Silicone rubber nano-composite material for roller washing machine door sealing rings and preparation method thereof

A technology of silicon rubber nanometer and drum washing machine, which is applied in the field of materials for the door sealing ring of drum washing machines. It can solve the problems that affect the washing quality of washing machines, people's healthy life, the lack of bactericidal and antibacterial functions, and the cleaning effect needs to be improved, so as to improve the user experience. Sensitivity, improvement of overall quality, and high bactericidal and antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

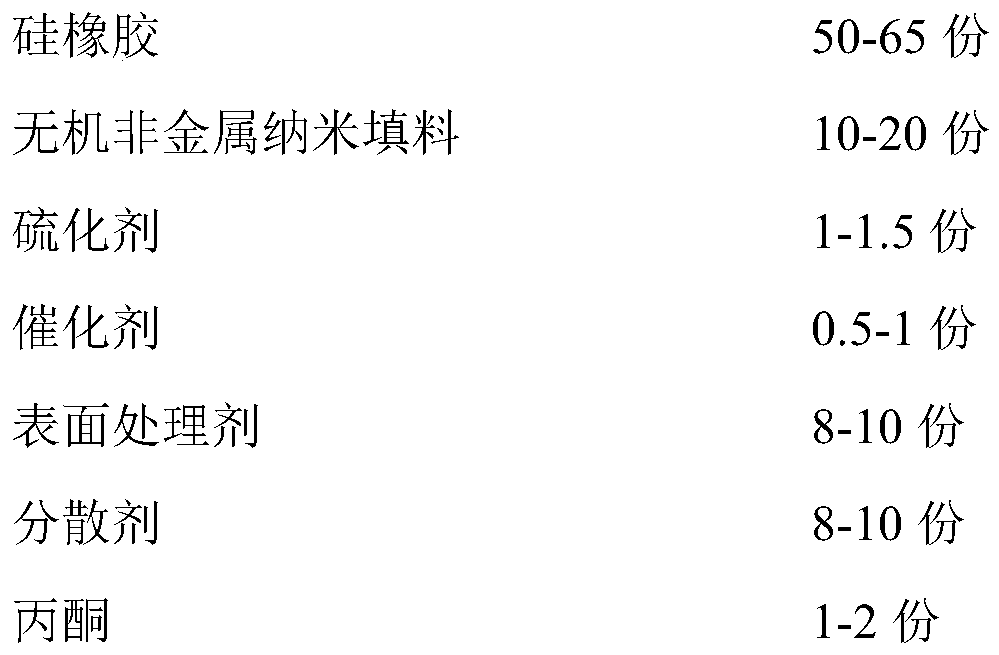

[0043] In terms of parts by mass, the raw material formula of the silicone rubber nanocomposite material for the door sealing ring of the drum washing machine is as follows:

[0044]

[0045] Among them, methyl vinyl silicone rubber, MVQ, grade: 101, produced by Shenzhen Anengfeng Silicone Rubber Co., Ltd.; nano-SiO 2 Filler, YTOy-011, produced by Shanghai Xingtian New Material Technology Co., Ltd., with an average particle size of 20nm; dicumyl peroxide DCP, produced by Sinopharm Chemical Reagent Co., Ltd.; stannous octoate catalyst, analytically pure, Shanghai Zhanyun Chemical Co., Ltd. Produced by the company; surface treatment agent isobutyltrimethoxysilane, CG-8430, produced by Nanjing Chengong Organic Silicon Material Co., Ltd.; dispersant acetone, provided by Xi'an Tianmao Chemical Co., Ltd., acetone for dropping, Xi'an Tianmao Chemical Co., Ltd. provided by the company.

[0046] During preparation, methyl vinyl silicone rubber, nano-SiO 2 Filler, vulcanizing agent...

Embodiment 2

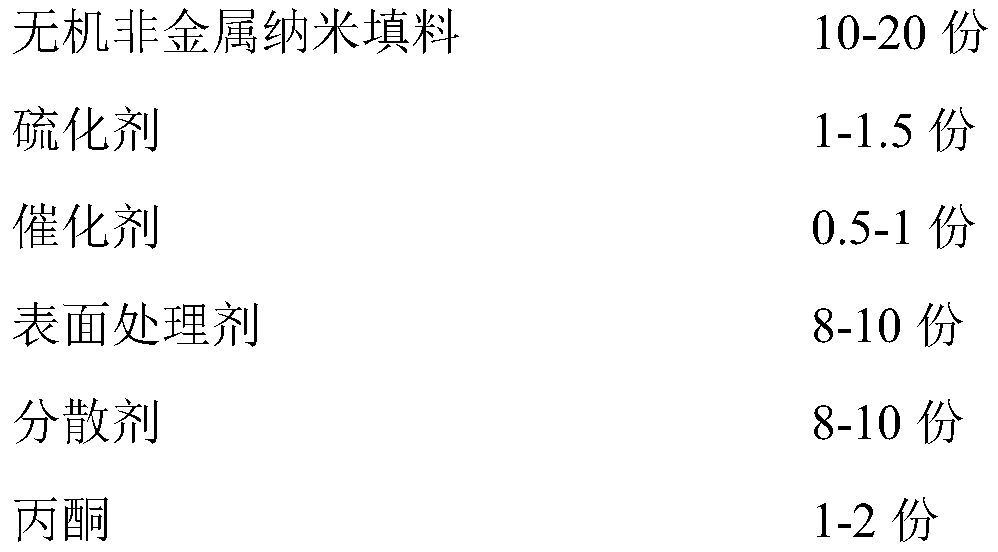

[0049] In terms of parts by mass, the raw material formula of the silicone rubber nanocomposite material for the door sealing ring of the drum washing machine is as follows:

[0050]

[0051] Among them, methyl vinyl silicone rubber, MVQ, grade: 101, produced by Shenzhen Anengfeng Silicone Rubber Co., Ltd.; nano-CaCO 3 Filler, produced by Jingjiang Tonggao Chemical Co., Ltd., with an average particle size of 50nm; sulfur Deosulf L 95, produced by Shanghai Sude Rubber Technology Co., Ltd.; catalyst dibutyltin dilaurate, T-12, produced by Jinan Haiyuan Chemical Co., Ltd.; surface treatment Agent n-octyltriethoxysilane, KH-832, produced by Nanjing Nengde Chemical Co., Ltd.; dispersant acetone, provided by Xi'an Tianmao Chemical Co., Ltd., acetone for dropping, provided by Xi'an Tianmao Chemical Co., Ltd.

[0052] This embodiment adopts nano-CaCO 3 As an inorganic non-metallic nanometer filler, other types of catalysts, vulcanizing agents, surface treatment agents and differen...

Embodiment 3

[0056] In terms of parts by mass, the raw material formula of the silicone rubber nanocomposite material for the door seal ring of the drum washing machine is as follows:

[0057]

[0058] Among them, methyl vinyl silicone rubber, MVQ, grade: 101, produced by Shenzhen Anengfeng Silicone Rubber Co., Ltd.; nano-ZnO, TZP-50, produced by Jiangsu Tianxing New Material Co., Ltd., with an average particle size of 30nm; Dicumyl oxide DCP, chemically pure, produced by Sinopharm Chemical Reagent Co., Ltd.; catalyst stannous octoate, analytically pure, produced by Shanghai Zhanyun Chemical Co., Ltd.; surface treatment agent dodecyltrimethoxysilane, CG-1231, Produced by Nanjing Chengong Organic Silicon Material Co., Ltd.; dispersant acetone, provided by Xi'an Tianmao Chemical Co., Ltd., and acetone for dropping, provided by Xi'an Tianmao Chemical Co., Ltd.

[0059] In this embodiment, zinc oxide is used as the inorganic non-metallic nano-filler, and other types of surface treatment age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com