Air conditioning unit drainage structure for railway vehicle

A technology for air-conditioning units and rail vehicles, which is applied to vehicle components, railway vehicle heating/cooling, railway car body components, etc. It can solve problems such as large vehicle space, drainage blockage, and endangering the safety of electrical equipment, and achieves easy cleaning and maintenance. Easy to clean and not easy to be blocked by mud and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

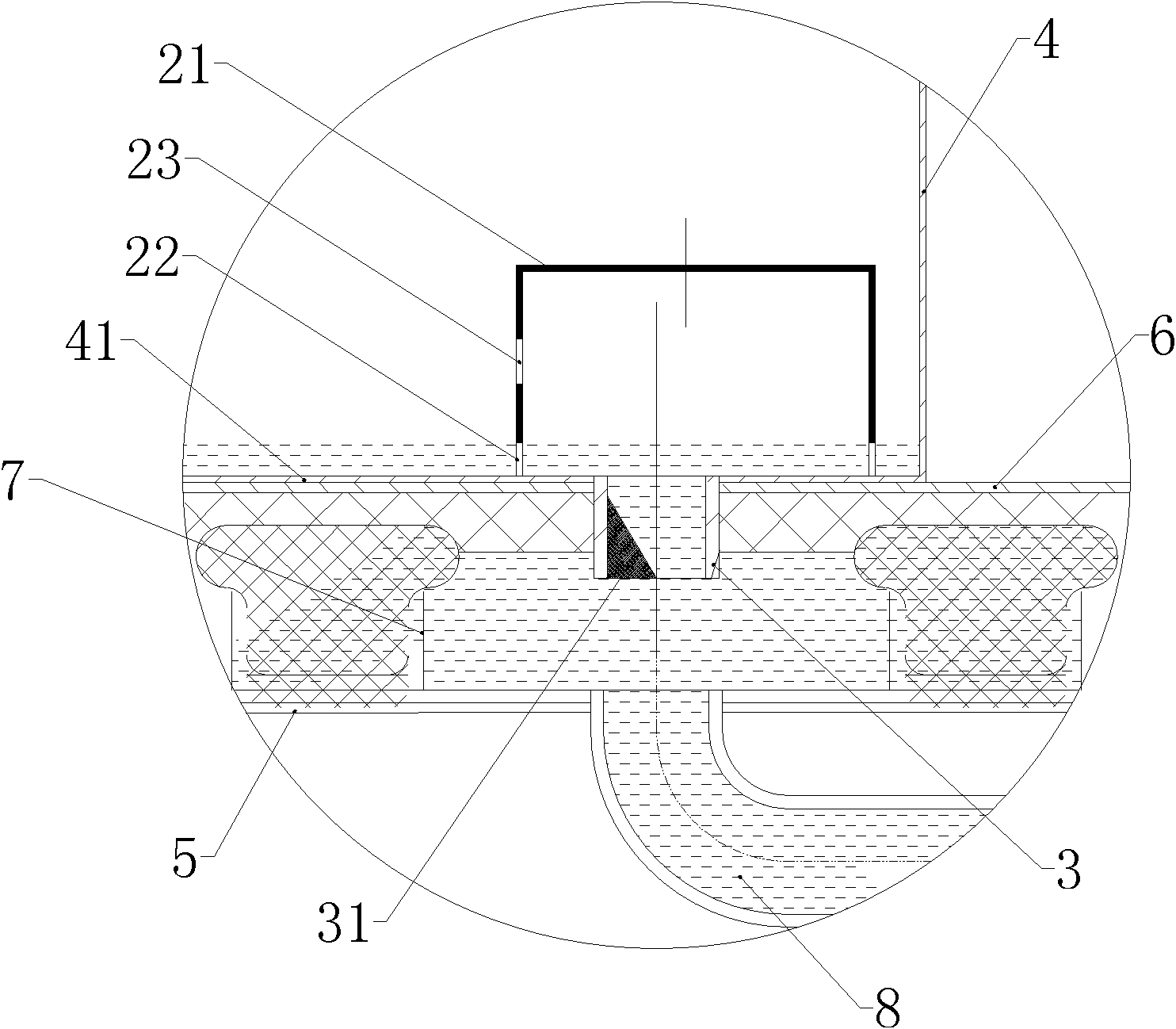

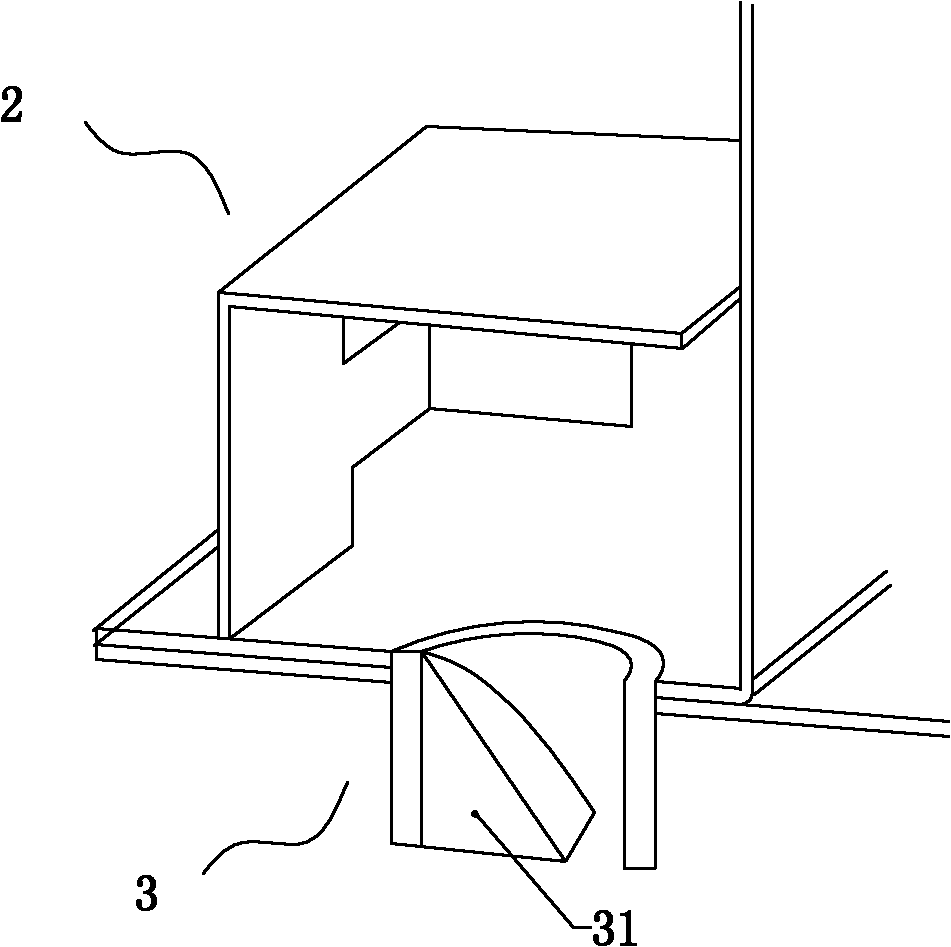

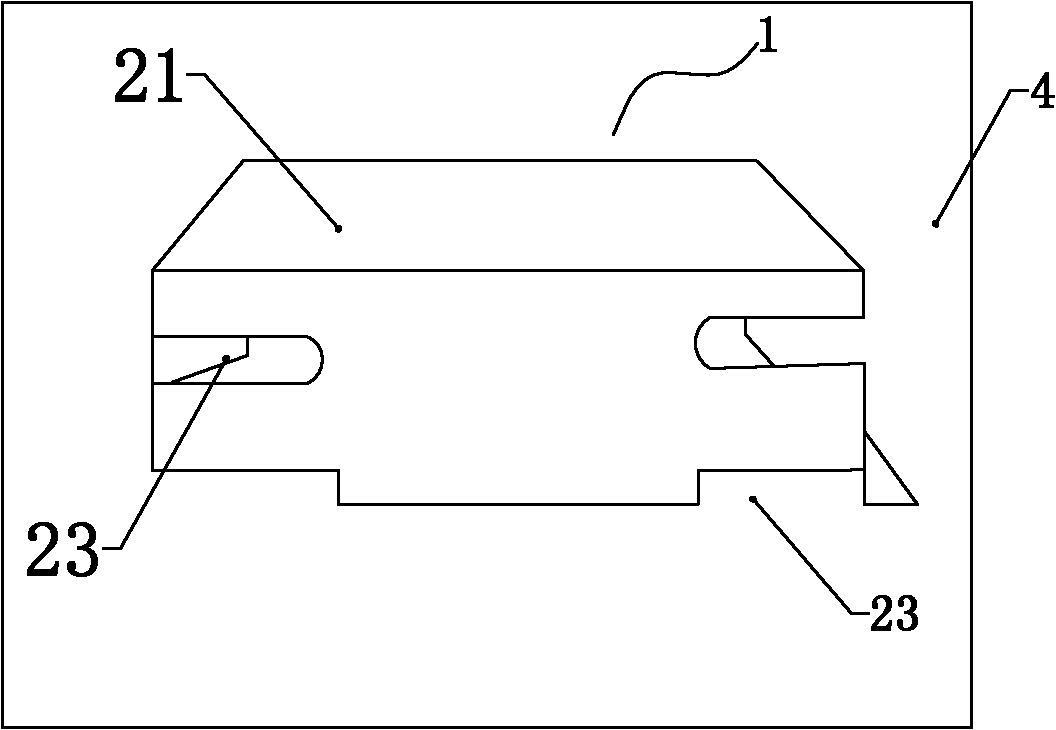

[0026] The drainage structure of the rail vehicle air-conditioning unit according to the present invention adopts the principle of two-stage water seal, and the first-stage water seal structure utilizes the principle of bypass to change the flow direction of the air through the change of the height of condensed water, and finally form a water seal. Thereby overcoming the air negative pressure, the condensed water can smoothly enter the water seal of the variable cross-section drainage pipe of the second stage. The second-stage water seal structure is to use variable cross-section drainage pipes to facilitate the formation of water seals through the principle of decreasing wind speed and dynamic pressure. The water seal structure has a small appearance. In order to facilitate the cleaning and maintenance work, the first-stage water seal structure is detachable, and the water seal structure can be disassembled and assembled by simple bare-hand operation, and the cleaning and main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com