High-strength high-heat-resistance flame-retardant silicone rubber material and preparation method thereof

A high heat resistance, silicone rubber technology, applied in the field of flame retardant polymer materials, can solve the problems of poor platinum flame retardant effect, low mechanical properties, flame retardant precipitation and other problems, and achieve excellent mechanical properties, small mechanical properties, High flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

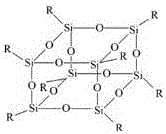

[0068] Preparation method based on caged polysilsesquioxane phosphorus-containing flame retardant:

[0069] (1) Weigh 242G of 29,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and 209GVTES dissolved in 300ML toluene after drying at 110℃ for 4H, pour into Stir the reaction vessel of the device, add 8G of azobisisobutyronitrile, heat and stir for 10H, and distill off toluene under reduced pressure at 110°C to obtain light yellow liquid DOPO-VTES.

[0070] (2) Dissolve 95GDOPO-VTES in methanol and add it to a reaction vessel equipped with a condenser, heat up to 80°C, add 2ML phosphoric acid dropwise, continue stirring for 24H, filter to obtain a white powder, rinse with deionized water 3 times, 100°C After vacuum drying, a phosphorus-containing flame retardant based on caged polysilsesquioxane was obtained with a yield of 97%.

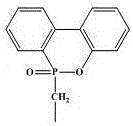

[0071] Preparation method of reactive phosphorus-containing silicon-containing flame retardant:

[0072] Dry 216G (1MOL) 9,10-dihydro-9-oxa-1...

Embodiment 1

[0075] In this embodiment, both component A and component B are calculated on the basis of 100 parts by mass fraction.

[0076] Preparation of component A: First, mix 50.98 parts of vinyl silicone rubber (molecular weight: 700,000), 4 parts of p-high vinyl silicone oil (viscosity of 2000mpa.s, vinyl content (mass fraction) 2.5%), and 3 parts of hydroxyl silicone oil (the hydroxyl content (mass fraction) is 5.2%) and put them into the vacuum kneader together, after stirring evenly, add 17 parts of hydrophobic fumed silica (specific surface area 280g / m2, dimethyl dichlorosilane modified ), after adding, continue kneading for 2 hours, mix 18 parts of compound flame retardant (the preparation ratio is calculated in parts by weight: 5.5 parts of melamine polyphosphate, 3.5 parts of ethyl aluminum hypophosphite, 3.5 parts of cage-based Add polysilsesquioxane phosphorus-containing flame retardant, 5.5 parts of reactive phosphorus-containing silicon-containing flame retardant) and 3 p...

Embodiment 2

[0080] In this embodiment, both component A and component B are calculated on the basis of 100 parts by mass fraction.

[0081] Preparation of component A: First, 45.98 parts of vinyl-terminated silicone rubber (molecular weight: 800,000), 8 parts of p-high vinyl silicone oil (viscosity of 6500mpa.s, vinyl content 1.26%), 2.5 parts of hydroxyl silicone oil (hydroxyl content 6%) together in a vacuum kneader, after stirring evenly, add 17.5 parts of hydrophobic fumed silica (specific surface area 320g / m2, modified by hexamethyldisilazane) in batches, after adding, Continue kneading for 2 hours, with 18 parts of compound flame retardant (its preparation ratio is calculated in parts by weight: 3 parts of melamine polyphosphate, 3 parts of ethyl aluminum hypophosphite, 6 parts based on cage polysilsesquioxane Phosphorus-containing flame retardant, 6 parts of reactive phosphorus-containing silicon-containing flame retardant) and 5 parts of cerium hydroxide were added to the vacuum k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com