Rubber reducing sleeve for aluminum plate cold composite rolling mill

A cold compounding, reducing sleeve technology, applied in the safety equipment of rolls, metal rolling, metal rolling, etc., can solve the problems of product quality and employee safety, mismatch of screw holes, labor-hours and other problems. Improve production and processing capacity, avoid screw falling off, and have the effect of high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

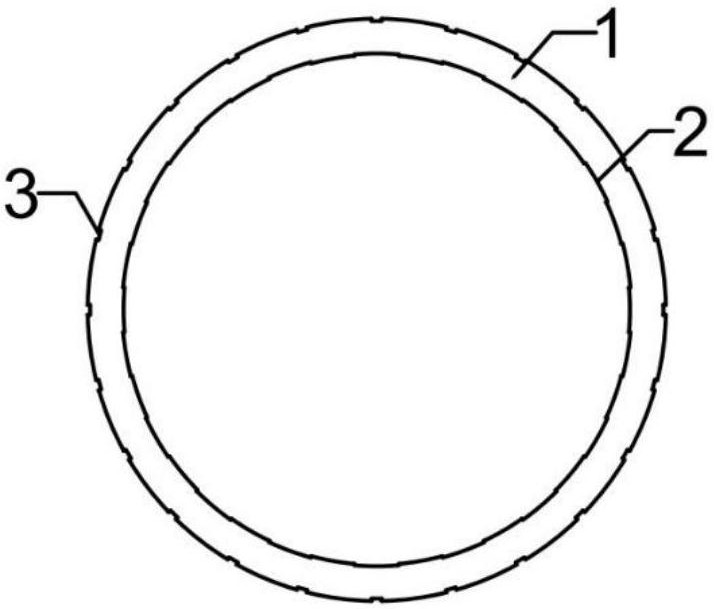

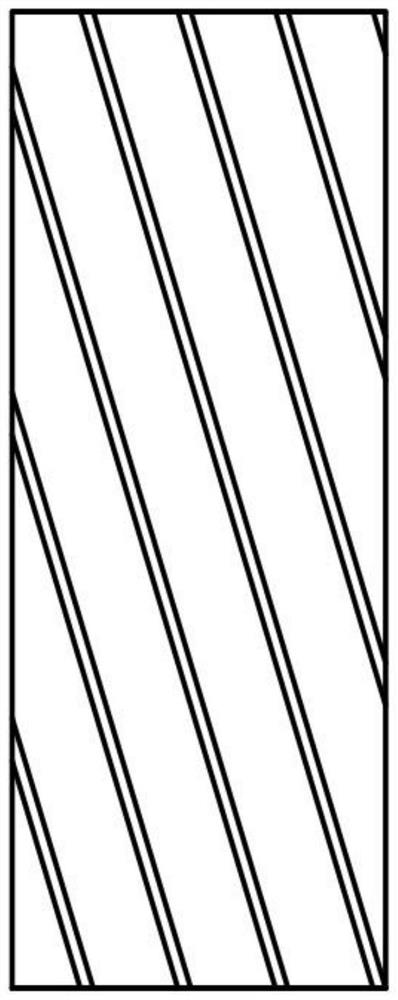

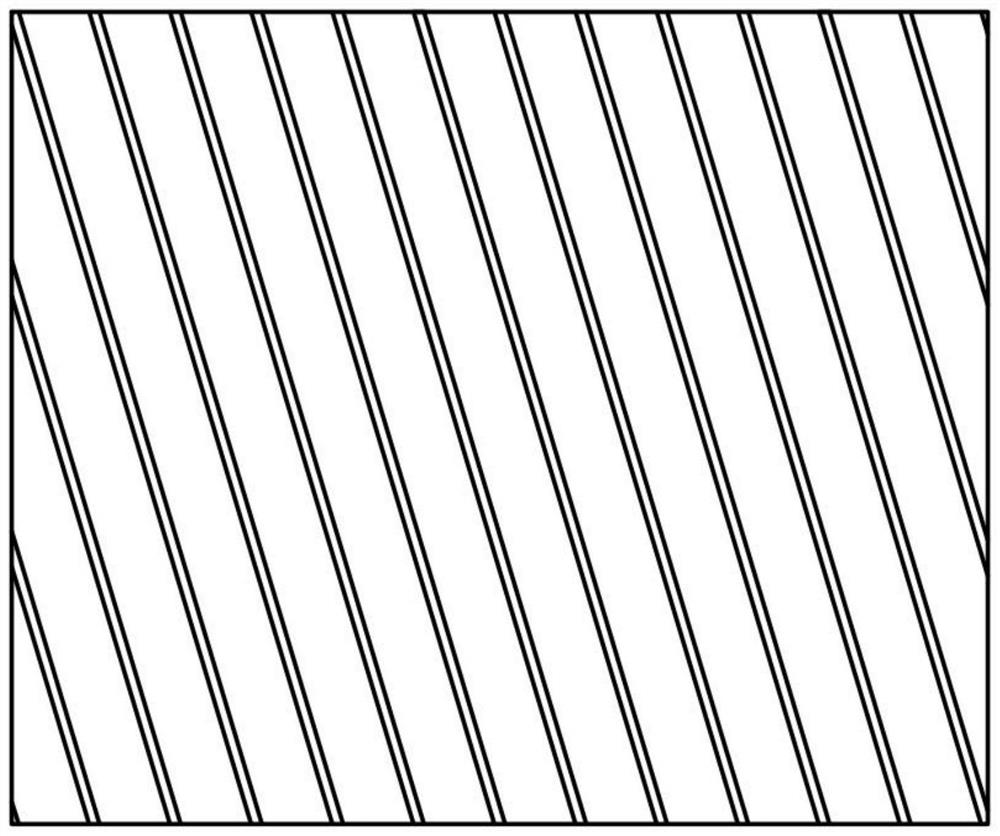

[0021] Such as Figure 1~3 As shown, a rubber reducing sleeve used for cold composite rolling mills of aluminum plates includes a sleeve 1 , a straight groove 2 and a spiral groove 3 .

[0022] A rubber variable-diameter sleeve used in cold compound rolling mills for aluminum plates. The shape of the sleeve is a cylinder, and the material of the sleeve is polyurethane rubber. The center of the sleeve is provided with a cone whose size matches the feeding cone of the cold compound rolling mill. Inner hole, there are several evenly distributed straight grooves on the inner wall of the inner hole, and there is a certain distance between two adjacent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com