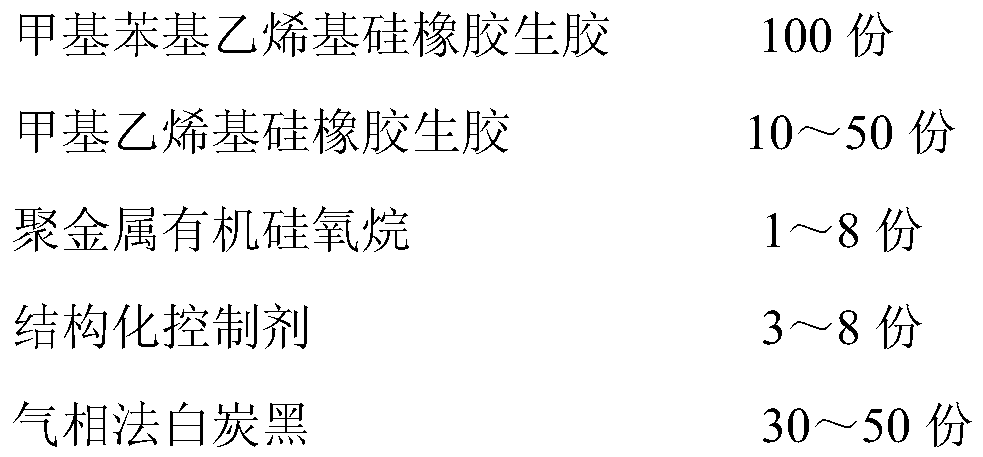

The invention provides flame-retardant high-temperature-resistant irradiation-resistant silicone rubber. The silicone rubber comprises the following components, by mass, 100 parts of raw methyl phenylvinyl silicone rubber, 10-60 parts of raw methyl vinyl silicone rubber, 1-10 parts of polyorganometallosiloxane, 2-10 parts of a structured control agent, 20-70 parts of fumed silica, 0.5-5 parts ofhigh vinyl phenyl silicone oil, 0.1-5 parts of a nanometer heat-resistant agent, 1-5 parts of nanometer radiation-resistant particles, 5-60 parts of a heat-resistant modified additive, 1-5 parts of aheat-resistant modified nitrogen flame retardant, 0.005-1 part of a platinum complex and 0.5-3.0 parts of a vulcanizing agent. The invention further provides a preparation method of the flame-retardant high-temperature-resistant irradiation-resistant silicone rubber. According to the flame-retardant high-temperature-resistant irradiation-resistant silicone rubber and the preparation method thereof, the prepared silicone rubber has very good high temperature resistance and irradiation resistance, is low-smoke, halogen-free, flame-retardant and water-resistant, and can be used as a nuclear powercable insulating material.

Owner:SHANGHAI ELECTRIC CABLE RES INST

Preparation method of high-performance fluoride rubber/silicone rubber cable sheath material

InactiveCN105802090AGood weather resistanceAccelerated corrosionRubber insulatorsInsulated cablesElastomerCalcium silicate

The invention discloses a preparation method of a high-performance fluoride rubber / silicone rubber cable sheath material. The preparation method comprises the following steps of performing primary mixing on fluoride rubber, silicone rubber, epoxy acrylate elastomer, hydrogenated butadiene-acrylonitrile rubber, maleic anhydride grafted polyethylene and methyl vinyl silicone rubber grafted methacrylic acid-2,2,2-trifluoroethyl to obtain a primary rubber compound; adding carbon nanotubes, stearic acid modified diatomite, calcium silicate, polyaniline nanofibers, sepiolite fibers and calcium hydroxide, and mixing for 1 to 5 minutes; adding 2,6-di-tert-butyl paraaminophenol, 2,5-di-tert-butylhydroquinone, nitrosodiphenylamine, butylmercaptooxo stannane, 5,5'- dimethyl-5,10-dihydracridine, and mixing for 3 to 8 minutes; adding stearic acid, inositol hexaphosphate, epoxidized linseed oil, active magnesium oxide, bisphenol AF, benzyl triphenyl phosphorus chloride, N,N'-meta phenylene bismaleimide, phenolic resin and an accelerator, mixing for 5 to 10 minutes and then vulcanizing for two times.

Owner:ANHUI HUAYU CABLE GRP

Drying and processing method for improving retention rate of carotenoid in pumpkins

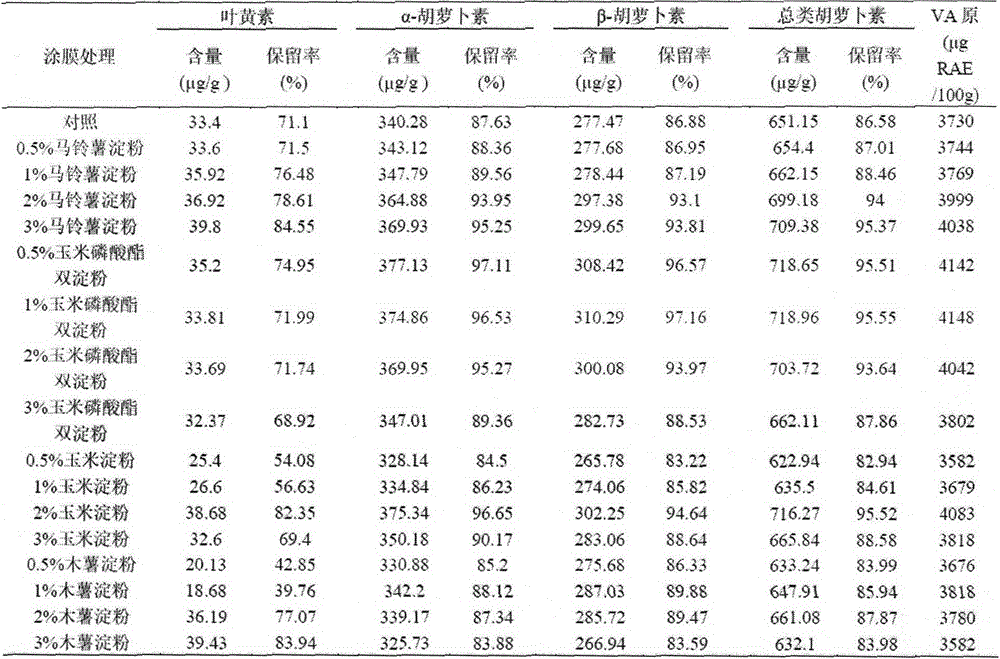

ActiveCN105994581AImprove drying qualitySimple pretreatment processFruits/vegetable preservation by heatingFood dryingBeta-CarotenePotato starch

The invention relates to the technical field of fruits and vegetables, in particular to a drying and processing method for improving the retention rate of carotenoid in pumpkins. Namely, the pumpkins are selected, cleaned and peeled, pulp and seeds are removed, the pumpkins are cut into slices of 4-6 mm, and then coating treatment is performed in a potato starch solution with the mass concentration of 2%-3% or a corn phosphate double-starch solution with the mass concentration of 0.5%-1.5% at the temperature of 80-85 DEG C for 5-15 minutes; drying treatment is performed in a vacuum microwave drying device after air drying, the microwave power is controlled to be 4-5 W / g, the vacuum degree is controlled to be 80-90 KPa, and the drying time is controlled to be 3-5 minutes; then freeze drying is performed, drying stops when the water content of the pumpkin slices is 3%-5%, and nitrogen filled packaging is conducted on products. The drying and processing method improves the retention rate of the carotenoids in the pumpkins to the most degree, the beta-carotene retention rate is 93% or above, the alpha-carotene retention rate is 94% or above, the lutein retention rate is 71% or above, and the provitamin A and color and luster of the products are kept well. In addition, by the adoption of the method, the drying time is saved, and the energy consumption of production is reduced.

Owner:JIANGSU ACAD OF AGRI SCI

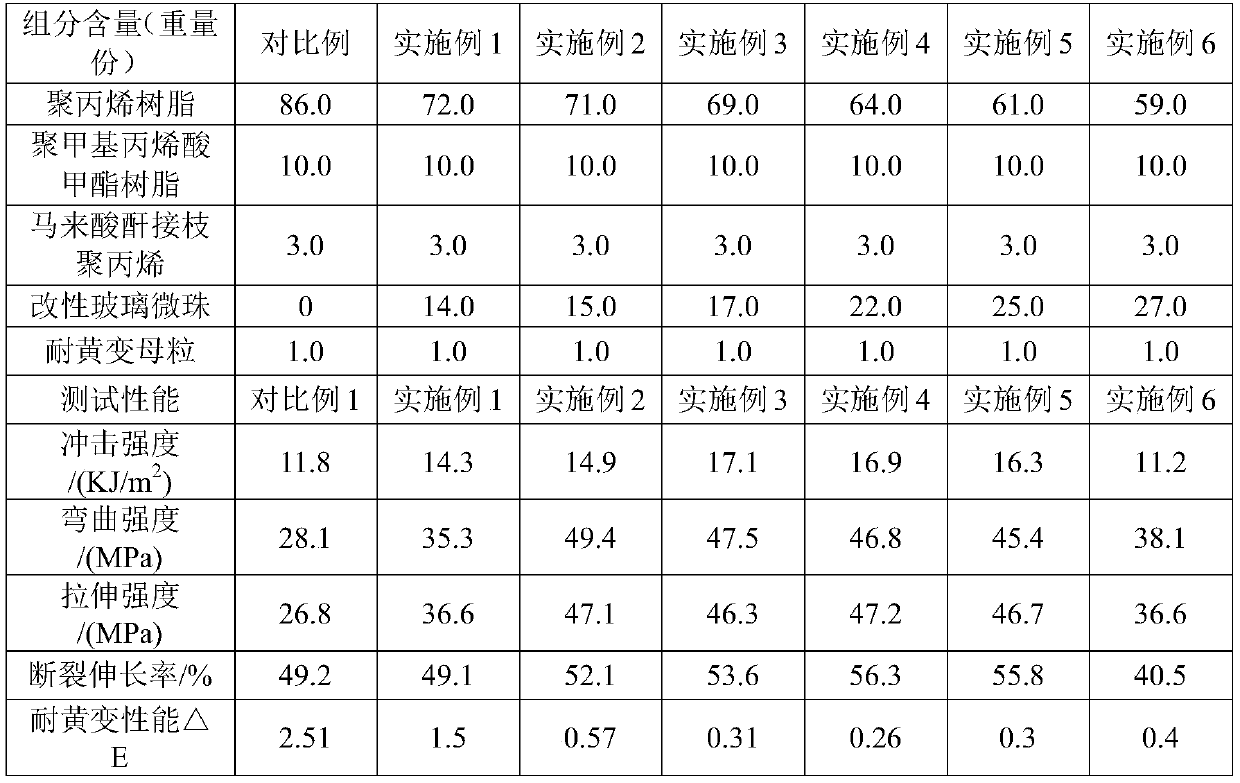

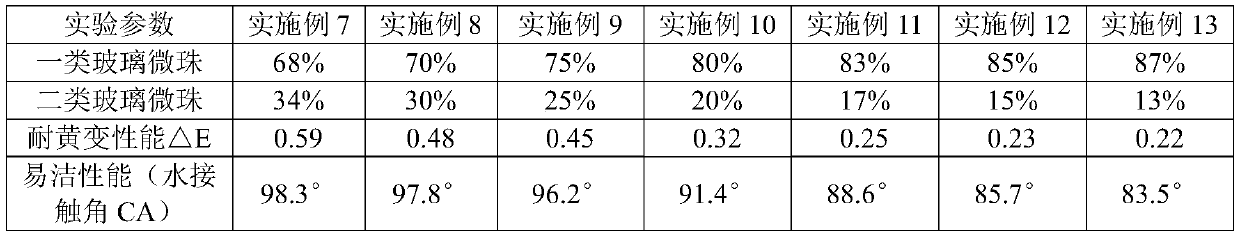

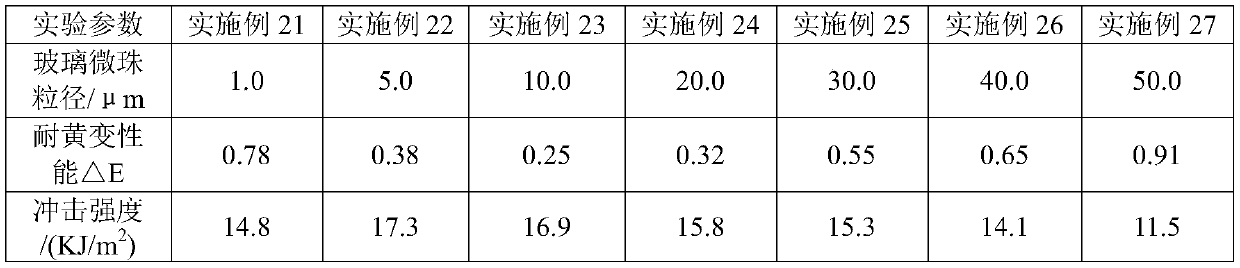

Modified glass microsphere and preparation method thereof and method for preparing composite resin product by using modified glass microsphere

The invention discloses a modified glass microsphere and a preparation method thereof and a method for preparing a composite resin product by using the modified glass microsphere. The modified glass microsphere includes a first class glass microsphere and a second class glass microsphere, a discontinuous metal layer and an ultraviolet absorbent wrap the surface of the first class glass microsphere, a hydrophobic material wraps the surface of the second class glass microphere, the coverage rate of the metal layer on the surface of the first glass microsphere is 45.0%-85.0%, and the modified glass microbead is added into the component of a common anti-yellowing product to improve the anti-yellowing property and the mechanical property of the product.

Owner:JOMOO KITCHEN & BATHROOM

Acrylic amide modified graft copolymer, preparation method and application thereof

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method for preparing 4-vinyl benzyl surface-active macromonomer

InactiveCN101543748BImprove surface activityImprove salt toleranceTransportation and packagingMixingChromatographic separationAlkylphenol

The invention discloses a method for preparing a 4-vinyl benzyl surface-active macromonomer, which is characterized by comprising the following steps: adding 20 portions of alkylphenol polyoxyethylene ether (CmH2m+1-C6H4-O-(CH2CH2O)nH, n is equal to 1 to 60, and m is equal to 1 to 20), 10 to 900 portions of solvent and 0.1 to 15 portions of catalyst into a three-mouth reaction flask with a reflux condensation device, and reacting for 1 hour under stirring at the room temperature; increasing temperature to 30 to 90 DEG C, adding 0.5 to 25 portions of 4-vinyl benzyl chloride into the reaction product, and continuously reacting for 6 to 48 hours; distilling the reaction product under reduced pressure to remove the solvent so as to obtain a crude product; and performing silica gel column chromatographic separation to obtain 4-vinyl benzyl alkylphenol polyoxyethylene ether with the yield of 62 to 94 percent. The 4-vinyl benzyl alkylphenol polyoxyethylene ether has excellent surface activity, and can be directly used as a surfactant. A water-soluble copolymer synthesized by taking the 4-vinyl benzyl alkylphenol polyoxyethylene ether as a surface-active macromonomer has the function of tackifying, or reducing solution surface tension and water-oil interfacial tension, and can be taken as a tackifying copolymer or a macromolecular surfactant for improving the oil recovery ratio.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

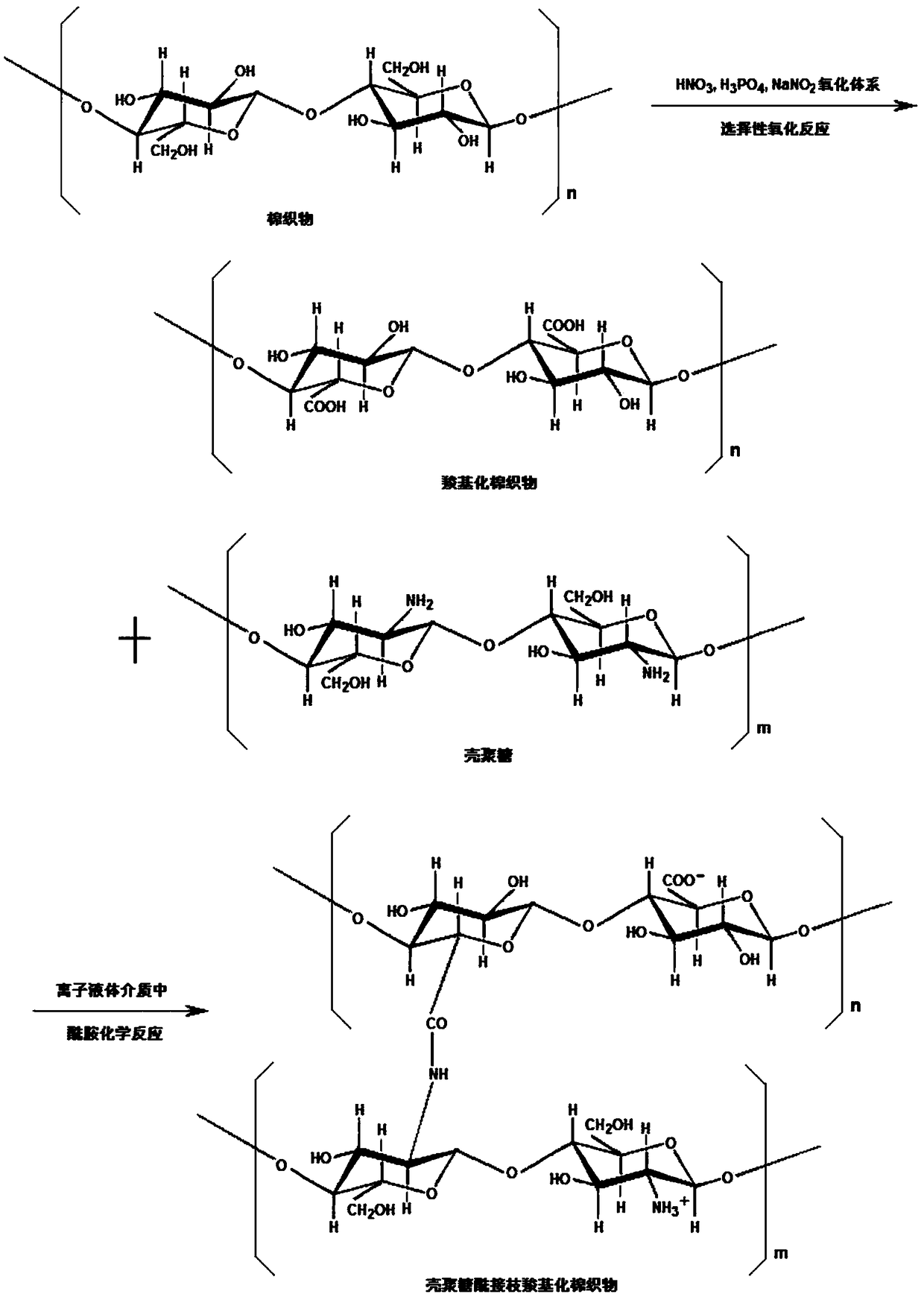

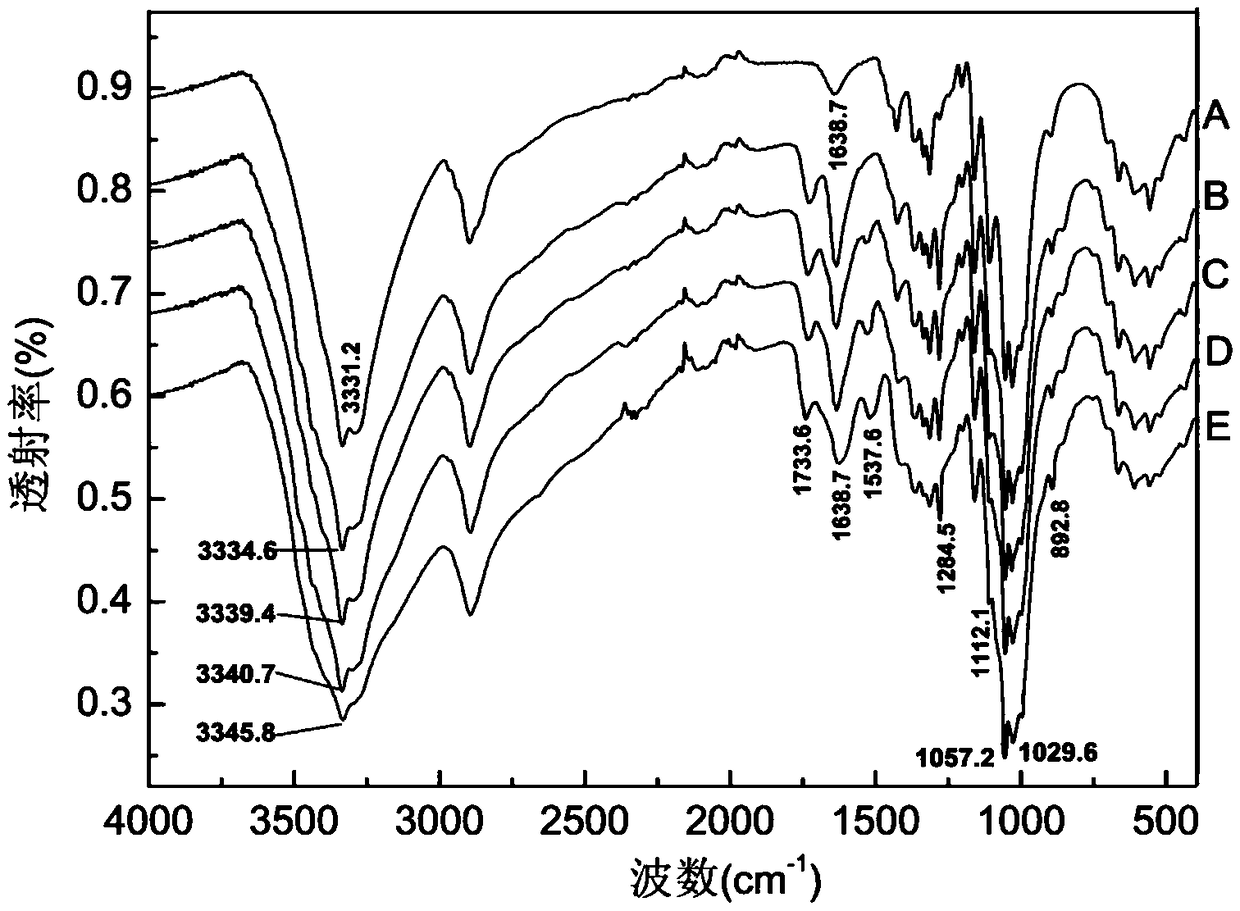

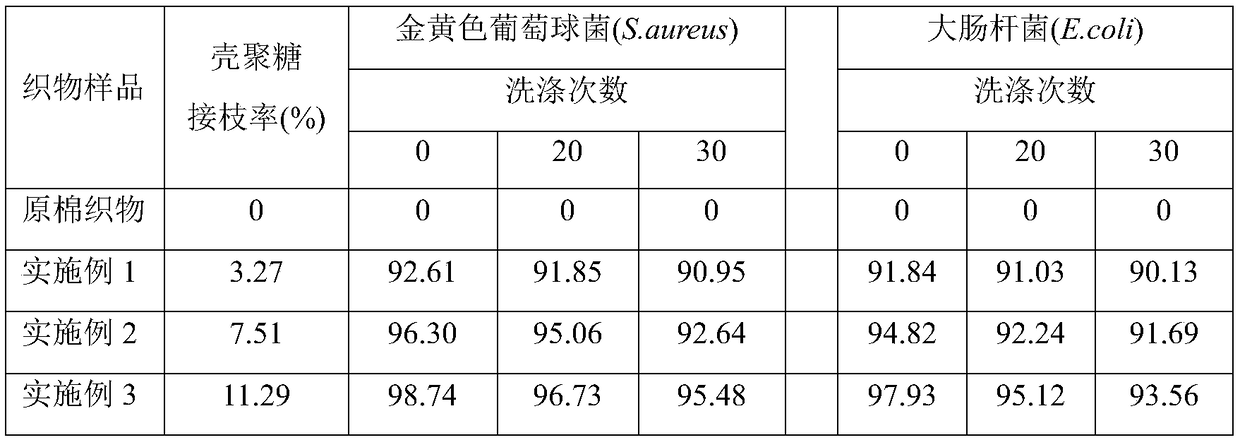

Method for preparing chitosan modified carboxylation cotton fabric in ionic liquid medium

ActiveCN109338724ALittle mechanical damageReduce hydrogen bondingBiochemical fibre treatmentWrinkle resistant fibresCross-linkChemical reaction

The invention discloses a method for preparing a chitosan modified carboxylation cotton fabric in an ionic liquid medium. The method is characterized by comprising the following steps: firstly, dissolving low-crystallization chitosan into an ionic liquid, carrying out selective oxidation on a cotton fabric after desizing and boiling in isopropanol in a concentrated nitric acid / strong phosphoric acid-sodium nitrite system, further stirring a carboxylation cotton fabric and chitosan in the ionic liquid medium at 30-40 DEG C to implement an amide chemical reaction, removing the ionic liquid, carrying out vacuum drying and water washing, thereby obtaining the chitosan modified carboxylation cotton fabric. The method disclosed by the invention is simple and feasible, rapid in amide reaction, high in grafting rate, possible in ionic liquid recycling and green and environmentally friendly, the prepared chitosan amide modified cotton fabric has a long-lasting and efficient antibacterial capability, is affiliative to human bodies, is safe and sanitary and good in wearing comfort, overcomes adverse influence caused by chemical cross-linking agents and acid solutions upon excellent propertiesof cotton fabrics and human health in conventional chitosan modification, and has wide practical application prospects.

Owner:SHAOXING MAIBAO TECH CO LTD

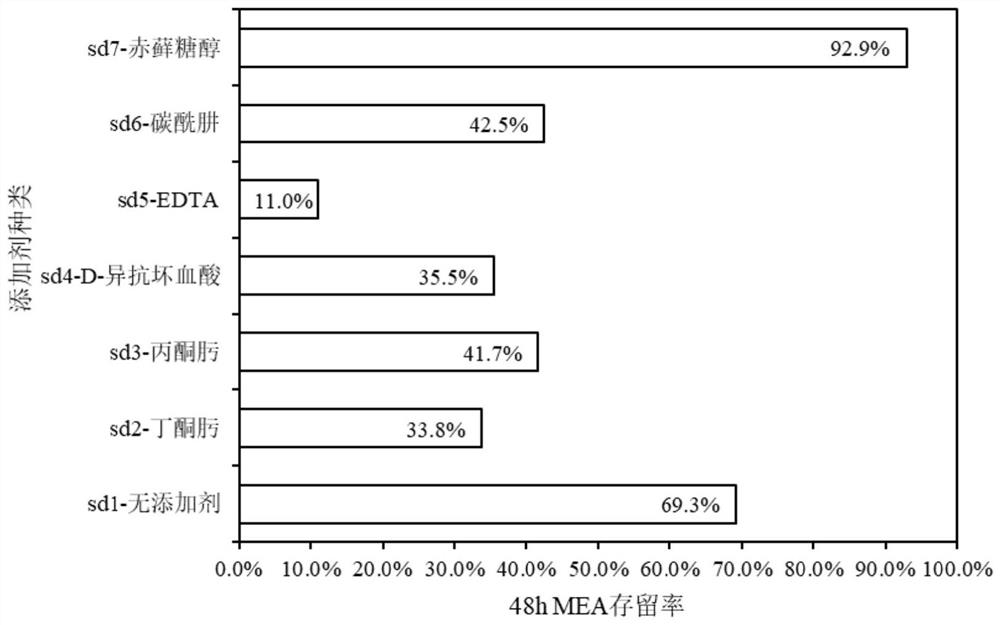

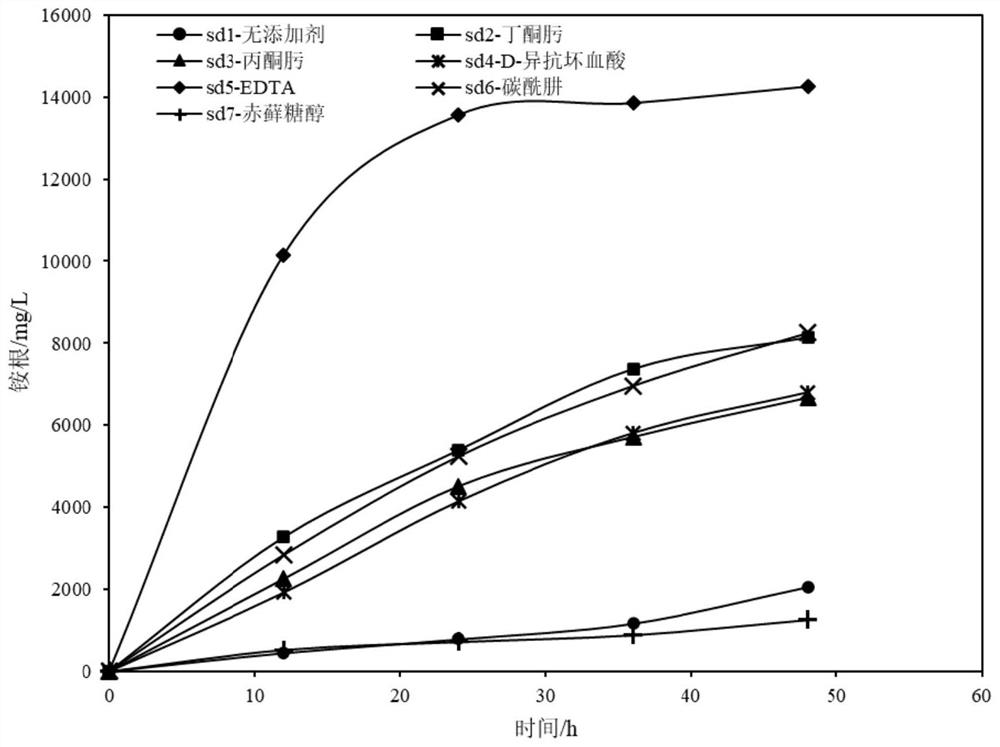

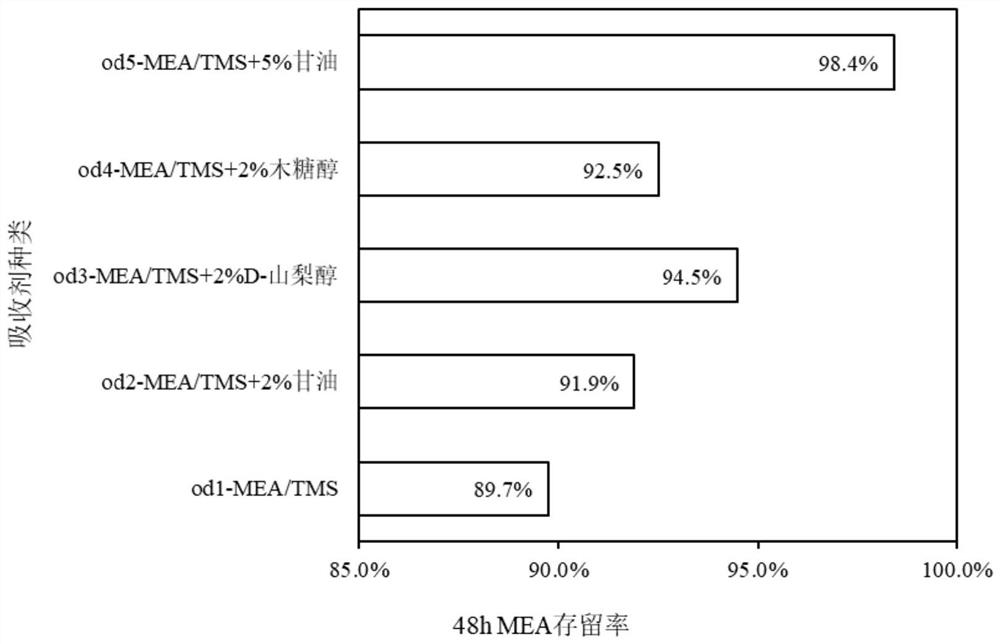

Oxidation inhibitor, carbon dioxide absorbent and carbon dioxide absorption method thereof

ActiveCN112546840AIncrease absorption rateExcellent cycle absorption performanceProductsGas treatmentSulfolaneCo2 absorption

The invention discloses an oxidation inhibitor, a carbon dioxide absorbent and a carbon dioxide absorption method thereof. The carbon dioxide absorbent comprises a mixed aqueous solution of ethanolamine (MEA) and sulfolane (TMS) and an oxidation inhibitor, wherein the oxidation inhibitor is selected from glycerol, D-sorbitol, xylitol and erythritol; and MEA and TMS account for 25%-50% and 20%-50%respectively, and the content of the oxidation inhibitor is greater than 0 and less than or equal to 10%. The method comprises the following steps: adding the carbon dioxide absorbent into an absorption tower for an absorption reaction with carbon dioxide gas to form a carbon dioxide absorption liquid; enabling the carbon dioxide absorption liquid to enter a phase splitter for standing and layering to form an enriched phase enriched with carbon dioxide and a lean carbon dioxide absorption phase; and enabling the enriched phase to enter a desorption tower to desorb high-purity carbon dioxide, and returning the absorption phase to the absorption tower as the carbon dioxide absorbent to continuously participate in the absorption reaction. The method has the advantages of good absorbent oxidation inhibition, high carbon dioxide absorption efficiency and the like.

Owner:TSINGHUA UNIV

Ticagrelor slow-release preparation as well as preparation and application thereof

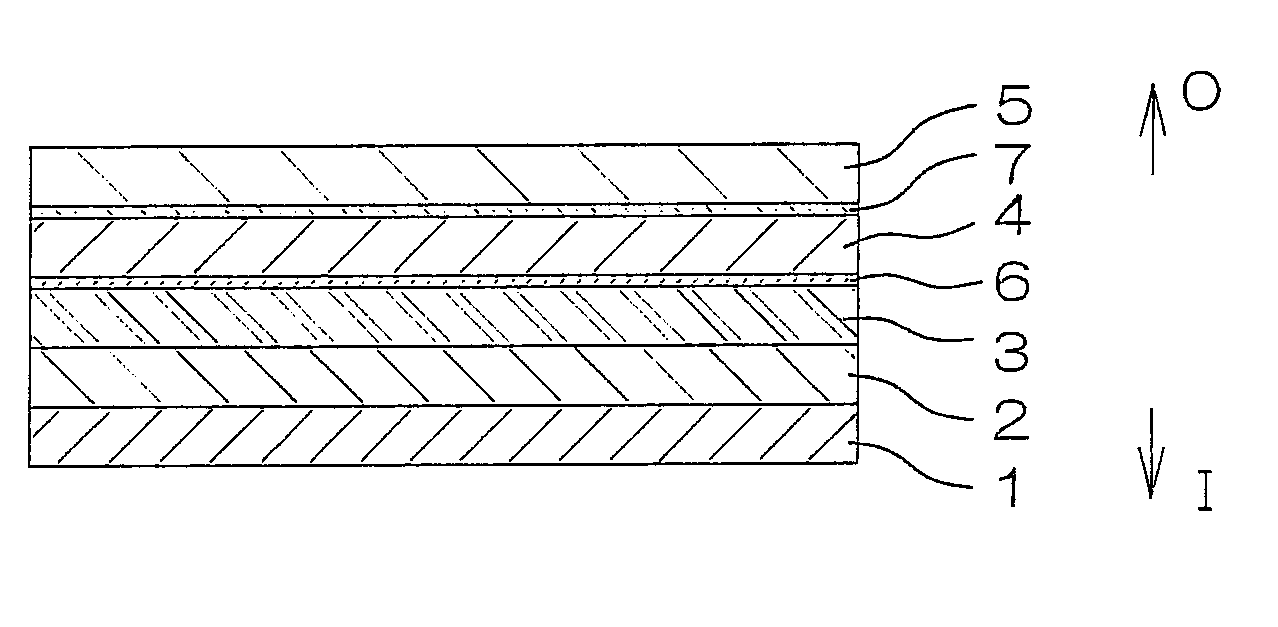

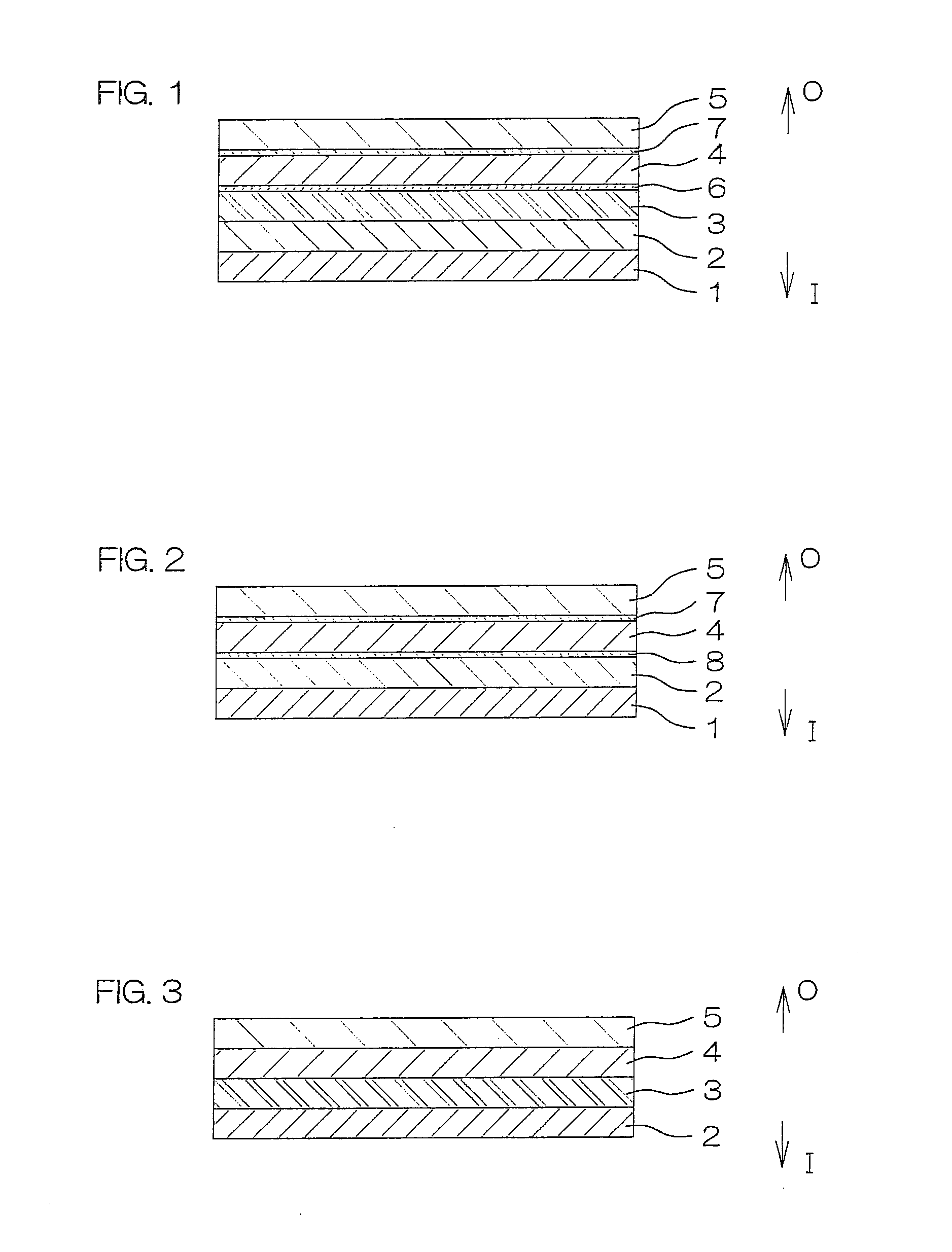

InactiveCN109806261AGood treatment effectImprove complianceOrganic active ingredientsPharmaceutical delivery mechanismTicagrelorPatient compliance

The invention belongs to the technical field of ticagrelor and in particular relates to a ticagrelor slow-release preparation as well as preparation and application thereof. The ticagrelor slow-release preparation provided by the invention comprises at least one rapid release layer and at least one slow release layer, wherein each of the rapid release layer and the slow release layer contains theticagrelor; the mass ratio of the content of the ticagrelor in the rapid release layer to the content of the ticagrelor in the slow release layer is 1 to (3 to 7); the ticagrelor slow-release preparation is used as a medicine for anti-platelet treatment; on one hand, the preparation has reasonable plasma drug peak concentration; on the other hand, the residual ticagrelor is slowly released and stable plasma drug concentration is maintained; the anti-platelet treatment effect is good and the bleeding tendency is reduced; the preparation is orally taken once each day and has good patient compliance and high utilization safety; the preparation method of the ticagrelor slow-release preparation has the advantages of simple technology, relatively low cost and good practicability.

Owner:梁江丽

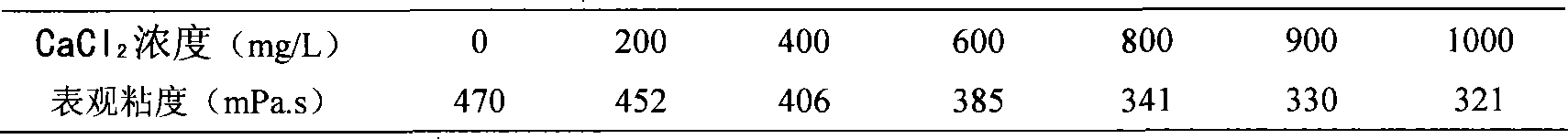

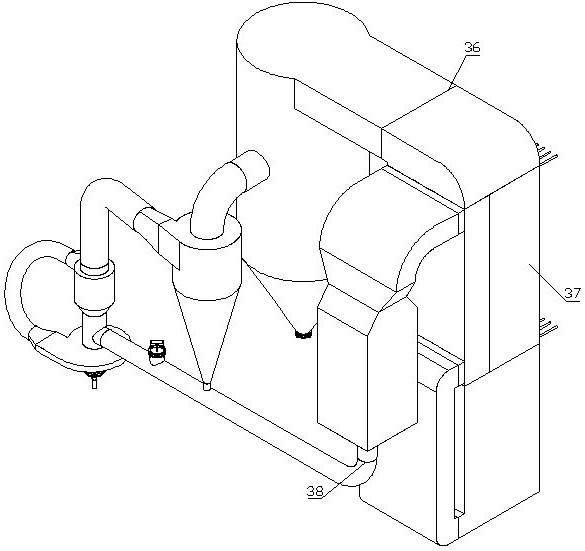

Gadenia yellow pigment extraction device and high-color-value gadenia yellow pigment extraction method

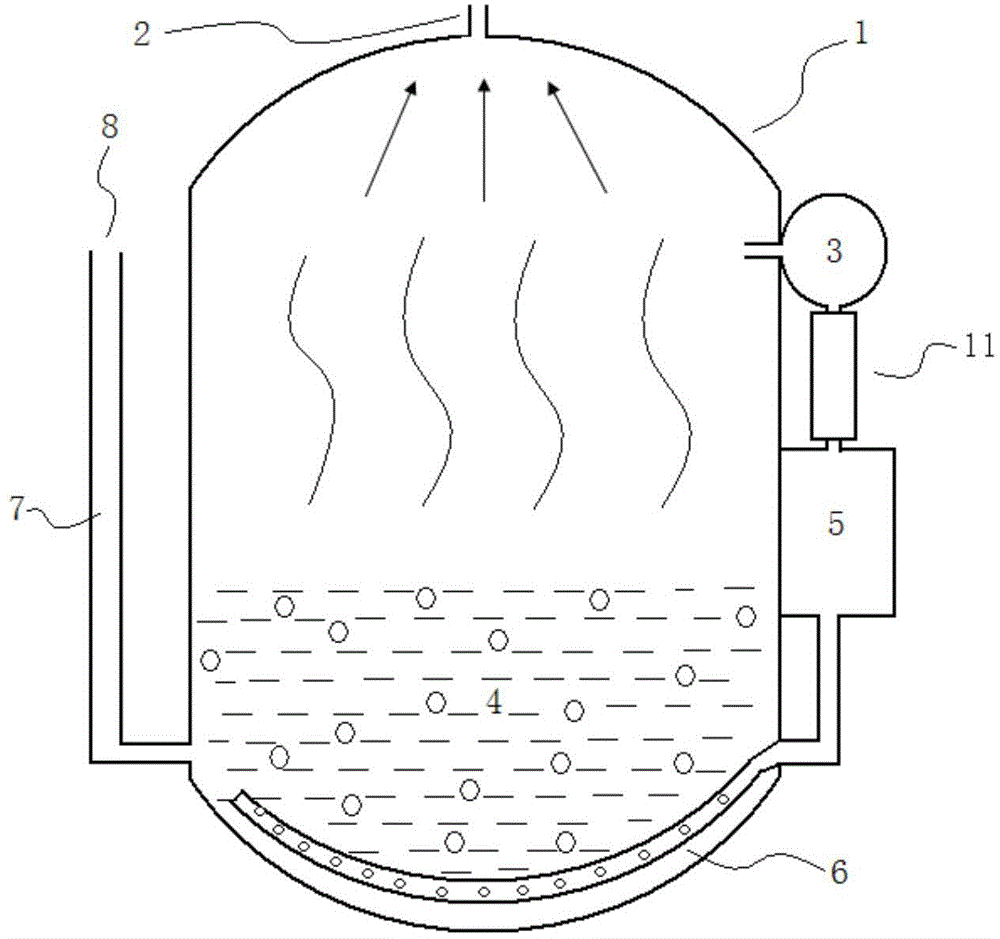

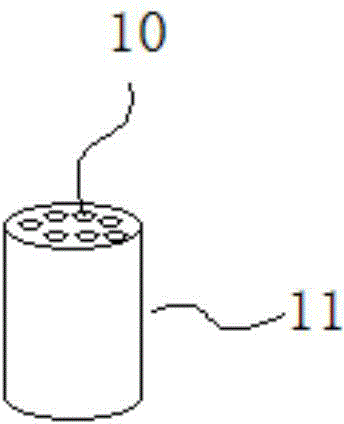

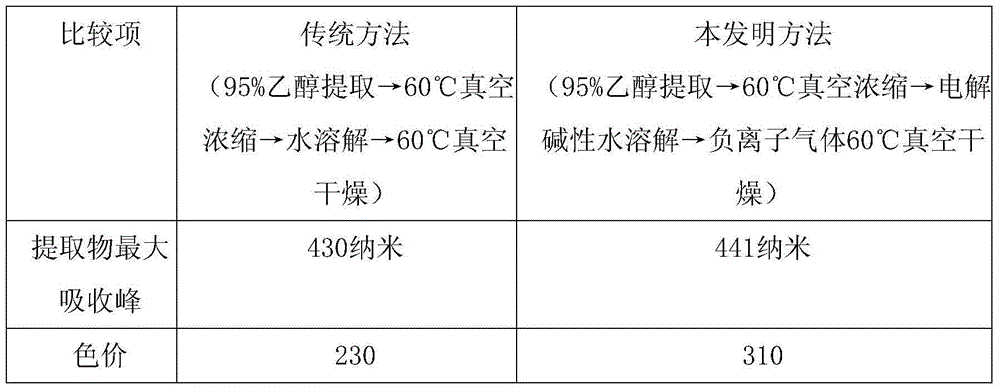

ActiveCN104548628AInhibition of oxidative degradationHigh priceEvaporator accessoriesNatural dyesIonProcess engineering

The invention relates to a gadenia yellow pigment extraction device and a high-color-value gadenia yellow pigment extraction method. The device comprises a vacuum drying tank, an extraction opening, a feeding device and a negative ion generation device, wherein the extraction opening is formed in the top of the vacuum drying tank, and the feeding device and the negative ion generation device are respectively arranged on the side wall; the feeding device comprises a feed inlet and a high-strong magnetic pipeline; the feed inlet is communicated with the interior of the vacuum drying tank through the high-strong magnetic pipeline; the negative ion generation device consists of a gas circulating pump, a gas heating column, a negative ion generation device and a gas guide pipe; the gas circulation pump comprises a gas inlet formed in the side wall of the vacuum drying tank; the height of the gas inlet is greater than that of the liquid inside the vacuum drying tank; the gas guide pipe extends into the vacuum drying tank from the bottom of the vacuum drying tank and is arranged below the liquid level; and the gas inlet is communicated with the gas guide pipe sequentially through the gas circulating pump, a gas heating column and the negative ion generation device. The gadenia yellow pigment extraction device has the advantages that a target product is effectively ensured not to be oxidized, no chemical reducing agents are required and the like.

Owner:GUANGSHUI DONGCHEN AGRI SCI & TECH

Water-soluble micro-crosslinked copolymer, preparation and use thereof

InactiveCN101302266BGood water solubilityGood molecular associationDrilling compositionSolubilityBottle

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method of traditional Chinese medicinal material ultrafine powder and processed product thereof

InactiveCN111940056AInhibition of oxidative degradationQuality improvementHuman health protectionCombination devicesProcess engineeringOxygen content

Owner:YUNNAN QIDAN PHARMA CO LTD

Engine performance recovery protective agent and processing technology thereof

The invention discloses an engine performance recovery protective agent and a processing technology. The engine performance recovery protective agent comprises the following components in parts by mass: 20-40 parts of base oil, 5-10 parts of purified MoDTCs, 5-10 parts of tricresyl phosphate, 10-30 parts of ZDDP, 10-20 parts of sodium chloride, 5-15 parts of a succinimide ashless dispersant and 5-10 parts of a clearing agent. In the high-temperature and high-pressure environment of an engine, when the protective agent is rubbed, the temperature rises rapidly, carbon disulfide and molybdenum disulfide are decomposed, convex-concave parts on the metal surface are filled and leveled up, and the smooth and anti-friction effects are achieved; the protective agent can repair metal abrasion and activate an oil seal under the condition that an engine is not disassembled, a molybdenum alloy protective layer which is extremely thin but has extremely high compressive strength and good abrasion resistance is formed on the metal surface, the lubricating performance is excellent, friction in the engine is greatly reduced, the oxidation resistance of lubricating oil is remarkably improved, oxidative degradation of the lubricating oil is effectively inhibited, formation of high-temperature sediments and low-temperature oil sludge is reduced, and super-strong protection is formed for the engine.

Owner:JIANGSU RUIAN AUTOMOBILE IND CO LTD

Benzotriazole-hindered amine composite photostabilizer and preparation method thereof

InactiveCN103012843BReduce lossLight stability and strong protection abilityOrganic chemistryBenzeneHindered amine light stabilizers

The invention discloses a benzotriazole-hindered amine composite photostabilizer of which the structural formula is disclosed in the specification, wherein R1 is H, CH3, C2H5, OCH3, OC2H5, Cl or Br, R2 is disclosed in the specification, R3 is alkyl group, alkoxy group or alkanoyl group, and R4 is H, alkyl group, alkoxy group or alkanoyl group. The invention also discloses a preparation method of the benzotriazole-hindered amine composite photostabilizer, which comprises diazo-coupling reaction, reduction ring-closing reaction, acyl-chlorination reaction, and alcoholization or ammonification reaction, thereby obtaining the benzotriazole-hindered amine composite photostabilizer.

Owner:ZHEJIANG SCI-TECH UNIV

Special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for ship cable

InactiveCN105860373AImprove low temperature resistanceEasy to processRubber insulatorsCalcium silicateCarbon nanotube

The invention discloses a special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for a ship cable. The material is prepared from fluoride rubber, fluorine-containing acrylate rubber, epoxy acrylate rubber, HNBR, maleic anhydride grafted polyethylene, stearic acid, active magnesium oxide, bisphenol AF, benzyl triphenyl phosphorus chloride, trimethylolpropane trimethacrylate, phenolic resin, carbon nanotubes, stearic acid modified diatomite, calcium silicate, polyaniline nanofiber, magnesium hydroxide, calcium hydroxide, inositol hexaphosphate, epoxidation triglyceride fatty acid, epoxy linseed oil, 2,6-ditert-butyl-p-aminophenol, 2,5-di-tert-butylhydroquinone, nitrosodiphenylamine, butylmercaptooxo stannane and accelerant. The special anti-ageing and low-temperature-resistant modified fluoride rubber sheath material for the ship cable is high in strength, good in anti-ageing performance, excellent in oil resistance and low temperature resistance and capable of meeting use requirements of ship cable sheaths.

Owner:ANHUI HUAYU CABLE GRP

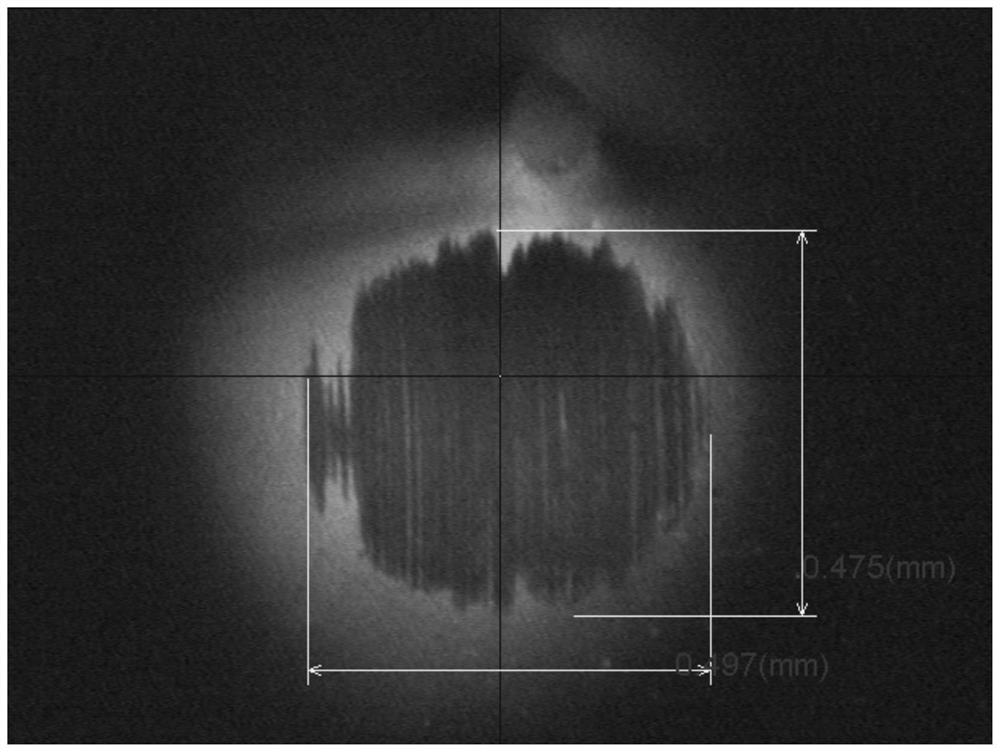

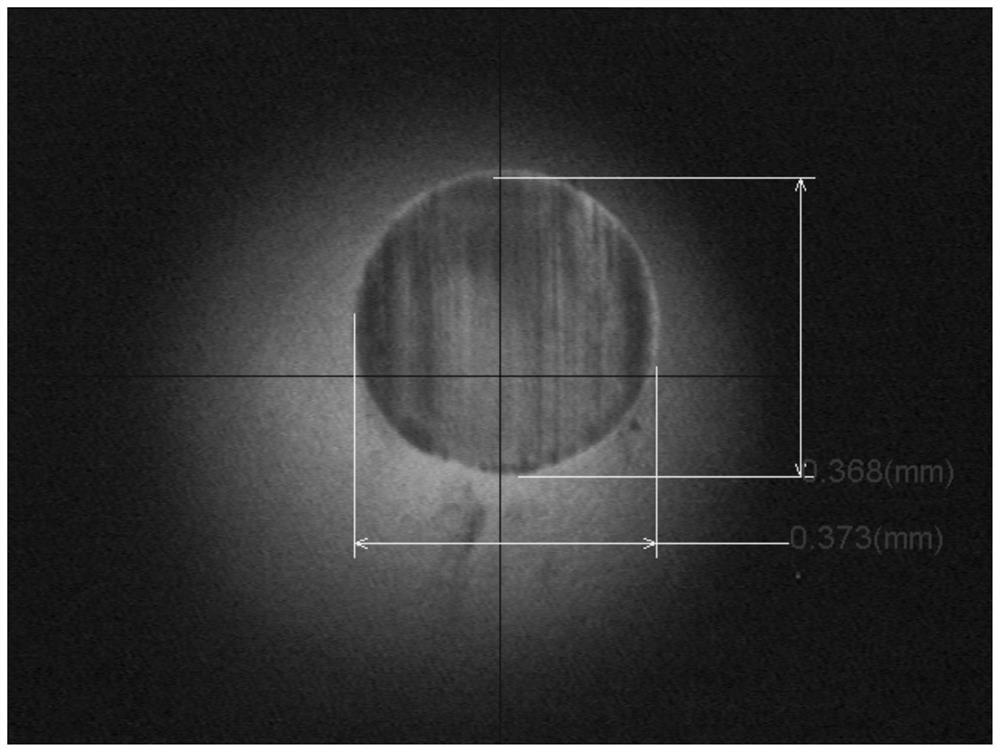

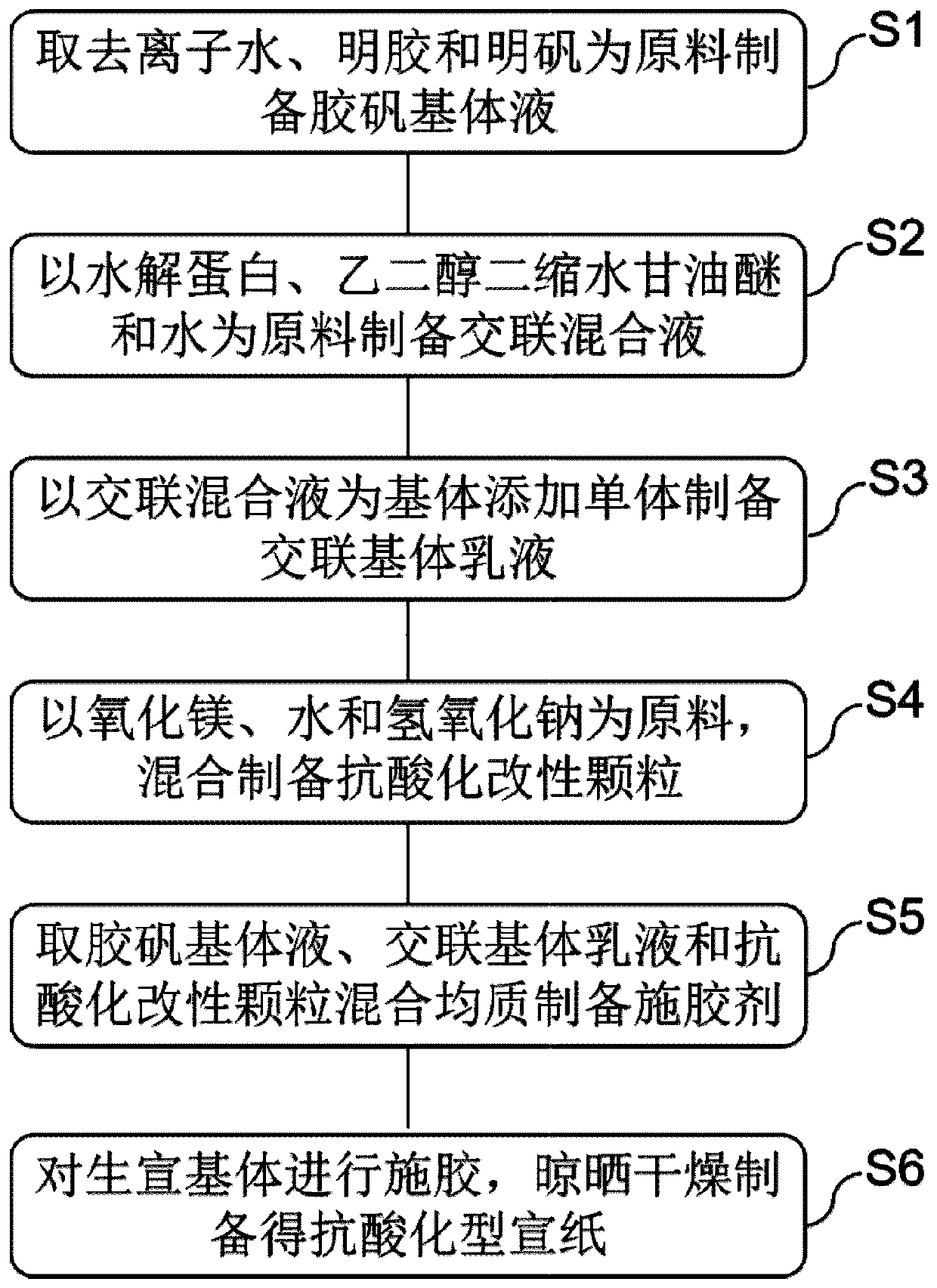

Preparation method of acidification-resistant Xuan paper

InactiveCN111287013AImprove bond strengthInhibition of oxidative degradationWater-repelling agents additionPaper/cardboardChemistryEmulsion

The invention provides a preparation method of acidification-resistant Xuan paper. The method includes firstly, preparing a gelatin-alum matrix liquid from deionized water, gelatin and alum; preparinga cross-linking mixed solution by taking hydrolyzed protein, ethylene glycol diglycidyl ether and water as raw materials; adding a monomer into the cross-linked mixed solution serving as a matrix toprepare a cross-linked matrix emulsion; mixing magnesium oxide, water and sodium hydroxide as raw materials to prepare acidification-resistant modifying particles; mixing the gelatin-alum matrix liquid, the cross-linked matrix emulsion and the acidification-resistant modifying particles, and homogenizing to prepare a sizing agent; performing sizing treatment on a Xuan paper matrix, airing and drying to obtain the acidification-resistant Xuan paper. The preparation method not only can effectively improve the color fastness of the Xuan paper in use, but also can reinforce cellulose in the Xuan paper material, so that the mechanical strength of the Xuan paper material is improved, and the storage period of the Xuan paper is prolonged.

Owner:YANGZHOU ANCIENT WIRE BOUND IND CO LTD

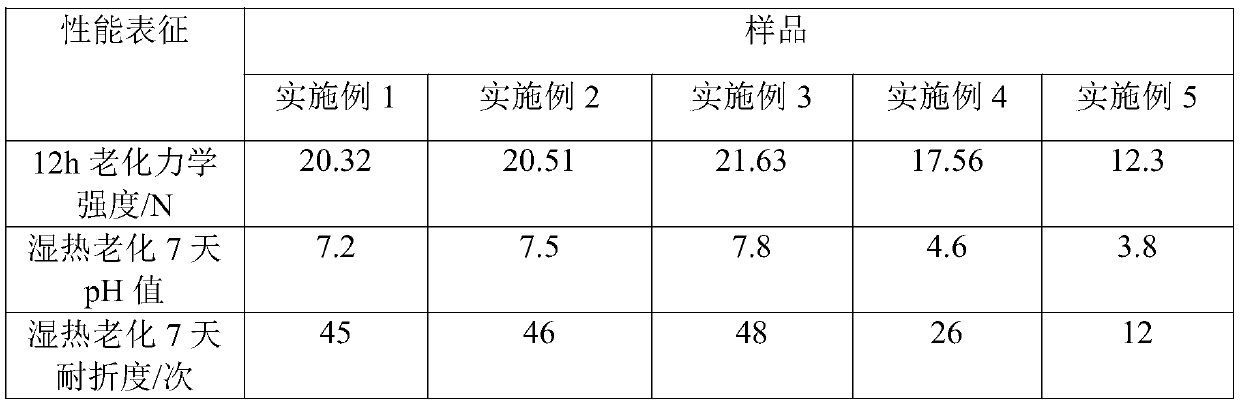

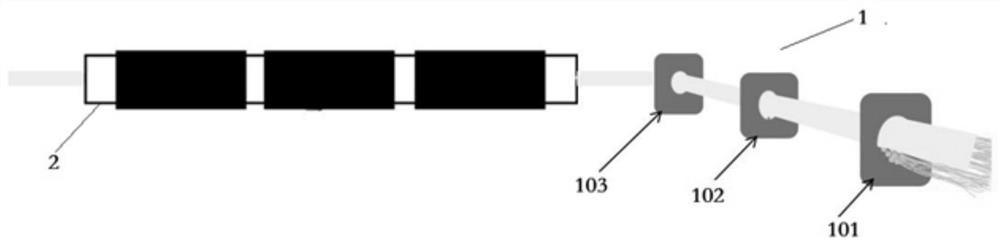

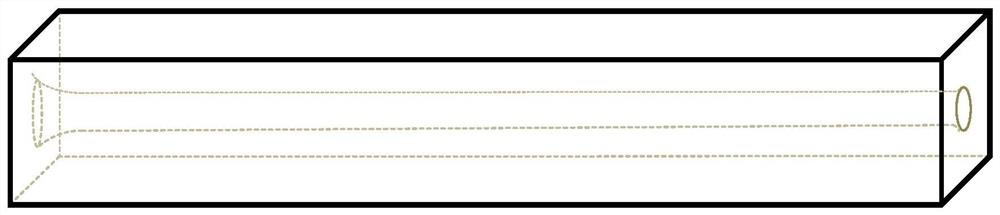

Aramid fiber composite core with environmental resistance and preparation method thereof

PendingCN112048905AImproves anti-photoagingImproves damp heat aging performanceLight resistant fibresAramidComposite material

The invention discloses an aramid fiber composite core with environmental resistance and a preparation method thereof, and belongs to the technical field of aramid composite core preparation. The aramid composite core comprises aramid fibers, a sizing agent anti-photoaging layer, a resin anti-photoaging layer and a hydrolysis-resistant layer. The preparation method comprises the following steps that anti-photoaging ZnO and TiO2 light shielding agents are correspondingly added into the sizing agent and resin, fibers passing through the sizing agent are dried, the fibers enter a gum dipping tankfor gum dipping, the fibers enter a curing mold after gum dipping, the fibers are pulled out and molded by a dragger, the prepared composite core is subjected to post-curing treatment and passes through deposition equipment after complete curing, the composite core surface is coated with a layer of compact hydrolysis-resistant coating layer such as PEEK or PA, and the treated aramid fiber composite core has anti-photoaging and damp-heat aging resistance.

Owner:福建创立佳科技有限公司 +3

Non-linear associating water-soluble quadripolymer, and preparation and use thereof

InactiveCN101463116BImprove rigidityHigh temperature resistanceTransportation and packagingMixingIonChemistry

The present invention discloses a non-linear associated water soluble quadripolymer as well as a preparation method and use thereof, comprising: adding 20 parts of acrylamide, 1-20 parts of nionic monomer or / and cationic monomer, 0.1-15 parts of macromonomer, 0.05-10 parts of hydrophobic monomer, 0.1-50 parts of surfactant and 60-1000 parts of deionized water to a three-necked reaction flask, adjusting the pH to be 3-9, adding 0.002-1 part of initiator (persulphate) at 30-75 DEG C after introducing N2 for 30min, reacting for 8-36h to obtain the quadripolymer PACH, diluting with water, and obtaining concentrated PACH solution. The macromonomer with a long chain and the hydrophobic monomer with a molecular association function are simultaneously introduced in a copolymer PACH, which can obtain the best synergistic viscosifying between rigid conformation of a molecular chain and molecular association and salt resistance. The non-linear associated water soluble quadripolymer is obtained. The copolymer is prepared into aqueous solution with the mass concentration of 0.2-3g / l and the surfactant concentration of 0.01-2mmol / l, added to a mixing vessel with a stirring device and evenly stirred at the room temperature to obtain a viscosified, salt-resistant and shear-resistant polymer oil displacement agent. The PACH has dual functions of a viscosifier and a high molecular surfactant; minute amount of a low molecular surfactant is added to the PACH solution, thus improving the apparent viscosity of the solution, reducing the surface tension of solution and the water-oil interfacial tension, and being beneficial to improving the crude oil recovery ratio. A copolymer PABE is prepared into the aqueous solution with the mass concentration of 0.05-7% to obtain high molecular surfactant with excellent surface activity, and the high molecular surfactant is used as an emulsifier, a demulsifier, a solubilizer and a wetting agent.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com