Patents

Literature

36results about How to "Improve production and processing effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

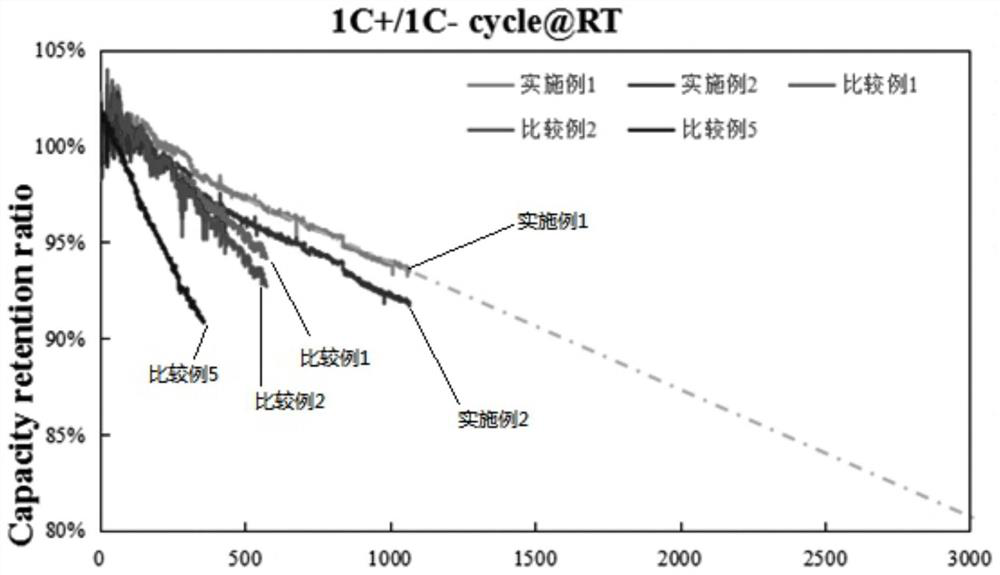

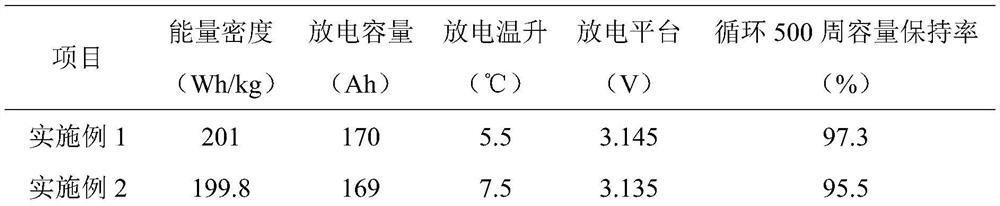

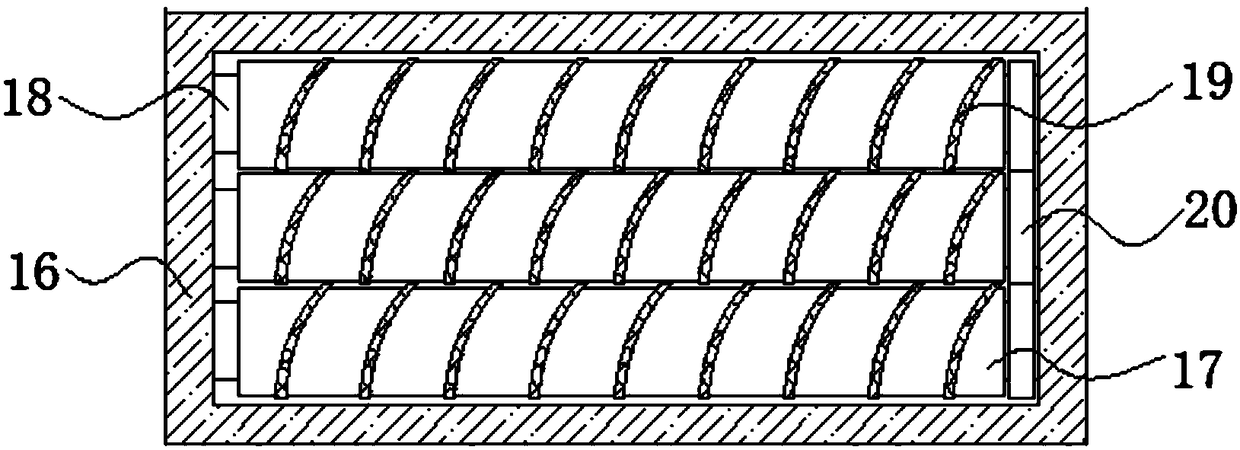

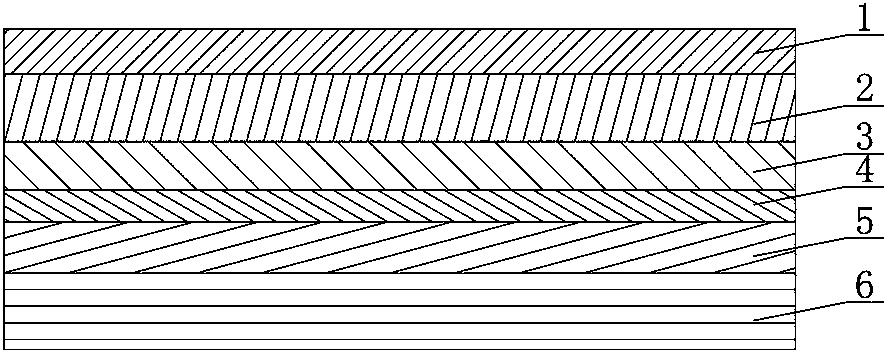

High-energy-density lithium iron phosphate battery

ActiveCN113078305ASignificant progressIncrease capacityMaterial nanotechnologyFinal product manufactureElectrolytic agentMagnesium doping

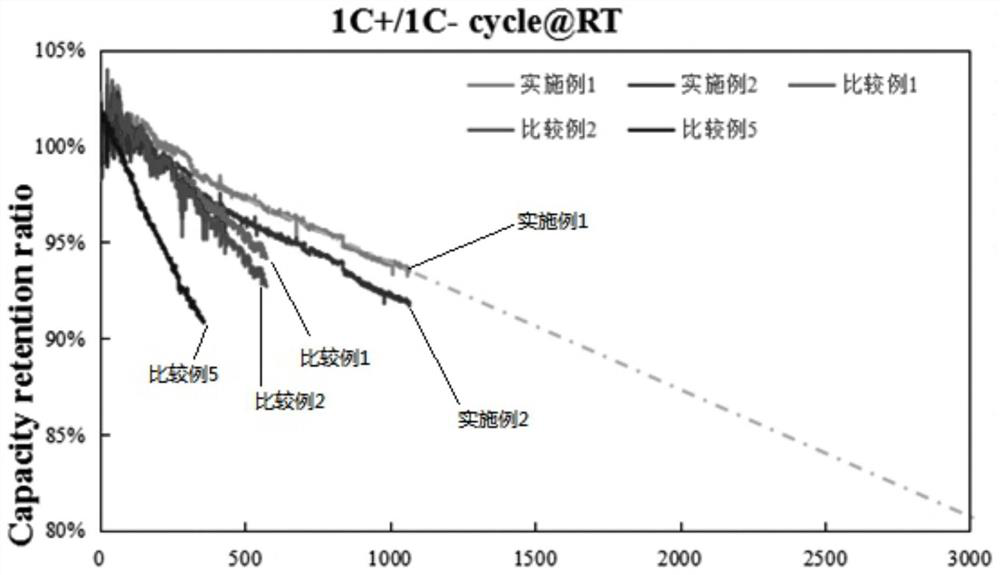

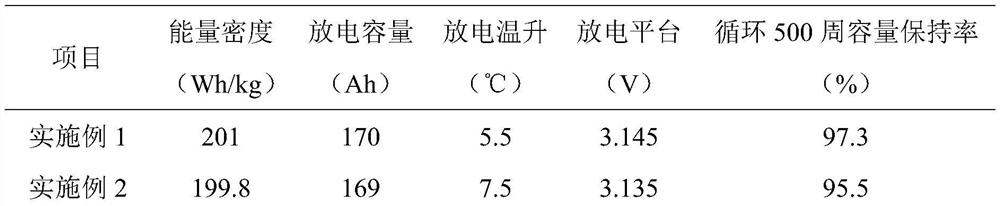

The invention belongs to the technical field of electrochemistry, and particularly relates to a high-energy-density lithium iron phosphate battery. A positive electrode active material is selected from titanium / magnesium-doped lithium iron phosphate, the surface density of a positive plate is 190-210 g / m<2>, the compaction density is greater than or equal to 2.60 g / cc, a negative electrode active material is carbon-coated single particle and secondary particle needle coke blend artificial graphite, and the compaction density of a negative plate is greater than or equal to 1.70 g / cc. The density of the electrolyte is equal to 1.15 g / cc, the wall thickness of the aluminum shell body is 0.40-0.50 mm, a positive electrode current collector is an aluminum foil with the diameter of 12-13 [mu]m, a negative electrode current collector is a copper foil with the diameter of 4.5 [mu]m, a diaphragm is a 7 + 2C + 2P ceramic gluing diaphragm, a conductive binder is used for replacing a positive electrode, the addition amount is 1.0-2.0%, and the weight ratio of a positive electrode active material to a positive electrode dressing is greater than or equal to 98%. According to the invention, the energy density of the battery is greatly improved and reaches 200Wh / kg.

Owner:江西安驰新能源科技有限公司

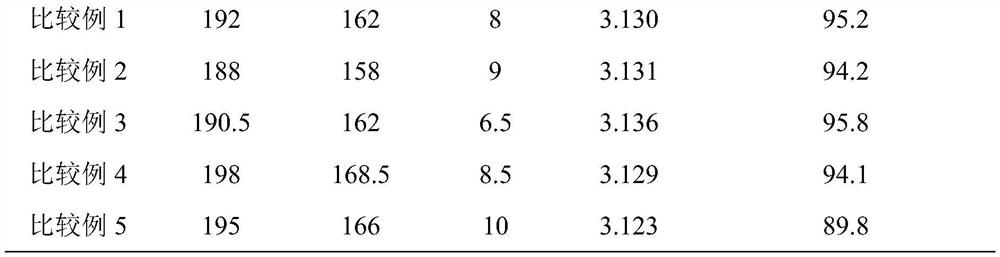

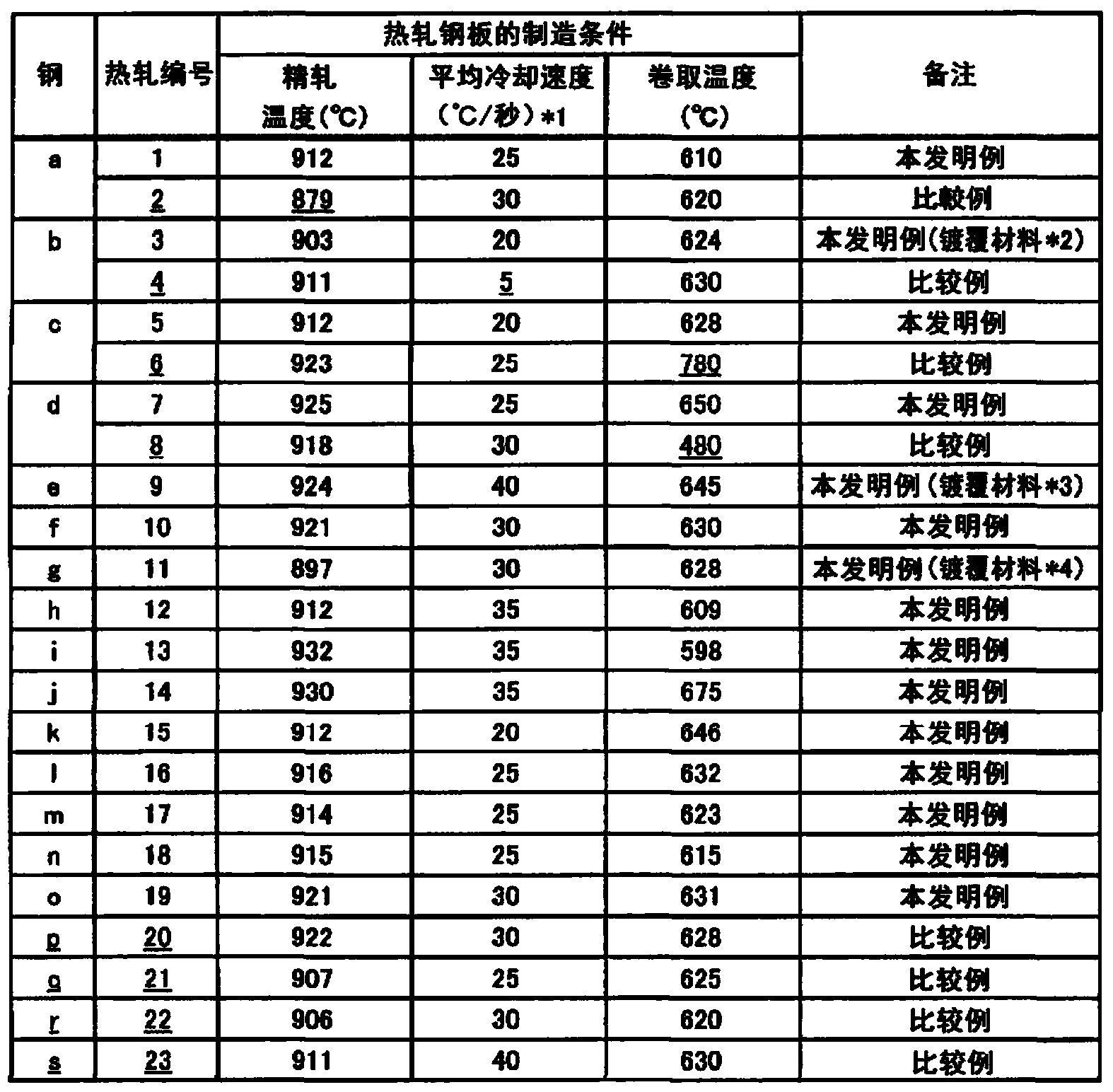

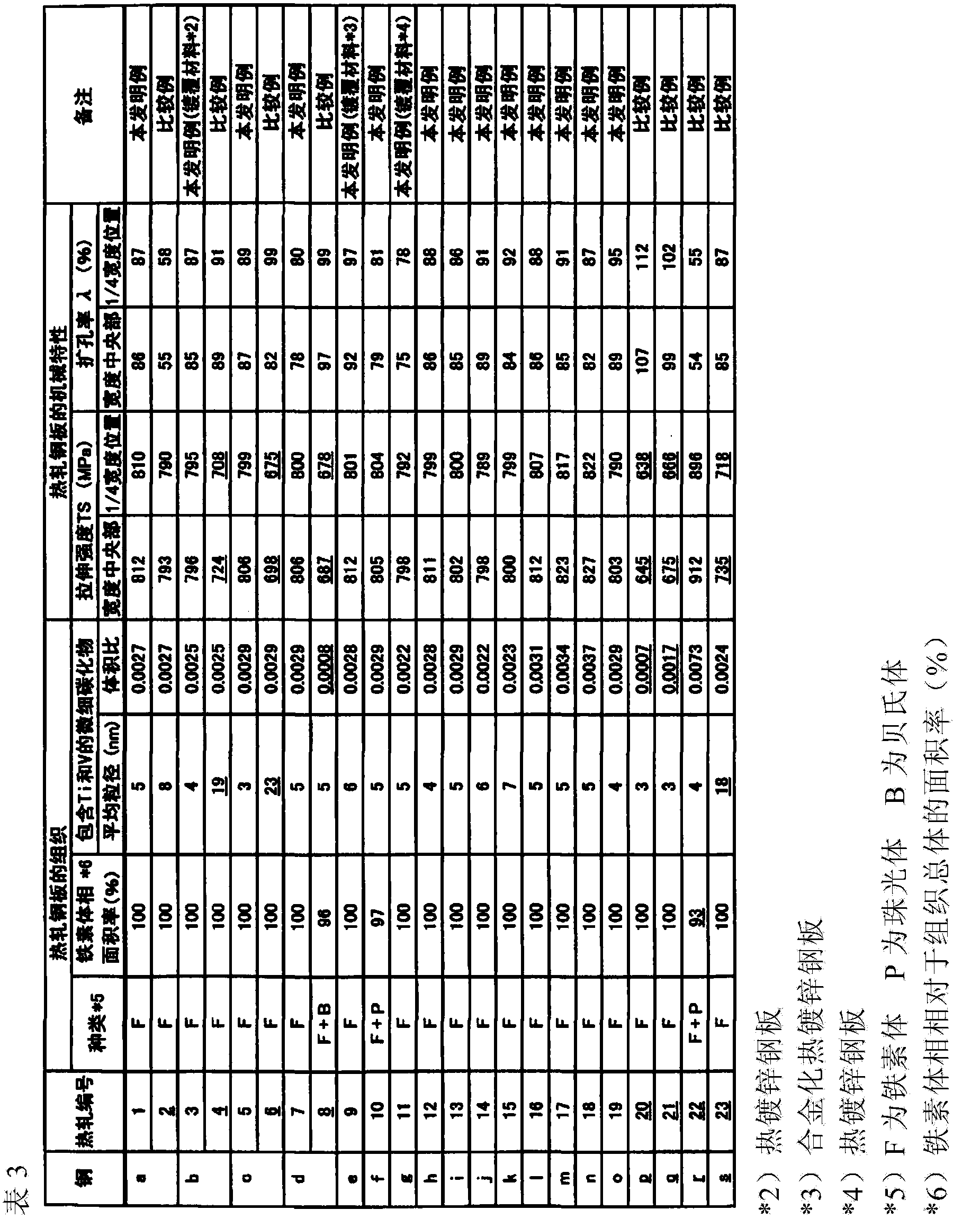

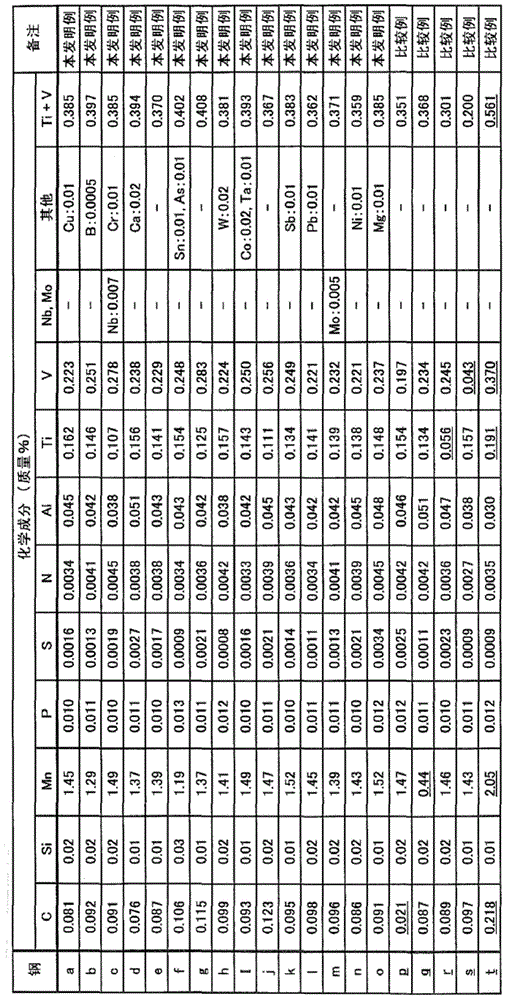

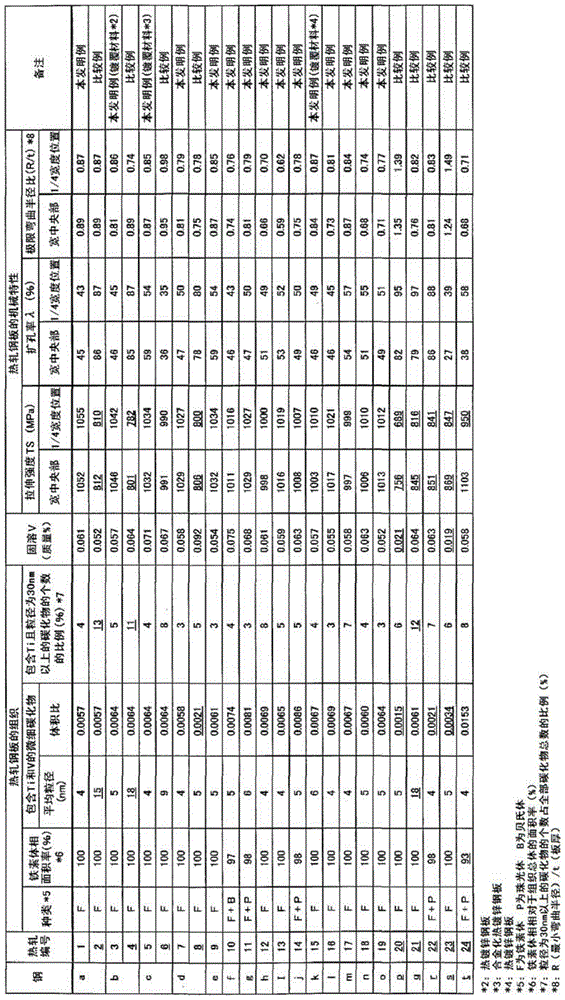

High-tensile-strength hot-rolled steel sheet and method for producing same

ActiveCN103930582AStable production processabilityImprove production and processing effectsHot-dipping/immersion processesFurnace typesCarbideUltimate tensile strength

Provided are: a high-tensile-strength hot-rolled steel sheet provided with both high strength and favorable workability (stretch flangeability), and moreover has superior material uniformity; and a method for producing same. The hot-rolled steel sheet has a tensile strength of at least 780 MPa, and has: a composition containing, by mass%, at least 0.03% and less than 0.07% of C, no greater than 0.3% of Si, 0.5-2.0% inclusive of Mn, no greater than 0.025% of P, no greater than 0.005% of S, no greater than 0.0060% of N, no greater than 0.1% of Al, 0.07-0.11% inclusive of Ti, and at least 0.08% and less than 0.15% of V in a manner such that Ti and V satisfy 0.18 <= Ti + V <= 0.24 (Ti and V being the amount contained (mass%) of the respective elements), the remainder comprising Fe and unavoidable impurities; a matrix such that the area ratio of ferrite phase with respect to the total structure is at least 95%; and a structure such that minute carbides containing Ti and V and having an average grain size of less than 10 nm are dispersed / precipitated, and the volume ratio of the minute carbides with respect to the total structure is at least 0.0020.

Owner:JFE STEEL CORP

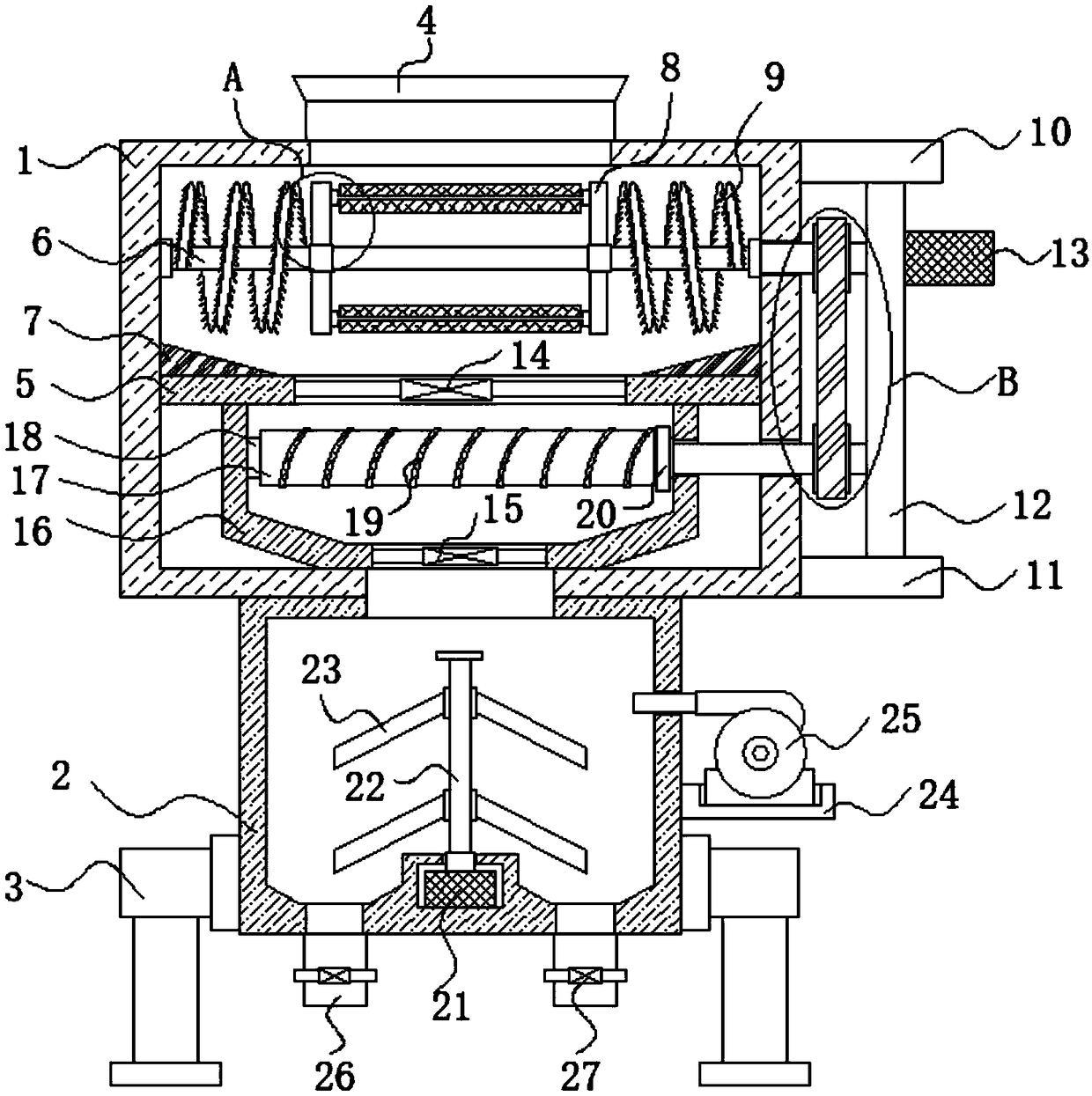

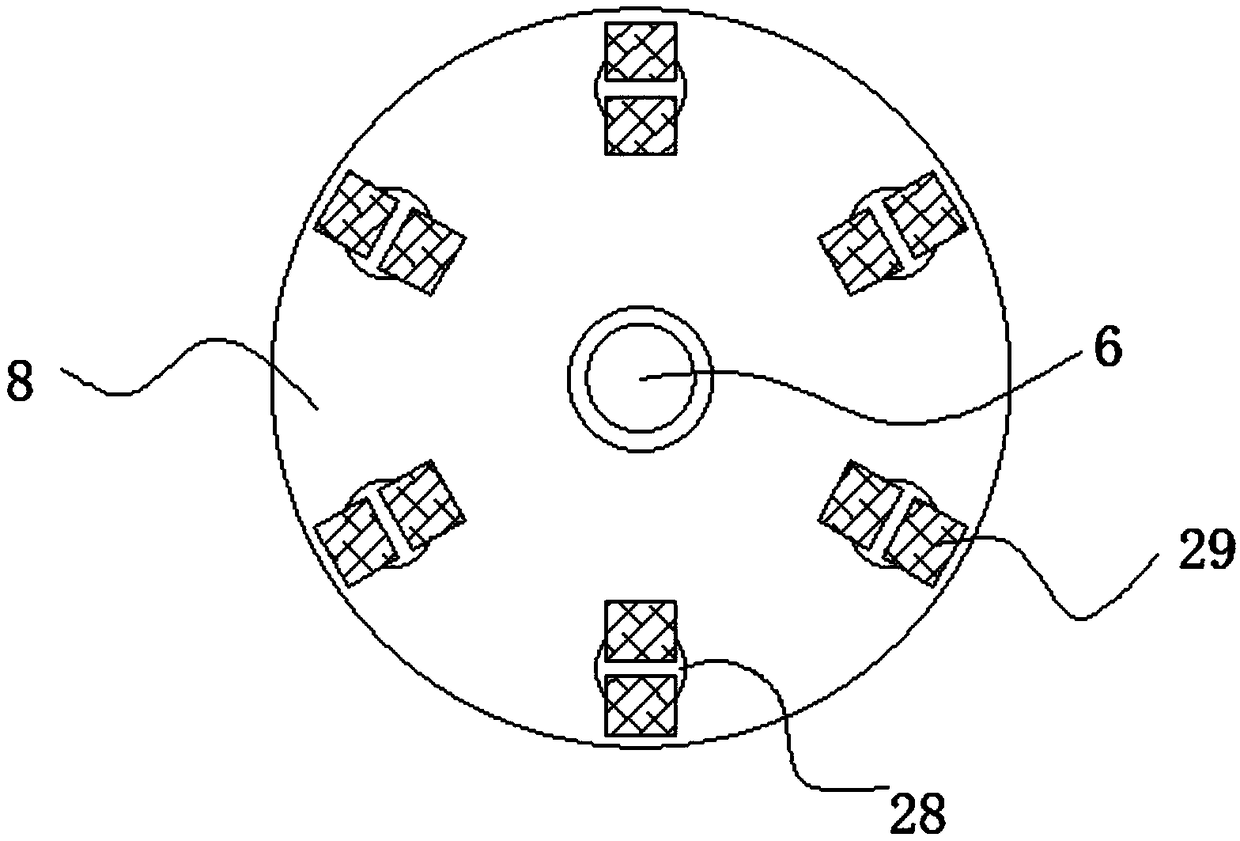

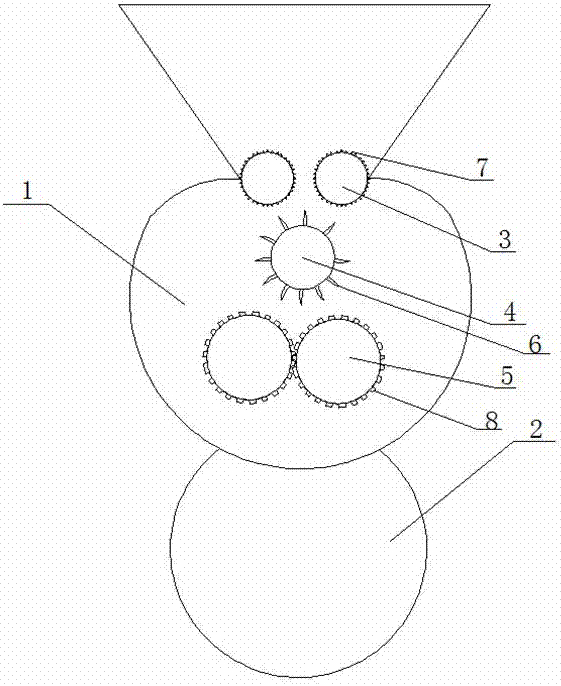

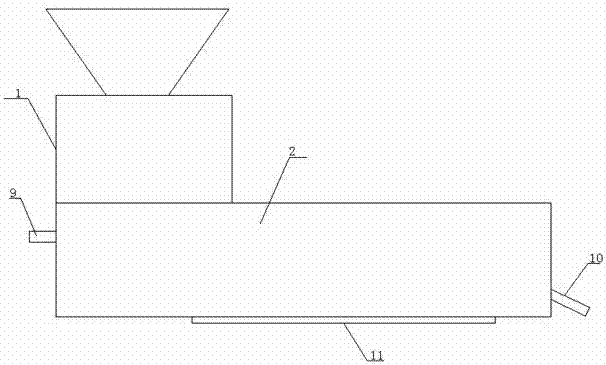

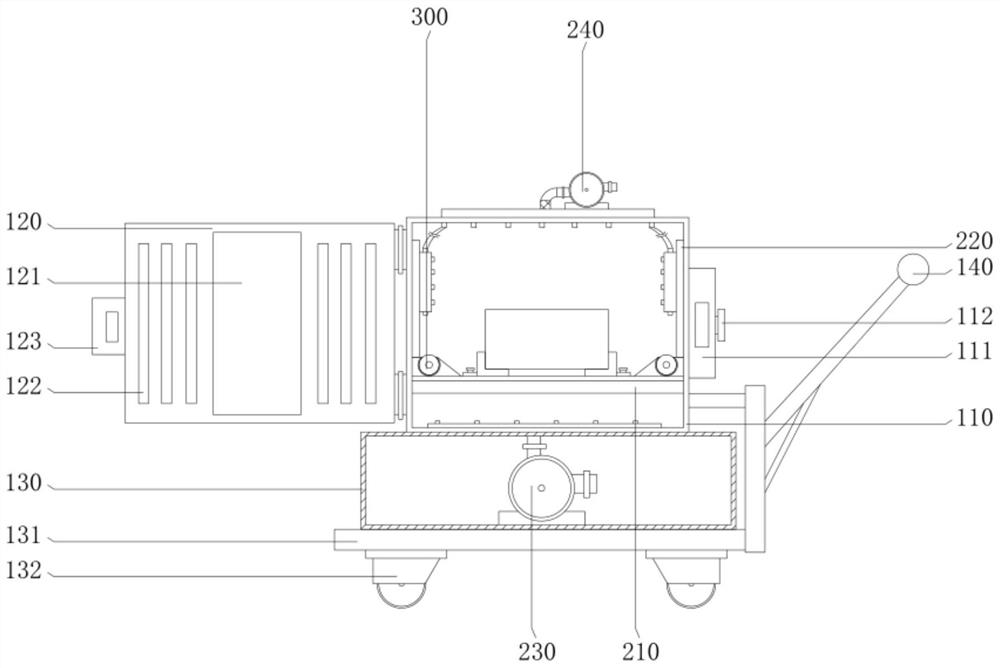

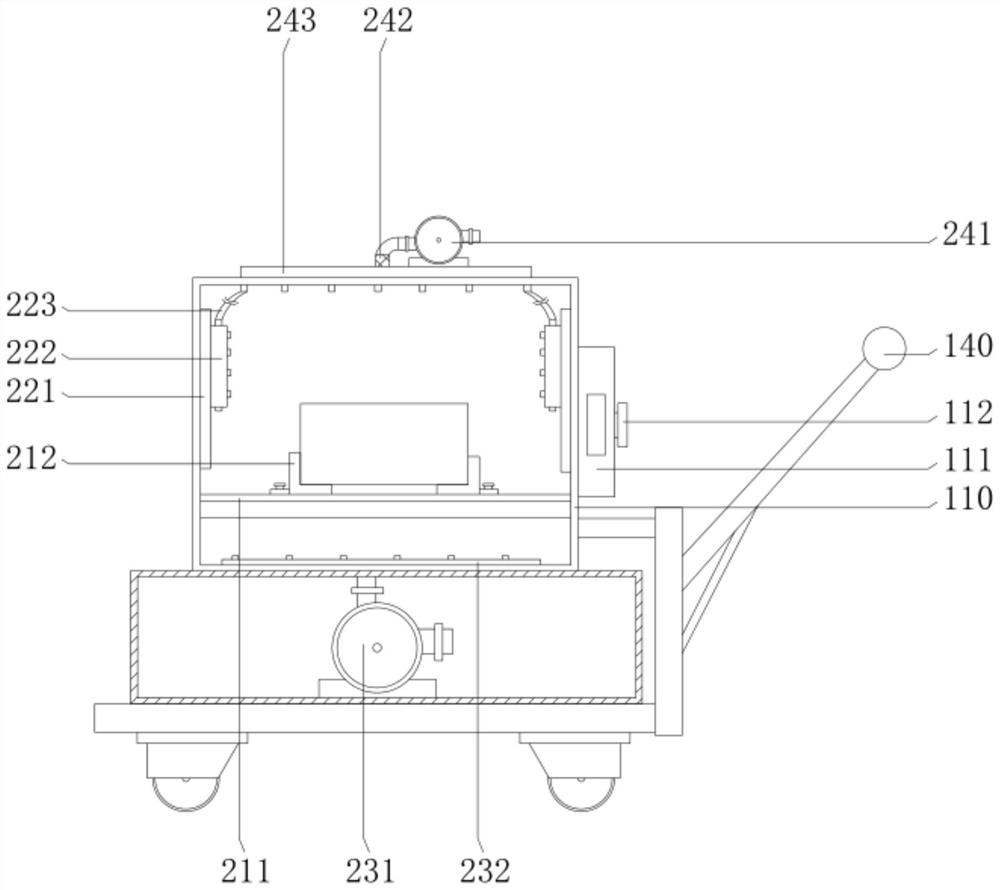

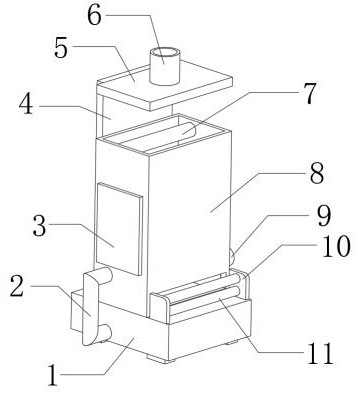

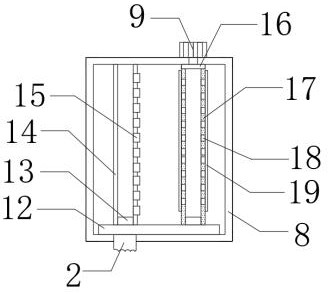

Chemical raw material processing device with drying function

InactiveCN108722594AImprove crushing efficiencyImprove uniformityRotary stirring mixersTransportation and packagingEngineeringRaw material

The invention discloses a chemical raw material processing device with a drying function. The chemical raw material processing device comprises a treatment box and a drying box. The treatment box is located at the upper end of the drying box. Two supporting frames are fixedly connected to the two sides of the drying box. A feeding channel is arranged at the upper end of the treatment box. A partition plate is fixedly connected in the treatment box and divides the treatment box into a pulverizing cavity and a grinding cavity. The pulverizing cavity is located above the grinding cavity. A rotation shaft is rotationally connected in the pulverizing cavity. The two sides of the rotation shaft are rotationally connected to the opposite inner walls of the pulverizing cavity correspondingly. Therotation shaft is fixedly sleeved with two fixing discs. The chemical raw material processing device is compact in structure, and through combination between a strip-shaped pulverizing blade and a grinding roller, the chemical raw material pulverizing efficiency and pulverizing uniformity are improved to a certain degree; and after the chemical raw materials are pulverized, uniform drying operation can be directly conducted on the chemical raw materials, and the producing and processing effect is good.

Owner:夏柱飞

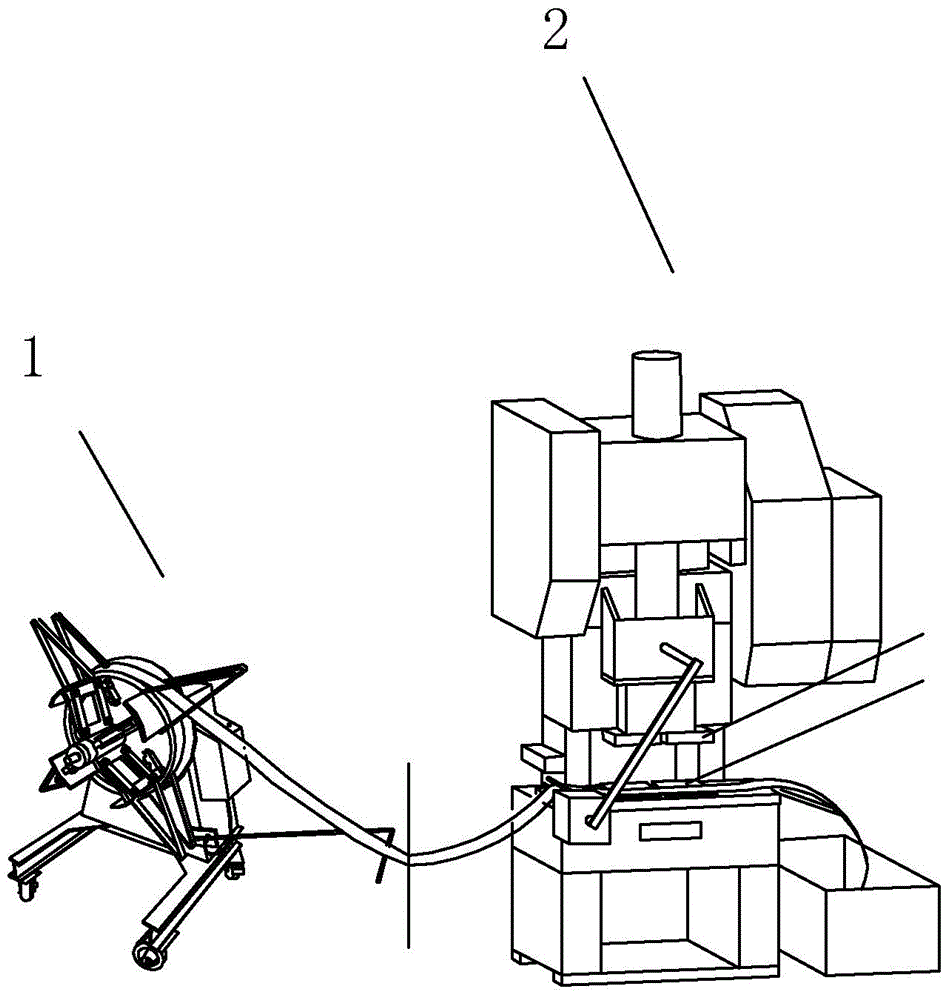

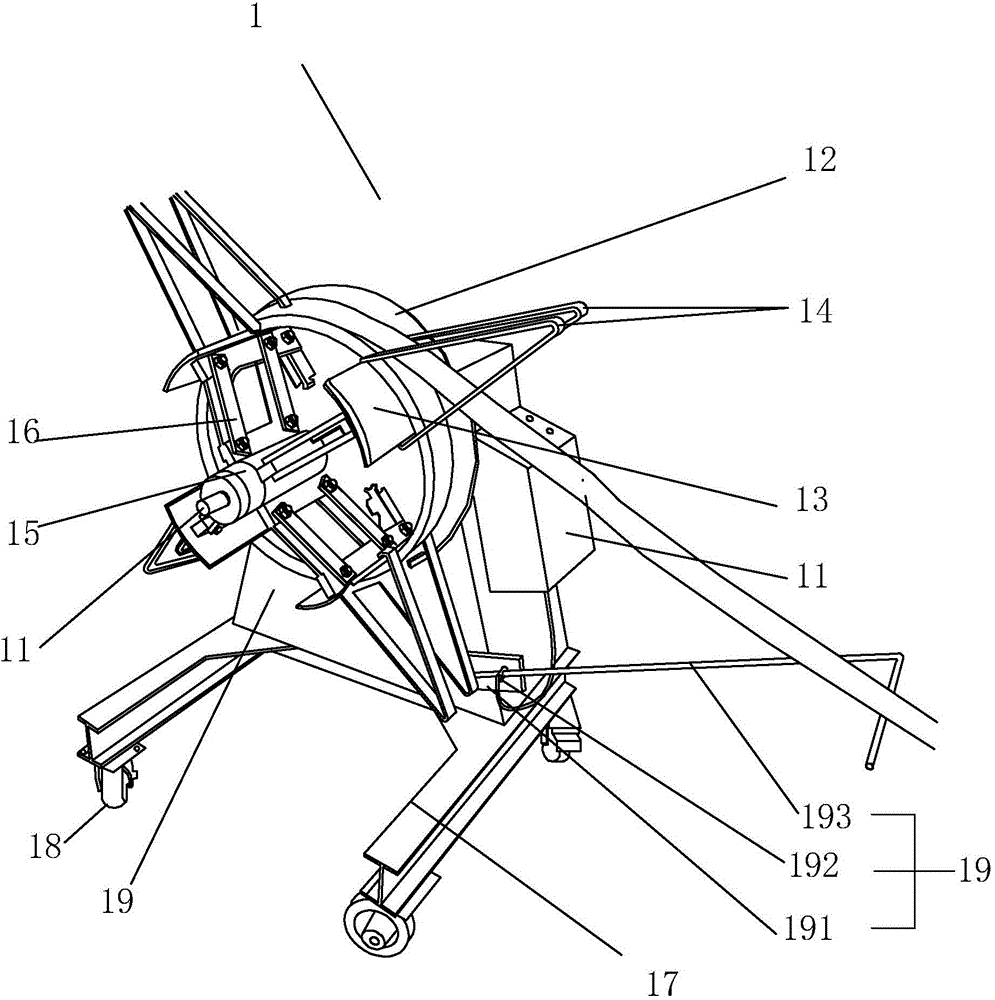

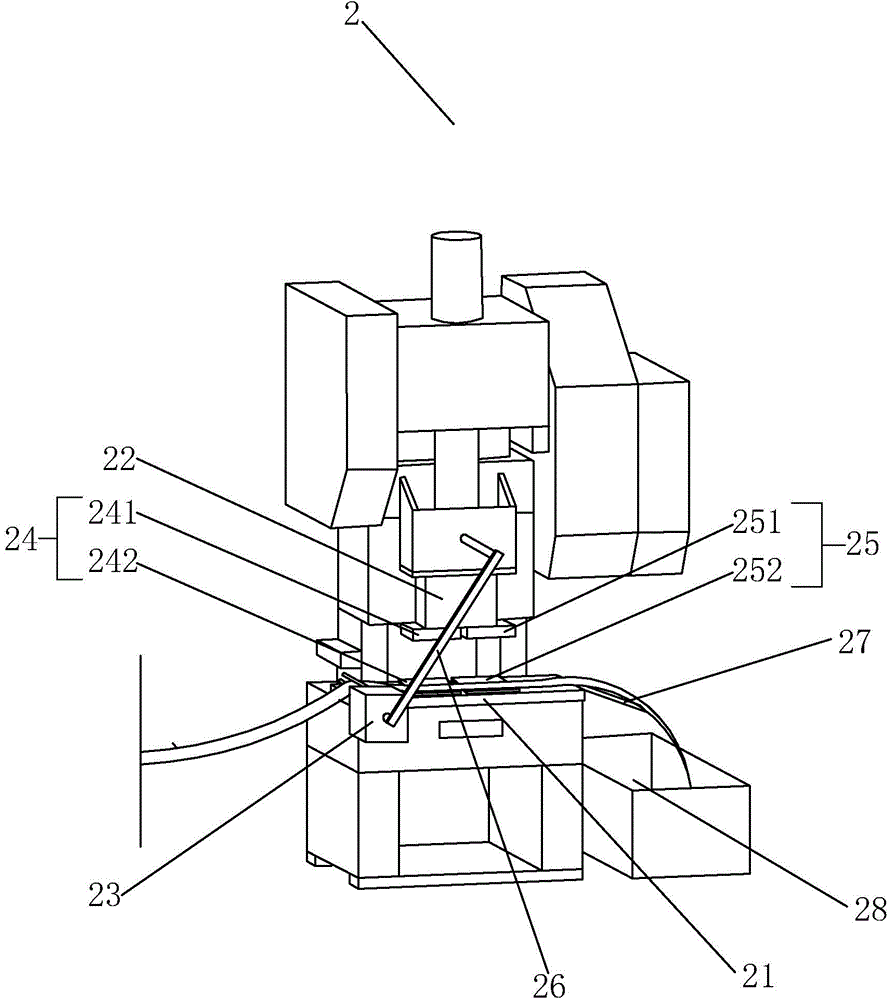

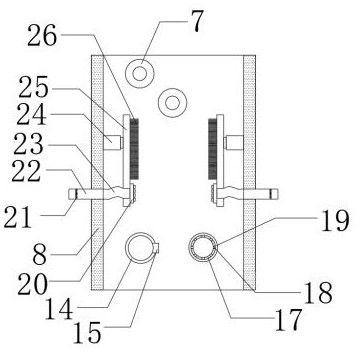

Punching equipment

InactiveCN104475608AEasy to carryEasy to adjustMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention discloses punching equipment. The punching equipment comprises a material delivery device and a punch press which are sequentially arranged. The punching equipment is characterized in that the material delivery device comprises a machine seat, wherein a rotary shaft and a coiling device are arranged on the machine seat, the coiling device is used for winding strip coils, the rotary shaft and the coiling device are coaxially arranged, the coiling device comprises a fixed retaining plate and a plurality of movable retaining plates, the movable retaining plates are used for winding the strip coils, retaining strips are arranged at the two sides of each strip coil on the corresponding movable retaining plate and are used for respectively limiting the corresponding strip coil, a bottom frame is arranged at the bottom part of the machine seat, rollers are arranged under the bottom frame, a sensing device and a stepping motor are arranged on the machine seat, the stepping motor is linked with the rotary shaft, and the sensing device is electrically connected with the stepping motor. The punching equipment has the advantages that by arranging the material delivery device which can synchronously work, the handling and position adjusting of the material delivery device are convenient, the strip coils can be actively conveyed, the influence on the punching process caused by the untimely material delivery is avoided, and the production and processing properties of the equipment are effectively improved.

Owner:NINGBO ZHENHAI XIUYANG ADVERTISEMENT DECORATION

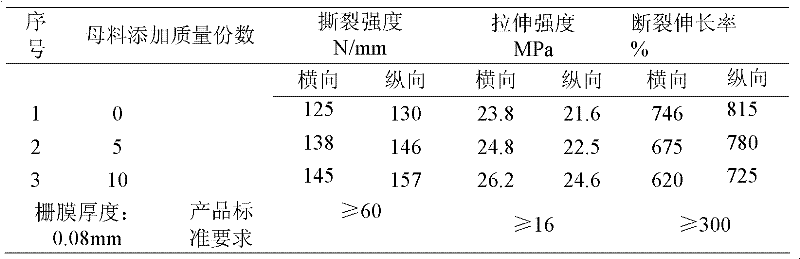

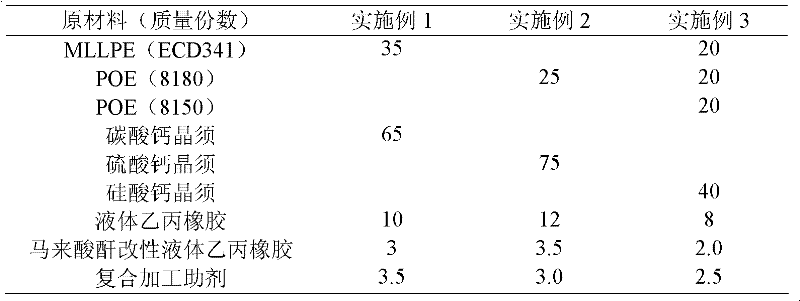

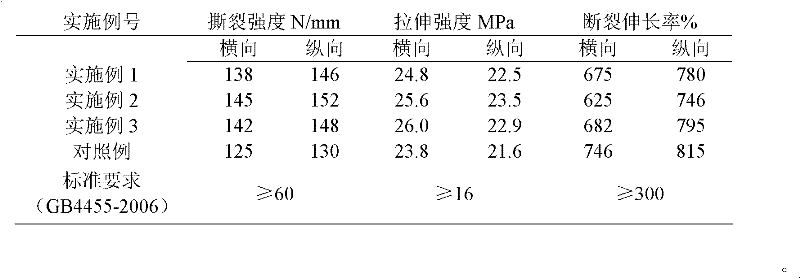

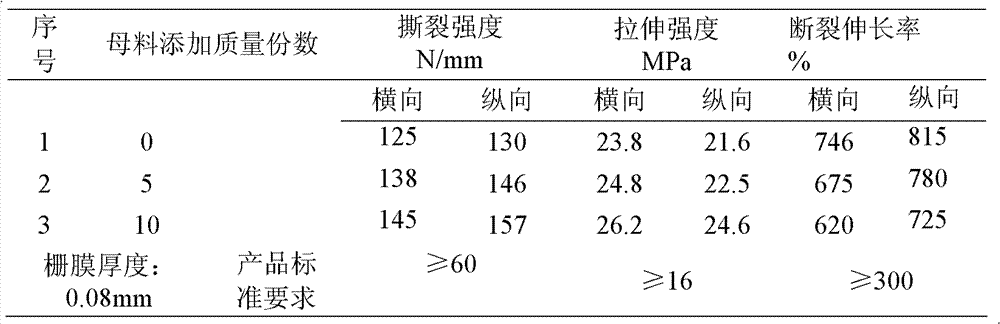

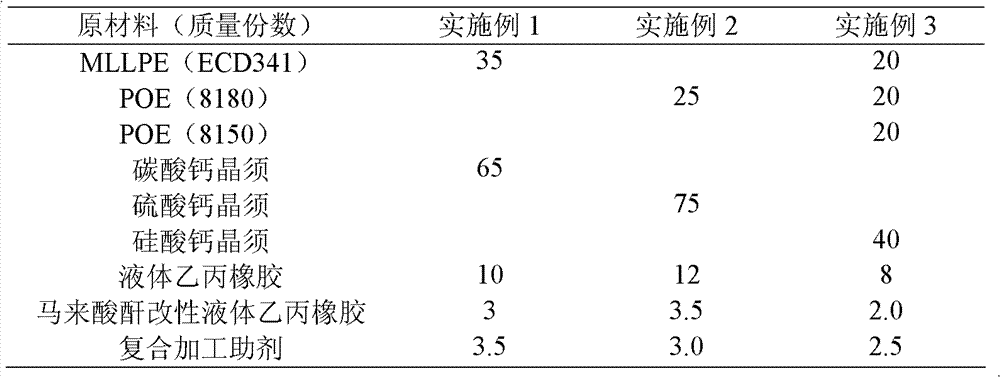

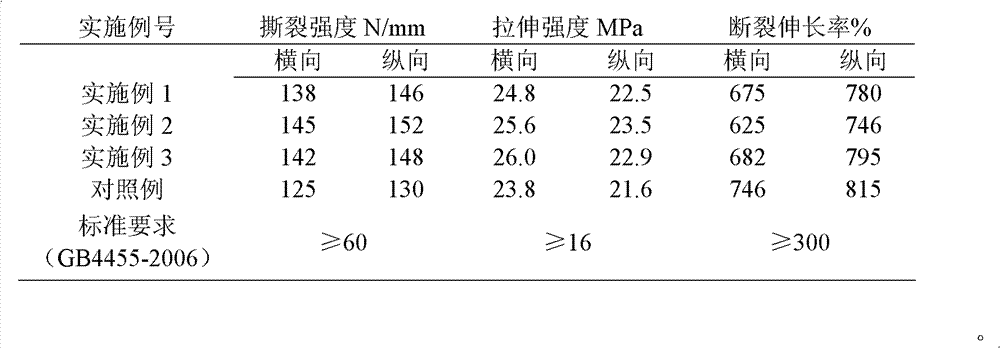

Production method for agricultural greenhouse film master batch reinforced by calcium salt crystal whiskers

InactiveCN102212225AGood processing performanceImprove strength performance and performancePelletizingChemistry

The invention relates to a production method for an agricultural greenhouse film master batch reinforced by calcium salt crystal whiskers. The master batch is prepared from the following raw materials in parts by weight: 40-75 parts of the calcium salt crystal whiskers, 25-60 parts of metallocene polyethylene, 5-15 parts of a compatibilizer and 1-3 parts of composite processing auxiliary agent. The production method comprises the following steps: mixing and stirring the calcium salt crystal whiskers, the compatibilizer and the composite processing auxiliary agent by virtue of a high-speed mixer; then adding metallocene polyethylene, and further mixing to obtain a mixture; and finally conveying the mixture to a double screw extruder, plasticizing, mixing and granulating to obtain the agricultural greenhouse film master batch reinforced by the calcium salt crystal whiskers. The agricultural greenhouse film master batch produced by the production method provided by the invention has excellent mechanical properties, can be used for the production of agricultural polyethylene films with good reinforcing and anti-aging effects, is also applicable to the production application of greenhouse films under the condition of plateau area weather and can be used for prolonging the service life of a product.

Owner:昆明春叶塑料制成品有限公司

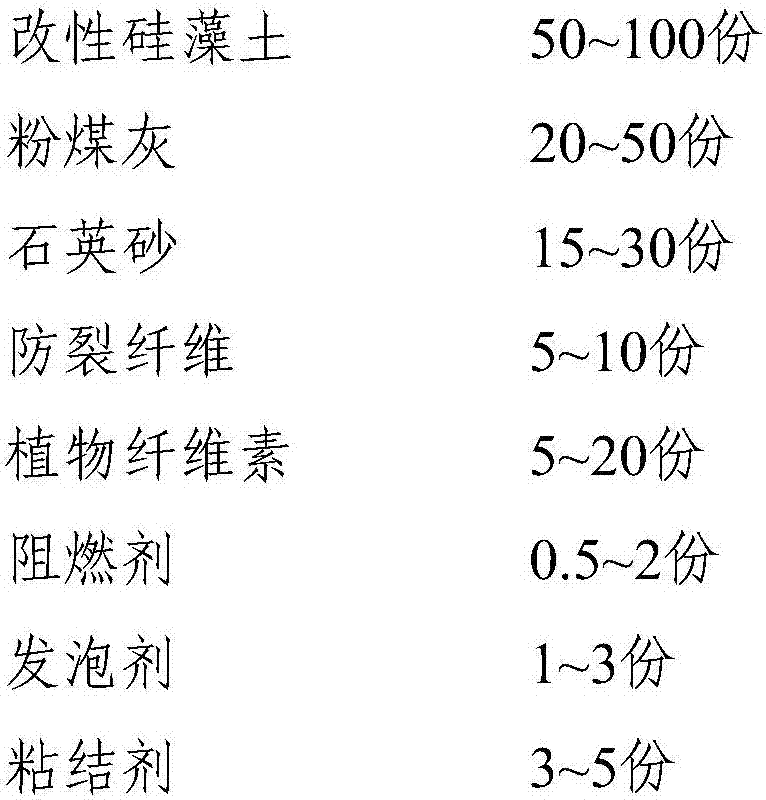

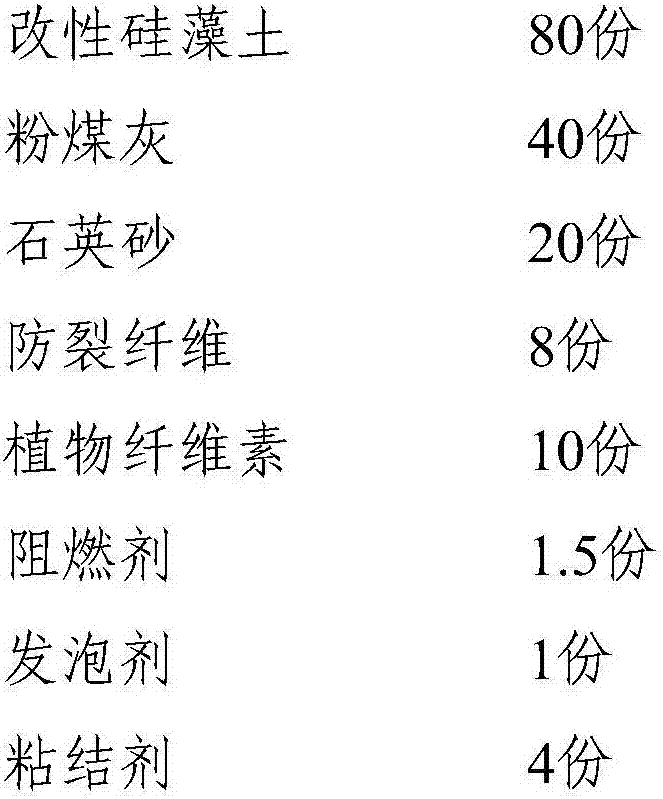

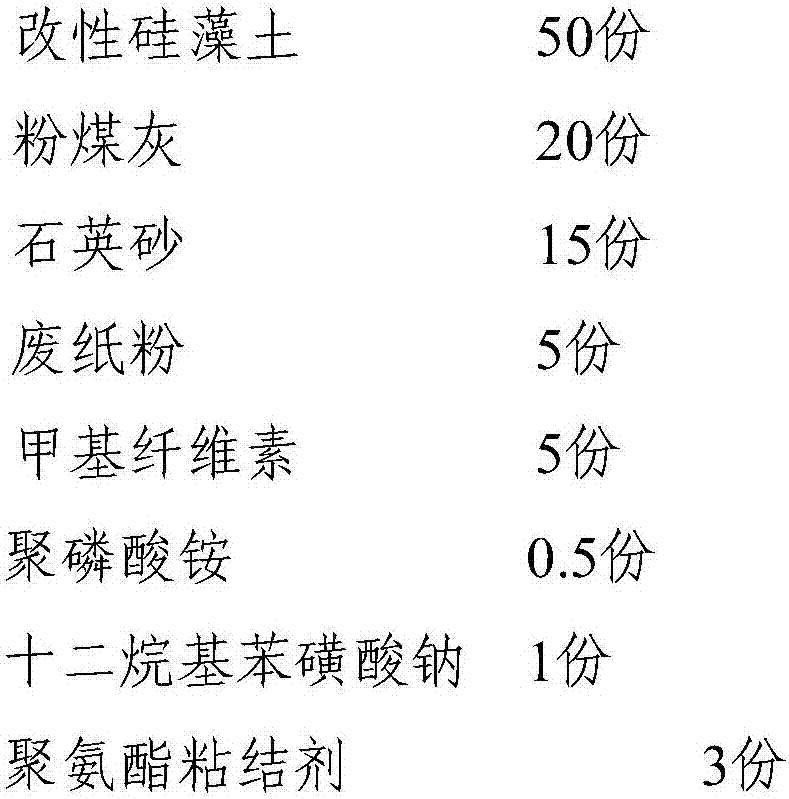

Diatomite building thermal insulation material

The invention relates to a diatomite building thermal insulation material prepared from the components in parts by weight: modified diatomite, coal ash, quartz sand, anti-cracking fibers, plant cellulose, a flame retardant, a foaming agent and a binding agent. The diatomite building thermal insulation material is prepared by stirring and uniformly mixing the modified diatomite, the coal ash, the quartz sand and the anti-cracking fibers according to the weight ratio; then, adding water, carrying out stirring while heating, and slowly adding the plant cellulose, the flame retardant, the foamingagent and the binding agent; and then, carrying out hot press molding to obtain the diatomite building thermal insulation material. The modified diatomite is used as a main raw material, so that the diatomite building thermal insulation material is high in porosity, good in thermal storage property and stable in chemical property; due to the addition of the anti-cracking fibers and the plant cellulose, the mechanical strength and flexibility are improved; due to the use of the binding agent and the flame retardant, the fire resistance of the thermal insulation material is improved; and the coal ash and waste paper powder are added as auxiliary materials, so that the utilization ratios of waste paper and coal ash are increased, and the diatomite building thermal insulation material is energy-saving and environment-friendly. The diatomite building thermal insulation material is simple in preparation method, low in cost, light in weight and convenient to construct and is an environment-friendly material.

Owner:东莞市爱乐居环保科技有限公司

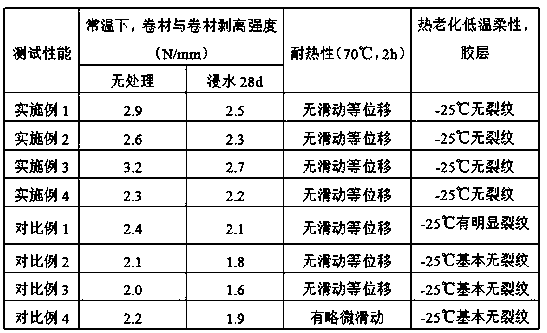

Special hot-melt pressure-sensitive adhesive for low-temperature waterproof coiled material butt-joint adhesive tape and preparation method thereof

InactiveCN111548758APromote plasticizationReduce high temperature viscosityNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolymer science

The invention relates to a special hot-melt pressure-sensitive adhesive for a low-temperature waterproof coiled material butt-joint adhesive tape and a preparation method thereof. The hot-melt pressure-sensitive adhesive comprises the following components in parts by weight: 50 to 60 parts of an SIS thermoplastic elastomer, 20 to 40 parts of a polyisobutylene compound, 5 to 10 parts of hydrogenated monomer resin, 10 to 15 parts of a tackifying resin compound, 1 to 2 parts of an antioxidant and 0.5 to 1.5 parts of an ultraviolet absorbent. Compared with the prior art, the hot-melt pressure-sensitive adhesive has the characteristics of high peel strength, good water resistance, and good low-temperature resistance, and can be widely applied to engineering construction of waterproof coiled materials.

Owner:SHANGHAI JIAHAO ADHESIVE PROD CO LTD

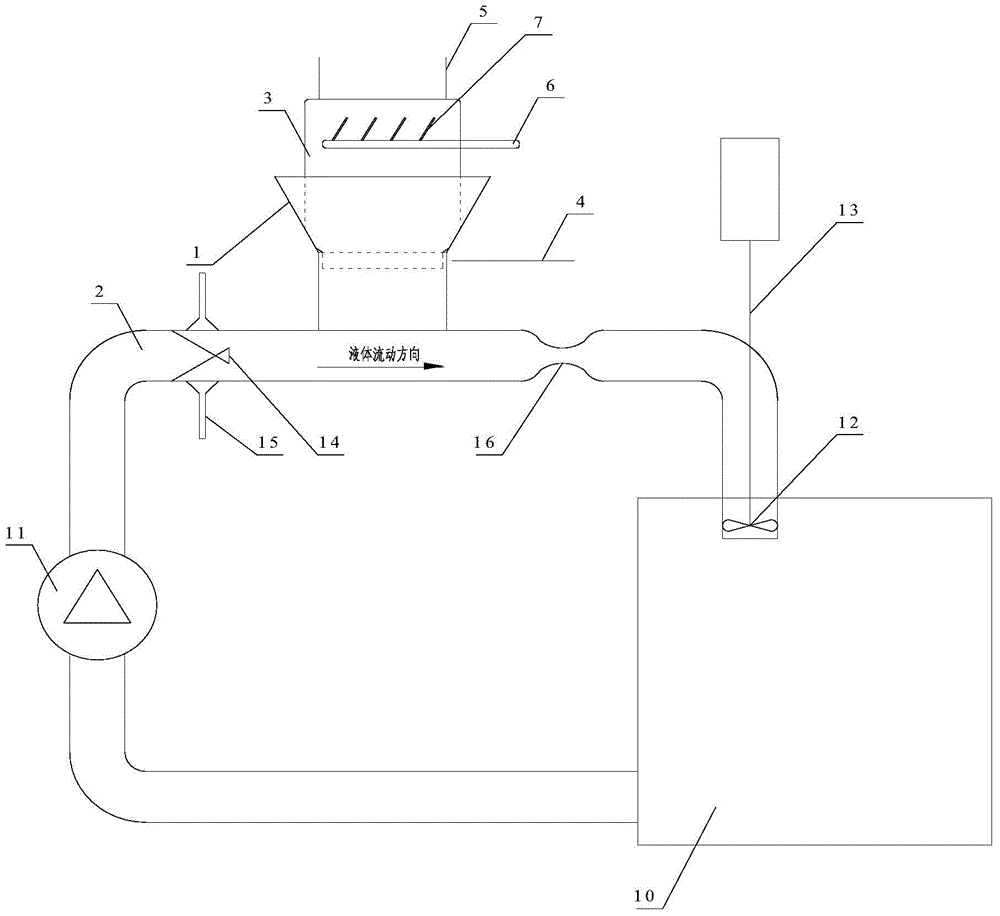

Powder material feeding system

InactiveCN104906991AAvoid security issuesAvoid harmMixing methodsMixer accessoriesEngineeringMechanical engineering

The present invention provides a powder material feeding system, including a feeding device and a circulation pipeline which is in sealing connection with the discharge end of the feeding device, the inside diameter of the upper part of the feeding device is gradually reduced, when one end of a powder material bag is on the feeding device, the inner wall of the powder material bag is in close contact with the inner wall of the feeding device, the lower part of the feeding device is provided with a cutting knife, the cutting knife is used to put the powder material bag into a cutting opening of one end of the feeding device. The beneficial effects are that: the powder material feeding system is simple in structure, prevents the powder material to fly upward, and a material is evenly mixed.

Owner:曹紫祎

Feeding structure

InactiveCN106391897AEasy to carryEasy to adjustMetal-working feeding devicesPositioning devicesStamping processMechanical engineering

The invention relates to a feeding structure. The feeding structure is characterized in that a movable baffle is capable of sliding along the radial direction of a rotary shaft on a fixed baffle; a sleeve shaft is arranged on the rotary shaft in a sleeving manner; the sleeve shaft is capable of sliding along the axial direction of the rotary shaft; a support is connected between the sleeve shaft and the movable baffle; and the sleeve shaft is in linkage connection with the movable baffle through the support. According to the feeding structure disclosed by the invention, with the adoption of the abovementioned technical scheme, carrying and position adjustment for a feeding device are facilitated, and a labour force during carrying and debugging processes is greatly reduced; and moreover, strip coils can be actively conveyed, and influence on a stamping process due to untimely feeding is avoided, thus the production and machining performance of equipment is effectively improved.

Owner:浙江旭辉智能装备有限公司

Feeding device

InactiveCN104841787AEasy to carryEasy to adjustMetal-working feeding devicesMetal working apparatusPunchingEngineering

The invention relates to a feeding device. The feeding device is characterized in that a winding device comprises a fixed baffle and a plurality of movable baffles which can be used for winding a strip coil; the two sides of the strip coil on the movable baffles are provided with stopping strips capable of limiting the strip coil; a bottom frame is arranged at the bottom of a base; rolling wheels are arranged under the bottom frame; the base is provided with a feeding induction device and a stepping motor which is linked with a rotary shaft; and the feeding induction device is electrically connected with the stepping motor and comprises a connection plate fixed on the base and a contact rod which is obliquely arranged relative to the connection plate. With the adoption of the technical scheme, the transportation and the position adjustment of the feeding device are facilitated and the labor force in an equipment transportation and regulation process is greatly alleviated; the strip coil can be initiatively conveyed and the influences on a punching process, caused by the fact that materials are not fed in time, are avoided; and the production and machining performances of the device are effectively improved.

Owner:新昌县澄潭镇苗平机械厂

Special permeable masterbatch for producing PE (poly ethylene) permeable membrane and preparation method of special permeable masterbatch

Owner:CHANGZHOU YINUO POLY TECH

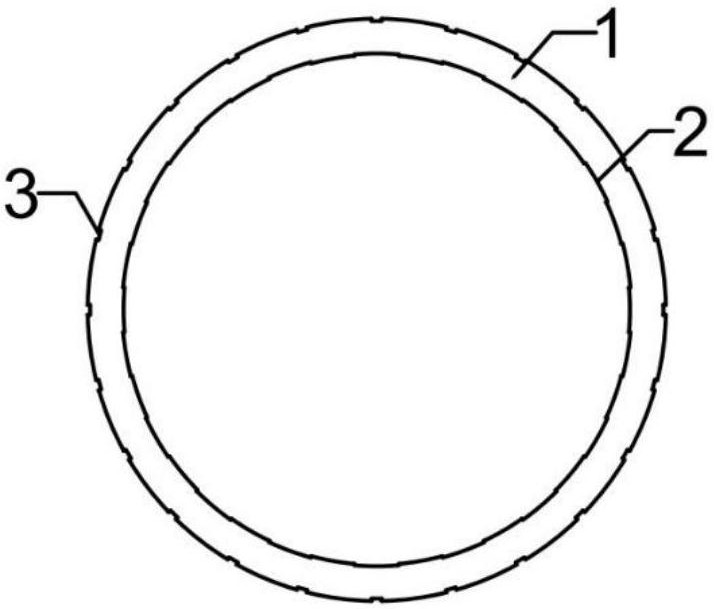

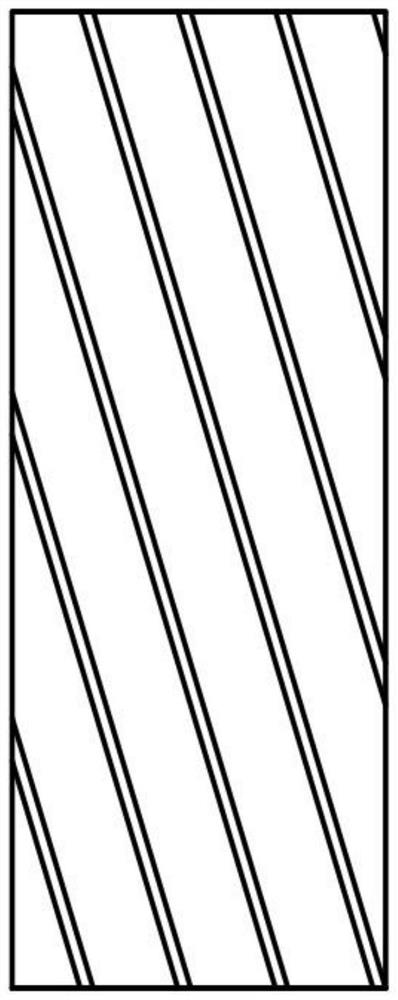

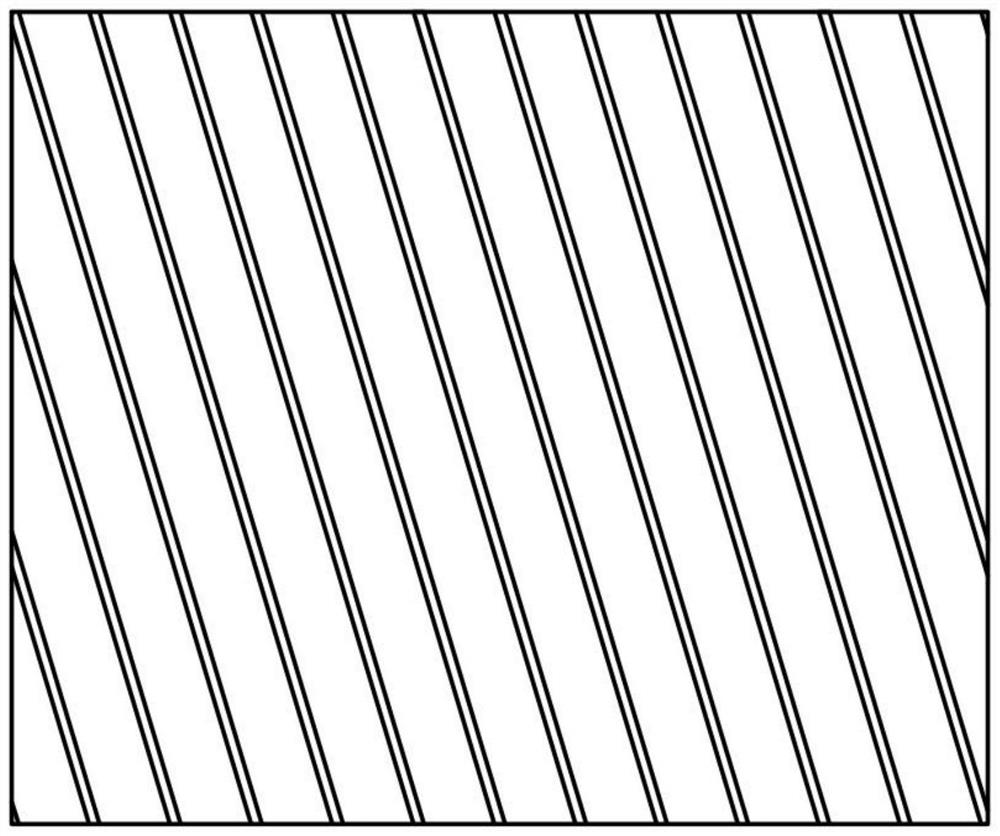

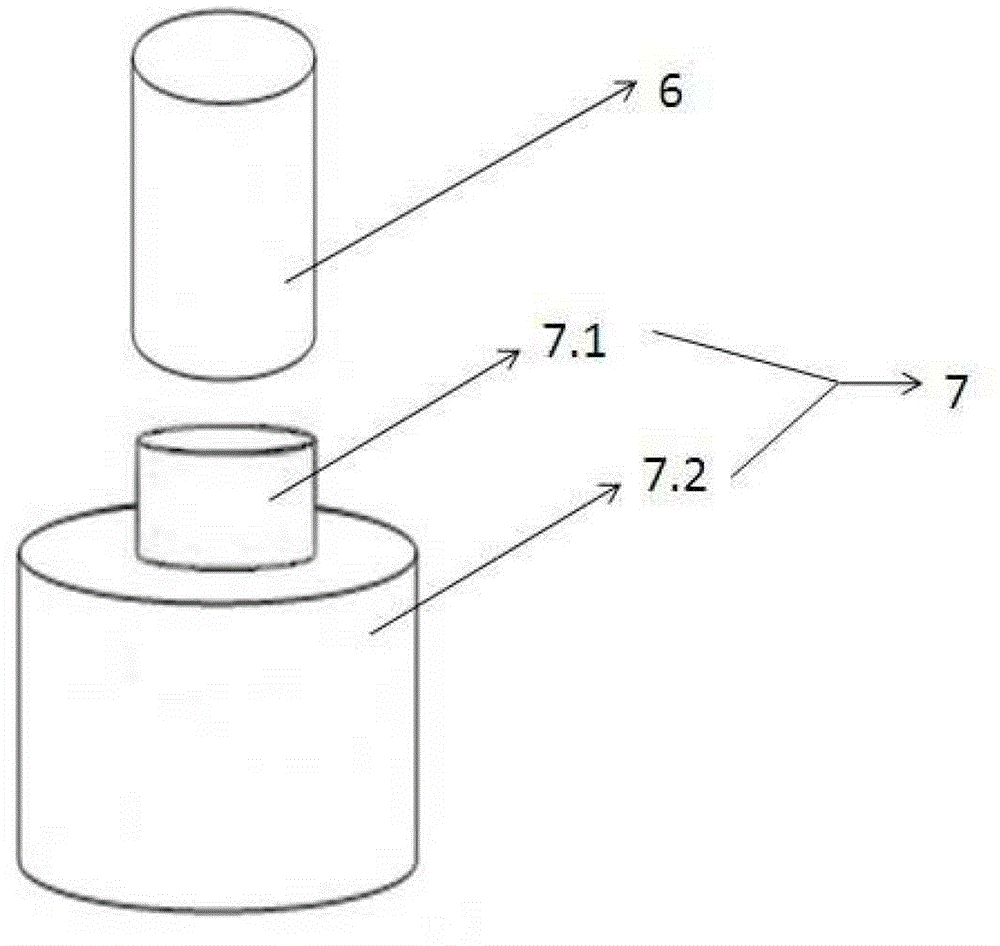

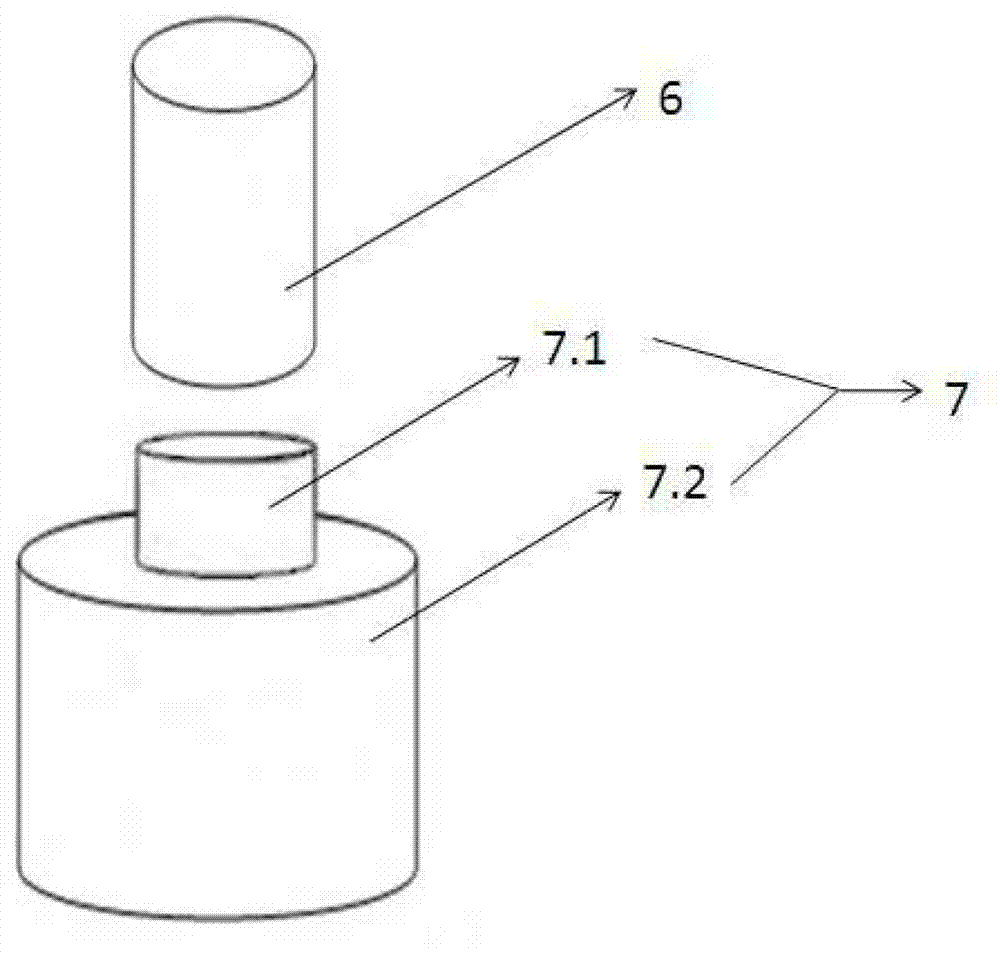

Rubber reducing sleeve for aluminum plate cold composite rolling mill

PendingCN114309090AEasy to operateAvoid the risk of sheddingRolling safety devicesMetal rolling arrangementsEngineeringRolling mill

The invention discloses a rubber reducing sleeve for an aluminum plate cold composite rolling mill, which comprises a cylindrical sleeve, the sleeve is made of polyurethane rubber, an inner hole matched with a feeding conical head of the cold composite rolling mill in size is formed in the center of the sleeve, and a plurality of uniformly distributed straight grooves are formed in the inner wall of the inner hole. A plurality of straight grooves are formed in the outer wall of the sleeve, a certain distance is formed between every two adjacent straight grooves, the direction of the straight grooves is consistent with the axial direction of the sleeve, the straight grooves penetrate through the sleeve from the upper surface of the sleeve to the lower surface of the sleeve, a plurality of evenly-distributed spiral grooves are formed in the outer wall of the sleeve, a certain distance is formed between every two adjacent spiral grooves, and the spiral grooves rotate rightwards. And the spiral angle is alpha.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

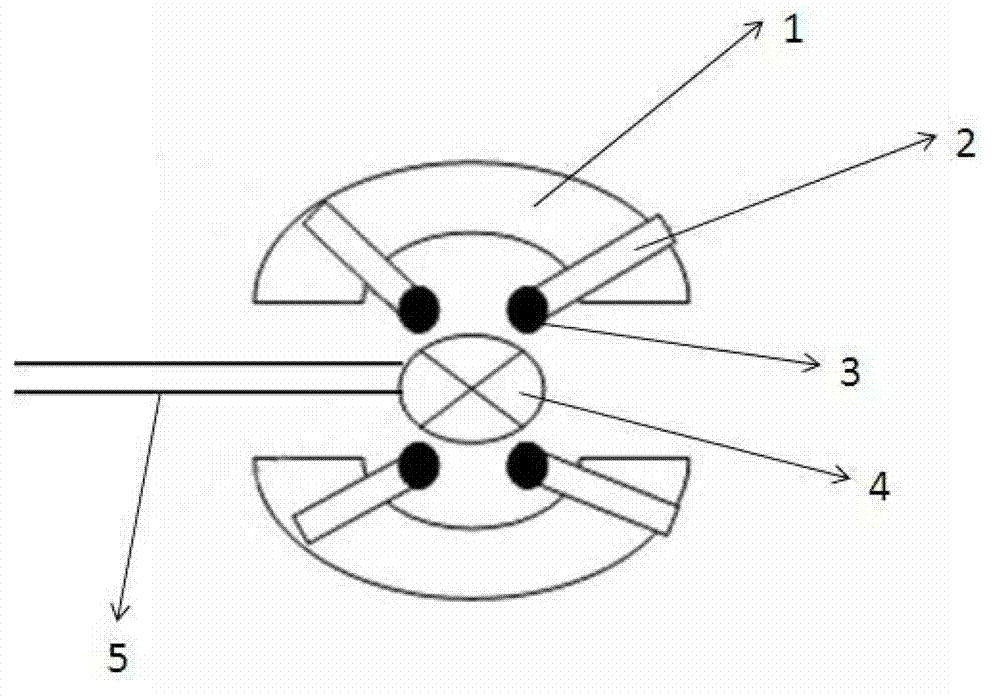

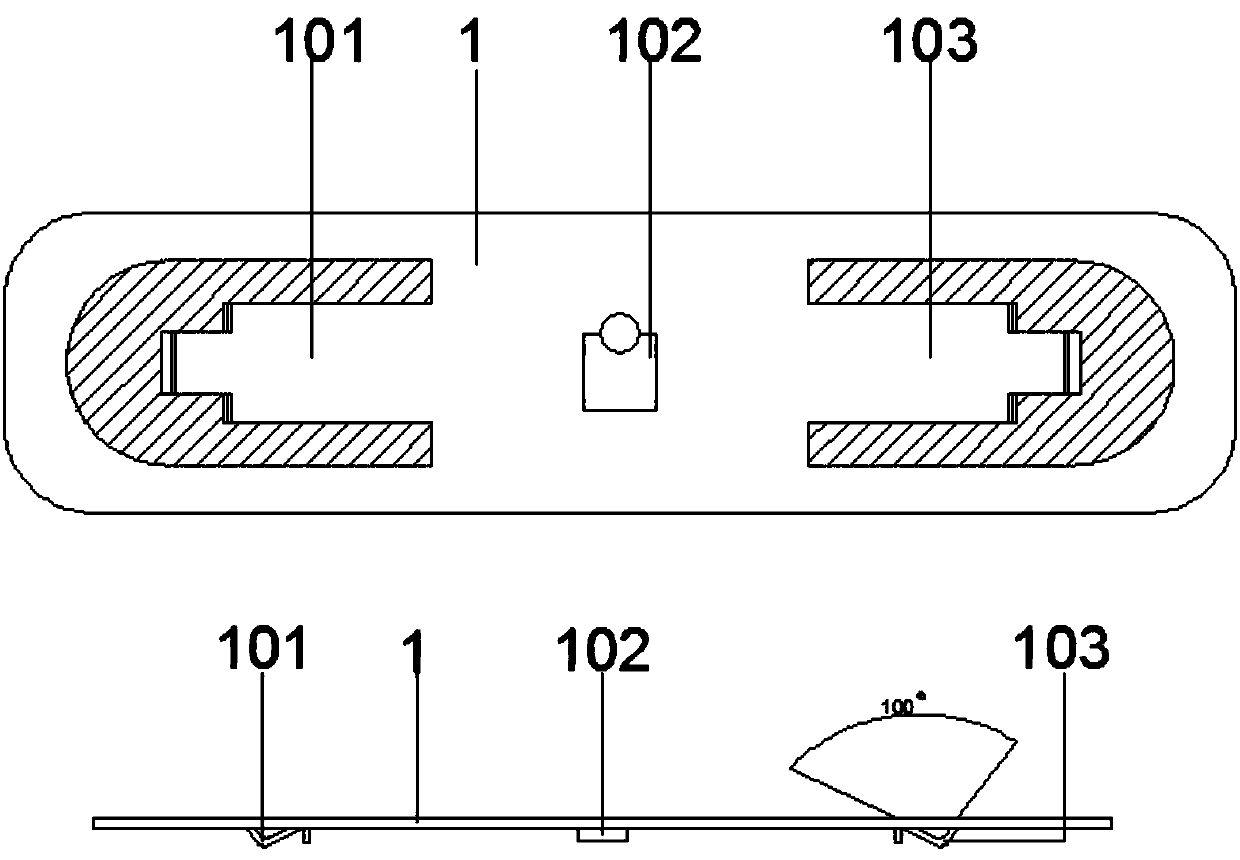

Chamfering machine capable of processing non-standard silicon wafer

ActiveCN102962743BEasy to processImprove production and processing effectsEdge grinding machinesWorking accessoriesMechanical engineeringSilicon

The invention provides a chamfering machine capable of processing a non-standard silicon wafer. The chamfering machine comprises a correcting system, wherein the correcting system comprises a wafer conveying arm; a round wafer absorption head is arranged at one end of the wafer conveying arm; the wafer absorption head is provided with two arch-shaped correcting clamp plates; strip-shaped positioning blocks are arranged at the two ends of each correcting clamp plate; one end of each positioning block is fixed to each correcting clamp plate through a shaft; each positioning block can be used for adjusting an angle according to the practical processing need; and a positioning wheel is arranged at the other end of each positioning block. The chamfering machine has the benefits as follows: the processing capability of the non-standard silicon wafer is improved under the condition that the original processing capability of equipment is maintained, so that the production and processing capabilities of the equipment are improved.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

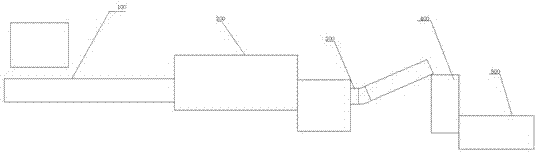

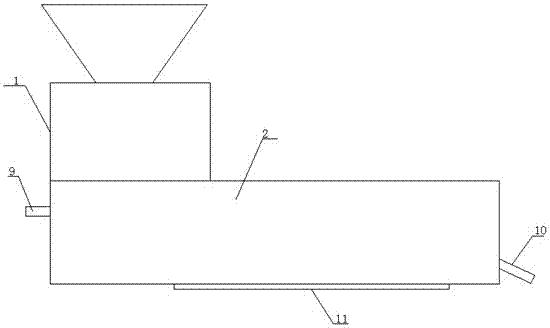

Sweet potato starch processing production line

InactiveCN107511228AImprove crushing efficiencyPrevent throwingGrain treatmentsPotato starchEngineering

The invention discloses a sweet potato starch processing production line and relates to the technical field of agricultural product processing machinery. The crusher of the present invention includes a crushing bin and a starch separation bin, the crushing bin is arranged above the starch separation bin; a shifting roller, a cutting roller and a crushing roller are arranged in the crushing bin, and the shifting rollers are two , symmetrically arranged at the feed port of the crushing bin, the cutting roller is arranged under the shifting roller, and the crushing roller is arranged under the cutting roller; several cutting knives are arranged on the cutting roller. The crusher of the invention has high crushing efficiency, can completely crush the sweet potato tubers, increases the starch precipitation speed, enhances the production and processing effect, and improves the production and processing efficiency.

Owner:CHONGQING RUNYOU AGRI DEV CO LTD

Production method for agricultural greenhouse film master batch reinforced by calcium salt crystal whiskers

Owner:昆明春叶塑料制成品有限公司

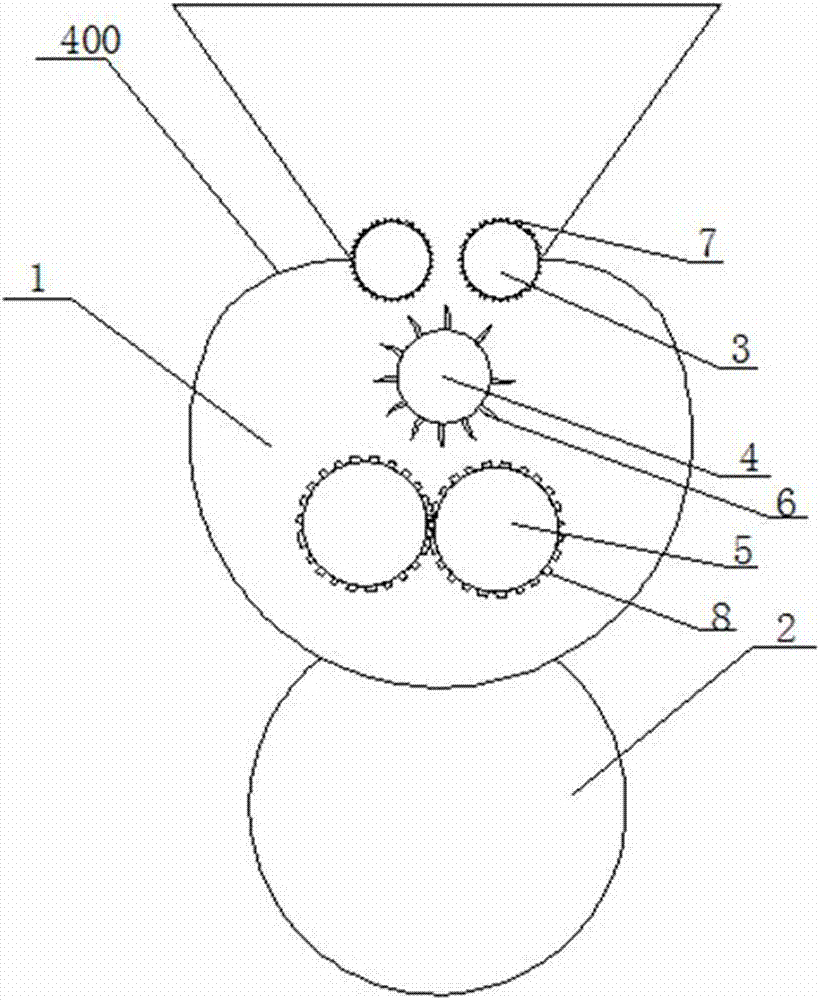

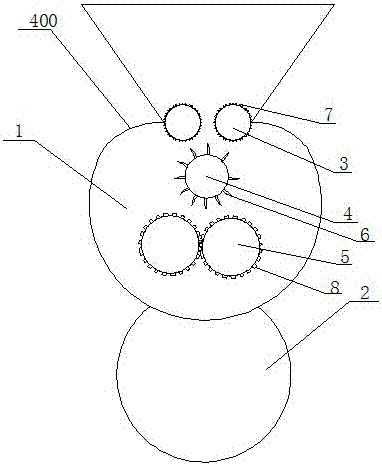

Crusher for sweet potato starch processing

InactiveCN107511229AImprove crushing efficiencyPrevent throwingGrain treatmentsPotato starchEngineering

The invention discloses a crusher for sweet potato starch processing, and relates to the technical field of agricultural product processing machines. The crusher comprises a crushing bin and a starch separation bin. The crushing bin is arranged above the starch separation bin. Material stirring rollers, a material cutting roller and crushing rollers are arranged in the crushing bin. The two material stirring rollers are symmetrically arranged at a feeding opening of the crushing bin, the material cutting roller is arranged below the material stirring rollers, and the crushing rollers are arranged below the material cutting roller. Multiple material cutting knives are arranged on the material cutting roller. The crusher is high in crushing efficiency, sweet potato tubers can be completely crushed, the starch precipitation speed can be increased, the producing and processing effect can be enhanced, and the producing and processing efficiency can be improved.

Owner:CHONGQING RUNYOU AGRI DEV CO LTD

Chamfering machine capable of processing non-standard silicon wafer

ActiveCN102962743AEasy to processImprove production and processing effectsEdge grinding machinesWorking accessoriesEngineeringMechanical engineering

The invention provides a chamfering machine capable of processing a non-standard silicon wafer. The chamfering machine comprises a correcting system, wherein the correcting system comprises a wafer conveying arm; a round wafer absorption head is arranged at one end of the wafer conveying arm; the wafer absorption head is provided with two arch-shaped correcting clamp plates; strip-shaped positioning blocks are arranged at the two ends of each correcting clamp plate; one end of each positioning block is fixed to each correcting clamp plate through a shaft; each positioning block can be used for adjusting an angle according to the practical processing need; and a positioning wheel is arranged at the other end of each positioning block. The chamfering machine has the benefits as follows: the processing capability of the non-standard silicon wafer is improved under the condition that the original processing capability of equipment is maintained, so that the production and processing capabilities of the equipment are improved.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

Efficient dust removal equipment for heavy calcium carbonate production

InactiveCN113477620AAvoid stockpilingEasy to blow upDispersed particle filtrationCleaning using gasesRubber ringDust control

The invention provides efficient dust removal equipment for heavy calcium carbonate production, and belongs to the technical field of dust removal. The efficient dust removal equipment for the heavy calcium carbonate production comprises a base, a dust collection assembly and a dust removal assembly. The base comprises a cabinet body and a box body; one side of the cabinet body and one side of the box body are open; the cabinet body is fixed to the top of the box body; the dust collection assembly comprises a barrel, a dust inlet, a fixed sleeve, a push rod, a push handle, a dust pushing block, a rubber ring, an abutting block and a dust discharging inclined face; the barrel is fixed to the side edge of the bottom of the cabinet body; the dust inlet is arranged on the upper end of the barrel; the rear end of the barrel is connected with the fixed sleeve; the fixed sleeve extends out of the cabinet body; the push rod movably penetrates through the fixed sleeve; one end of the push rod is provided with the push handle, and the other end of the push rod is provided with the dust pushing block; and the outer wall of the dust pushing block is provided with the rubber ring and abuts against the inner wall of the barrel. Dust is collected through the dust inlet through the barrel, dust is prevented from being accumulated at corners, and the dust removal effect is good.

Owner:胡健

Automobile product production processing and spraying auxiliary system

InactiveCN106607215AImprove production and processing effectsEasy to sprayLiquid spraying apparatusSupporting systemAutomotive product

The invention relates to an automobile product production processing and spraying auxiliary system which comprises a bottom supporting system; a feeding system is arranged at the upper part of the bottom supporting system; a mixing system is arranged at the upper part of the feeding system; a separation treatment plate is arranged at the upper part of the mixing system; a charging system is arranged at the upper part of the separation treatment plate; a discharging system is arranged on the left side of the feeding system; a plurality of discharging holes are formed in the lower part of the discharging system; a bearing mechanism is arranged on the left side of the discharging system; a power system is arranged on the right side of the mixing system; a power system shaft is arranged on the left side of the power system; a mixing mechanism is arranged on the side surface of the power system shaft; a free lifting system bracket is arranged at the upper part of the left side of the mixing system; a free lifting system is arranged on the free lifting system bracket; an automatic extension mechanism is arranged at the lower part of the free lifting system; and a boosting sliding block is arranged at the lower part of the automatic extension mechanism. With the adoption of the automobile product production processing and spraying auxiliary system, spraying for automobile product production processing can be carried out effectively, and the spraying effect is improved.

Owner:重庆昂鼎机械制造有限公司

A high energy density lithium iron phosphate battery

ActiveCN113078305BSignificant progressIncrease capacityMaterial nanotechnologyFinal product manufactureElectrolytic agentMagnesium doping

The invention belongs to the technical field of electrochemistry, and in particular relates to a high-energy density lithium iron phosphate battery. The positive electrode active material is selected from titanium / or magnesium doped lithium iron phosphate, and the surface density of the positive electrode sheet is 190-210 g / m. 2 , compacted density ≥2.60g / cc, negative electrode active material is carbon-coated single particle and secondary particle needle coke blended artificial graphite, negative electrode compaction density ≥1.70g / cc, electrolyte density equal to 1.15 g / cc, the wall thickness of the aluminum shell is between 0.40 and 0.50 mm, the positive electrode current collector is 12-13 μm aluminum foil, the negative electrode current collector is 4.5 μm copper foil, the diaphragm is 7+2C+2P ceramic coated diaphragm, the positive electrode is Substitute the conductive binder, the addition amount is 1.0-2.0%, and the weight ratio of the positive electrode active material to the positive electrode dressing is ≥98%. The invention greatly improves the energy density of the battery, reaching 200Wh / kg.

Owner:江西安驰新能源科技有限公司

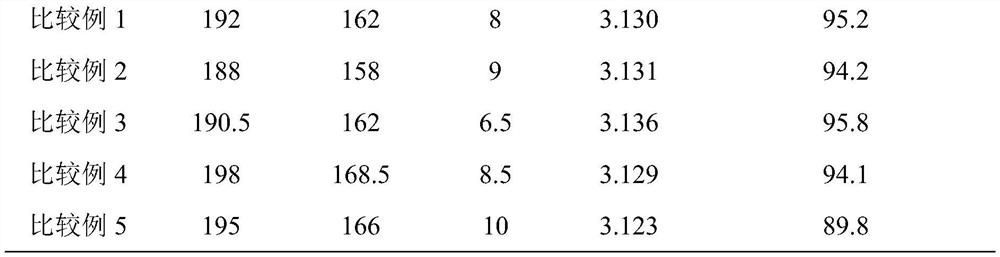

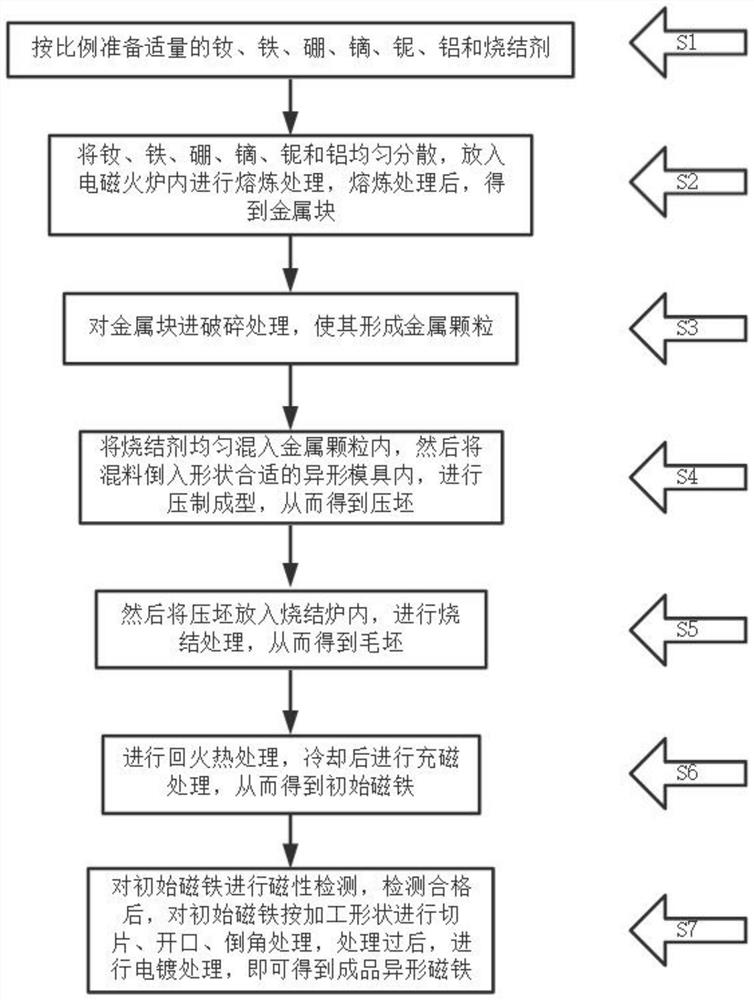

Special-shaped magnet processing technology

PendingCN114255982AImprove processing efficiencyReduce consumptionInductances/transformers/magnets manufactureMagnetic materialsCompression moldingDysprosium

The invention provides a special-shaped magnet processing technology, and relates to the technical field of magnet processing, and the special-shaped magnet processing technology comprises the following steps: S1, preparing a proper amount of neodymium, iron, boron, dysprosium, niobium, aluminum and a sintering agent in proportion; according to the preparation method, neodymium, iron, boron, dysprosium, niobium and aluminum are uniformly dispersed and subjected to dispersion smelting to form a metal block, then the metal block is crushed, a sintering agent is mixed into metal particles, the mixed material is poured into a special-shaped mold, compression molding is carried out to obtain a pressed blank, then sintering is carried out, heat treatment is carried out after sintering, and magnetizing is carried out after treatment. In the sintering process, the sintering agent can assist in blank forming, the sintering temperature is reduced, the sintering time is shortened, so that the blank can be rapidly formed, energy consumption is effectively reduced, the occupied time of a sintering furnace is shortened, and the machining efficiency of the finished special-shaped magnet is improved. And a better production and processing effect is achieved.

Owner:苏州天一精密制造有限公司

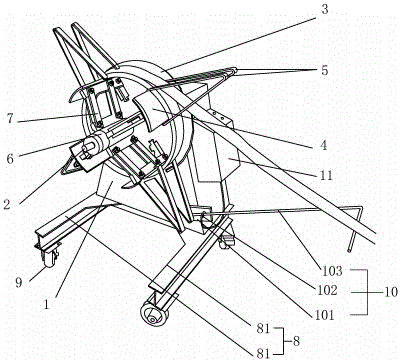

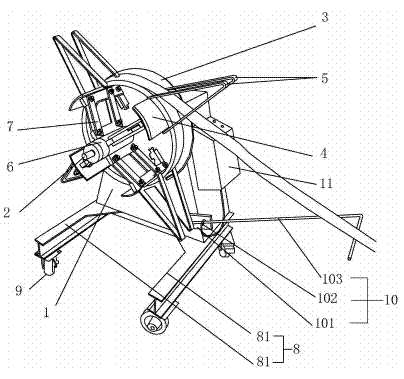

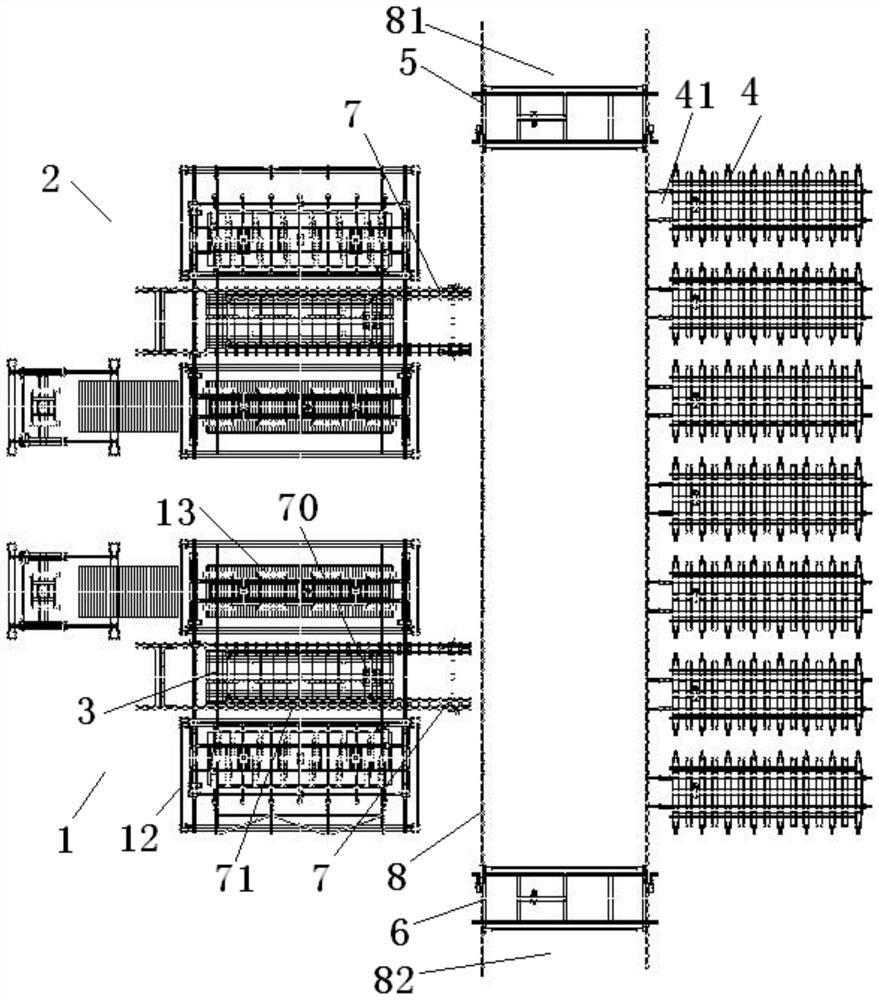

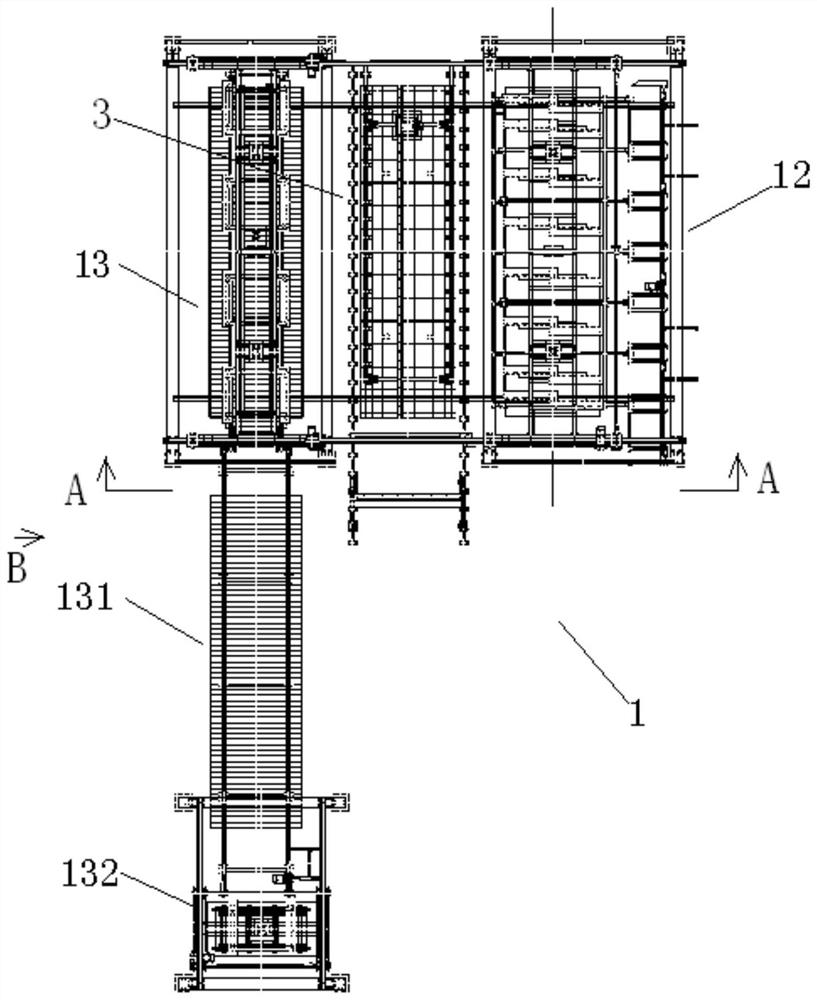

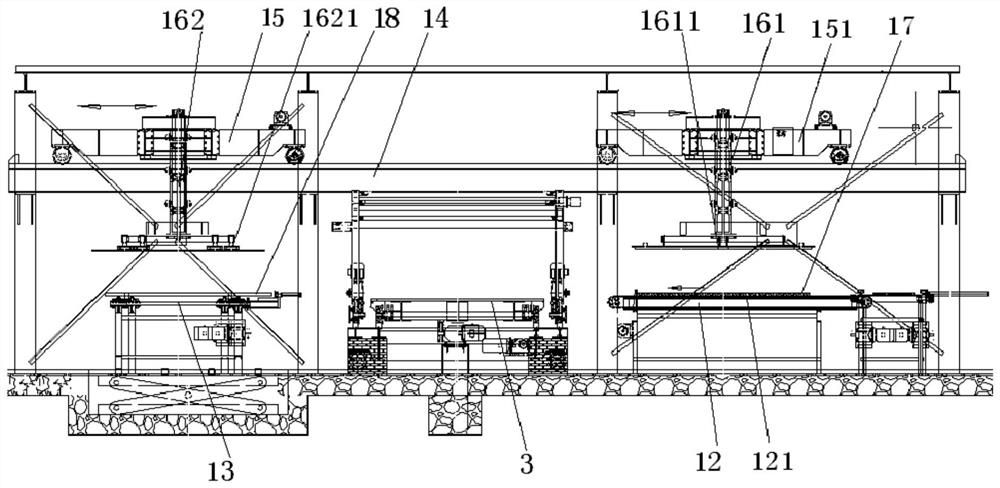

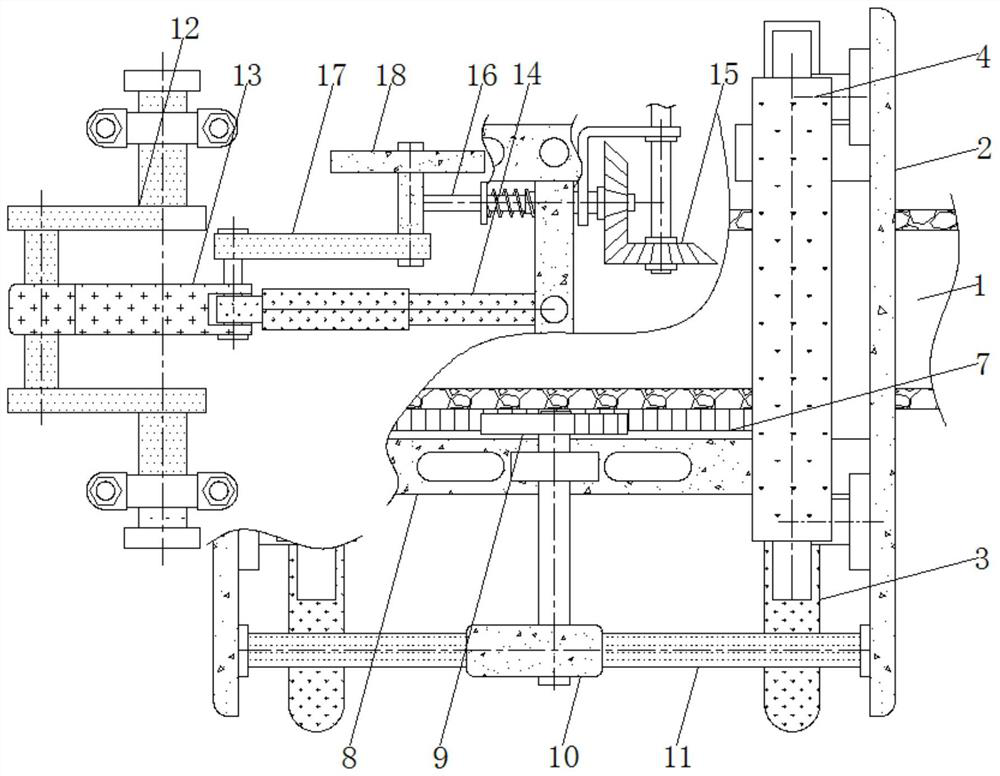

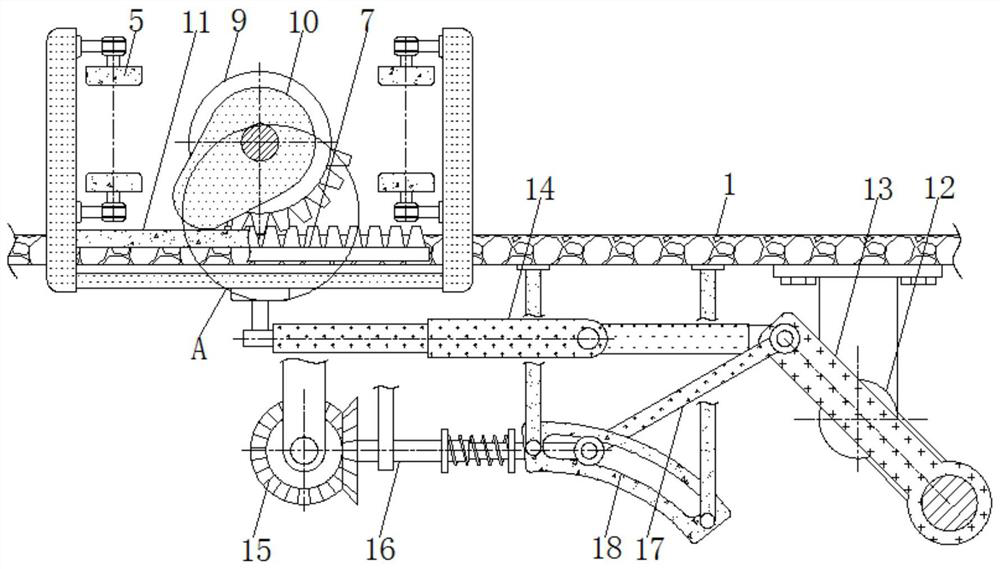

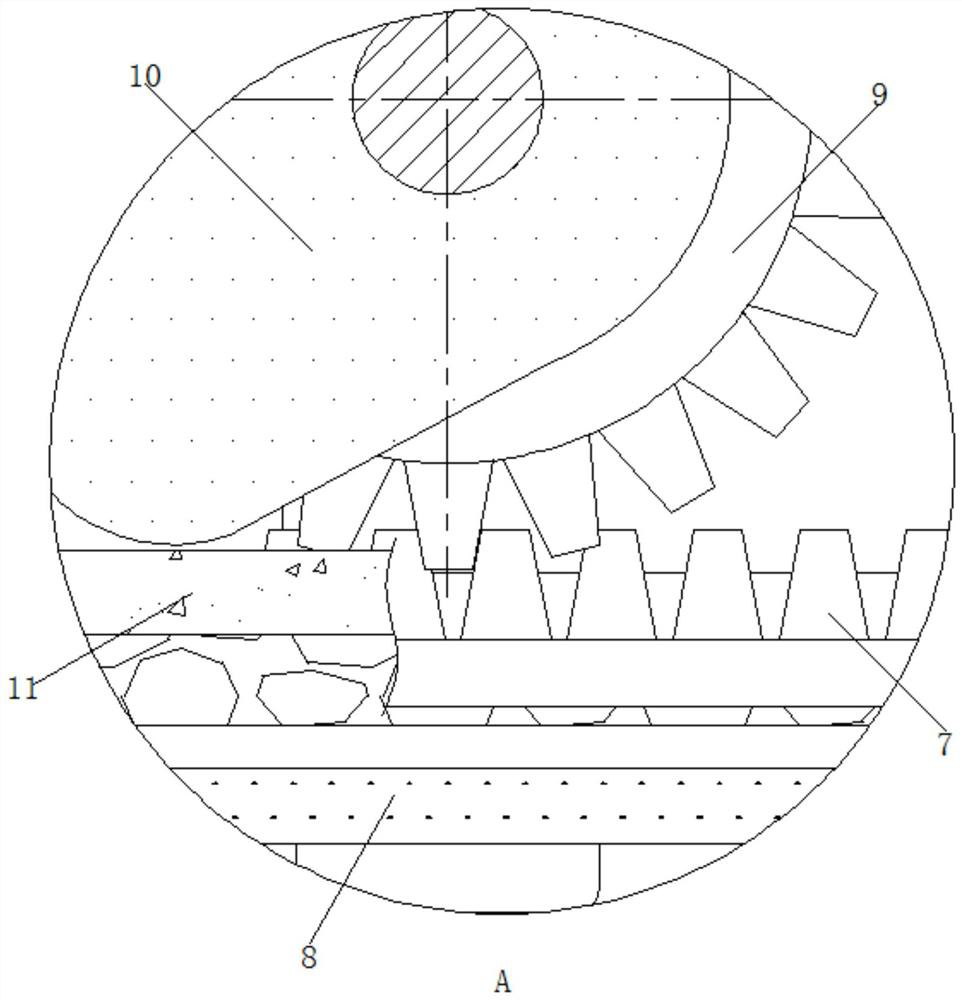

A multi-machine parallel cross-laminated wood processing device

ActiveCN107379143BImprove production and processing effectsEfficient cyclePlywood pressesVeneer pressesMaterial transportIndustrial engineering

The invention discloses a multi-machine parallel cross-laminated wood processing device, comprising multiple sets of feeding mechanisms, gluing mechanisms, multiple paving vehicles, multiple pressing machines, transfer vehicles and unloading vehicles; When the car moves along the lateral track to the side of the longitudinal track, it can be connected to any set of longitudinal tracks, so that the paving car can be driven to the transfer car along the longitudinal track from the blank grouping station on the longitudinal track, or the unloading car can carry the load. The paving vehicle is driven out from the unloader and enters the blank assembly station along the longitudinal track; the transfer vehicle runs between the material transport station, one of the completed blank assembly stations and the idle press; unloading The car runs between the press at the end of the compaction and the unloading station. Through the coordination of the feeding mechanism and the working time of the press and the optimal coordination of the movement of the paving vehicle, the device can form a good cycle of the assembly and the green compact, which can achieve very high production efficiency and greatly improve the production and processing capacity of CLT. .

Owner:JIANG SU GLOBAL CLT CO LTD

High-tensile hot-rolled steel sheet and manufacturing method thereof

InactiveCN103917680BImprove production and processing effectsHas tensile strengthHot-dipping/immersion processesFurnace typesSheet steelCarbide

The present invention relates to a hot-rolled steel sheet and a manufacturing method thereof. The hot-rolled steel sheet contains: in mass %, C: more than 0.05% and not more than 0.13%, Si: not more than 0.3%, and Mn: not less than 0.5% and 2.0% Below, P: 0.025% or less, S: 0.005% or less, N: 0.0060% or less, Al: 0.1% or less, Ti: 0.07% or more and 0.18% or less, V: more than 0.13% and 0.30% or less, and Ti and V satisfies 0.25<Ti+V≤0.45 (Ti, V: content of each element (mass %)), and solid solution V: 0.05% or more and less than 0.15%, and the balance contains Fe and unavoidable impurities; iron A matrix in which the area ratio of the element phase to the overall structure is 95% or more; and fine carbides containing Ti and V with an average particle size of less than 10 nm are dispersed and precipitated, and the volume ratio of the fine carbides to the overall structure is 0.0050 or more, A structure in which the number of carbides containing Ti and having a particle size of 30 nm or more accounts for less than 10% of the total number of carbides.

Owner:JFE STEEL CORP

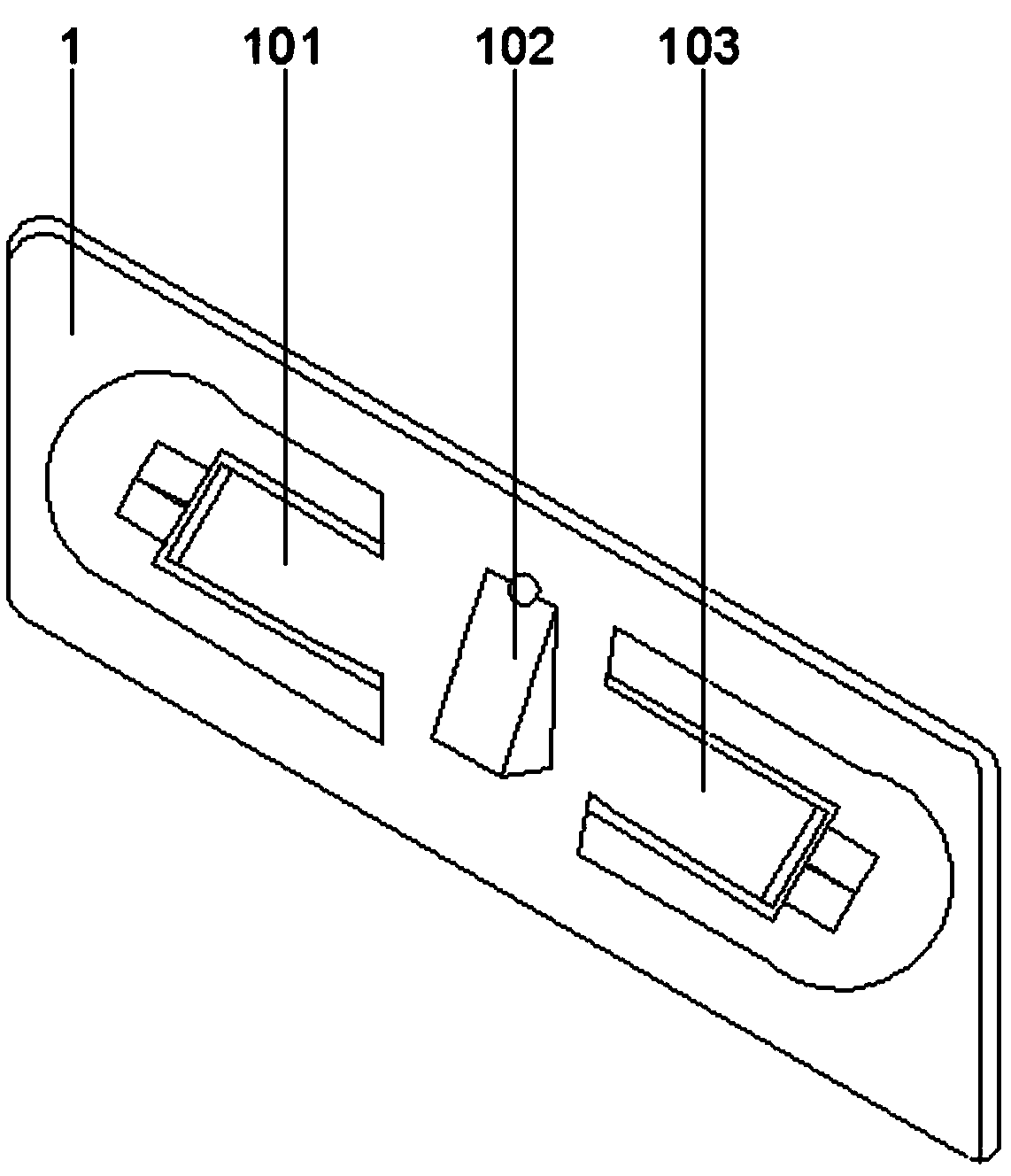

Metal ceiling support connecting piece

The invention relates to the technical field of connecting devices, in particular to a metal ceiling support connecting piece. The metal ceiling support connecting piece comprises a connecting body, afirst support, a second support, a first buckle, a springback piece and a second buckle, the first buckle and the second buckle are arranged at the two ends of the interior of the connecting body correspondingly, and the connecting body, the first buckle and the second buckle are arranged to be of an integrated structure. The spring back piece is formed in the middle of the interior of the connecting body, the connecting body and the springback piece are connected in a buckled mode, and the first support and the second support are mounted at the two ends of the rear portion of the connectingbody. The connecting body is connected with the first support and the second support in a buckled mode. According to the metal ceiling support connecting piece, through structural improvement, by combining the prior art, the metal ceiling support connecting piece has the advantages that connecting of main skeletons is easy and easy to operate, the construction difficulty coefficient is low, and dismounting is convenient if a problem is found, the problems and defects in the prior art are solved / overcome, and the purpose that the practicability is better is achieved.

Owner:张家港鋐荣金属科技有限公司

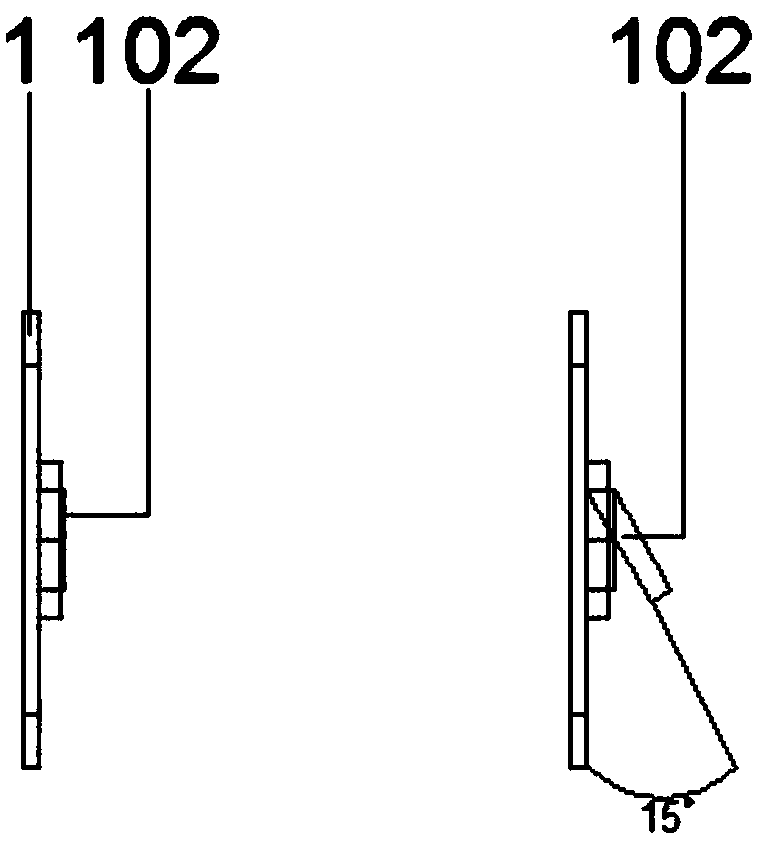

Preheating method for mother liquor in re-consolidation boiling section

InactiveCN112110875AReduce running timeReduce damage frequencyOrganic chemistryFluidized bedProcess engineering

The invention relates to a method for preheating a mother liquor in a re-consolidation boiling section. The method comprises a re-consolidation mother liquor tank, a re-consolidation boiling kettle and a coarse consolidation bin, and is characterized in that a plate type heat exchanger is additionally arranged in front of the re-consolidation mother liquor tank, and the mother liquor in the re-consolidation mother liquor tank enters the re-consolidation boiling kettle after being subjected to heat exchange by high-temperature condensate of a fluidized bed in a plate type fluidized bed. The method comprises the following steps: (1) preheating a re-consolidation mother liquor to 80-85 DEG C by using a fluidized bed high-temperature condensate through a plate type heat exchanger; (2) adding coarse consolidation sugar and the preheated re-consolidation mother liquor into a re-consolidation boiling kettle, and controlling the mass ratio of the coarse consolidation sugar to the consolidationmother liquor to be 1-1.3:1; and (3) heating the materials in the re-consolidation boiling kettle to 90-95 DEG C, and then pumping the material into the next working section. The method has the advantages that the re-consolidation mother liquor is preheated by utilizing the waste heat of the idle condensate, so that a large amount of power consumption and steam are saved; the operation time of the re-consolidation circulating pump is shortened to 2-2.5 h, so that the mechanical seal damage frequency is reduced; and the production and processing capacity of the re-consolidation process is improved, and the production efficiency is improved.

Owner:ANHUI JINGHE IND

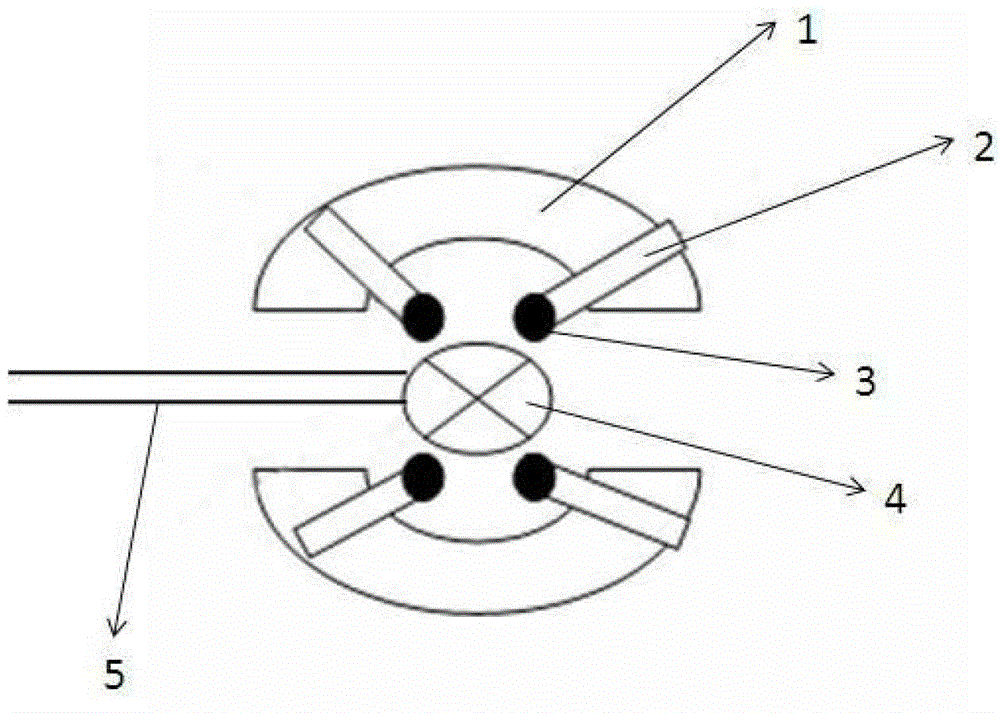

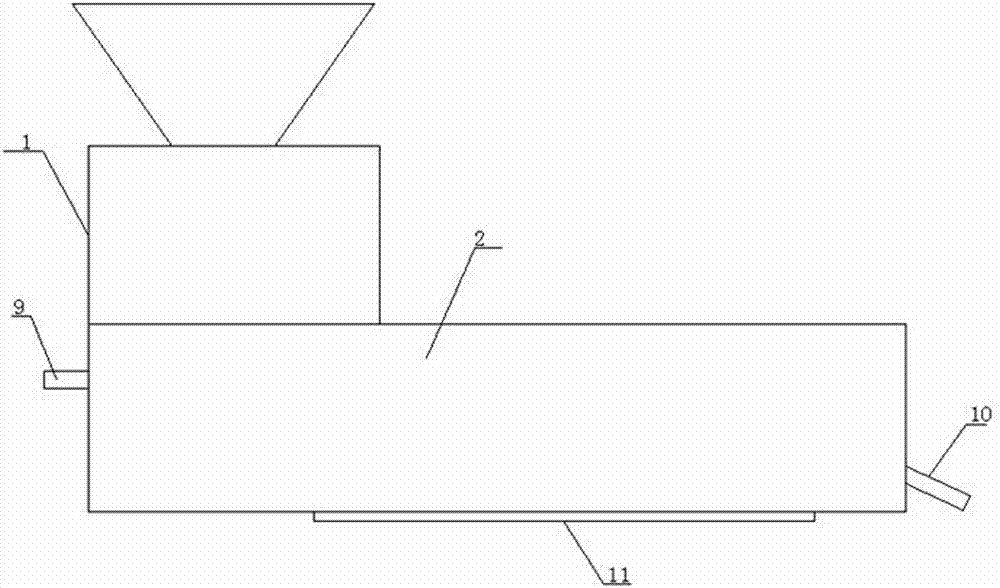

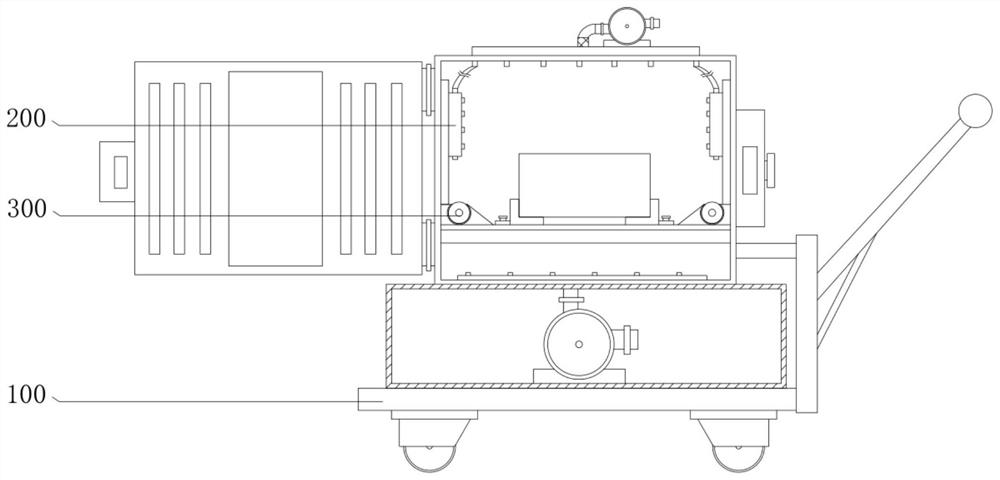

Variable-stroke type automatic circular tube clamping device based on intelligent manufacturing technology

InactiveCN112811161AGood clamping and conveying effectImprove production and processing effectsConveyorsConveyor partsManufacturing technologyGear wheel

The invention relates to the technical field of intelligence, and discloses a variable-stroke type automatic circular tube clamping device based on an intelligent manufacturing technology. The variable-stroke type automatic circular tube clamping device comprises a machine body, wherein support plates are connected to the surface of the machine body in a sliding manner; rotating rods are movably connected to the surfaces of the support plates; push plates are movably connected to the surfaces of the support plates; clamp plates are arranged on the surfaces of the push plates; pull rods are movably connected to the surfaces of the push plates; racks are arranged on the side surfaces of the machine body; a connecting plate is arranged on the surfaces of the support plates; a first gear is arranged on the surfaces of the racks; and a cam is movably connected to the surface of the connecting plate. According to the variable-stroke type automatic circular tube clamping device based on the intelligent manufacturing technology disclosed by the invention, through cooperative application of the racks and the first gear, cooperative application of the cam and a pressing rod, cooperative application of the rotating rods and the pull rods as well as the push plates, and the mutual cooperation between the clamp plates, the circular tube can be conveyed at a fixed distance in a clamping manner, and the clamping and conveying effect of the circular tube is good, and the production processing effect of the circular tube can be effectively improved.

Owner:杭州晁浴家用电器有限公司

Acrylic color changing film manufacturing method

InactiveCN109575823AWith self-cleaning functionImprove production and processing effectsFilm/foil adhesive primer layersEster polymer adhesivesSputteringMetallic materials

The invention discloses an acrylic color changing film manufacturing method. The method includes steps: taking a base material layer, preparing a mixture A and a mixture B, subjecting the mixture A and the mixture B to methacrylic resin A, and coating the base material layer with the methacrylic resin A to form a coloring layer; preparing a mixture C and a mixture D, subjecting the mixture C and the mixture D to reaction to obtain methacrylic resin B, and coating the coloring layer with the methacrylic resin B to form a functional layer; adopting a metal material for forming a metal layer on the functional layer by means of vacuum evaporation or magnetron sputtering; preparing a mixture E and a mixture F, and subjecting to reaction to obtain an acrylic pressure-sensitive adhesive; coatinga release film with the acrylic pressure-sensitive adhesive to obtain a pressure-sensitive adhesive layer; pressing the pressure-sensitive adhesive layer on the metal layer, stripping the base material layer, and coating one surface of the coloring layer with an anti-doodling layer to obtain an acrylic color changing film. The acrylic color changing film manufacturing method has advantages that ply adhesion of the color changing film is improved, influences on overall appearance due to film layer shedding are avoided, and the self-cleaning performance of the color changing film is improved.

Owner:浙江龙游道明光学有限公司

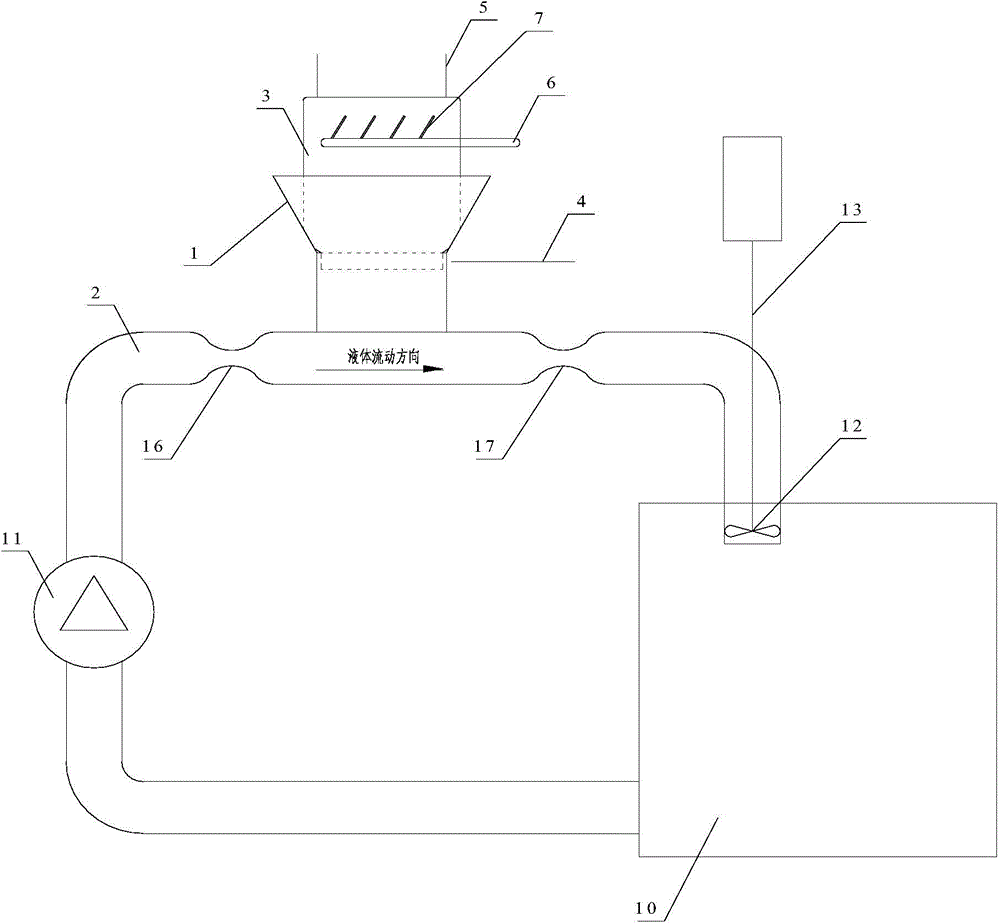

Producing, machining and processing system of motorcycle parts

InactiveCN106608311AImprove production and processing effectsEasy production and processingVehiclesSupporting systemTreatment system

The invention relates to a producing, machining and processing system of motorcycle parts. The producing, machining and processing system comprises a bottom supporting system, wherein a left bearing mechanism is arranged on the left side of the upper part of the bottom supporting system, and a right bearing mechanism is arranged on the right side of the upper part of the bottom supporting system; a bearing device is arranged on the upper part of the right side of the left bearing mechanism; a liquid loading system is mounted at the upper part of the bearing device; liquid loading system pipelines are separately arranged on the left side and the right side of the upper part of the liquid loading system; liquid inlet systems are separately arranged on the upper part of each of the liquid loading system pipelines; a liquid discharging pipe is arranged on the right side of the liquid loading system; a liquid loading pipe is arranged at the lower part of the liquid discharging pipe; a plurality of liquid outlet holes are formed in the lower part of the liquid loading pipe; a producing, machining and processing system is mounted at the lower part of the liquid outlet holes; and a lower partition plate is mounted at the lower part of the producing, machining and processing system. Through the adoption of the producing, machining and processing system disclosed by the invention, the producing, machining and processing effect of the motorcycle parts can be effectively improved, and the producing, machining and processing of the motorcycle parts are facilitated.

Owner:CHONGQING BATENG MACHINERY CO LTD

Cloth drying device for textile products processing

InactiveCN111793916AAvoid damageImprove securityMechanical cleaningPressure cleaningWater storage tankProcess engineering

The invention belongs to the technical field of textile products, in particular to a cloth drying device for textile products processing. The problem of high temperature damage to the surface of clothduring use of an existing cloth drying device is solved. According to the following scheme, the cloth drying device includes a drying box, the bottom outer wall of the drying box is connected with awater storage tank by bolts, the bottom outer wall of one end of the water storage tank is connected with a water guide pipe by bolts, the outer wall of one side of the circumference of the water guide pipe is connected with a water suction pump by bolts, and the inner wall of the bottom of one side of the drying box is connected with a water distribution pipe through bolts. According to the clothdrying device for textile products processing, by arranging a mounting plate and a brush, after the cloth sprayed with water mist on the surface is dried by a first hot air blower, the rising cloth is cleaned by the brush, thread residues on the surface of the cloth are removed by the brush, and the effect of cloth production and processing is improved.

Owner:安利

Sweet potato starch processing production line

InactiveCN107511230AImprove crushing efficiencyPrevent throwingGrain treatmentsProduction linePotato starch

The invention discloses a sweet potato starch processing production line and relates to the technical field of agricultural product processing machinery. The present invention includes a crushing bin and a starch separation bin, the crushing bin is arranged above the starch separation bin; a shifting roller, a cutting roller and a crushing roller are arranged in the crushing bin, and there are two shifting rollers arranged symmetrically Out of the feed port of the crushing bin, the cutting roller is arranged under the shifting roller, and the crushing roller is arranged under the cutting roller; several cutting knives are arranged on the cutting roller. The crusher of the invention has high crushing efficiency, can completely crush the sweet potato tubers, increases the starch precipitation speed, enhances the production and processing effect, and improves the production and processing efficiency.

Owner:CHONGQING RUNYOU AGRI DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com