Efficient dust removal equipment for heavy calcium carbonate production

A technology of heavy calcium carbonate and dust removal equipment, which is applied in the directions of cleaning methods, cleaning methods and utensils using gas flow, separation of dispersed particles, etc., can solve the problem of affecting the production and processing efficiency of calcium carbonate production equipment and poor production and processing results , easy to deposit at the corners, etc., to improve the production and processing effect, improve the production and processing efficiency, and improve the processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

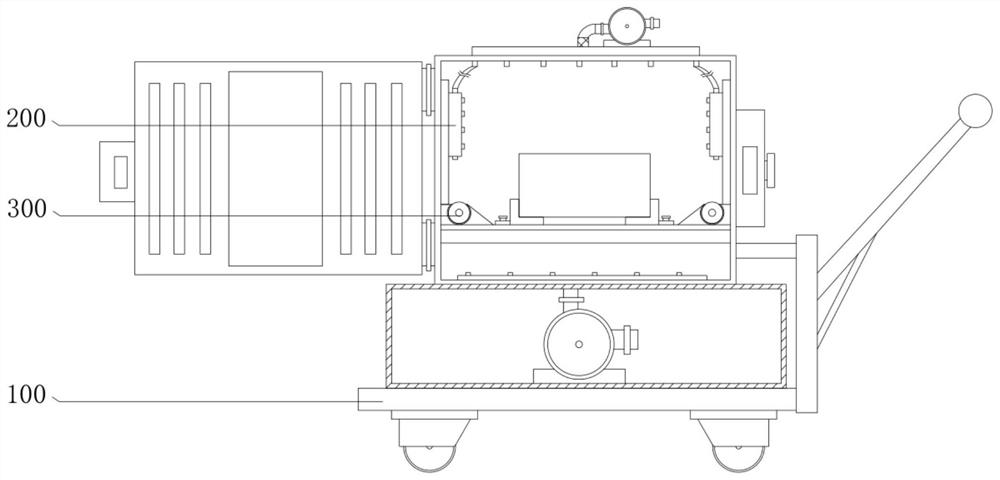

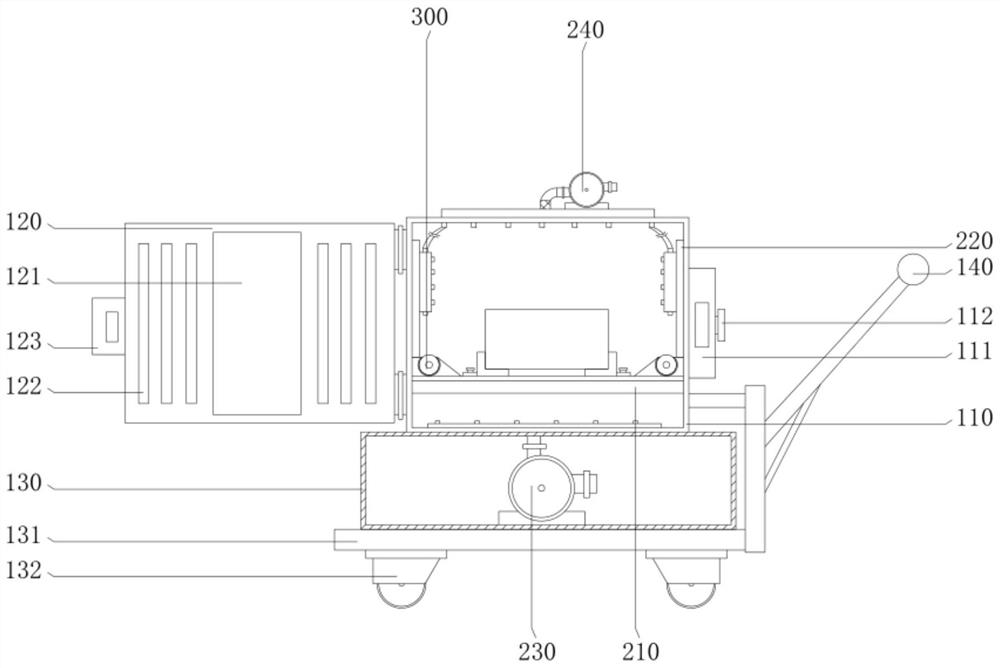

[0039] see Figure 1-6 , the present invention provides a technical solution: a high-efficiency dust removal equipment for heavy calcium carbonate production includes a base 100 and a dust removal assembly 200, the base 100 is used to support and fix the dust removal assembly 200, and is convenient for the dust removal assembly 200 to carry out dust blowing and pumping Dust filtration processing.

[0040] see Figure 1-Figure 3 , the base 100 includes a cabinet body 110 and a cabinet body 130, both sides of the cabinet body 110 and the cabinet body 130 are provided with openings, which is convenient for cleaning the inside of the cabinet body 130, and the inside of the cabinet body 110 is used for placing processing equipment, and the cabinet body 110 is fixed on the top of the cabinet 130, the cabinet 110 is fixed on the top of the cabinet 130 by bolts, a cabinet door 120 is arranged on one side of the cabinet 110, the cabinet door 120 and the cabinet 110 are rotated, and on...

Embodiment 2

[0043] see Figure 1-6 , the present invention provides a technical solution: a high-efficiency dust removal equipment for heavy calcium carbonate production includes a base 100 and a dust removal assembly 200, the base 100 is used to support and fix the dust removal assembly 200, and is convenient for the dust removal assembly 200 to carry out dust blowing and pumping Dust filtration processing.

[0044] see Figure 1-Figure 3 , the base 100 includes a cabinet body 110 and a cabinet body 130, both sides of the cabinet body 110 and the cabinet body 130 are provided with openings, which is convenient for cleaning the inside of the cabinet body 130, and the inside of the cabinet body 110 is used for placing processing equipment, and the cabinet body 110 is fixed on the top of the cabinet 130, the cabinet 110 is fixed on the top of the cabinet 130 by bolts, a cabinet door 120 is arranged on one side of the cabinet 110, the cabinet door 120 and the cabinet 110 are rotated, and on...

Embodiment 3

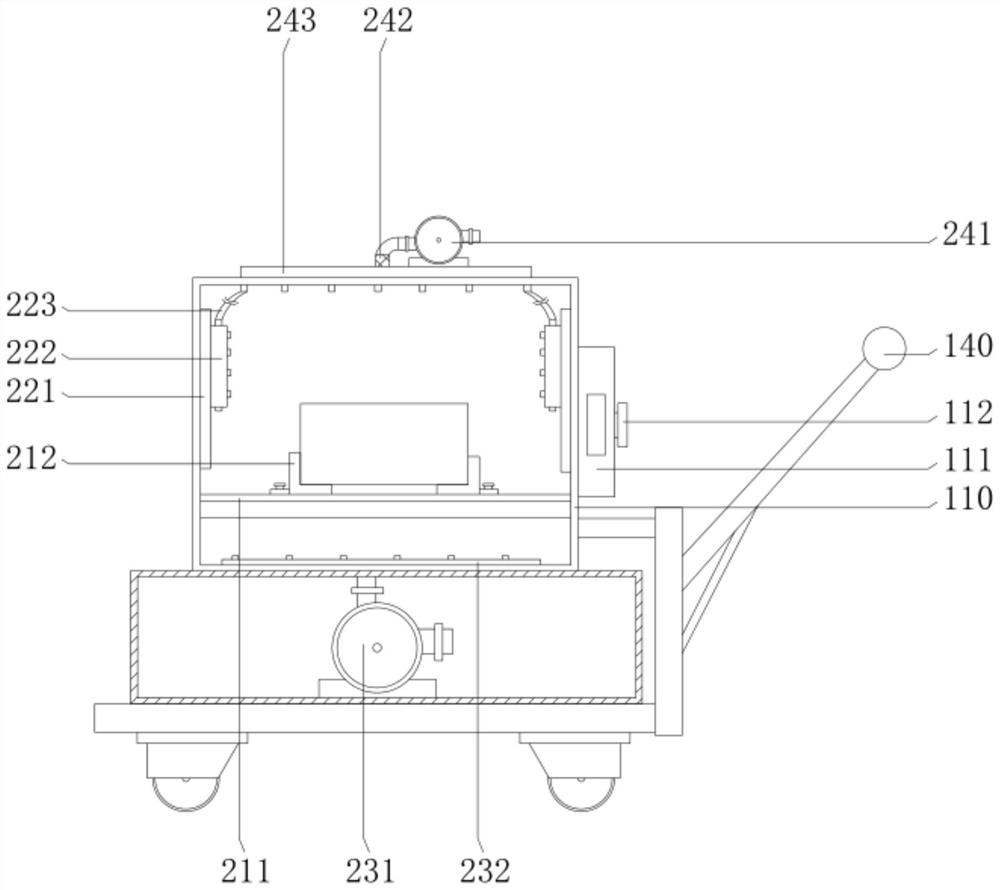

[0047] see Figure 1-4 , the present invention provides a technical solution: a high-efficiency dust removal equipment for the production of heavy calcium carbonate includes a base 100, a dust removal assembly 200 and a dust collection assembly 300, the base 100 is used to support and fix the dust removal assembly 200, which is convenient for dust removal assembly 200 performs dust blowing and dust extraction and filtering processing, and the dust collection assembly 300 collects the dust in the corners.

[0048] see Figure 1-Figure 3 , the base 100 includes a cabinet body 110 and a cabinet body 130, both sides of the cabinet body 110 and the cabinet body 130 are provided with openings, which is convenient for cleaning the inside of the cabinet body 130, and the inside of the cabinet body 110 is used for placing processing equipment, and the cabinet body 110 is fixed on the top of the cabinet 130, the cabinet 110 is fixed on the top of the cabinet 130 by bolts, a cabinet doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com