Patents

Literature

143 results about "LTV vinyl silicone rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone rubber for composite insulator and preparation method thereof

The invention discloses a silicone rubber for a composite insulator, wherein the silicone rubber comprises the following raw materials in parts by weight: 30-50 parts of methyl vinyl silicone rubber A, 50-70 parts of methyl vinyl silicone rubber B, 25-50 parts of fumed silica, 100-130 parts of aluminium hydroxide, 1-6 parts of silane coupling agent, 0.2-2 parts of ultraviolet absorber, 2-6 parts of zinc oxide, 0.5-3 parts of triethanolamine, 0.2-1 parts of stearic acid, 0.5-2 parts of hydrogen-containing silicone oil, 0.2-1 parts of vinyl silicone oil, 0.5-3 parts of color masterbatch rubber, 2-6 parts of hydroxyl silicone oil and 0.5-1 parts of vulcanizing agent. The silicone rubber provided by the invention can achieve the following performances: the tensile strength is larger than 4 MPa; the breaking elongation is larger than 350%; the peel strength is larger than or equal to 12 KN.m<-1>; the shore hardness is 60+ / -5 degrees; the thermal aging tensile strength retention is larger than or equal to 90%; the anti-creep track passes a grade of 1A4.5; the flame retardance reaches a grade of FV-0; the average static contact angle is larger than 105 degrees; the electrical surface resistivity is larger than 2*10<15> omega; the dielectric constant is smaller than 3.8; and the dielectric loss angle tangent is smaller than 0.01.

Owner:PINGGAO GRP +2

High-temperature resisting methyl vinyl silicone rubber

The invention discloses high-temperature resisting methyl vinyl silicone rubber as well as a prescription and a preparation process thereof. The high-temperature resisting modified silicon rubber material which has more than 300 DEG C of application temperature and can not crack when according with requirements of 550 DEG C, 4mm distance and high-temperature radiation for more than 12 minutes is prepared by adopting the following steps of: adding cerium oxide and polymide into the prescription in which methyl vinyl silicon crude rubber is taken as a rubber raw material to improve the heat-resisting temperature, adding hydroxy silicone oil, dimethyl silicon oil and a silane coupling agent to improve the oil-resisting performance, adding precipitation method white carbon black and gas-phase method white carbon black to improve the tearing-resistance strength, adding quartz power and kieselguhr to improve the tensile strength and matching technical schemes of the preparation process. The high-temperature resisting methyl vinyl silicone rubber overcomes the problems and the defects of poor high-temperature and aging resistance performance and short service life of the common silicone rubber in the prior art, satisfies the special requirements for the heat-resisting performance, the electrical strength and the mechanical strength of automotive rubber products, and ensures that the silicone rubber products achieve the aims of improving the high-temperature resistance performance and prolonging the service life.

Owner:NINGBO GUANGMING RUBBER & PLASTIC

High temperature mixing silicone rubber as well as preparation method and application thereof

ActiveCN104761911AHelp with installationExtended service lifePolymer scienceLTV vinyl silicone rubber

The invention discloses high temperature mixing silicone rubber as well as a preparation method and an application thereof. According to the high temperature mixing silicone rubber disclosed by the invention, raw methyl phenyl vinyl silicone rubbers with different proportions are added in the raw methyl vinyl silicone rubber to serve as raw rubber, hydrophobic gas phase white carbon black is used as fillers, and ageing resistant additives are added, so that the obtained high temperature mixing silicone rubber has excellent high temperature ageing resistance. The high temperature mixing silicone rubber disclosed by the invention has the advantages of good high temperature ageing resistance, long service life, ultralow permanent compression deformation and is capable of automatically forming an oil film to isolate water vapor, and the like, and the high temperature mixing silicone rubber is particularly suitable for automobile sealing elements and has a good application prospect.

Owner:XINAN TIANYU SILICONE CO LTD +1

150-DEG C high-strength high-electric-property oil-resistant irradiation crosslinking halogen-free flame retardant environment-friendly polyolefin cable material and production method thereof

ActiveCN103642114AWith high temperature resistanceWear-resistantPlastic/resin/waxes insulatorsPolymer sciencePolyolefin

The invention provides a 150-DEG C high-strength high-electric-property oil-resistant irradiation crosslinking halogen-free flame retardant environment-friendly polyolefin cable material which is applied to the products such as an electric equipment wire, a motor lead wire, an oil platform cable, a photovoltaic cable, a marine cable, an automobile wire and a rolling stock cable. The cable material is prepared from the following raw materials: ethylene-propylene-diene monomer, high-density polyethylene, metallocene polyethylene, methyl vinyl silicone rubber, nitrile silicone rubber, a sensitizer, a halogen-free flame retardant, an antismoke agent, an anti-aging agent, an antioxidant, a lubricant, a softener, an active agent, white carbon black, talcum powder and a coloring agent. The polyolefin cable material provided by the invention has good comprehensive performance in high-temperature resistance, wear resistance, high electric property, oil resistance, high strength, low smoke, no halogen, good fluidity and the like; and the environment-friendly performance meets the requirements of electric wires and cables.

Owner:河南通达久通电缆有限公司

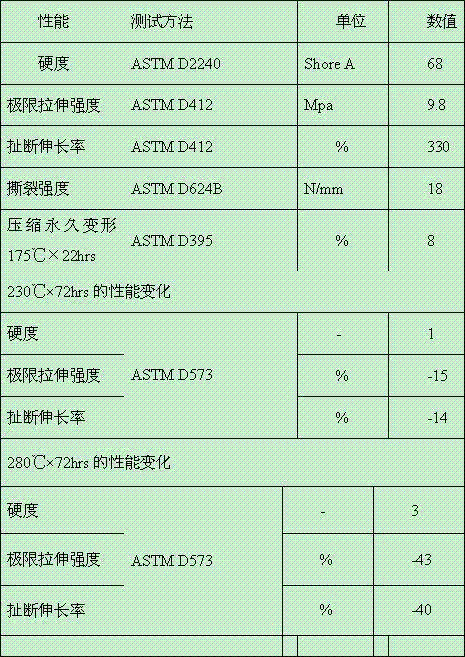

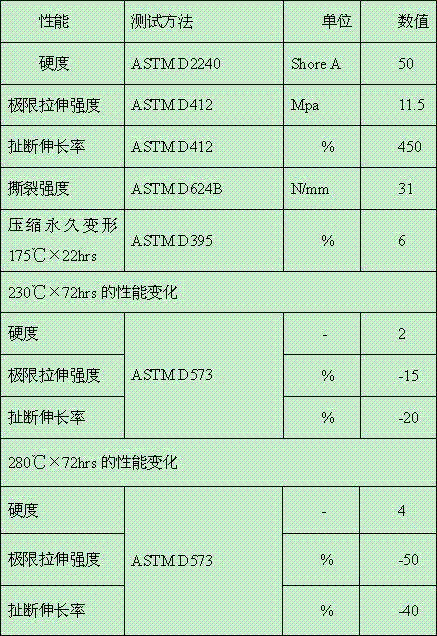

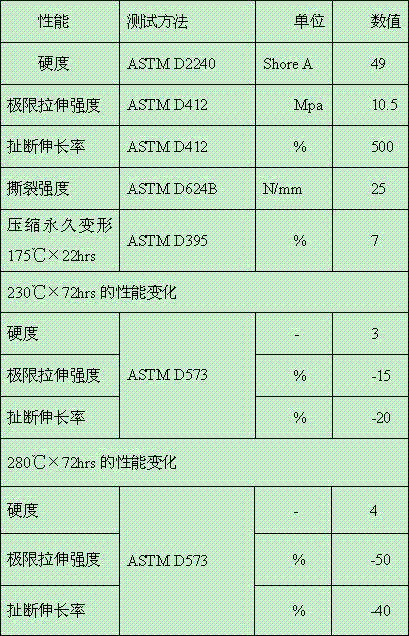

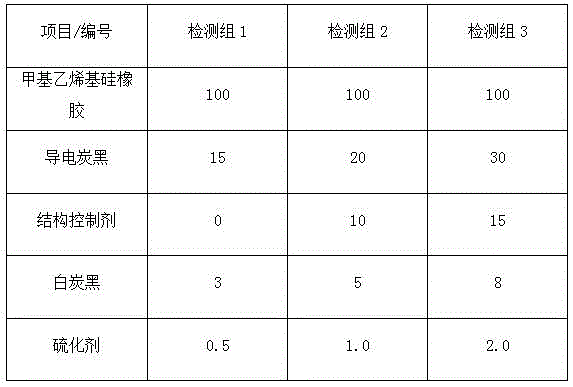

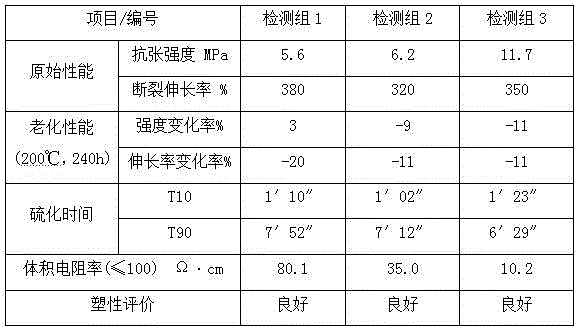

Semiconductive silicon rubber screening material for traveling cable and preparation method thereof

The invention relates to a semiconductive silicon rubber screening material for a traveling cable and a preparation method thereof, and belongs to the technical field of cable screening materials. The semiconductive silicon rubber screening material comprises the following raw materials by weight: 100 parts of silicon rubber, 15-30 parts of conductive carbon black, 3-8 parts of white carbon black, 0.5-2 parts of dicumyl peroxide and 5-15 parts of hydroxyl silicone oil, wherein the silicon rubber is methyl vinyl silicone rubber, dimethyl silicone rubber or methyl phenyl vinyl silicone rubber; and the conductive carbon black has an average particle size of less than 20 nm and specific resistance of 0.35-0.50 omega.cm. The selected silicon rubber is high in plasticity and good in softness and serves as a base material of the semiconductive screening material, so that the disadvantage of film hardening due to strong constitutive property of the conductive carbon black can be avoided, thereby enabling the semiconductive screening material to be good in production and processing performance.

Owner:SICHUAN MINGXING CABLE

Olefin-based rubber highly flame-retardant and oil-resistant heat-shrinkable sleeve and preparation method thereof

ActiveCN102276928AStrong cross-linkingImprove flame retardant performanceTubular articlesPolymer sciencePolyolefin

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

High-strength high-heat-resistance flame-retardant silicone rubber material and preparation method thereof

The invention discloses a high-strength high-heat-resistance flame-retardant silicone rubber material and a preparation method thereof. The high-strength high-heat-resistance flame-retardant silicone rubber material is composed of components A and B, wherein the component A comprises vinylsiloxane rubber, high vinyl silicone oil, hydrogen-containing silicone oil, hydrophobic fumed silica, a cross-linking inhibitor, a composite flame retardant and heat-resistant aids; the component B comprises vinylsiloxane rubber, high vinyl silicone oil, a platinum catalyst, a composite flame retardant, heat-resistant aids and hydrophobic fumed silica. The preparation method comprises the following steps: mixing the component A and the component B according to a mass ratio of 1:1, and curing at the temperature of 80-140 DEG C for 10 minutes, so as to obtain the high-strength high-heat-resistance flame-retardant silicone rubber material. The high-strength high-heat-resistance flame-retardant silicone rubber material disclosed by the invention is high in flame-retardant property, excellent in mechanical property, odorless and simple and convenient in vulcanization, does not need to be subjected to secondary vulcanization and is widely applied to the fields of space flight and aviation, locomotives, nuclear power, medical treatment, chemical machinery and the like.

Owner:SHANDONG SHIP TECH RES INST

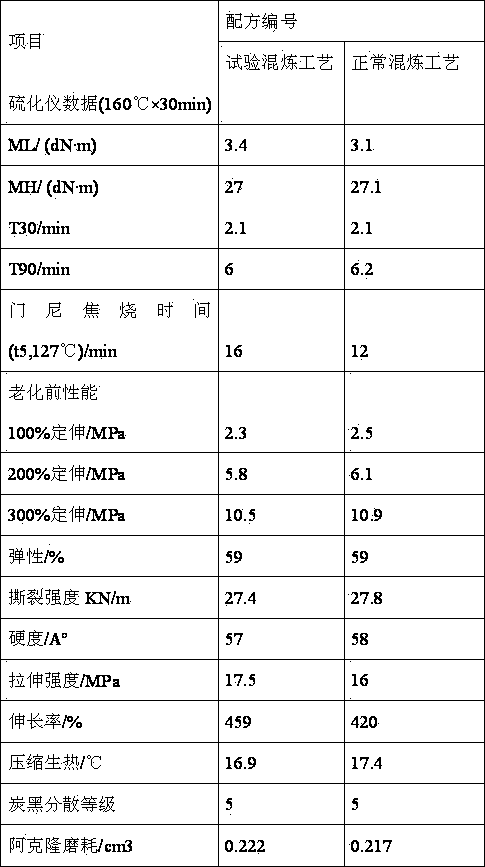

High-temperature-resistant strong-resilience high-safety mixed rubber

The invention discloses high-temperature-resistant strong-resilience high-safety mixed rubber, and is characterized in that the mixed rubber comprises the following components by the weight percentage: 10-30% of natural rubber, 5-10% of chloroprene rubber, 5-10% of polyisoprene, 4-6% of polybutadiene, 5-15% of white carbon black, 8-12% of a silicon alkyl coupling agent, 10-20% of methyl vinyl silicone rubber, 3-4% of tetravinyltetramethylcyclotetrasiloxane, 1-2% of a catalyst, 1-3% of dimethyl hydroxyl silicone oil, 8-10% of dihydroxydiphenylsilane, 2-3% of a heat stabilizer, 2-3% of a surface modification agent, 5-8% of zinc oxide, 1-2% of stearic acid, 2-6% of sulfur, 1-2% of an accelerator, and 1-3% of other auxiliary agents. The wear resistance is improved, the life problem is overcome, introduction of butyl rubber is known to be capable of improving a wet-skid resistance ability of the mixed rubber, and the obtained mixed rubber has excellent mechanical properties, resilience and high-temperature resistance; and through innovating a rubber mixing technology and changing a feeding sequence, a portion of parts of the sulfur is put in masterbatch rubber to prolong the rubber scorching time, and the rubber processing safety performance is ensured.

Owner:佛山市华勇有机硅有限公司

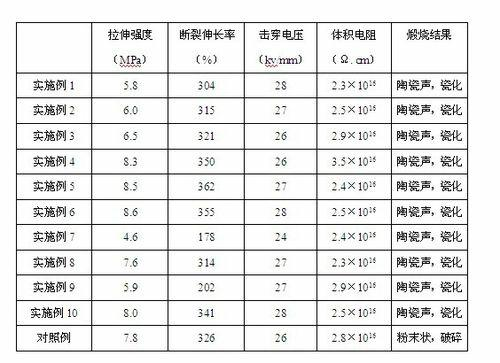

Method for preparing ceramifiable silicon rubber refractory material by adopting radiation crosslinking process

ActiveCN102618040AEasy to processMature technologyPlastic/resin/waxes insulatorsInsulated cablesRubber materialPolymer science

The invention relates to a method for preparing a ceramifiable silicon rubber refractory material by adopting a radiation crosslinking process and belongs to the field of fire-resistant wires and cables. The method comprises the specific steps of: A-, evenly mixing 100 parts of methyl vinyl silicone rubber, 40-60 parts of ceramic powder, 40-65 parts of reinforcing filler, 3-5 parts of cyclosilazane and (5-20)*(10-5) parts of chloroplatinic acid to prepare daub-shaped silicon rubber; B-, extruding the daub-shaped silicon rubber to obtain a molded initial product of the ceramifiable silicon rubber refractory material; and C-, performing irradiation on the initial product by high-energy rays to obtain a product of the ceramifiable silicon rubber refractory material. The method for preparing the ceramifiable silicon rubber refractory material by adopting the radiation crosslinking process is convenient and energy-saving, is lower in cost, is easy in crosslinking degree control and is high in crosslinking efficiency. Toxic chemical additives are not used in the crosslinking process, and thus, the prepared vulcanizing silicone rubber is stable in physicochemical properties and is good in mechanical property and electrical property. The product is strong in weather fastness, ageing resistance and fatigue durability and is also longer in service life.

Owner:SICHUAN INST OF ATOMIC ENERGY

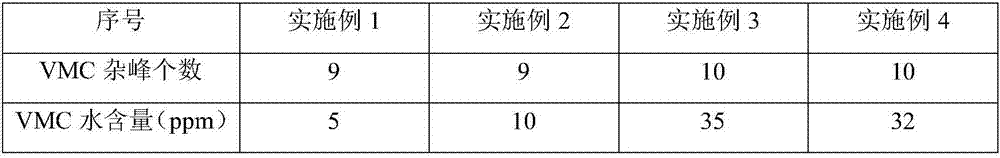

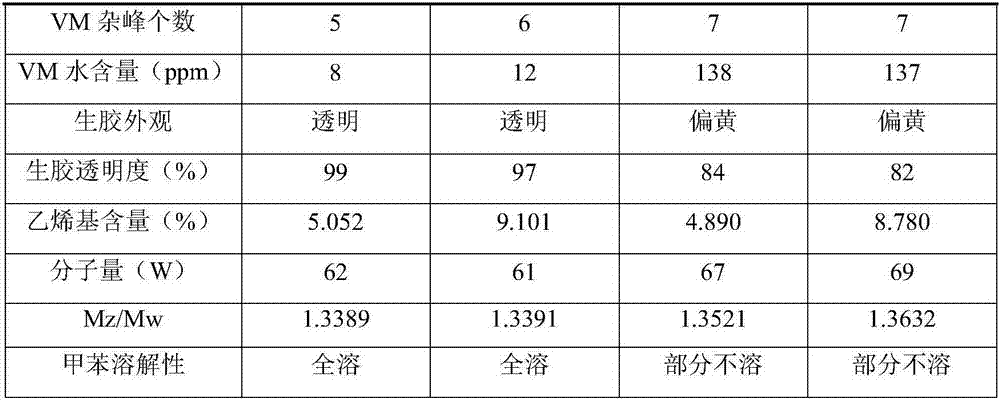

Production technology of methyl vinyl silicon rubber

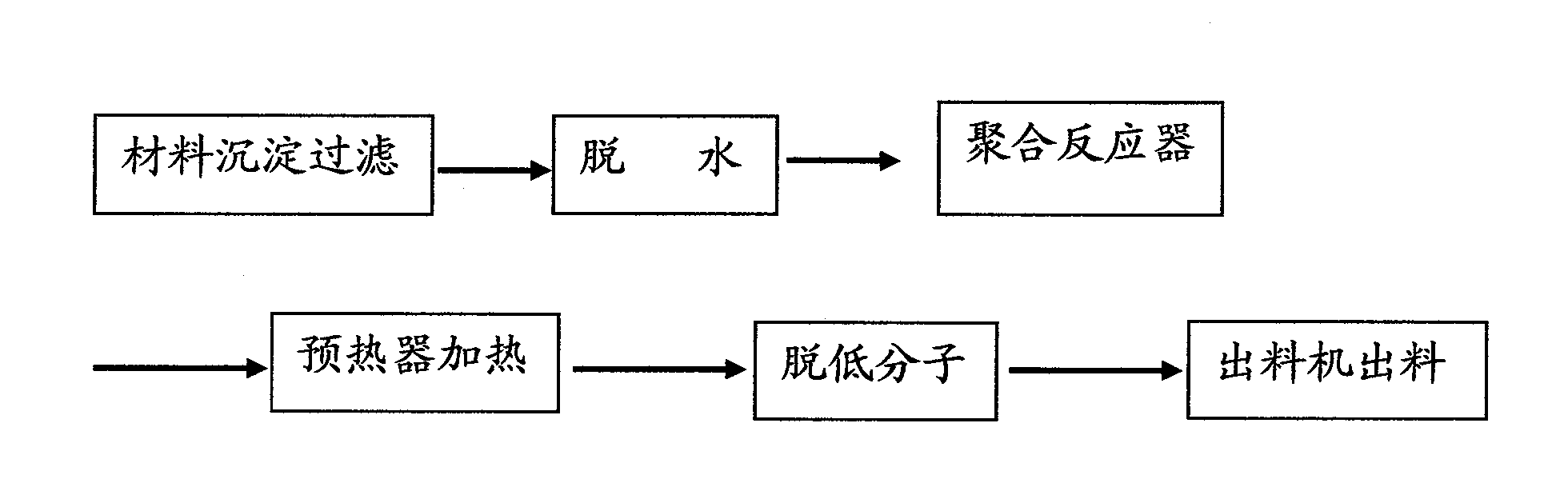

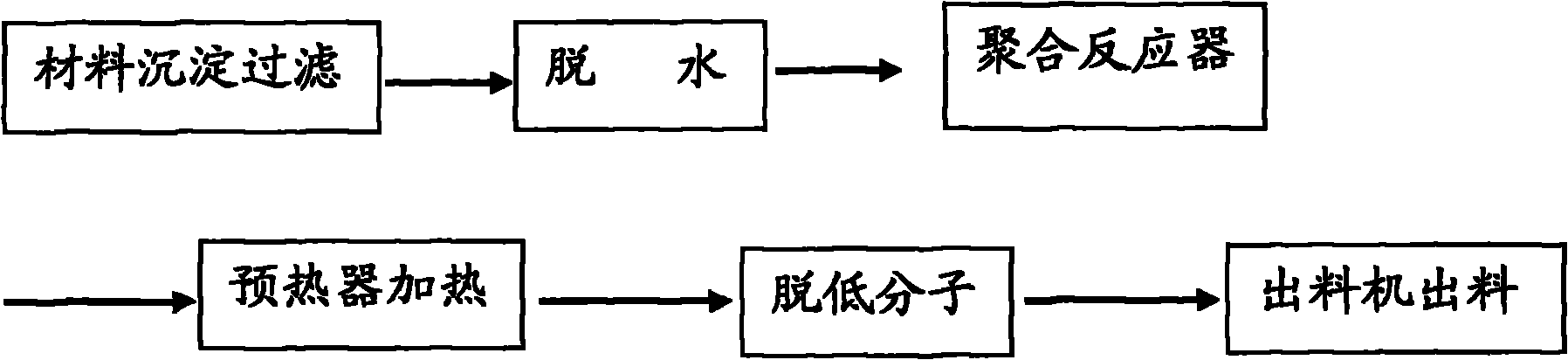

The invention relates to a production technology of high-transparency and high-vinyl methyl vinyl silicon rubber. The production technology comprises the following steps of performing primary filtering and fine filtering on DMC, so as to remove colored impurities including iron rust and the like; removing impurities from auxiliary materials, VMC and divinyltetramethyldisiloxane through vacuum bubble dehydration and physical dynamic adsorption; using a high-temperature and low-pressure dehydration technology, adding the dehydrated material into a polymerizing kettle, adding a catalyst, VMC and a termination sealing agent to polymerize, and balancing after the polymerizing is completed; preheating the balanced rubber material, and then sending into a low molecule removal device to remove low molecule and produce the rubber. The production technology has the advantages that the problems of easiness in crosslinking and broad distribution of molecular weight in the high-vinyl raw rubber are solved; in the low molecule removal process, the gradual heating manner is adopted, and the problems of falling and crosslinking of vinyl, instability of vinyl content, slight yellowing of a product and the like due to continuous high temperature of local part in the raw rubber production heating process are solved.

Owner:HUBEI XINGRUI SILICON MATERIAL CO LTD

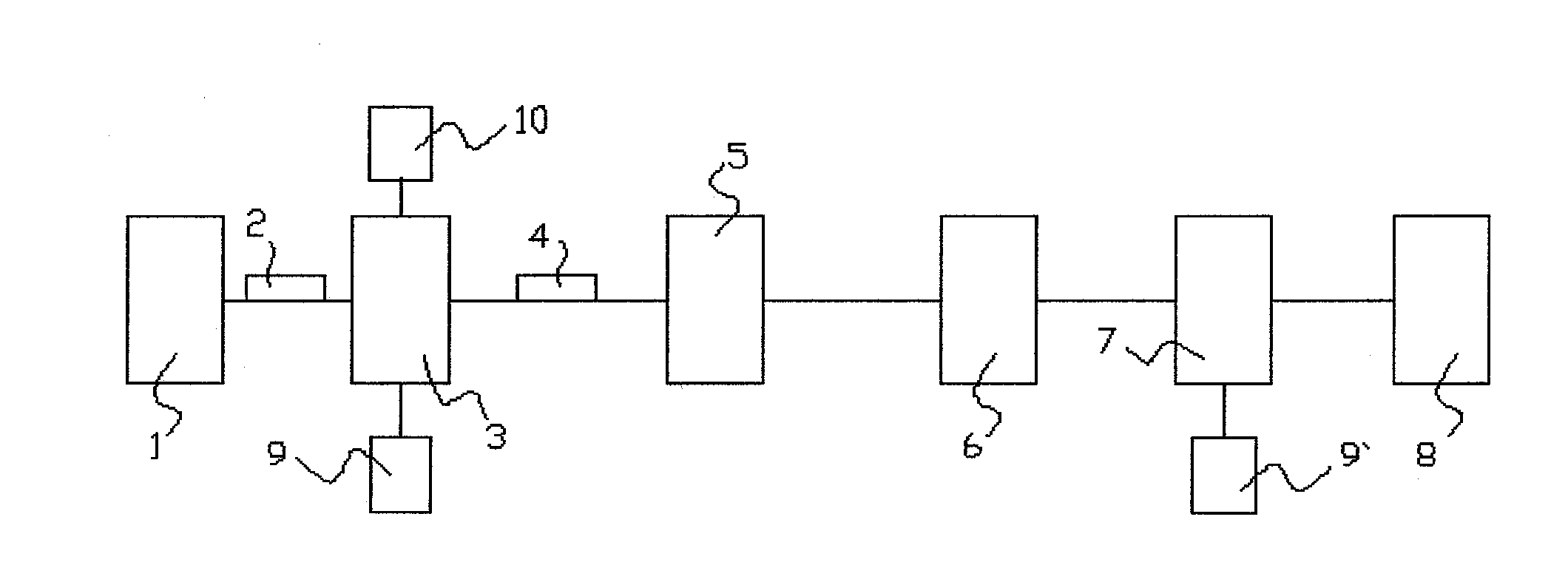

Production process and equipment of methyl vinyl silicone rubber

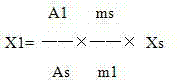

The invention discloses a production process and production equipment of methyl vinyl silicone rubber, which relate to a raw rubber polymerization process. The invention is characterized in that the production equipment of the methyl vinyl silicone rubber consists of a filter, a metering tank, a dehydrating kettle, a metering pump, a preheater, a polymerization cylinder, a low molecule removing device, a nitrogen generator, a vacuum pump, a discharging machine and the like. The filter is connected with the dehydrating kettle through the metering tank, the dehydrating kettle is connected with the preheater through the metering pump; the preheater is connected with the polymerization cylinder by a pipe; the polymerization cylinder is connected with the low molecule removing device, and the low molecule removing device is connected with the discharging machine by a pipe. The production process of the methyl vinyl silicone rubber comprises: metering dimethyl carbonate (DMC) by the filter; and filling the DMC into the dehydrating kettle, adding alkaline cement, end-capping agent and the like in mixing amount, delivering the mixture to the polymerization kettle through a preheater and a feeding pump, performing polymerization at a certain temperature, filling the reaction solution in the low molecule removing device to remove low molecules under vacuum and filling into the discharging machine to generate raw robber.

Owner:刘宏领

Real leather silicone rubber polymer synthetic leather and manufacturing technology thereof

ActiveCN108823340AOvercome the disadvantage of not being able to coat silicone rubber polymersEasy to operateCoatingsLeather surface finishingManufacturing technologyPolymer science

The invention discloses a real leather silicone rubber polymer synthetic leather, which comprises real leather. A priming silicone rubber layer is painted on the real leather. A matte hand-feeling oilsurface layer is painted on the priming silicone rubber layer. The priming silicone rubber layer is composed of following raw materials in parts by weight: 100 to 200 parts of vinyl silicone rubber based glue, 5 to 10 parts of polyvinyl silicone oil, 1 to 3 parts of tackifier, 1 to 3 parts of silane coupling agent, 5 to 20 parts of hydrogen containing silicone oil, 0.5 to 2 parts of platinum catalyst, 5 to 20 parts of color paste pigment, and 0.05 to 0.2 part of inhibitor. The invention also discloses a manufacturing technology of the real leather silicone rubber polymer synthetic leather. The shortage that silicone rubber polymer cannot be painted on real leather is overcome; provided is a method that can paint silicone rubber polymer on real leather; the method is simple and easy to perform, the operation is simple, at the same time, the processing cost is low, and the production is simple, convenient, environmentally friendly, and pollution-free.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

Preparation method of gas sample in vinyl gas chromatography analysis of 110 methylvinyl silicone rubber

The invention relates to a preparation method of a gas sample in vinyl gas chromatography analysis of 110 methylvinyl silicone rubber. The preparation method comprises the following steps of: adding potassium hydroxide to a sample under certain conditions for pyrolysis to generate an ethylene gas; collecting the gas with a head-space sample bottle; detecting the gas by a hydrogen flame ionization detector through adopting a gas chromatography; and quantifying the gas by an external standard method. The preparation method of the gas sample, disclosed by the invention, is simple in preparation method, short in test time and reduced in analyst body health damage caused by poisonous and harmful reagents and pollution to environment caused by recycling and discharging of waste liquor and meets the requirements of production and detection.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

PU applying silicone rubber zipper film, coating technology and application thereof

ActiveCN108582928AGood bonding firmnessLow costSlide fastenersSynthetic resin layered productsHydrogenPolymer science

The invention discloses a PU applying silicone rubber zipper film, which comprises a processed PU film and a silicone rubber layer, the PU film is applied on the silicone rubber layer, the silicone rubber layer comprises the following raw materials in parts by mass: 100-120 parts of a vinylsilane rubber component A, 100-120 parts of a vinylsilane rubber component B, 10-30 parts of a color paste pigment, 3-10 parts of a silane coupling agent, 3-10 parts of low-viscosity hydroxyl silicone oil, and 1-3 parts of polyether modified hydrogen silicone oil. The invention also discloses a coating technology of the PU applying silicone rubber zipper film and an application thereof. The coating technology has the advantages that the process is simple, cost is low, the production efficiency is high, the zipper film is easily processed, post-forming is realized, weatherability is good, hydrolysis resistance and high / low temperature resistance are good, color fastness is good, and cleaning is easy,and the PU applying silicone rubber waterproof zipper film has the advantages that the waterproof performance is good, the cost is low, and the usage life is long.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

TPU-attached silicone rubber zipper film, coating technology and application of TPU-attached silicone rubber zipper film

InactiveCN108467500AHas anti-agingHas weather resistanceLiquid surface applicatorsSlide fastenersWeather resistancePolymer science

The invention discloses a TPU-attached silicone rubber zipper film. The TPU-attached silicone rubber zipper film includes a preprocessed TPU thin film and a silicone rubber layer, and the TPU thin film is attached to the silicone rubber layer; the silicone rubber layer is prepared from, by weight, 100-120 parts of vinylsiloxane rubber A component, 120-150 parts of vinylsiloxane rubber B component,30-50 parts of vinyl silicone oil, 10-30 parts of color paste pigment and 3-10 parts of silane coupling agent. The invention further discloses a coating technology and application of the TPU-attachedsilicone rubber zipper film. The TPU-attached silicone rubber zipper film is simple in technology, low in cost and high in production efficiency; the TPU-attached silicone rubber zipper film has thecharacteristics of a TPU material and the advantages of silicone rubber, wherein the TPU material is characterized by being easy to process and capable of post-shaping, and the silicone rubber has theadvantages of being good in weather resistance, hydrolysis resistance, high-temperature resistance, low-temperature resistance and color fastness and easy to clean. A prepared waterproof zipper madeof the TPU-attached silicone rubber is good in waterproof performance, low in cost and long in service life.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

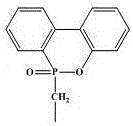

Halogen-free flame retardant silicone rubber composition

InactiveCN103102690ADoes not affect processabilityNo effect on mechanical propertiesPolymer scienceVulcanization

The invention discloses a halogen-free flame retardant silicone rubber composition, comprising the ingredients in parts by weight as follows: 100 parts of unvulcanized methylphenylvinyl silicone rubber, 10-20 parts of halogen-free flame retardant, 1-4 parts of calcium carbonate, 5-7 parts of diatomite, 1-5 parts of hydroxyl silicone oil, 0.5-4 parts of vulcanization crosslinking agent and 20-30 parts of fumed silica, wherein the unvulcanized methylphenylvinyl silicone rubber is taken as a main material and an organic phosphates additive is added to prepare the halogen-free flame retardant silicone rubber composition. The obtained silicone rubber composition is good in flame retardance; the additives used by the composition disclosed by the invention do not influence processability and physical mechanical performance of the silicone rubber; and the silicone rubber composition disclosed by the invention does not generate toxic and harmful gas and smoke when being burned and does not cause environment pollution.

Owner:JIANGSU JIFU NEW MATERIAL

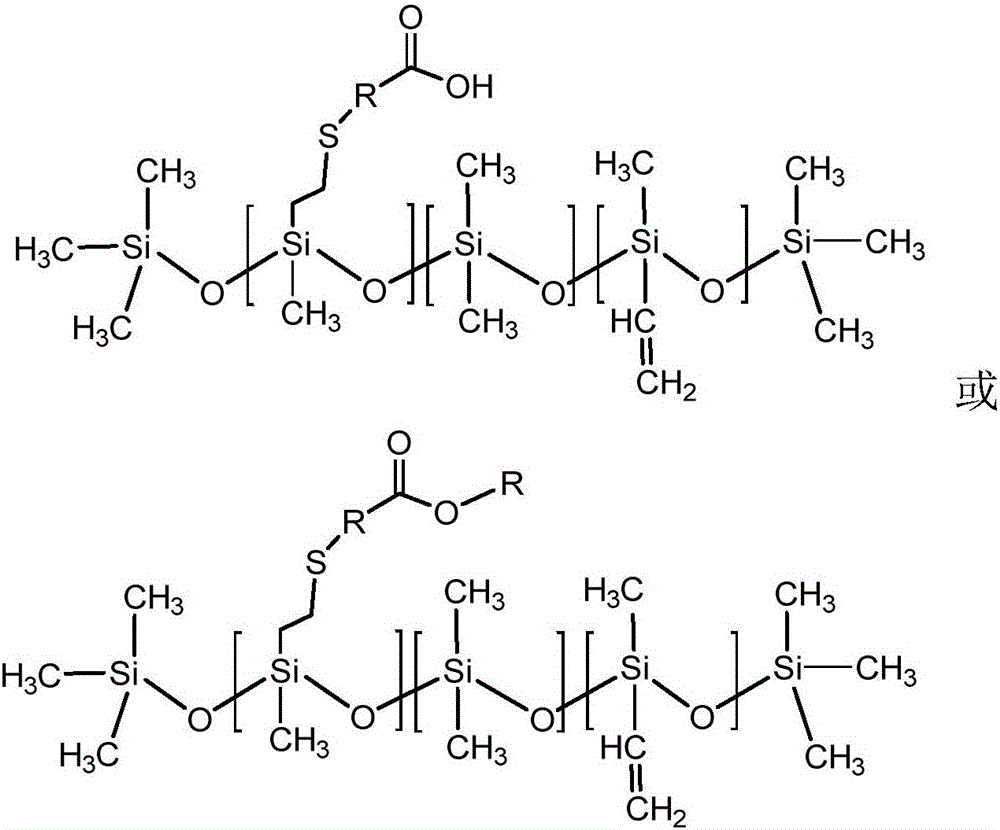

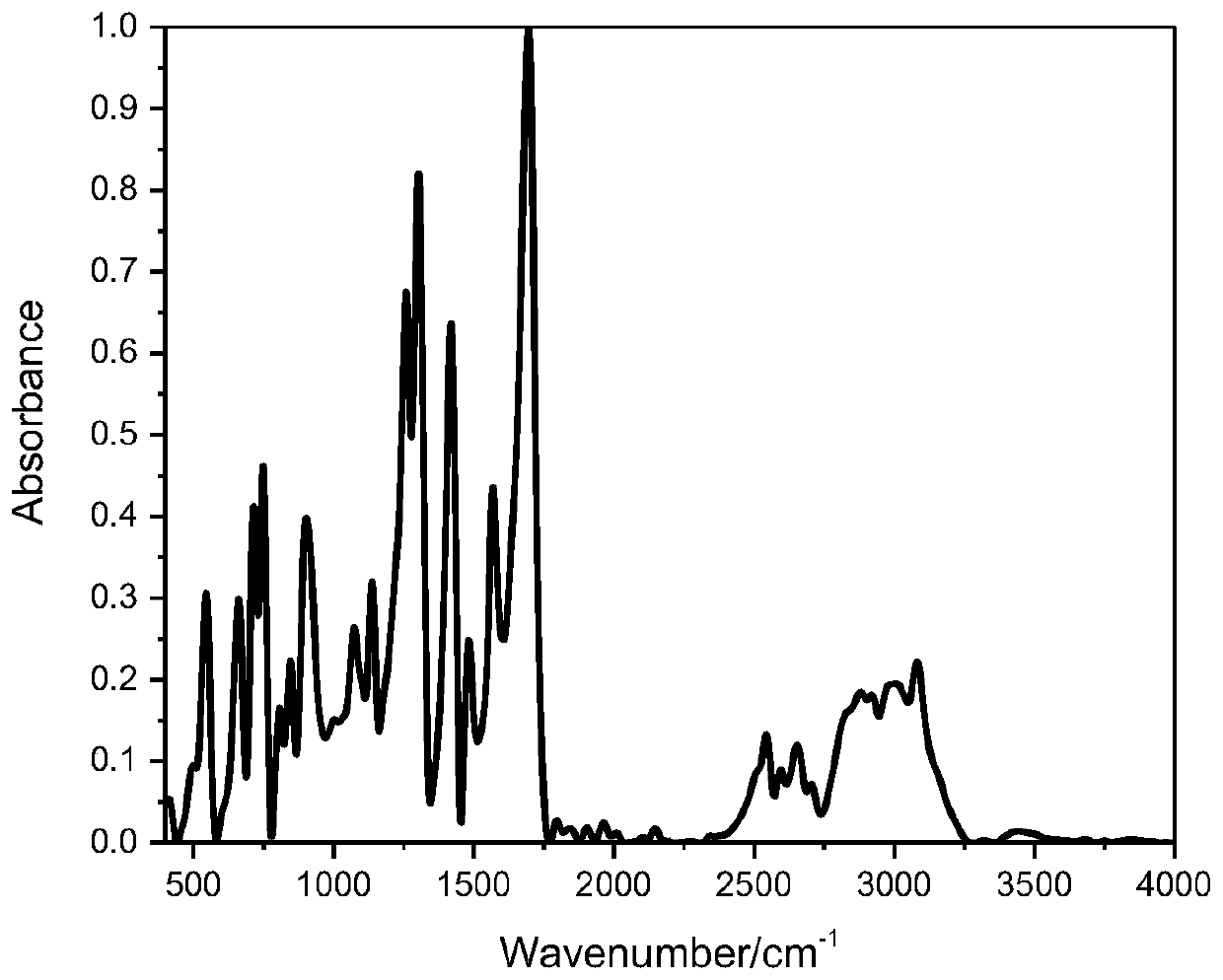

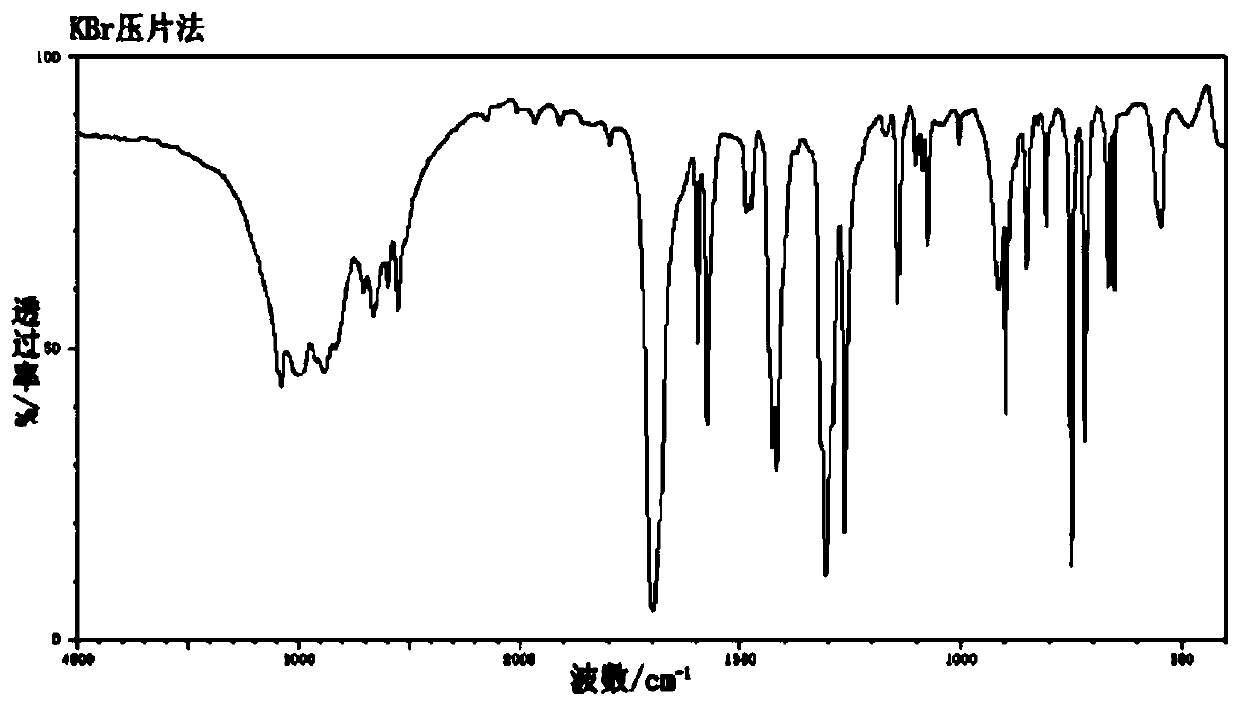

Hydrophobic sulfydryl-modified silicone rubber and preparation method thereof

The invention relates to surface-modified vulcanized silicone rubber and a preparation method thereof, belonging to the field of preparation of a new material. The preparation method can be used for preparing a series of silicone rubber containing carboxyl and ester group by controlling reaction conditions and material proportions. The prepared sulfydryl-modified silicone rubber has relatively high molecular weight, and the number average molecular weight is more than 200000. By adding the carboxyl and ester group, the hydrophilicity of the surface of the silicone rubber can be well increased, so that the silicone rubber can be widely applied to the field of biomedical materials with relatively high hydrophilicity requirements. In addition, the molar fraction of the carboxyl or ester group on the molecular chain of the silicone rubber can be controlled by adjusting the content of double bonds in methyl vinyl silicone rubber. The carboxyl and ester group of the lateral chain of the sulfydryl-modified silicone rubber have certain reaction activity, and the application prospect of utilizing the carboxyl and ester group for modification so as to further improve the performance of the silicone rubber is excellent.

Owner:BEIJING UNIV OF CHEM TECH

Silicone rubber synthetic leather for outdoor furniture and manufacturing technology of silicone rubber synthetic leather

InactiveCN108729244AFulfil requirementsAging resistantFurniture partsCoatingsAging resistancePlatinum catalyst

The invention discloses silicone rubber synthetic leather for outdoor furniture. The silicone rubber synthetic leather for the outdoor furniture comprises substrate cloth which is covered with a silicone rubber layer for the outdoor furniture; the silicone rubber layer is covered with a matt hand feeling oil surface layer for the outdoor furniture and is prepared from the following raw materials in parts by mass: 100-200 parts of vinyl silicone rubber-based rubber, 5-10 parts of high vinyl silicone oil, 10-20 parts of vinyl MQ resin, 5-15 parts of methyl MQ resin, 5-20 parts of hydrogen-contained silicone oil, 1-2 parts of tackifier, 0.1-0.5 part of platinum catalyst, 5-20 parts of color paste pigment and 0.02-0.1 part of inhibitor. Liquid silicone rubber is used to prepare the outdoor used synthetic leather; the synthetic leather can well meet the requirement of the outdoor furniture to the synthetic leather, has the advantages of ageing resistance, hydrolysis resistance, yellowing resistance and the like and has the characteristics of waterproofness, ventilation, easiness in cleaning, nontoxicity and environmental protection at the same time.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

Material for preparing artificial bones and preparation method thereof

ActiveCN104399121AHigh elongation at breakHigh tensile strengthProsthesisO-Phosphoric AcidWear resistant

The invention provides a material for preparing artificial bones and a preparation method thereof. The material comprises the following raw materials in parts by weight: 5 to 15 parts of vinyl silicone rubber, 0.8 to 2.2 parts of hydroxy silicone oil, 2.5 to 4.5 parts of fumed silica, 3 to 10 parts of chitin, 2 to 7 parts of hydroxy apatite, 1 to 4 parts of phosphoric acid, 0.6 to 1.8 parts of bone morphogenetic protein, 0.4 to 1 part of calcium hydroxide, and 0.5 to 1.2 parts of nano cellulose. The provided material has the advantages of large break elongation rate, high tensile strength, good wear resistant property, good corrosion resistant performance, easiness in moulding, and good biocompatibility.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

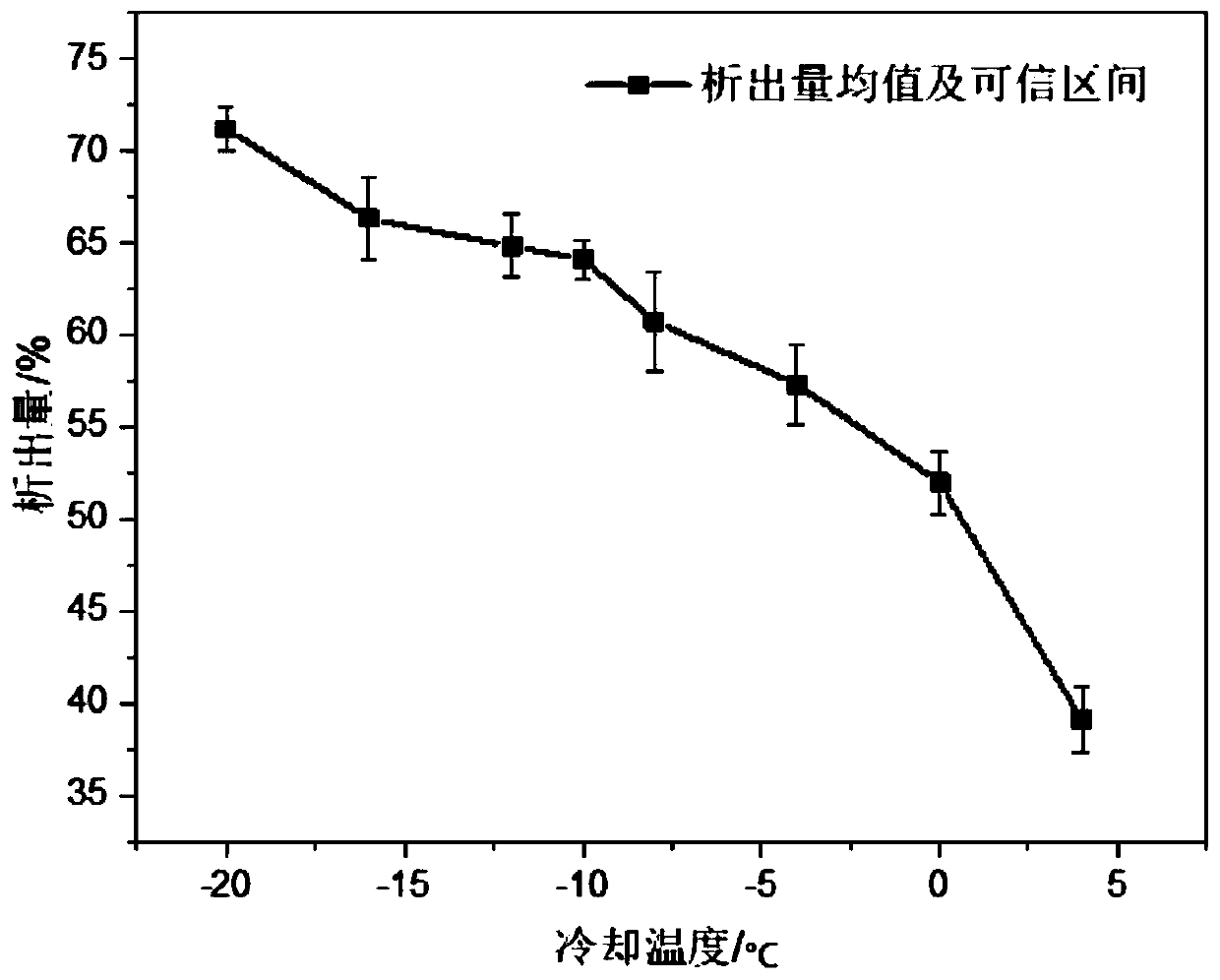

Low-cost environment-friendly method for preparing epoxidized silicone rubber

The invention discloses a low-cost and environment-friendly method for preparing epoxidized silicone rubber. The method comprises the following steps: taking 1-10 parts of high vinyl silicone rubber,100 parts of an organic peroxy acid poor solvent and 0.5-12 parts of an epoxidation reagent; mixing the high vinyl silicone rubber with the organic peroxy acid poor solvent; after complete dissolution, adding the epoxidation reagent for reaction to obtain epoxidized silicone rubber solution; storing the obtained solution at low temperature to separate out a deoxidation product of the epoxidation reagent and an unreacted epoxidation reagent, then precipitating epoxidized silicone rubber; and performing washing and drying to obtain the epoxidized silicone rubber. The preparation method is more scientific and reasonable, the produced epoxidized silicone rubber has the molecular weight of original high vinyl silicone rubber and is free of gel, the performance of the epoxidized silicone rubberis more stable, the strength of the epoxidized silicone rubber is higher, meanwhile, the production cost is reduced, and the method is more suitable for mass production.

Owner:BEIJING UNIV OF CHEM TECH

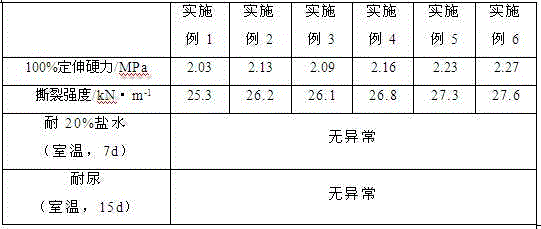

Composite artificial endocranium and preparation method thereof

InactiveCN104399128AExcellent 100% constant elongation hardnessHigh tear strengthProsthesisPolymer sciencePolyethylene glycol

The invention provides a composite artificial endocranium and a preparation method thereof. The artificial endocranium is composed of the following raw materials in parts by weight: 50 to 75 parts of vinyl silicone rubber, 2 to 5 parts of hydroxy silicone oil, 1 to 4 parts of polyethylene glycol, 40 to 60 parts of fumed silica, 0.7 to 1.7 parts of 2,5-dimethyl-2,5-di(t-butylperoxy)hexane, 20 to 35 parts of polylactic acid, 5 to 12 parts of tricalcium phosphate, 2 to 6 parts of chitosan, and 1 to 4 parts of polytetrafluoroethylene. The provided artificial endocranium has an excellent 100% stress at definite elongation, tear strength, biocompatibility, and blood compatibility, and is capable of tolerating brine and urine for a long time.

Owner:SUZHOU VIVOTIDE BIOTECH

Ultraviolet-resistant and hydrolysis-resistant silicon rubber leather and coating process thereof

The invention discloses ultraviolet-resistant and hydrolysis-resistant silicon rubber leather which comprises constitution raw materials in parts by mass: 100-200 parts of a vinyl silicon rubber-basedadhesive, 20-30 parts of vinyl silicon oil, 10-20 parts of dimethyl silion oil, 10-30 parts of hydrogen-containing silicon oil, 0.1-0.5 part of a thickening agent, 0.1-0.3 part of a platinum catalyst, 5-20 parts of a paste pigment and 0.01-0.05 part of an inhibitor. The leather is simple in process, high in production efficiency and low in production cost, the silicon rubber leather has both ultraviolet rays and hydrolysis properties, yellowing and color fading caused by ultraviolet rays can be avoided in long-term use, and in addition, good hydrolysis resistance can be achieved in damp or water.

Owner:GUANGDONG TIANYUE NEW MATERIAL CO LTD

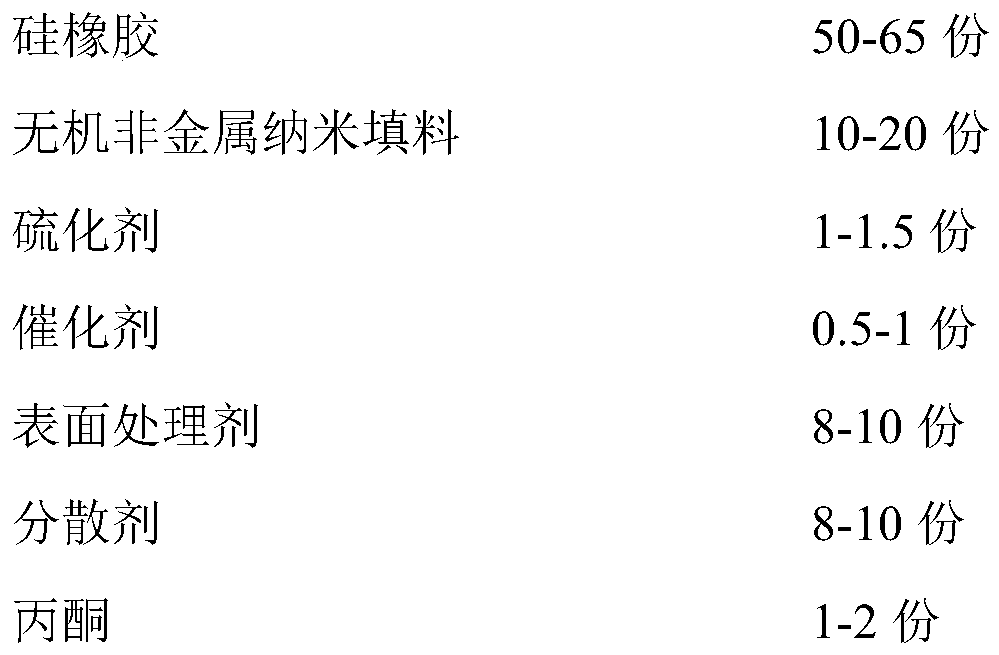

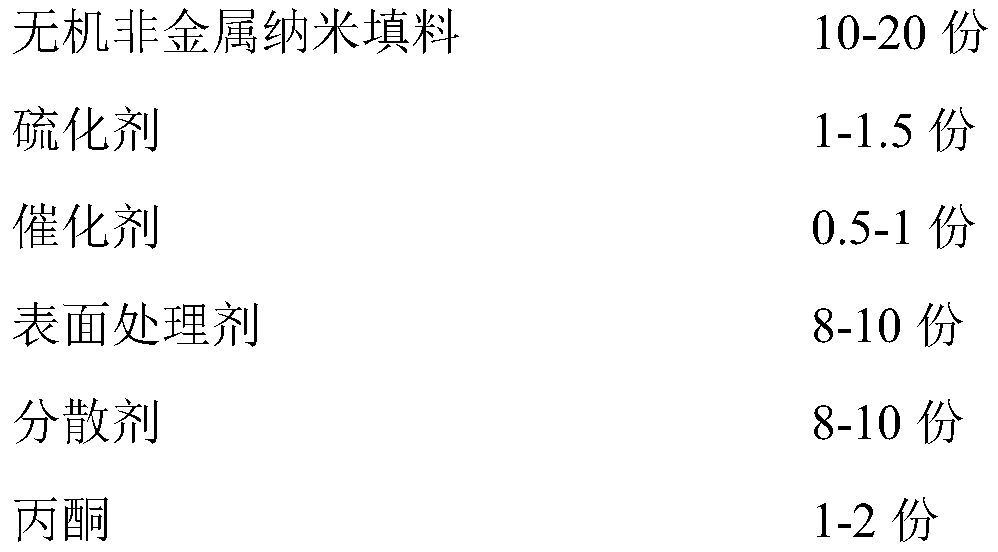

Silicone rubber nano-composite material for roller washing machine door sealing rings and preparation method thereof

The invention discloses a silicone rubber nano-composite material for roller washing machine door sealing rings and a preparation method thereof. The preparation method of the silicone rubber nano-composite material for the roller washing machine door sealing rings comprises adding acetone into silicone rubber during mixing to form an acetone-methyl vinyl silicone rubber emulsion; mixing and dispersing inorganic nonmetallic nano-filler into dispersing agent, and then mixing in surfactant to obtain a mixed dispersion; adding the mixed dispersion into the acetone-methyl vinyl silicone rubber emulsion for high-speed shearing and uniform mixing to obtain a silicone rubber mixed emulsion containing the inorganic nonmetallic nano-filler; adding sulfurizing agent and catalysts into the silicone rubber mixed emulsion, then injecting the mixture into a hot die for shaping, preserving heat at 55-65 DEG C, and heating the die to 160-175 DEG C. The silicone rubber nano-composite material for the roller washing machine door sealing rings is high in bacteria killing and inhibiting efficiency, wide in sterilization range, short in action time, high in safety, capable of achieving self-cleaning effects and highly applicable to manufacturing the roller washing machine door sealing rings.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of silicone rubber material for rubber hoops

InactiveCN103923467AImprove environmental adaptabilityWide range of temperature adaptationChemical industryPolymer science

The invention discloses a preparation method of a silicone rubber material for rubber hoops. The silicone rubber material for rubber hoops is prepared from the following raw materials in parts by weight: 100 parts of vinylsiloxane rubber, 40-65 parts of fumed silica, 0.2-2 parts of coloring agent, 2-15 parts of vinyl silicone oil, 3-10 parts of hydroxy silicone oil, 2-8 parts of diphenyl silanediol, 0.5-1.5 parts of organic peroxide and 3-5 parts of cerium oxide; the silicone rubber material for rubber hoops can be obtained by carrying out mixing process modification treatment on the raw materials. The silicone rubber material for rubber hoops is wide in temperature adaptation range and high in environmental adaptation, can be used for producing various structure type rubber hoops and additionally producing and manufacturing multi-class products, such as sealing parts, shock-absorbing buffer parts, spacers and membranes, and is widely applied to multiple fields of aerospace, nuclear industry, electrommunication, chemical industry, medicine, ships and the like.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

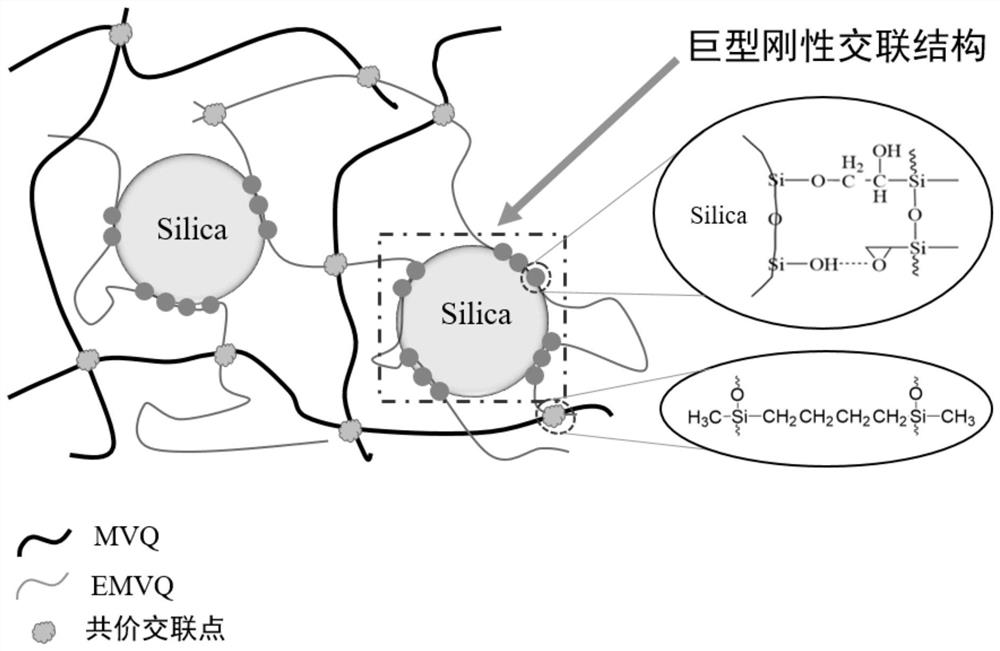

High-tear-resistance white carbon black/methyl vinyl silicone rubber composite material and preparation method thereof

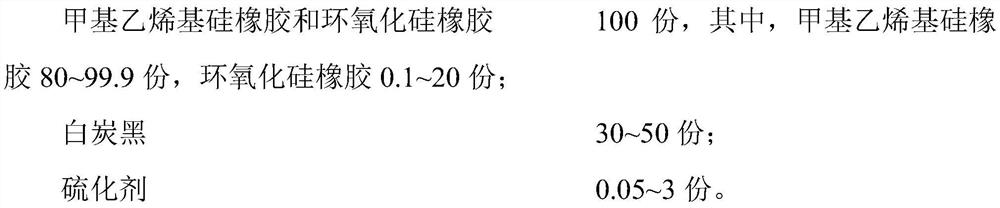

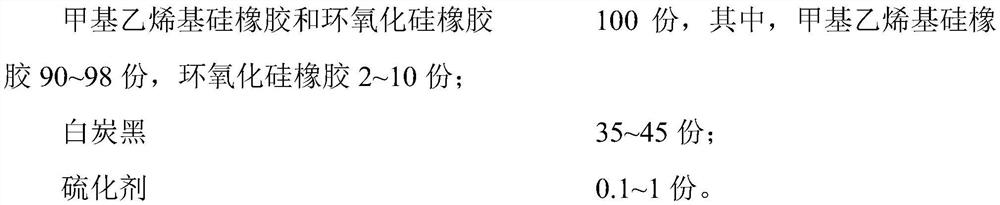

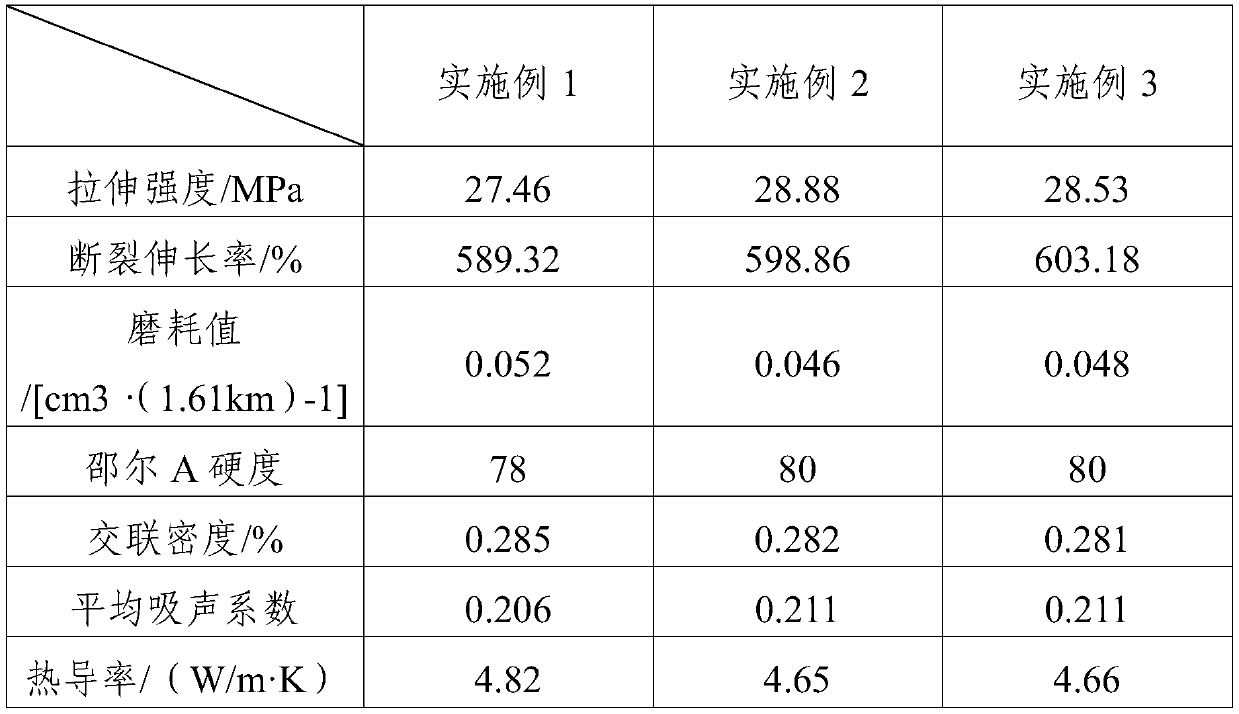

The invention discloses a high-tear-resistance white carbon black / methyl vinyl silicone rubber composite material and a preparation method thereof. The high-tear-resistance silicone rubber composite material is prepared from the following components in parts by weight: 100 parts of methyl vinyl silicone rubber and epoxidized silicone rubber (80-99.9 parts of methyl vinyl silicone rubber and 0.1-20 parts of epoxidized silicone rubber), 30-50 parts of white carbon black and 0.05-3 parts of a vulcanizing agent. According to the epoxy silicone rubber, epoxy groups can react with hydroxyl groups on the surface of the white carbon black to inhibit structuralization of the white carbon black and improve dispersity, meanwhile, the epoxy silicone rubber can participate in cross-linking of the methyl vinyl silicone rubber to form a giant rigid cross-linked structure with the white carbon black as the center, stress is diffused through cross-linking points of the white carbon black when the material is subjected to stress, so that the composite material has high tear strength. The tensile strength of the prepared silicone rubber composite material can reach 10 MPa, the elongation at break can reach 600%, and the tear strength can reach 60 kN / m.

Owner:BEIJING UNIV OF CHEM TECH

Automobile tire rubber material with excellent sound absorption performance and preparation method thereof

The invention provides an automobile tire rubber material with excellent sound absorption performance and a preparation method thereof, and relates to the field of rubber materials. The composition isprepared from the following components in parts by weight: 30-50 parts of natural rubber, 60-80 parts of epoxidized solution polymerized styrene-butadiene rubber, 40-60 parts of butadiene rubber, 20-30 parts of high-strength methyl vinyl silicone rubber, 5-15 parts of eucommia ulmoides gum grafted butyl methacrylate, 4-8 parts of polyisoprene, 5-10 parts of zinc oxide whisker, 5-10 parts of porous carbon nanotubes, 5-10 parts of aluminum oxide, 10-15 parts of nano attapulgite, 30-40 parts of carbon black, 20-30 parts of organic modified white carbon black, 20-30 parts of nano calcium carbonate, 5-10 parts of microcrystalline wax, 5-10 parts of stearic acid, 1-3 parts of sulfur, 1-3 parts of a homogenizing agent A78, 0.1-5 parts of an accelerant and 1-5 parts of an anti-aging agent. The automobile tire rubber material provided by the invention has excellent mechanical properties, excellent sound absorption and heat conduction properties, and great market application prospects, and canbe widely popularized to reduce noise brought by automobile tires on the road surface.

Owner:安徽品罗科技有限公司

Ceramic fire-resistant flame-retardant silicone rubber as well as preparation method and use method thereof

InactiveCN112029289AImprove fire and flame retardant performanceHigh mechanical strengthPolymer scienceStearic acid

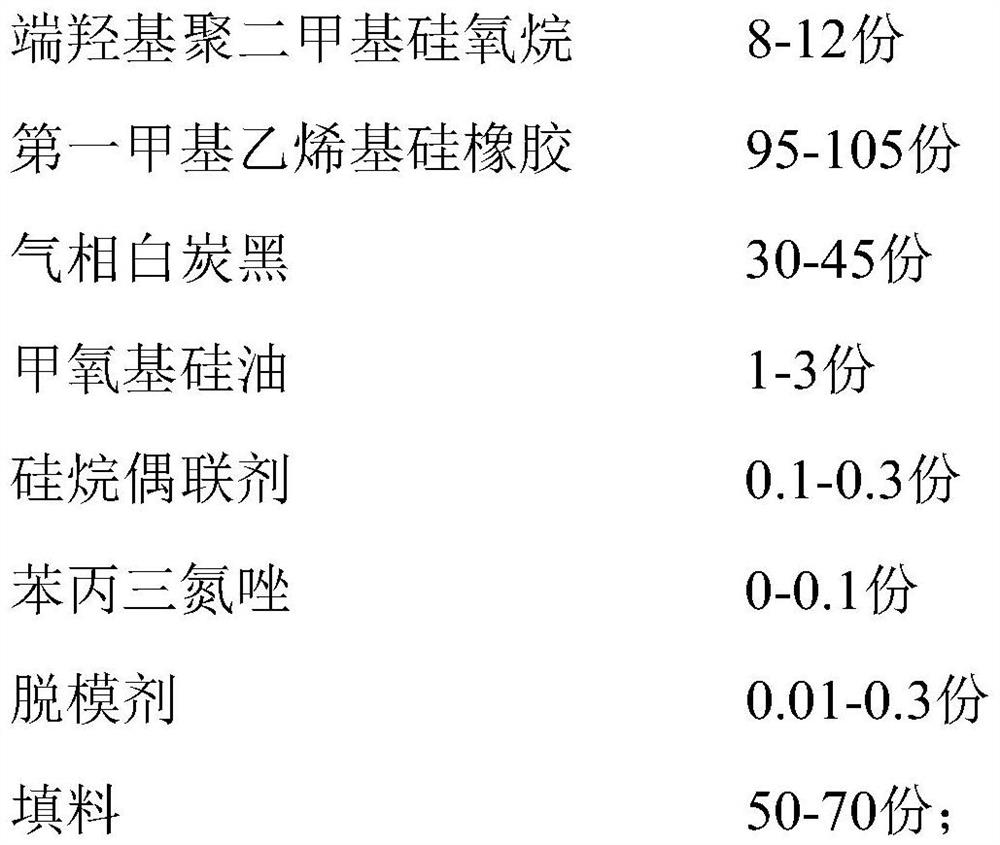

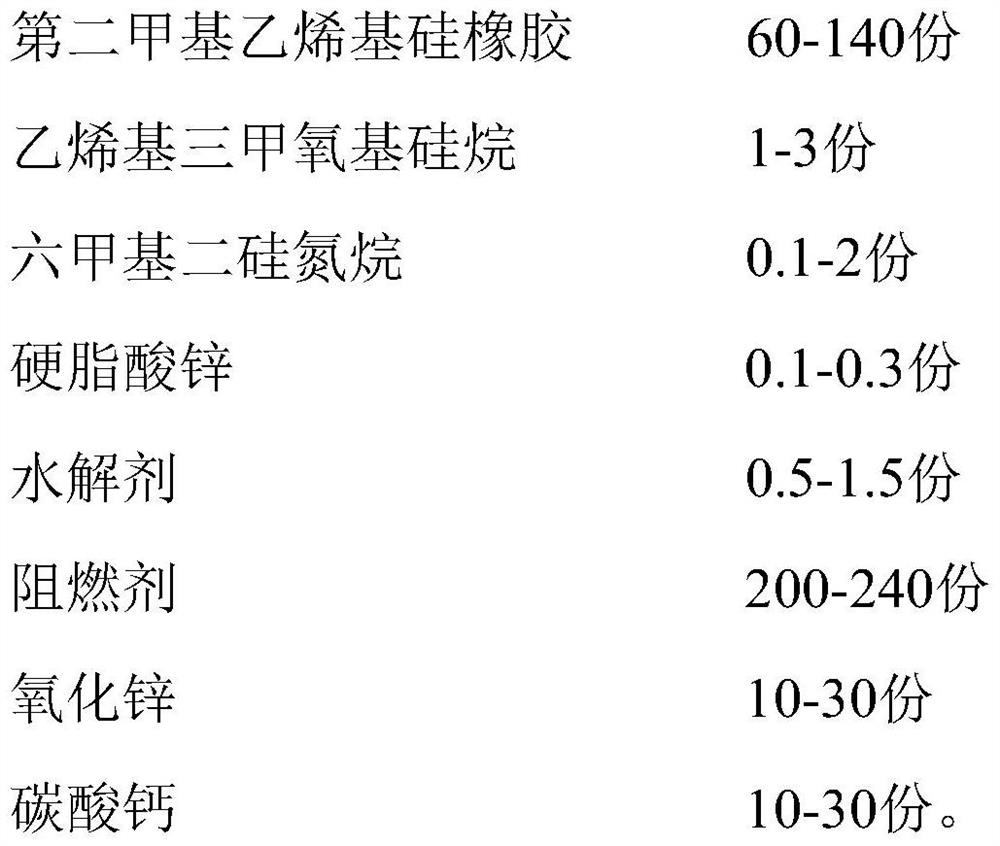

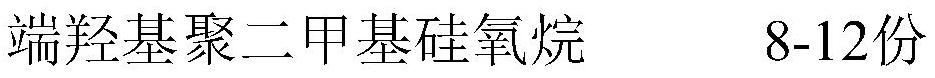

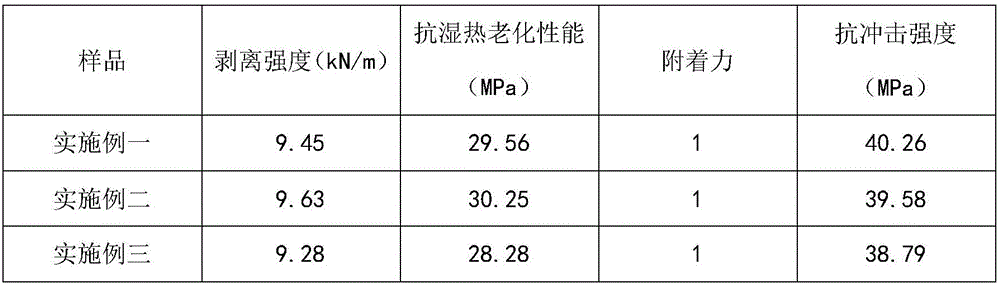

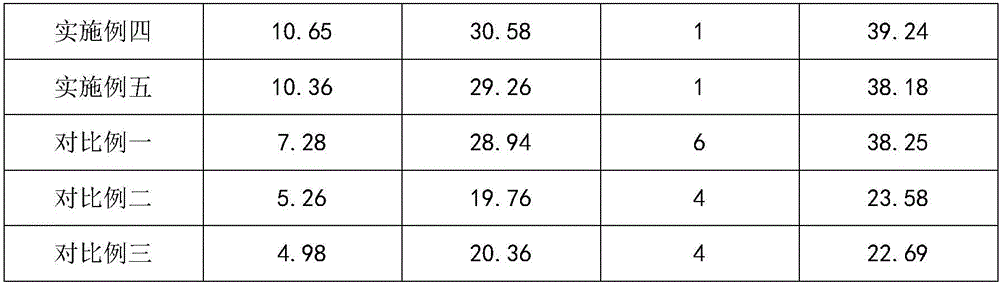

The invention relates to the technical field of silicone rubber, in particular to ceramic fire-resistant flame-retardant silicone rubber as well as a preparation method and a use method thereof. The silicone rubber is prepared from the following raw materials in parts by weight: 8-12 parts of hydroxyl-terminated polydimethylsiloxane, 95-105 parts of first methyl vinyl silicone rubber, 30-45 partsof fumed silica, 1-3 parts of methoxy silicone oil, 0.1-0.3 part of a silane coupling agent, 0-0.1 part of benzotriazole, 0.01-0.3 part of a release agent, 50-70 parts of a filler, 60-140 parts of second methyl vinyl silicone rubber, 1-3 parts of vinyl trimethoxy silicon, 0.1-2 parts of hexamethyldisilazane, 0.1-0.3 part of zinc stearate, 0.5-1.5 parts of a hydrolysis agent, 200-240 parts of a flame retardant, 10-30 parts of zinc oxide and 10-30 parts of calcium carbonate. The ceramic fire-resistant flame-retardant silicone rubber has good fire-resistant and flame-retardant performance and excellent comprehensive performance, and the preparation method of the ceramic fire-resistant flame-retardant silicone rubber is simple.

Owner:东莞市朗晟材料科技有限公司

Acrylic ester adhesive and preparing method thereof

InactiveCN106244095AReduce exothermic peak temperatureReduce internal stressMacromolecular adhesive additivesGraft polymer adhesivesSolventAcrylate

The invention discloses an acrylic ester adhesive and a preparing method thereof. The defect that an acrylic ester adhesive is bad in stripping resistance is overcome. The acrylic ester adhesive is characterized by being prepared from A components and B components, wherein the weight ratio of the A components to the B components is 1:1; the A components are prepared from metacrylic acid ester, methacrylic acid, modified ethylene propylene diene monomer, phenolic inhibitor, antioxidant, solvent, A-type accelerant, assistant and thickening filler; the B components are prepared from metacrylic acid ester, methacrylic acid, methyl vinyl silicone rubber, phenolic inhibitor, solvent, B-type accelerant, coupling agent and thickening filler; as the modified ethylene propylene diene monomer is contained in the A components, the whole structural performance of the A components can be enhanced, whole stripping is facilitated during stripping, and the stripping resistance of the A components is improved; as the poly-methyl vinyl silicone rubber is contained in the B components, the integration structural performance of the B components can be remarkably increased, and the stripping resistance of the B components is improved.

Owner:苏州工业园区莱博特瑞新材料科技有限公司

Flame-retardant sheath with excellent mechanical properties for mining rubber-sheathed cables

InactiveCN105199226AFacilitate cross-linkingImprove flame retardant performanceRubber insulatorsPlastic/resin/waxes insulatorsPhosphorous acidSodium Bentonite

The invention discloses a flame-retardant sheath with excellent mechanical properties for mining rubber-sheathed cables. The flame-retardant sheath comprises, by weight, 20-40 parts of methyl phenyl vinyl silicone rubber, 30-45 parts of polypropylene, 1-2 parts of 2, 5-dimethyl-2, 5-di-(tert-butyl peroxide) hexane, 2-4 parts of tert-butyl p-methylbenzoate, 0.5-1.5 parts of tetra-isopropyl di-(phosphorous acid didodecyl ester) titanate, 30-45 parts of microcapsule-coated ammonium polyphosphate, 1-3 parts of trioctyl phosphate, 2-4 parts of cresyl diphenyl phosphate, 0.5-1.5 parts of N-hydroxymethyl propionamide methyl phosphate ester, 10-20 parts of expandable graphite, 5-9 parts of bentonite, 5-10 parts of chitin, 1-3 parts of horseradish, 1-3 parts of antioxidants and 1-3 parts of lubricants. The flame-retardant sheath has the advantages of antibacterial and flame-retardant properties and excellent mechanical properties.

Owner:ANHUI LAND GRP

High-temperature vulcanized silicone rubber with both electrical conductivity and ceramization potential, and preparation method thereof

The invention discloses high-temperature vulcanized silicone rubber with both conductivity and ceramization potential, and a preparation method thereof. The high-temperature vulcanized silicone rubbercomprises the following components: raw methyl vinyl silicone rubber, raw methyl phenyl vinyl silicone rubber, a reinforcing filler, a conductive medium, a structured control agent, a fluxing agent,a ceramic forming filler, a coupling agent, a release agent and a vulcanizing agent. The method comprises the following steps: putting raw heat-vulcanized silicone rubber, the reinforcing filler, namely fumed silica, and silicone oil into an internal mixer, and carrying out stirring; uniformly blending the ceramic forming filler and the fluxing agent, and carrying out surface treatment by using the coupling agent; performing surface activation pretreatment on the conductive medium; and blending the above materials in a kneading machine to prepare the high-temperature vulcanized ceramic silicone rubber with both conductivity and ceramization potential. According to the invention, the advantages of good electrical properties and good mechanical properties are ensured, and the prepared rubberhas characteristics of easy processing, good weather resistance, good aging resistance and good low temperature resistance, and has important significance in the widening of the application fields ofsilicone rubber.

Owner:苏州雷朗新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com