Air turbine handpiece

a handpiece and air turbine technology, applied in the field of handpieces of air turbines, can solve the problems of generating negative pressure in the turbine room, contaminant inhalation of patient saliva and blood etc., and inhalation of ambient air, so as to prevent cross infection between patient and operator or among patients, prevent negative pressure from being generated efficiently, and prevent foreign material from being inhaled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0054]As shown in the FIG. 7, an air turbine handpiece 1 of this embodiment that applies the present invention comprises a neck portion 2 grasped by an operator, a head portion 3 installed consecutively to the tip side of the neck portion 2, and a grip portion 4 installed consecutively behind the neck portion 2, and a hose 5 with built-in feed pipe and exhaust pipe (not shown) is connected with the rear end of the grip portion 4.

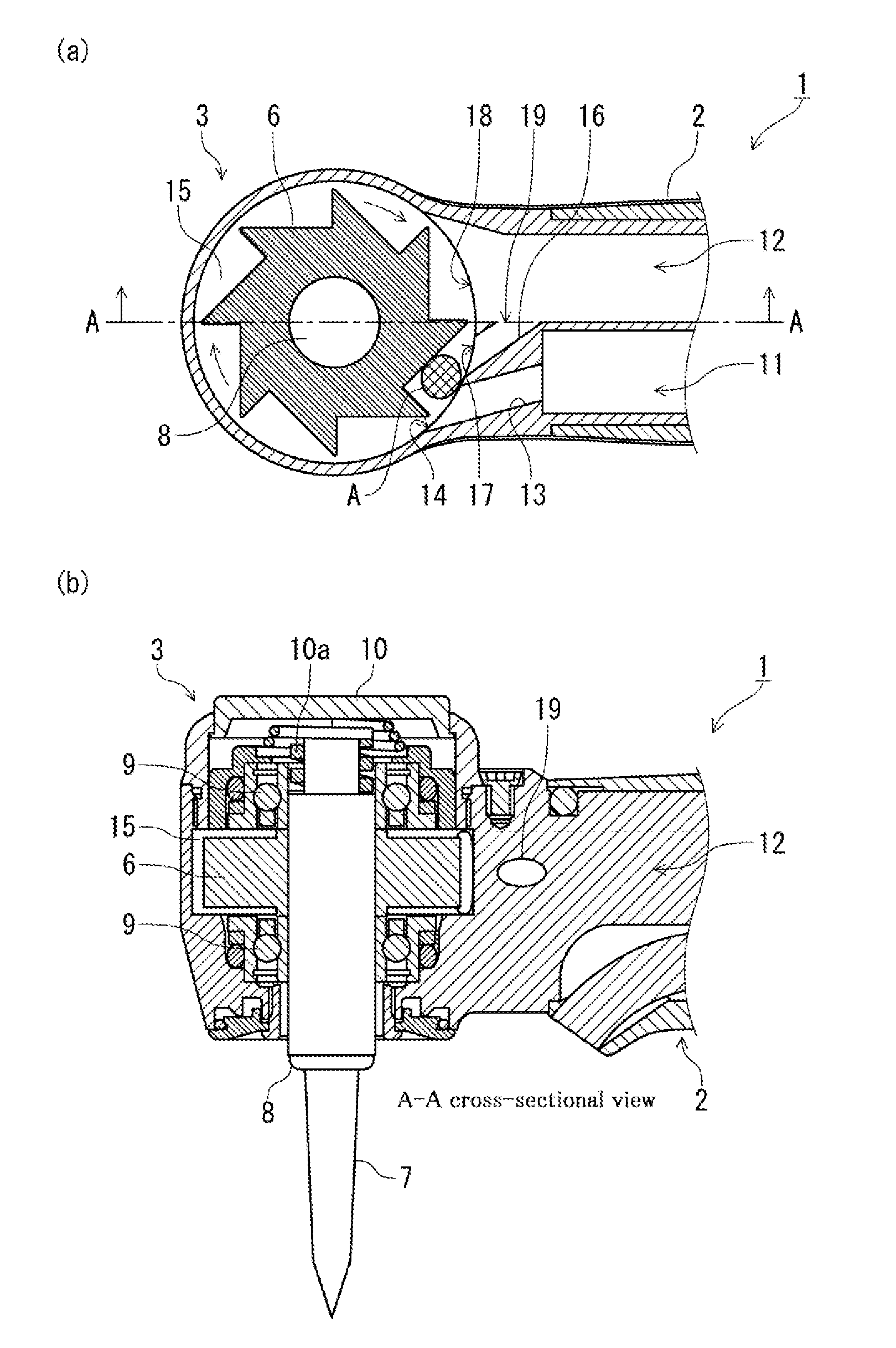

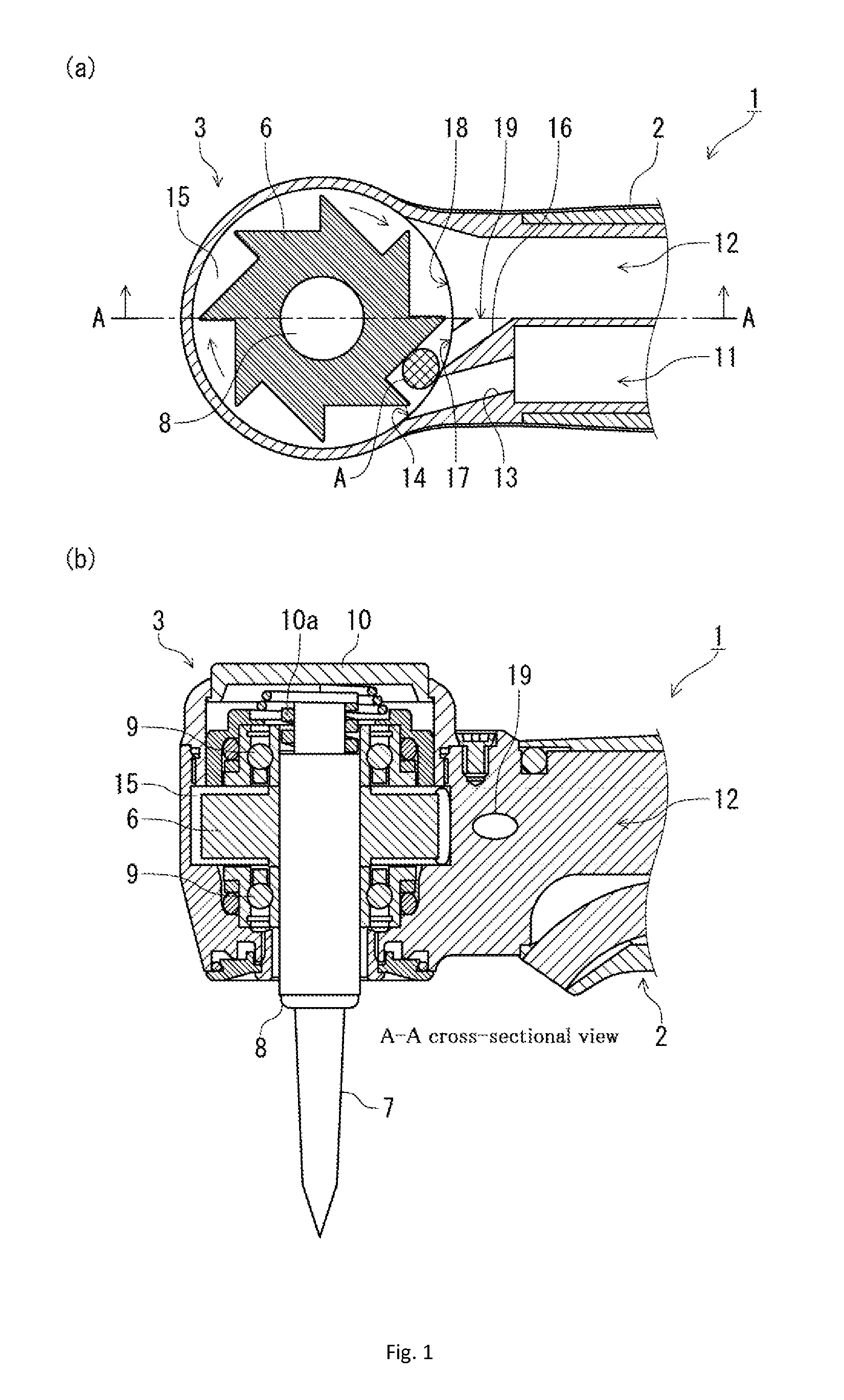

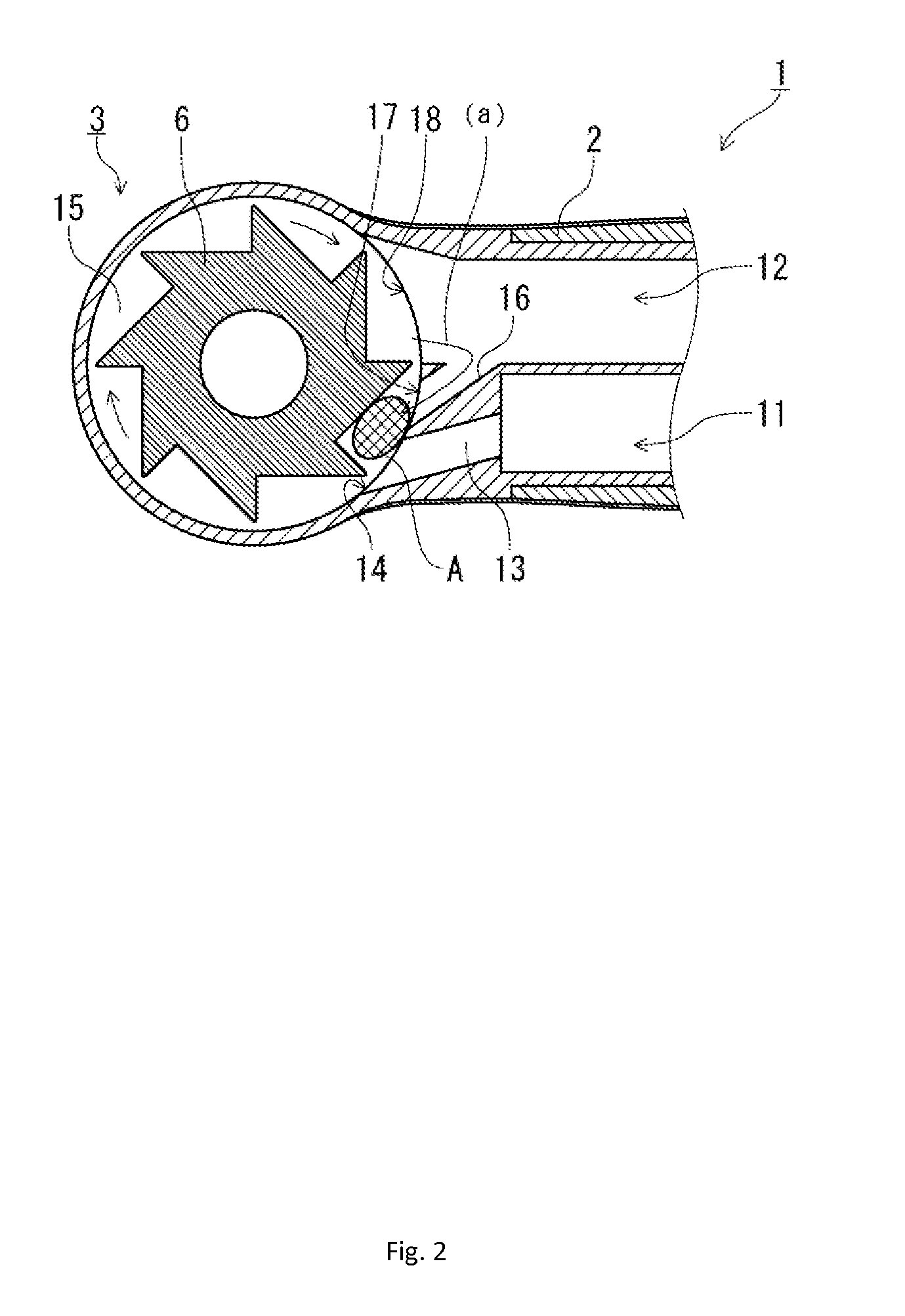

[0055]As shown in FIG. 1, a turbine room 15 is formed in the interior of the head portion 3 of the air turbine handpiece 1, and a turbine blade 6 is fixed to a chuck 8 that supports a tool 7, in interior of the turbine room 15, and is rotatably supported by ball bearings 9 of one pair of upper and lower sides through the chuck 8. Moreover, on the upper end of the chuck 8, the tool 7 is constructed detachably by compressing a pushbutton 10 against energisation of a spring 10a. Furthermore, at the side of the neck portion 2 of the head portion 3, an air supply...

second embodiment

[0063]FIG. 5 shows second embodiment of an air turbine handpiece of the present invention. As shown in FIGS. 5 (a) and (b), in an air turbine handpiece 1 according to the present embodiment 2, is constructed in such a manner that instead of the fact that the reflux exit 17 of the reflux duct 16 is opened to the air supply port 14 near the air supply duct 11 in the above first embodiment, the reflux exit 21 of the reflux duct 20 communicated with the reflux entry 22 opened to the exhaust duct 12, is opened to near the air supply port 14 in the nozzle 13 of the air supply duct 11 near.

[0064]In this case, when the supply of air from the air supply duct 11 is stopped, as shown in FIG. 6 by an arrow (b), the exhaust air exhausted by the inertia rotation of turbine blade 6 is entered in the nozzle 13 from the reflux exit 21 through the reflux entry 22 of reflux duct 20, and is flowed to the area A of the turbine blade 6. As a result, although in the case of present embodiment, the operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com