Flame-retardant high-temperature-resistant radiation-resistant silicone rubber and preparation method thereof

A silicone rubber and radiation-resistant technology, which is applied in the field of flame-retardant, high-temperature, radiation-resistant silicone rubber and its preparation, can solve the problem of not mentioning flame retardancy, not mentioning high temperature resistance and flame retardant performance, and general high temperature resistance. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

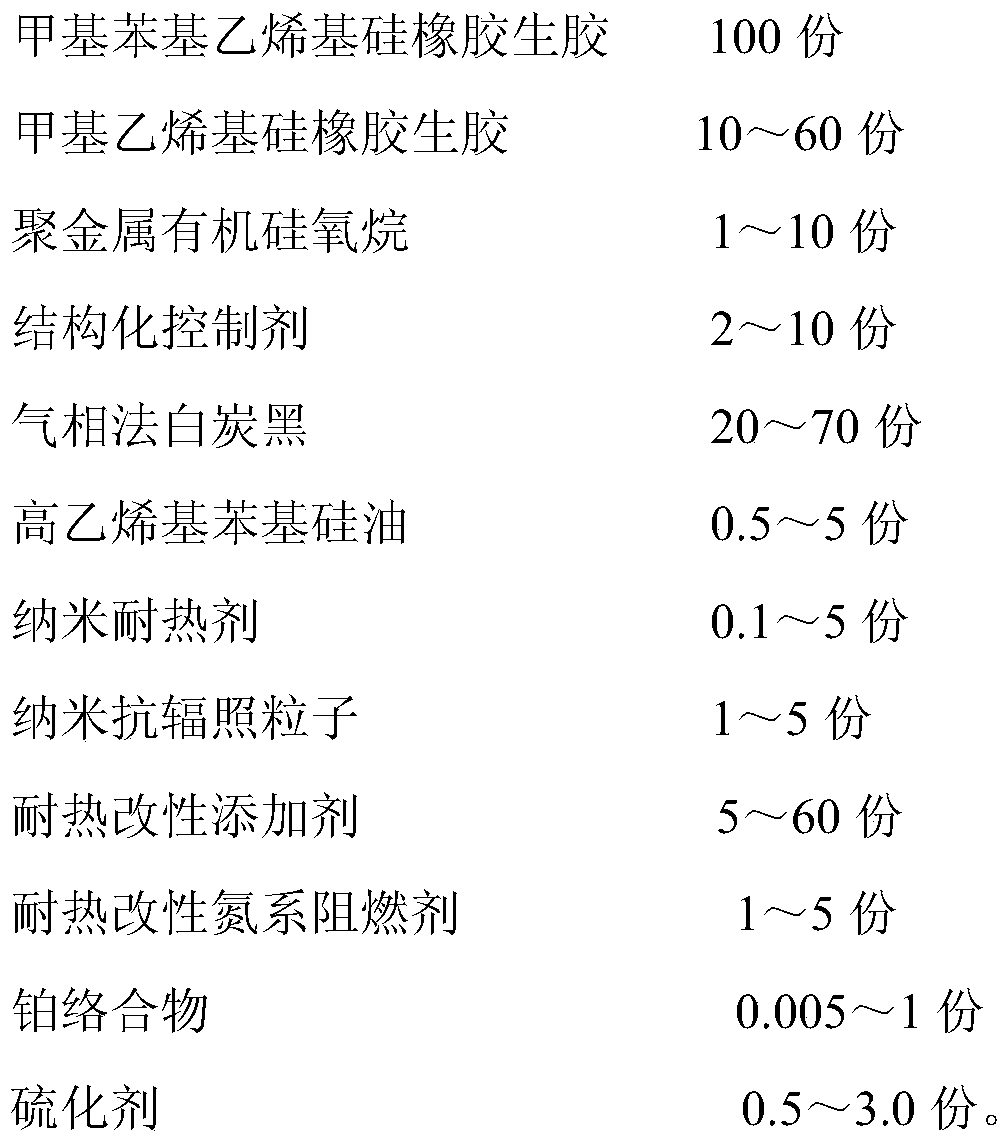

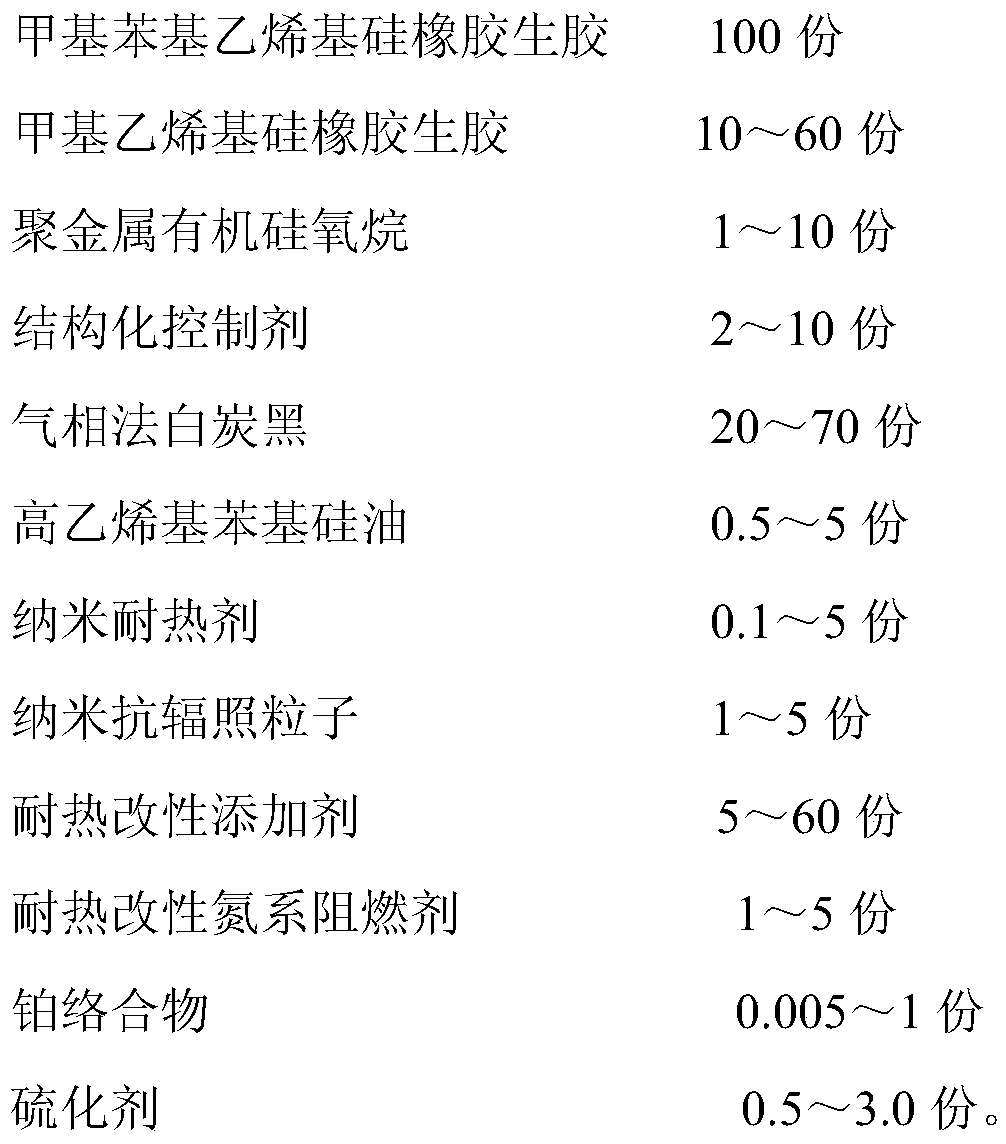

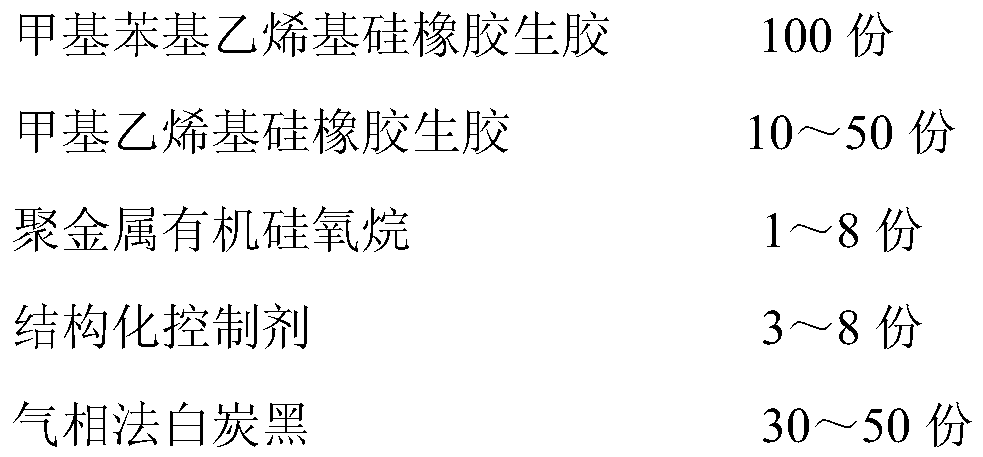

Method used

Image

Examples

Embodiment 1

[0106] A flame-retardant, high-temperature, radiation-resistant silicone rubber material, comprising the following components in parts by mass: 100 parts of methyl phenyl vinyl silicone rubber raw rubber, 10 parts of methyl vinyl silicone rubber raw rubber, polytitanium 1 part of organosiloxane, 3 parts of phenyltrimethoxysilane, 20 parts of fumed silica, 0.5 part of high vinyl phenyl silicone oil, 1 part of nano cerium dioxide, 1 part of nano barium sulfate, heat-resistant modification 20 parts of superfine silica powder, 2 parts of heat-resistant modified melamine cyanurate, 0.05 part of platinum divinyltetramethyldisiloxane complex, di(2,4-dichlorobenzoyl peroxide) ) 0.8 parts.

[0107] Wherein, methyl phenyl vinyl silicone rubber raw rubber is a compound with structural formula (1), R 1 is methyl, m 1 , n 1 , o 1 is an integer greater than zero, m 1 +n 1 +o 1 =1300,n 1 / (m 1 +n 1 +o 1 ) = 20.0%, o 1 / (m 1 +n 1 +o 1 ) = 0.5%. Methyl vinyl silicone rubber raw...

Embodiment 2

[0116] A flame-retardant, high-temperature, radiation-resistant silicone rubber material, comprising the following components in parts by mass: 100 parts of methyl phenyl vinyl silicone rubber raw rubber, 20 parts of methyl vinyl silicone rubber raw rubber, polyiron 2 parts of organosiloxane, 5 parts of phenyltriethoxysilane, 40 parts of fumed silica, 2 parts of high vinyl phenyl silicone oil, 2 parts of nano titanium dioxide, 2 parts of nano boron carbide, heat-resistant modified super 20 parts of fine silicone resin powder, 3 parts of heat-resistant modified melamine cyanurate, 0.2 parts of platinum divinyltetramethyldisiloxane complex, 2,5-dimethyl-2,5-di (tert-butyl peroxy) hexane 1.5 parts.

[0117] Wherein, methyl phenyl vinyl silicone rubber raw rubber is a compound with structural formula (2), R 2 is methyl, m 2 , n 2 , o 2 is an integer greater than zero, m 2 +n 2 +o 2 =1000,n 2 / (m 2 +n 2 +o 2 ) = 30.0%, o 2 / (m 2 +n 2 +o 2 ) = 0.2%. Methyl vinyl sili...

Embodiment 3

[0126] A flame-retardant, high-temperature, radiation-resistant silicone rubber material, comprising the following components in parts by mass: 100 parts of methyl phenyl vinyl silicone rubber raw rubber, 50 parts of methyl vinyl silicone rubber raw rubber, polycerium 8 parts of organosiloxane, 8 parts of diphenyldimethoxysilane, 50 parts of fumed silica, 4 parts of high vinyl phenyl silicone oil, 3 parts of nano-ferric oxide, 4 parts of nano-gallium nitride, 0.5 parts of carbon nanotubes, 40 parts of heat-resistant modified ultrafine silicon powder, 1 part of heat-resistant modified melamine cyanurate, 0.5 parts of platinum divinyltetramethyldisiloxane complex, benzene peroxide 3.0 parts of tert-butyl formate.

[0127] Wherein, methyl phenyl vinyl silicone rubber raw rubber is a compound with structural formula (3), R 3 is methyl, m 3 , n 3 , o 3 ,p 1 is an integer greater than zero, m 3 +n 3 +o 3 +p 1 =1500, (n 3 +o 3 ) / (m 3 +n 3 +o 3 +p 1 ) = 25.0%, p 1 / (m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com