Pressure-balanced electric motor wheel drive for a pipeline tractor

a technology of electric motor and hydraulic motor, which is applied in the direction of railway components, railway tracks, roads, etc., can solve the problems of pipeline tractor devices that cannot be driven by conventional means, can not be operated reliably or reliably, and lose traction of self-propelled pipeline tractor devices, so as to reduce the susceptibility of internal motors, prevent loss of traction, and contribute to the overall durability and reliability of pipeline tractor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

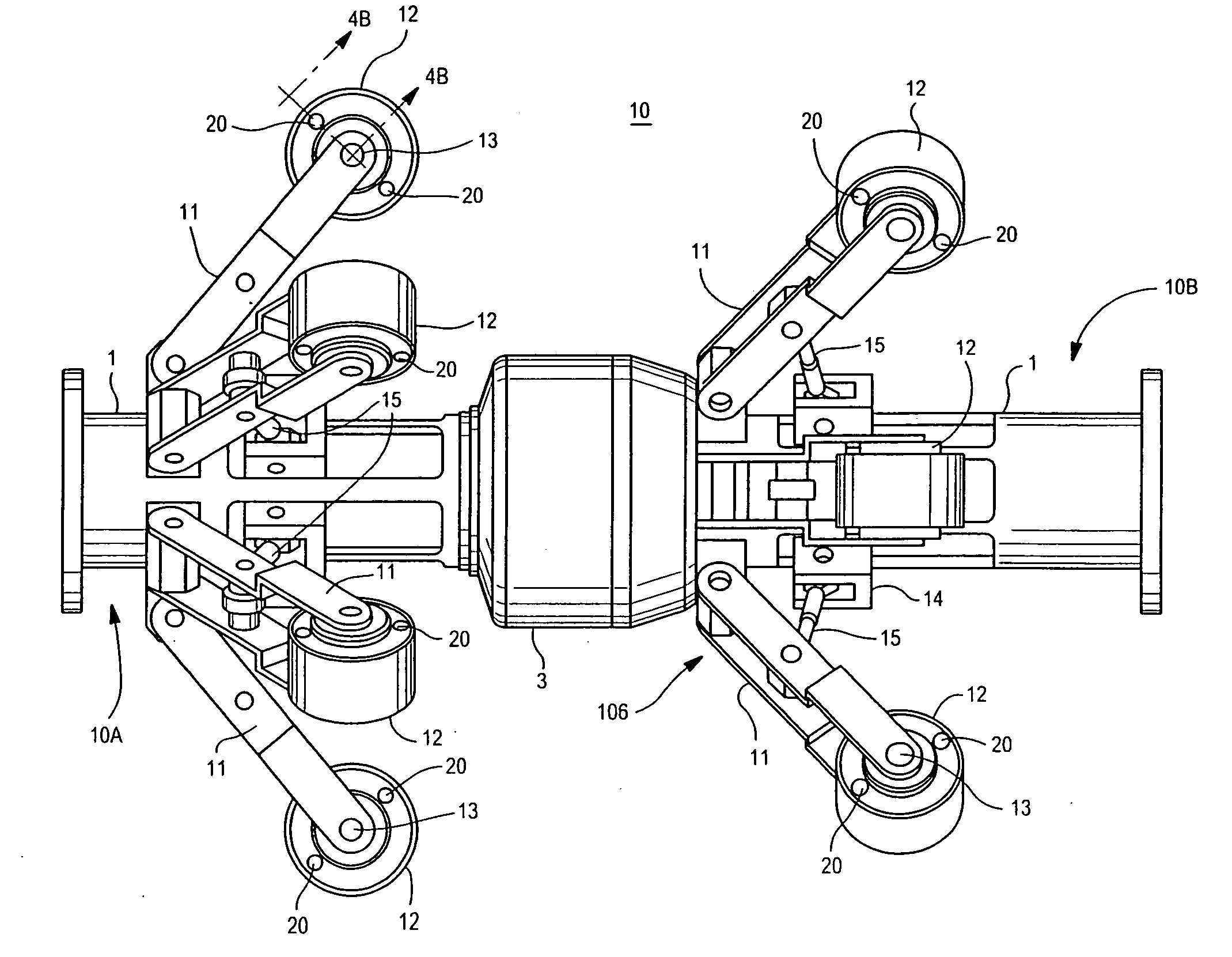

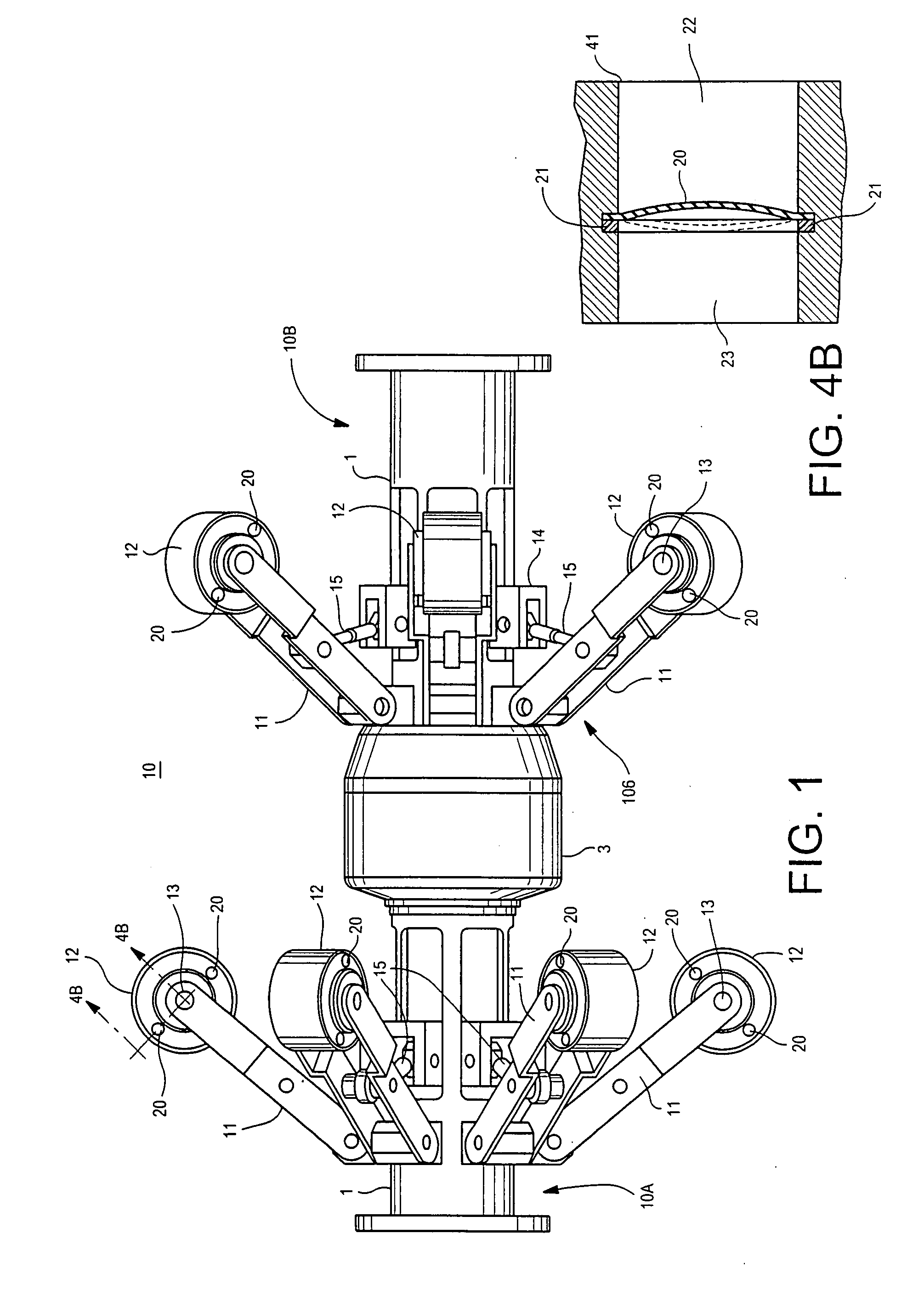

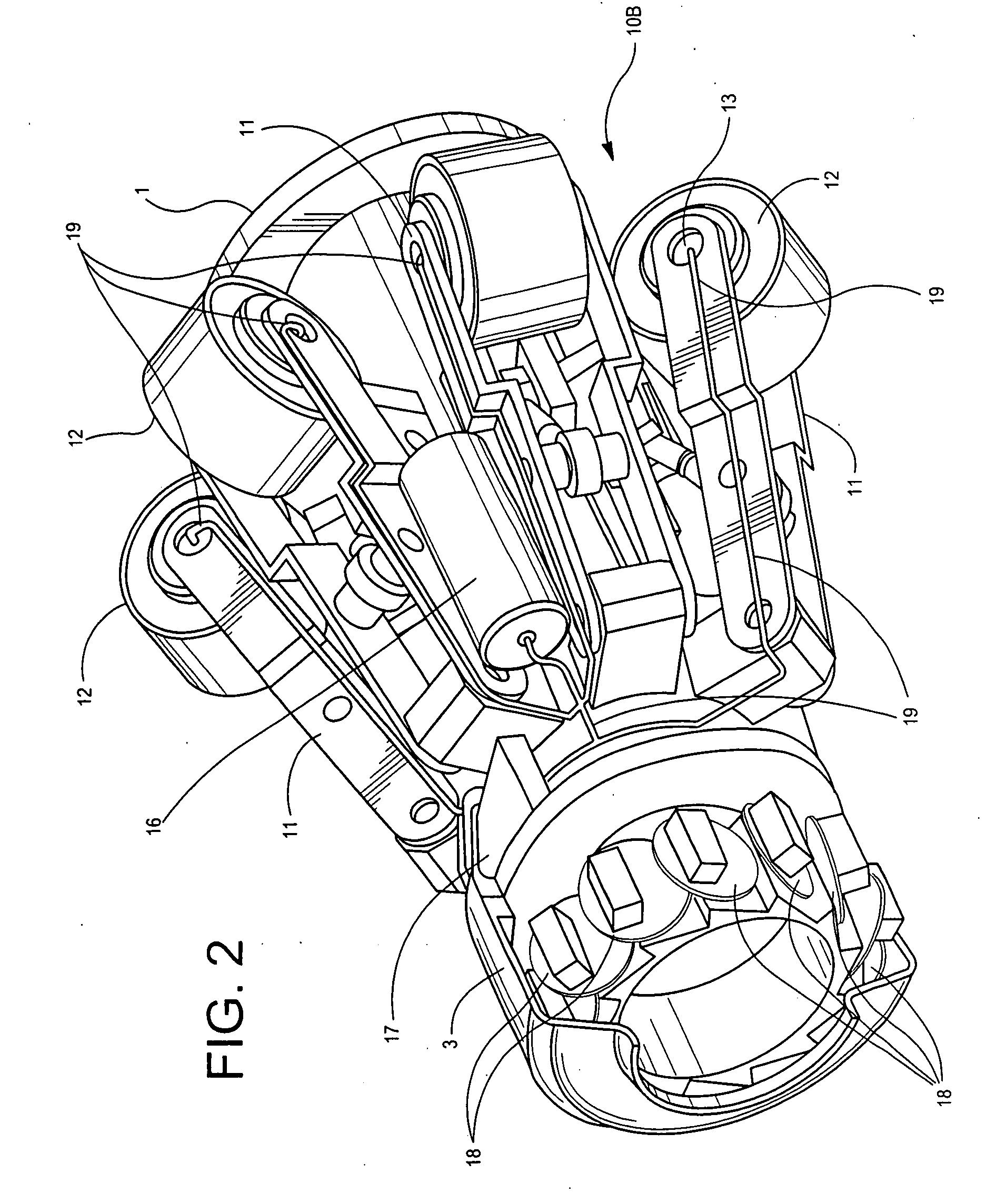

[0019]FIGS. 1 through 3 show various views of a non-limiting example implementation of a self-propelled mechanical crawler or tractor device 10 having self-contained motorized traction drive wheels 12 mounted on twelve drive wheel support extension arms that are pivotally attached and circumferentially arranged about the exterior of a basically cylindrically shaped main chassis 1. Alternative drive configurations having fewer or a greater number of circumferentially mounted drive wheel support extension arms with self-contained motor drive wheels are also possible for tractor 10.

[0020]FIG. 1 presents a side view of tractor device 10 in which only seven of the twelve drive wheel support extension arms with motorized drive wheel assemblies are visible. In this non-limiting illustrative example, tractor device 10 is made up of a modular front and rear chassis section (10a and 10b) with each chassis section having six radially arranged support extension arms 11 that each support a drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com