Semiconductive silicon rubber screening material for traveling cable and preparation method thereof

A shielding material and silicone rubber technology, applied in the field of cable shielding materials, can solve the problems of high cost of shielding materials, unstable product quality, easy cracking, etc., and achieve the effect of preventing powder from flying, avoiding threats to health, and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

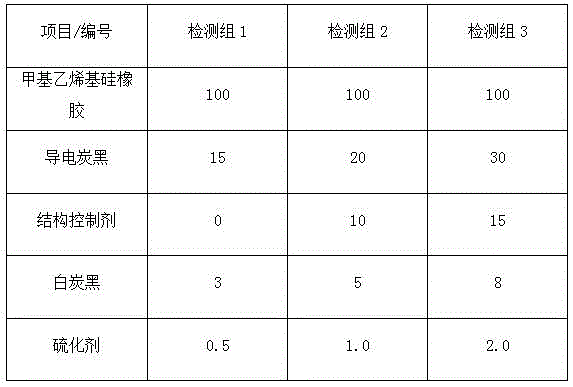

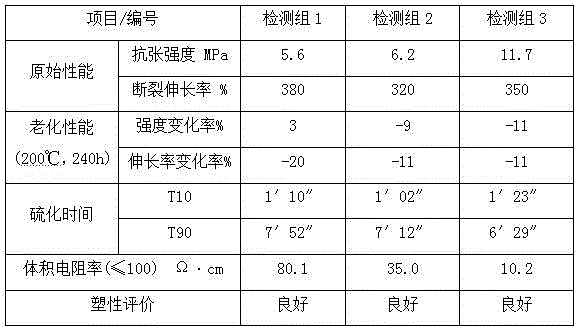

Embodiment 1

[0047] A semiconductive silicone rubber shielding material for mobile cables, comprising the following raw material components in parts by weight:

[0048] Silicone rubber 100 parts

[0049] Conductive carbon black 15 parts

[0050]White carbon black 3 parts

[0051] Dicumyl peroxide 0.5 parts

[0052] 5 parts of hydroxyl silicone oil;

[0053] The silicone rubber is methyl vinyl silicone rubber, dimethyl silicone rubber or methylphenyl vinyl silicone rubber; the conductive carbon black has an average particle size of less than 20nm and a specific resistance of 0.35Ω·cm.

Embodiment 2

[0055] A semiconductive silicone rubber shielding material for mobile cables, comprising the following raw material components in parts by weight:

[0056] Silicone rubber 100 parts

[0057] Conductive carbon black 30 parts

[0058] White carbon black 8 parts

[0059] 2 parts dicumyl peroxide

[0060] 15 parts of hydroxyl silicone oil;

[0061] The silicone rubber is methyl vinyl silicone rubber, dimethyl silicone rubber or methylphenyl vinyl silicone rubber; the conductive carbon black has an average particle size of less than 20nm and a specific resistance of 0.50Ω·cm.

Embodiment 3

[0063] A semiconductive silicone rubber shielding material for mobile cables, comprising the following raw material components in parts by weight:

[0064] Silicone rubber 100 parts

[0065] Conductive carbon black 22.5 parts

[0066] White carbon black 5.5 parts

[0067] Dicumyl peroxide 1.25 parts

[0068] 10 parts of hydroxyl silicone oil;

[0069] The silicone rubber is methyl vinyl silicone rubber, dimethyl silicone rubber or methylphenyl vinyl silicone rubber; the conductive carbon black has an average particle size of less than 20nm and a specific resistance of 0.425Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com