Dust inhibiting agent used during railway transportation process of powdered materials and preparation method thereof

A technology for railway transportation and dust suppressant, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of bacterial growth, difficult storage, transportation, etc., and achieve the effect of increasing the validity period, inhibiting bacterial growth, and achieving good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A dust suppressant used in the railway transportation of bulk materials, the dust suppressant comprises the following ingredients in parts by weight:

[0042] Polyvinyl alcohol 10~15

[0043] Starch 10~20

[0044] Polyacrylamide 1~5

[0045] Carboxymethyl cellulose 15~20

[0046] Natural vegetable gum 10~15

[0047] Surfactant 1~5

[0048] Antifreeze additive 3~5

[0049] Antibacterial agent 0.5~1.

[0050] Further, the starch is: one or a mixture of potato starch, cereal starch, and bean starch.

[0051] Further, the natural vegetable gum is one or a mixture of Tianqing gum, Arabic gum, and peach gum.

[0052] Further, the surfactant is: sodium dodecylbenzenesulfonate, sodium dodecylsulfate, sodium tetradecylbenzenesulfonate, sodium pentadecylbenzenesulfonate, hexadecylbenzene One or a mixture of sodium sulfonate, sodium heptadecylbenzenesulfonate, and sodium octadecylbenzenesulfonate.

[0053] Further, the antifreeze additive is: one or a mixture of calcium c...

Embodiment 2

[0064] This embodiment is an improvement made on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be regarded as this embodiment. content, which will not be repeated here.

[0065] The weight and number ratio of each raw material of the dust suppressant of the present embodiment is:

[0066] Polyvinyl alcohol 12

[0067] tapioca starch 16

[0068] Polyacrylamide 2

[0069] Carboxymethylcellulose 18

[0070] Tian Qingjiao 13

[0071] Sodium dodecylbenzenesulfonate 3

[0073] Sodium Benzoate 0.7

[0074] The preparation method of described dust suppressant comprises the following steps:

[0075] (1) Weigh polyvinyl alcohol, tapioca starch, polyacrylamide, carboxymethyl cellulose, Tianqing gum, sodium dodecylbenzenesulfonate, sodium chloride, and sodium benzoate in proportion;

[0076] (2) ...

Embodiment 3

[0082] This embodiment is an improvement made on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be regarded as this embodiment. content, which will not be repeated here.

[0083] The weight and number ratio of each raw material of the dust suppressant of the present embodiment is:

[0084] Polyvinyl alcohol 14

[0085] cornstarch 16

[0086] Polyacrylamide 4

[0087] Carboxymethylcellulose 18

[0088] Gum Arabic 13

[0089] Sodium dodecylbenzenesulfonate 2

[0090] Sodium Lauryl Sulfate 1

[0091] Sodium chloride 2

[0092] Sodium silicate 1

[0093] Sodium Benzoate 0.7.

[0094] Please refer to Example 2 for the preparation method of the dust suppressant.

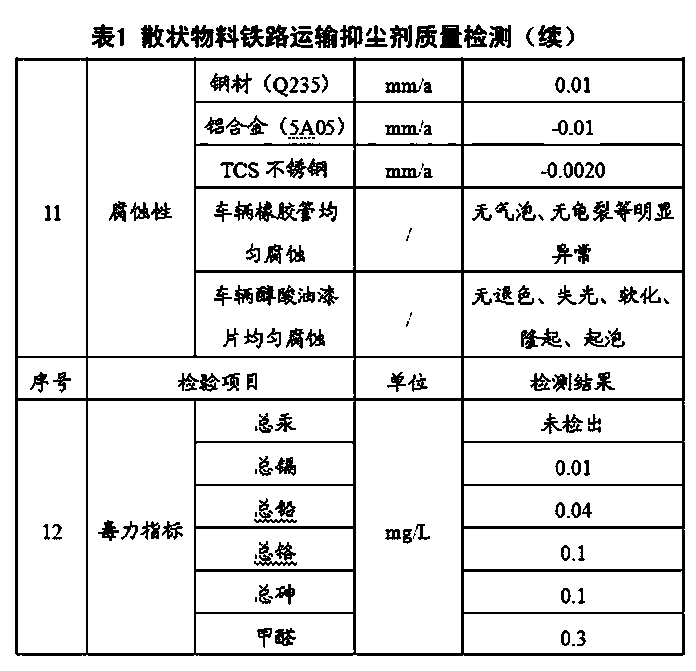

[0095] In order to test the performance of the dust suppressant, the applicant commissioned the Railway Transport Packaging Inspection Station of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com