Patents

Literature

360results about How to "Avoid negative pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

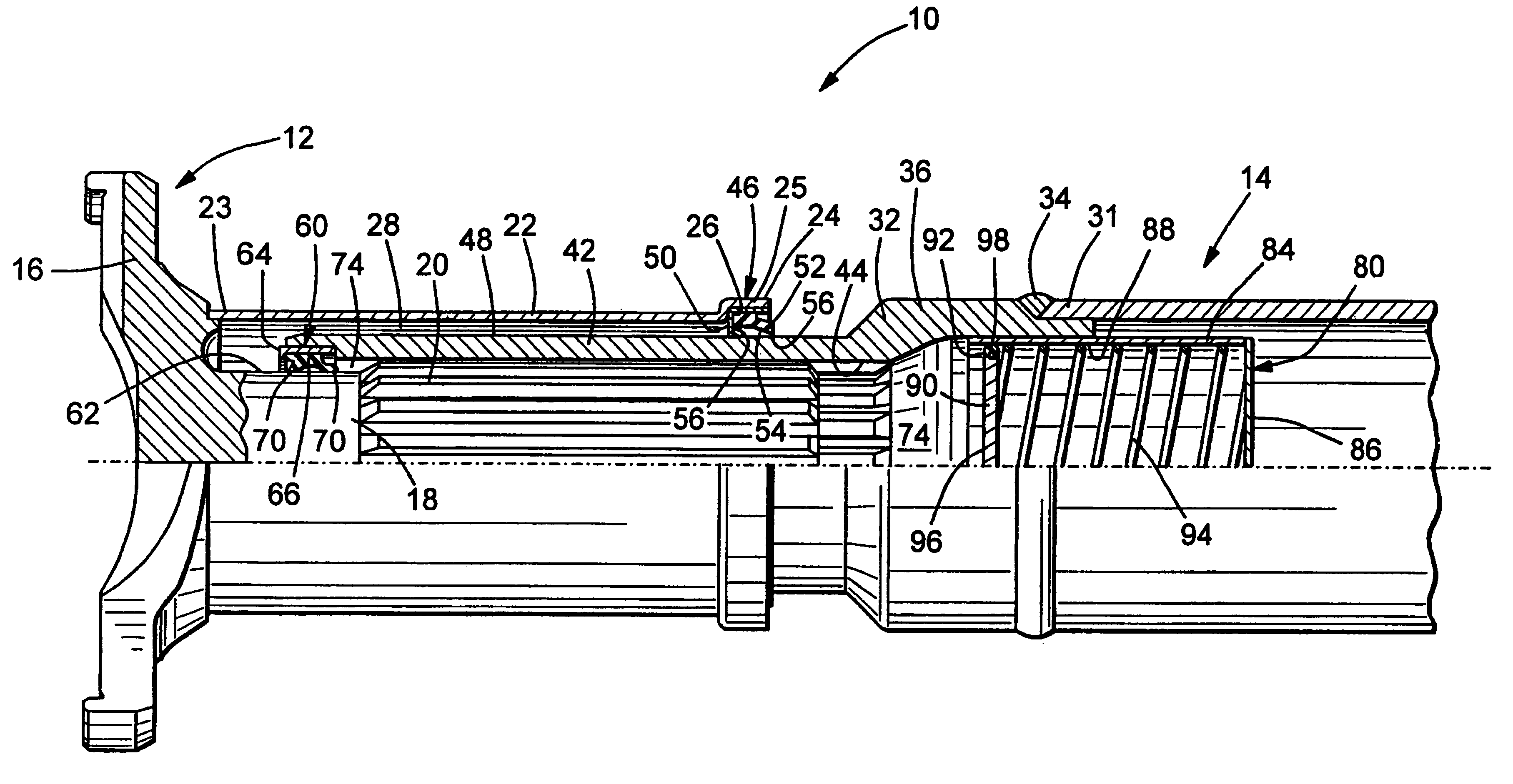

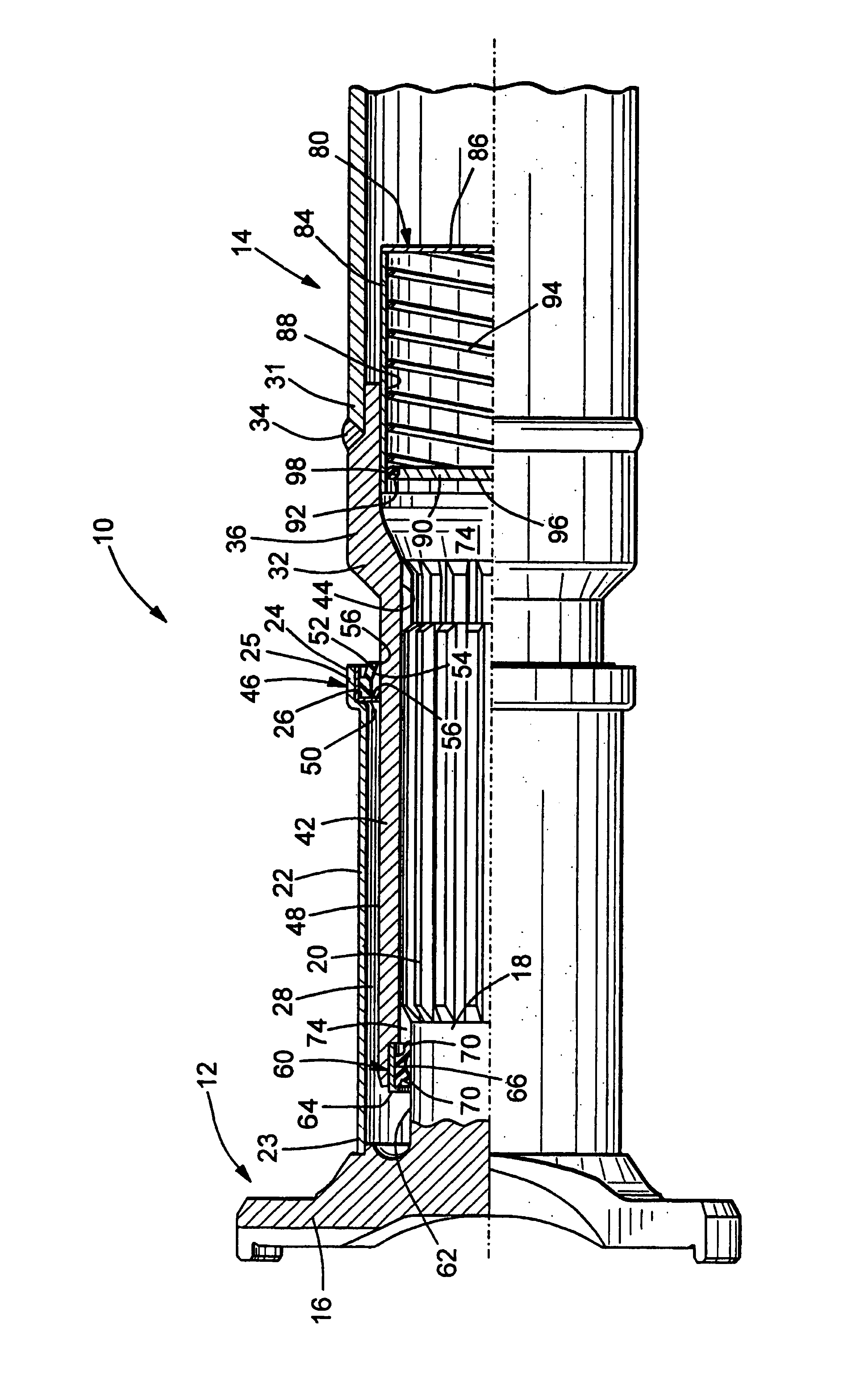

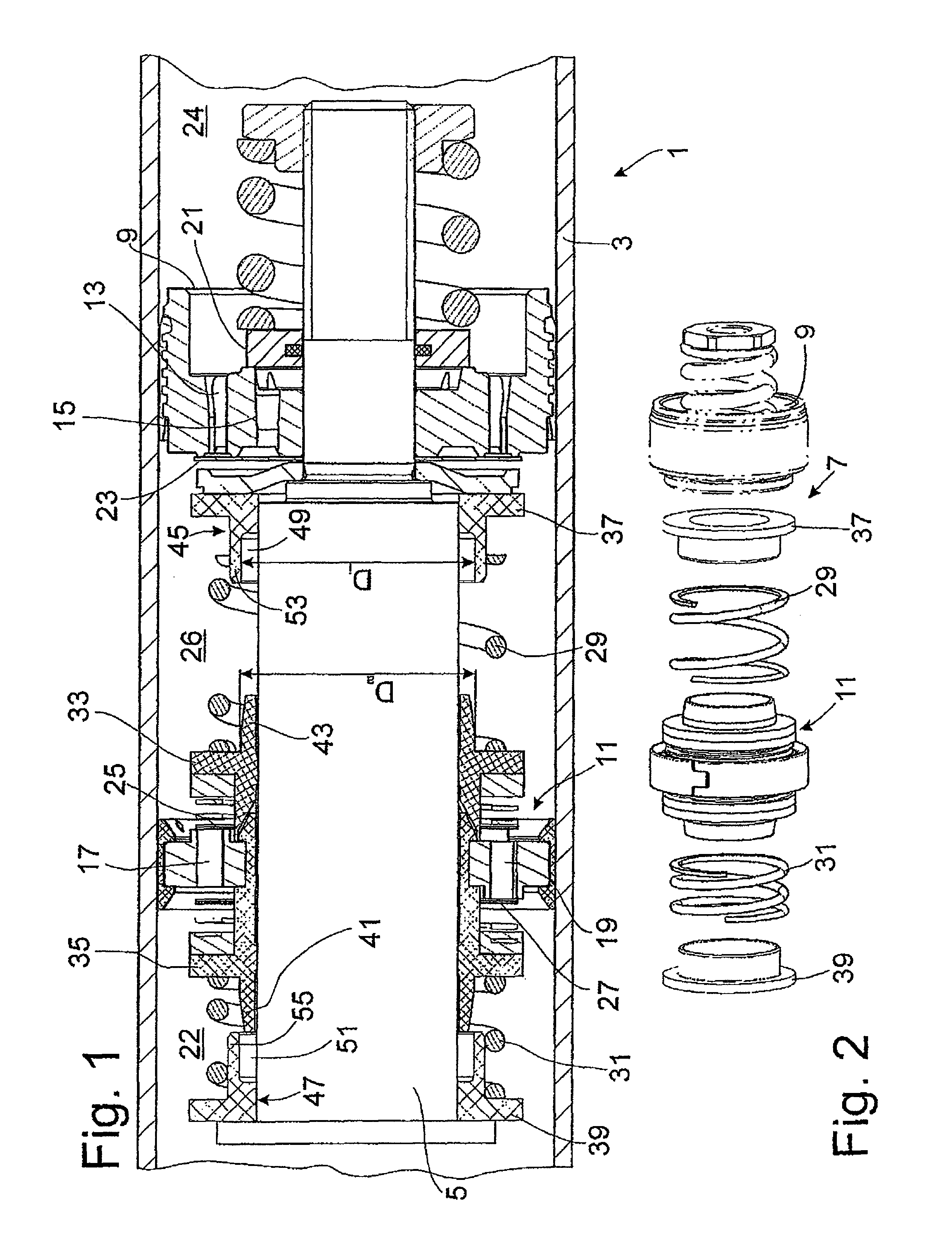

Safety needle with positive flush

ActiveUS7097637B2Easy to disassembleAvoid negative pressureMedical devicesInfusion needlesLocking mechanismEngineering

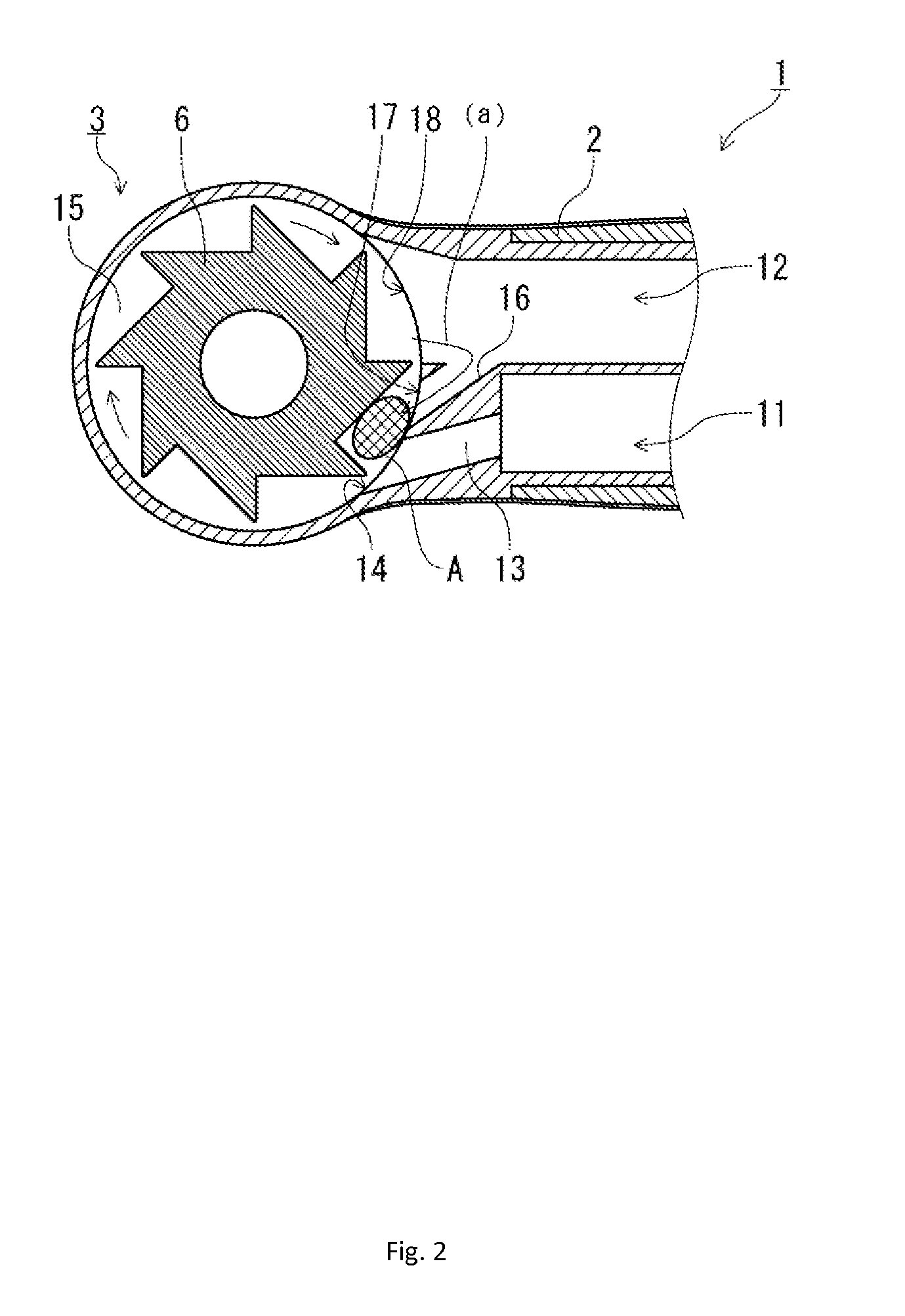

A safety needle device and positive flush mechanism for use with a vascular access port. In one embodiment, the combination needle assembly includes a needle, a body and a base, the body being collapsible to expunge fluid therefrom as the needle is withdrawn from a vascular access port. In another embodiment, the combination needle assembly includes a needle, a housing and a reservoir, the housing squeezing the reservoir to expunge fluid therefrom as the needle is withdrawn from the port. In another embodiment, the needle assembly includes a compression plate and balloon extension, the compression plate forcing fluid out of the balloon extension as the needle is withdrawn from the port. In all embodiments, the needle assembly is configured to provide a positive flush to overcome negative pressures in the vascular access port, while also providing a locking mechanism to prevent accidental needle sticks.

Owner:CR BARD INC

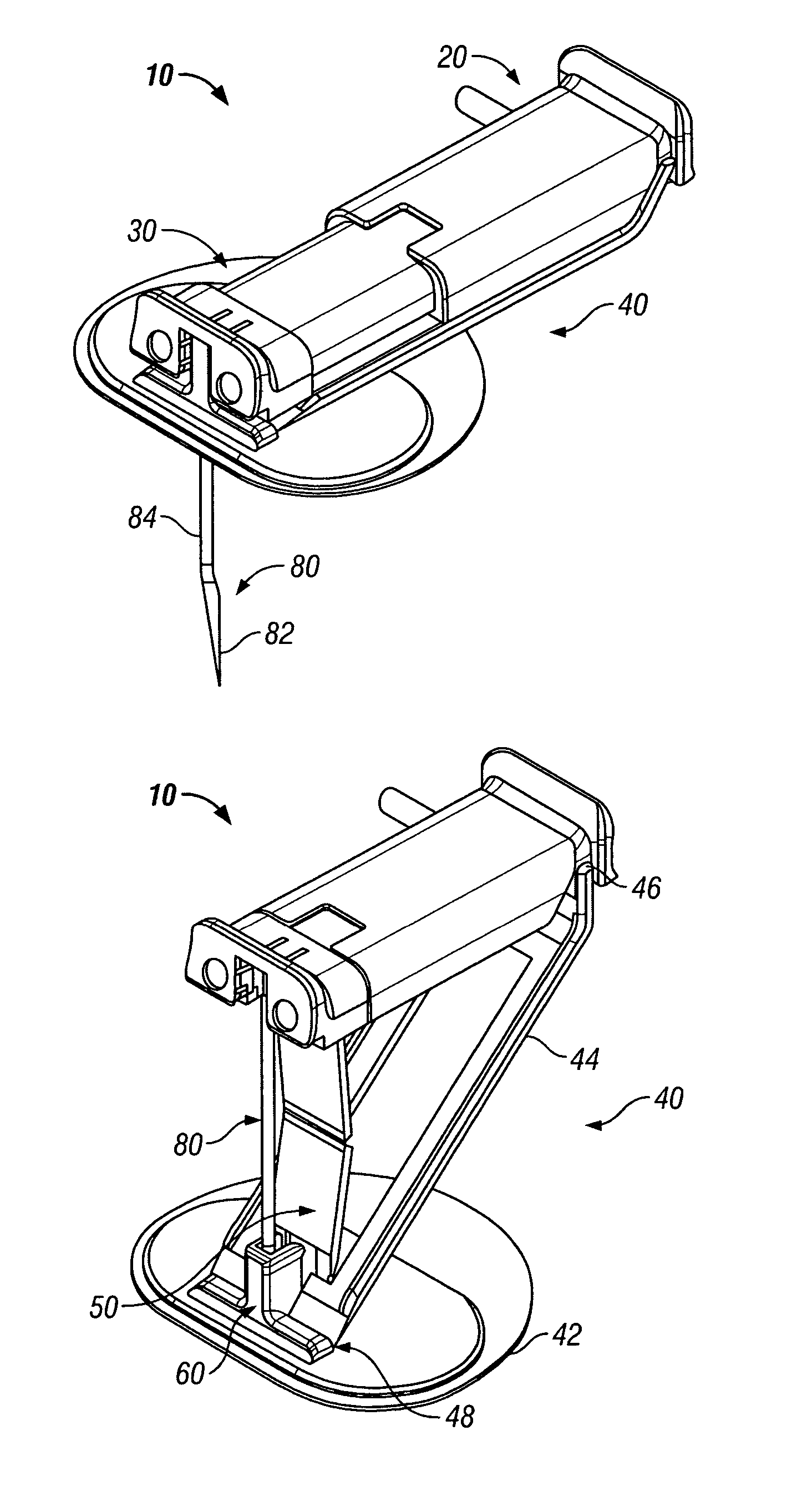

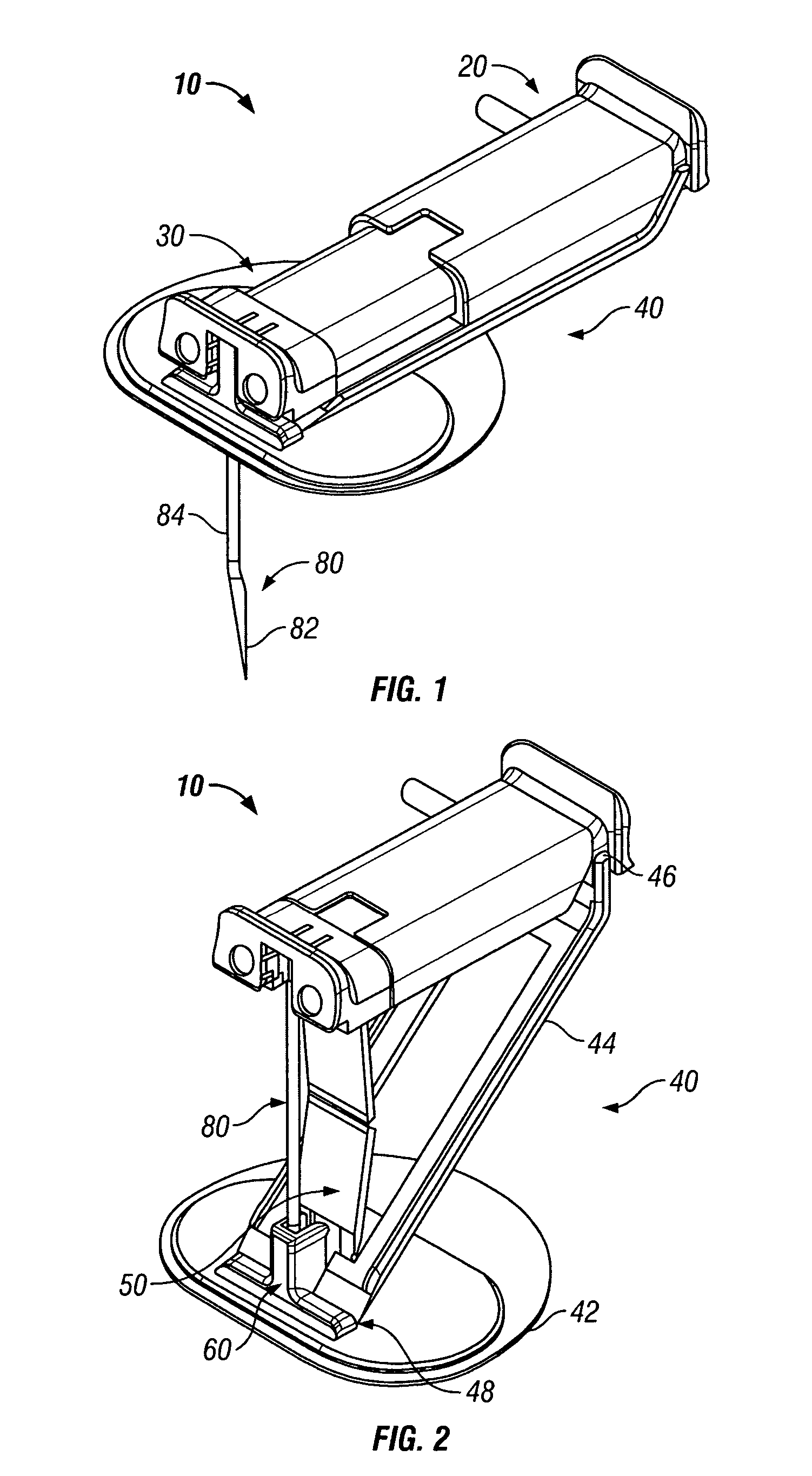

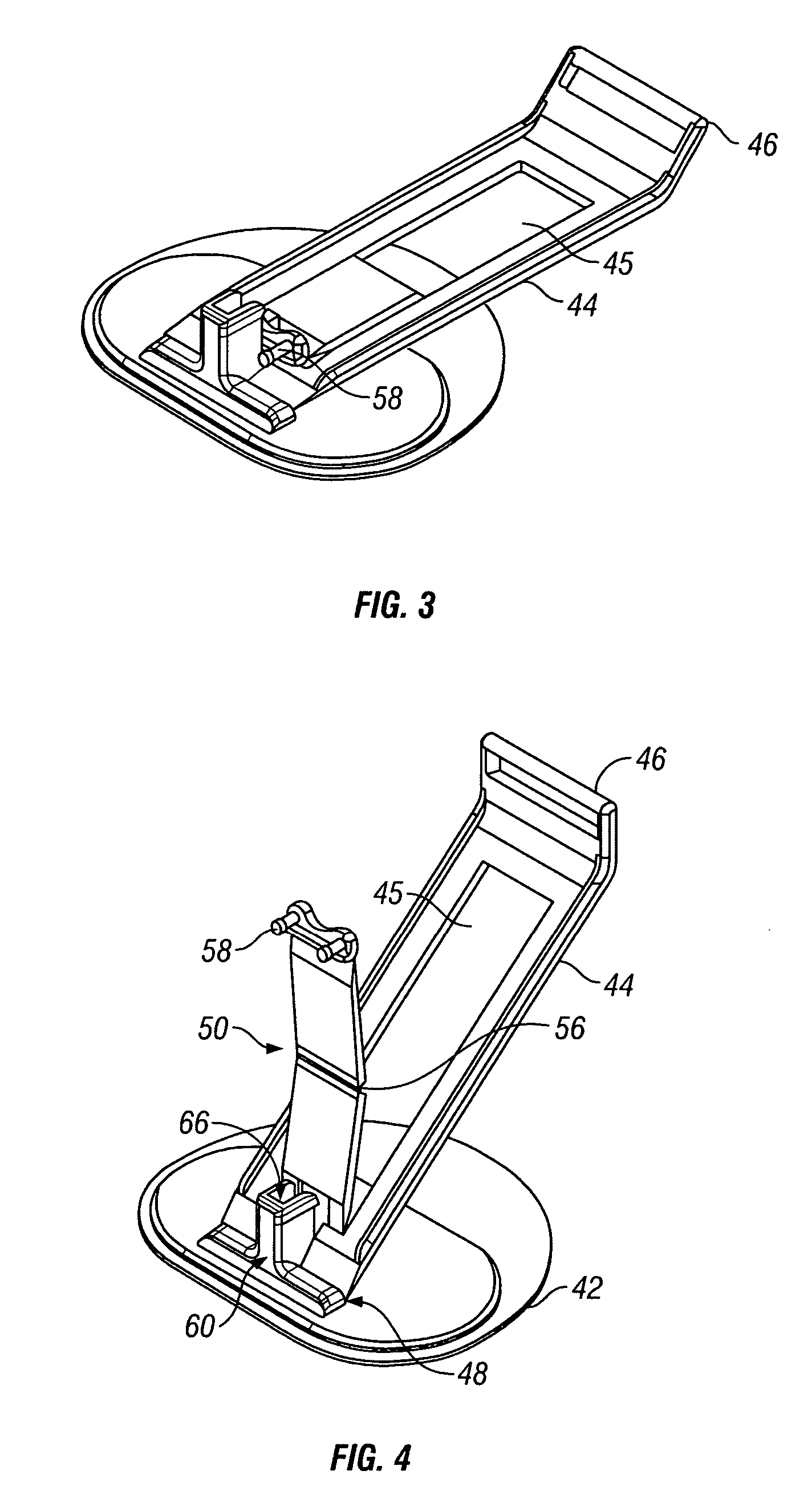

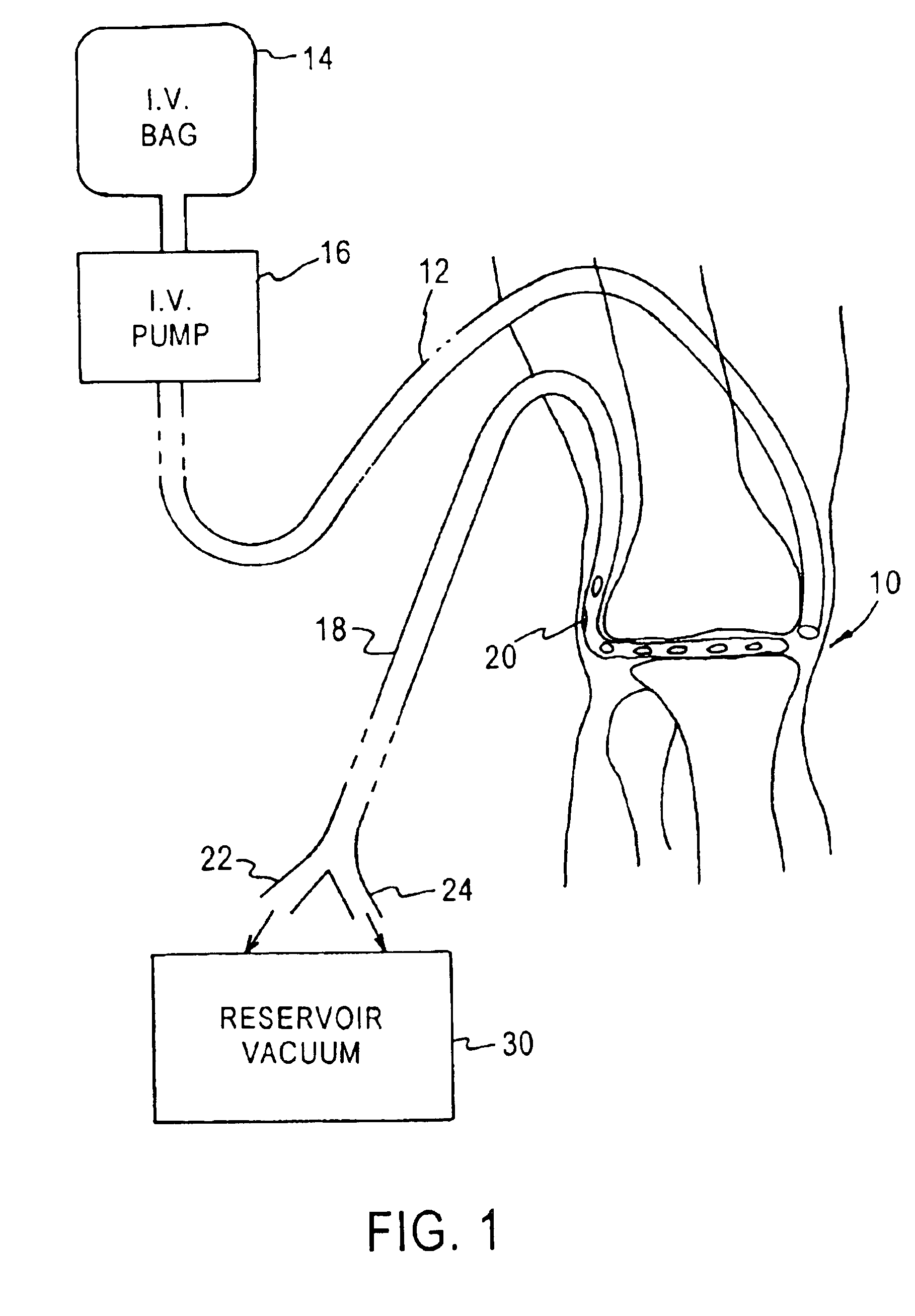

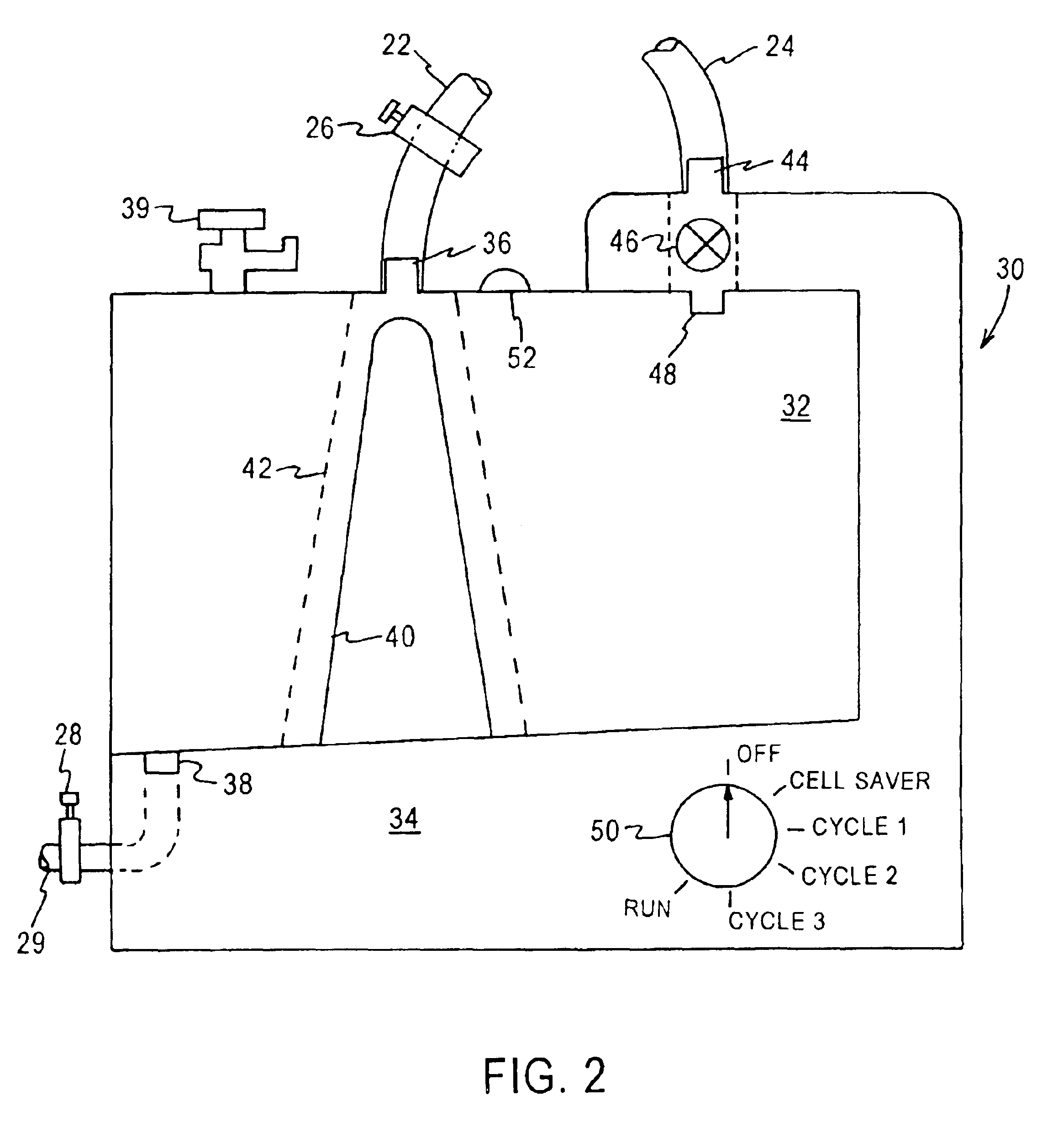

Treatment of wound or joint for relief of pain and promotion of healing

InactiveUS6887228B2Relieve painPromote healingOther blood circulation devicesEnemata/irrigatorsBody jointsBiomedical engineering

Owner:MCKAY DOUGLAS WILLIAM

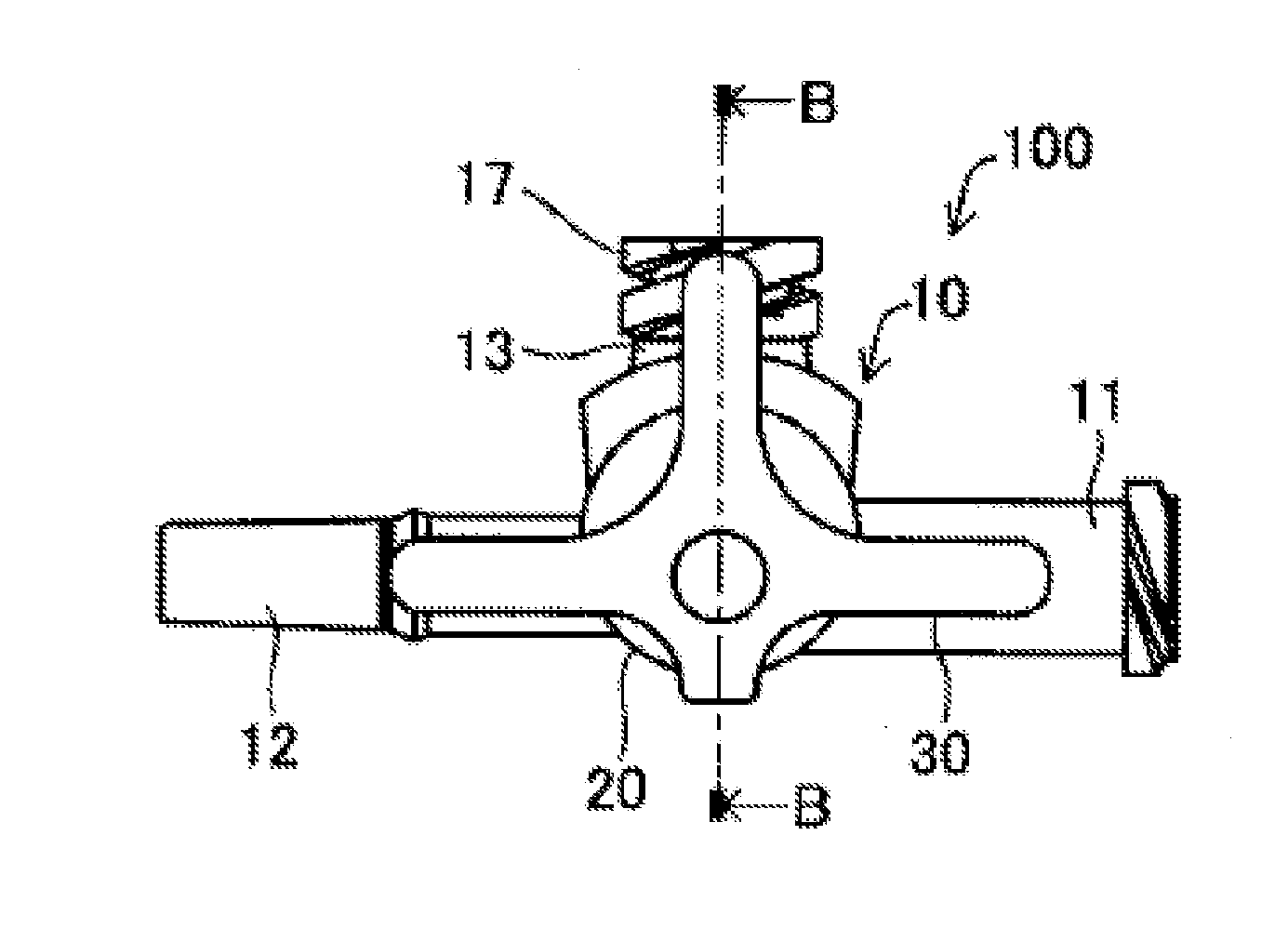

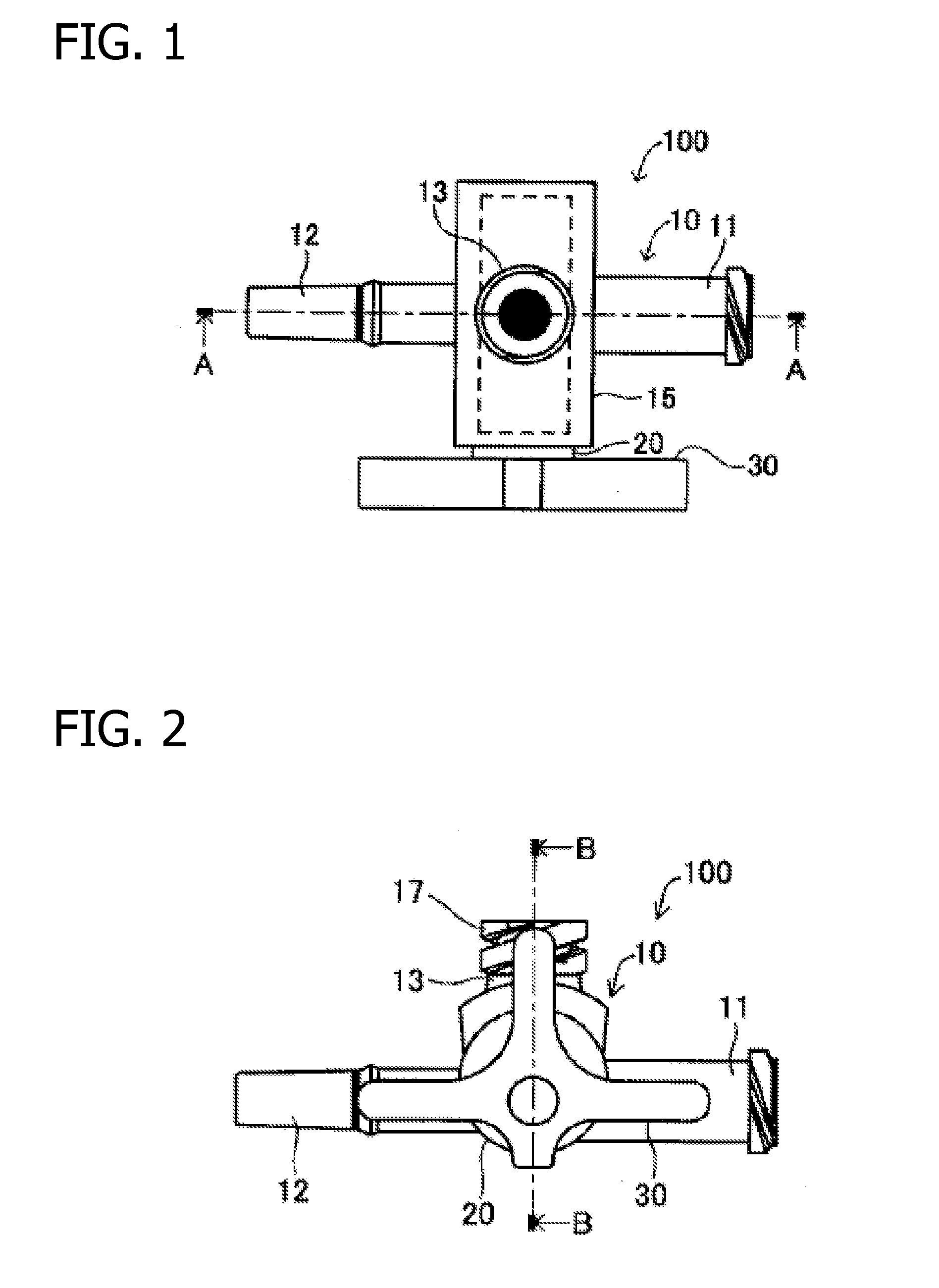

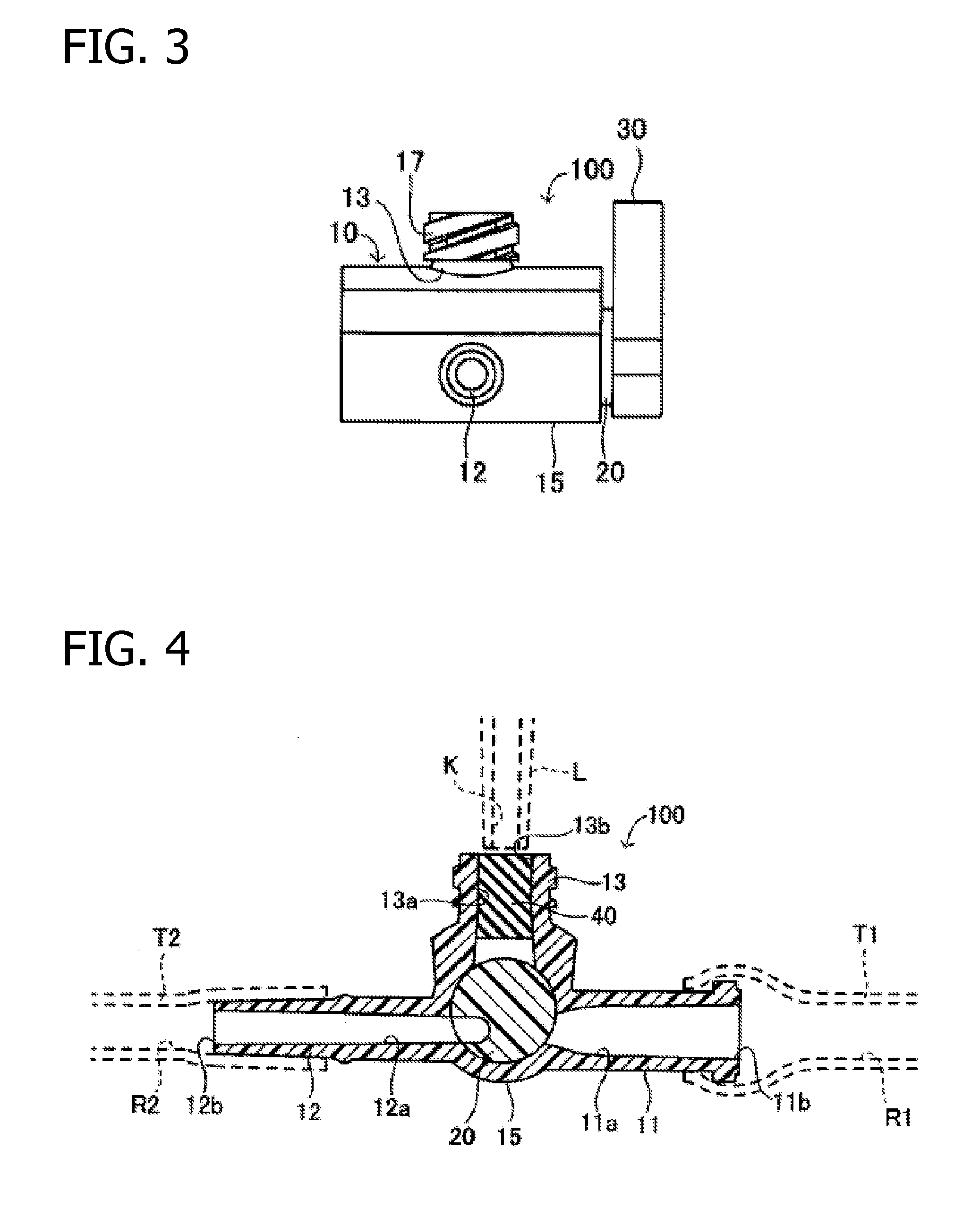

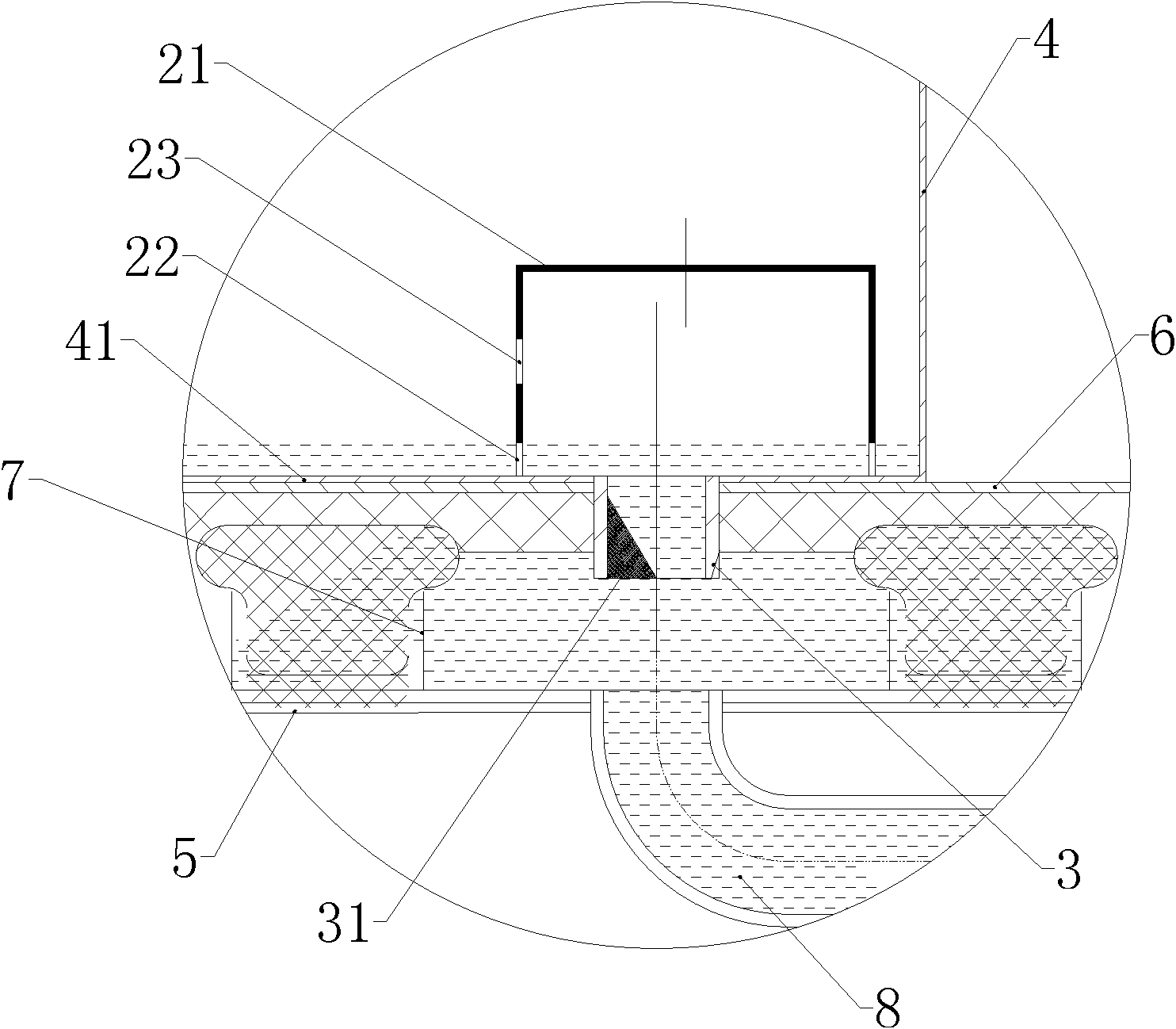

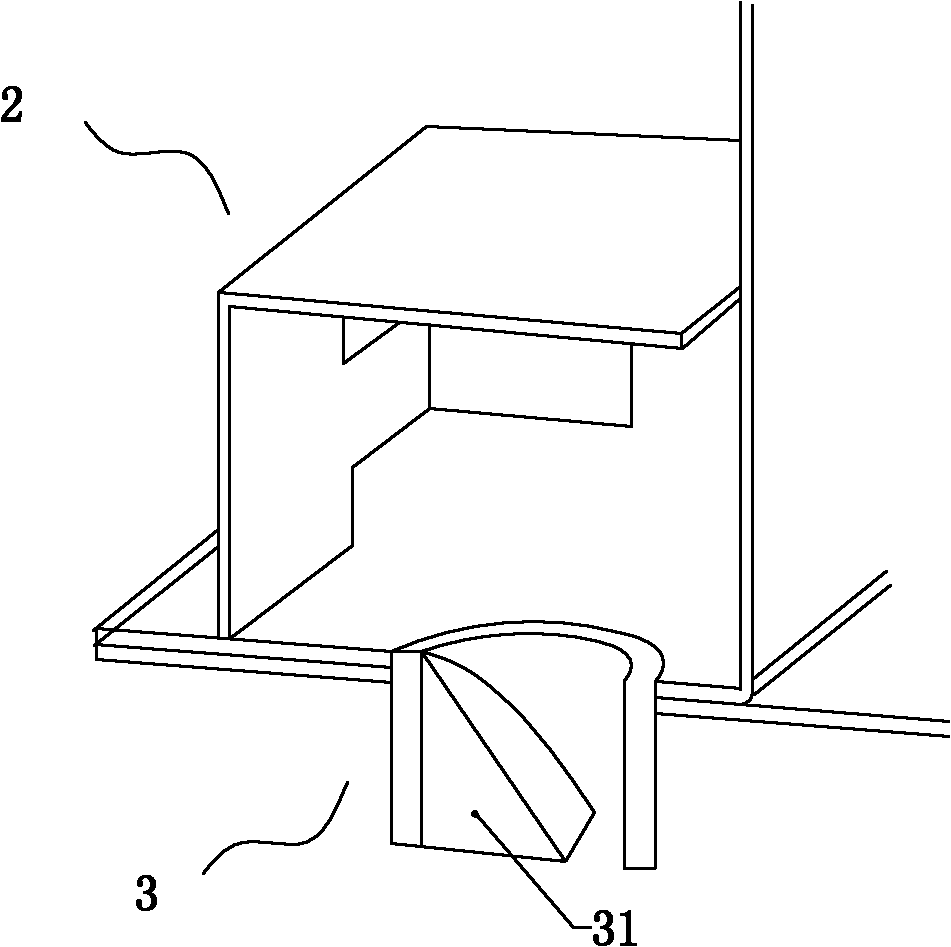

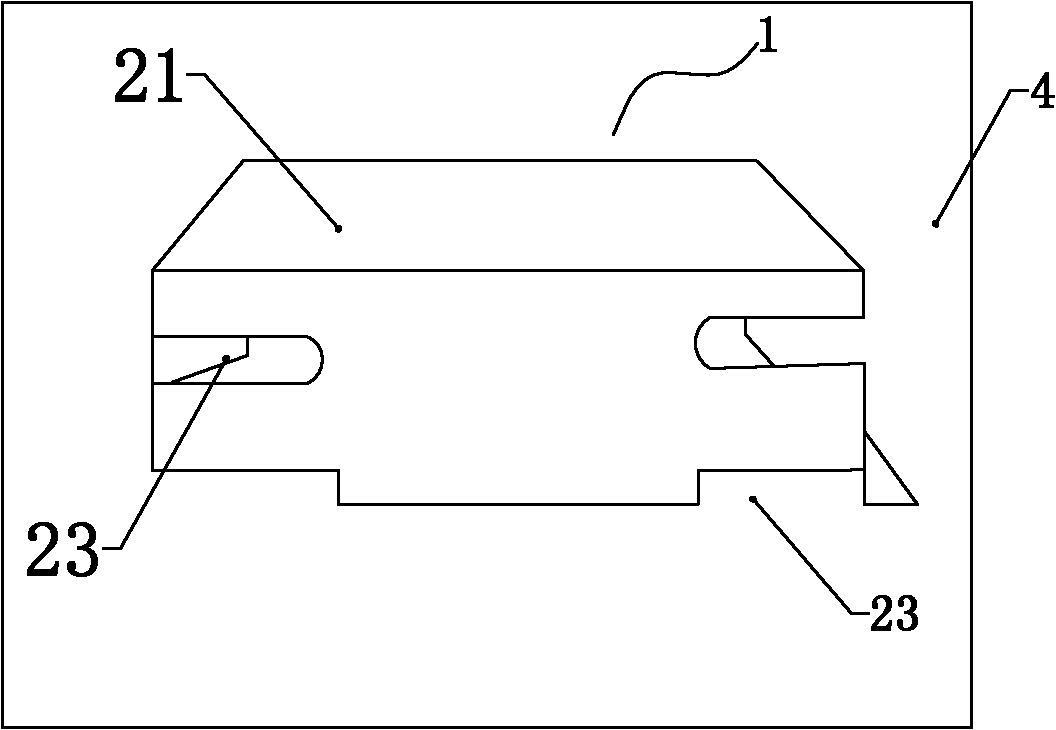

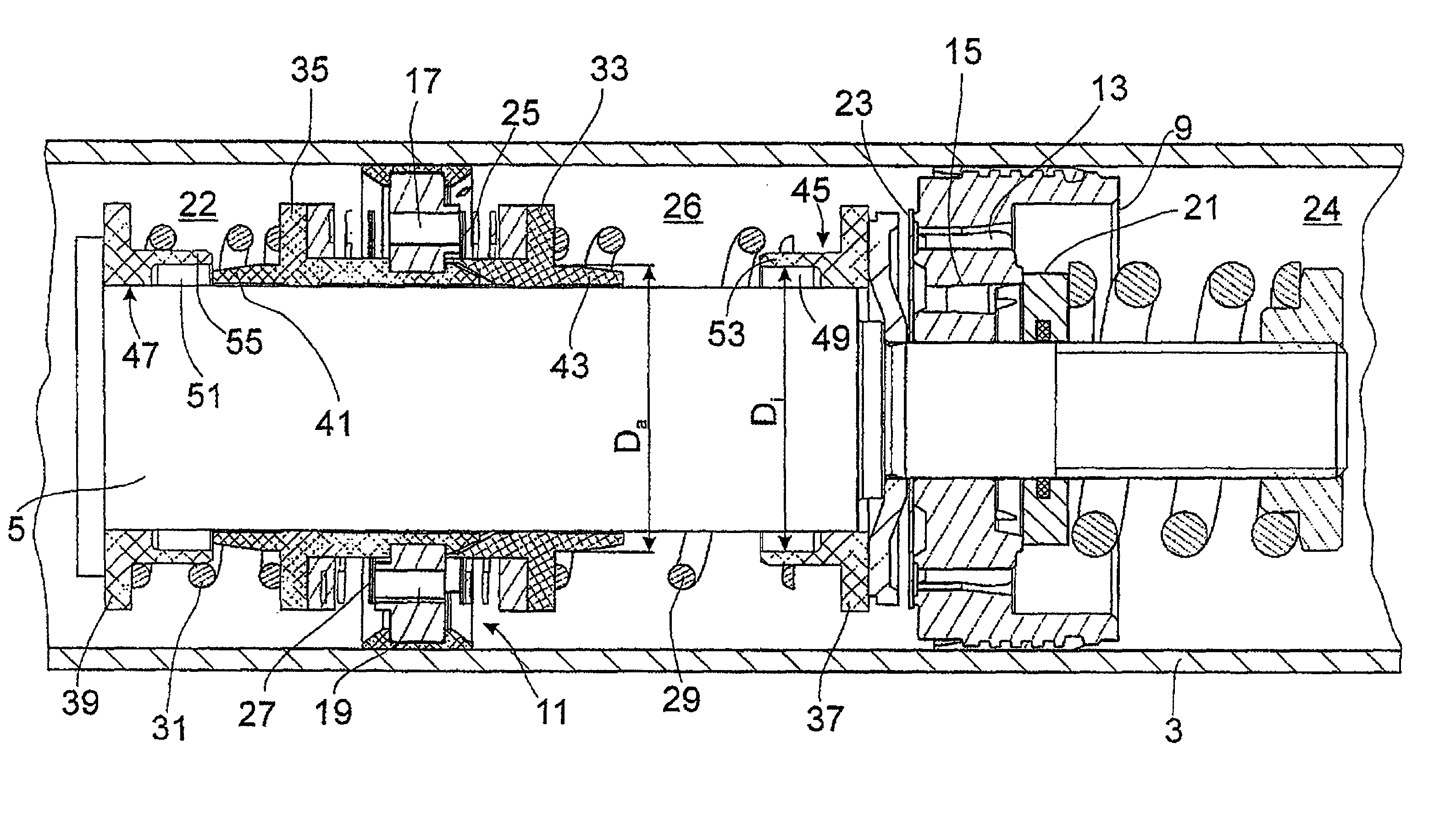

Connector

InactiveUS20070219483A1Constant pressureConvenient to accommodateMedical devicesTube connectorsStopcockM.2

The present invention is directed to a connector with which negative pressure in the channel space in the connector can be prevented during luer removal, in a closed-system connector. A slit ( 49 ) is furnished in valve body ( 40 ) of three-way stopcock ( 100 ). During luer access and luer removal, first and second moving parts (M 1 and (M 2 ) to the left and right of slit ( 49 ) enter and withdraw from first and second valve body accommodating chambers ( 51 ) and ( 52 ), respectively. First and second valve body accommodating chambers ( 51 ) and ( 52 ) are formed outside of channel space (S), so the operation whereby first and second moving parts (M 1 ) and (M 2 ) enter and withdraw during luer access and luer removal does not affect the change in volume of channel space (S) and negative pressure can be prevented from occurring in channel space (S) by the aforementioned entry and withdrawal.

Owner:TYCO HEALTHCARE GRP LP

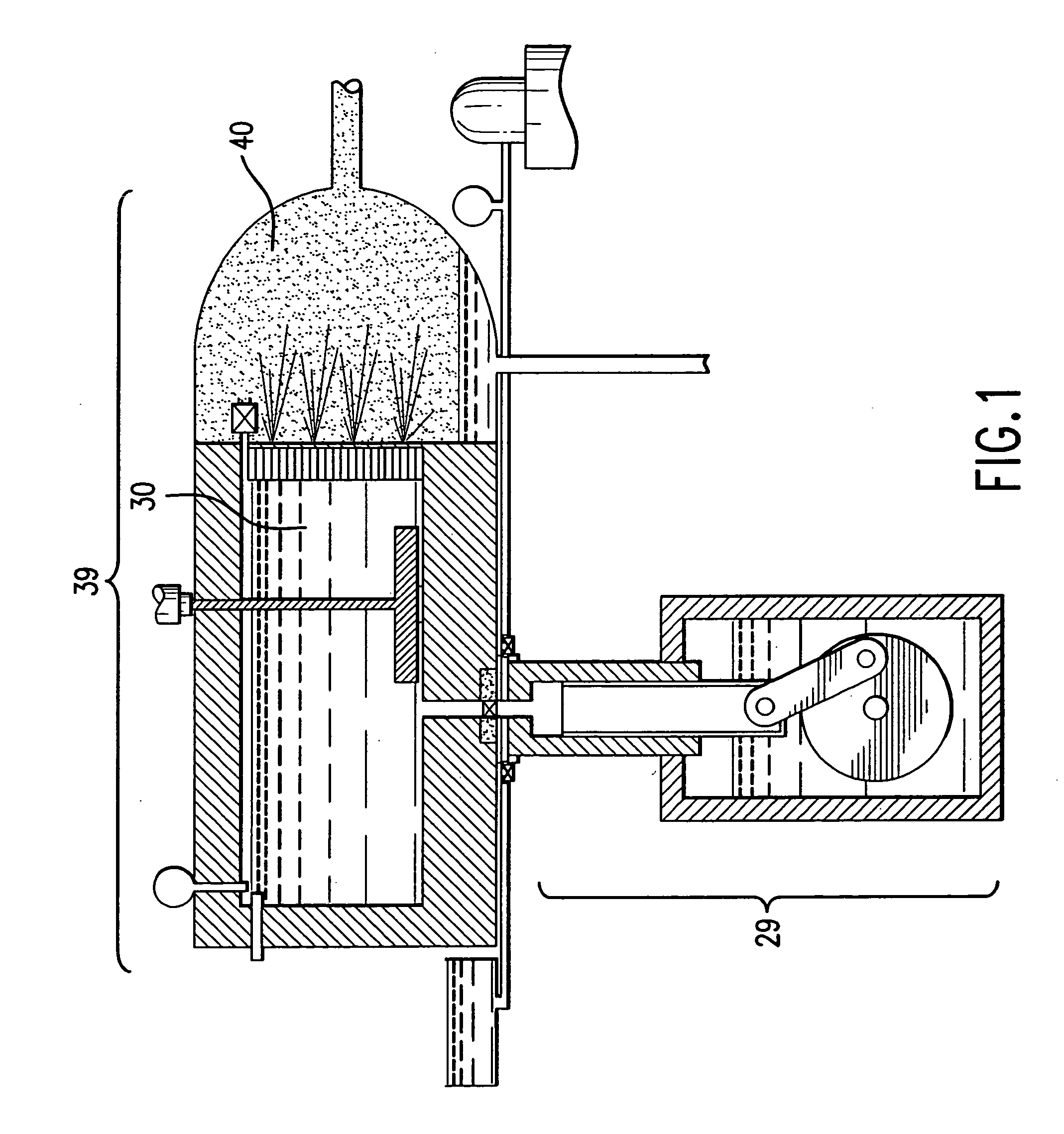

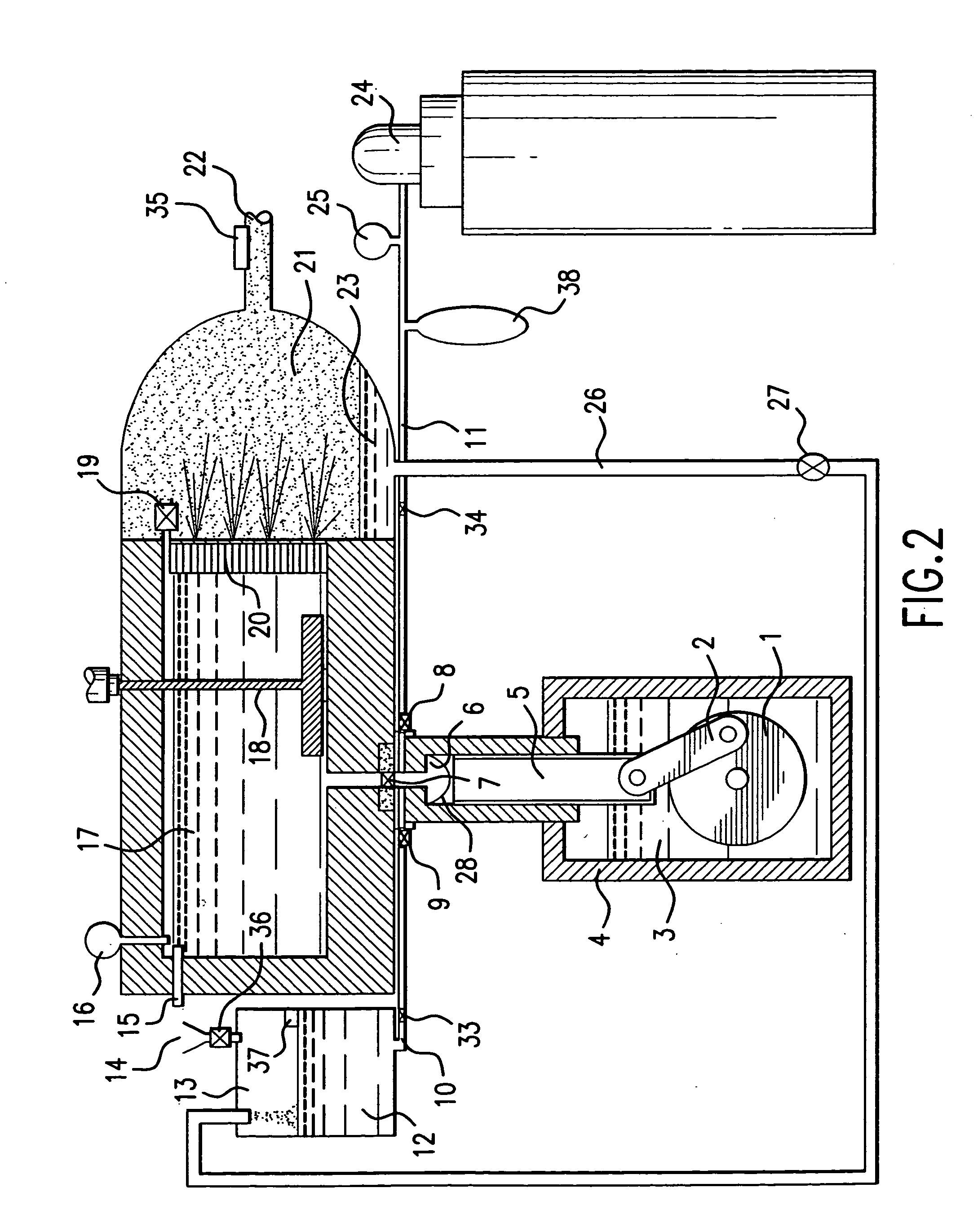

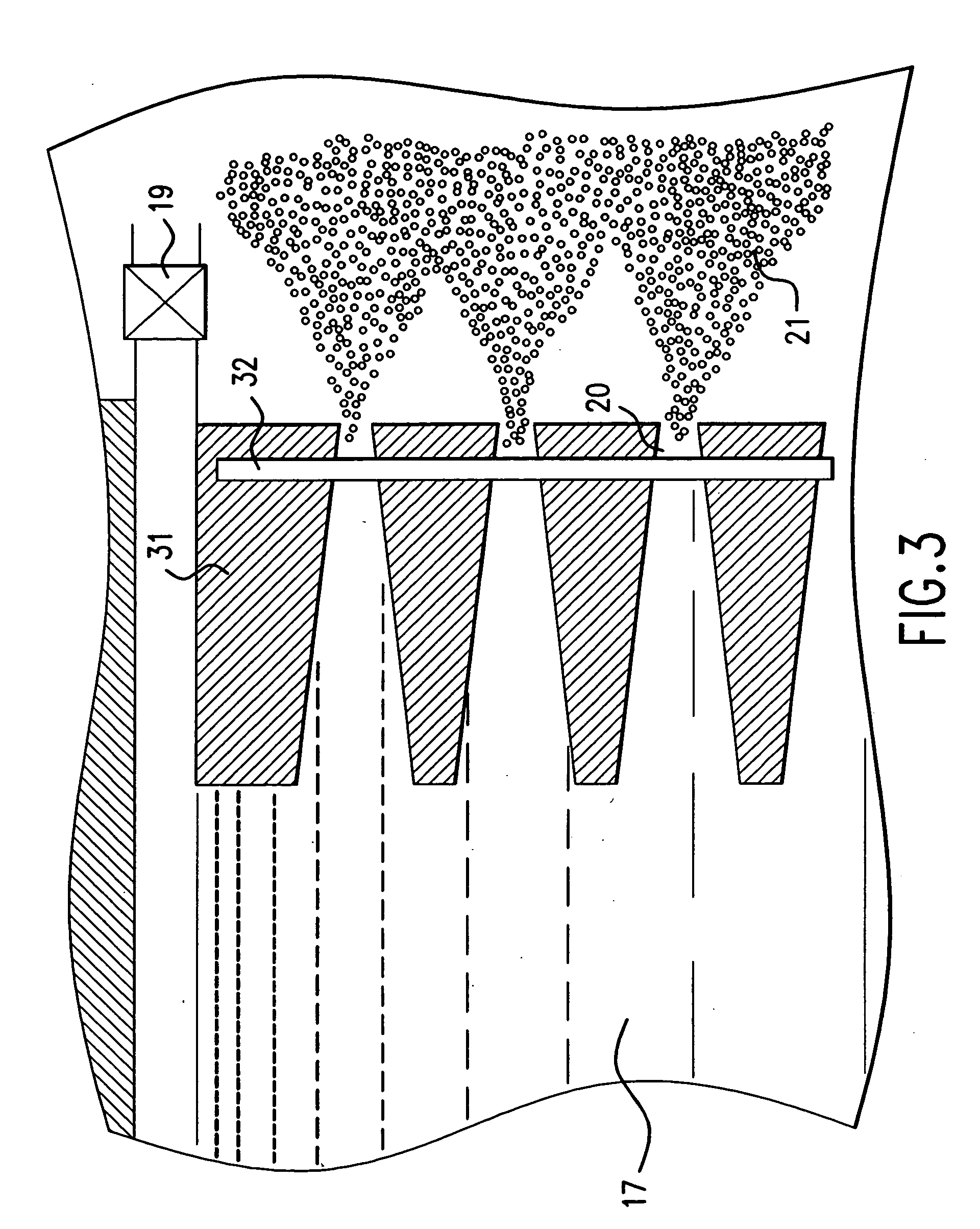

Method and device for generating mists and medical uses thereof

InactiveUS20050042170A1Brain damage can be avoidedLower body temperatureRespiratorsPowdered material dispensingBiomedical engineeringMedical procedure

The present invention is directed to a method and device for generating a mist. Mist is created by a sudden drop in the pressure of a gas / liquid mixture. This results in the rapid expansion of the volume of the gas component and the consequent breaking of the liquid into tiny droplets. The method and device allow for the precise control of both the size of the liquid droplets and the density of the mist produced. The mists may be used in a wide variety of applications, including medical procedures in which the body temperature of a patient is rapidly changed and any industrial procedure where a mist is needed.

Owner:THE BRIGHAM & WOMENS HOSPITAL INC

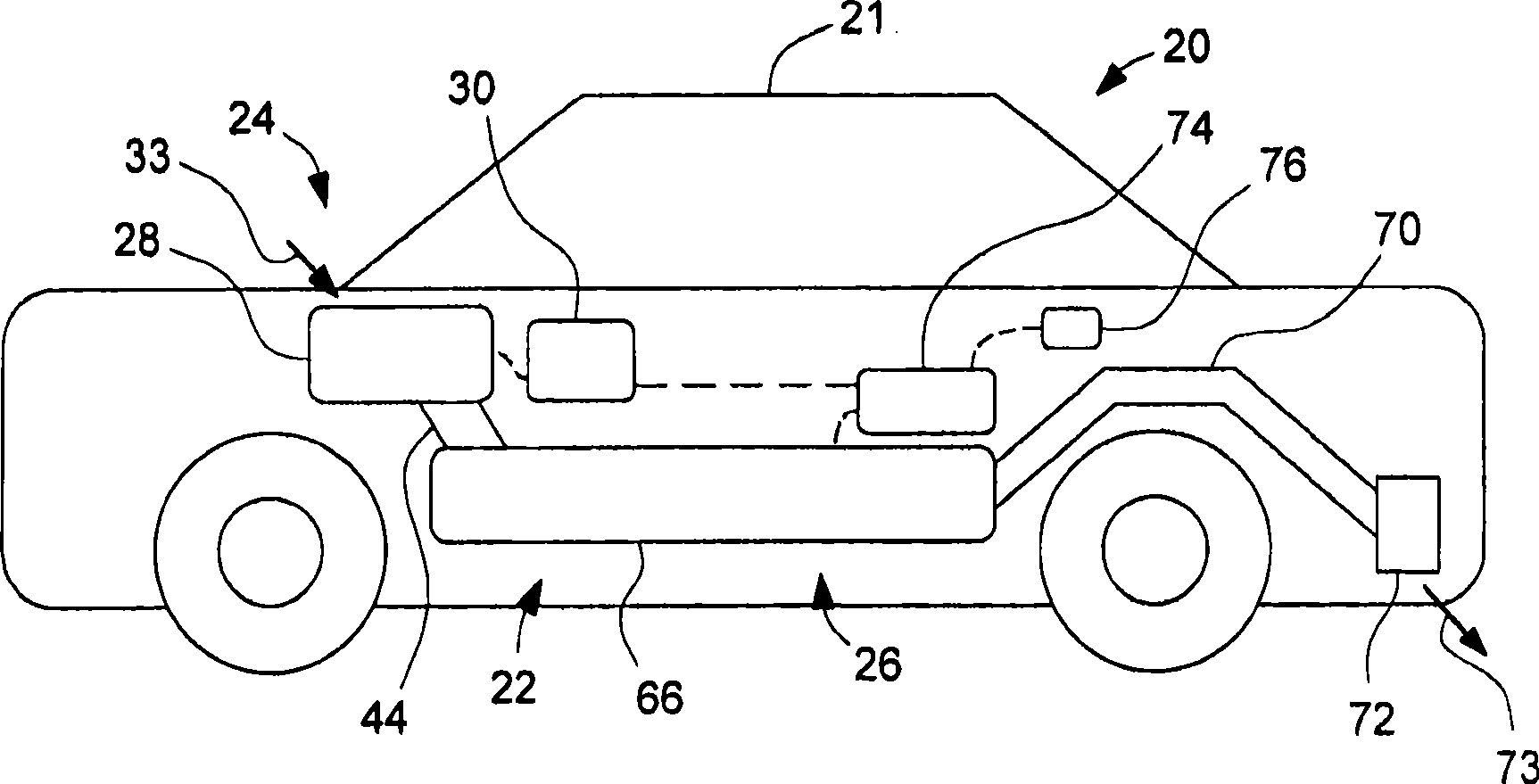

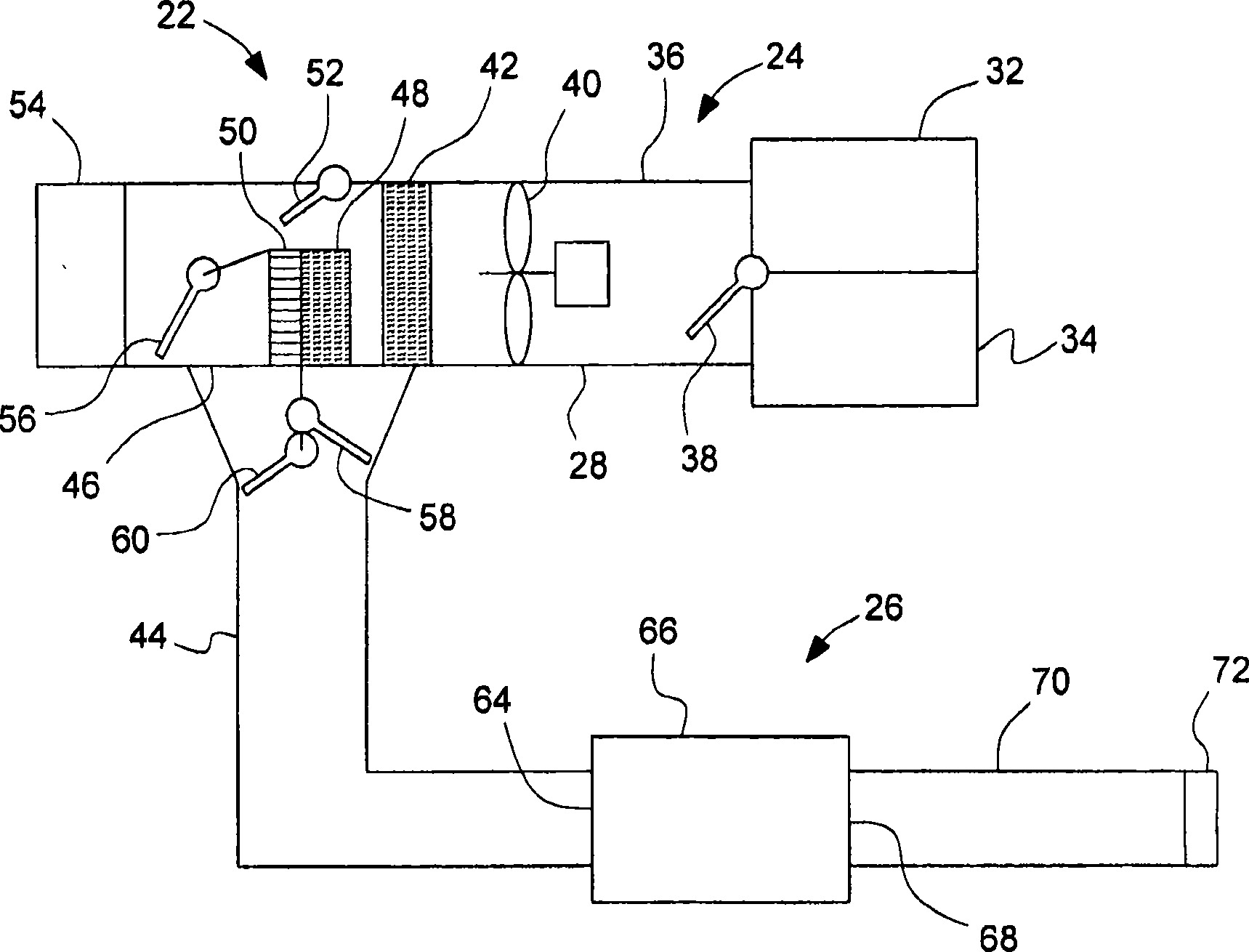

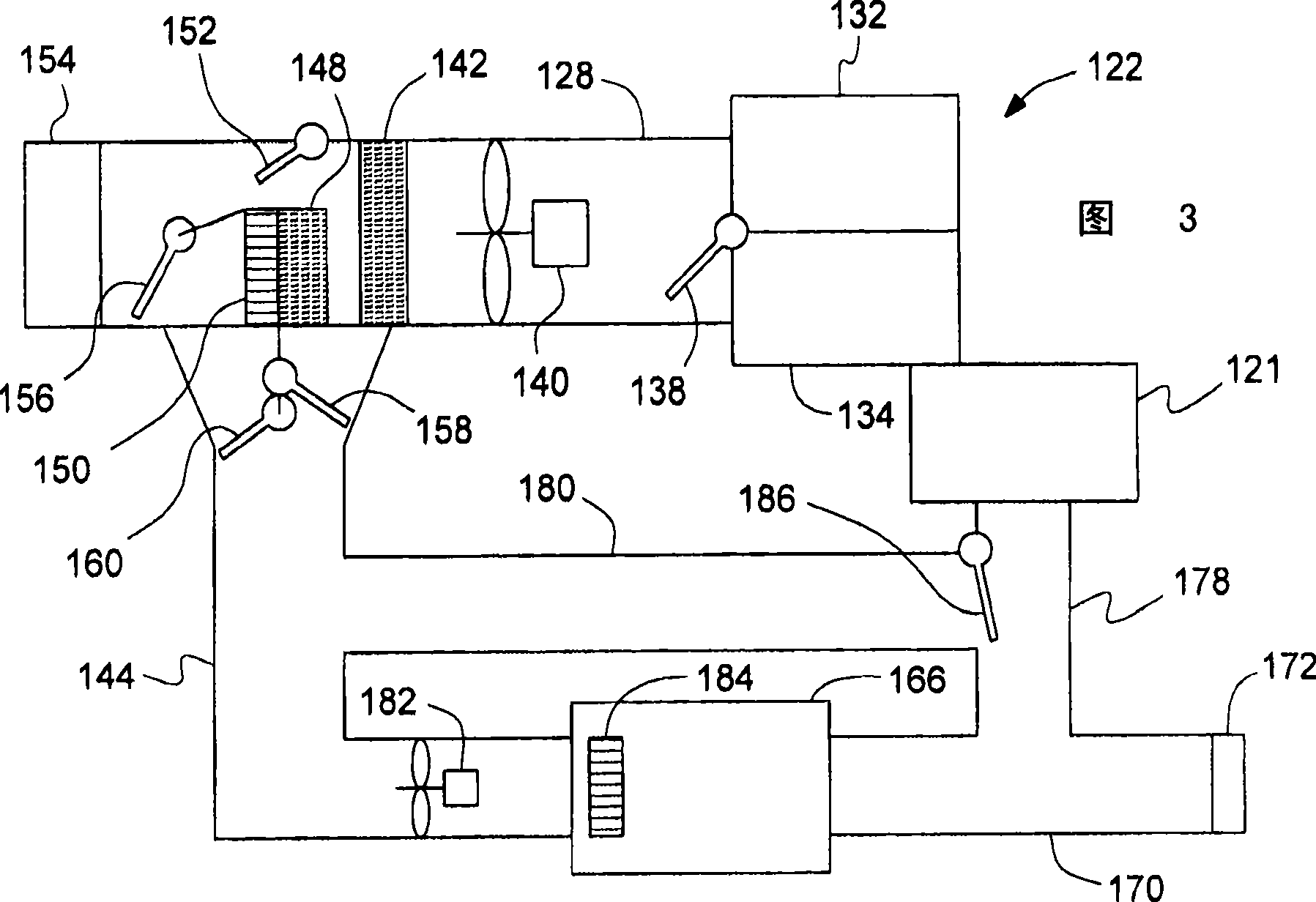

Vehicle hvac and battery thermal management

InactiveCN101386285AImprove performanceExtend battery lifePower to auxillary motorsPropulsion by batteries/cellsEngineeringBattery thermal management

Owner:GM GLOBAL TECH OPERATIONS LLC

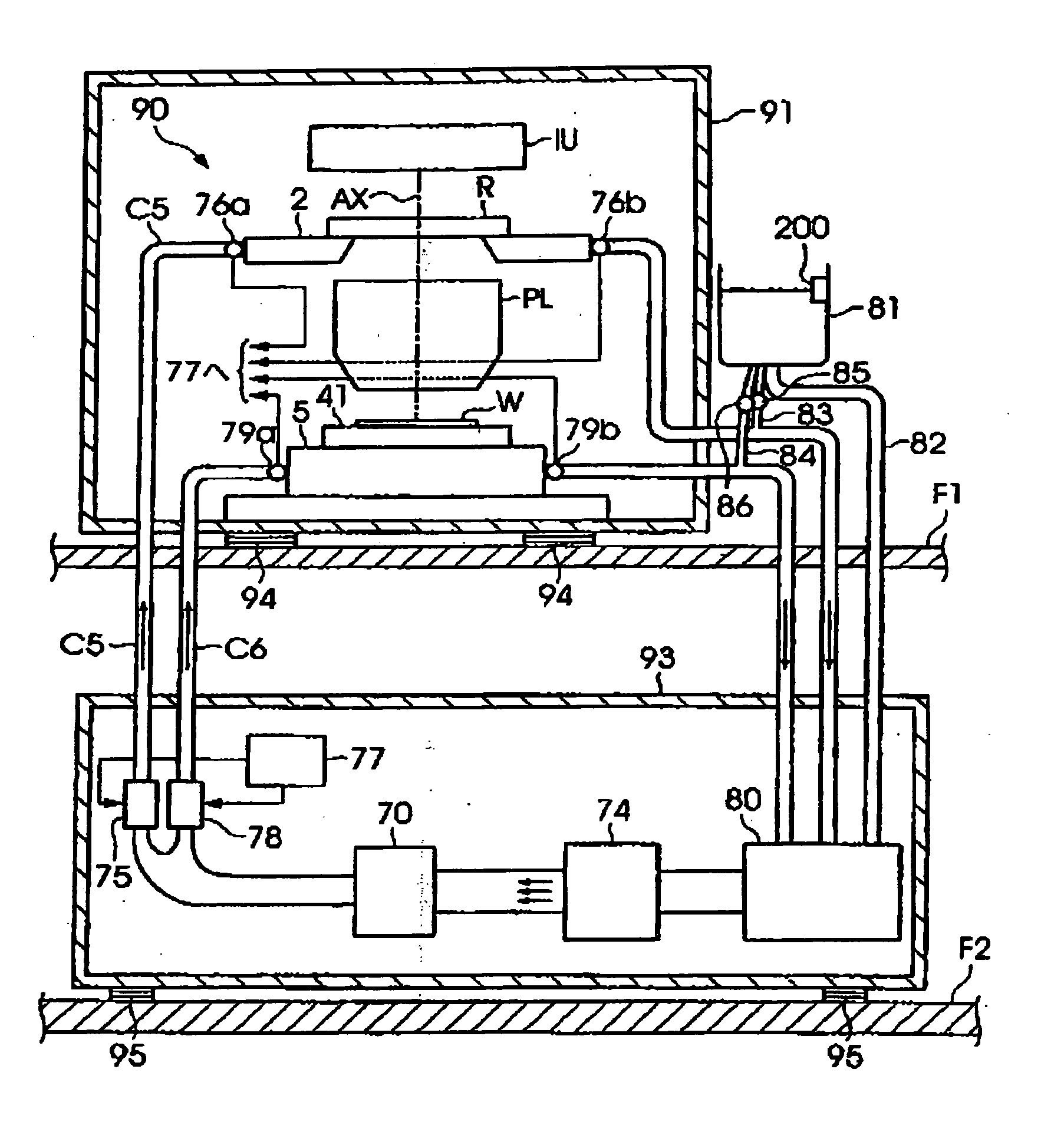

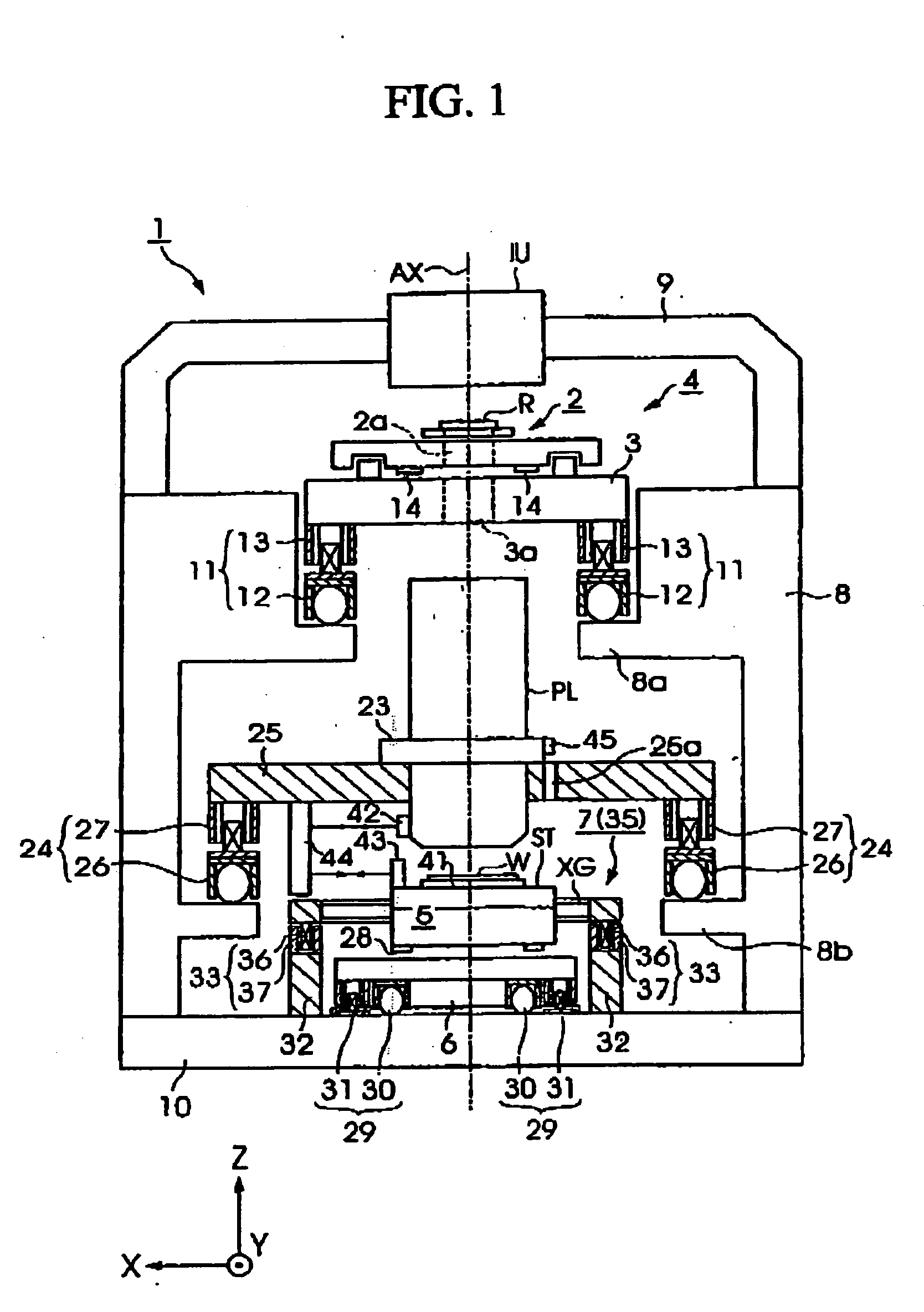

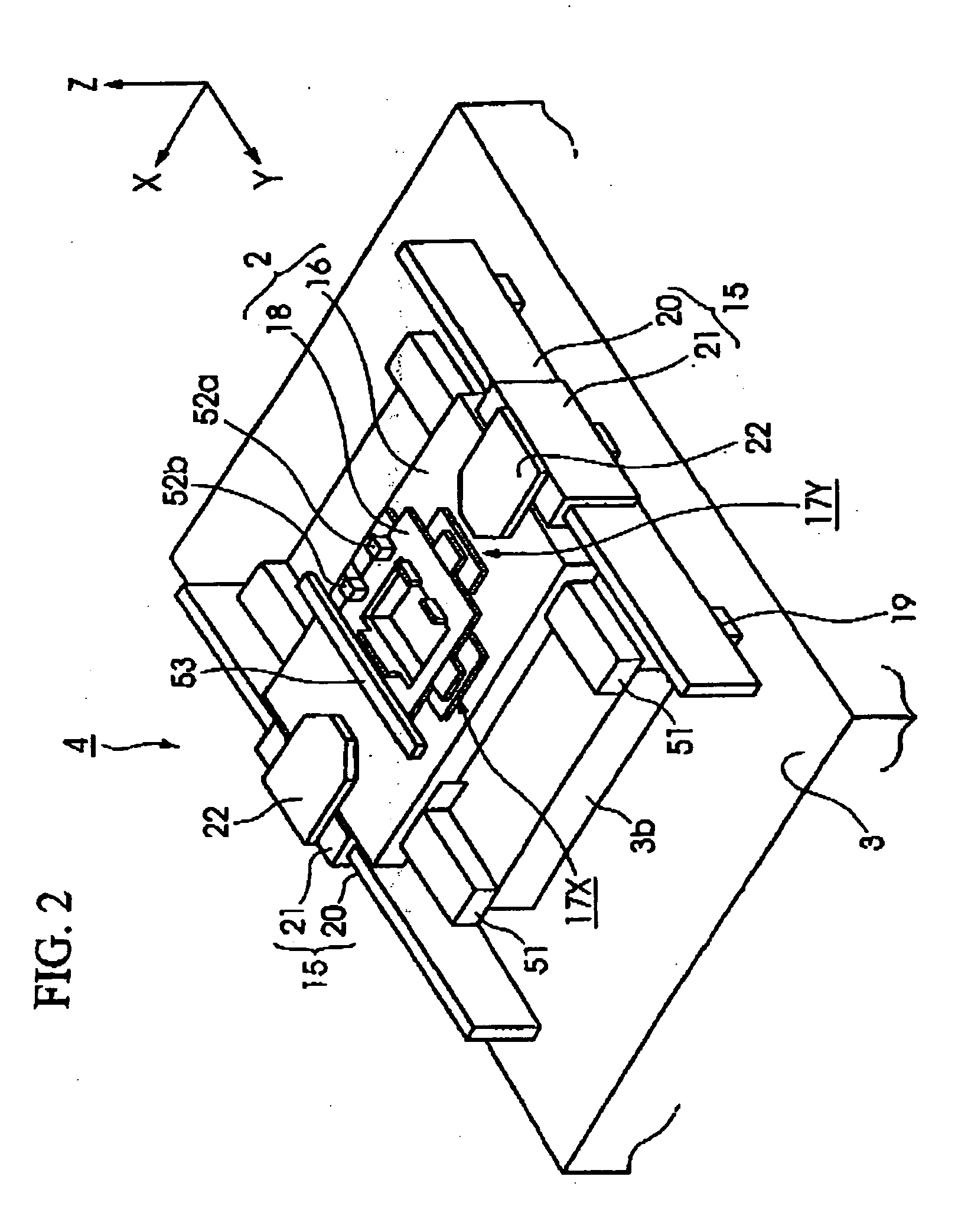

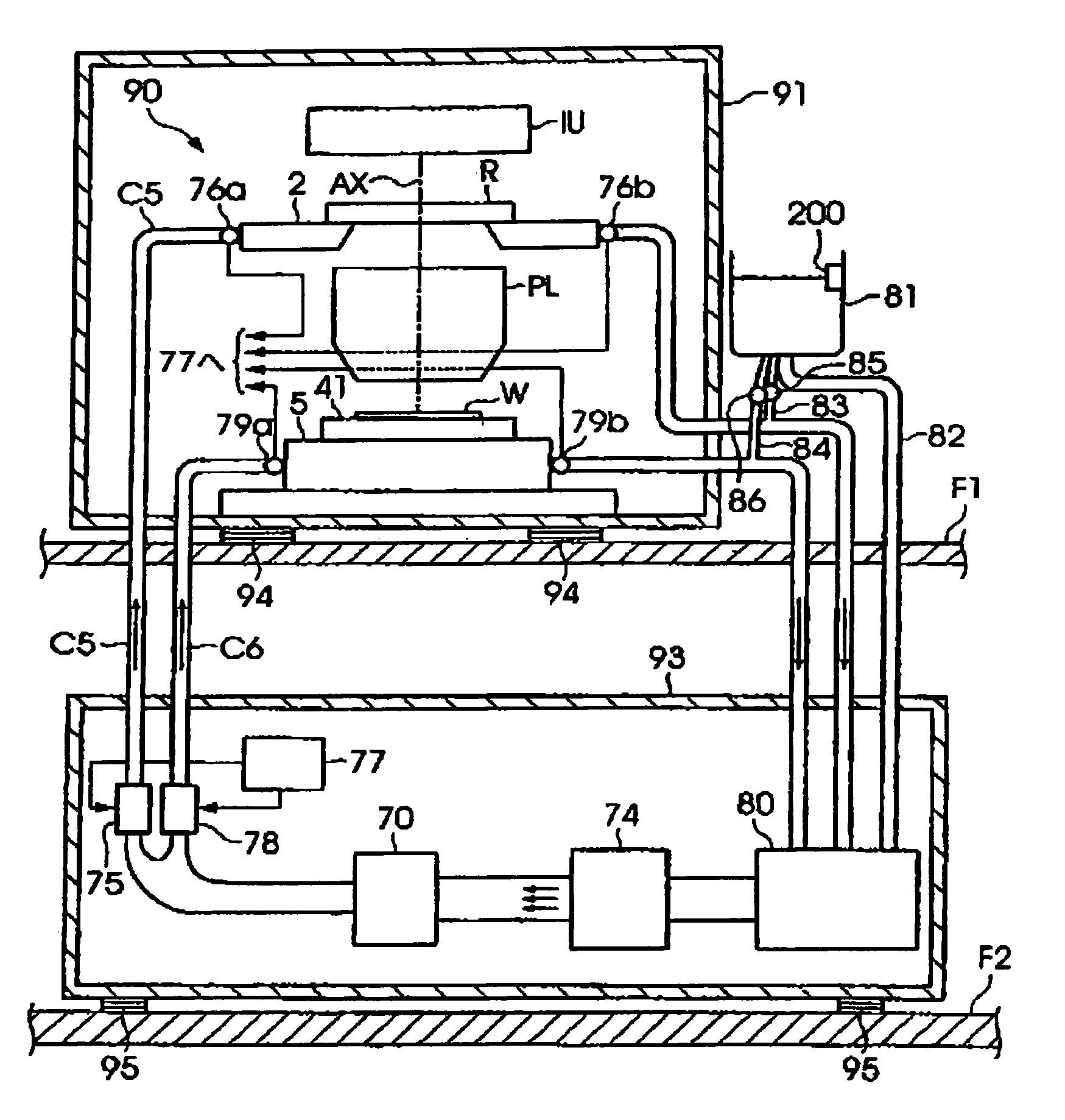

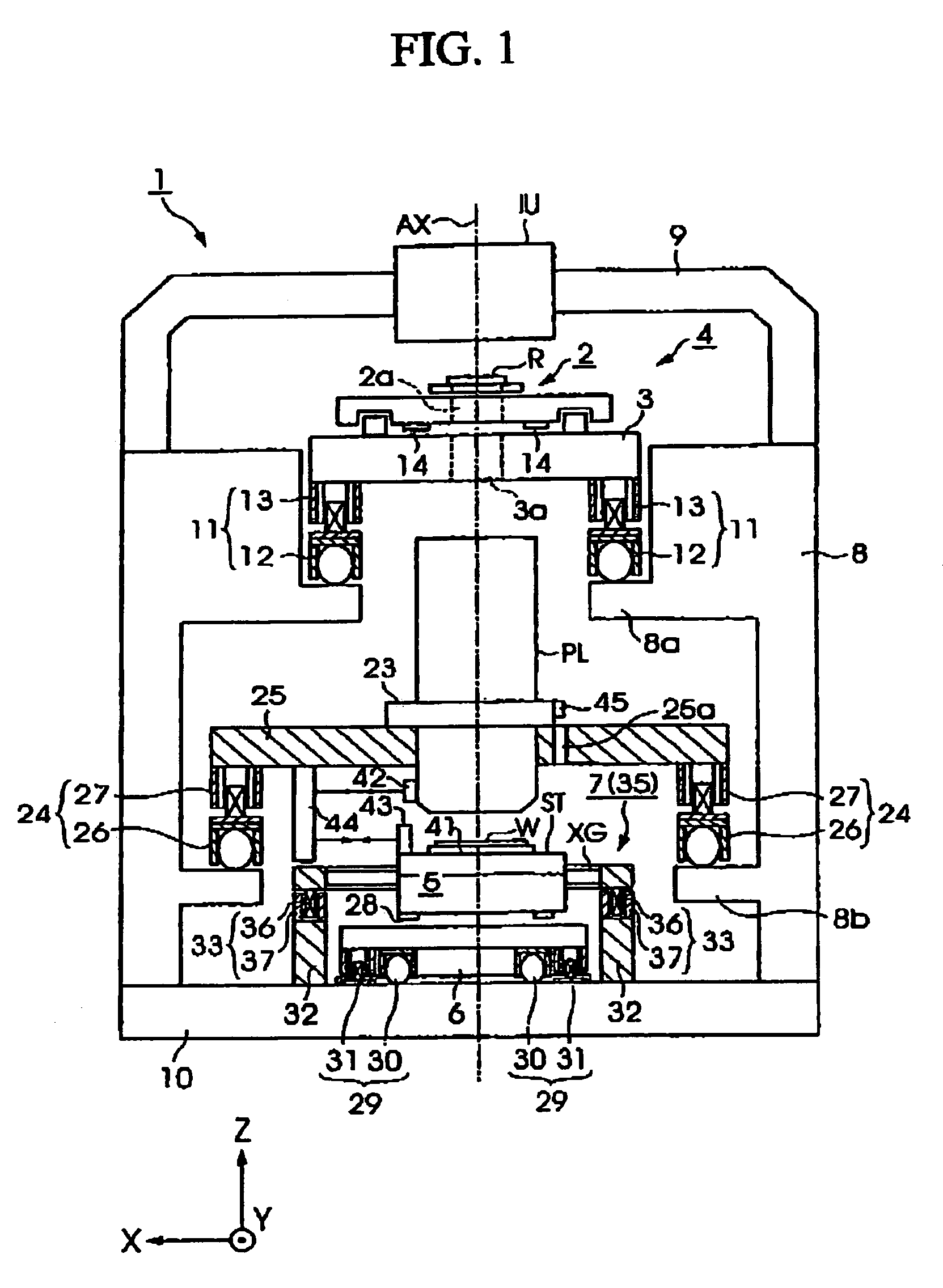

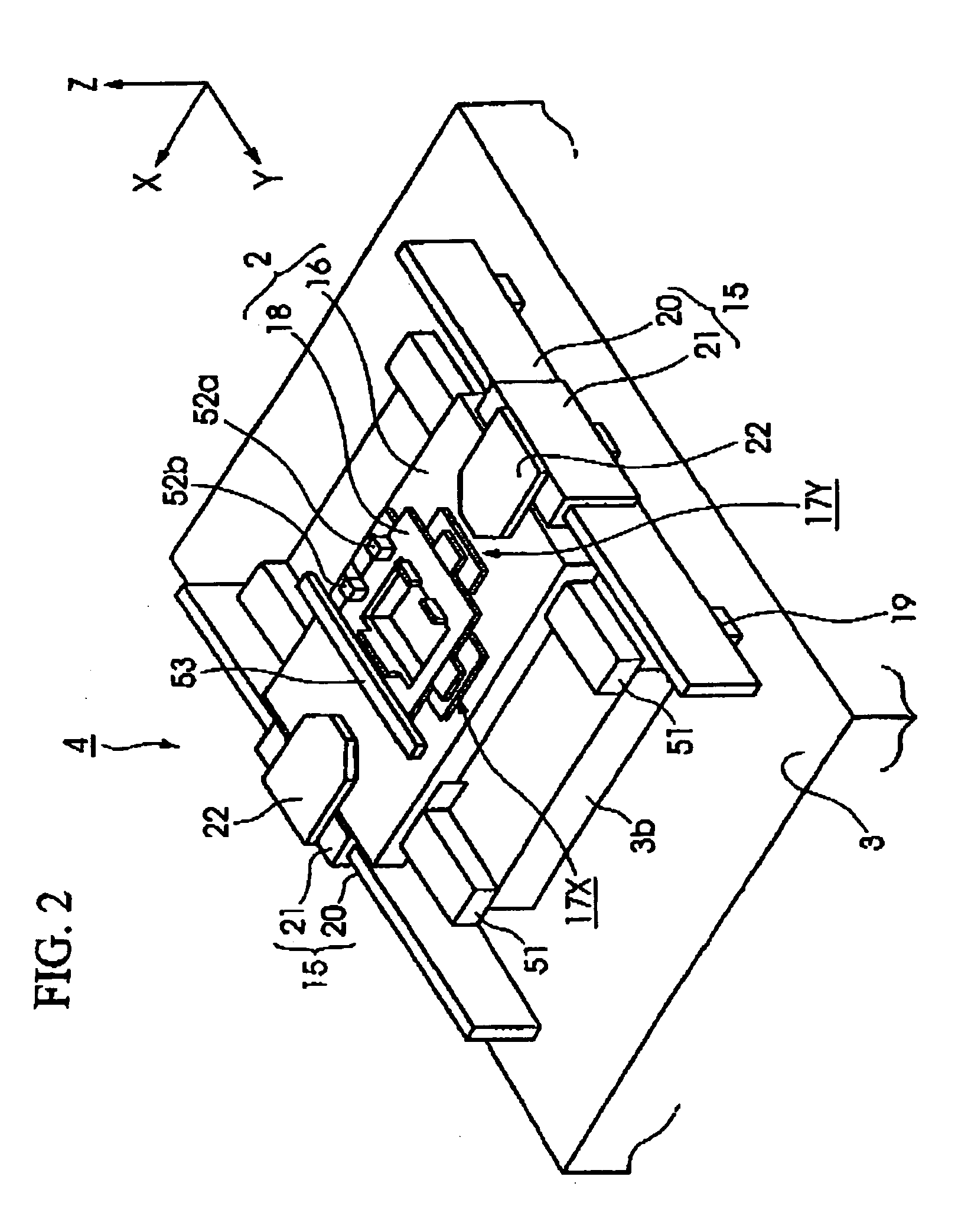

Exposure system and method for manufacturing device

InactiveUS20050140946A1Avoid it happening againReduce back pressurePhotomechanical exposure apparatusMicrolithography exposure apparatusTemperature controlCooling capacity

An exposure system is provided which can maintain a predetermined performance of the exposure apparatus stably by maintaining a cooling capacity by preventing a negative pressure from being generated in a circulation path of the liquid and preventing the back pressure from increasing even if at least a part of a temperature adjusting device is disposed under a disposition surface of the exposure apparatus due to the disposition area. A sealed tank which stores the cooling agent which is circulated in the circuiting systems and a pump, etc., which circulates the cooling agent are disposed under the disposition surface FL of the exposure system. The reticle stage and the wafer stage which are objects of which the temperature is supposed to be controlled are disposed above the disposition surface FL. A tank which open to air is provided so as to prevent the negative pressure from being generated in the reticle stage, etc. such that the tank and the tank are connected by a connecting piping arrangement. Also, the piping arrangement which eliminates the bubbles which are contained in the cooling agent which is circulated in the circulating systems are connected to the circulating systems.

Owner:NIKON CORP +1

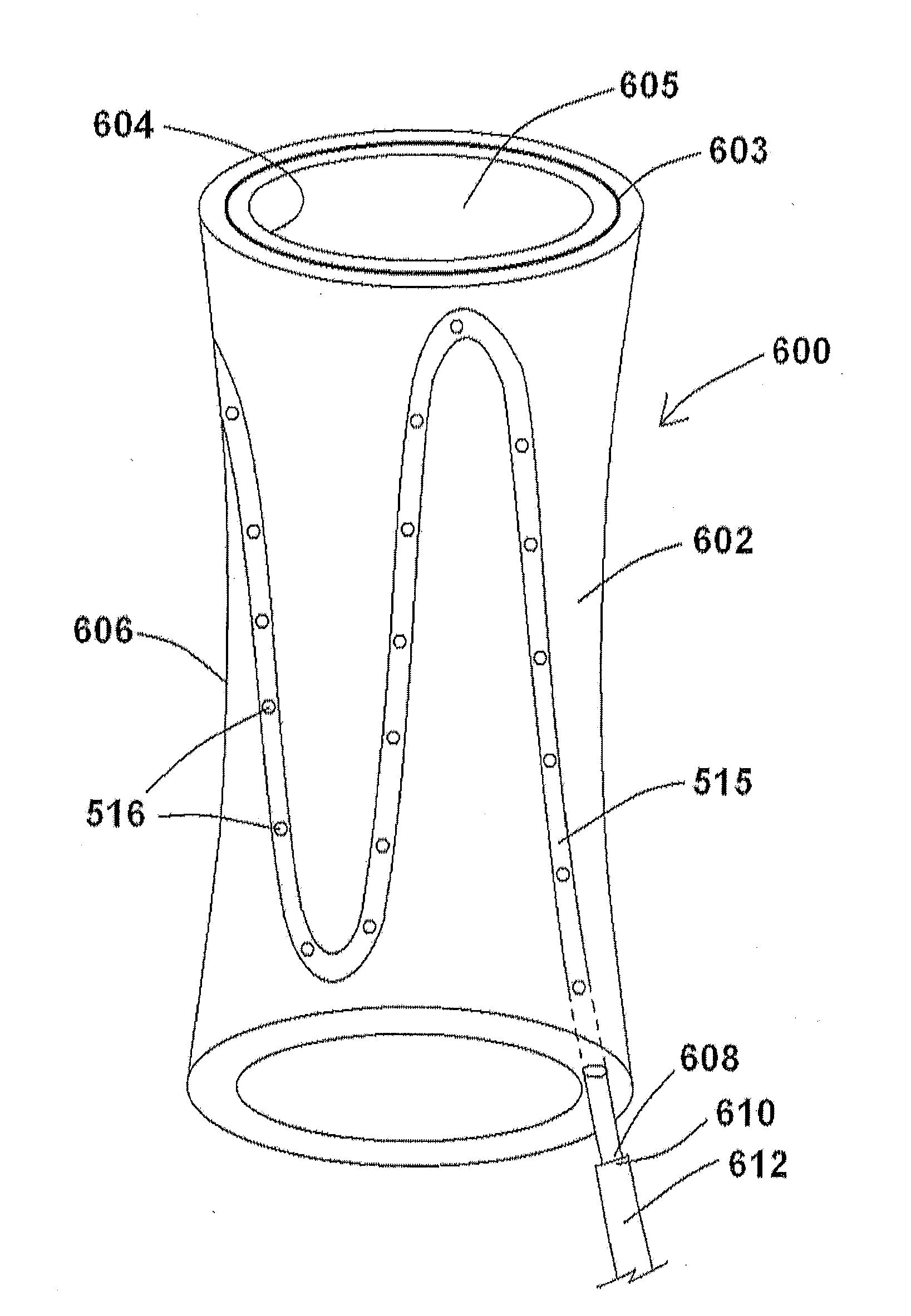

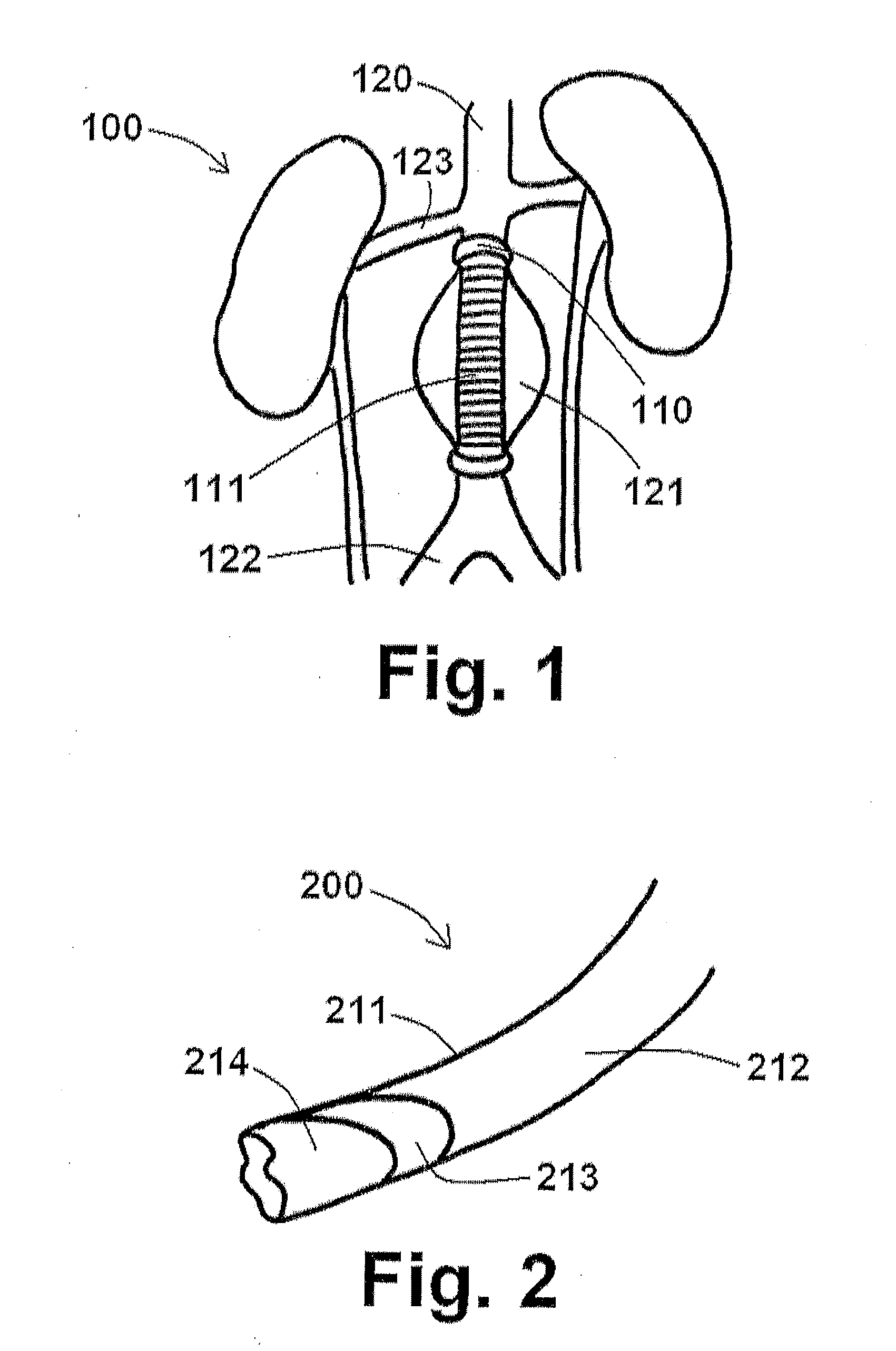

Endoprosthesis assemblies and methods for using the same

ActiveUS20110230952A1Minimizing and preventing and ruptureAvoid flowStentsDiagnosticsProsthesisOrgan of Zuckerkandl

Endoprosthesis assemblies and methods for using the same. In at least one embodiment of an endoprosthesis assembly of the present disclosure, the endoprosthesis assembly comprises an endoprosthesis comprising an impermeable inner wall defining an endoprosthesis lumen sized and shaped to permit fluid to flow therethrough, a distal balloon positioned at or near a distal end of the endoprosthesis, the distal balloon capable of inflation to anchor the distal end of the endoprosthesis within a luminal organ, and a proximal balloon positioned at or near a proximal end of the endoprosthesis, the proximal balloon capable of inflation to anchor the proximal end of the endoprosthesis within the luminal organ, wherein when the endoprosthesis assembly is positioned within the luminal organ at or near an aneurysm sac, inflation of the distal balloon and the proximal balloon effectively isolates the aneurysm sac and prevents fluid within the aneurysm sac from flowing past the distal balloon and the proximal balloon and into other areas of vasculature adjacent to the aneurysm sac.

Owner:CVDEVICES

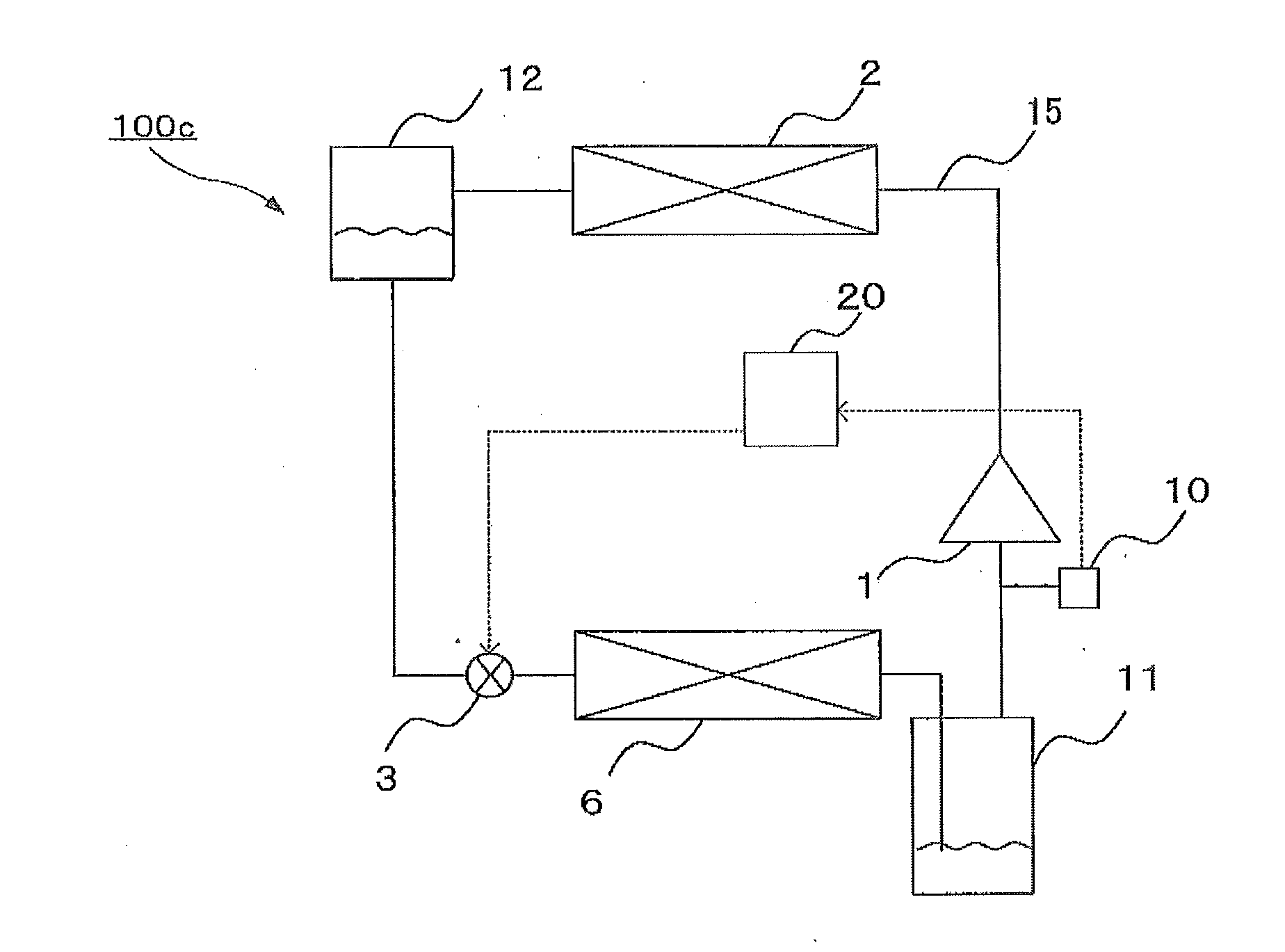

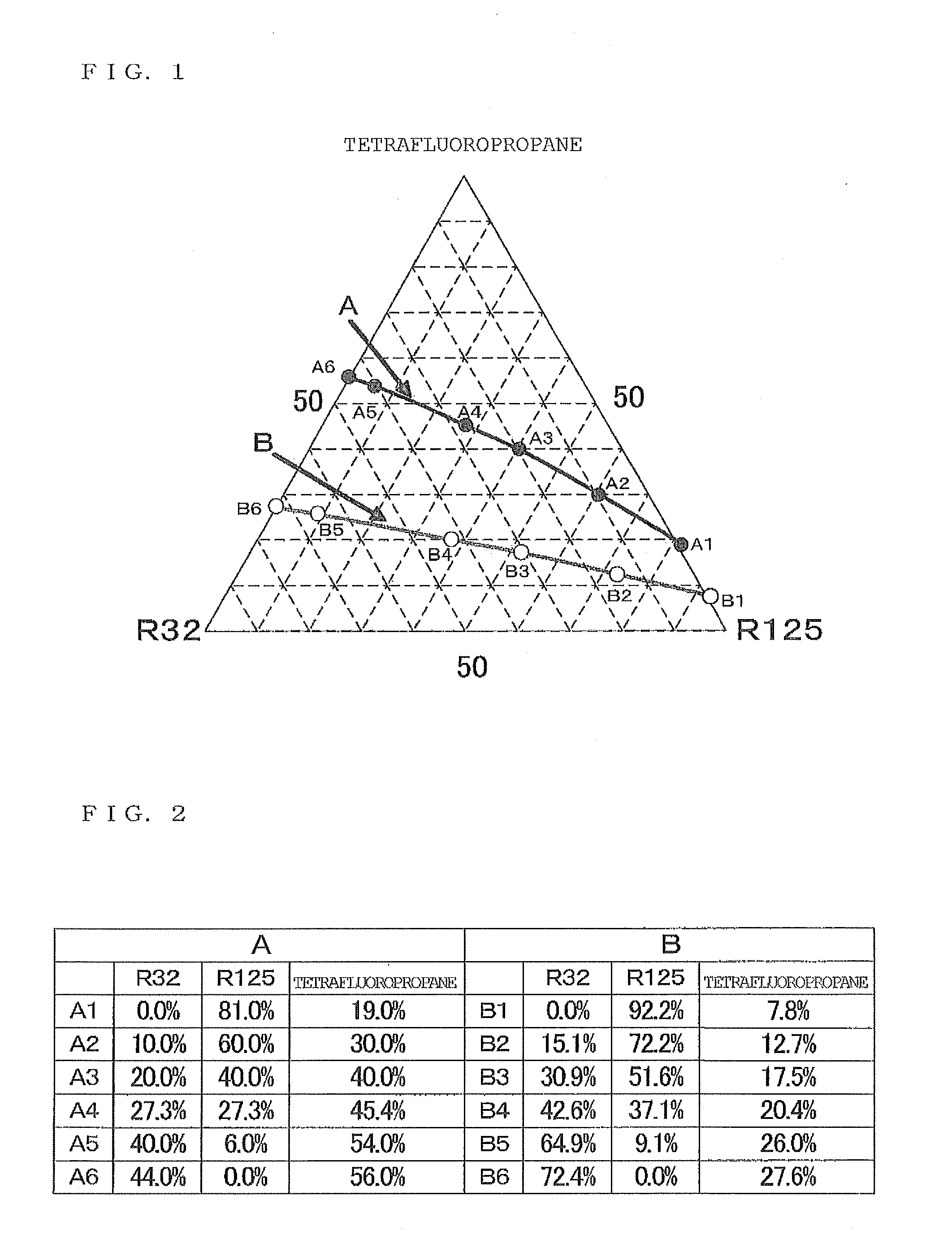

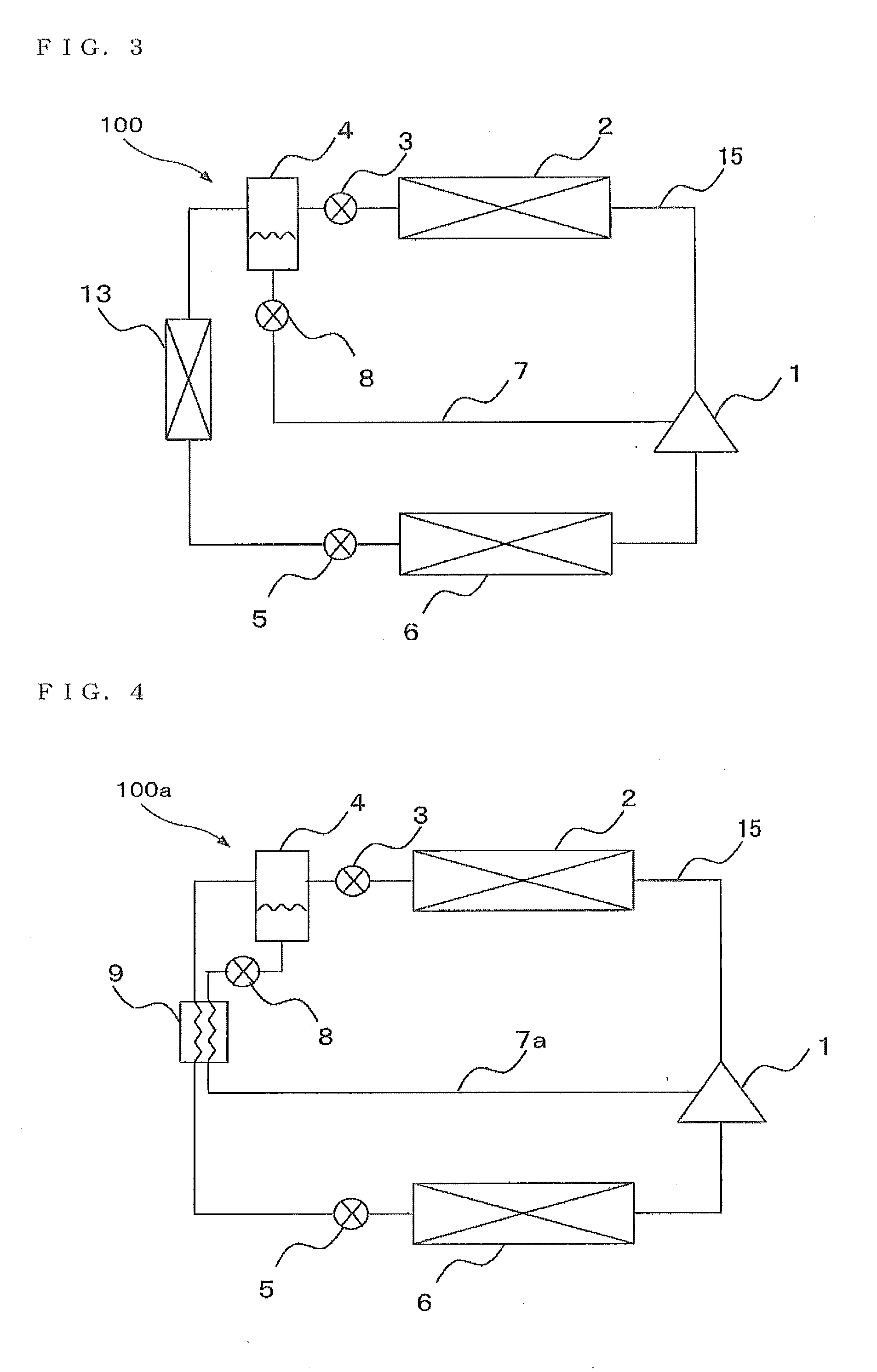

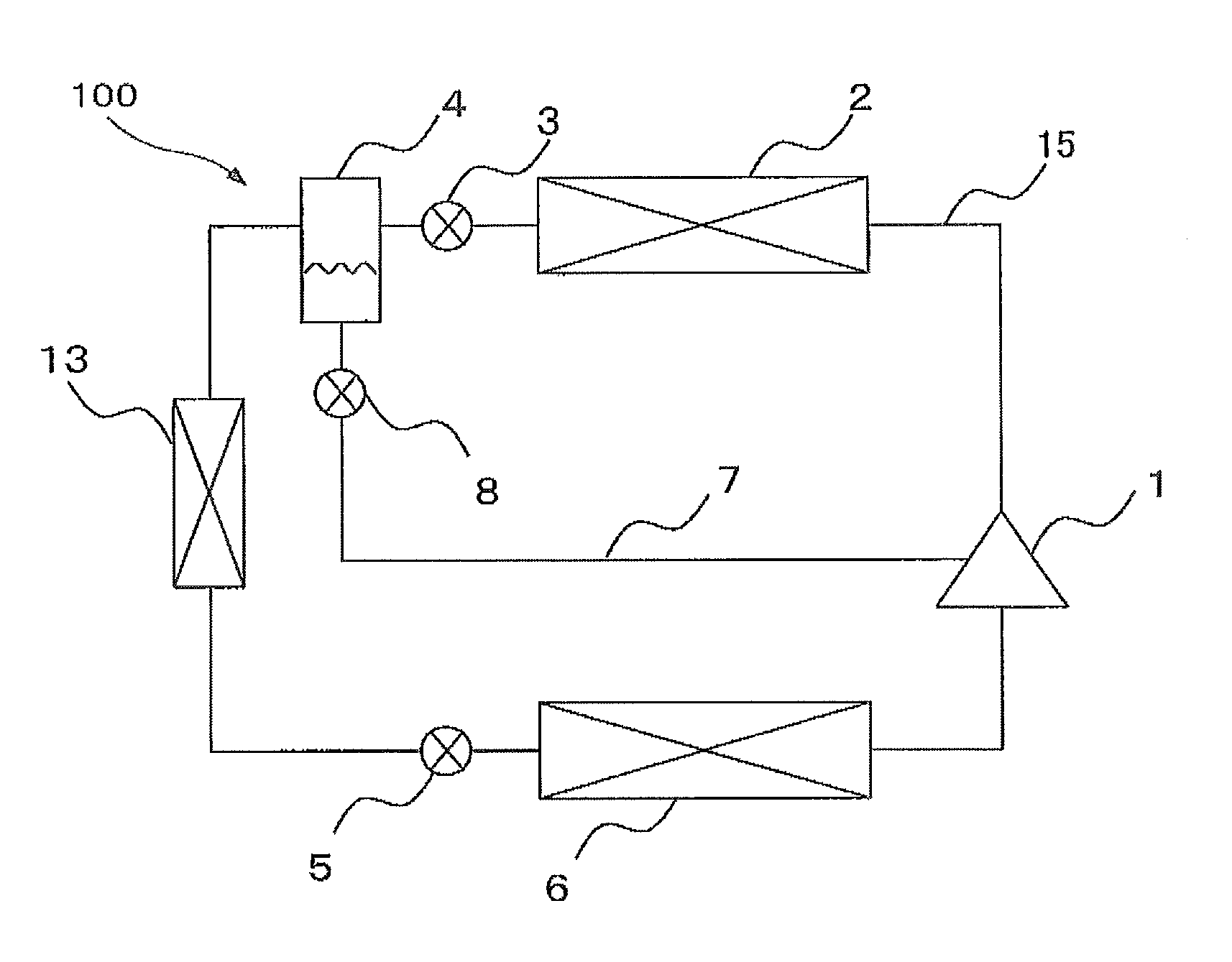

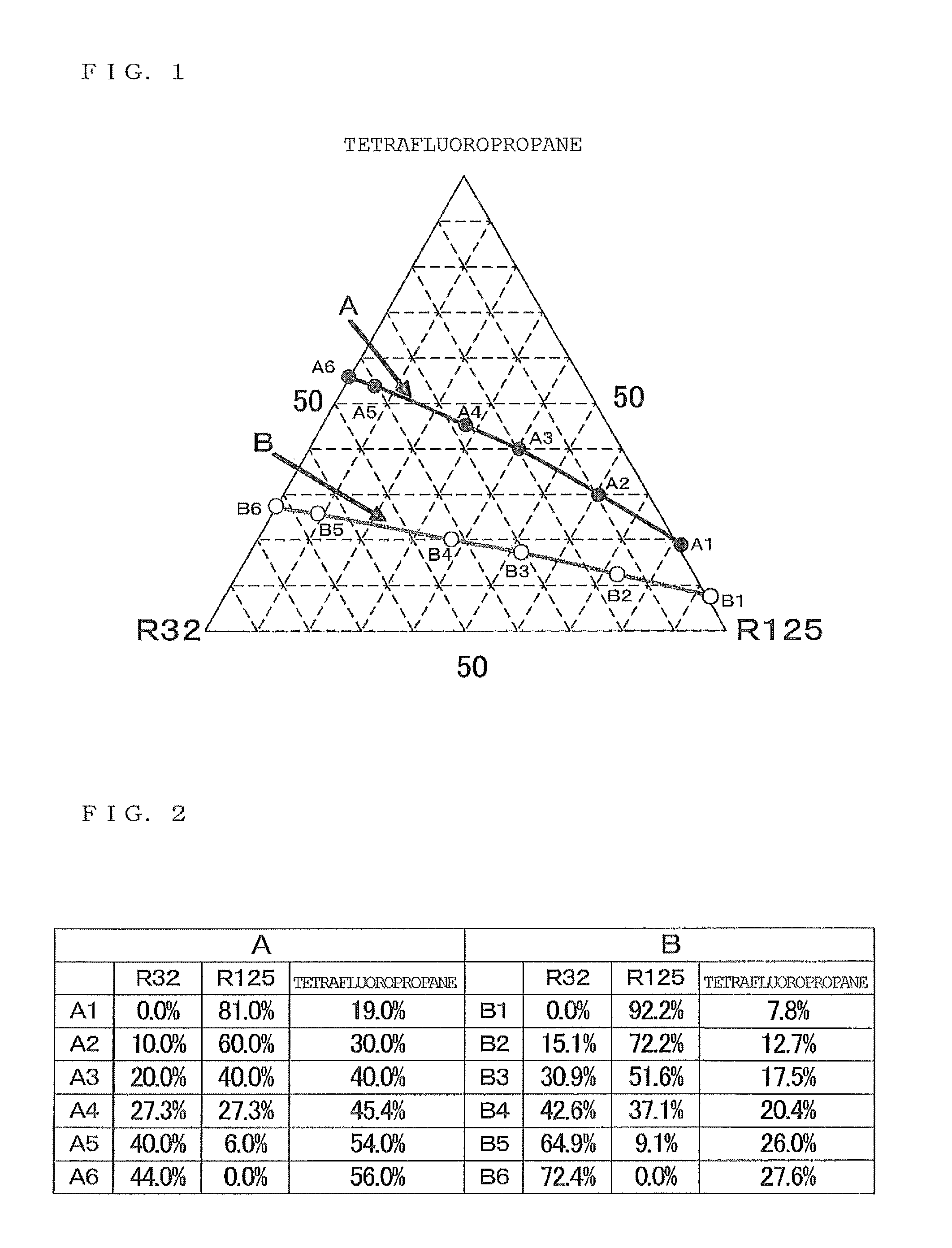

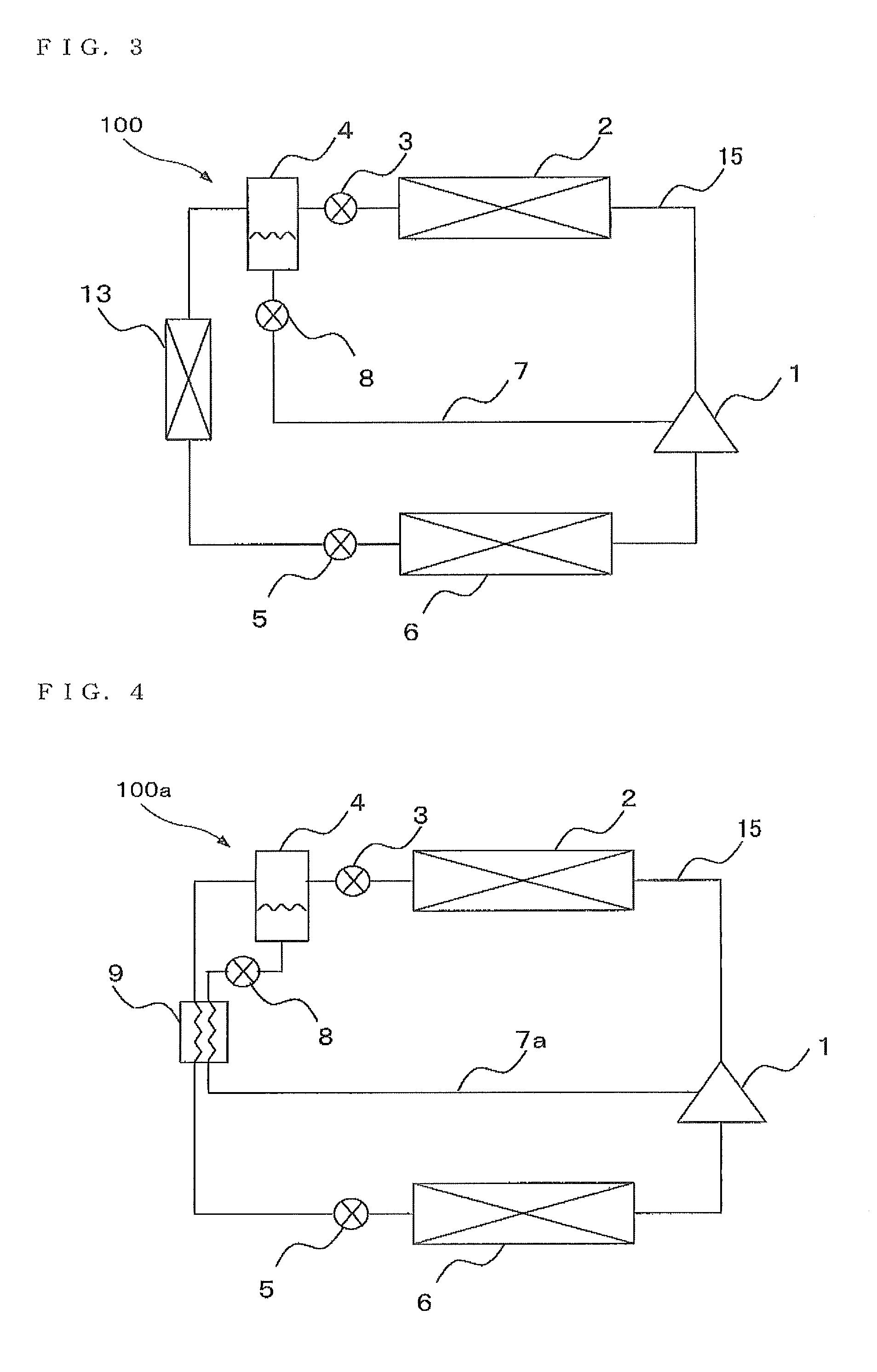

Non-azeotropic refrigerant mixture and refrigeration cycle apparatus

ActiveUS20110079042A1Avoid negative pressureGuaranteed uptimeCompression machines with non-reversible cycleHeat-exchange elementsBoiling pointEngineering

Disclosed is a non-azeotropic refrigerant mixture containing tetrafluoropropane as a high-boiling refrigerant and a refrigeration cycle apparatus in which a non-azeotropic refrigerant mixture containing tetrafluoropropane as a high-boiling refrigerant circulates through a refrigeration cycle so as to avoid occurrence of negative pressure in a low-pressure circuit.The non-azeotropic refrigerant mixture is characterized in that a mixing ratio of a high-boiling refrigerant and a low-boiling refrigerant is determined so that a saturated vapor line where pressure is 0.00 MPa is not higher than −45° C. in a low-pressure circuit formed between the decompressor to the compressor.

Owner:MITSUBISHI ELECTRIC CORP

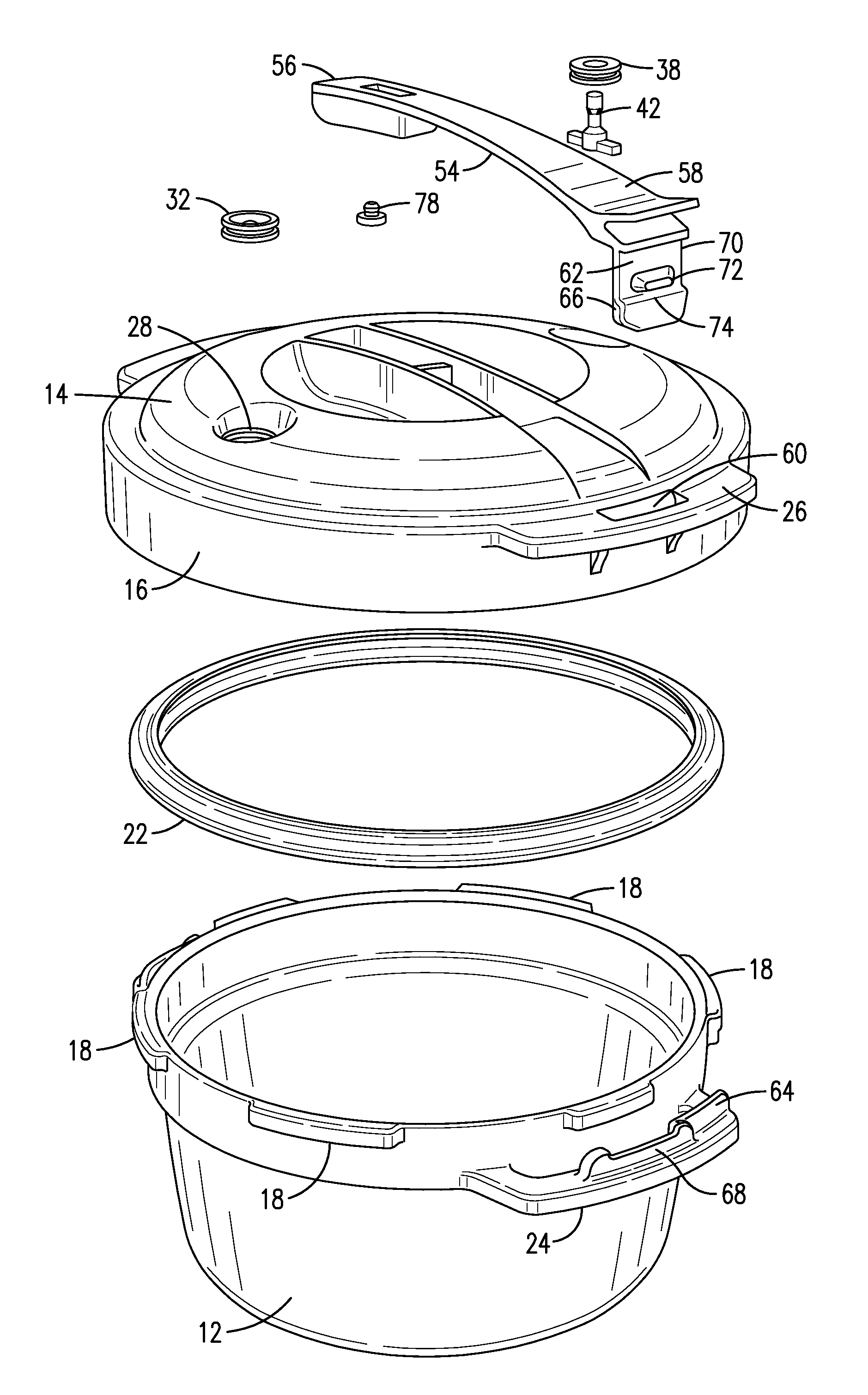

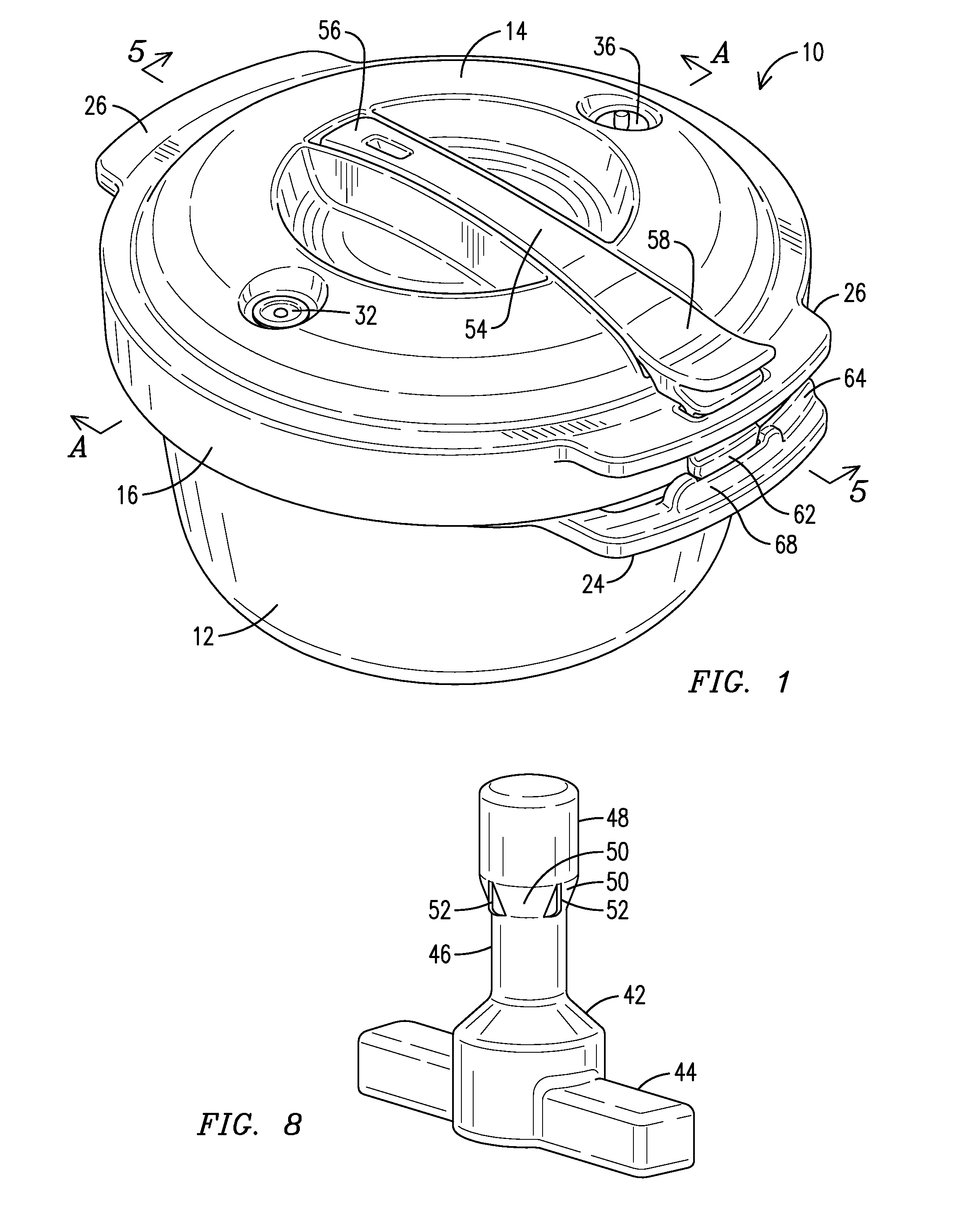

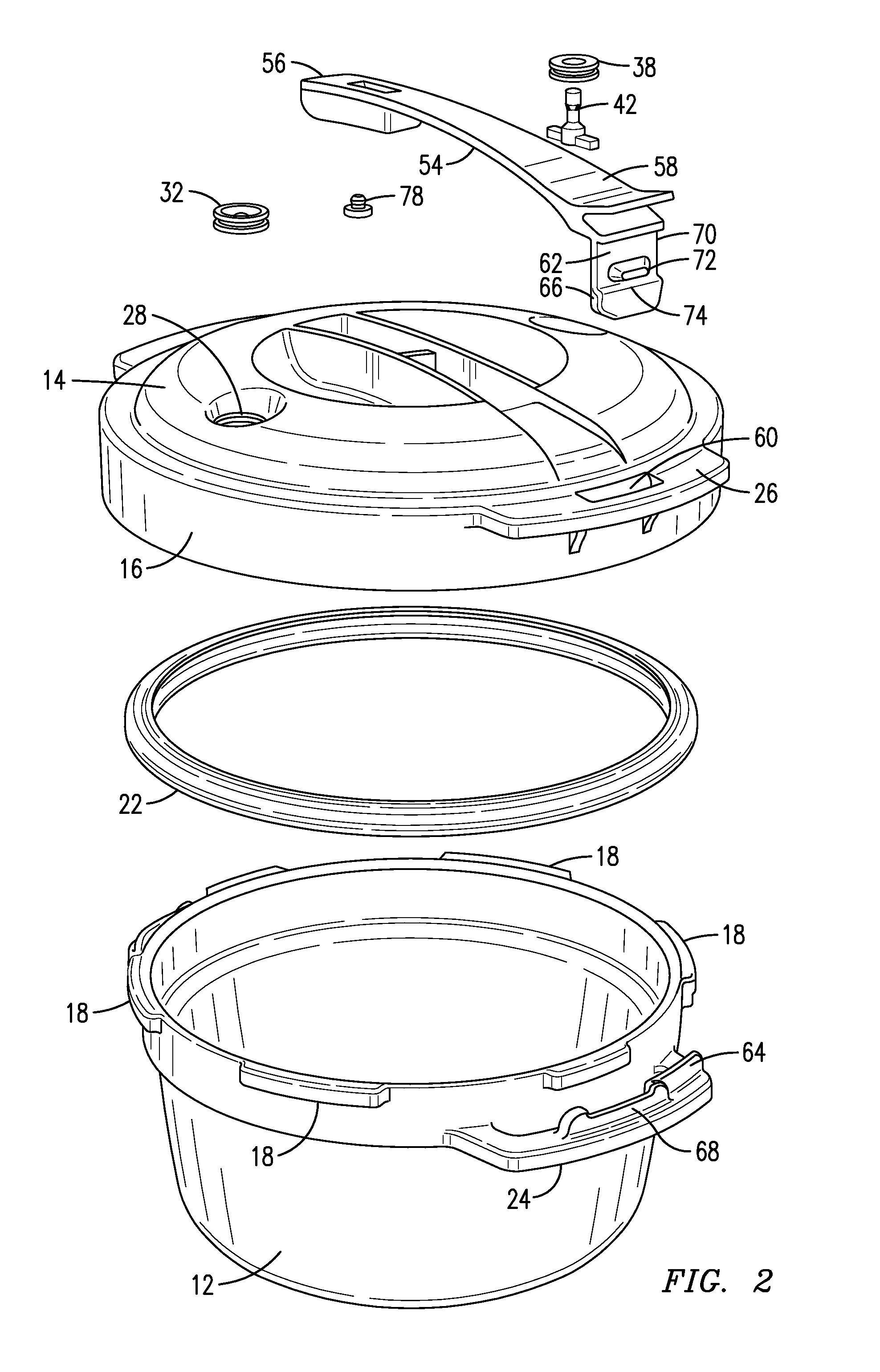

Microwave pressure cooker

ActiveUS20140339223A1Prevent openingAvoid negative pressureMicrowave heatingPressure-cookersInternal pressureEngineering

Microwave pressure cooker including safety interlock mechanism. A blow vent is provided in cooker lid, and a lock bar is pivoted to cooker lid in a position to block blow vent when lock bar is resting under its own weight. Free end of lock bar includes a lock tab. Lock tab extends through a slot at periphery of lid. Cooker base includes handle with a cam section ending in a lock wall. Cooker lid is placed on base in a release position and rotated to a locking position. During rotation lock tab rides over cam section and then falls adjacent lock wall, thus sealing blow vent. After cooking cover is physically prevented from rotating back to release position by lock tab abutting lock wall. User must physically lift lock bar to unseal blow vent to ensure internal pressure is released. A spline may hold lock bar in raised position.

Owner:DART IND INC

Lubricating oil supplying system for internal combustion engine

InactiveUS7331323B2Simplifying the hydraulic circuitAvoid developmentEqualizing valvesSafety valvesControl signalExternal combustion engine

Owner:HITACHI LTD

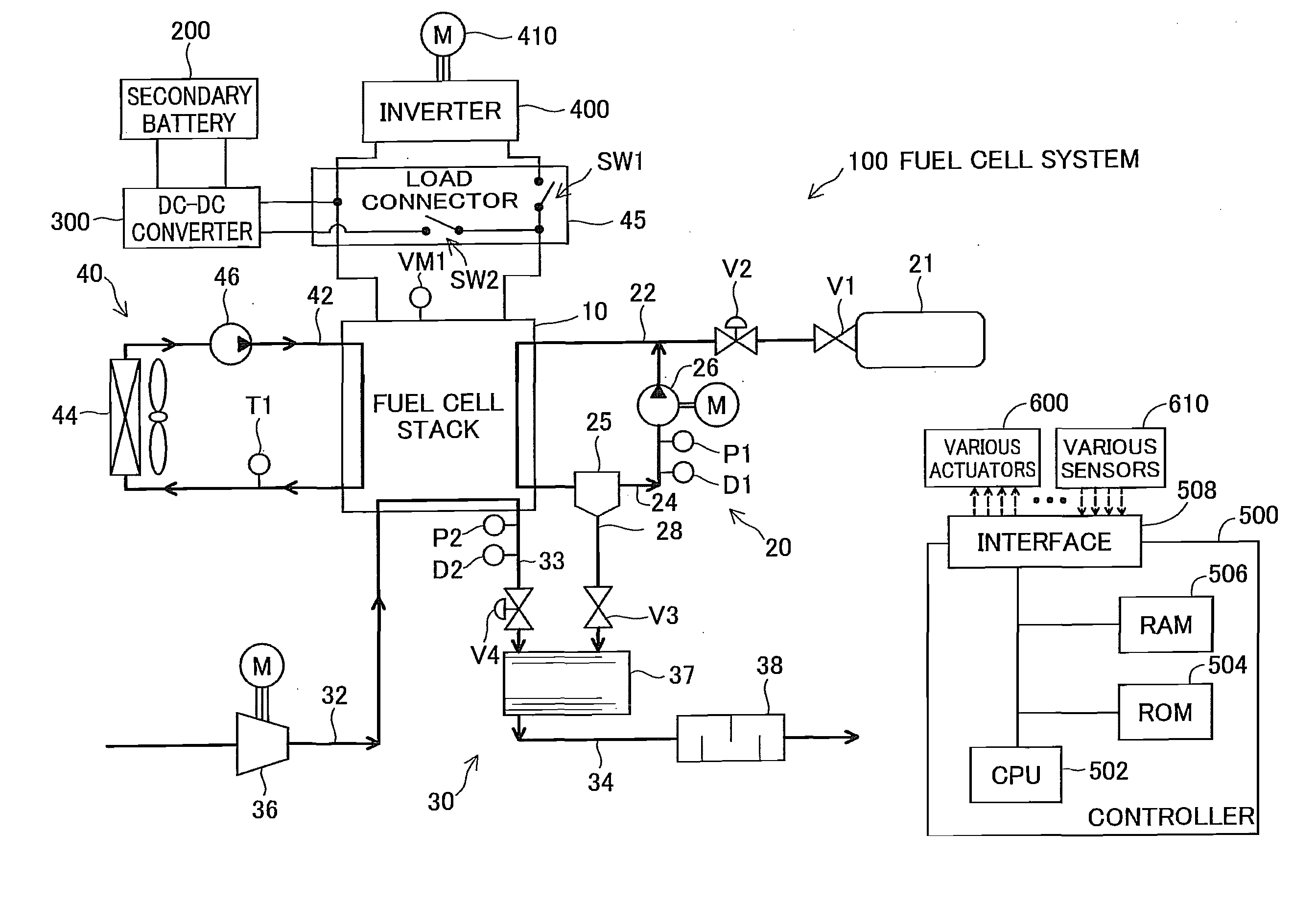

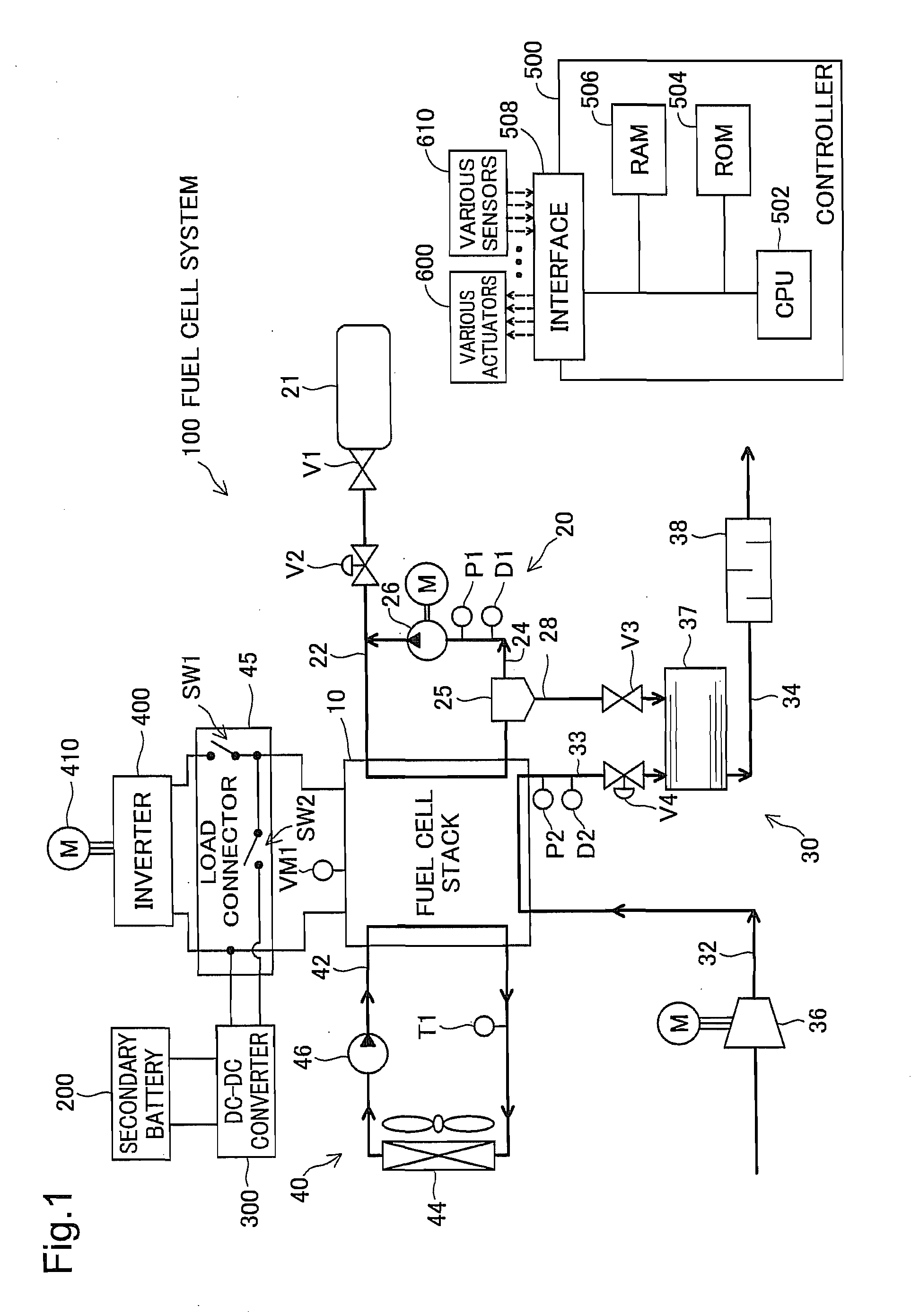

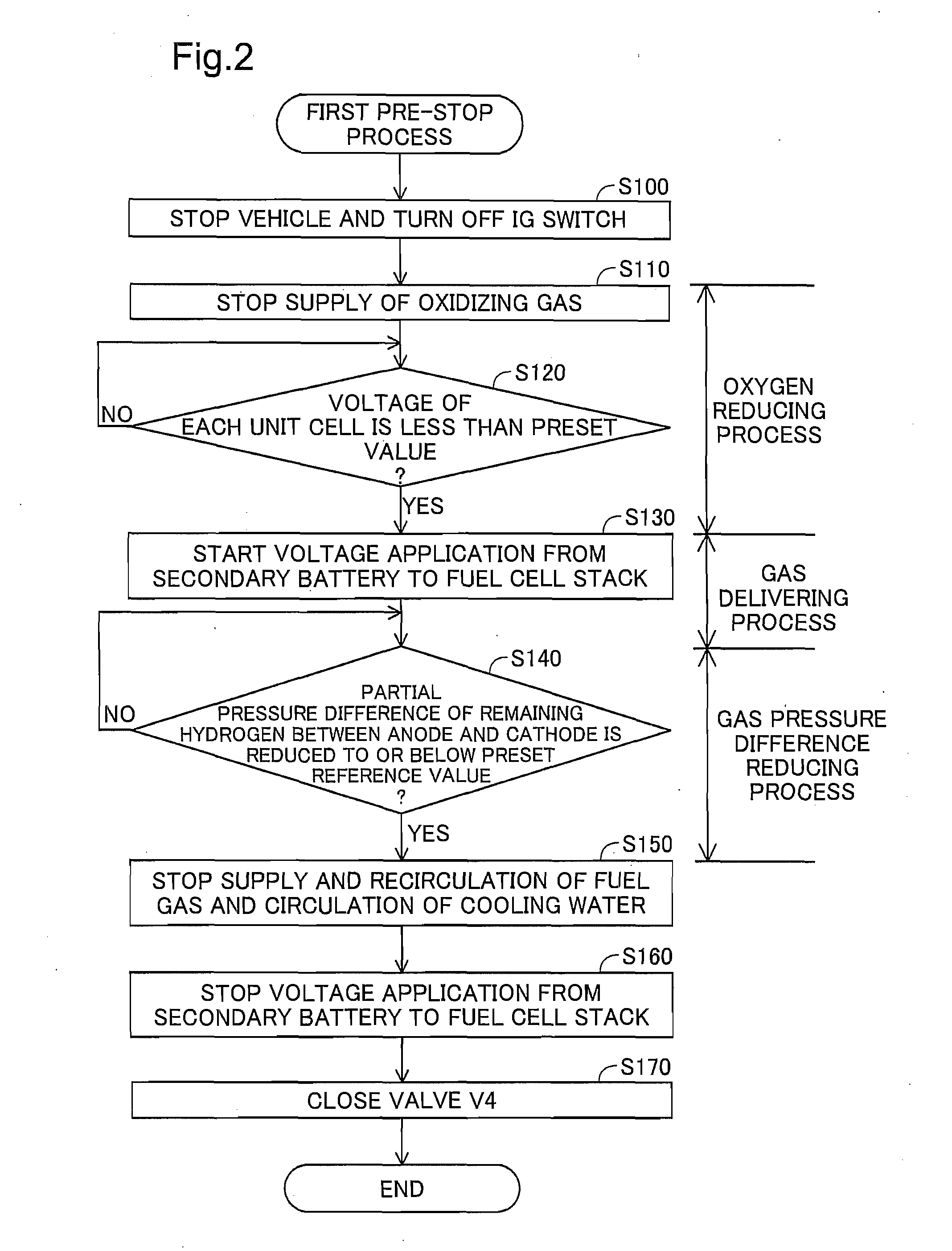

Fuel cell system and method of stopping fuel cell system

ActiveUS20120276460A1Reduce variationPrevent oxidationFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsGas supply

In a fuel cell system, a controller is programmed to control a first gas supply mechanism to deliver a first gas containing a fuel gas to a cathode in a pre-stop process performed at a system stop of the fuel cell system. The controller is programmed to control the first gas supply mechanism to stop the delivery of the first gas in a first state where a partial pressure difference between an anode and the cathode with respect to at least the fuel gas of remaining gases in the anode and in the cathode is reduced to or below a preset reference value.

Owner:TOYOTA JIDOSHA KK

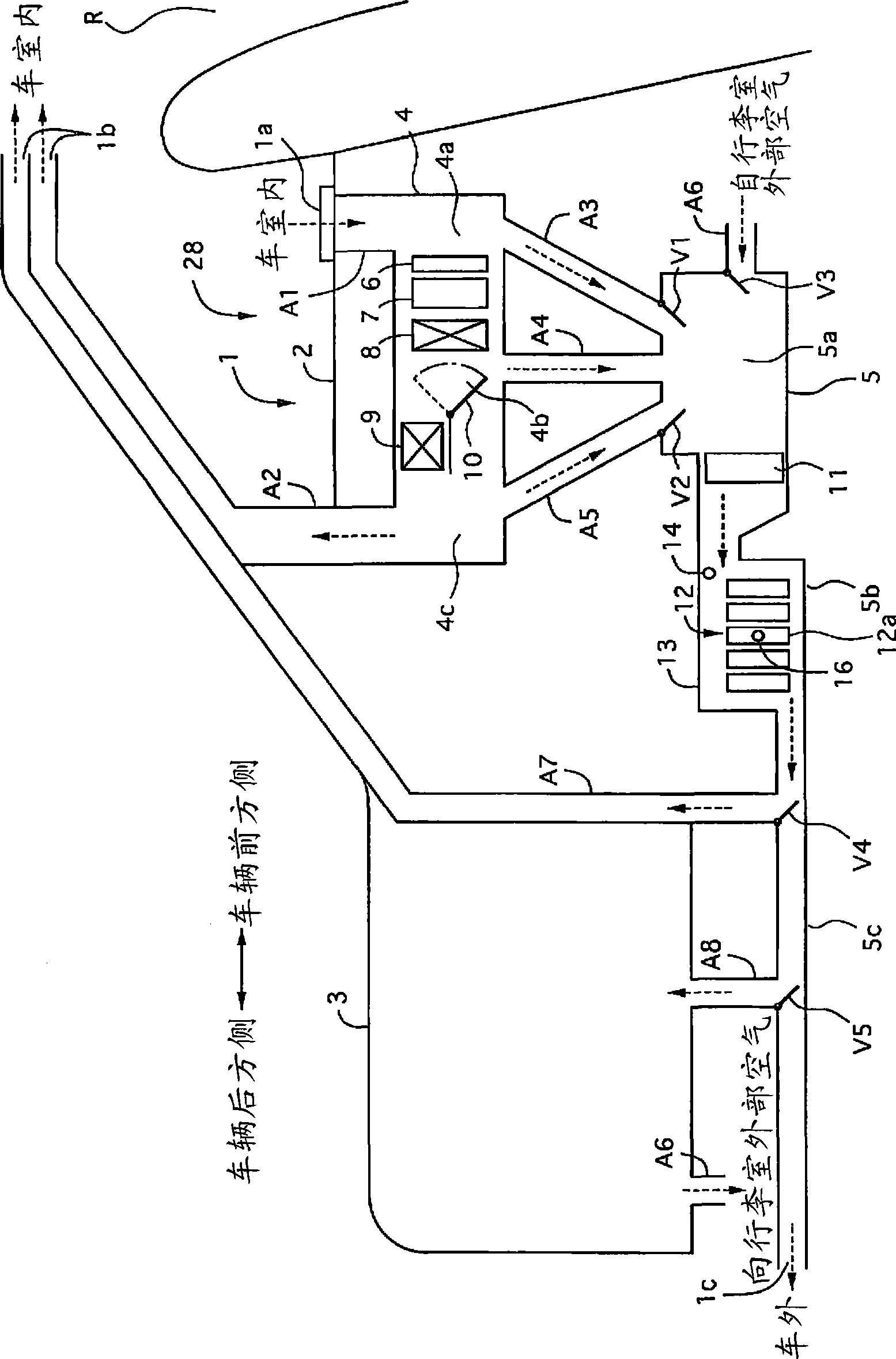

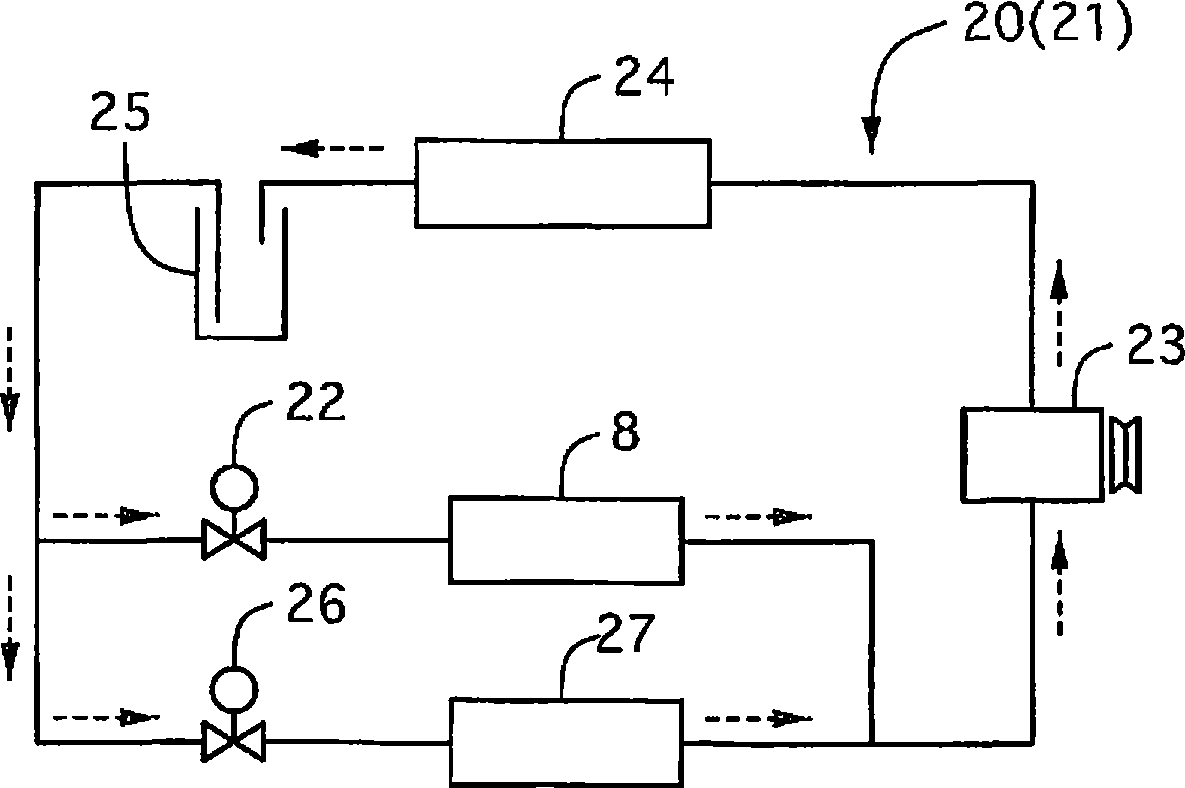

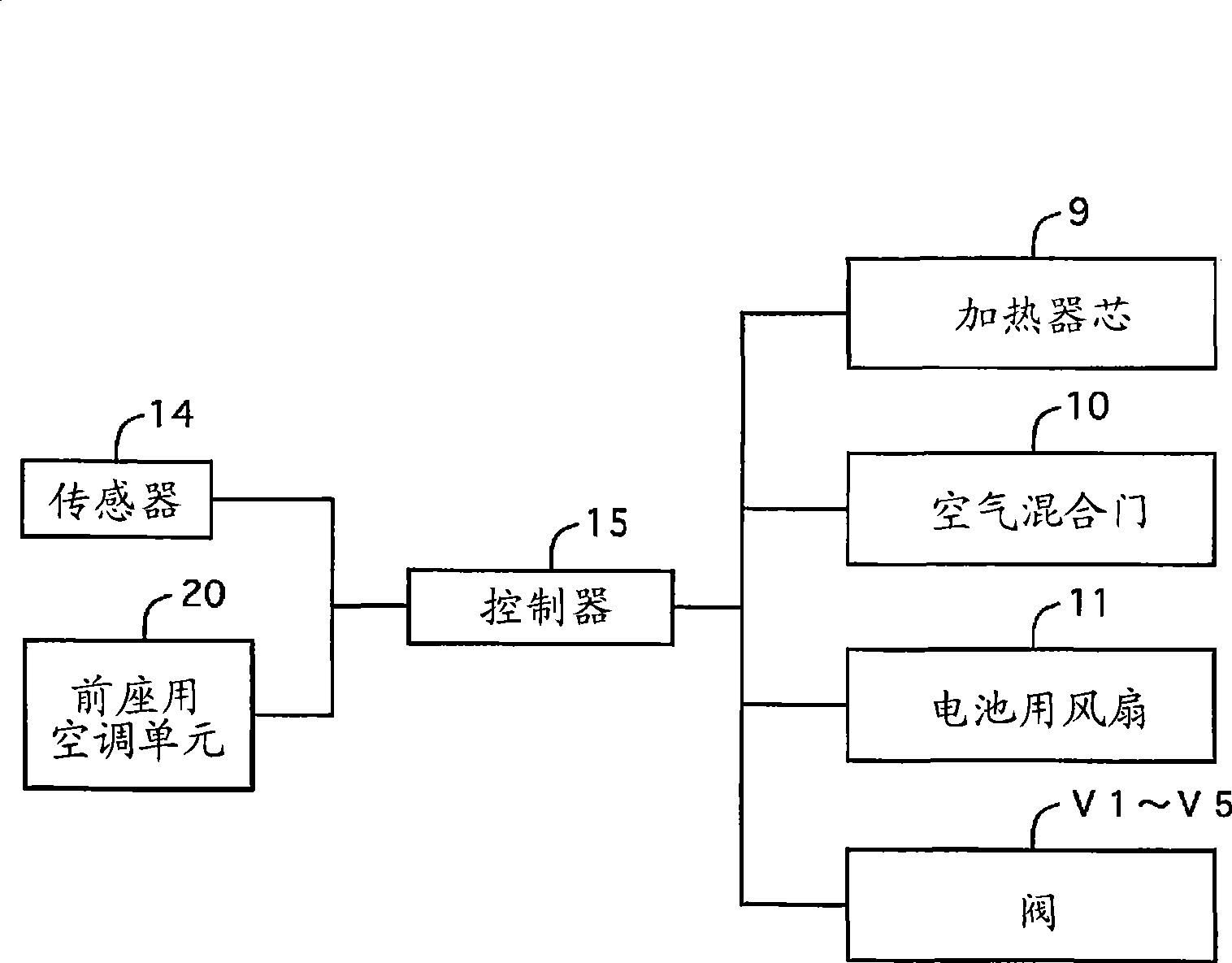

Battery temperature control device of vehicle

InactiveCN101468588AA/C efficiency dropsAvoid negative pressureAir-treating devicesElectric devicesTemperature controlEngineering

Owner:CALSONIC KANSEI CORP

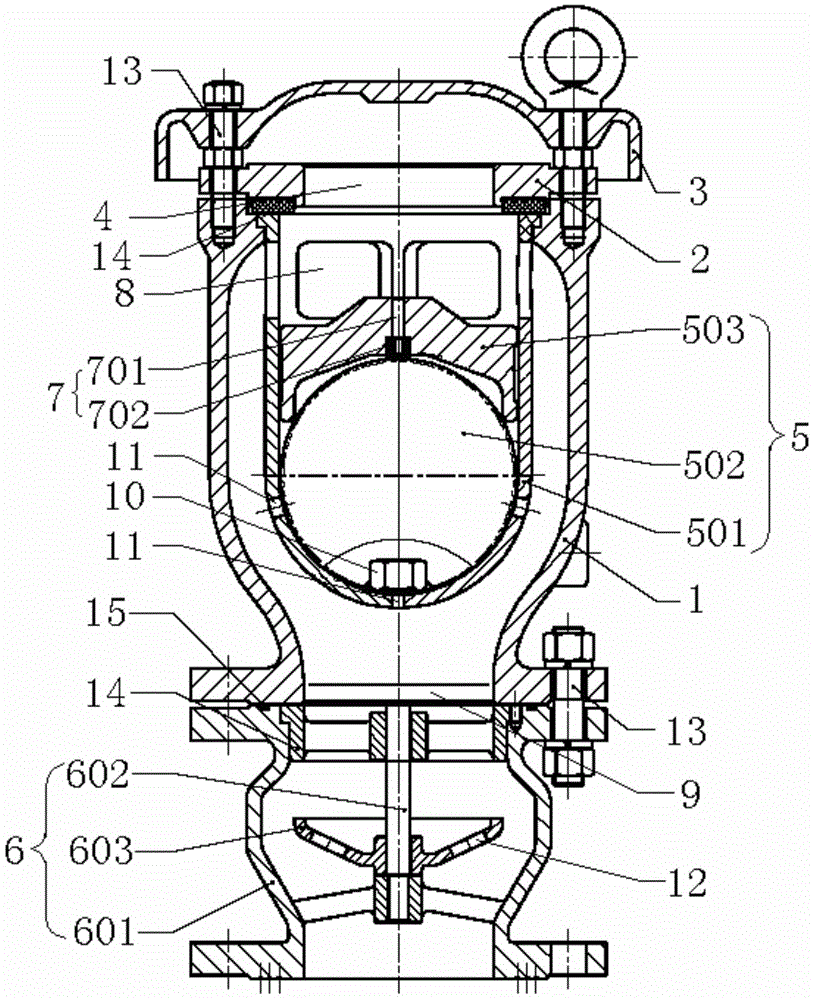

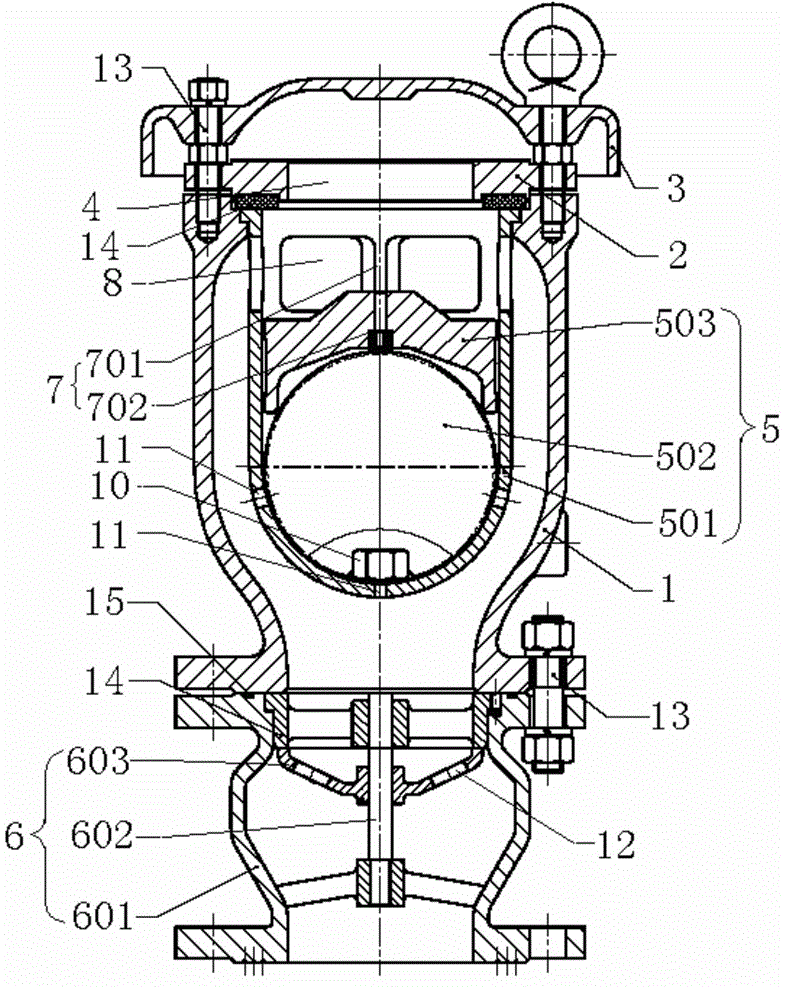

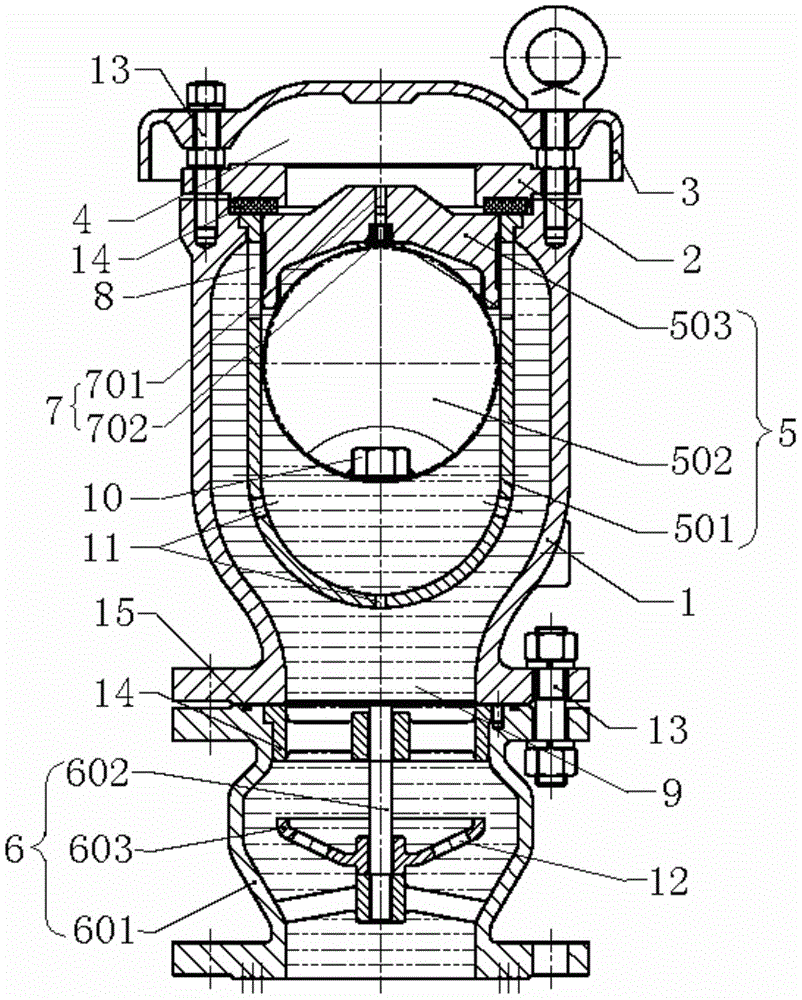

Water hammer air valve and water hammer gas discharging method during pipeline use

ActiveCN104896184AAvoid blowingAvoid air blockageValve members for absorbing fluid energyPipe elementsEngineeringWater hammer

The invention discloses a water hammer air valve and a water hammer gas discharging method during pipeline use. The water hammer air valve comprises a valve body, a bonnet and a protective cover, wherein the bonnet is provided with an opening, the protective cover is disposed on the opening, the valve body is provided with a valve opening for being communicated with a pipeline, a high-speed gas feeding and discharging device which is used for discharging gases stayed in the pipeline during water filling to the outside and shutting down the valve after pipeline water filling is completed is disposed in the inner cavity of the valve body, the output end of the high-speed gas feeding and discharging device is communicated with the outside through the opening of the bonnet, and the valve opening of the valve body is communicated with a bottom gas discharging throttling device for limiting the gas displacement of the pipeline to the inner cavity of the valve body; a trace gas discharging device for discharging mixed, residual and / or precipitated gases in the pipeline to the outside through the opening of the bonnet after the high-speed gas feeding and discharging device shuts down the valve is further disposed in the high-speed gas feeding and discharging device. By the water hammer air valve, water hammer reduction and pipeline safety protection are achieved, blowing blocking during high-speed gas discharging is avoided, and valve closing water hammer is eliminated.

Owner:ZHUZHOU SOUTHERN VALVE

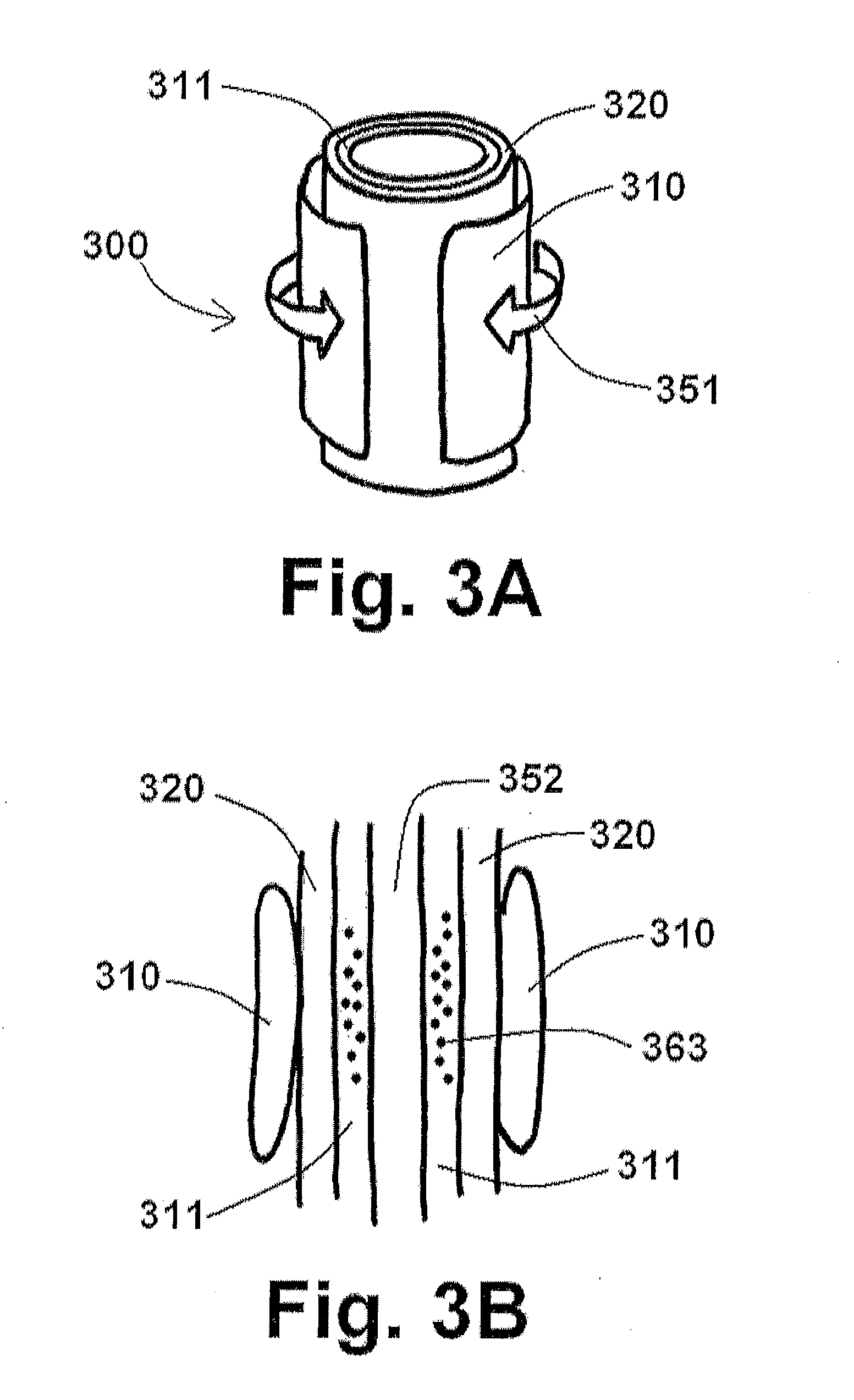

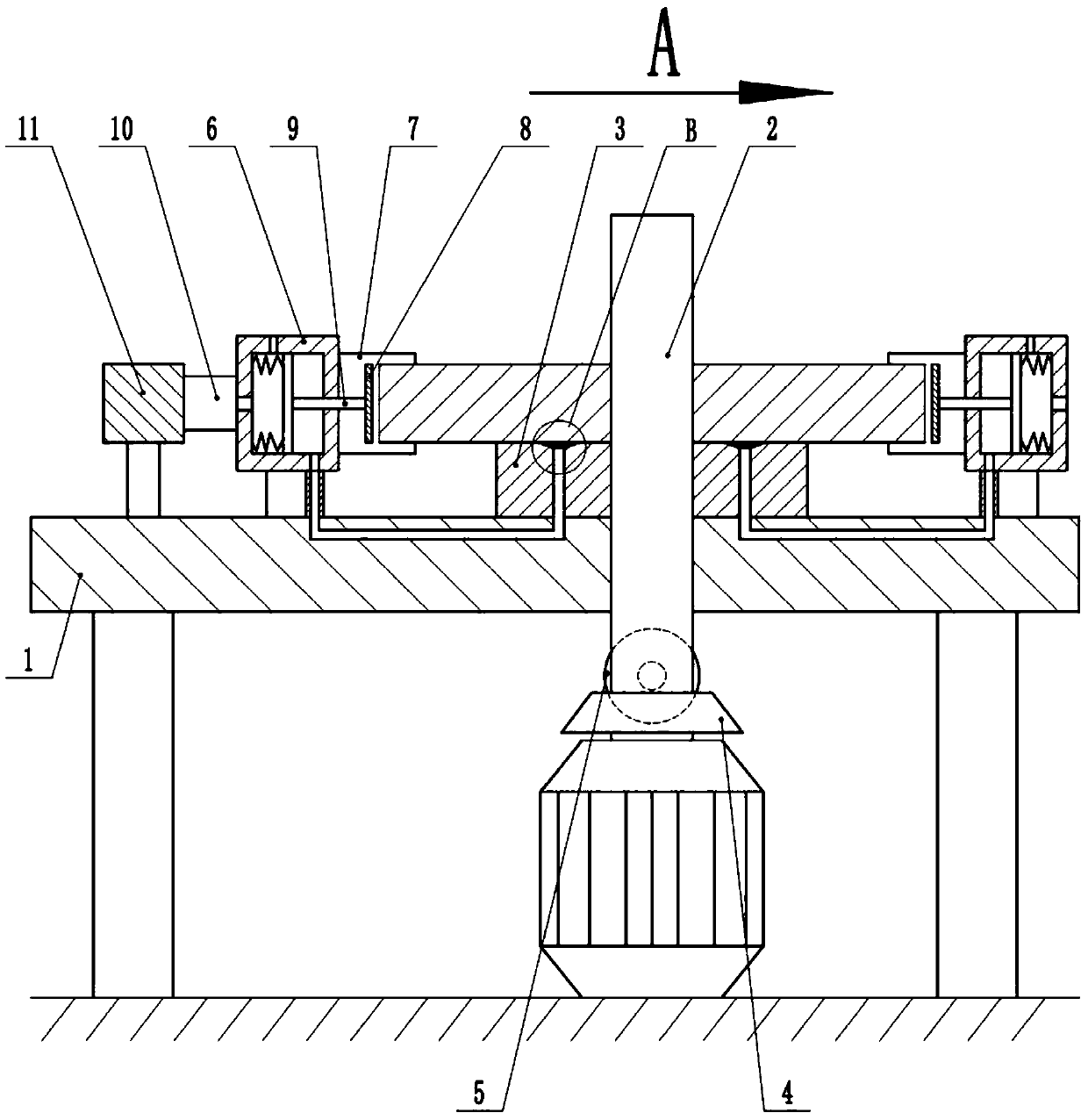

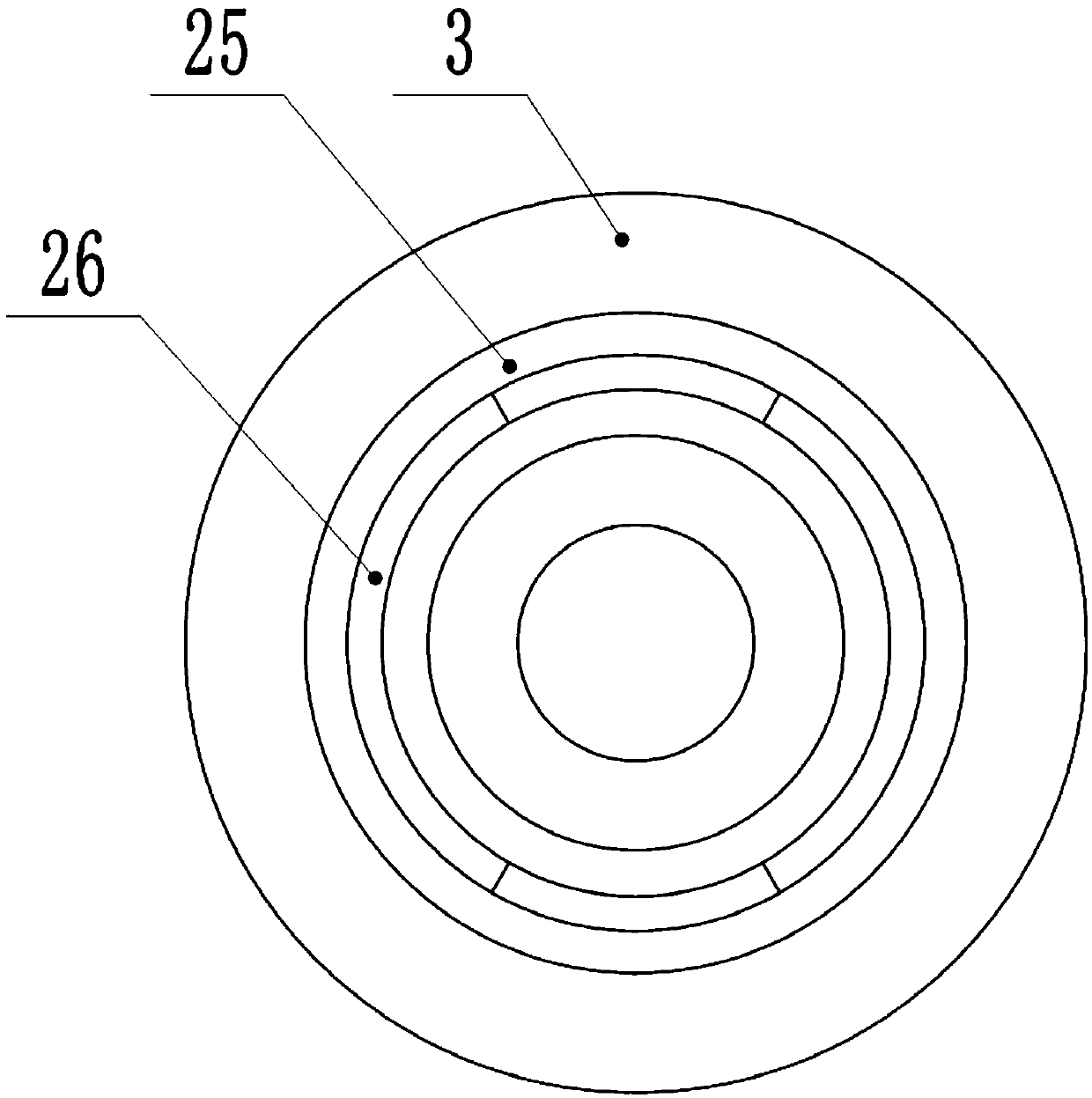

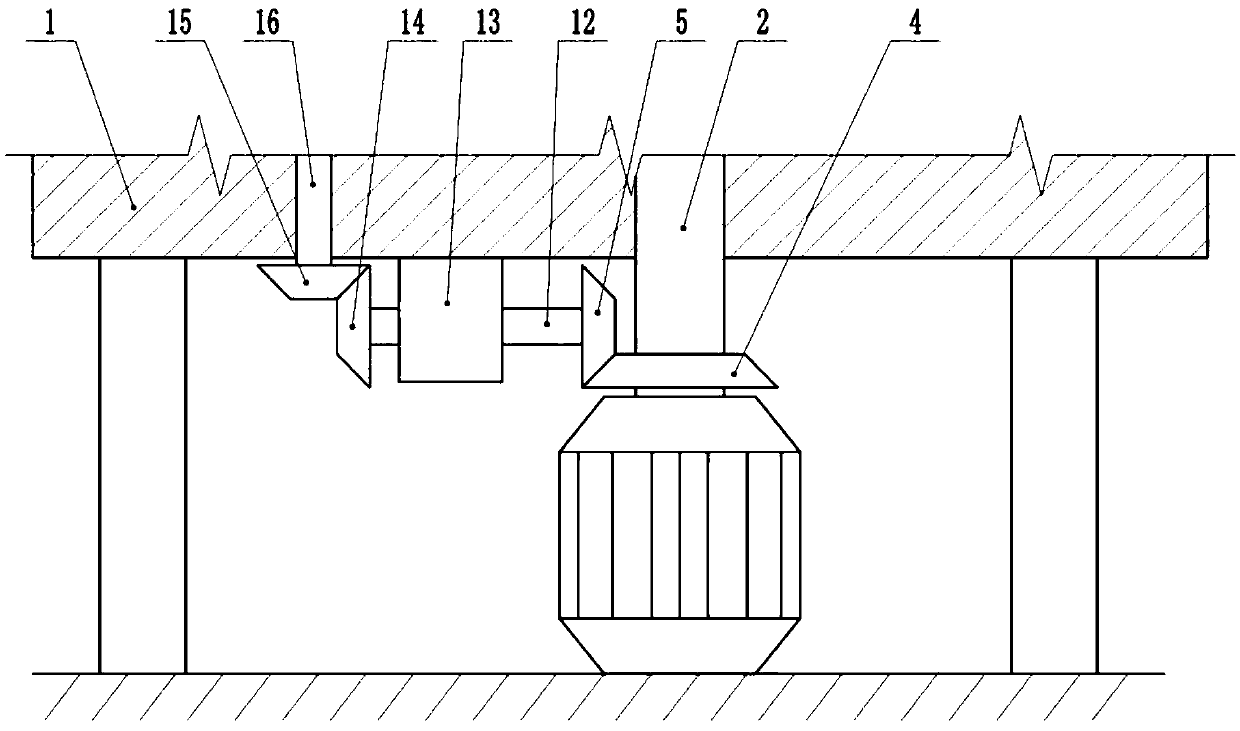

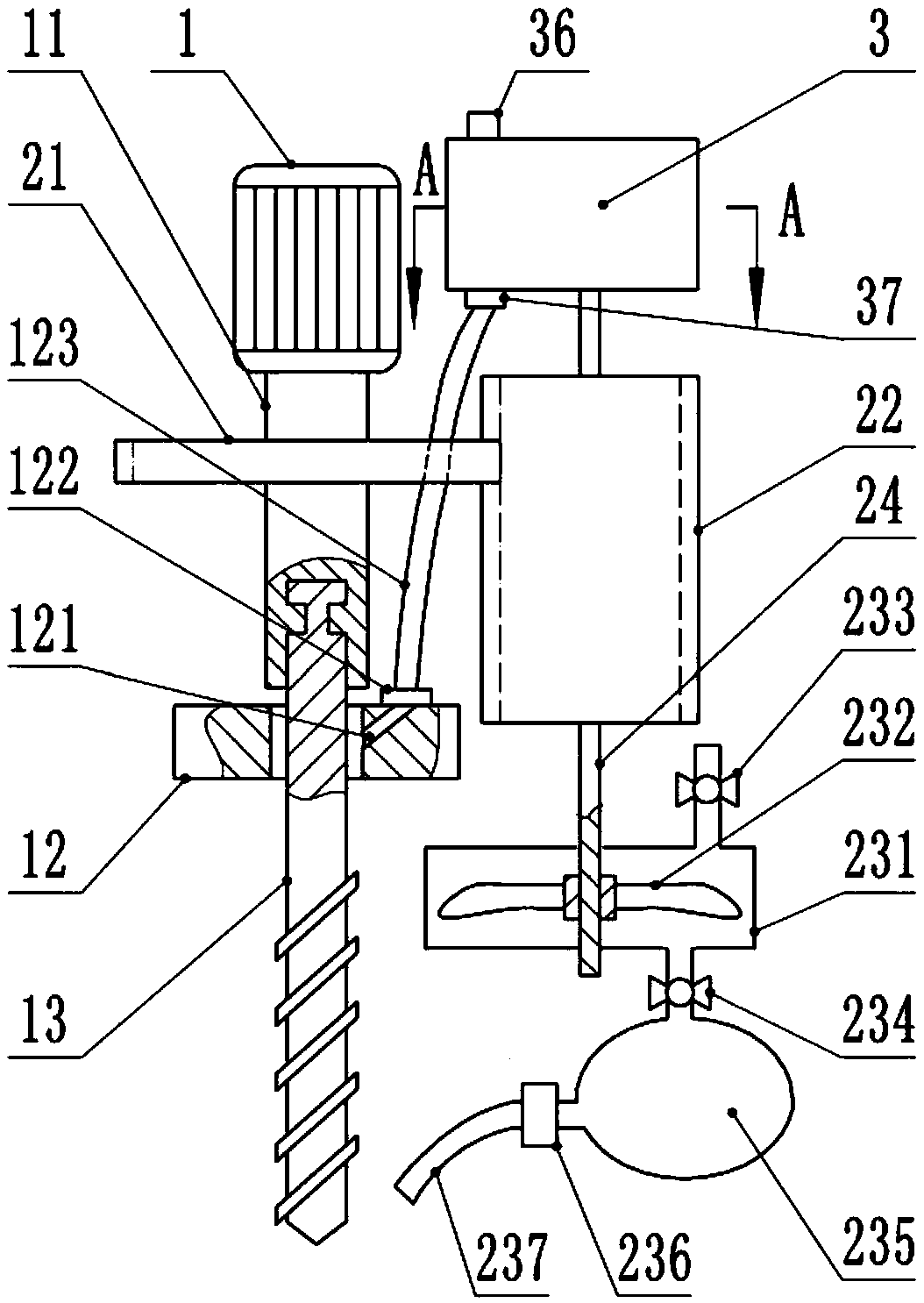

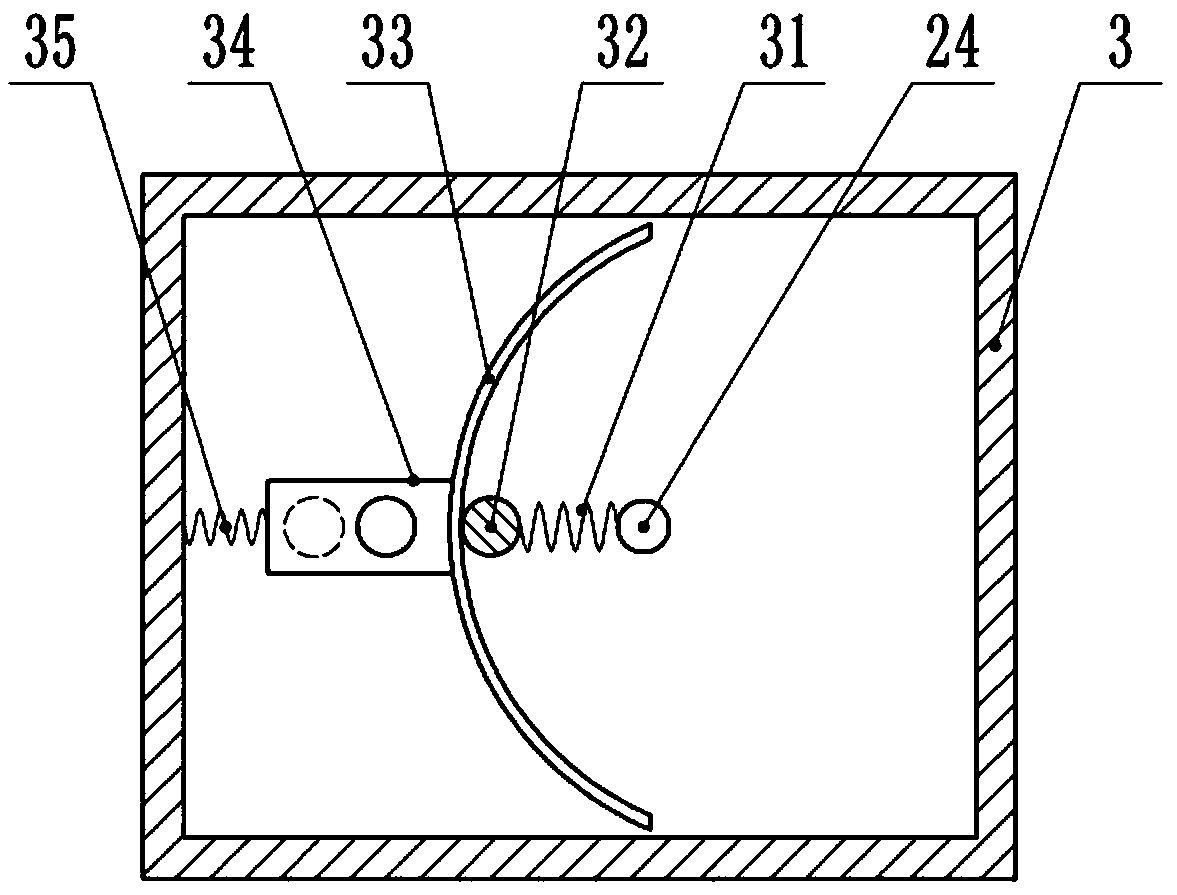

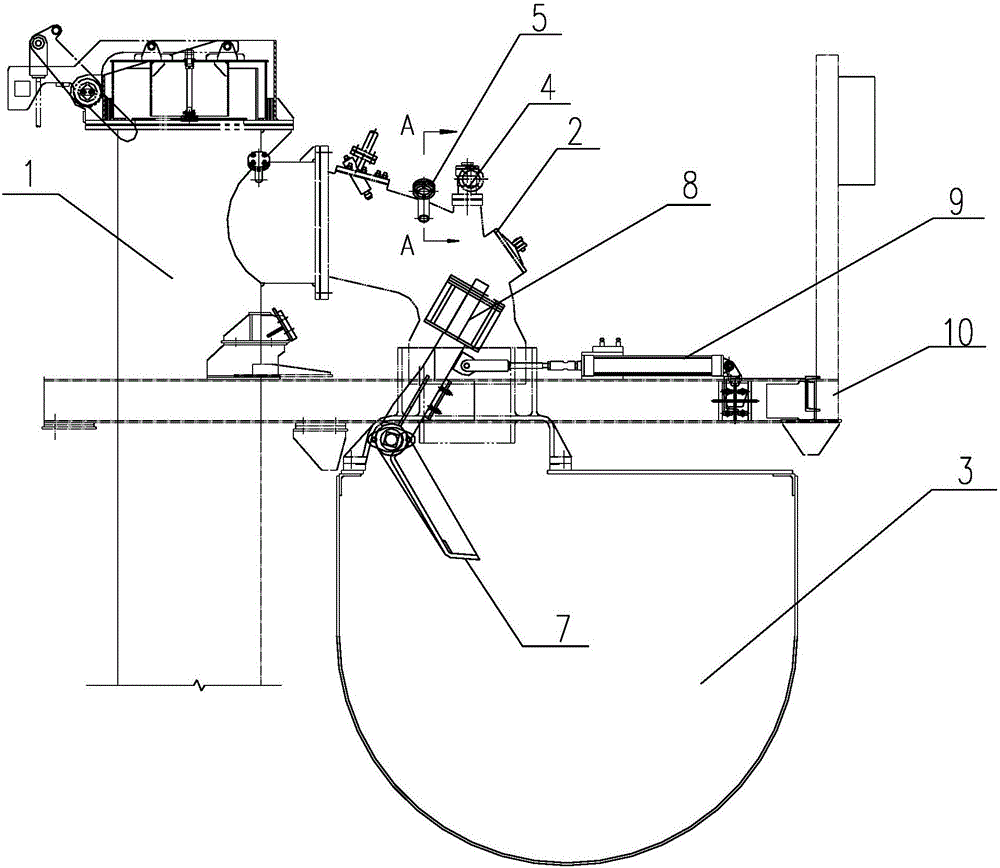

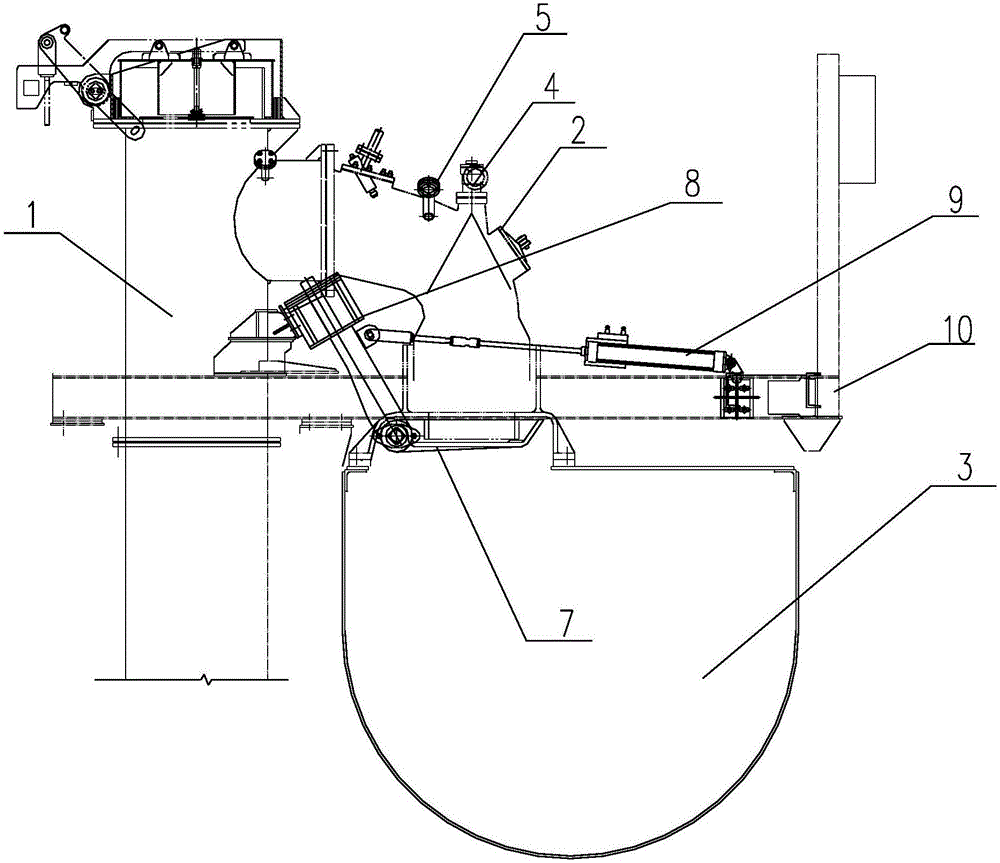

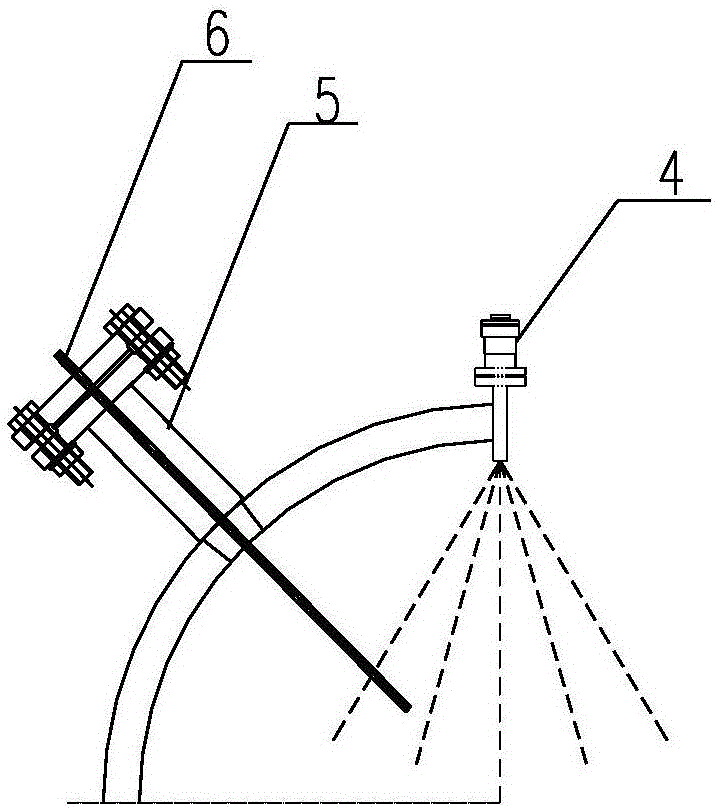

Grinding equipment for inner walls and outer walls of annular accessories

ActiveCN109551321ARealize switchingAvoid short intervalsRevolution surface grinding machinesGrinding drivesMachining processMachine tool

The invention belongs to the technical field of machine tools or devices or processes used for grinding or polishing, and particularly discloses grinding equipment for inner walls and outer walls of annular accessories. The grinding equipment comprises a workbench. A motor is arranged below the workbench. An output shaft of the motor penetrates through the workbench and is rotationally connected with the workbench. A locating portion for fixing workpieces through negative pressure is arranged on the output shaft of the motor. A left clamp rod and a right clamp rod are arranged on the two sidesof the output shaft of the motor correspondingly. A transmission mechanism is connected to the output shaft of the motor and is connected with grinding mechanisms. Each grinding mechanism comprises agrinding cover and a grinding piece. An elastic part is arranged between each grinding piece and the corresponding grinding cover. The grinding mechanisms are arranged on the two sides of the outputshaft of the motor. The transmission mechanism is used for enabling the grinding mechanisms to move in the direction close to or away from the output shaft of the motor at the same time. The equipmentis to solve the problems that in the prior art, grinding of the inner walls and the outer walls of the workpieces needs to be achieved by multiple kinds of equipment or multiple tools, and consequently the machining process is complex.

Owner:宁波隆锐机械制造有限公司

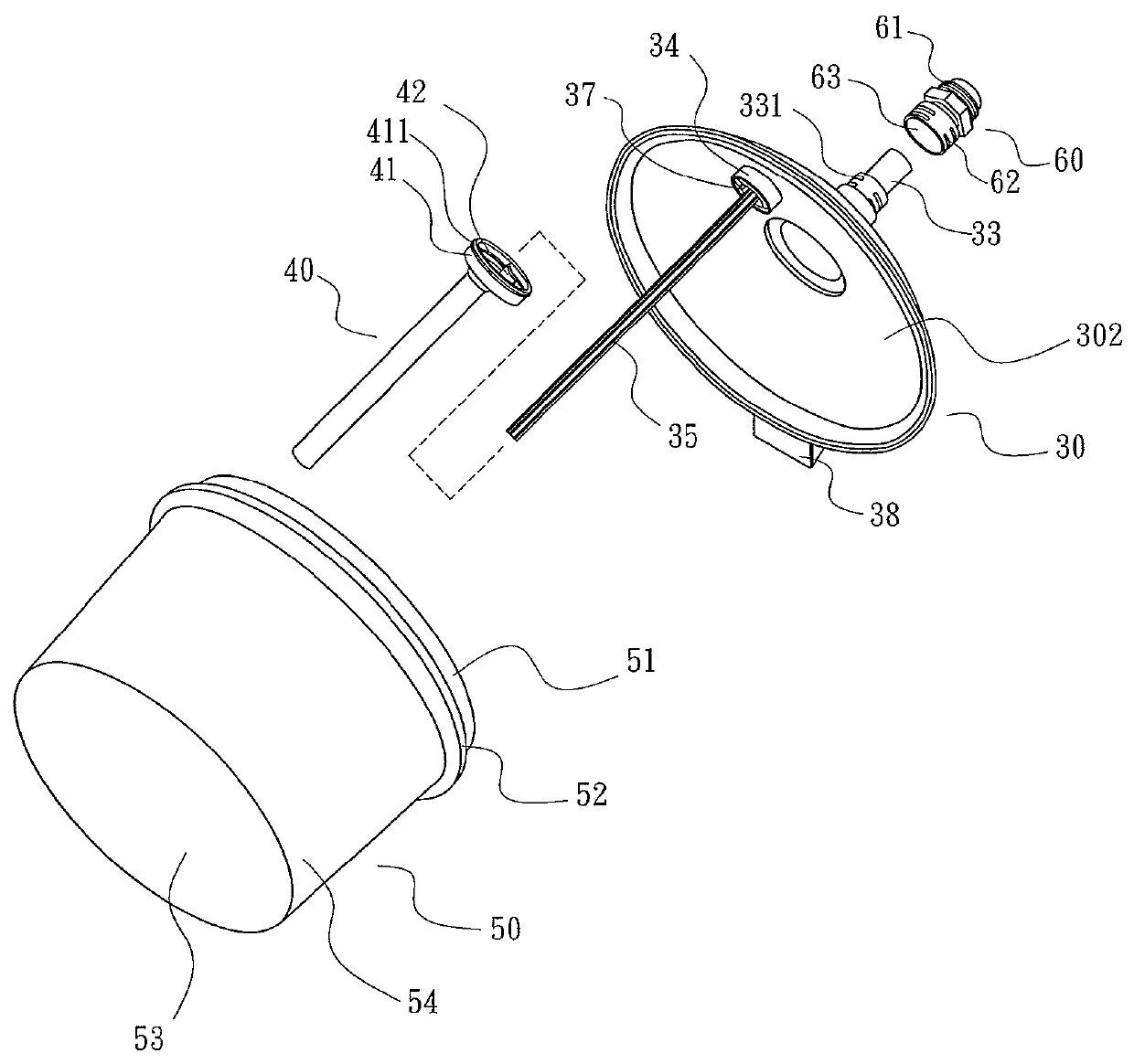

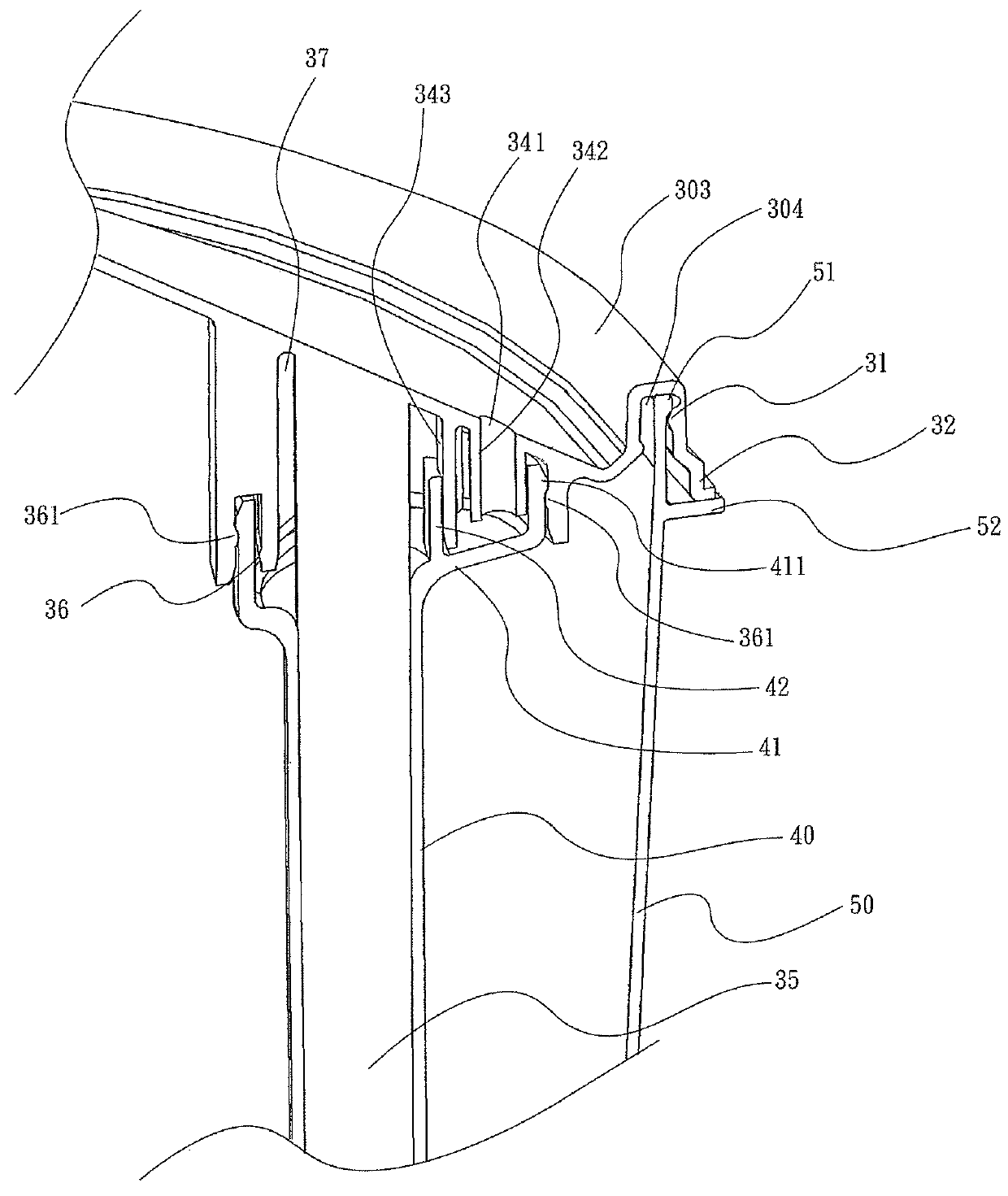

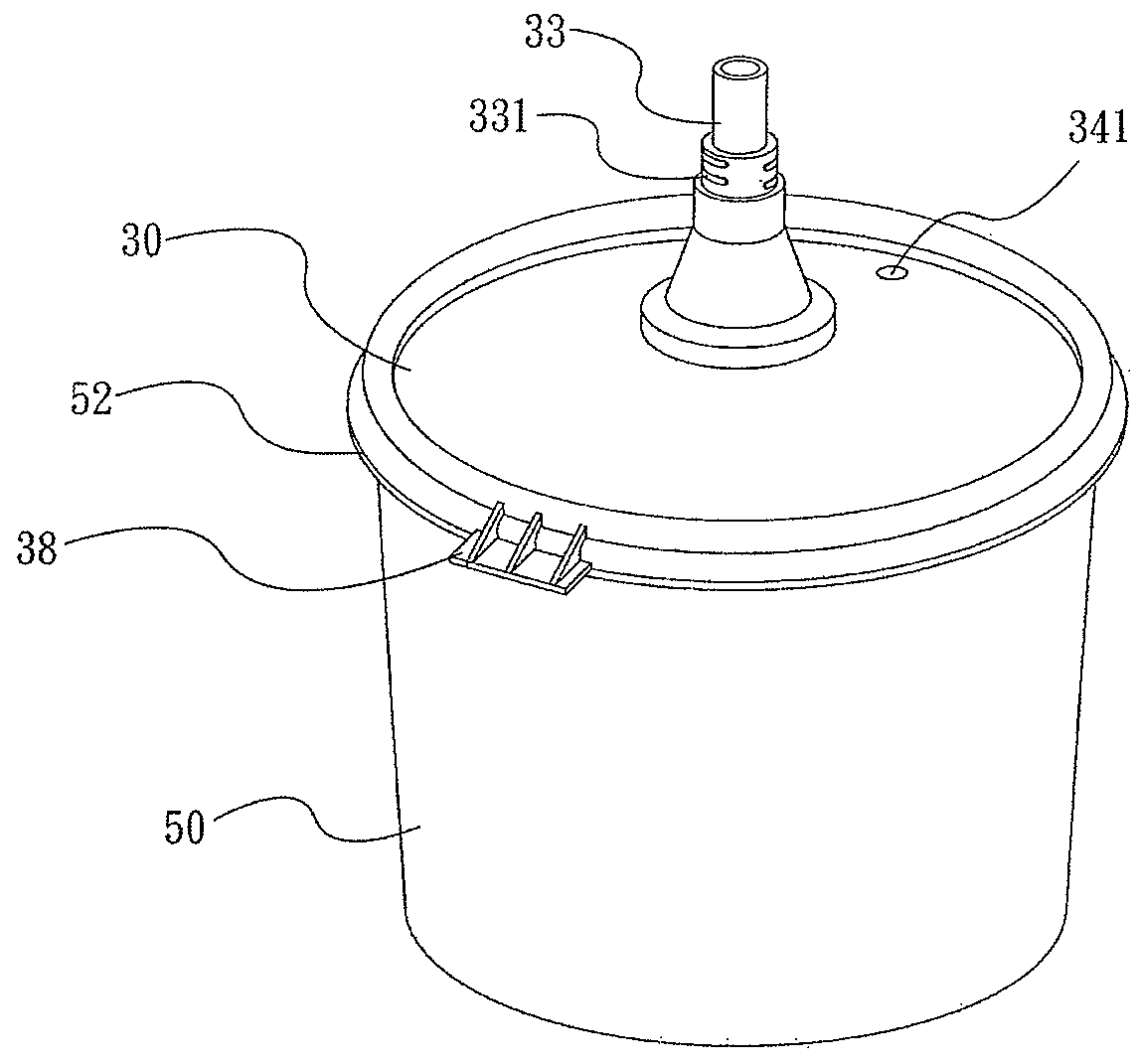

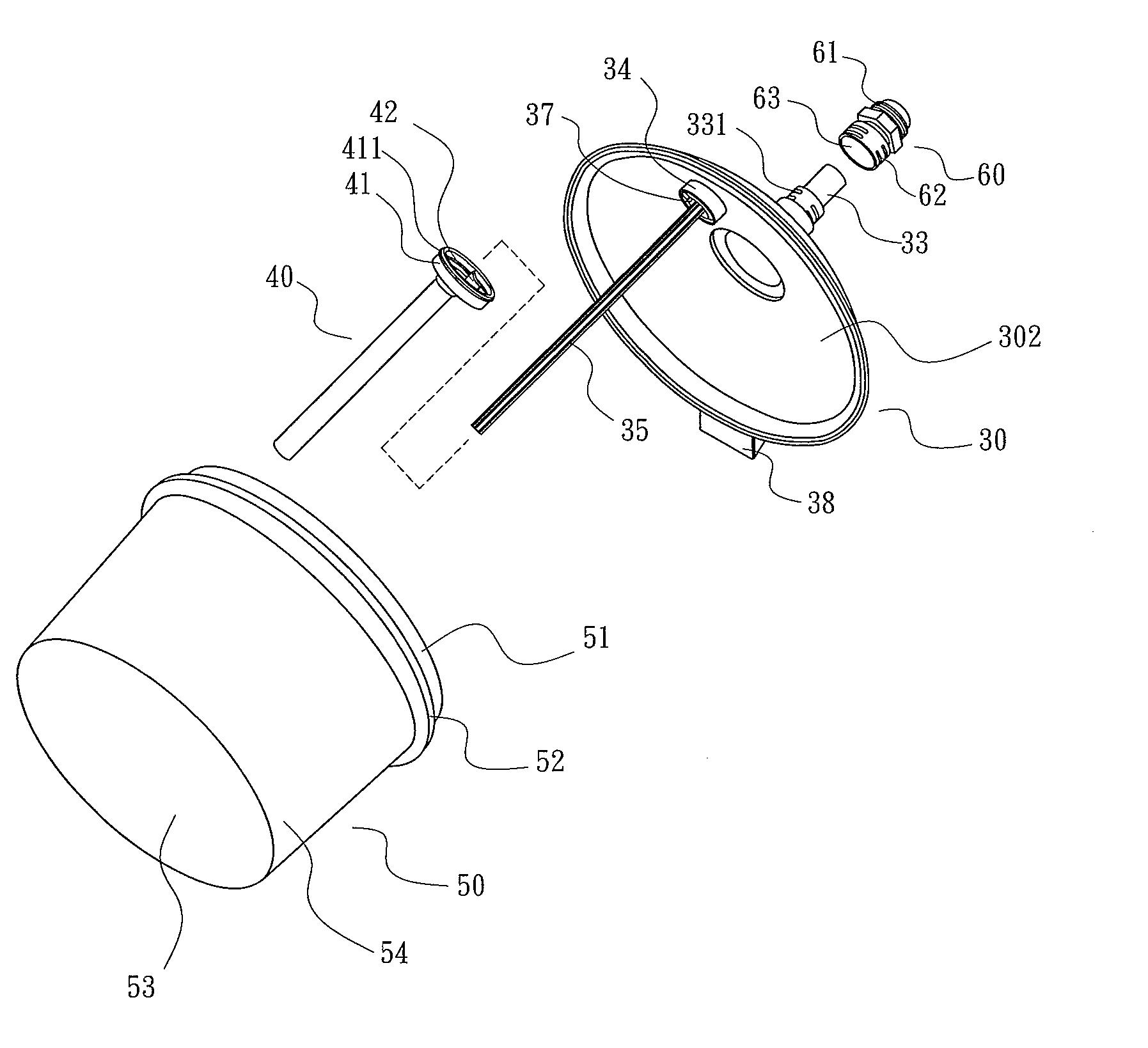

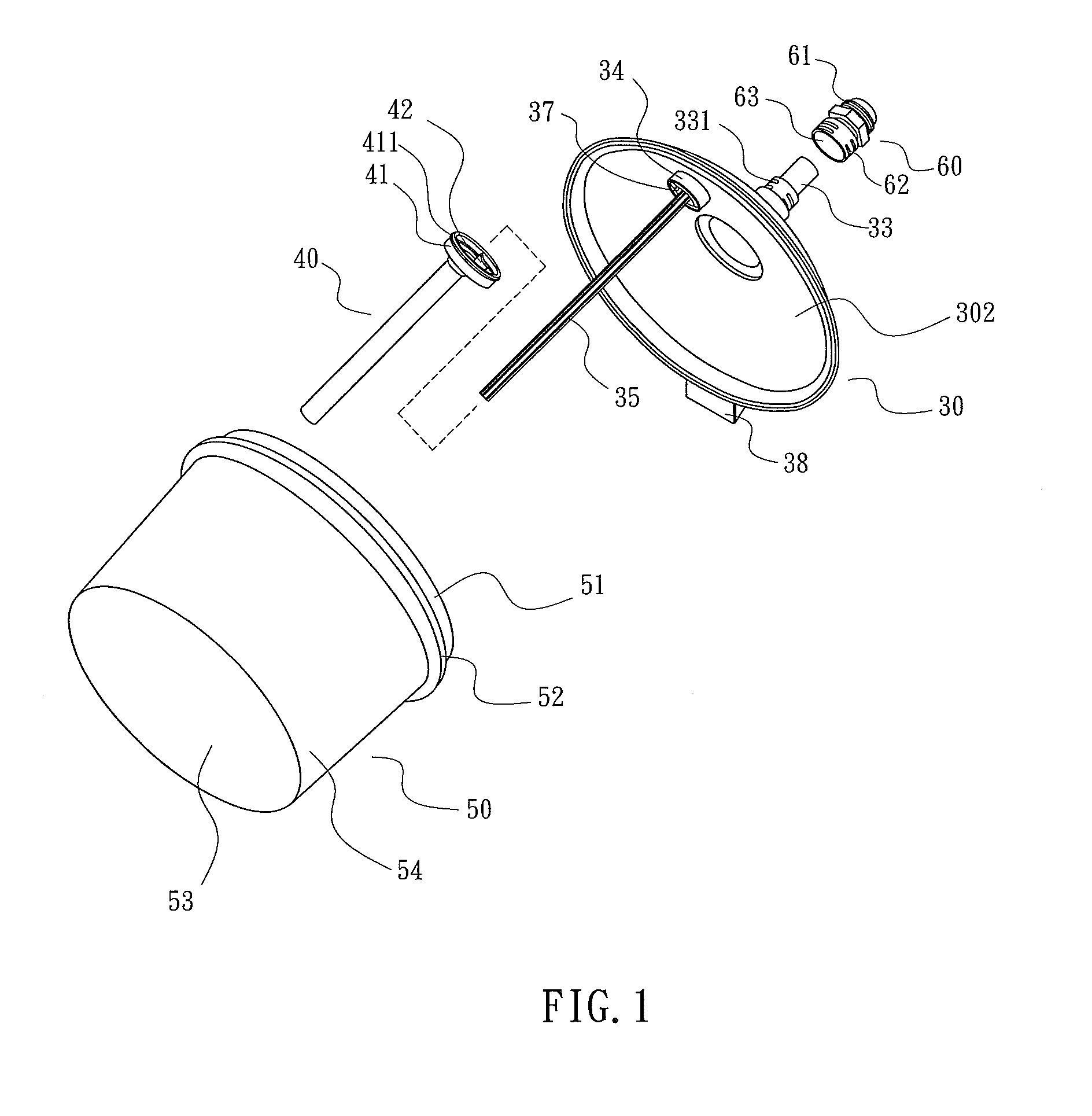

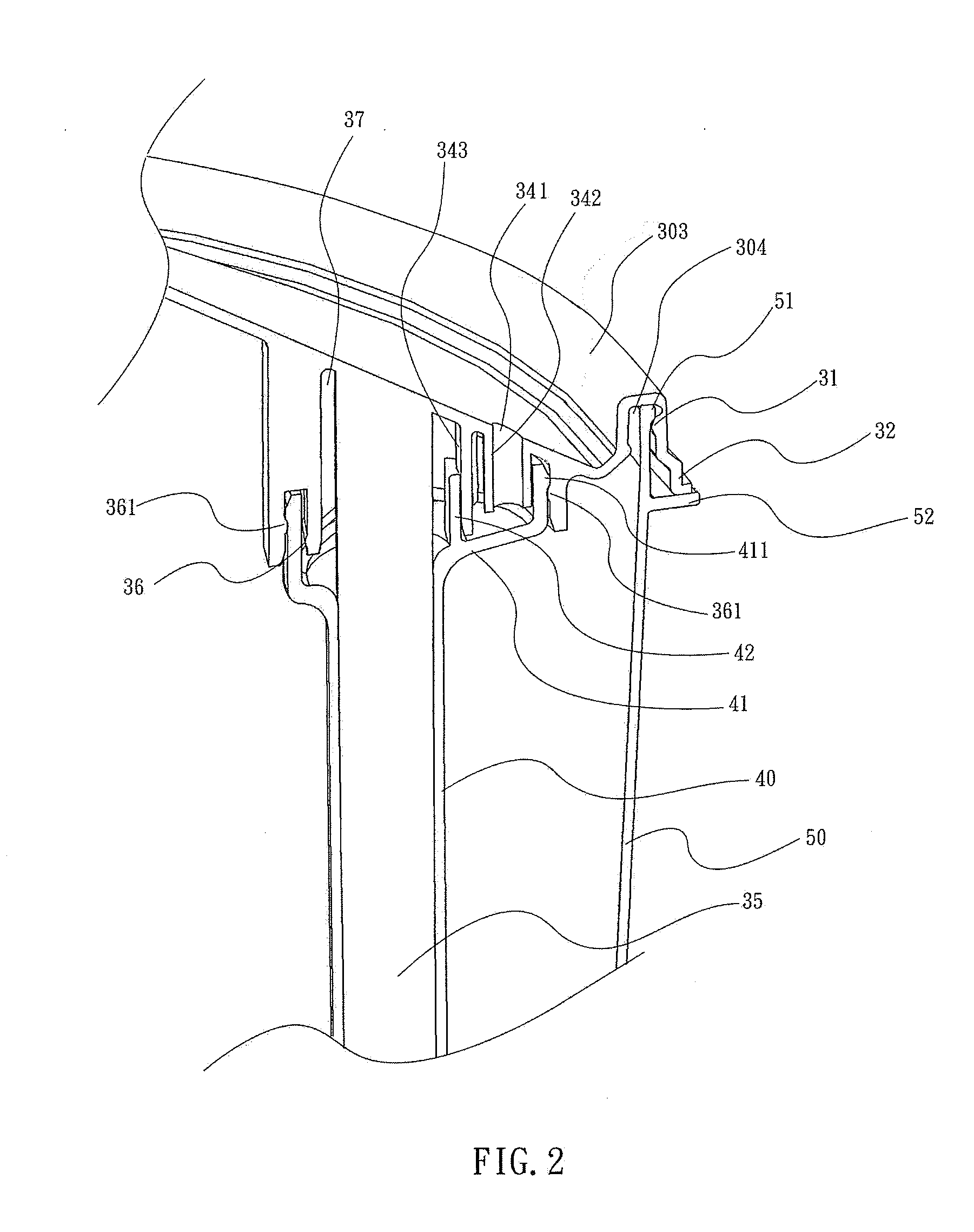

Paint cup for spray gun

InactiveUS9227208B2Eliminate undesirable drippingGuaranteed uptimeLiquid spraying apparatusCouplingEngineering

A paint cup for a spray gun includes a container containing paint solvents, a lid body covering an upper opening of the container, and a ventilation member mounted in the container. The lid body includes an annular coupling portion protruding from an inner surface thereof, an inner rod located in the annular coupling portion, and a vent extending into an annular coupling groove of the annular coupling portion. A gap is formed between the ventilation member and the inner rod. When the container is turned upside-down, the paint solvents in the gap will flow into an accommodating groove formed between the inner rod and the annular coupling portion, and ambient air circulates in the container via the vent and the gap.

Owner:LIN CHIN HSIN

Paint Cup for Spray Gun

InactiveUS20140103143A1Eliminate undesirable drippingGuaranteed uptimeLiquid spraying apparatusCouplingAmbient air

A paint cup for a spray gun includes a container containing paint solvents, a lid body covering an upper opening of the container, and a ventilation member mounted in the container. The lid body includes an annular coupling portion protruding from an inner surface thereof, an inner rod located in the annular coupling portion, and a vent extending into an annular coupling groove of the annular coupling portion. A gap is formed between the ventilation member and the inner rod. When the container is turned upside-down, the paint solvents in the gap will flow into an accommodating groove formed between the inner rod and the annular coupling portion, and ambient air circulates in the container via the vent and the gap.

Owner:LIN CHIN HSIN

Drilling device

InactiveCN108788913AAffect qualityReduce entryMaintainance and safety accessoriesLow speedEngineering

The invention relates to the technical field of drilling machining and discloses a drilling device. The drilling device comprises a drill bit and a driving gear connected with the drill bit coaxially.The driving gear is meshed with a driven gear. A liquid box is arranged above the driven gear. A liquid outlet is formed in the liquid box. A stop block for opening or closing the liquid outlet is arranged in the liquid box. The stop block is provided with an outlet. The outlet and the liquid outlet are arranged in a staggered manner. A compression spring is fixedly connected between the stop block and the inner wall of the liquid box. A second rotating shaft is connected in the liquid box in a rotating manner. The second rotating shaft and the driven gear are connected coaxially. The secondrotating shaft is fixedly connected with a tension spring. A gravity ball is fixedly connected to the other end of the tension spring. The gravity ball abuts against an arc-shaped block intermittently. According to the drilling device, along with the change of rotating speed of the drill bit, the centrifugal force borne by the gravity ball changes, thus the size of the opening degree of the liquidoutlet of the liquid box is adjusted, the flow amount of cutting fluid can be adjusted automatically according to the rotating speed of the drill bit, and the situation that when the speed of the drill bit is low, too much cutting fluid flows out, and waste is caused is avoided.

Owner:CHONGQING YOUBO MACHINERY MFG

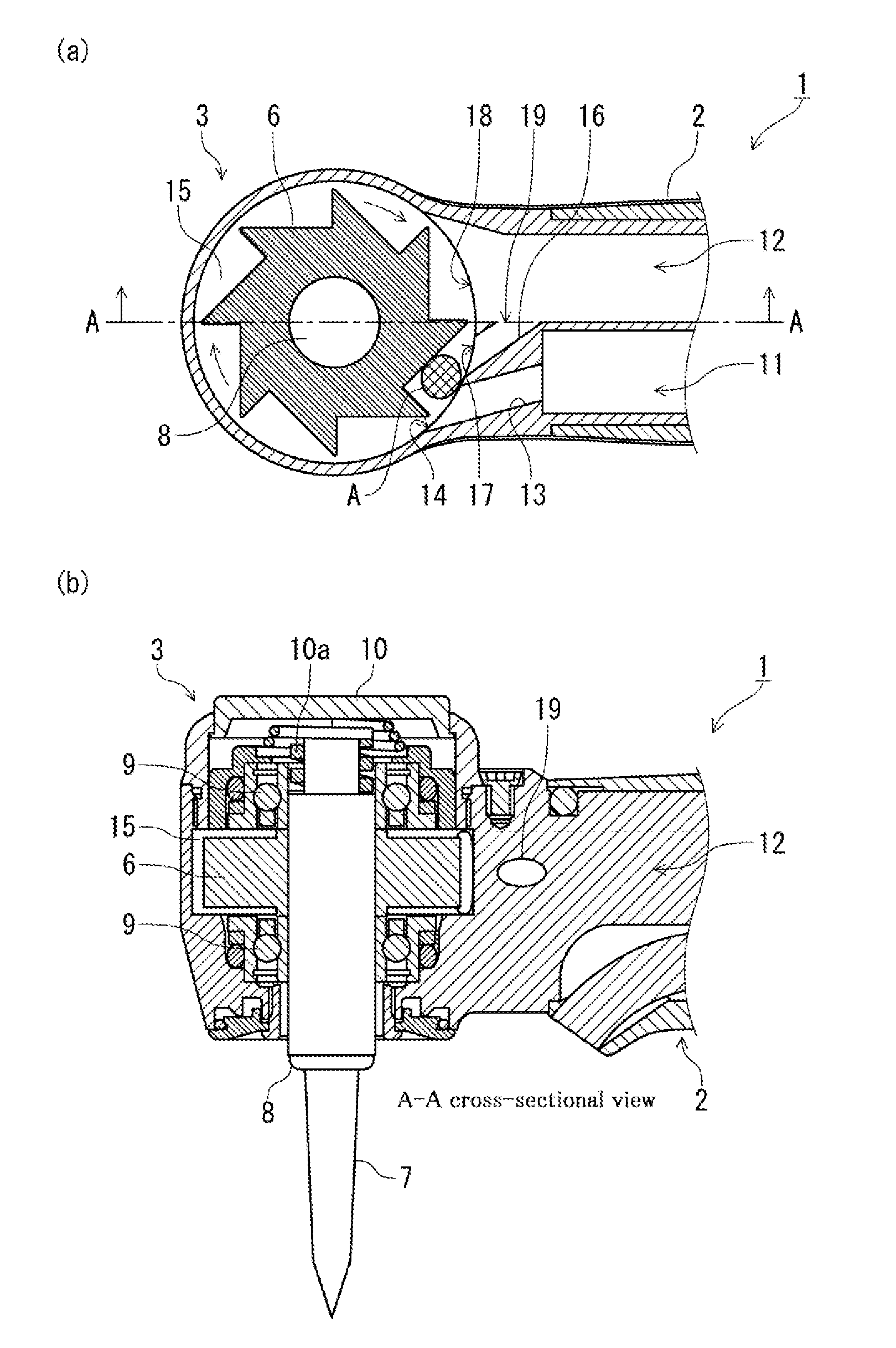

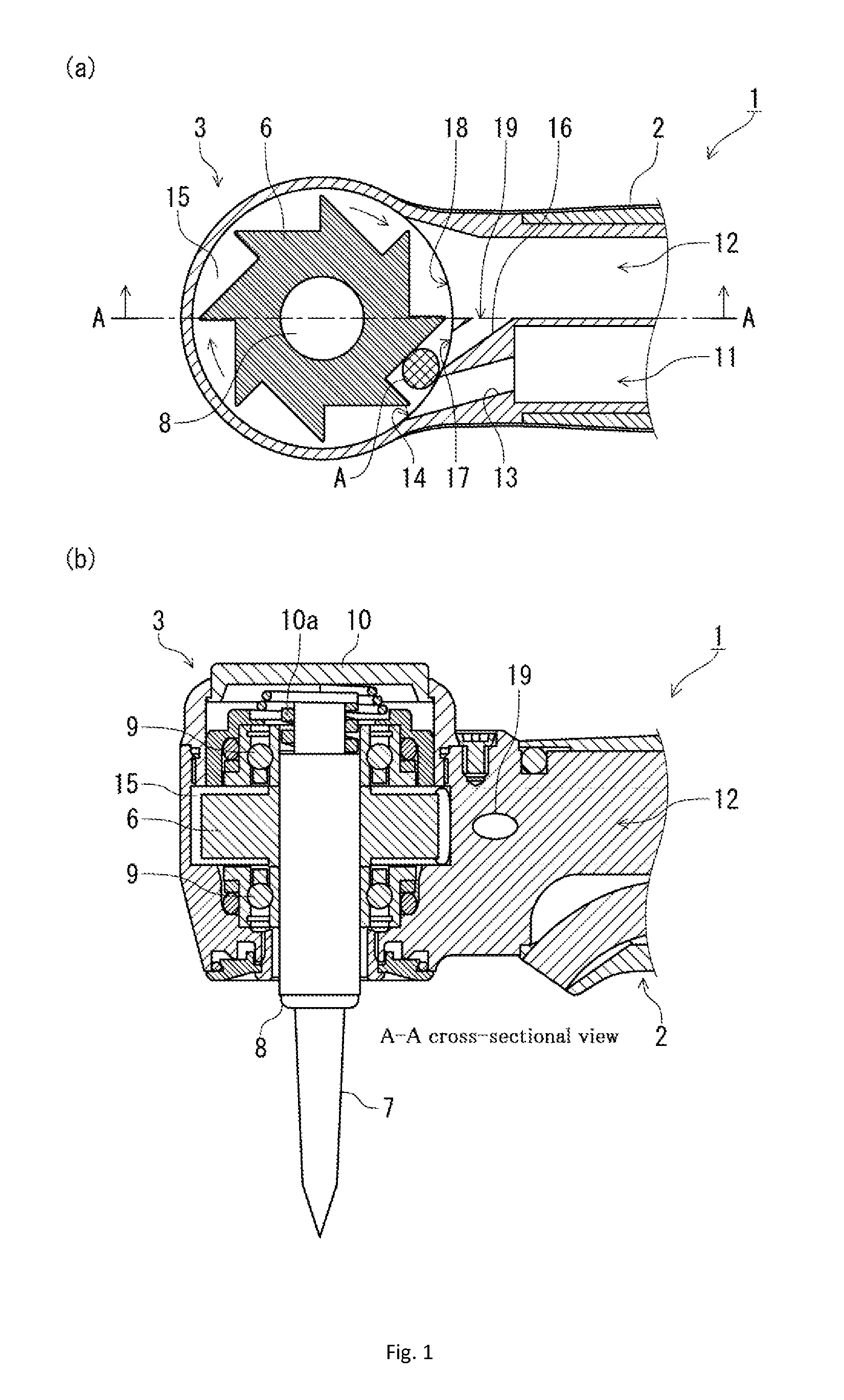

Air turbine handpiece

InactiveUS20130266430A1Prevent materialLow pricePump componentsRotary non-positive displacement pumpsTurbine blade

An air turbine handpiece having: a head portion with built-in free turbine blade, a neck portion installed consecutively with the head portion and grasped by an operator, a grip portion installed consecutively with the neck portion, an air supply duct for driving the turbine blade, and an exhaust duct for exhausting the air. The exhaust duct is provided with a reflux duct, open at one end to the exhaust duct, and open at the other end to the turbine room as the exhaust exit, a value in which an aperture at the reflux exit of the reflux duct is divided by an aperture in the air supply port of the air supply duct, becomes one or less, and the reflux exit of the reflux duct is opened to the turbine room near the air supply port between the air supply port and the exhaust exit.

Owner:YOSHIDA DENTAL MFG

Exposure system and method for manufacturing device

InactiveUS7106414B2Improve efficiencyDesirable performancePhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringCooling capacity

An exposure system is provided which can maintain a predetermined performance of the exposure apparatus stably by maintaining a cooling capacity by preventing a negative pressure from being generated in a circulation path of the liquid and preventing the back pressure from increasing even if at least a part of a temperature adjusting device is disposed under a disposition surface of the exposure apparatus due to the disposition area. A sealed tank which stores the cooling agent which is circulated in the circuiting systems and a pump, etc., which circulates the cooling agent are disposed under the disposition surface FL of the exposure system. The reticle stage and the wafer stage which are objects of which the temperature is supposed to be controlled are disposed above the disposition surface FL. A tank which open to air is provided so as to prevent the negative pressure from being generated in the reticle stage, etc. such that the tank and the tank are connected by a connecting piping arrangement. Also, the piping arrangement which eliminates the bubbles which are contained in the cooling agent which is circulated in the circulating systems are connected to the circulating systems.

Owner:NIKON CORP +1

Modification method for adjusting pressure of single-hole carbonization chamber in existing coke oven

InactiveCN106167711AGood effectAvoid negative pressureCoke oven safety devicesCarbonizationEngineering

The invention relates to a modification method for adjusting pressure of a single-hole carbonization chamber in an existing coke oven. The modification method includes 1), mounting a pressure measurement pipe guide sleeve on a bridge pipe, penetrating a pressure measurement pipe into the pressure measurement pipe guide sleeve to enter the bridge pipe, enabling the extending end to be located at the spraying range of an ammonia water spray nozzle, mounting an actuator on a gas collection pipe operating platform or a gas collection pipe, connecting the power output end of the actuator with a moving rod of a water-sealed valve disc, and connecting the pressure measurement pipe and the actuator with a computer control system; 2), according to different quantities of raw coke oven gas, generated in different working periods, of the coke oven, adjusting the pressure of the bridge pipe based on three adjustment stages, namely earlier stage, middle stage and last stage, and enabling the pressure in the carbonization chamber to be constantly kept micro positive from coal feeding to coke discharging. The modification method has the advantages that the existing coke oven can have a function of automatically adjusting the pressure of the single-hole carbonization chamber; the structure and the method are simple and easy, the modification method is quite suitable for modification of existing coke ovens, and modification without oven shutdown can be realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

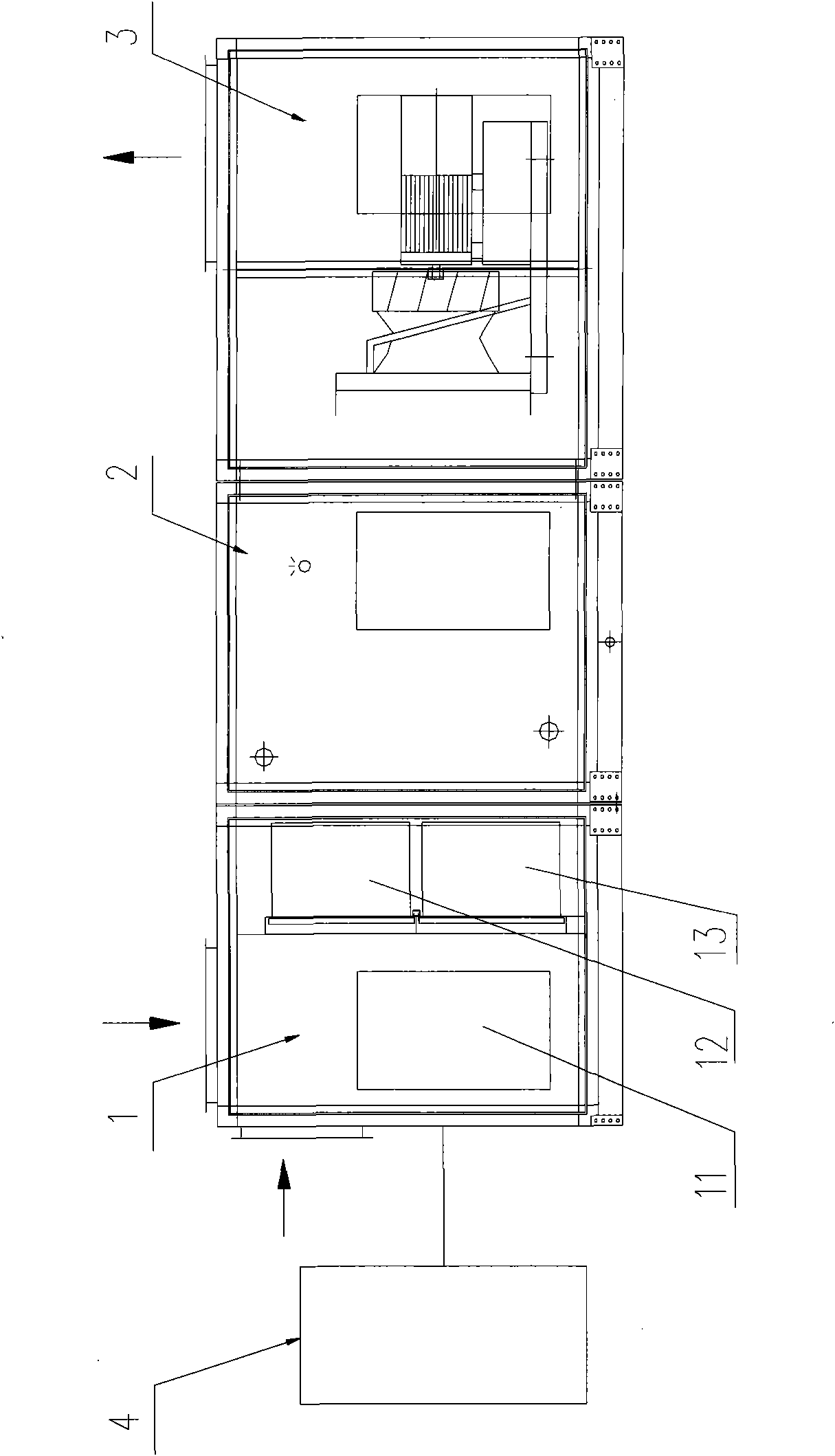

Humiture automatic control type purifying combined air conditioning unit for

InactiveCN101684958AGood anti-cold bridge performanceImprove aestheticsSpace heating and ventilation safety systemsLighting and heating apparatusHybrid filterSurface cooling

The invention discloses a humiture automatic control type purifying combined air conditioning unit, which relates to the technical field of the purification engineering of pharmacy, electron, an animal house and the like, in particular to the technical field of purifying air conditioning units for purifying air. The humiture automatic control type purification combined air conditioning unit comprises a hybrid filter section, a surface cooling, heating and humidifying section, an air outlet section of a blower fan and a control section, wherein one side of the control section is provided with the hybrid filter section, the surface cooling, heating and humidifying section and the air outlet section of the blower fan which are interconnected with each other; and the control section is connected with the hybrid filter section, the surface cooling, heating and humidifying section respectively. The purifying humiture automatic control type combined air conditioning unit realizes the aims ofconvenient use, simple structure, high integration degree and automatic control.

Owner:苏州市黄浦空调净化设备有限公司 +1

Non-Azeotropic refrigerant mixture and refrigeration cycle apparatus

ActiveUS8443624B2Promote decompositionLow chemical stabilityCompression machines with non-reversible cycleHeat-exchange elementsBoiling pointEngineering

Disclosed is a non-azeotropic refrigerant mixture containing tetrafluoropropane as a high-boiling refrigerant and a refrigeration cycle apparatus in which a non-azeotropic refrigerant mixture containing tetrafluoropropane as a high-boiling refrigerant circulates through a refrigeration cycle so as to avoid occurrence of negative pressure in a low-pressure circuit.The non-azeotropic refrigerant mixture is characterized in that a mixing ratio of a high-boiling refrigerant and a low-boiling refrigerant is determined so that a saturated vapor line where pressure is 0.00 MPa is not higher than −45° C. in a low-pressure circuit formed between the decompressor to the compressor.

Owner:MITSUBISHI ELECTRIC CORP

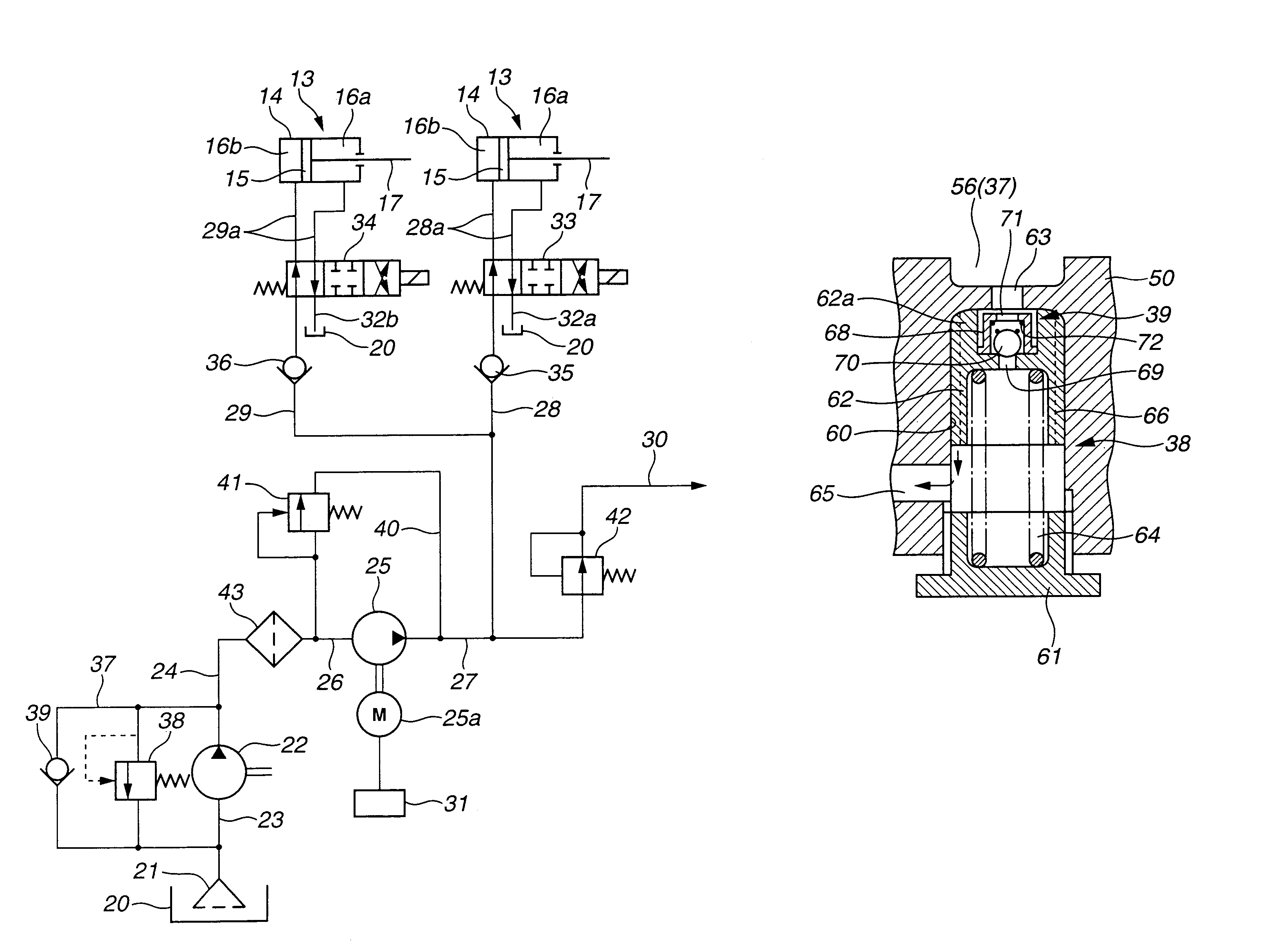

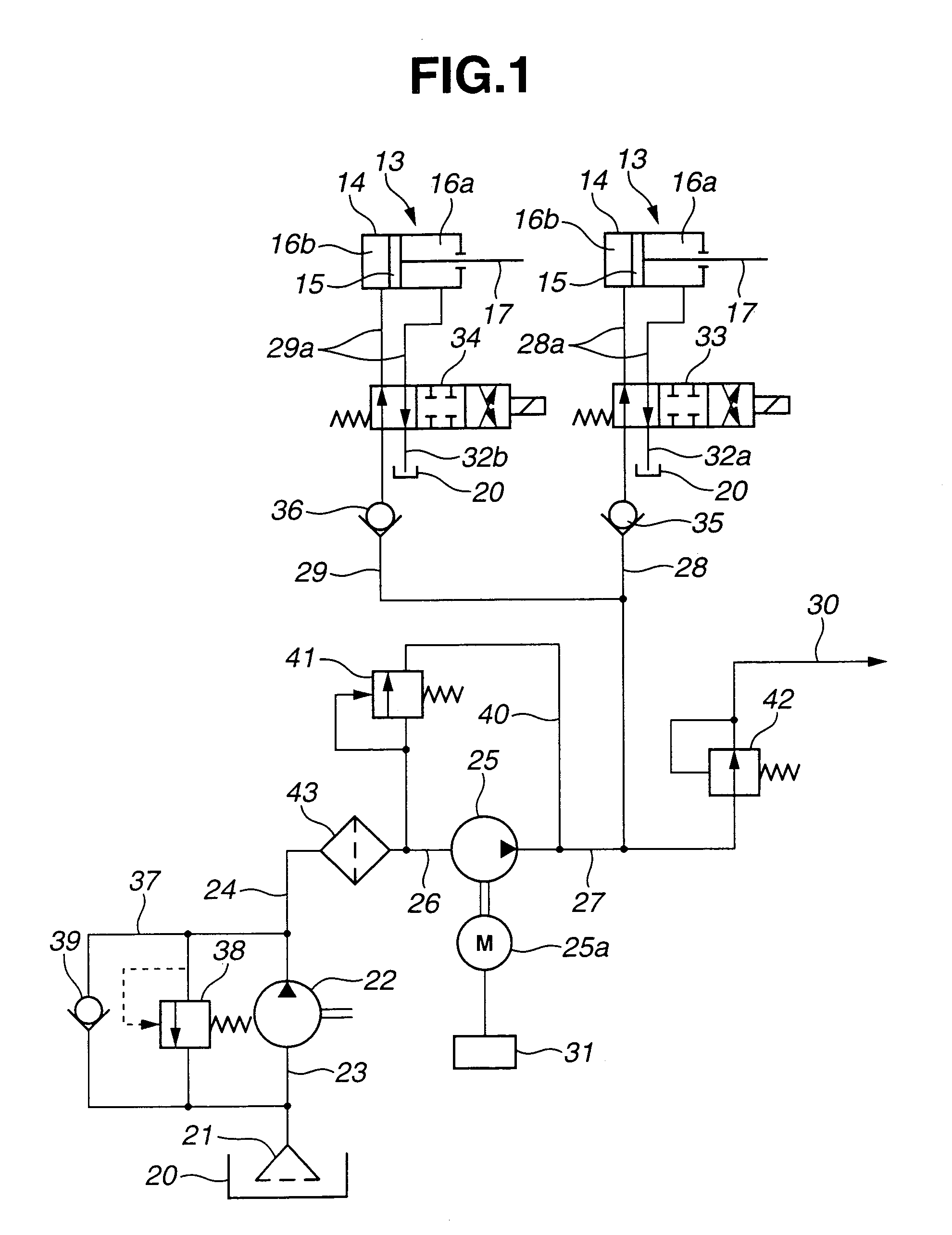

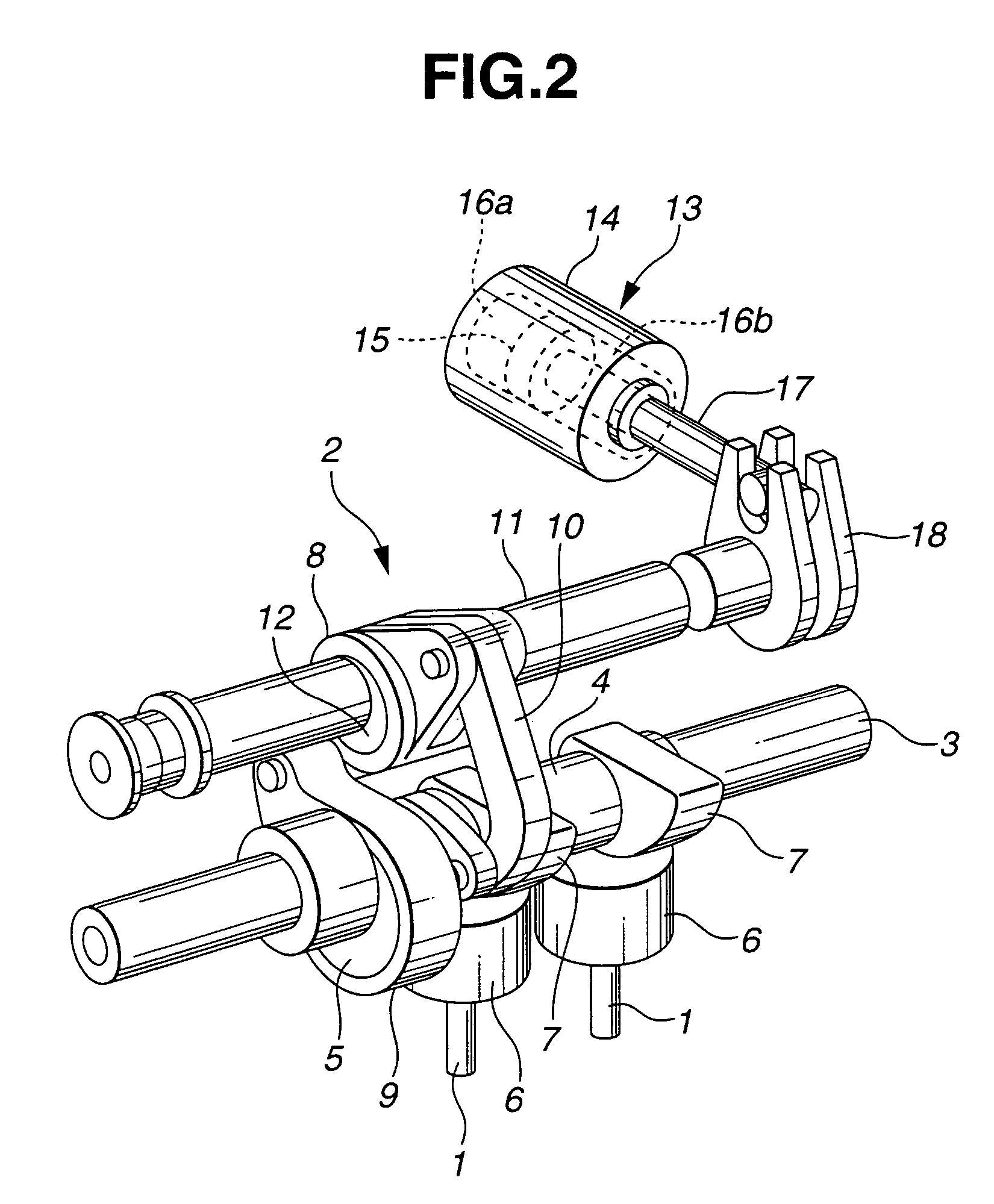

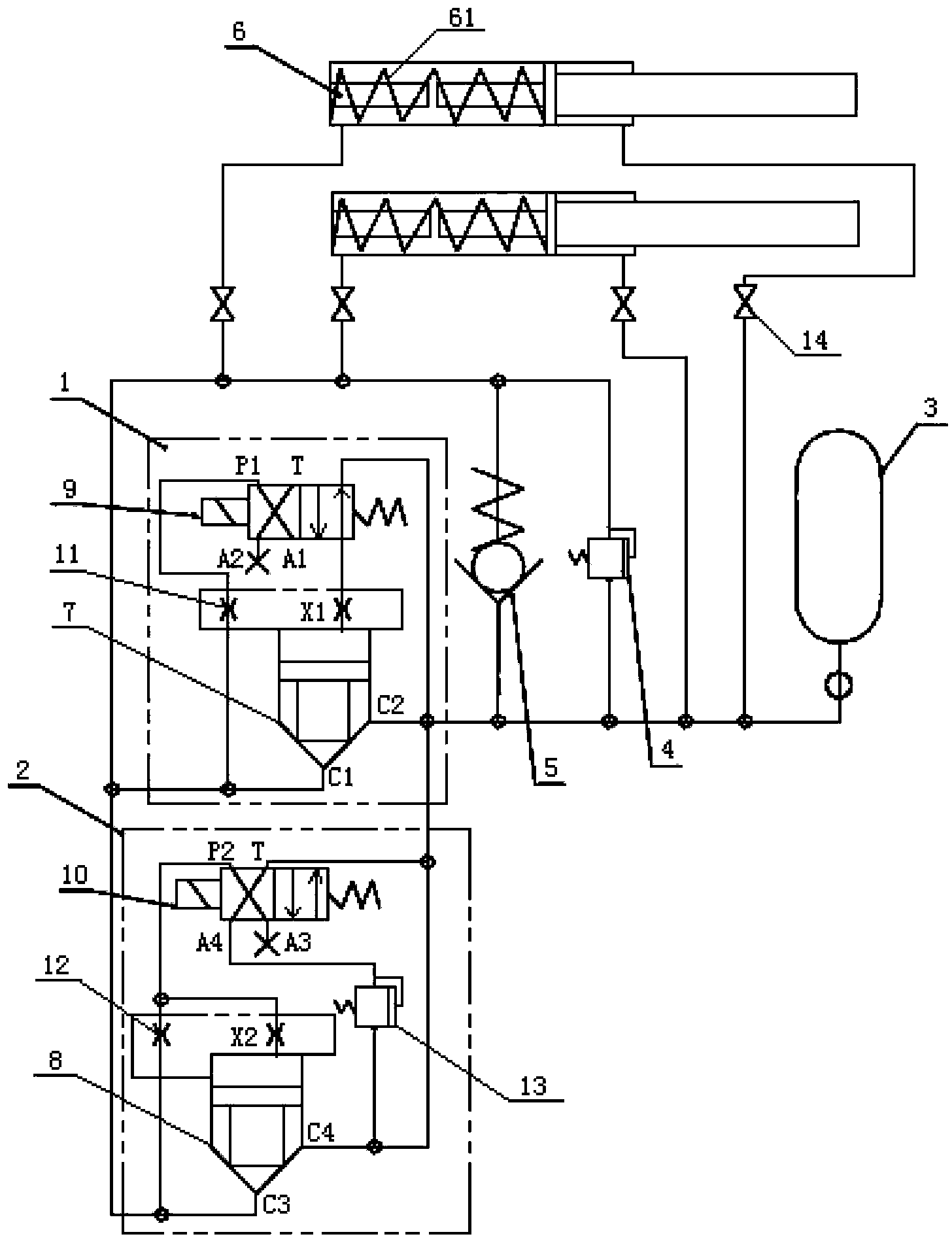

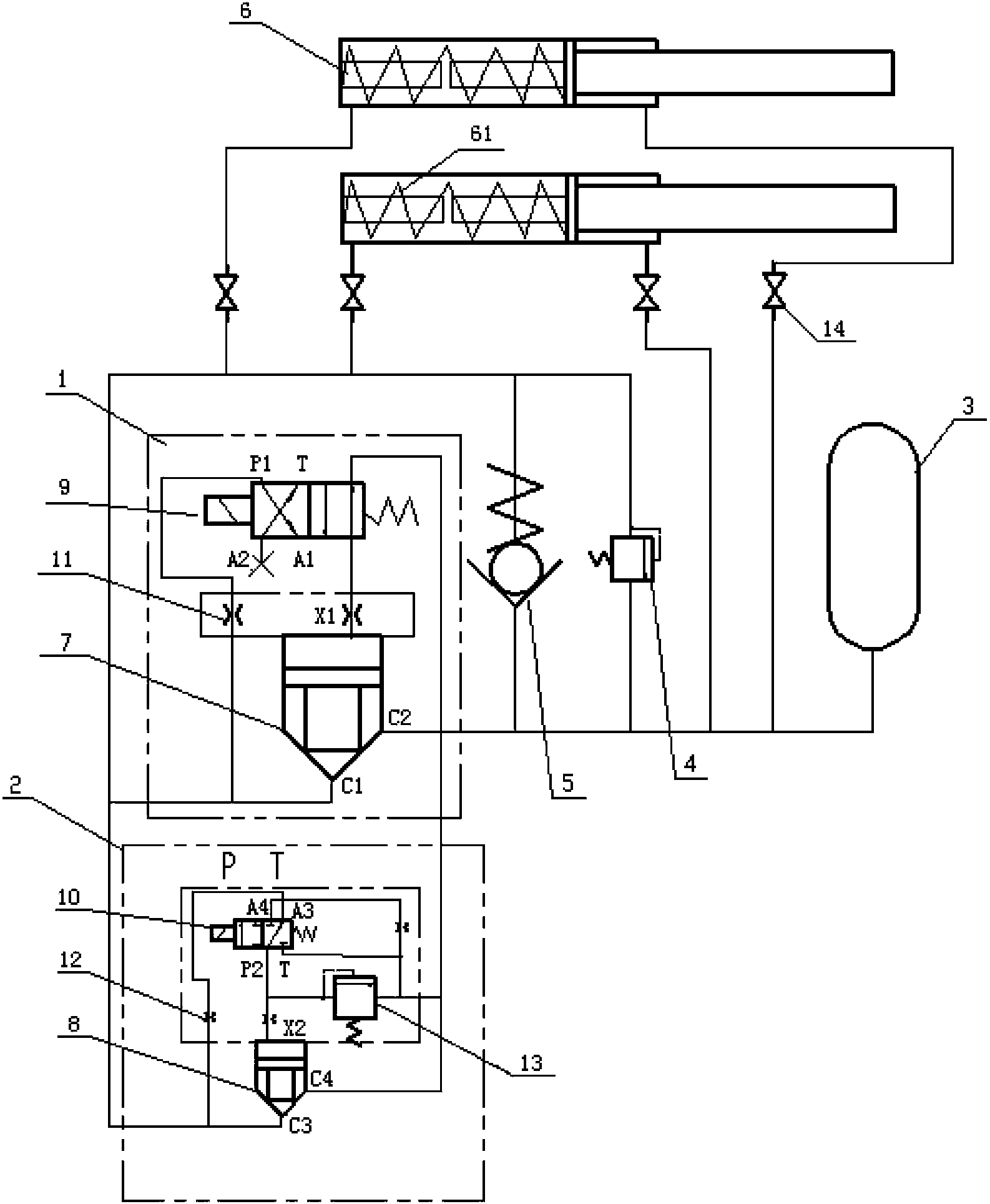

Backwards-tilting prevention hydraulic control system of arm support and tower crane

ActiveCN103350964AAvoid negative pressureAvoid vacuumingServomotor componentsCranesControl engineeringTower crane

The invention discloses a backwards-tilting prevention hydraulic control system of an arm support and a tower crane. The backwards-tilting prevention hydraulic control system comprises a buffer oil cylinder (6), a low-pressure energy accumulator (3) and a sensing control device, wherein a flow control valve group (1), a pressure control valve group (2) and a safety valve (4) are connected in parallel between the rodless cavity of the buffer oil cylinder and the low-pressure energy accumulator; the sensing control device is used for controlling hydraulic oil in the rodless cavity to selectively flow through one of the flow control valve group, the pressure control valve group and the safety valve and to finally flow to the low-pressure energy accumulator; when the hydraulic oil flowing to the low-pressure energy accumulator flows through the flow control valve group, the size of a buffering force generated in the buffer oil cylinder is in positive correlation with that of the flow of the hydraulic oil flowing through the flow control valve group; when the hydraulic oil flowing to the low-pressure energy accumulator flows through the pressure control valve group, the buffering force is basically constant. The backwards-tilting prevention hydraulic control system has no oil pump and oil tank, is simple, saves energy, and has the advantages of saving energy in changing amplitudes and generating a basically constant buffering force in a sudden condition of tilting backwards.

Owner:ZOOMLION HEAVY IND CO LTD

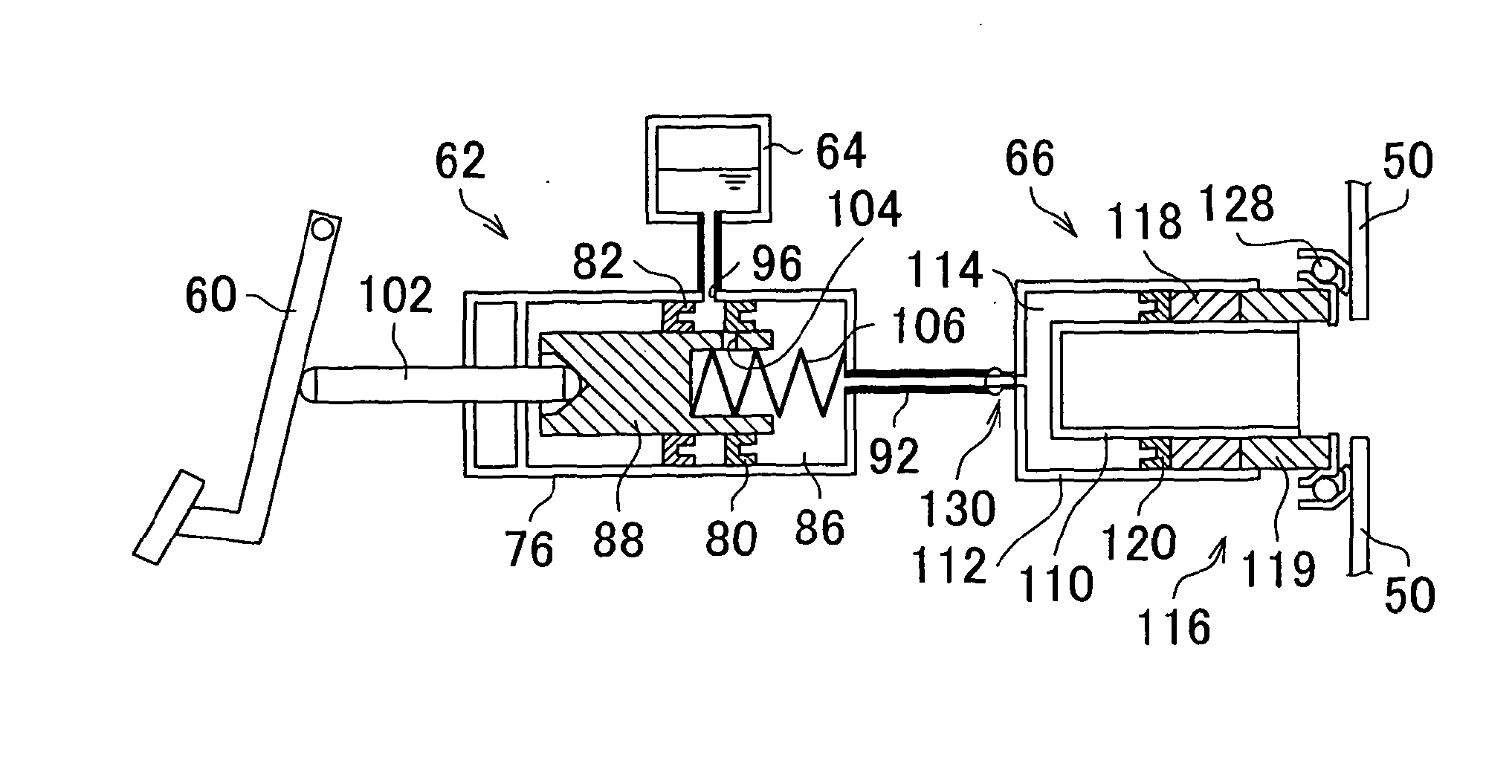

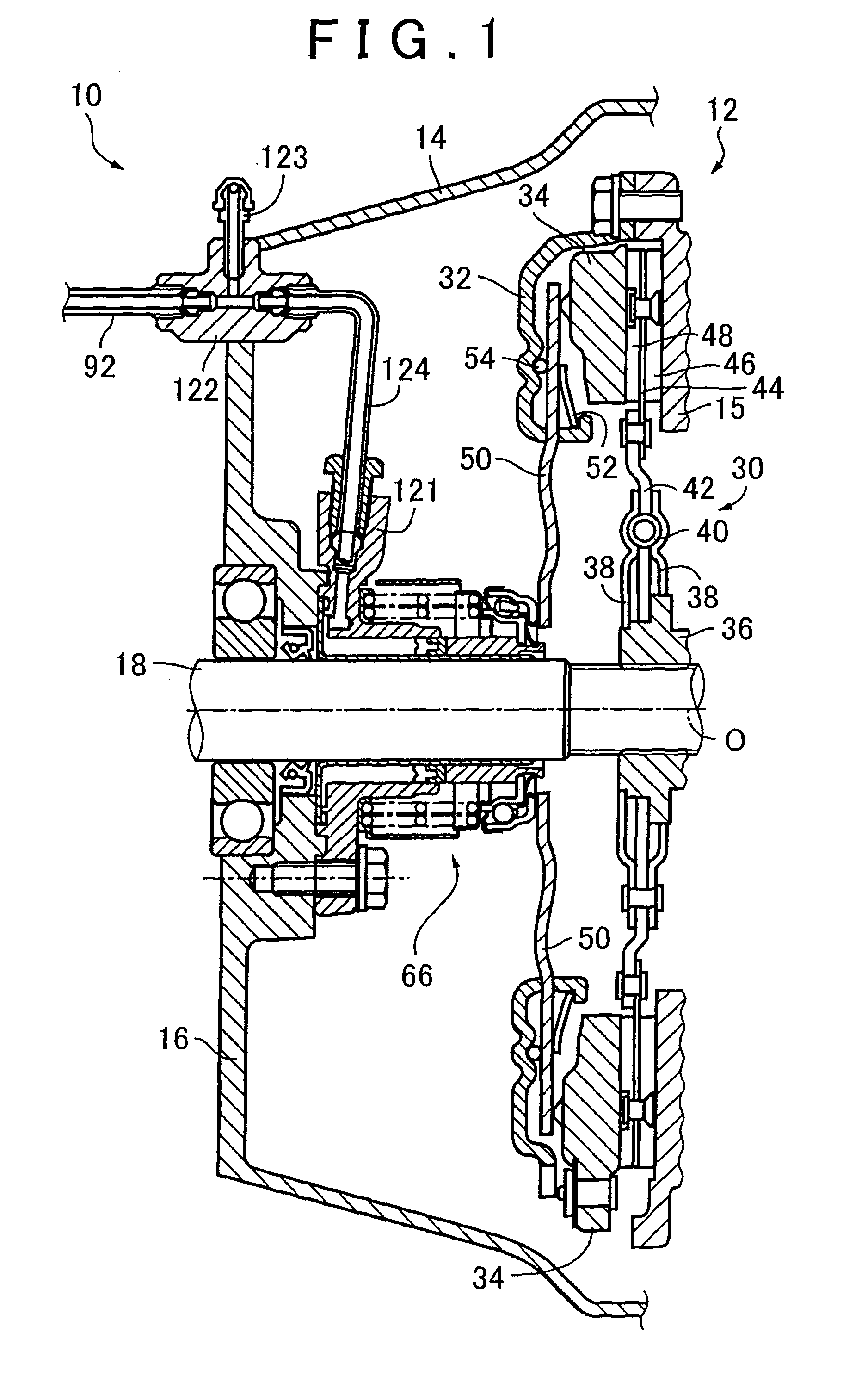

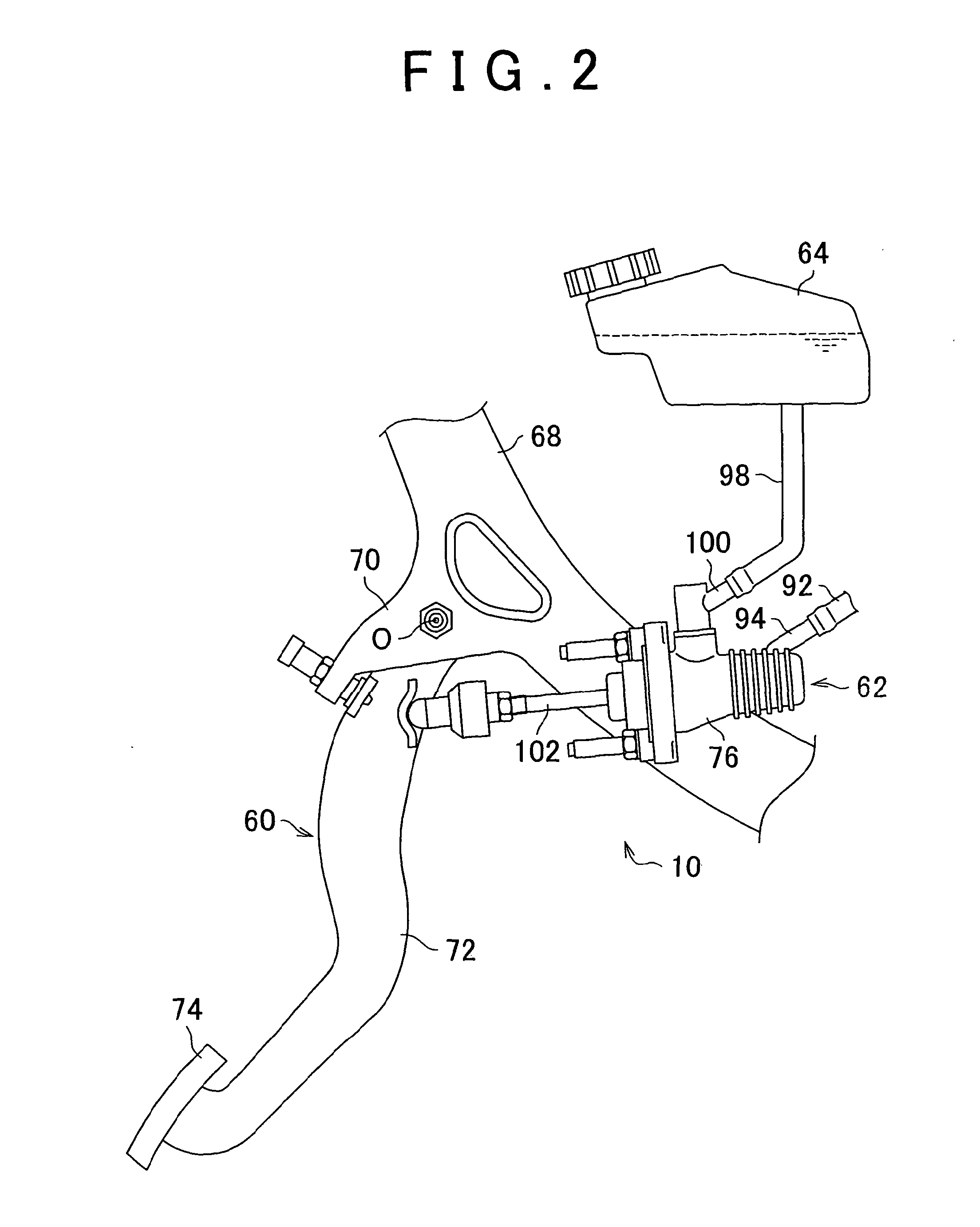

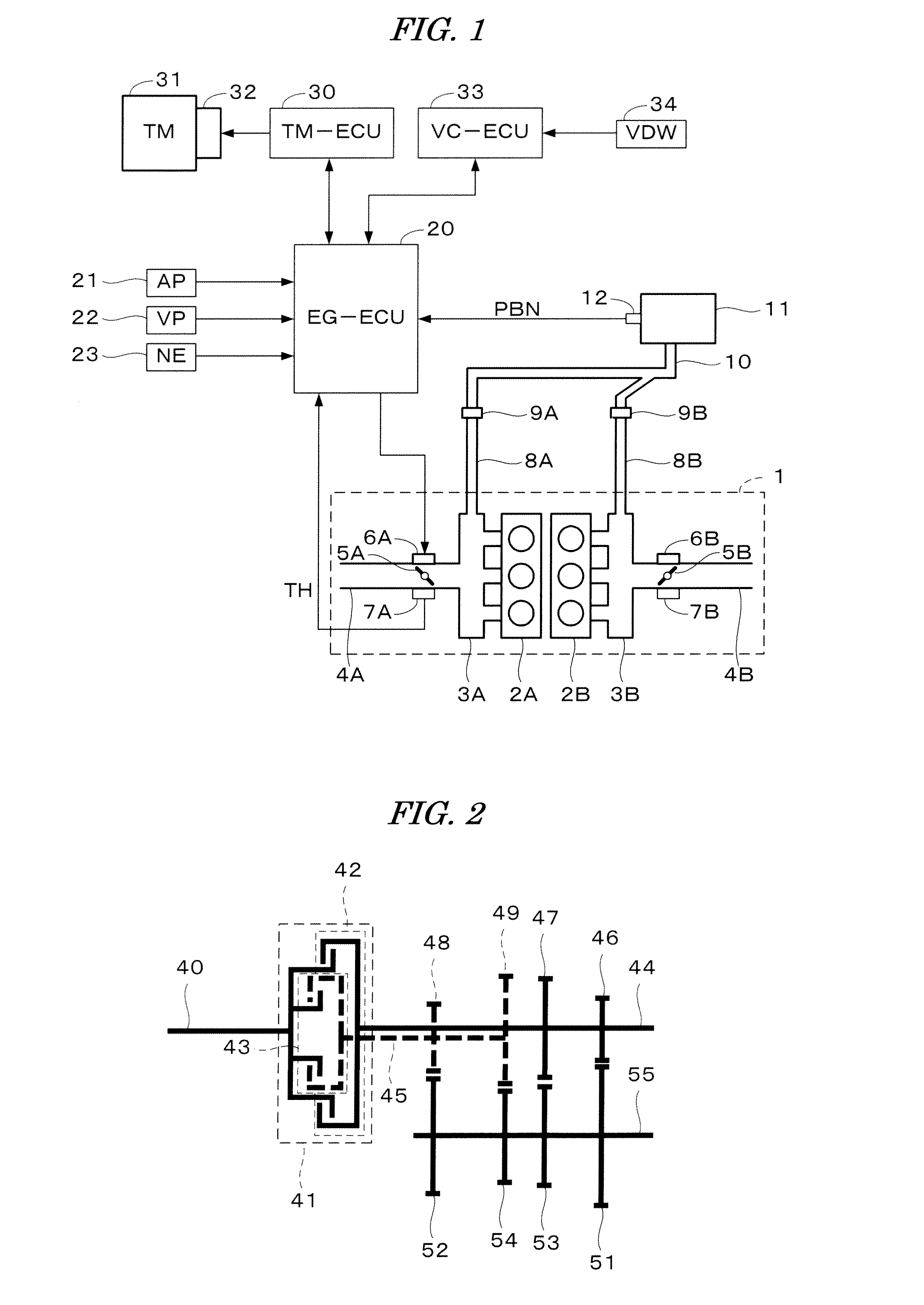

Vehicle hydraulic clutch apparatus

InactiveUS20120186934A1Easy to provideEasy to operateFluid actuated clutchesMaster cylinderEngineering

A vehicle hydraulic clutch apparatus includes a clutch master cylinder that generates clutch working oil pressure in response to operation of a clutch pedal, and a concentric slave cylinder that engages and releases a friction clutch as the clutch working oil pressure generated by the clutch master cylinder is supplied thereto and discharged therefrom via an oil passageway. A flow restraint device (130, 200) that restrains flow of the working oil from a concentric slave cylinder (66) side to a clutch master cylinder (62) side which occurs according to operation of the clutch pedal (60) is provided in the concentric slave cylinder (66).

Owner:TOYOTA JIDOSHA KK +1

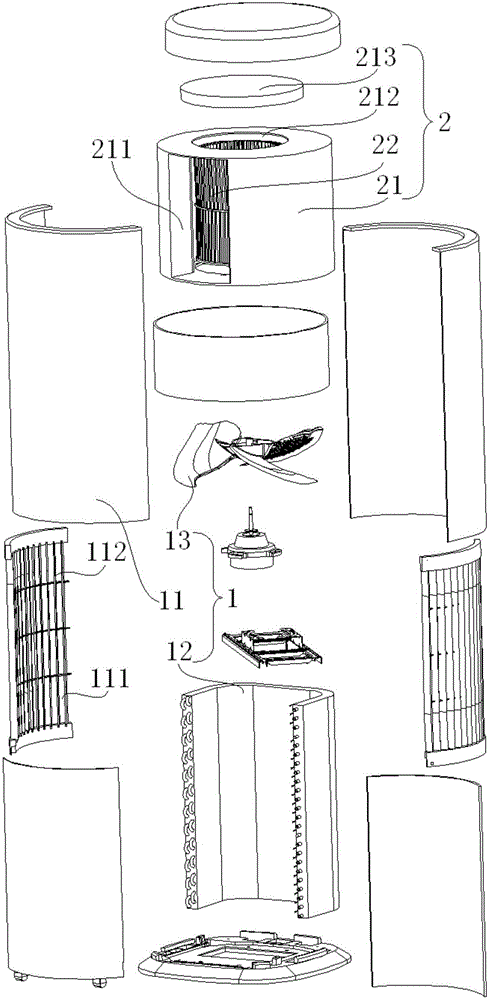

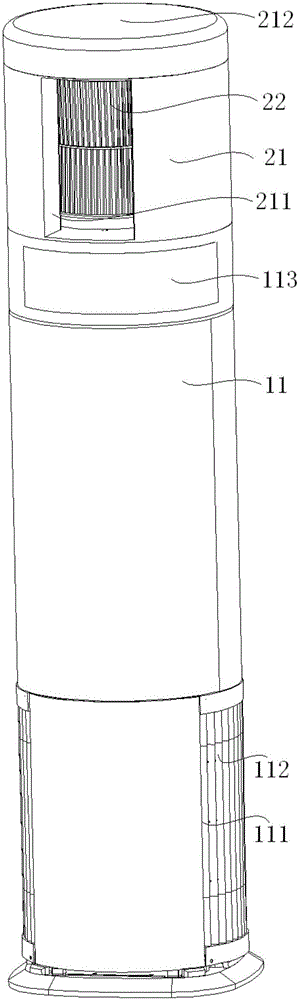

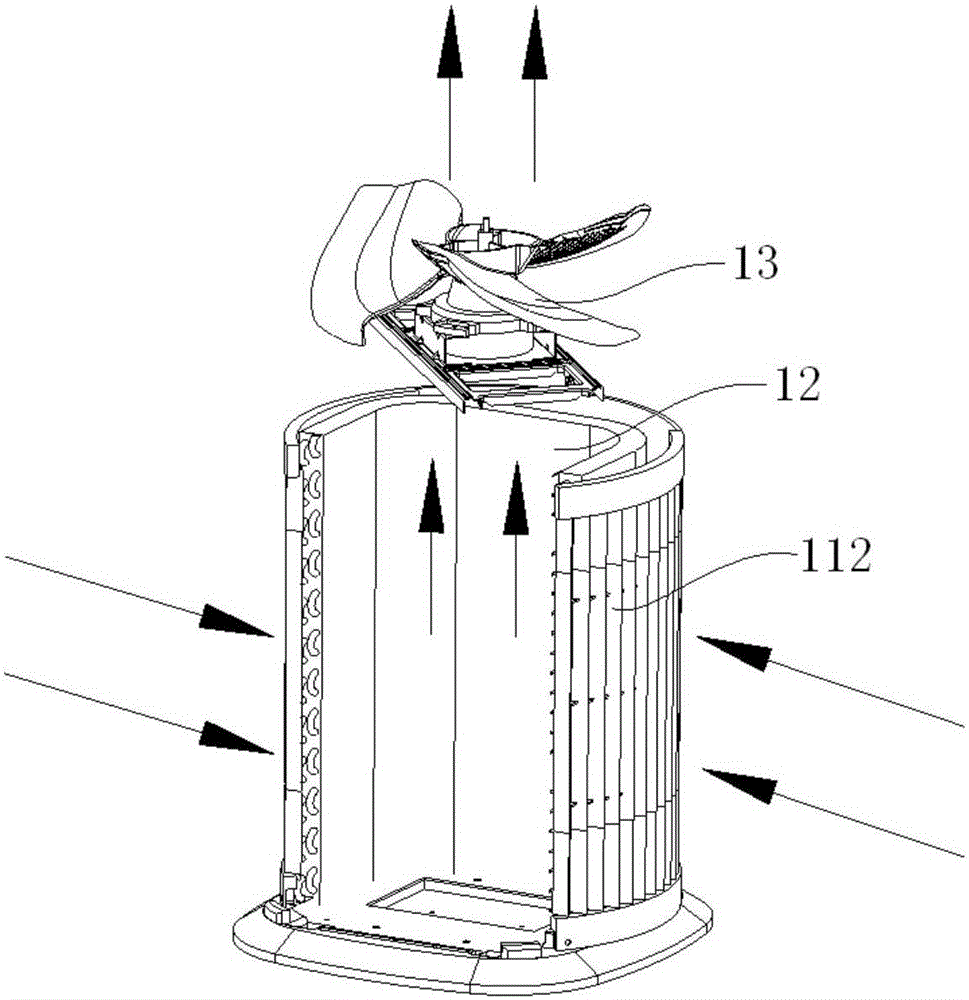

Cabinet type air conditioner capable of achieving remote air supply

ActiveCN106091215AHigh speedFaster, but faster static pressureLighting and heating apparatusAir-flow control membersPulp and paper industryCentrifugal fan

The embodiment of the invention provides a cabinet type air conditioner capable of achieving remote air supply and relates to the technical field of air conditioners. By means of the cabinet type air conditioner capable of achieving remote air supply, the problem that an existing cabinet type air conditioner cannot achieve wide-area air supply and is short in air supply distance is solved. The cabinet type air conditioner capable of achieving remote air supply comprises a fixed unit and a rotating unit. The fixed unit comprises a fixed shell, an evaporator and an axial flow fan, wherein the evaporator and the axial flow fan are located in the fixed shell, and a first air inlet is formed in the position, corresponding to the evaporator, of the side wall of the fixed shell. The rotating unit comprises a rotating shell and a centrifugal fan located in the rotating shell. The rotating shell is located on the upper portion of the fixed shell and communicates with the interior of the fixed shell. The rotating unit and the fixed unit are connected through a guide mechanism. The rotating unit is connected with a drive assembly which can drive the rotating unit to rotate relative to the fixed unit. The cabinet type air conditioner capable of achieving remote air supply is suitable for adjusting the indoor temperature.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Pressure regulator assembly for use with a slip joint in a driveshaft assembly

InactiveUS7052398B2Avoid negative pressureMaintaining positive pressureClutchesYielding couplingPressure regulatorEngineering

A slip joint includes a structure that prevents a negative pressure situation from occurring within a sealed lubricant chamber during operation thereof. The slip joint includes a male splined member having a plurality of external splines formed thereon that cooperate with a plurality of internal splines formed on a female splined member. The cooperating splines are disposed within a lubricant chamber defined at one end by a seal assembly and at the other end by a pressure regulator assembly. The pressure regulator assembly includes a housing having an open end that faces toward the lubricant chamber. A pressure plate is disposed within the housing of the pressure regulator assembly and is supported for sliding movement relative thereto. A spring urges the pressure plate toward the open end of the housing and the lubricant chamber. As a result, the pressure plate maintains a positive pressure situation within the lubricant chamber, thereby deterring contaminants from passing through the seal assembly into the region of the cooperating splines.

Owner:DANA AUTOMOTIVE SYST GRP LLC

Air conditioning unit drainage structure for railway vehicle

ActiveCN102126504AAvoid negative pressureLess prone to cloggingRailway heating/coolingVehicle heating/cooling devicesPulp and paper industryAir conditioning

The invention discloses an air conditioning unit drainage structure for a railway vehicle. The air conditioning unit drainage structure comprises a drainage disk arranged on the bottom plate of an air conditioning unit, and is characterized by also comprising a first-level water seal structure and a second-level water seal structure; the first-level water seal structure comprises a cover body covered on the drainage disk of the air conditioning unit; the bottom of the cover body is provided with a plurality of notches; the notches and the bottom of the drainage disk form a water inlet passage; a bypass passage is formed in the middle of the cover body; the second-level water seal structure is a variable cross-section drainage pipe; and the opening of the variable cross-section drainage pipe is positioned at the bottom of the drainage disk in the cover body. The required installation space of the air conditioning unit drainage structure is small, the air conditioning unit drainage structure can overcome the negative pressure of the air conditioning unit sufficiently, and has a water seal function; and dust is hardly blocked.

Owner:GUANGZHOU ZHONGCHE RAIL WAY VEHICLES AIR CONDITIONING EQUIP

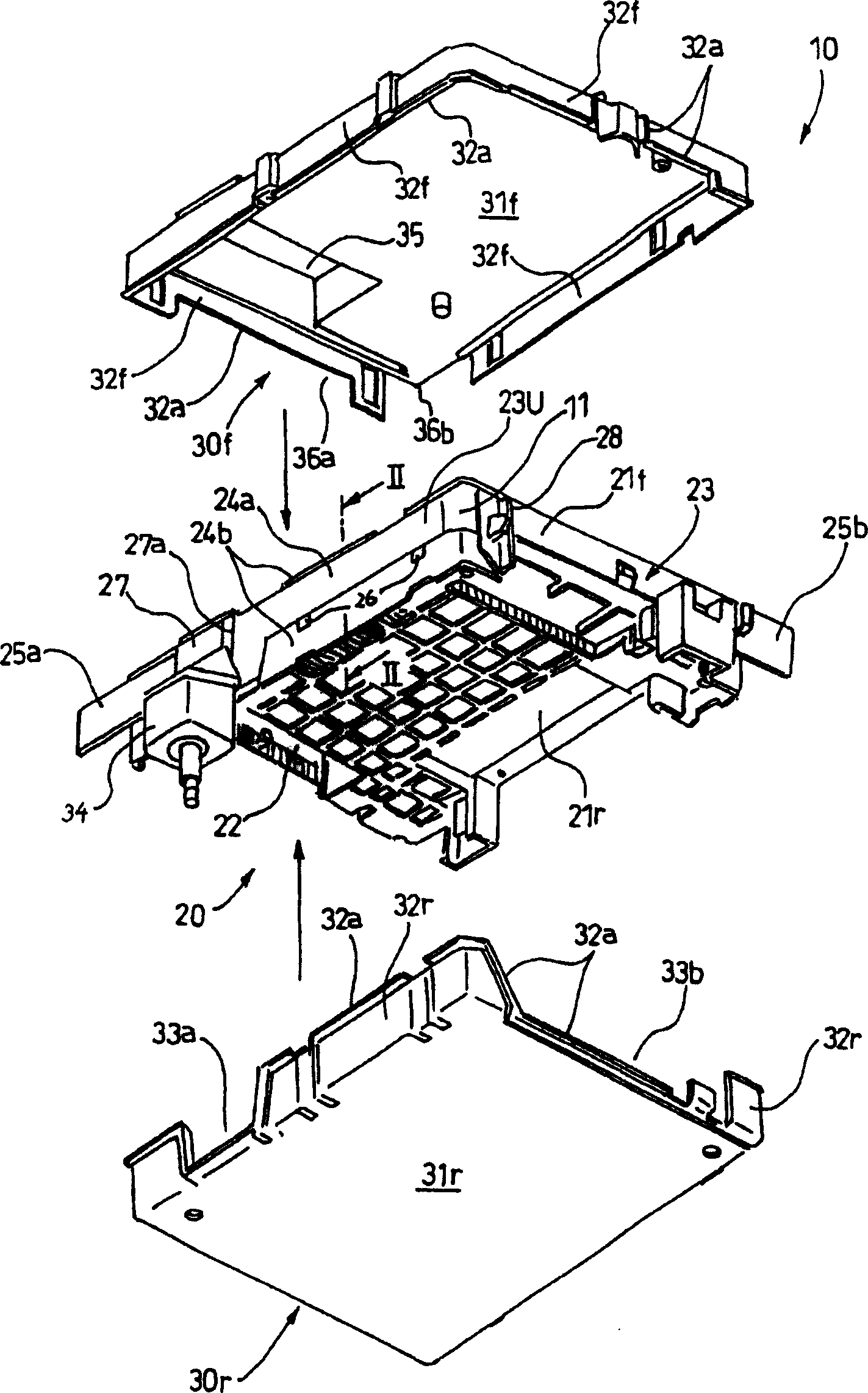

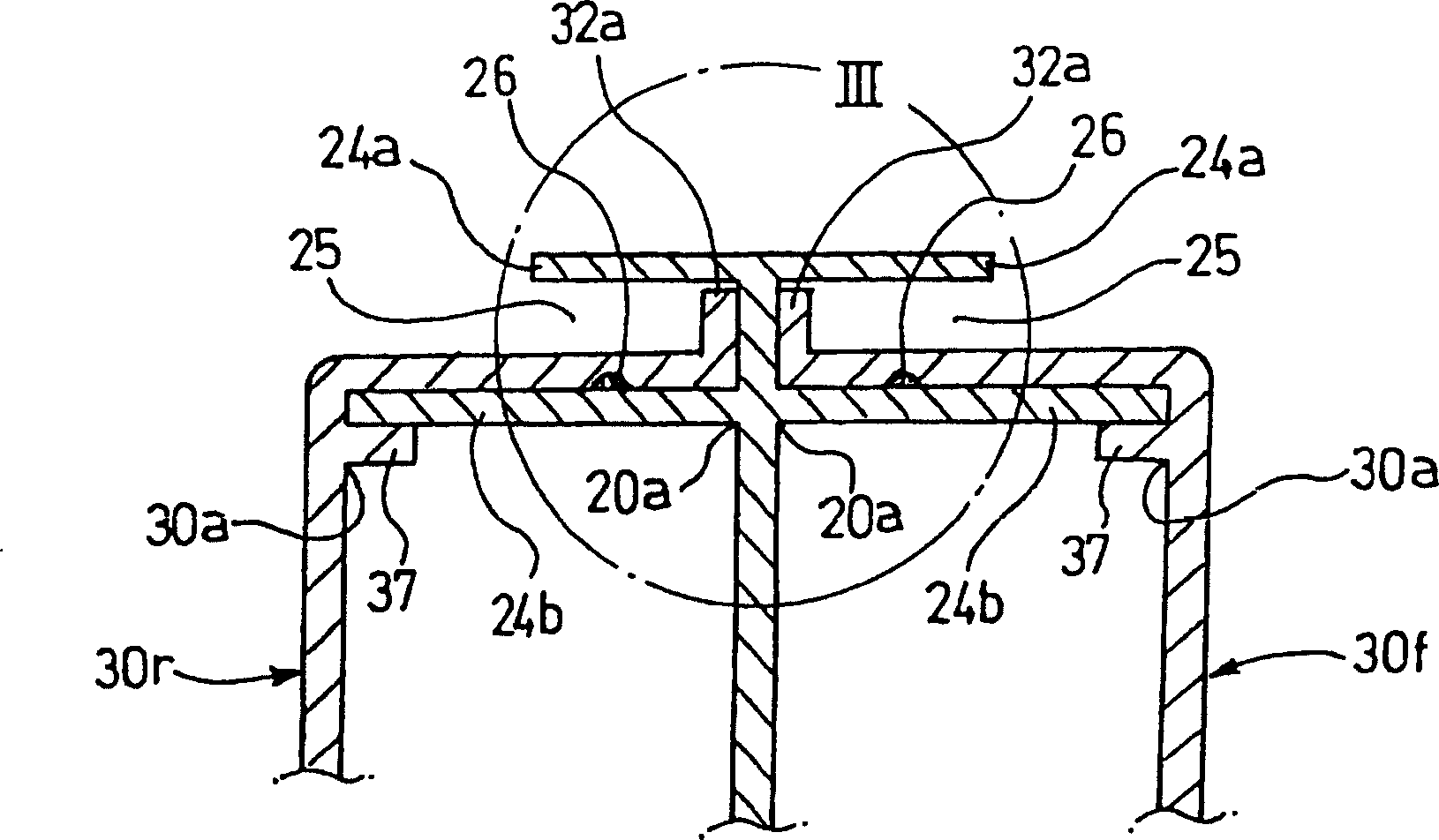

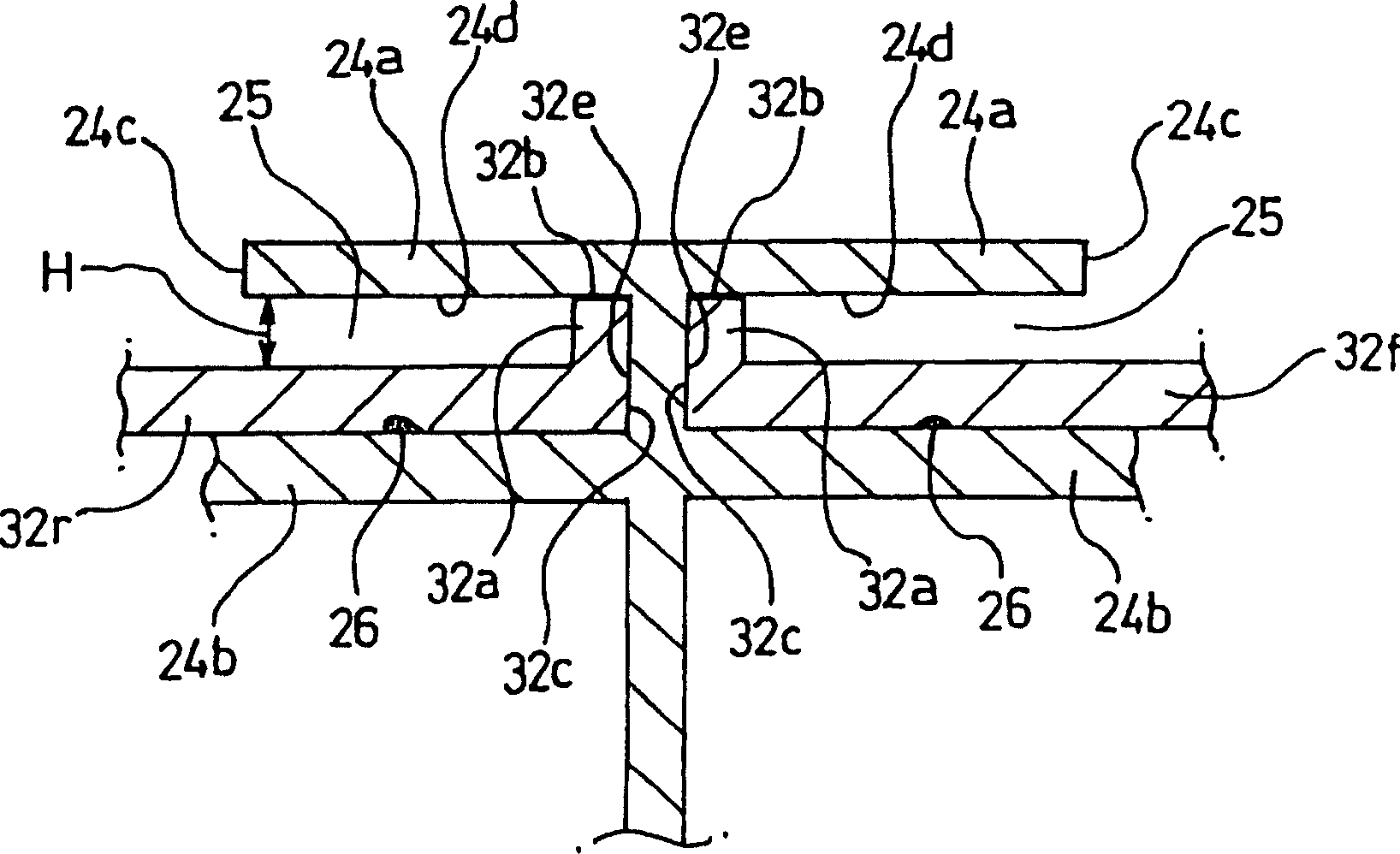

Waterproof structure of electtrical terminal box

ActiveCN1540823AAvoid negative pressureAvoid stockpilingElectrical apparatusInterior spaceExtended side

To provide the waterproof structure of an electric connection box which can be surely waterproofed. A part of an outer wall 24a is swelled to provide swelled parts 25a, 25b, thereby realizing preventing of water from dropping on a part which is influenced by scattered water, such as a fuse plate, a connector block, etc. That is, since the side wall 24a of the box is extended so as to cross the scattered water over the influenced part, the water drops down along the extended side wall 24a. Or, since the swelled parts 25a, 25b shut off or turn the flow of the water, the water is prevented from being flooded into the interior along the outer wall by a capillarity. (C)2005,JPO&NCIPI.

Owner:YAZAKI CORP

Vibration damper

InactiveUS7743895B2Increase the effective sectionAvoid negative pressureSpringsNon-rotating vibration suppressionEngineeringPiston rod

Vibration damper comprising a cylinder in which a piston rod is guided with freedom of axial movement, where the piston rod cooperates with a piston arrangement comprising a first, stationary piston and at least one additional piston, which is supported on the piston rod with freedom of axial movement against the elastic force of at least one restoring spring, where the cylinder is divided by the stationary piston and by the minimum of one axially movable piston into a working space on the side of the piston facing the piston rod, a working space on the side of the piston facing away from the piston rod, and a working space between the two pistons, where valve-equipped through-openings control a connection between the working spaces, and where the axial movement of the minimum of one axially movable piston is limited by a hydraulic pressure stop.

Owner:ZF FRIEDRICHSHAFEN AG

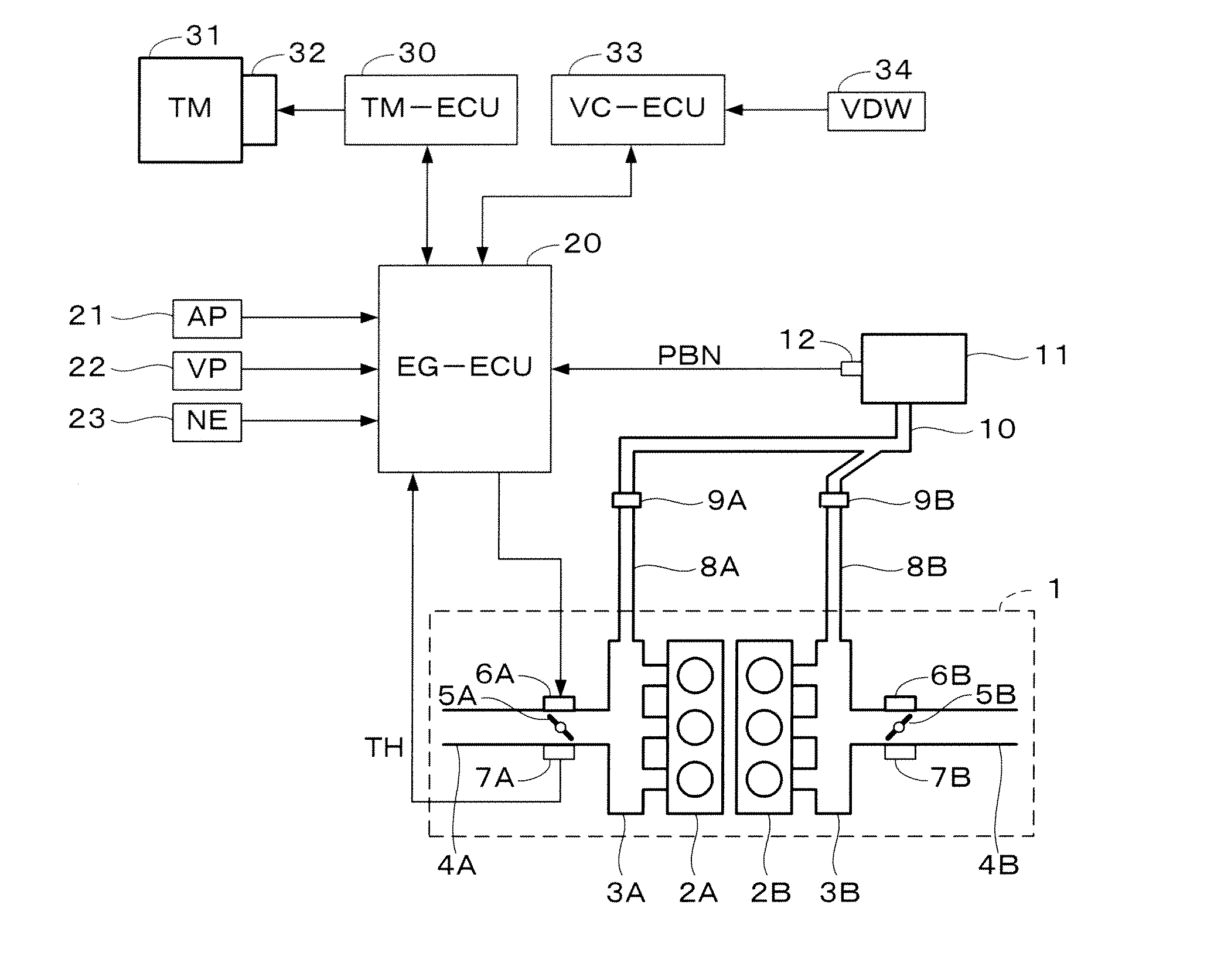

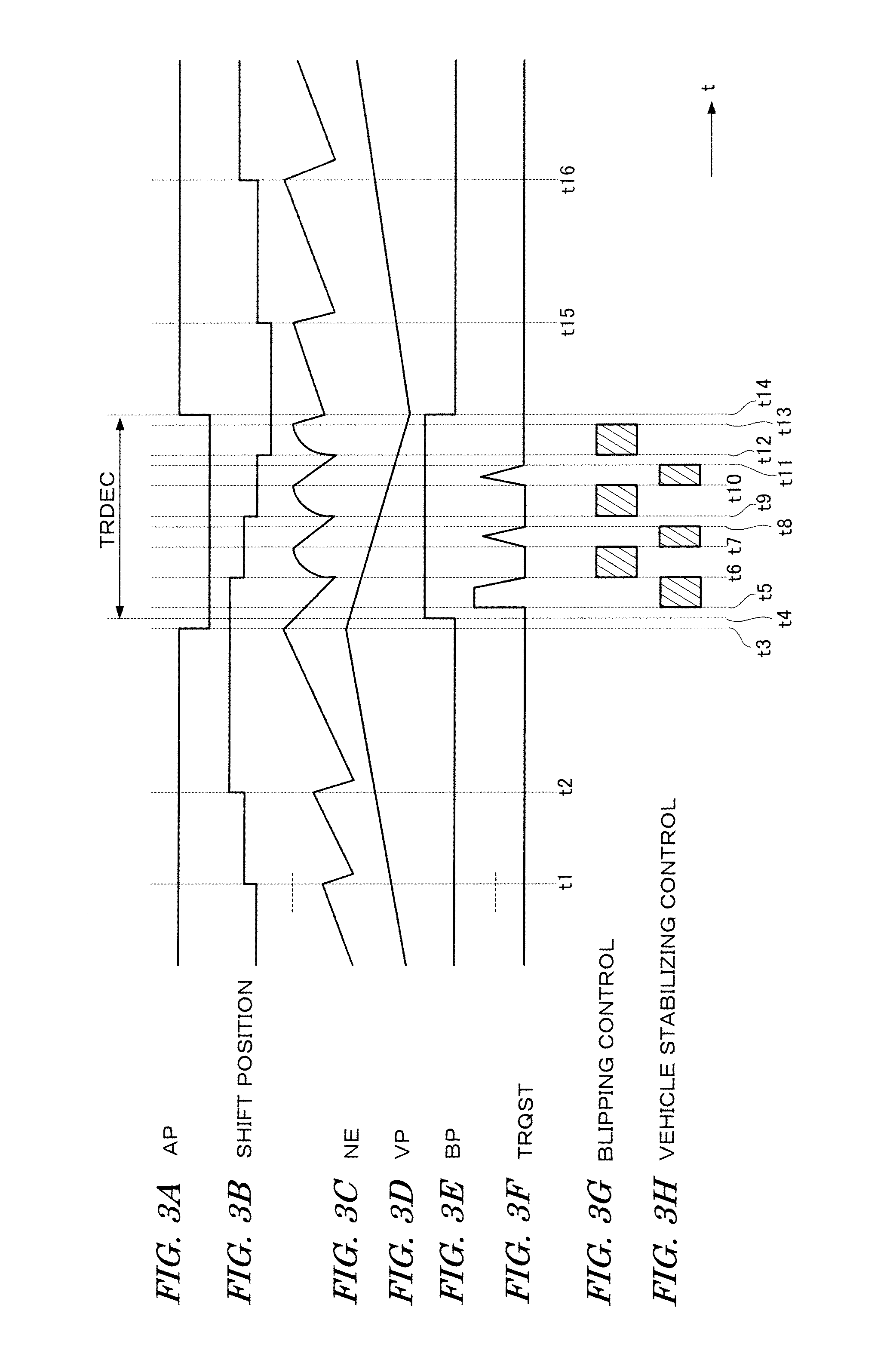

Control system for internal combustion engine

InactiveUS20110017171A1Reduce pressureAvoid negative pressureElectrical controlAnalogue computers for trafficControl systemInternal combustion engine

A control system for an internal combustion engine having a plurality of cylinders including first and second cylinder groups. The first and second intake systems correspond respectively to the first and second cylinder groups, and first and second throttle valves are provided respectively in the first and second intake systems. An output of the engine is reduced upon deceleration of a vehicle driven by the engine. A pressure parameter indicative of an assisting force generated by a brake booster is detected. An intake negative pressure is supplied to the brake booster from the first and second intake systems. One of the first and second throttle valves is opened to increase the engine output when the pressure parameter is equal to or less than a first threshold value which indicates that the assisting force of the brake booster has decreased.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com