Patents

Literature

168 results about "Brushless DC electric motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A brushless DC electric motor (BLDC motor or BL motor), also known as electronically commutated motor (ECM or EC motor) and synchronous DC motors, are synchronous motors powered by direct current (DC) electricity via an inverter or switching power supply which produces an alternating current (AC) electric current to drive each phase of the motor via a closed loop controller. The controller provides pulses of current to the motor windings that control the speed and torque of the motor.

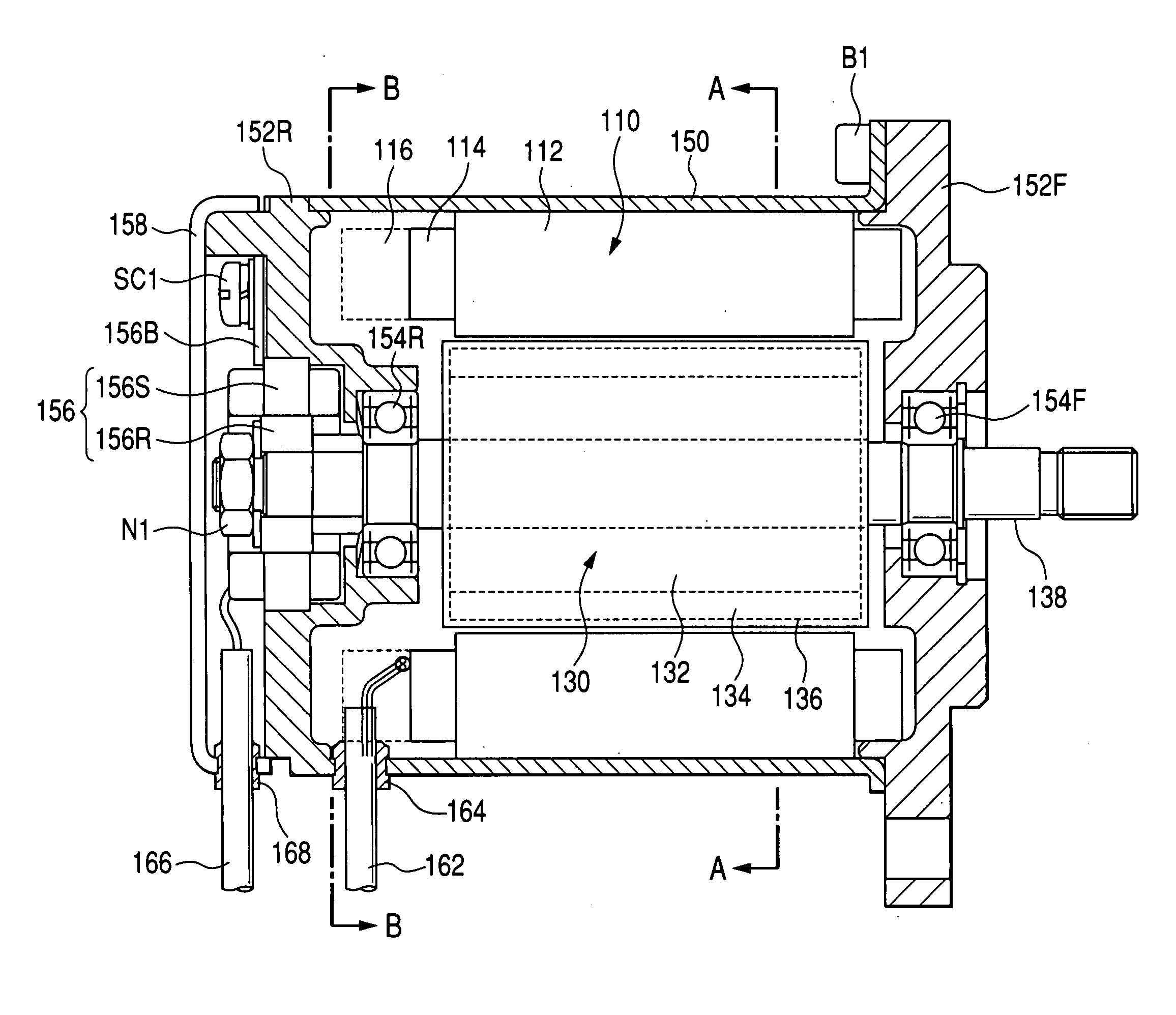

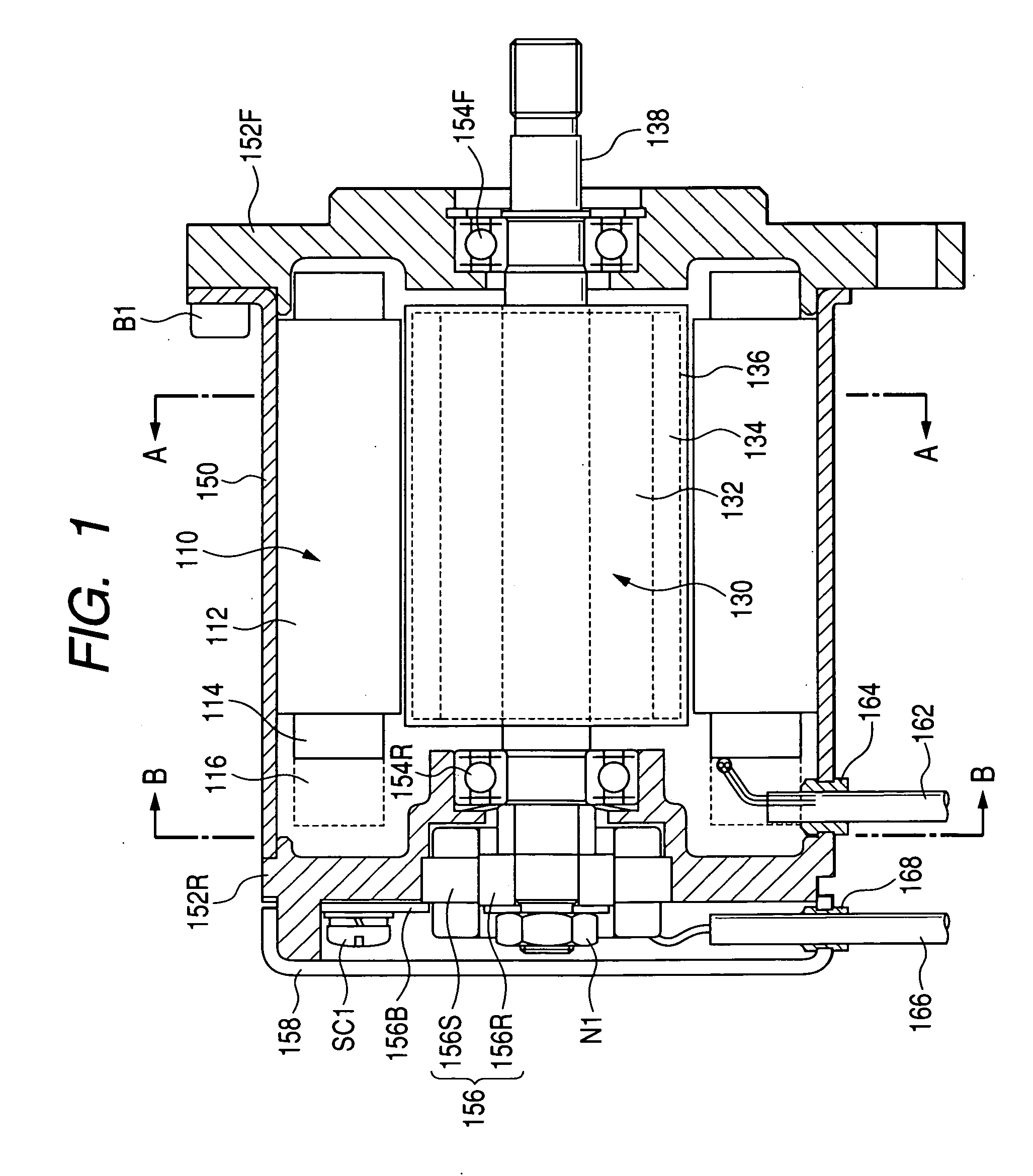

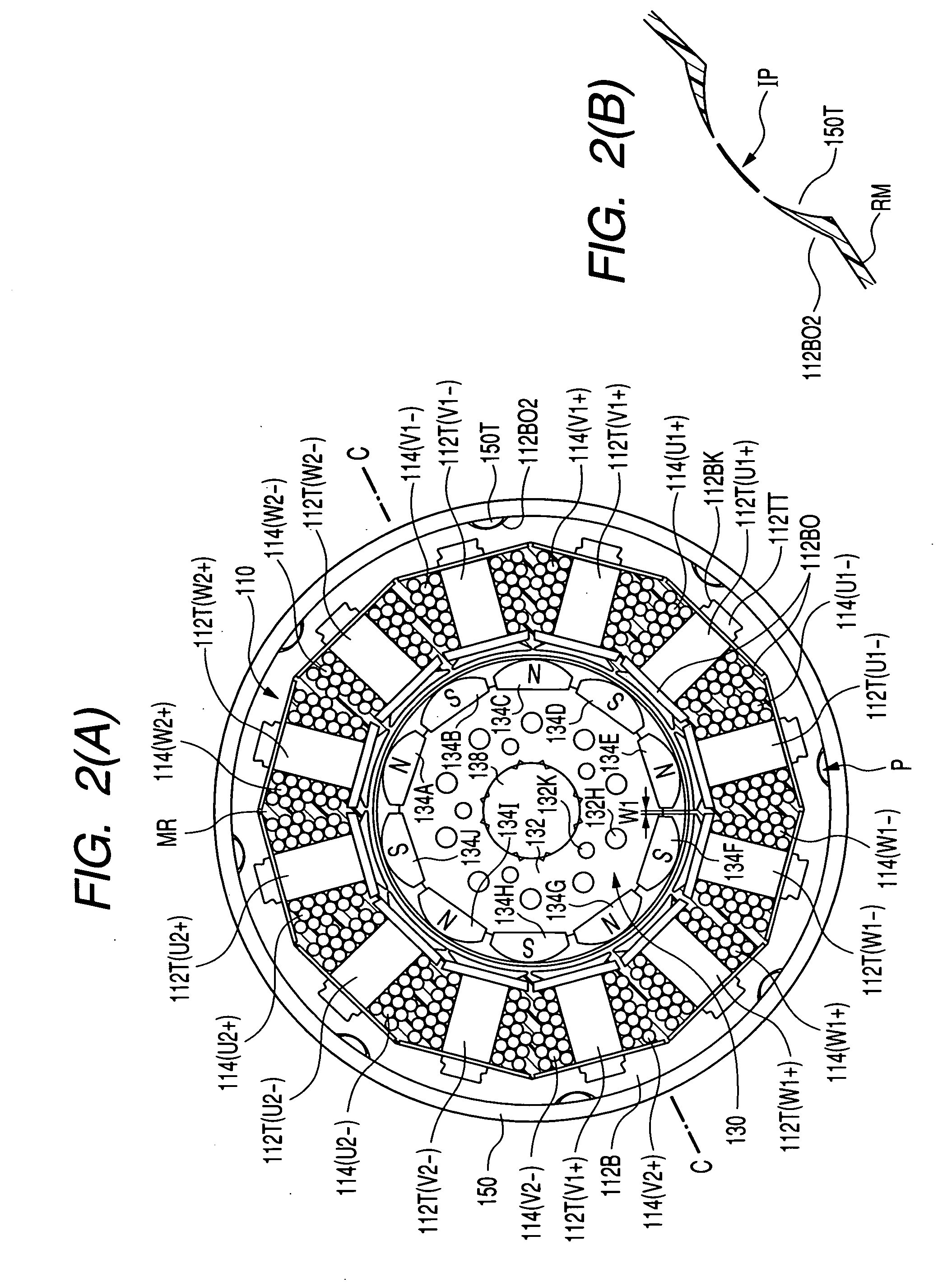

DC brushless motor for electrical power steering and the production method thereof

InactiveUS20050269895A1Torque pulsation can be reducedEffective reduction of torque pulsationAssociation with control/drive circuitsWindings insulation shape/form/constructionBrushless motorsElectric power steering

The stator core of a motor comprises an annular back core, and a plurality of tees created separately from the back core and secured onto the inner periphery of the back core. A stator coil is wound on each of the tees by a distributed or concentrated winding method. The stator core and stator coil are formed by molding.

Owner:HITACHI LTD

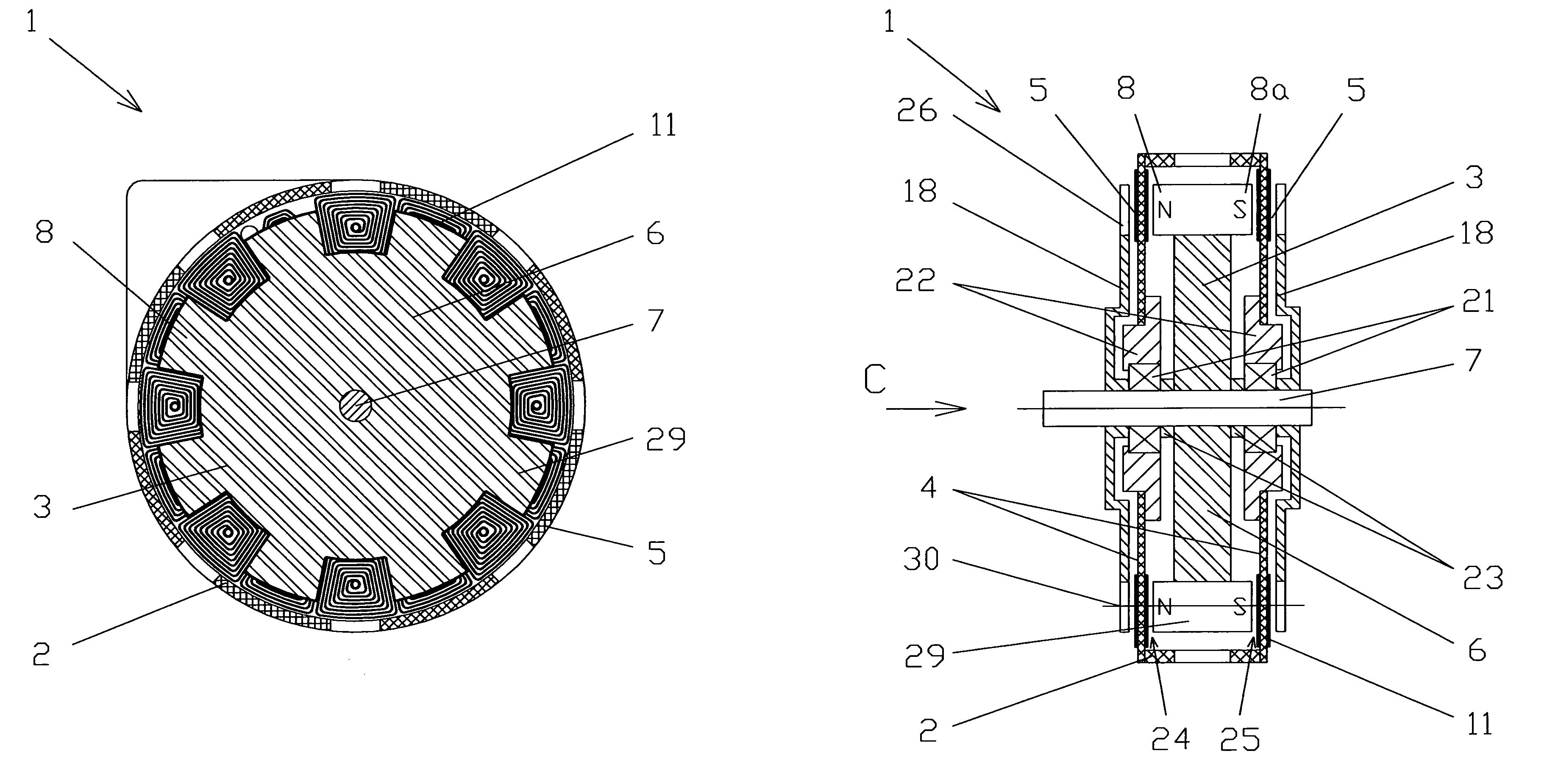

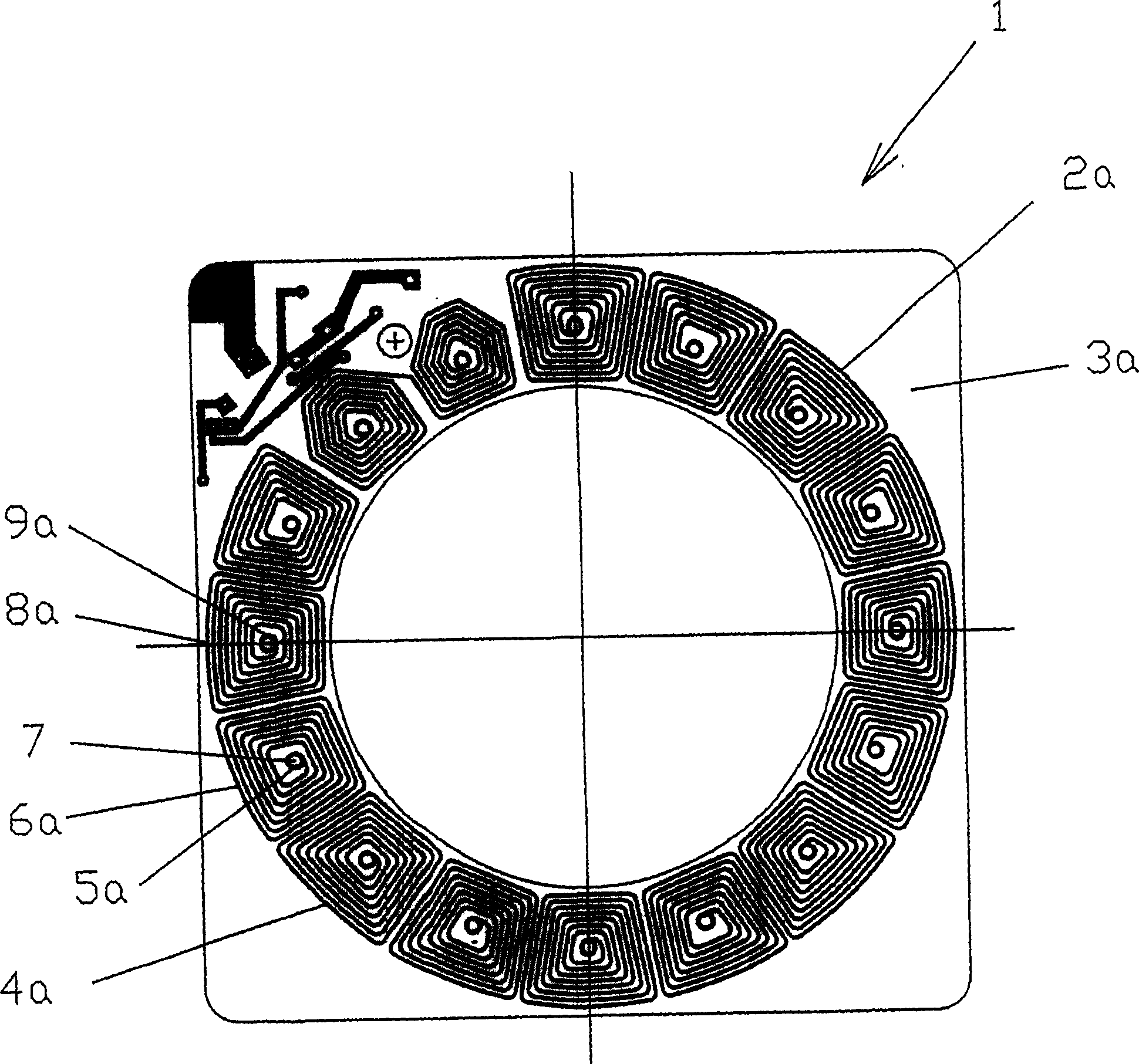

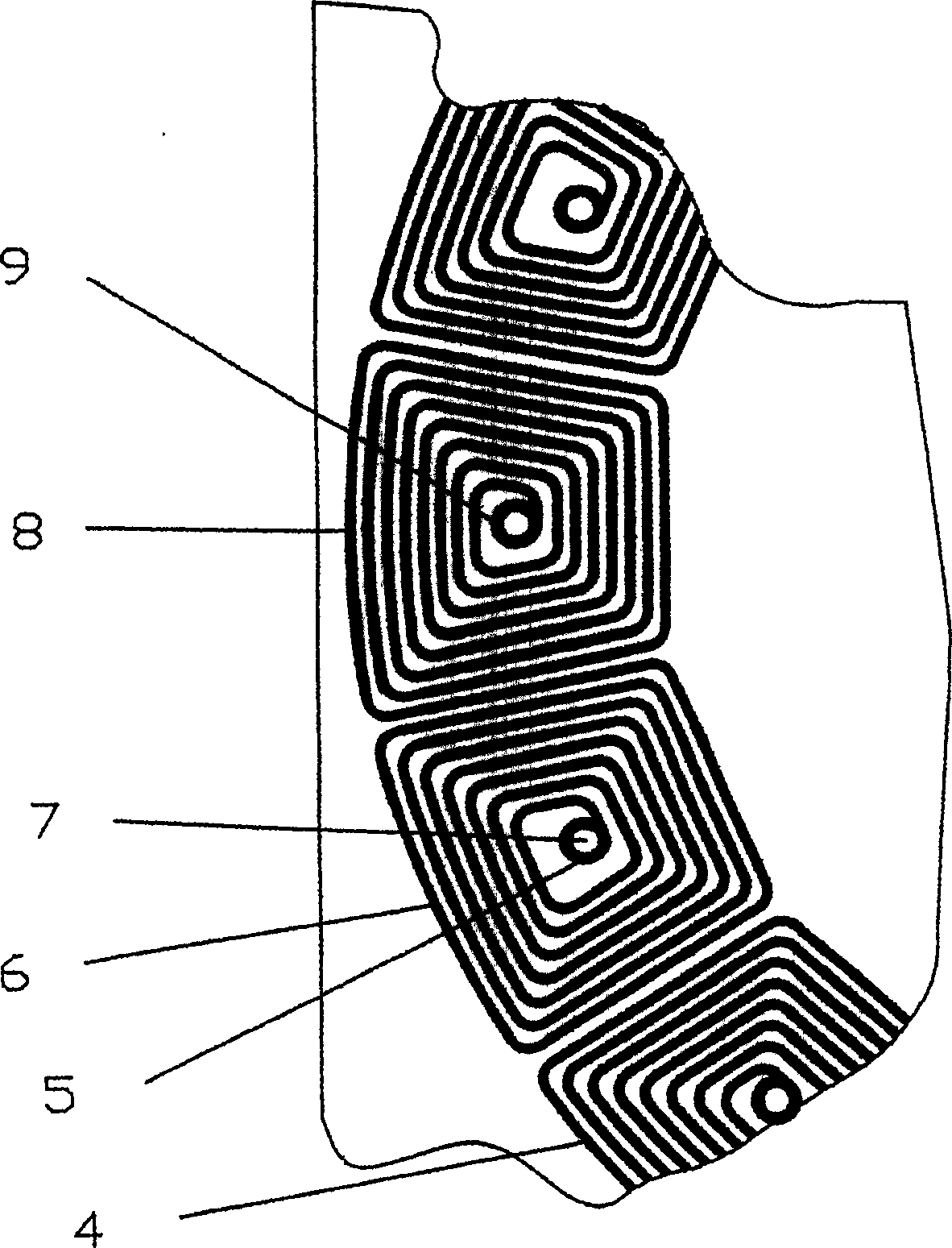

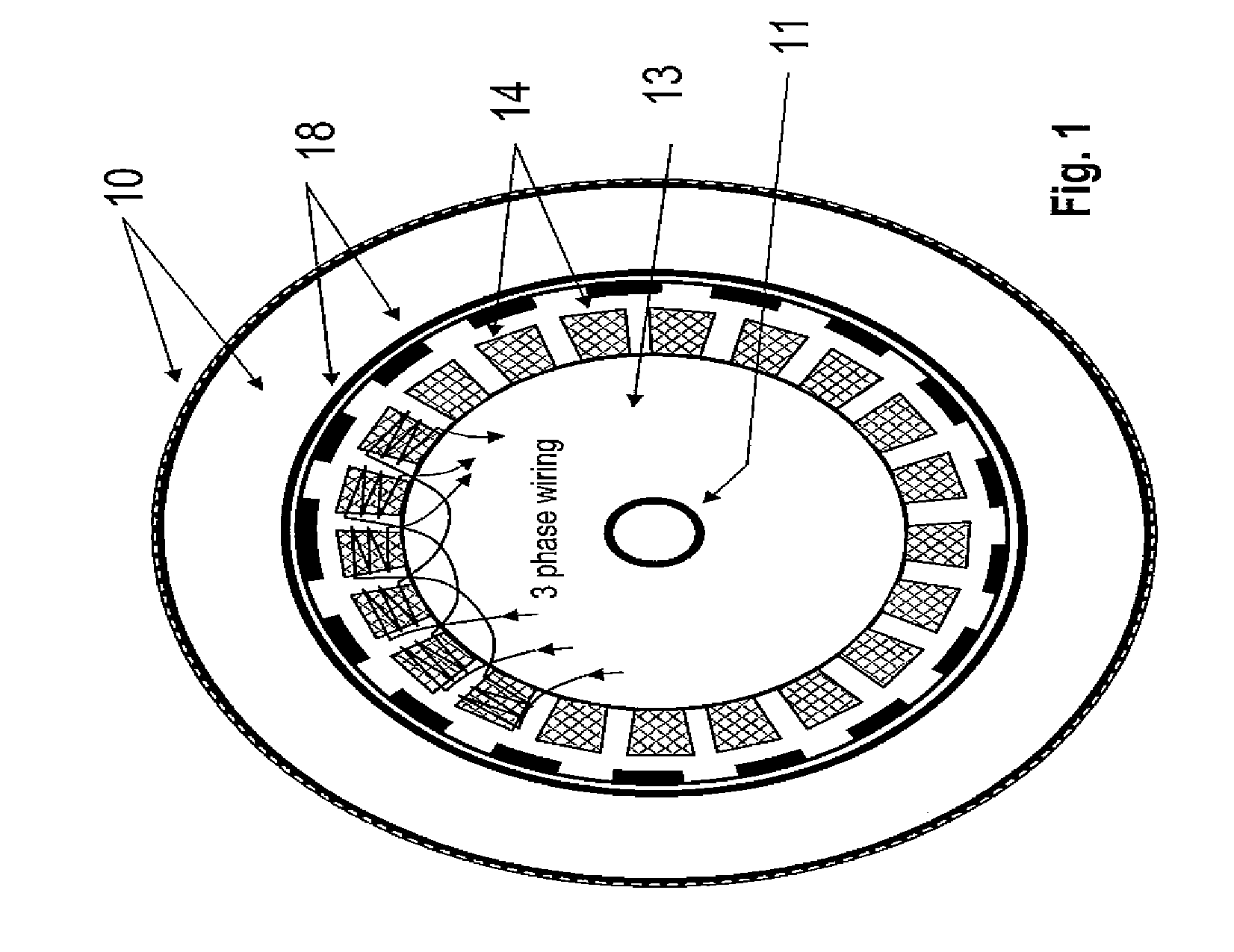

Brushless DC electric motor

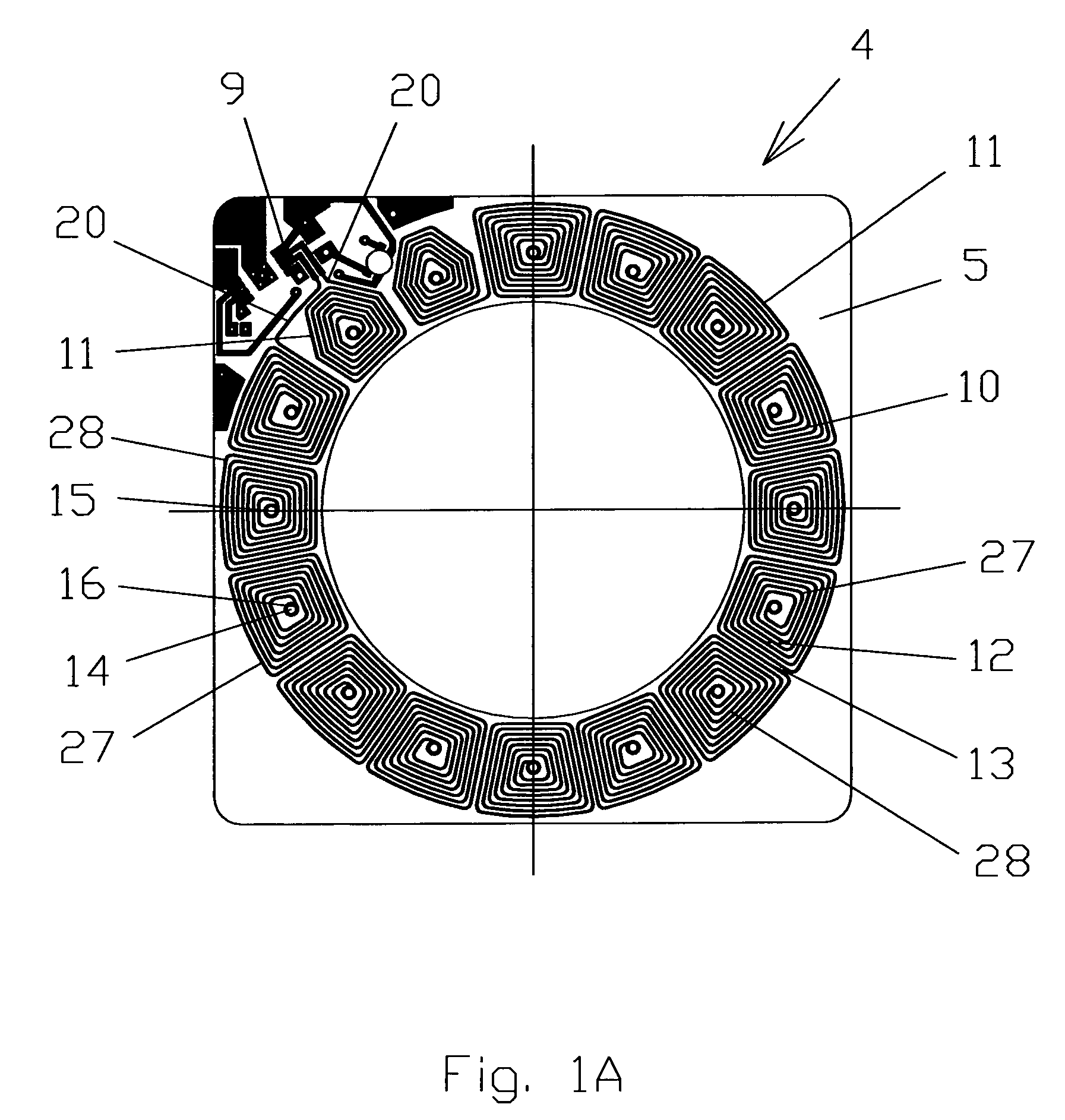

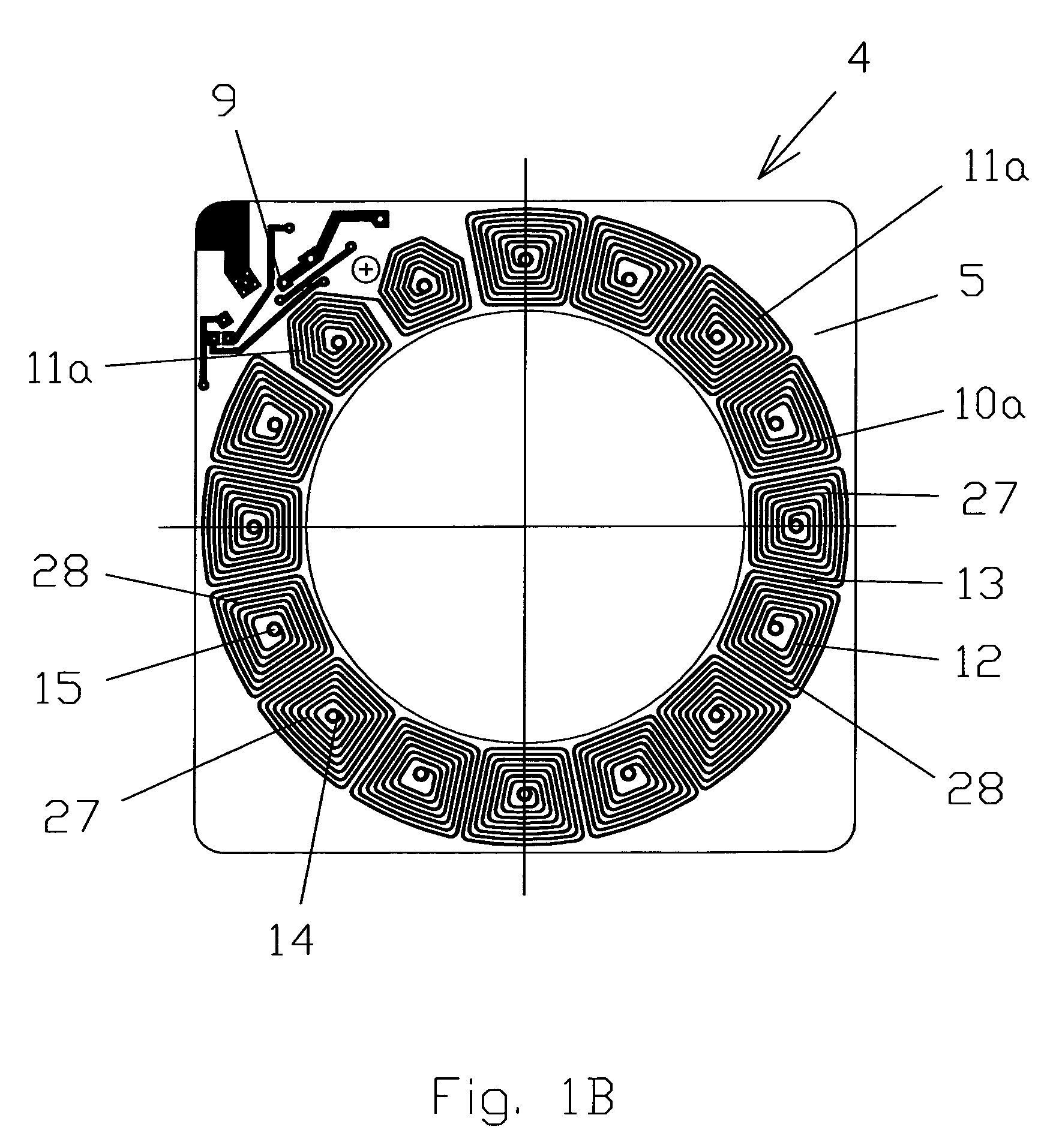

InactiveUS7112910B2Reduce the overall heightSynchronous generatorsMagnetic circuit rotating partsCircular discMagnetic poles

An electric motor comprises a housing, a magnetic rotor and a stator which comprises at least one circuit board. The magnetic rotor comprises a disk with circumferentially arrayed magnetic poles. The circuit board on each side comprises one layer of circumferentially arrayed coil windings arranged in pairs, thus each pair made as a spiral that extends from a center of a start coil winding to a center of an end coil winding with the same turn direction of the spiral in relation to each of centers. The layers are the same in transparent view and shifted angularly in such a way thus centers of the start coil windings from one side of the circuit board coincided and electrically connected by via's with centers of the end coil windings on the other side of the circuit board.

Owner:ADVANCED ROTARY SYST

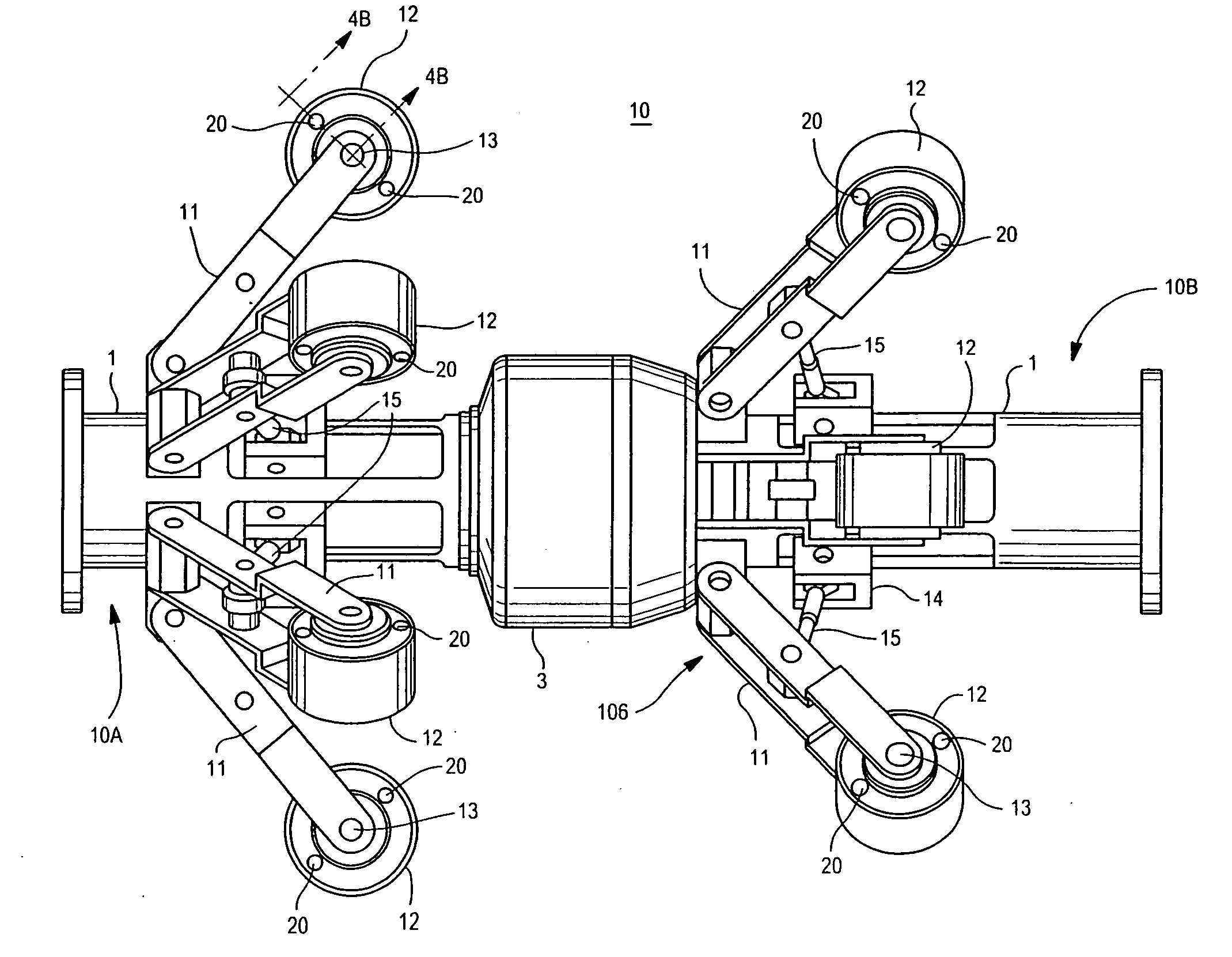

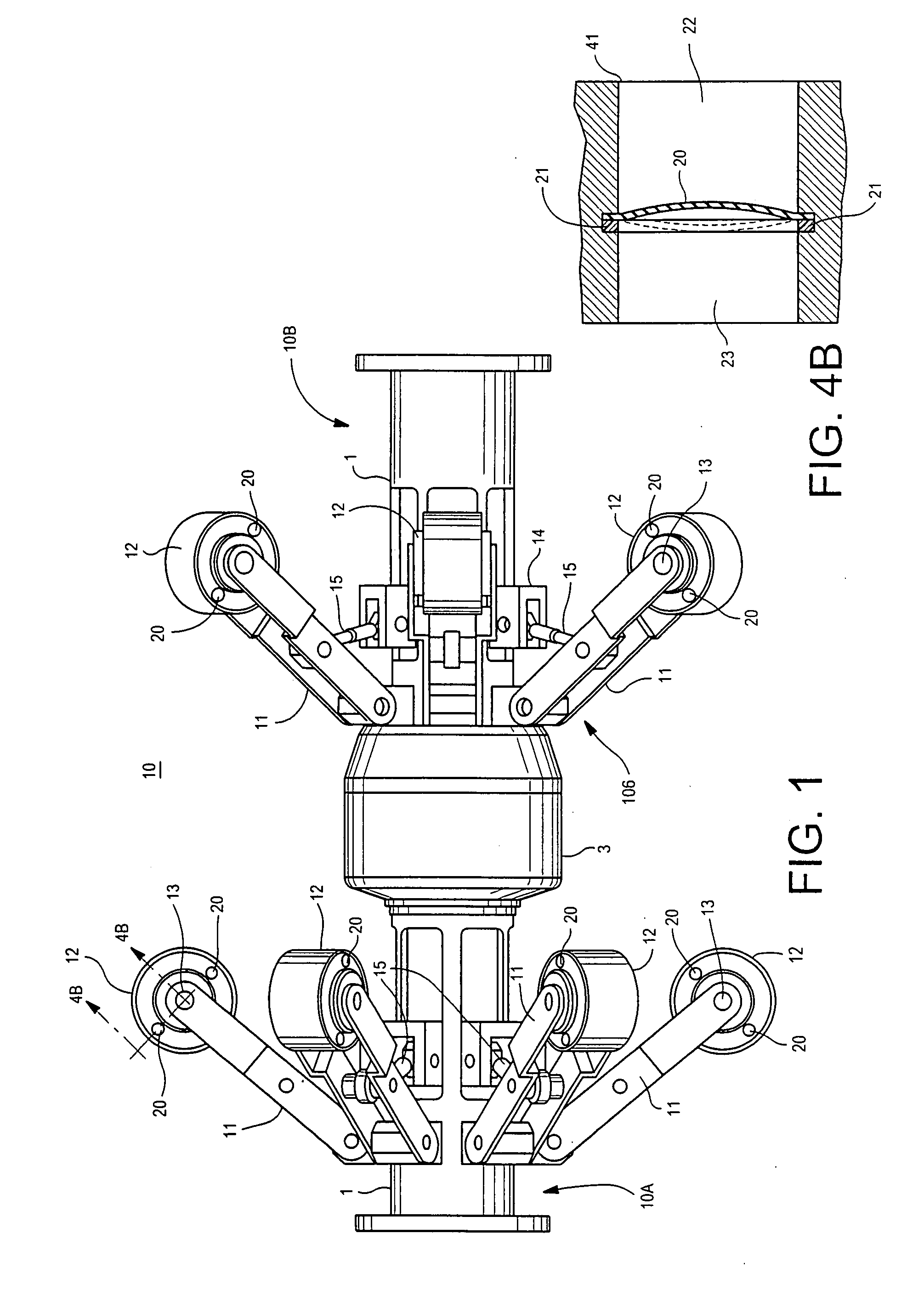

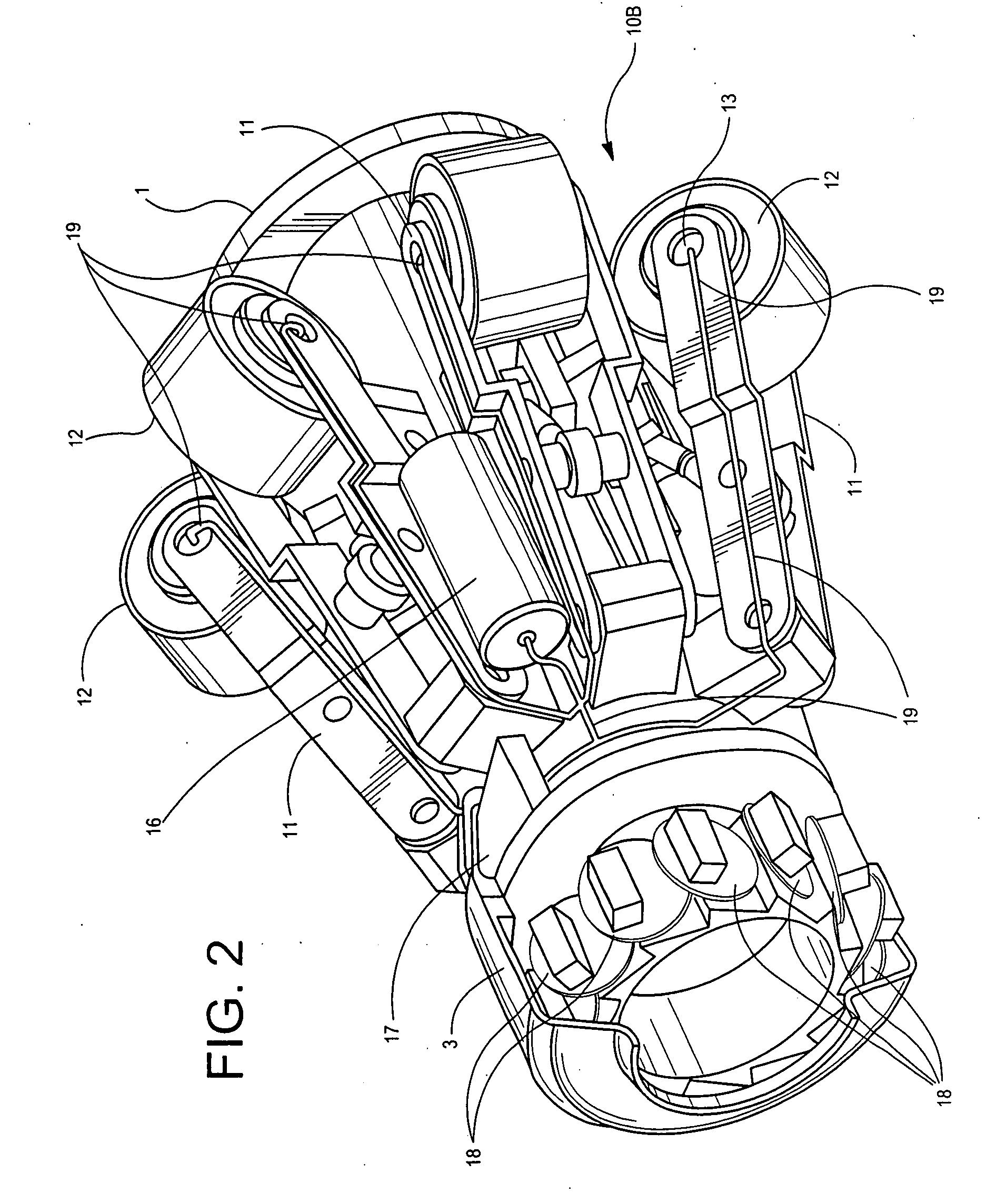

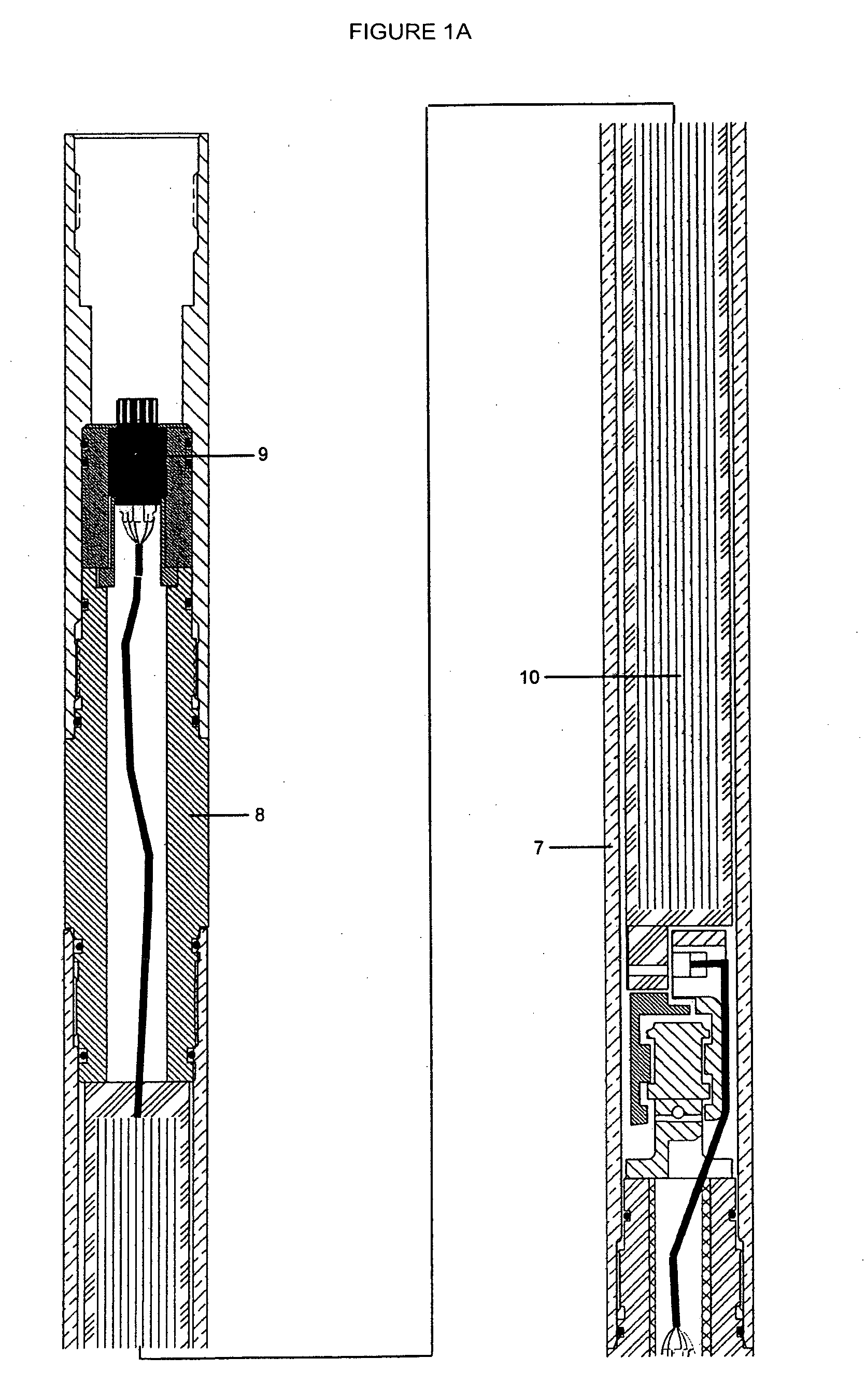

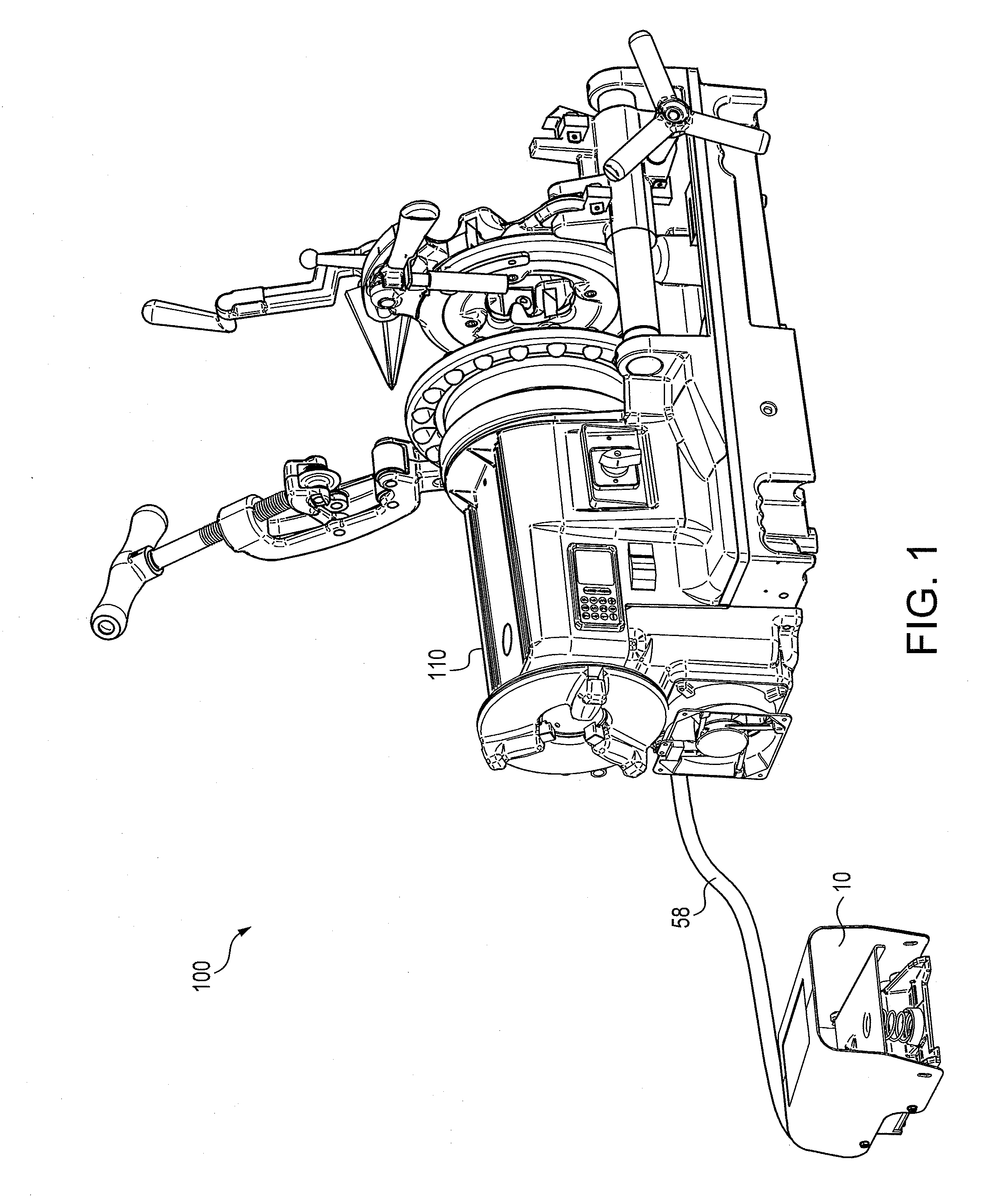

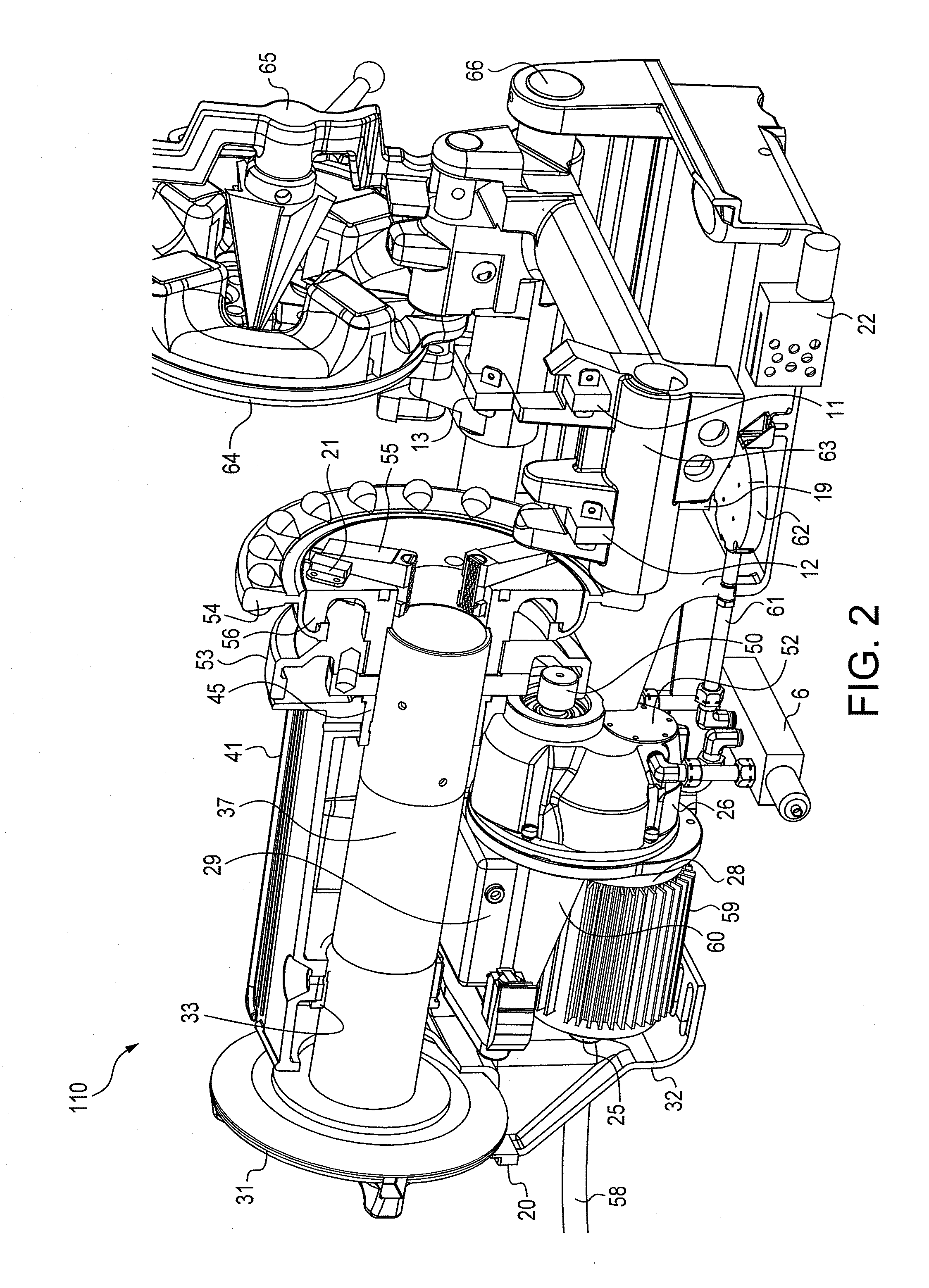

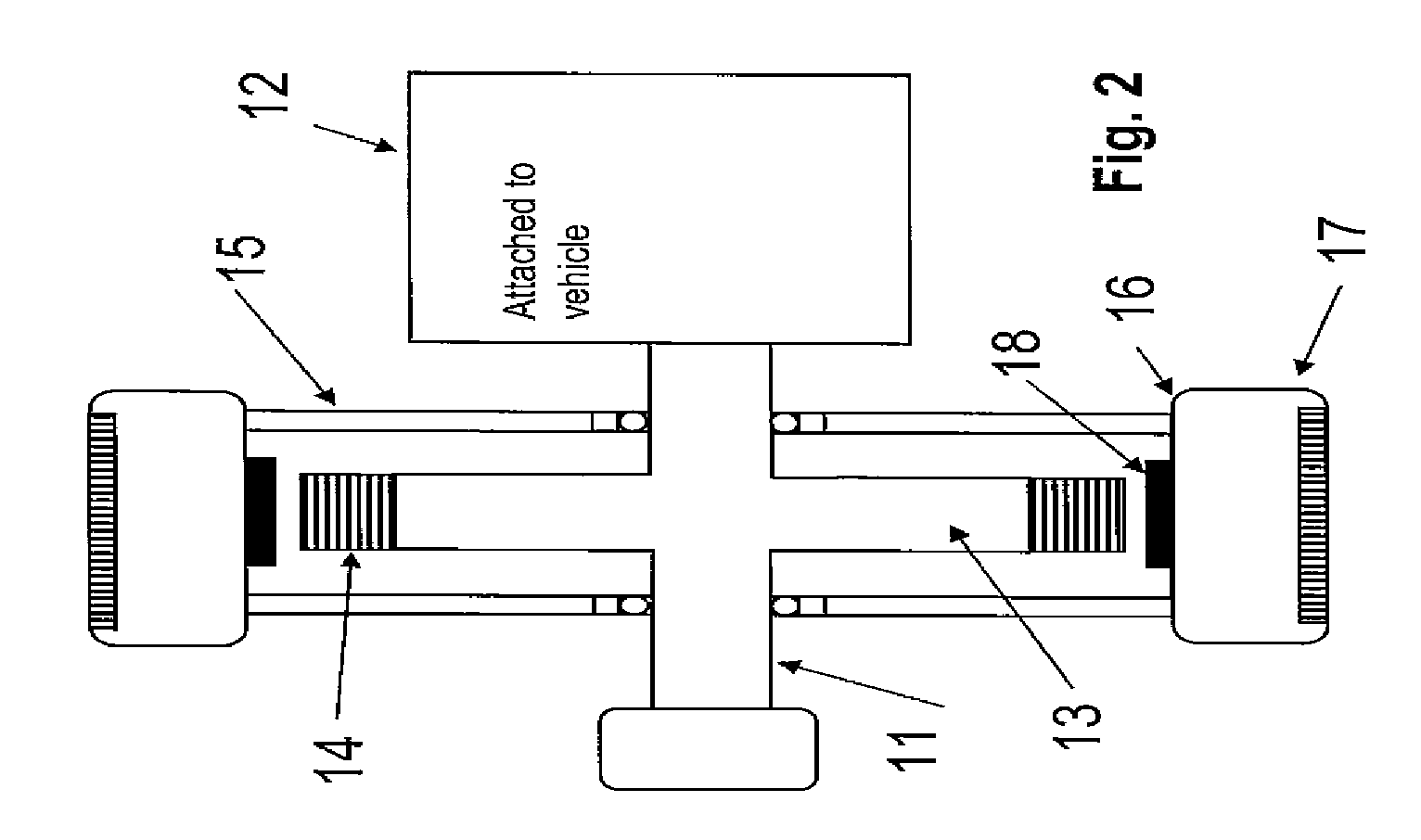

Pressure-balanced electric motor wheel drive for a pipeline tractor

InactiveUS20080245258A1Avoid lostReduce sensitivityRailway tunnelsRailway componentsMotor driveAmbient pressure

A self-propelled crawler / tractor apparatus is disclosed for traveling through a tubular pipeline while conducting pipeline wall inspection operations and / or towing gear for cleaning, maintenance and the like. The crawler / tractor apparatus is propelled by a plurality of radially positioned motorized traction wheels. Each motorized traction wheel includes a brushless DC electric motor along with clutch, gearbox and other mechanical drive components integrated into a compact self-contained motorized wheel assembly which is sealed and filled with an electrically non-conductive lubricating / cooling oil. The seal integrity at each wheel assembly is maintained against oil leakage and debris ingress by a pressure-balancing mechanism which matches internal oil pressure to the exterior ambient pressure present in the pipeline. The electric motor drive for each traction wheel is individually controlled via an onboard computer to provide a wide range of torque and wheel speeds.

Owner:GENERAL ELECTRIC CO

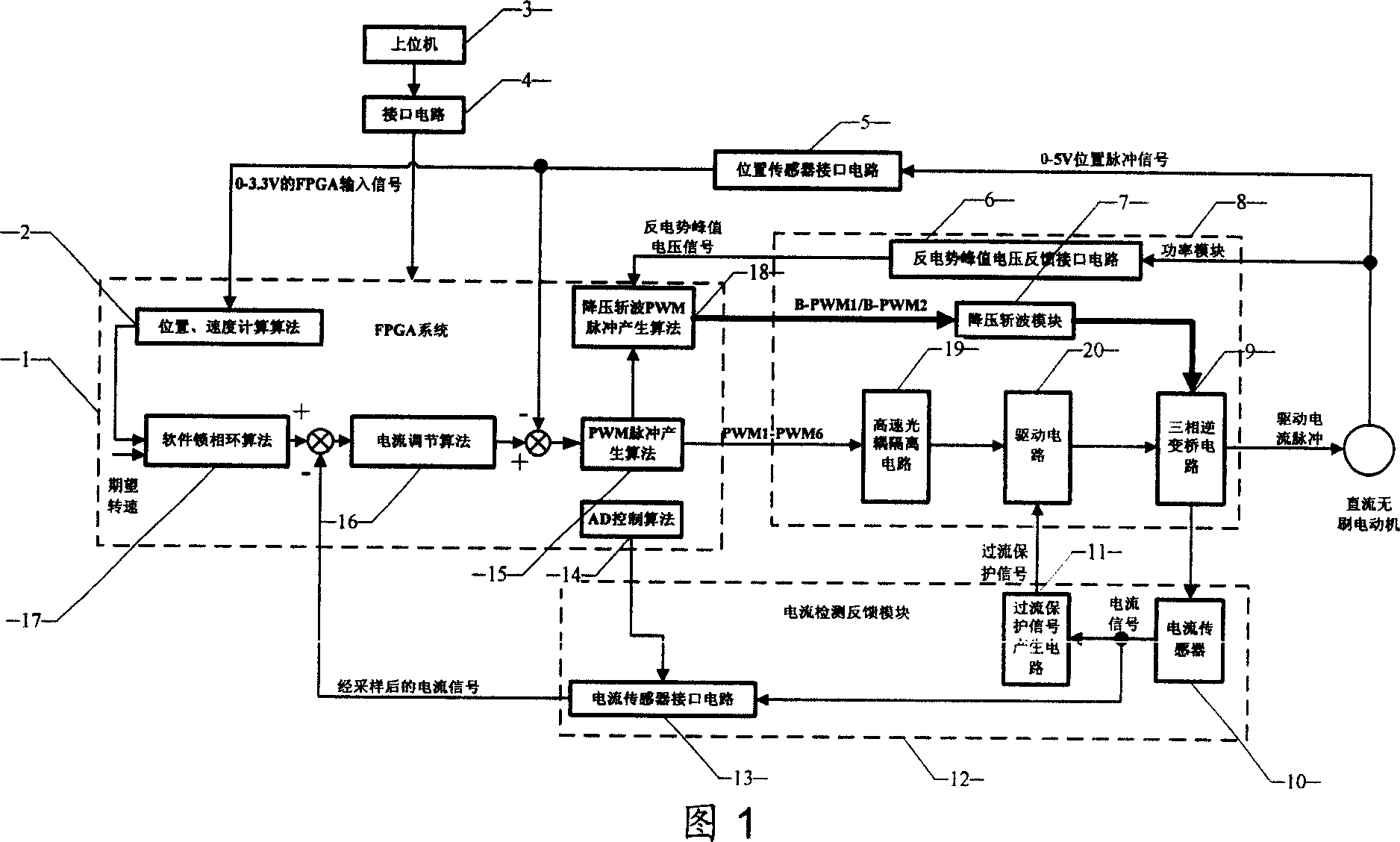

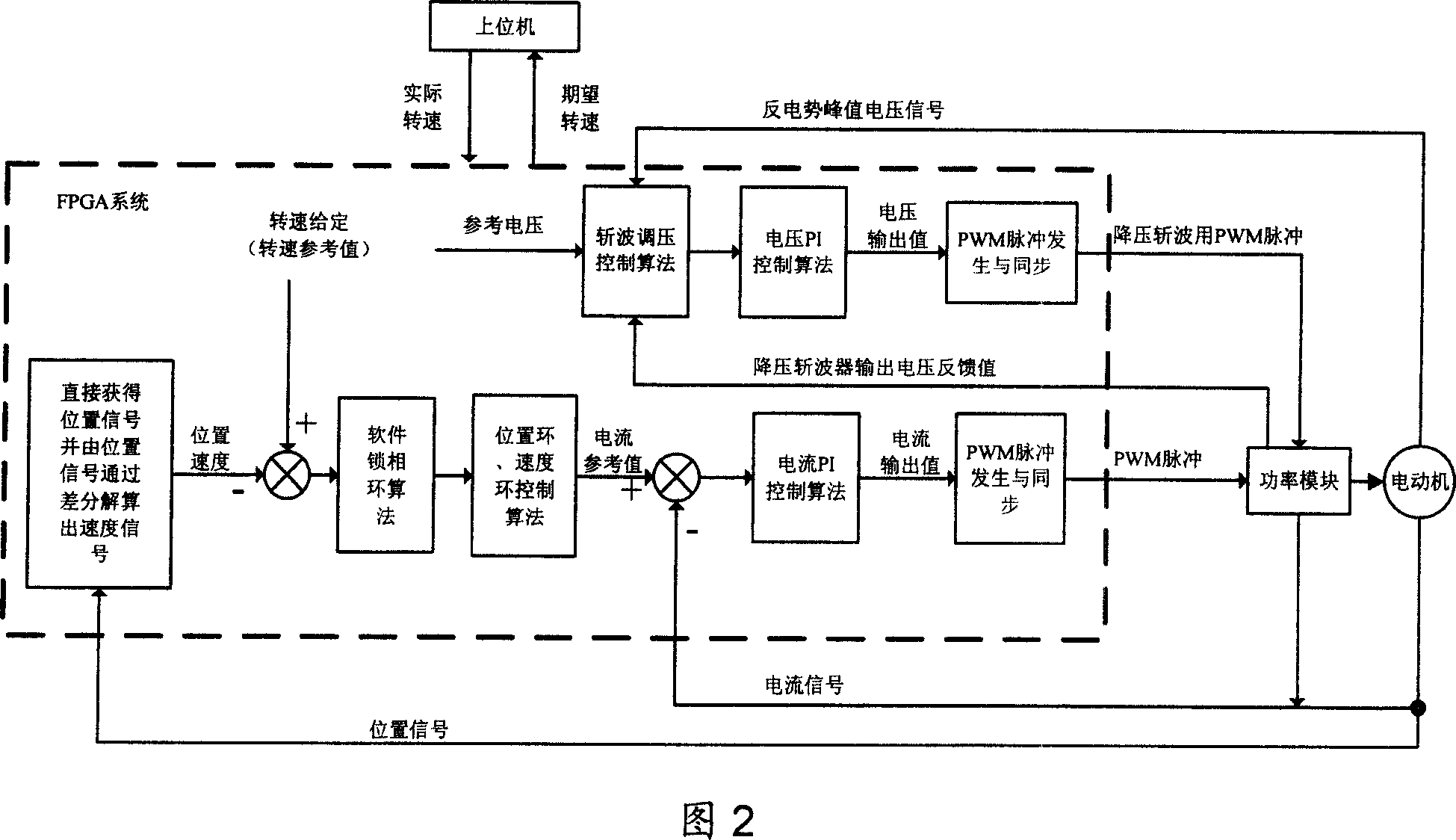

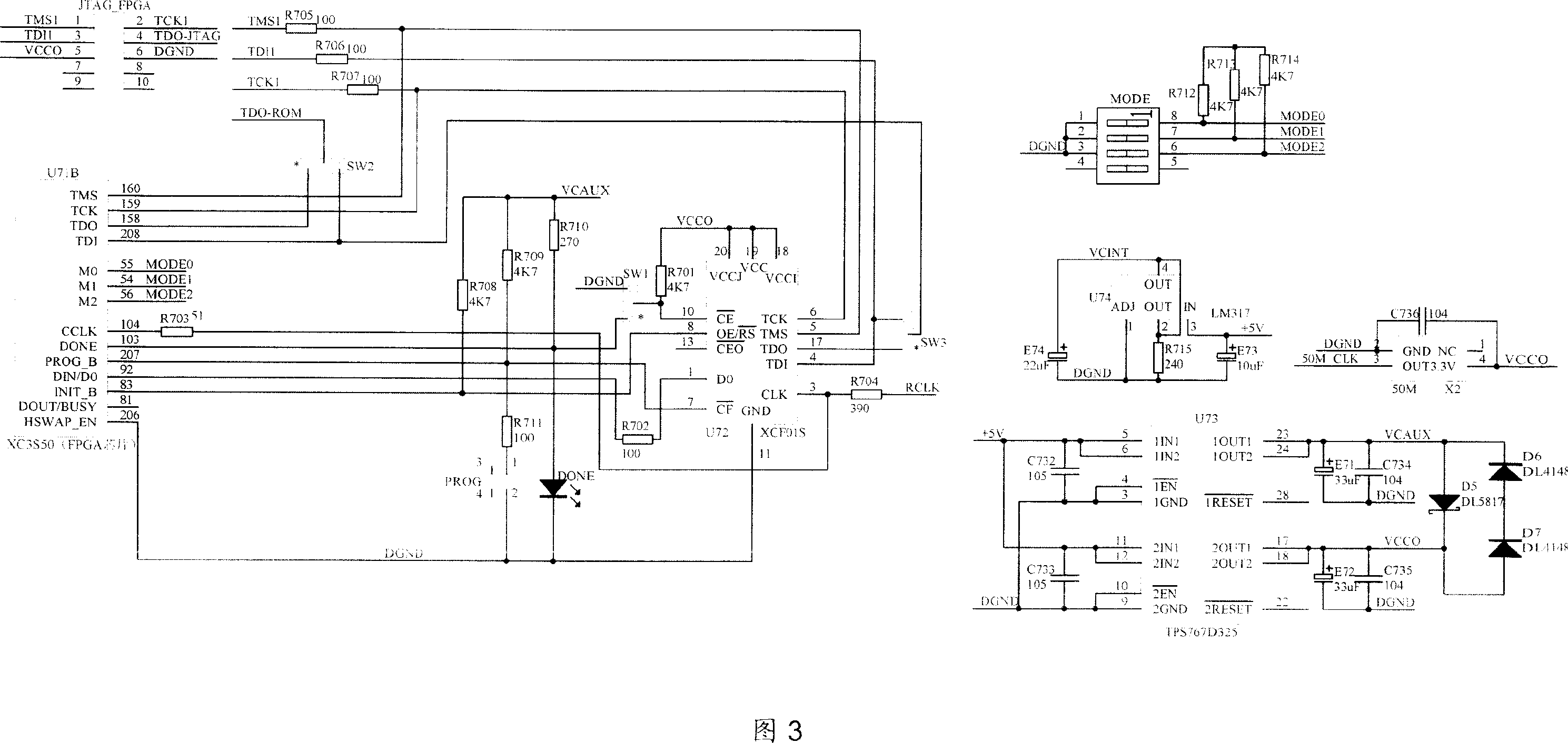

A low-loss, high reliability integration magnetic levitation flywheel DC brushless motor control system

InactiveCN1968003AHigh control precisionHighly integratedField or armature current controlElectronic commutatorsBrushless motorsFpga implementations

The invention relates to a magnetic suspension flywheel direct-current non-brush motor controlling system, wherein it comprises FPGA system, direct-current detecting feedback module, positioning sensor interface circuit, and power module; the FPGA module obtains request rotation speed from super machine, via sensor interface circuit and feedback module to obtain position signal and current signal, and the control algorism of FPGA, to calculate out the control value, and process reduction chopper PWM modulation, and amplify via amplifying module to generate the needed control current, and realize control accurately. The invention has low power consumption and high reliability.

Owner:BEIHANG UNIV

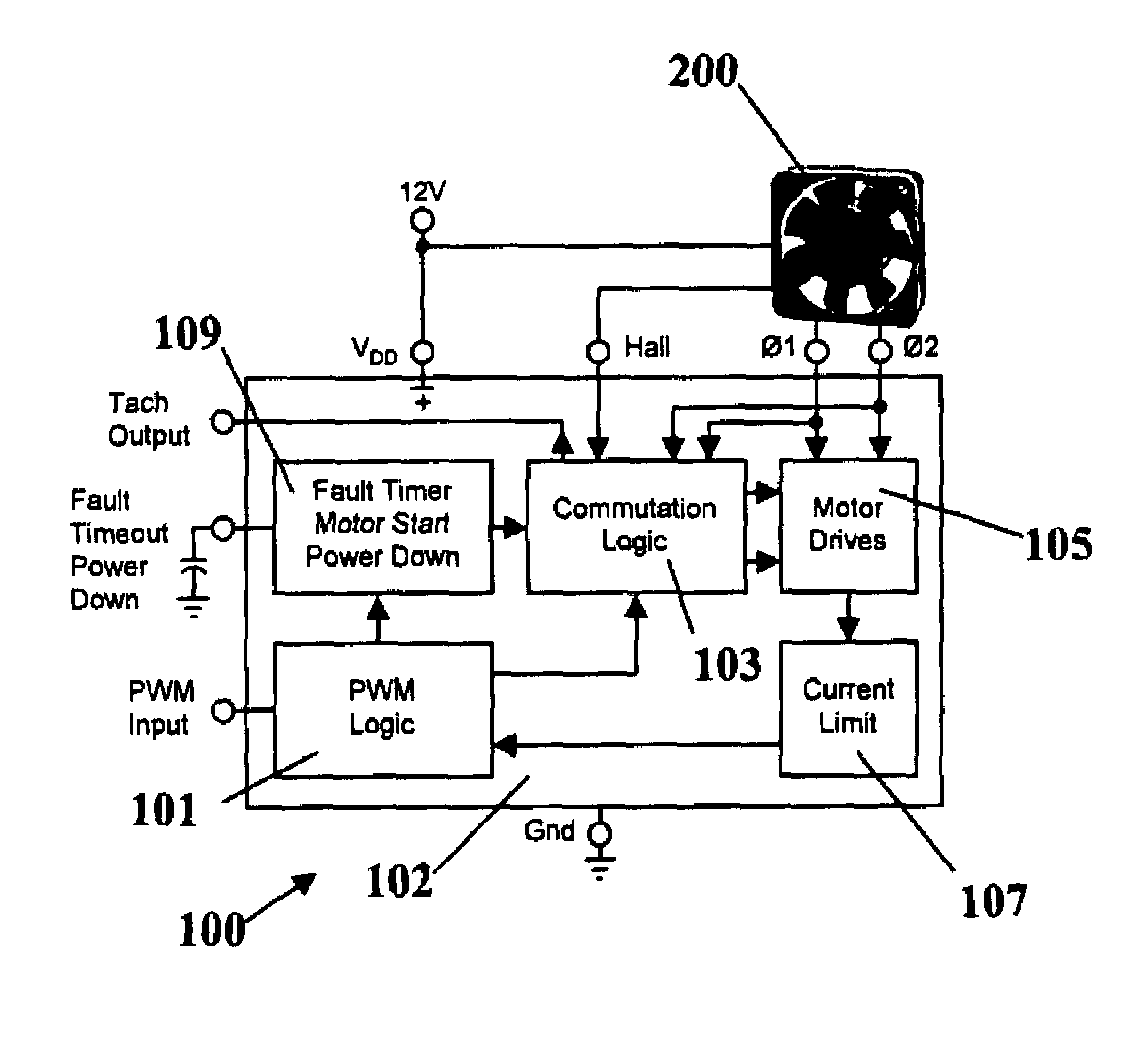

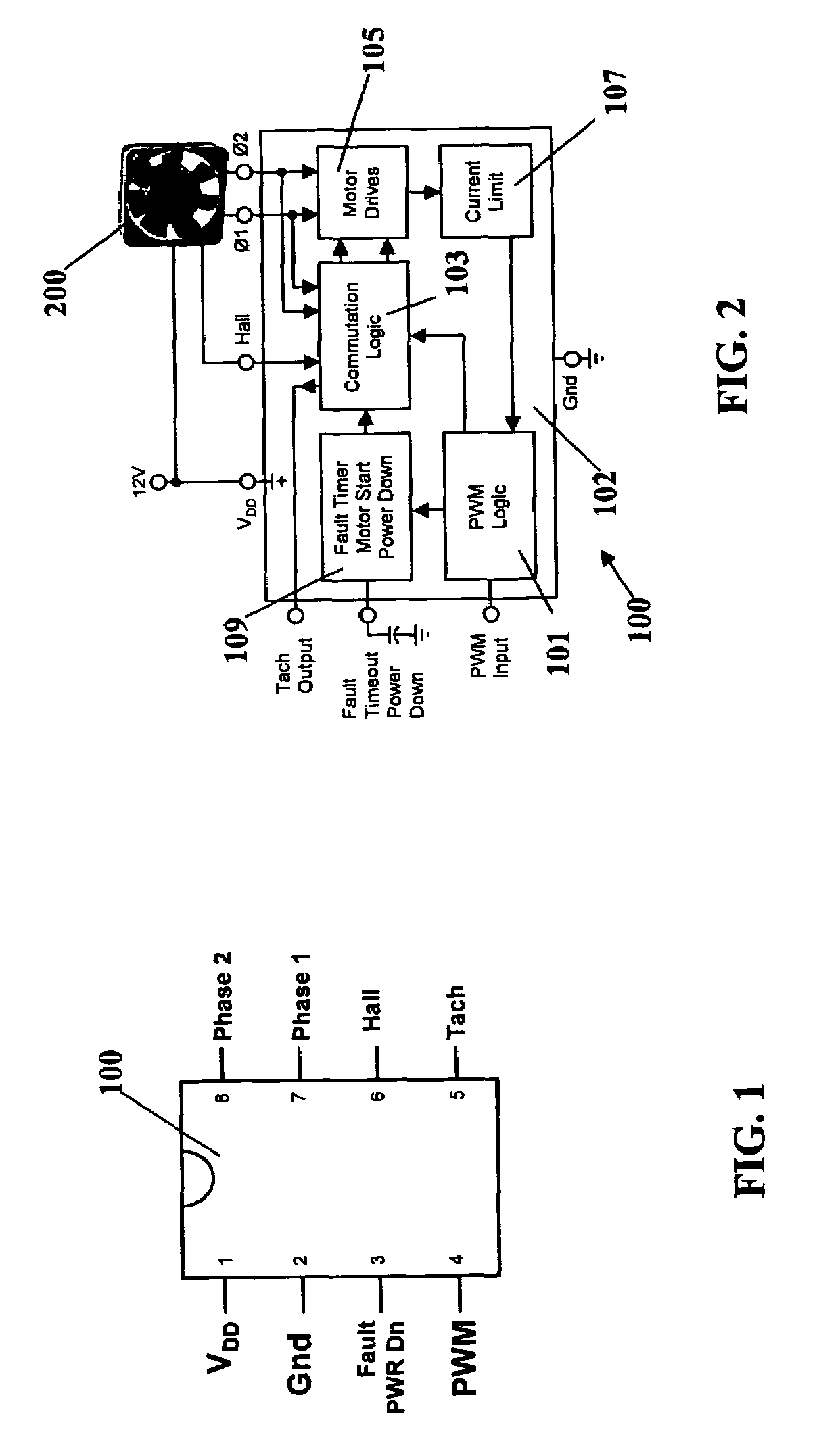

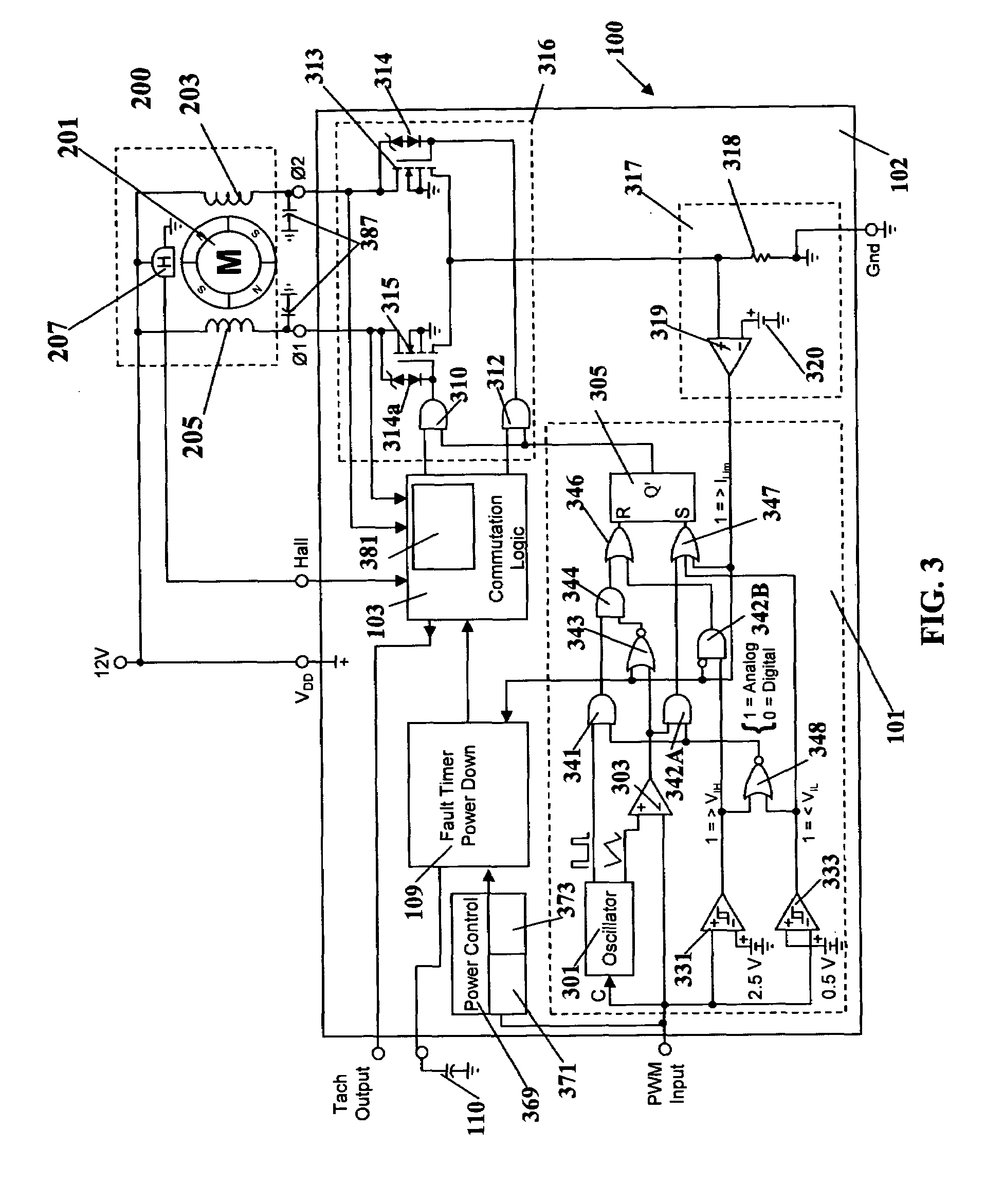

Controller arrangement with adaptive non-overlapping commutation

A PWM controller for a direct current brushless motor comprising first and second windings includes a motor drive circuit receiving pulse width modulation control signals to drive the first and the second windings; and a control circuit having inputs coupled to the first and second windings to control a pulse width modulation control circuit such that pulse width modulated control signals are provided to the motor drive circuit only when the voltage across the first and second windings are at a predetermined level.

Owner:OL SECURITY LIABILITY CO

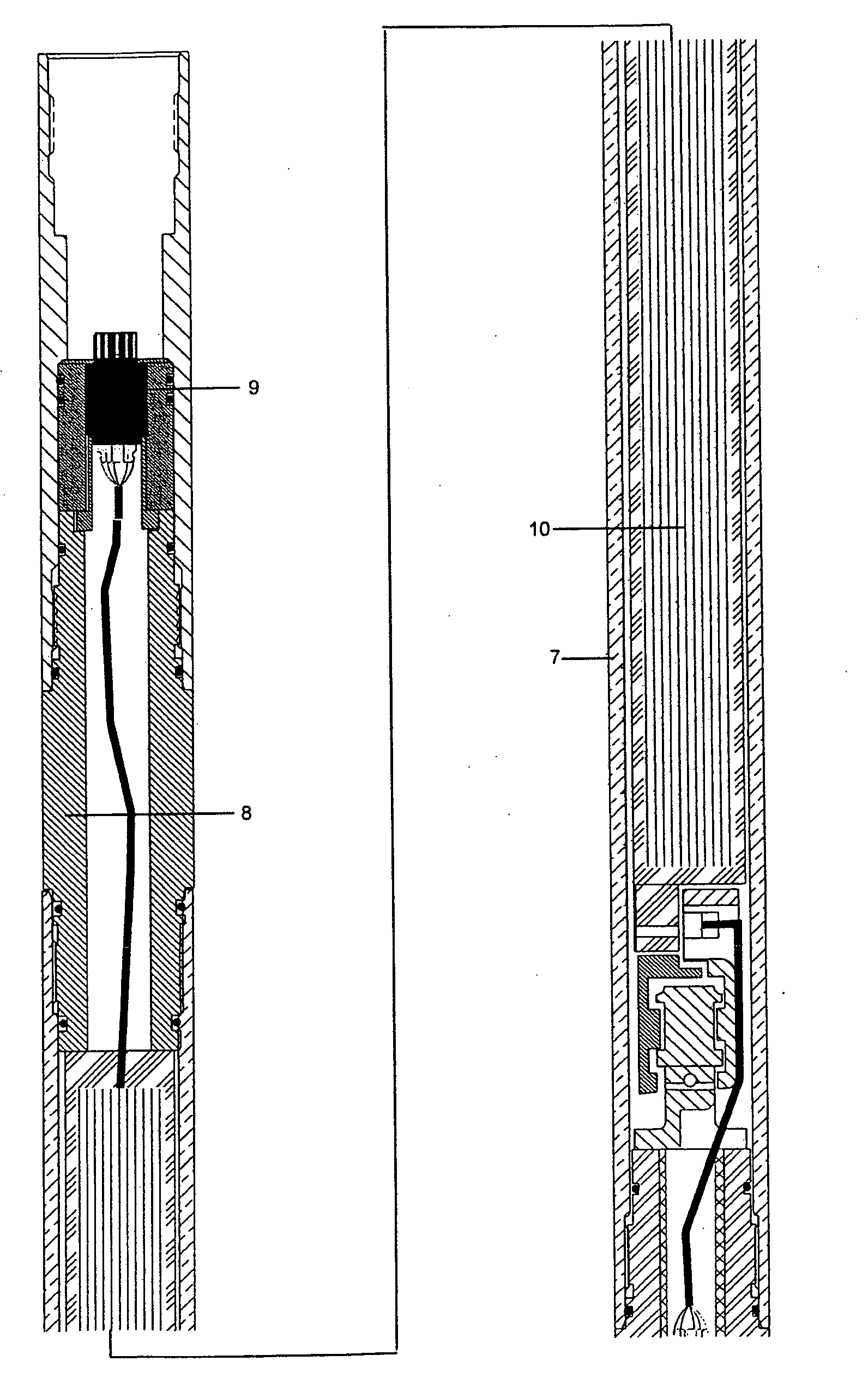

Intelligent efficient servo-actuator for a downhole pulser

An improved energy efficient intelligent pulser driver used for generating a mud pulse in a MWD (measurement while drilling) application. In the pulser driver, a direct current (DC) powered control circuit activates a three-phase DC brushless motor that operates a servo-valve. Opening of the servo-valve equalizes pressure in a plenum causing the operation of a main valve reducing flow area and causing a pressure spike in the mud column. Closing of the servo-valve creates a reduction in mud pressure that operates the main valve and increases the flow area causing an end to the pressure spike. The servo-valve is powered both in opening and closing operations by the motor.

Owner:NEWSCO DIRECTIONAL & HORIZONTAL DRILLING SERVICES INC CO BORDEN LADNER GERVAIS LLP +1

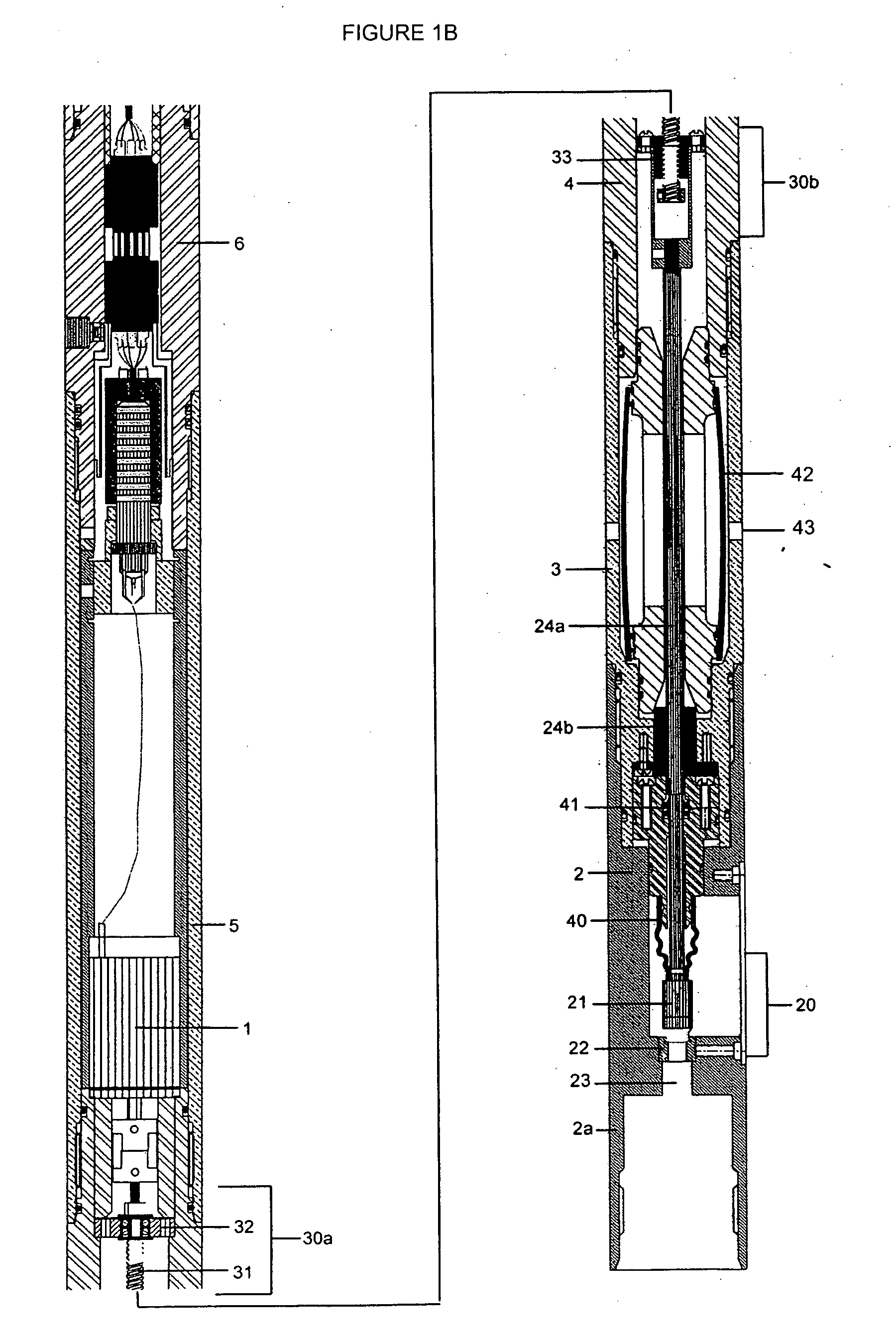

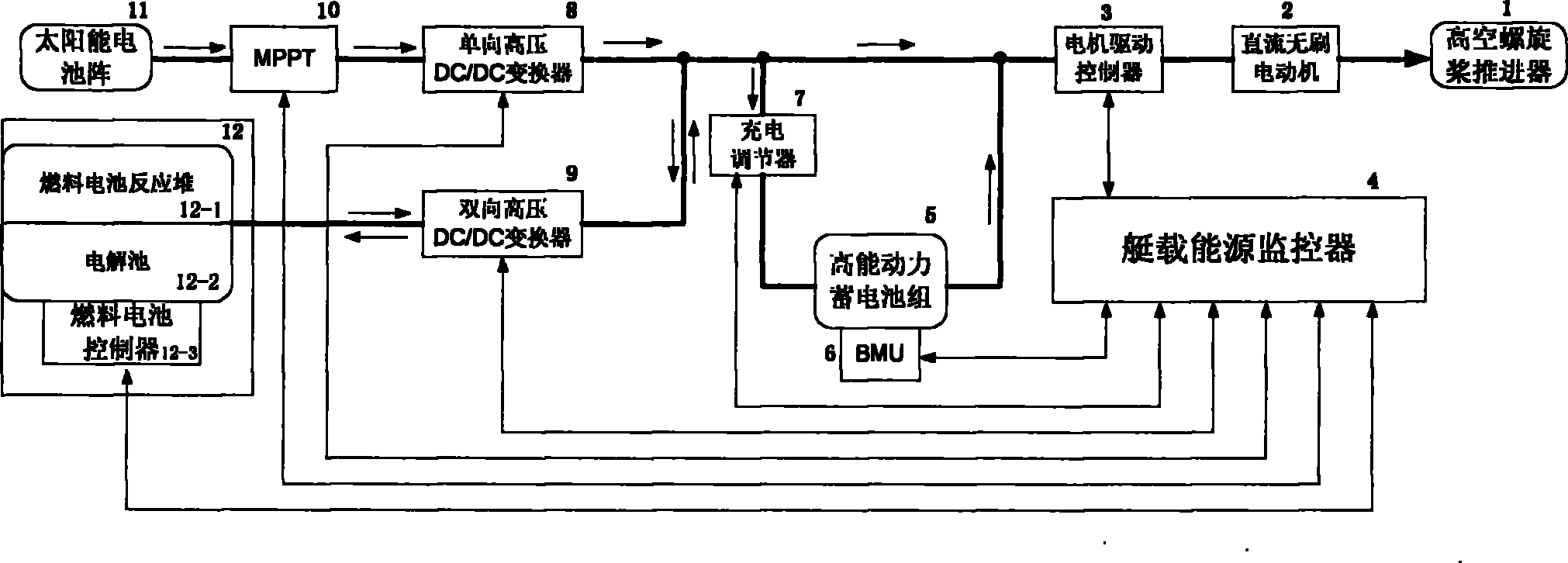

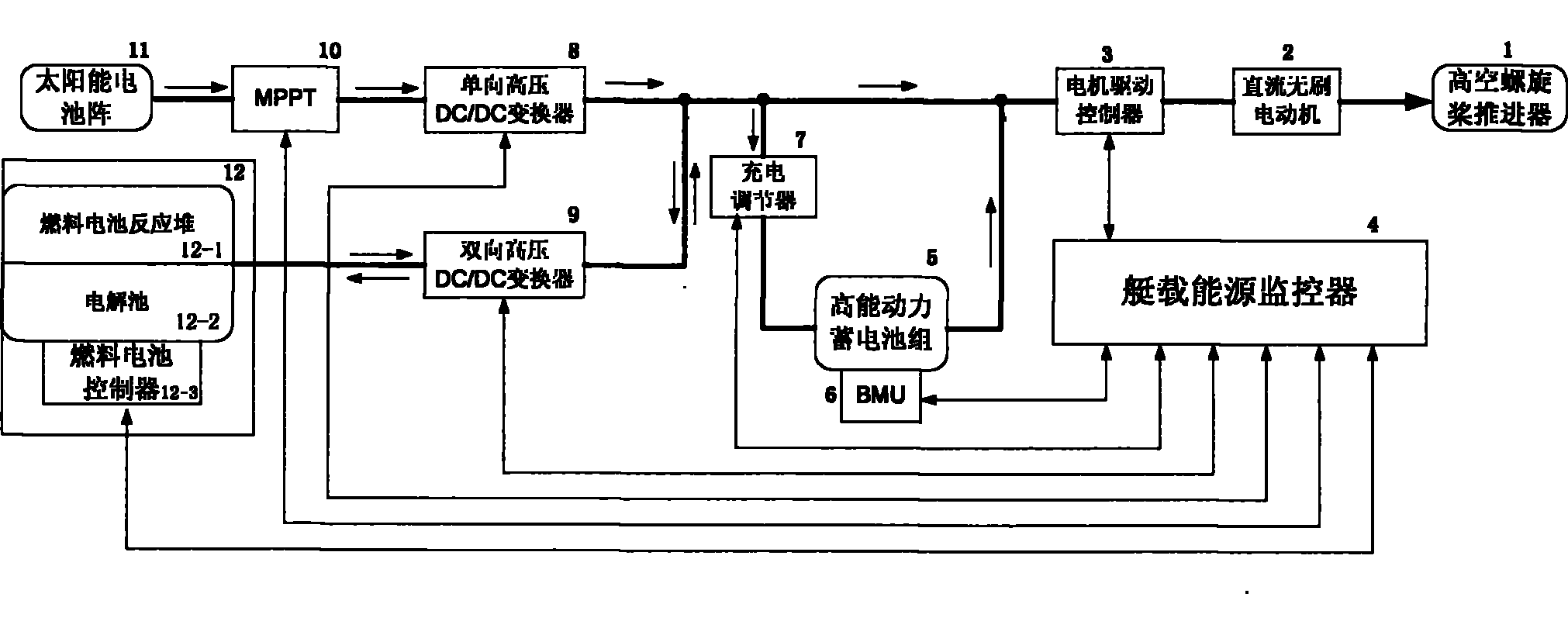

Energy supply system for stratosphere electricity-electricity hybrid solar airship

ActiveCN102060107AGuaranteed mobilityEnsure safetyBatteries circuit arrangementsCosmonautic power supply systemsBrushless motorsHigh energy

The invention discloses an energy supply system for a stratosphere electricity-electricity hybrid solar airship. The system is an electricity-electricity hybrid energy supply system which takes a solar battery array as a main power supply, takes a regenerative hydrogen-oxygen fuel cell and a high-energy power storage battery pack as auxiliary power supplies, takes a direct-current brushless motor and driving controller as drive devices, takes an energy monitor as an energy distribution system, and takes a one-way DC / CD converter and a two-way DC / CD converter as voltage regulating devices. The solar battery array is connected with the one-way high-voltage DC / CD converter with maximum power point tracking through a cable; the one-way high-voltage DC / CD converter is connected with the driving controller of the direct current brushless motor through the cable; the controller controls the direct current brushless motor to drive a high altitude propeller; the one-way high-voltage DC / CD converter is connected with the two-way high-voltage DC / CD converter through the cable; and the one-way high-voltage DC / DC converter is connected with a charging regulator of the high-energy power storage battery pack. The energy supply system realizes reasonable distribution of power based on the energy monitor, and ensures the maneuvering safety and long service life of the stratosphere electricity-electricity hybrid solar airship.

Owner:BEIHANG UNIV

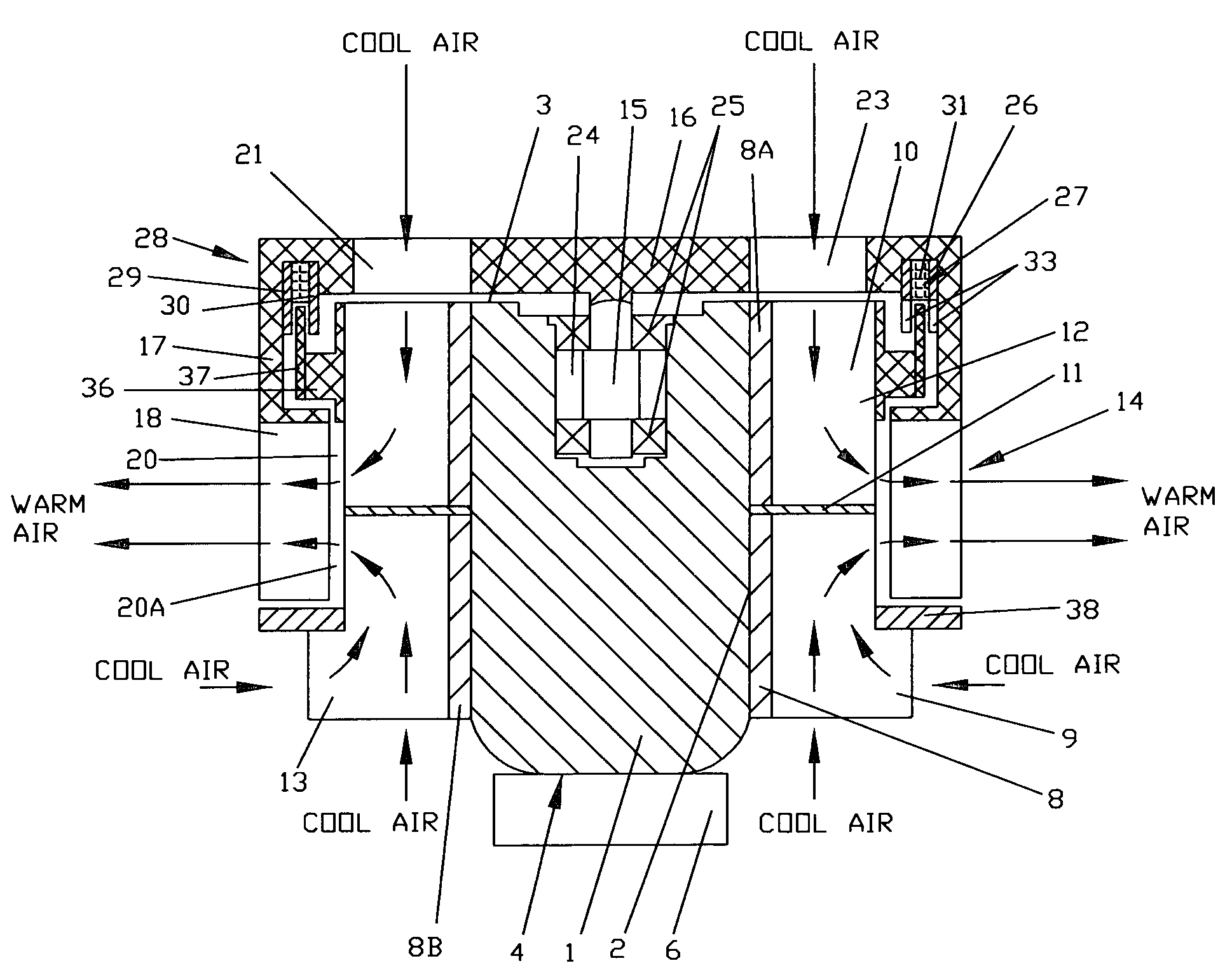

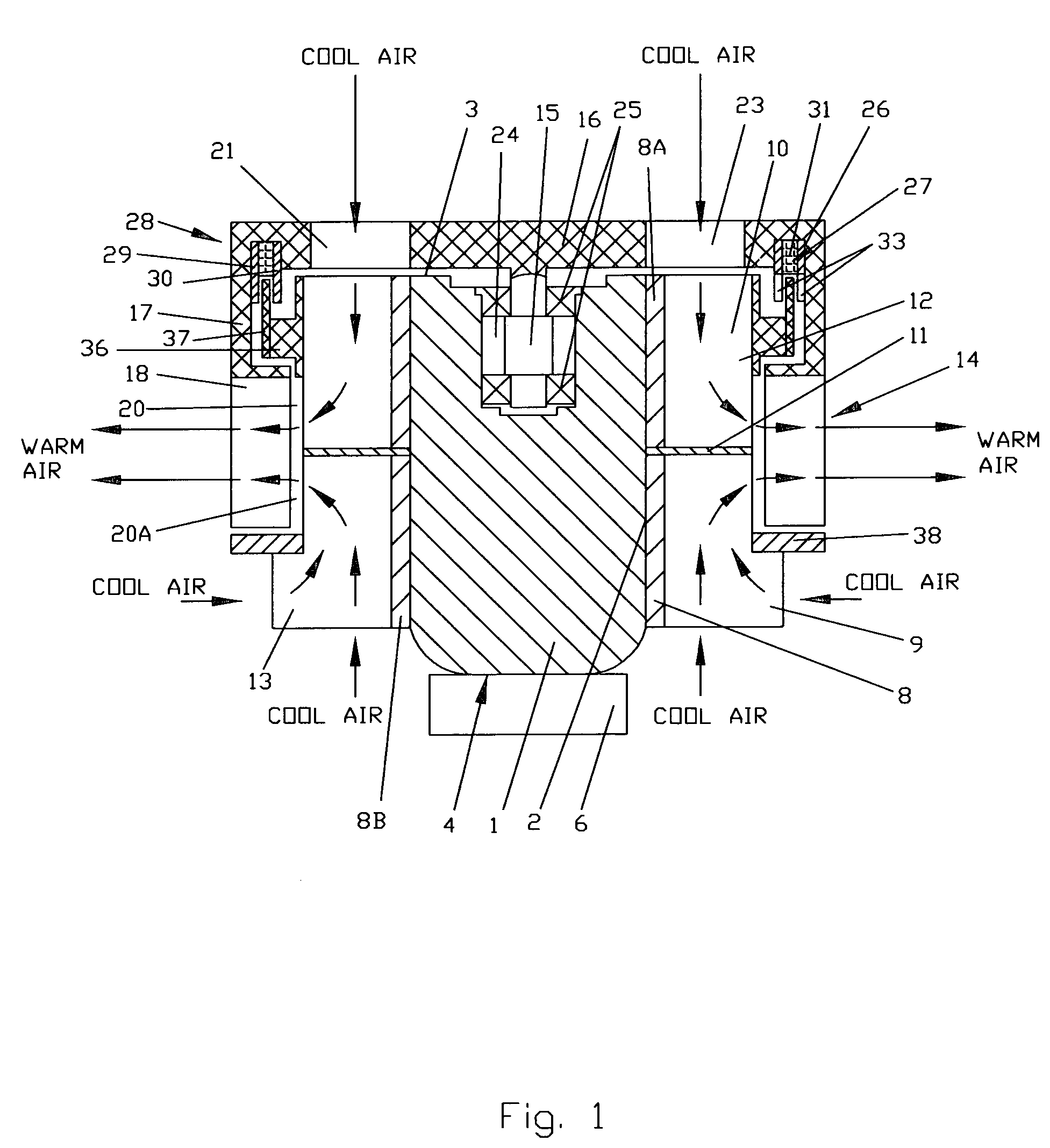

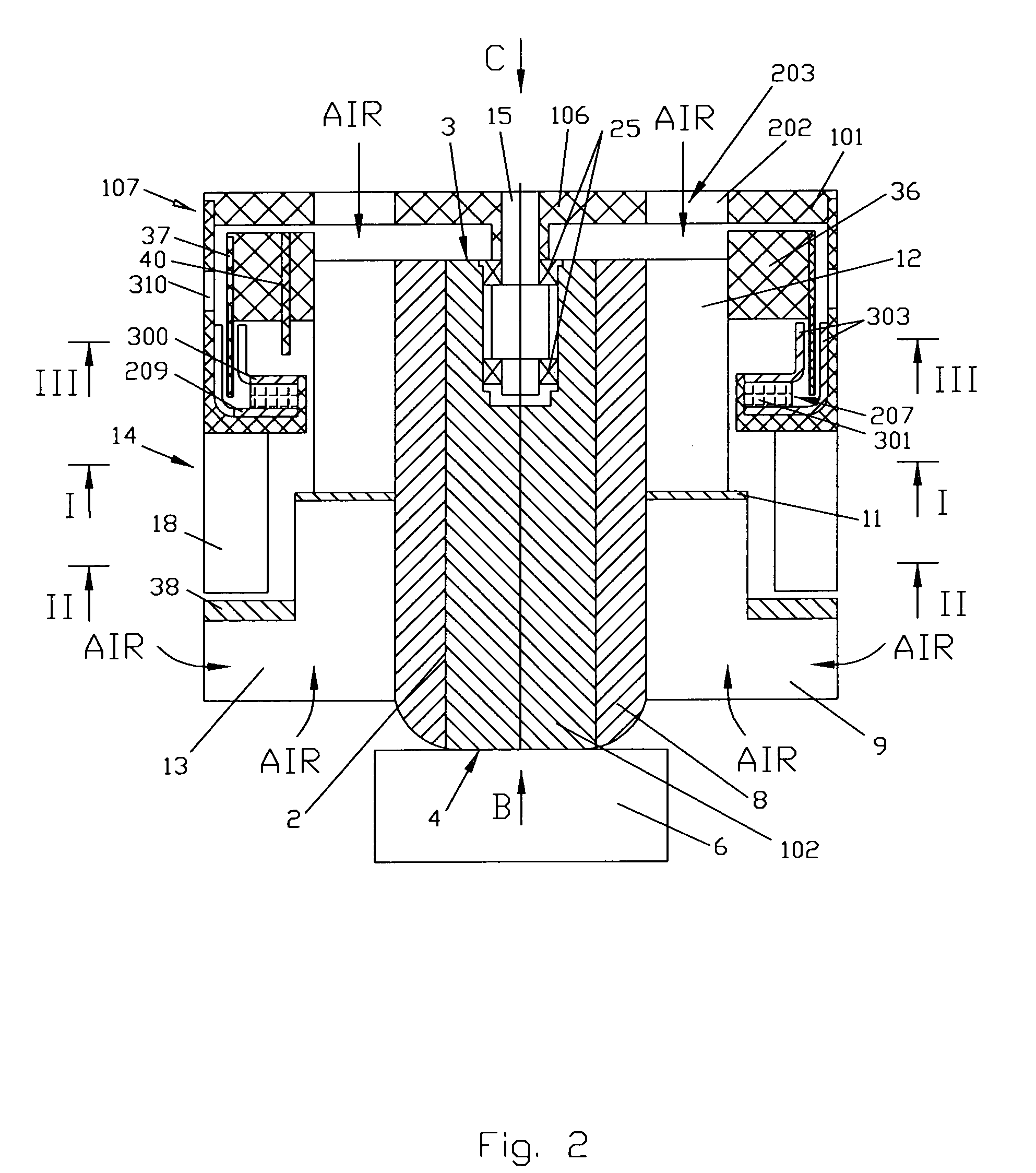

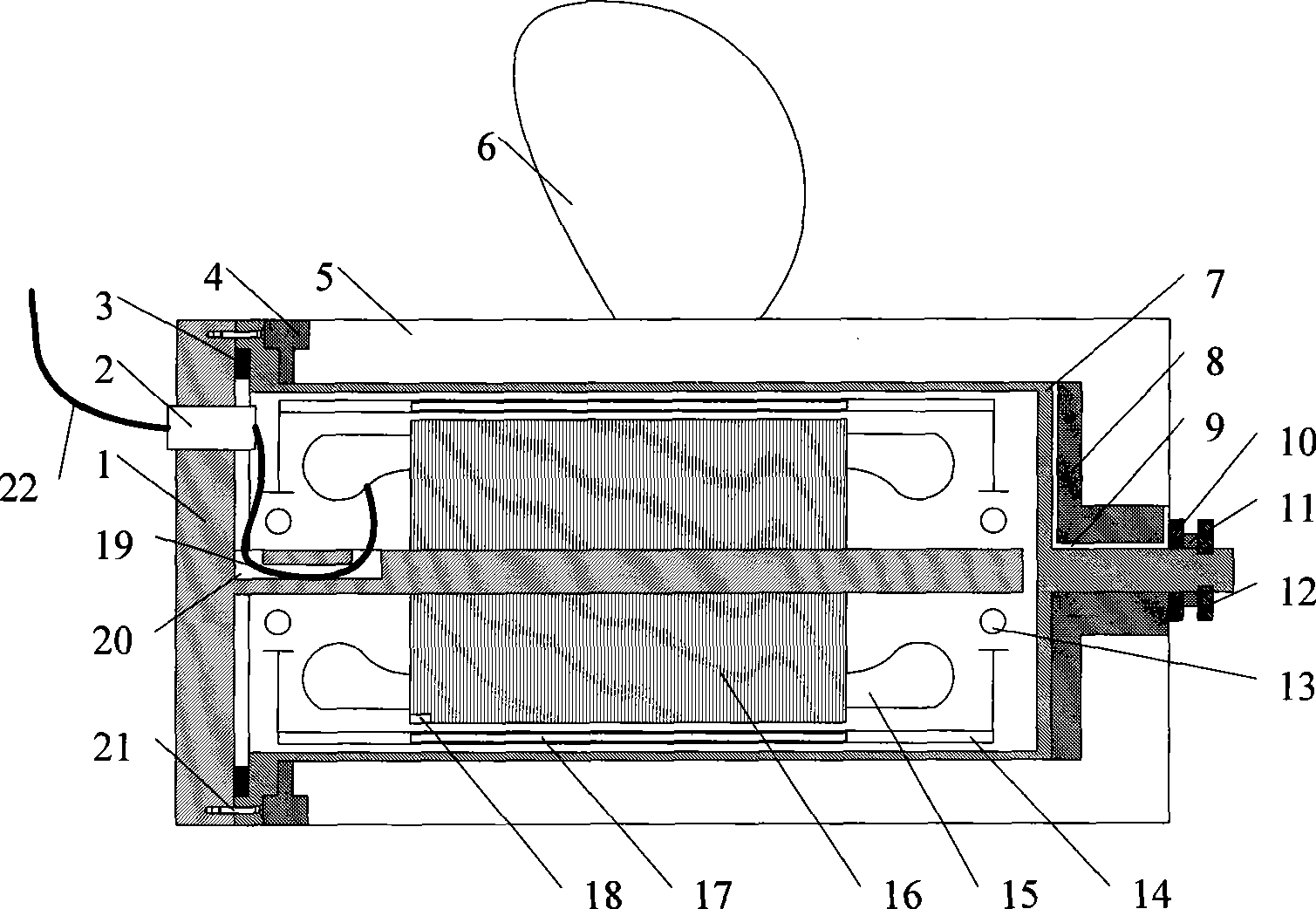

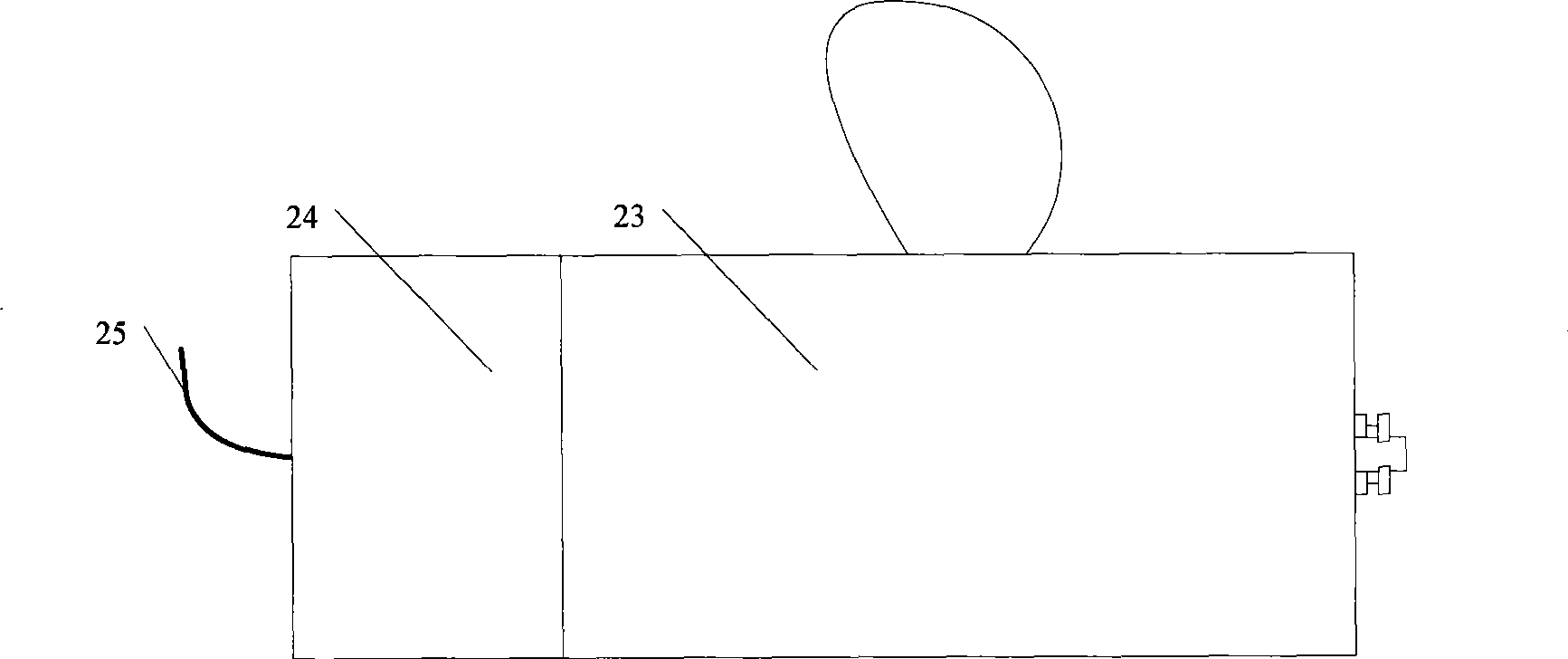

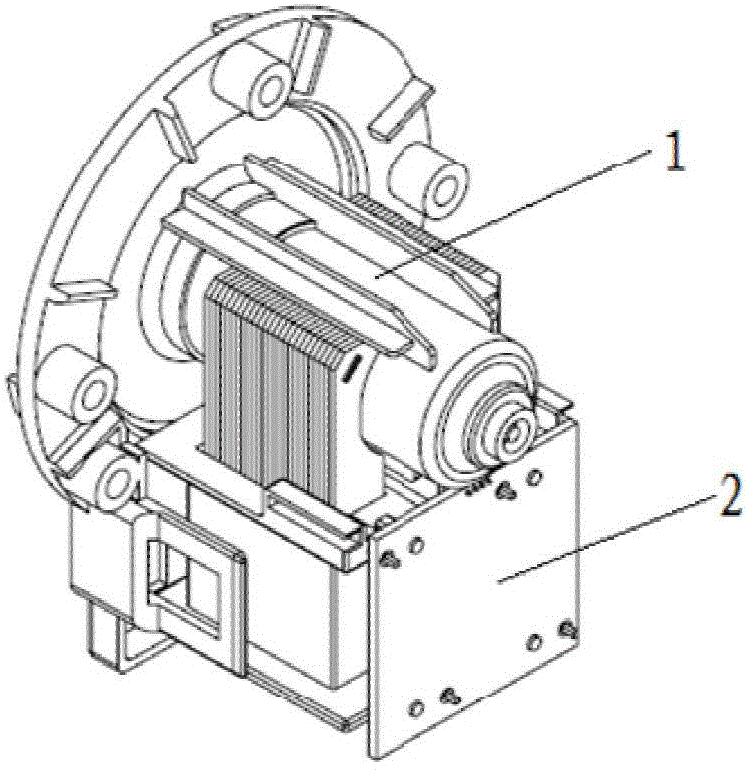

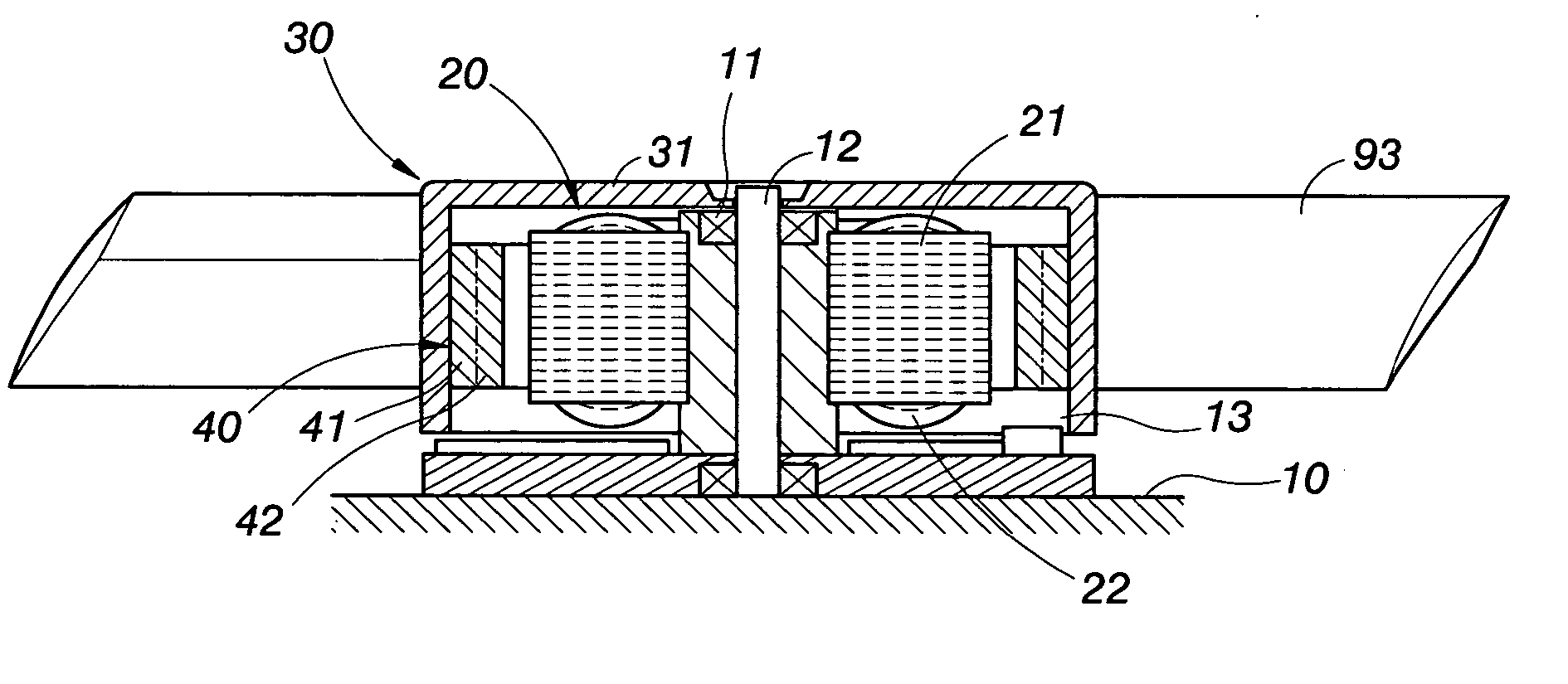

Cooler for electronic devices

InactiveUS7044202B2Improve cooling effectIncrease temperature differenceSemiconductor/solid-state device detailsSolid-state devicesCold airPath length

A cooler for electronic devices provides cool air to the inlet sides of the heat sink by using a radial blower with blades located around air outlets of the heat sink. This blower is driven by a brushless DC electric motor. The motor has an opening in the center allowing for the transfer of incoming air to the center of the heat sink. The rotors outer circumferential arrayed poles are rigidly secured to the frame of the radial blower. The stator of the motor is rigidly secured to the heat sink and has an opening in its center. The stator comprises circumferential arrayed coils on circuit board material. When the current flows through the stator coils, the coils acquire a magnetic polarity. The poles of the rotor and stator coils attract and repel depending on the polarities. The cool air comes simultaneously from opposite sides of the heat sink. For this reason the heat sink has a divider located approximately in the middle of the heat sink fins. The blades of the radial blower are located around the air outlets on the heat sink. Because the ambient air is drawn in from both sides of the heat sink the air path length through the heat sinks channels is effectively halved. This results in an increased cooling ability for the heat sink because of the increase in temperature differentials.

Owner:ADVANCED ROTARY SYST

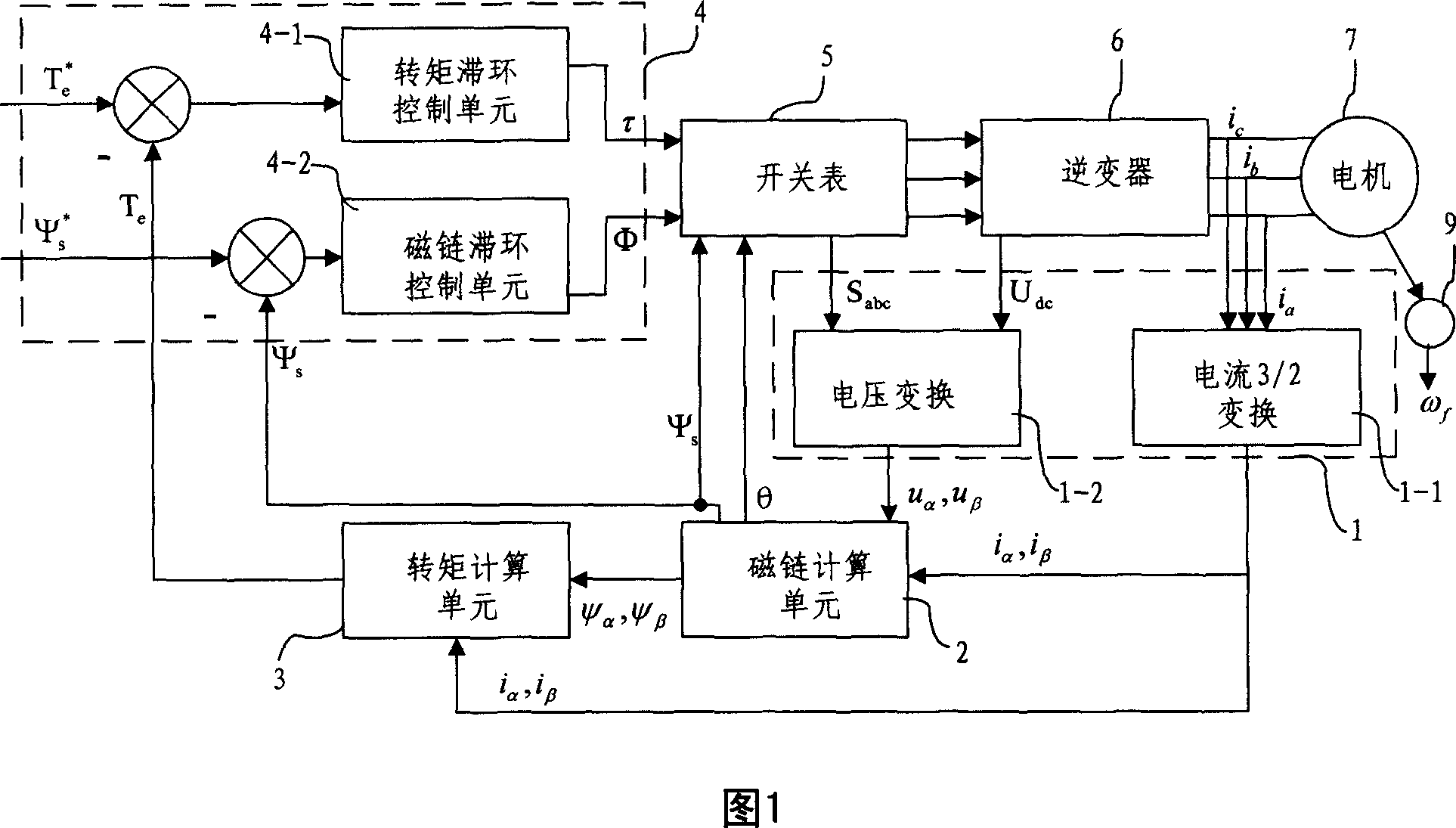

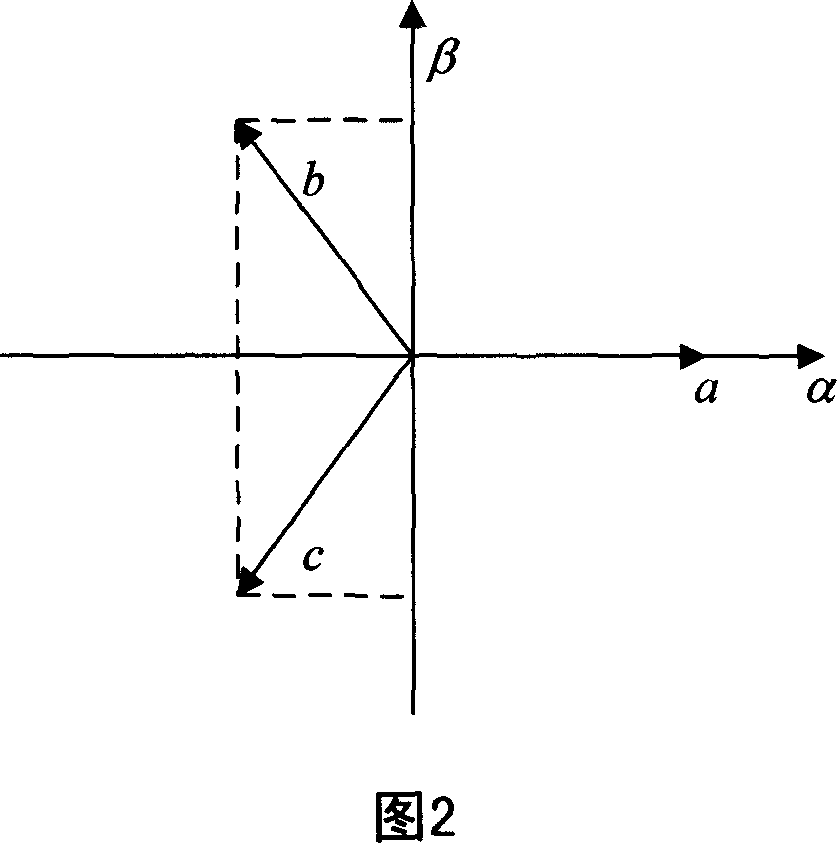

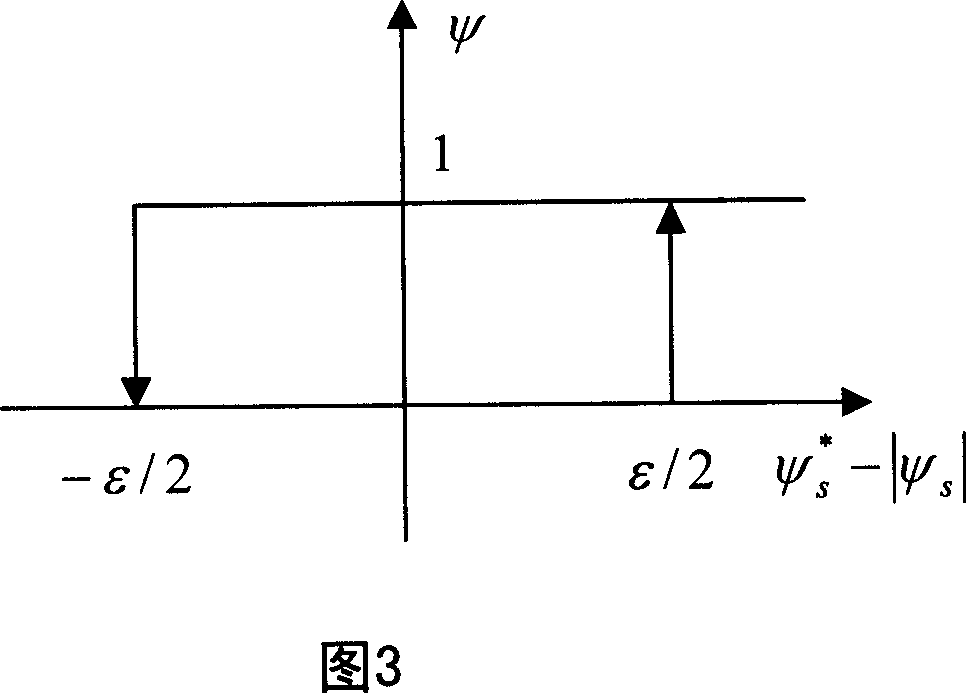

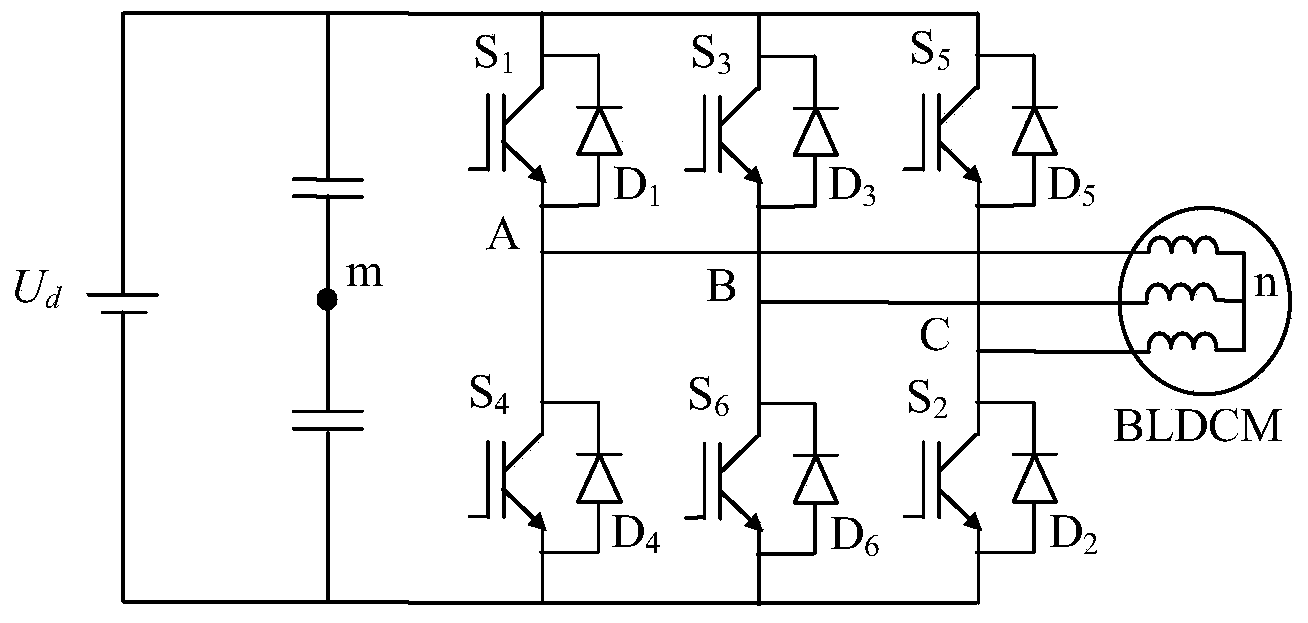

Direct torque brushless DC servo control system and its working method

ActiveCN101056084AImprove control effectQuick responseElectronic commutation motor controlVector control systemsSwitching frequencyTransformation unit

The present invention relates to a direct-torque brushless DC servo-control system and the working method thereof. The controller includes a coordinate transformation unit, a magnetic linkage computing unit, a torque computing unit, a magnetic linkage and a torque hysteresis control unit, a switch watch and an inverter unit; in the direct-torque brushless DC servo-control system in the present invention, the magnetic linkage and torque hysteresis control unit are used for comparing the stator magnetic linkage Psi s from the magnetic linkage computing unit and the stator torque Te from the torque computing unit respectively with the reference value Psi s * and T*e, and for outputting the magnetic linkage adjusting signal Tau and torque adjusting signal Phi having the corresponding frequency of 4-8kHz according to the compared result to improve the switch frequency of the inverter and reduce the torque pulsation. The system in the present invention has a good control effect to the torque and a quick response, and the problem of the torque pulsation of the brushless DC electric motor is solved.

Owner:常州今创电工有限公司

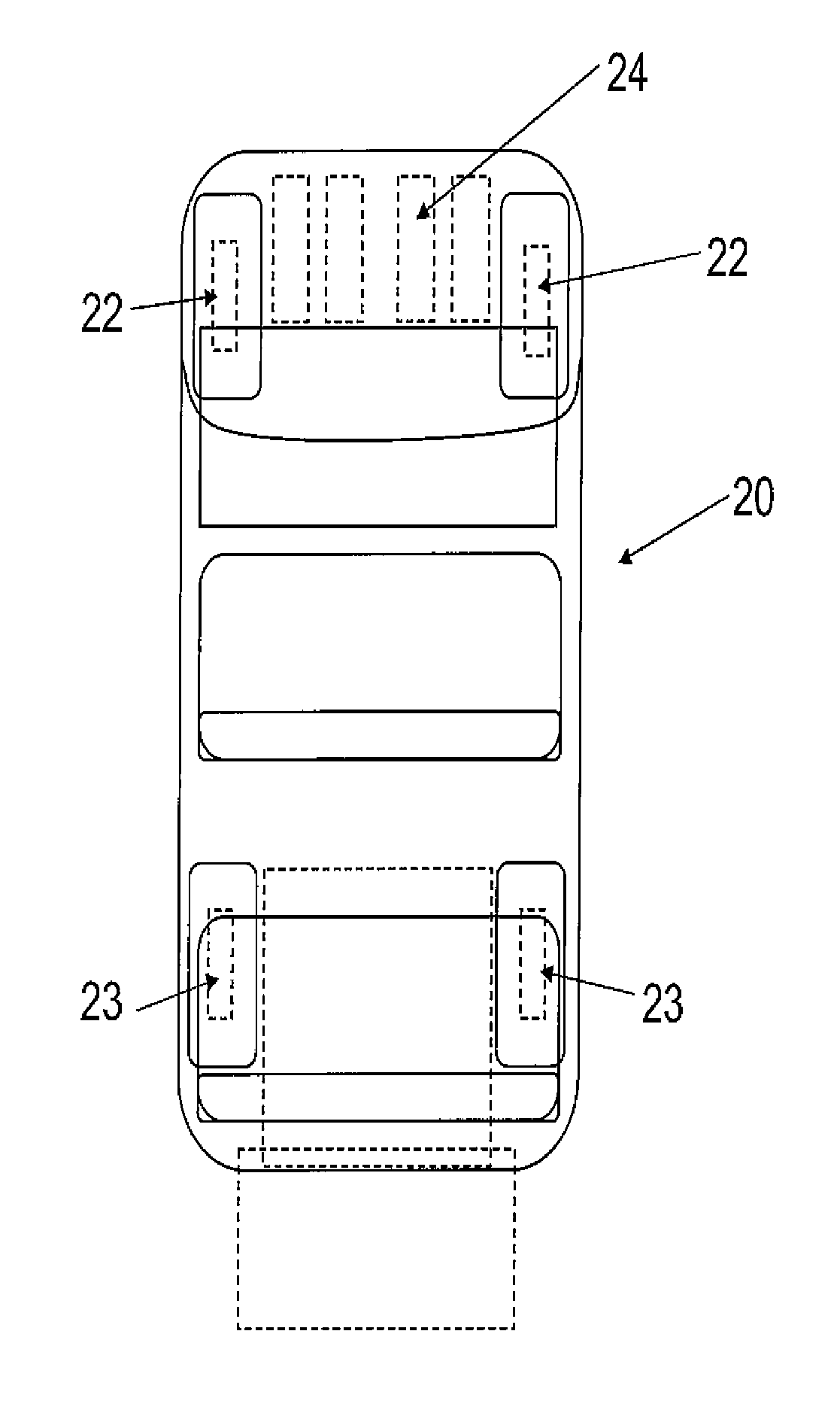

Brushless DC electric motor

InactiveCN1520632AMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesConductor Coil

An electric motor comprises a housing, a magnetic rotor and a stator which comprises at least one circuit board. The magnetic rotor comprises a disk with circumferentially arrayed magnetic poles. The circuit board on each side comprises one layer of circumferentially arrayed coil windings arranged in pairs, thus each pair made as a spiral that extends from a center of a start coil winding to a center of an end coil winding with the same turn direction of the spiral in relation to each of centers. The layers are the same in transparent view and shifted angularly in such a way thus centers of the start coil windings from one side of the circuit board coincided and electrically connected by via's with centers of the end coil windings on the other side of the circuit board.

Owner:ADVANCED ROTARY SYST

Underwater integrated electric motor thruster

InactiveCN101369767AImprove efficiencyReduce axial sizeMagnetic circuit rotating partsPropulsion power plantsBrushless motorsUnderwater

The present invent provides a underwater integration motor thruster, including a DC brushless motor composed of a stator core and a rotor; the stator core is mounted on a shaft fixed on a base, the external surface of the stator core has a groove, and an armature winding locates in the groove; the rotor spider is mounted on the shaft by a bearing, and a magnetic pole made of permanent magnetic material is mounted on the rotor spider; a air-tight case is fixed on the base, the top of the air-tight case is equipped with a mounting shaft for a sleeve barrel which is mounted on the mounting shaft; the cable wire of the armature winding is drawing off from a sealing plug. The invention eliminates influence of a mechanical retarding mechanism and an output shaft to the performance of the underwater motor thruster; the thruster has small dimension, less weight and high propulsion efficiency; the invention resolves the sealing problem of the underwater motor thruster and avoids using complicated dynamic sealing apparatus. The reliability of the underwater motor thruster is improved, and even though the propeller being entwined or stopped by underwater obstacles, the thruster motor can work still, thus the thruster is protected from being damaged.

Owner:HARBIN ENG UNIV

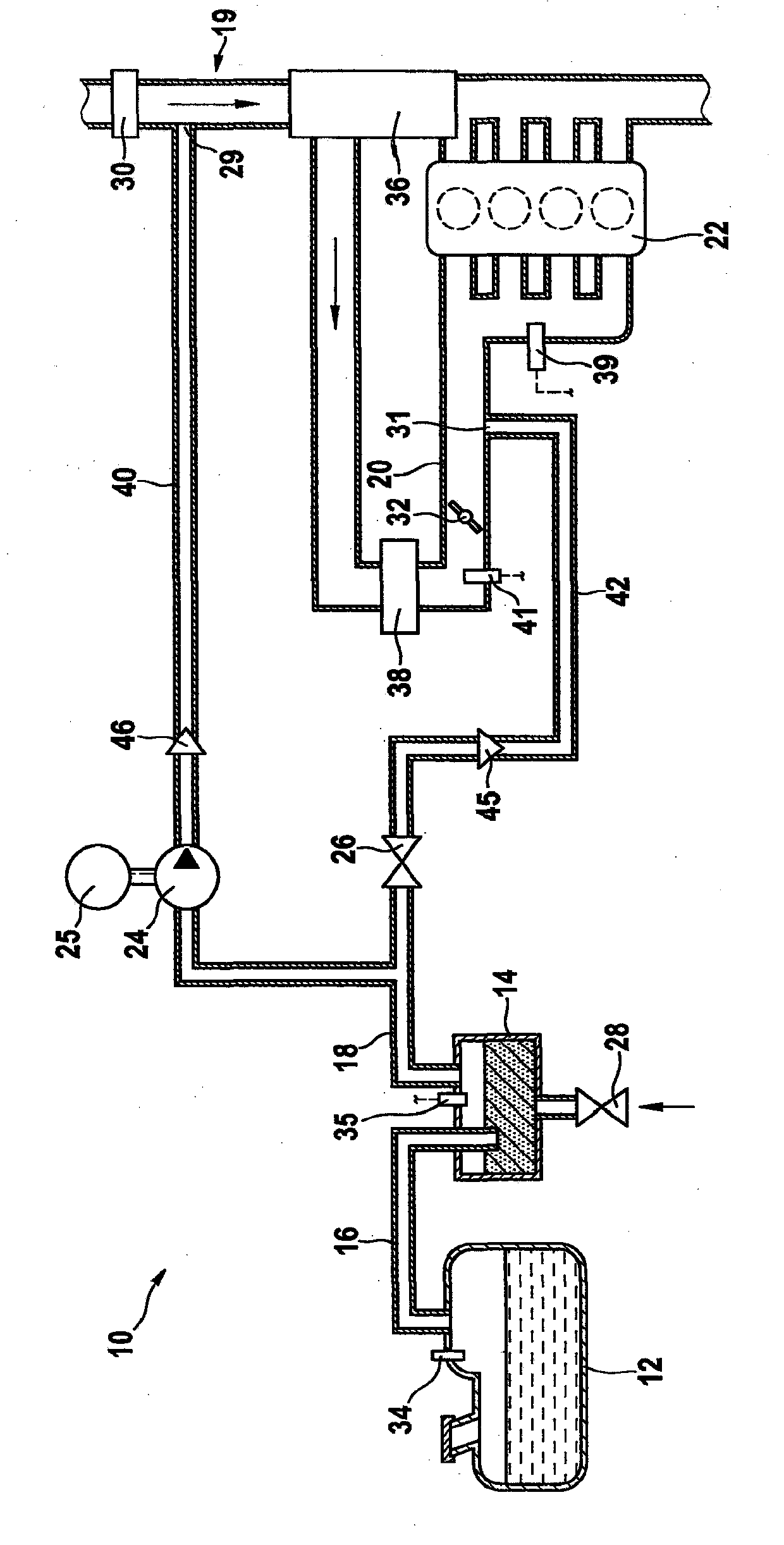

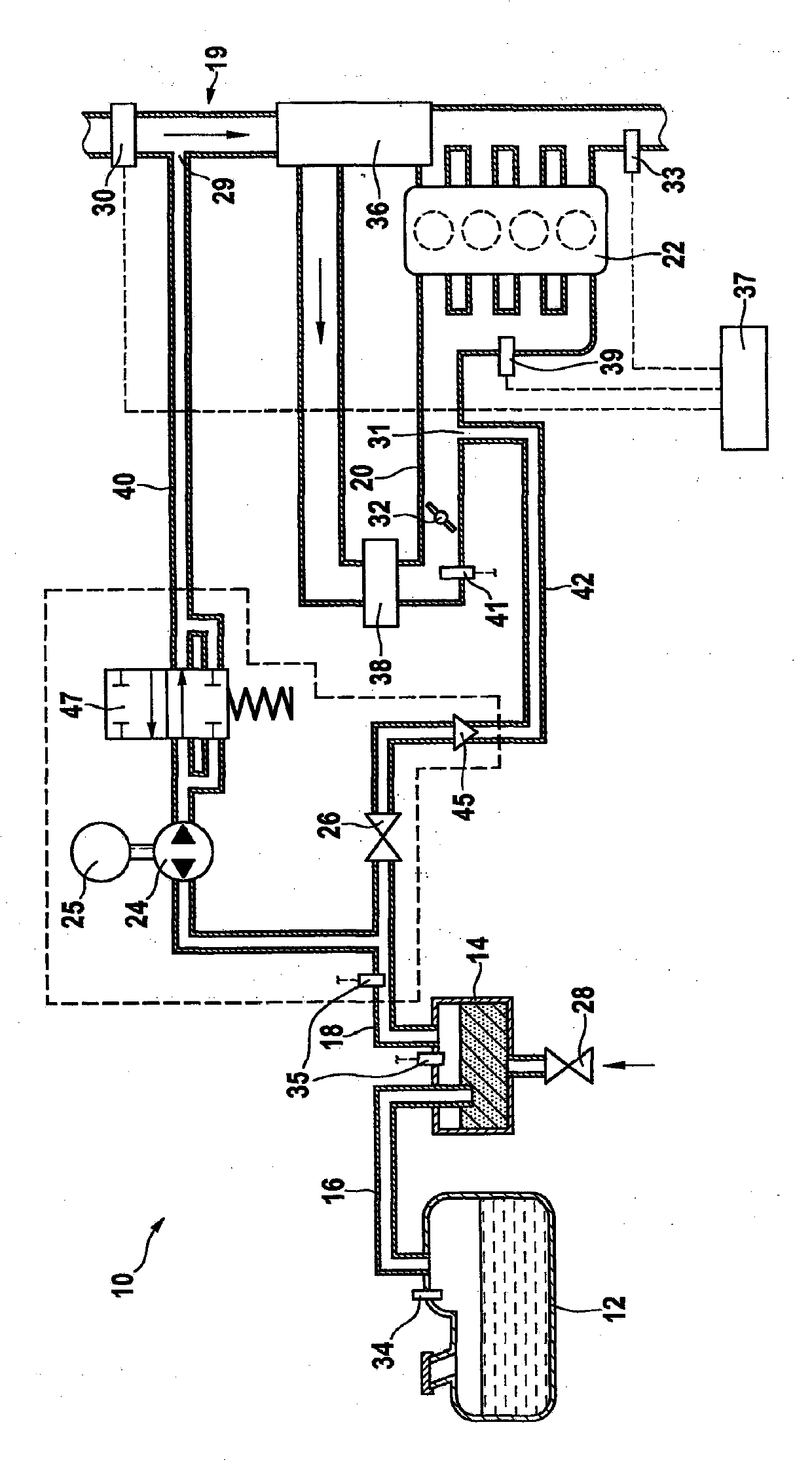

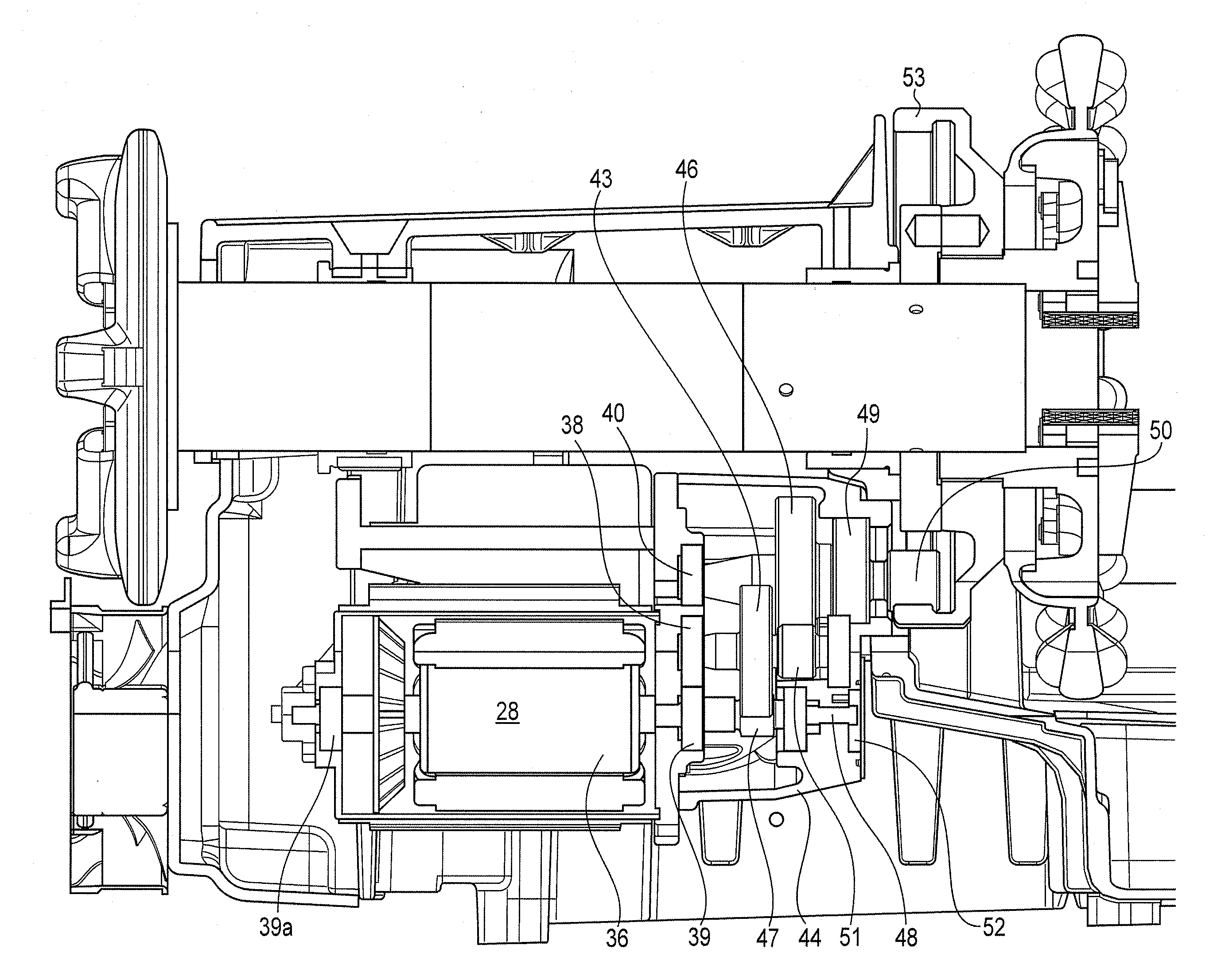

Air supply system of an internal combustion engine

InactiveCN103797240ADetermining the regeneration rateDetermining the pressure differenceElectrical controlInternal combustion piston enginesExhaust valveTurbocharger

The invention relates to a venting system (10) for a fuel tank (12), comprising a sorption filter (14) for temporarily storing fuel evaporating from the fuel tank (12) and comprising a delivery device (24) arranged between the sorption filter (14) and an air supply system of an internal combustion engine (22) in a fluid-conducting manner. The internal combustion engine (22) is a turbocharged engine with a turbocharger unit (36) and a throttling device (32) in the air supply system. The sorption filter (14) is connected to the air supply system in a fluid-conducting manner by means of a first line (40) at a first inlet point (29) arranged upstream of the turbocharger unit (36) and by means of a second line (42) at a second inlet point (31) arranged downstream of the throttling device (32). A tank venting valve (26) is arranged in the second line (42), and the first line (40) branches off from the second line (42) upstream of the tank venting valve (26) in the flow direction towards the second inlet point (31). According to the invention, the delivery device (24) is additionally advantageously driven using a brushless DC electric motor (25).

Owner:ROBERT BOSCH GMBH

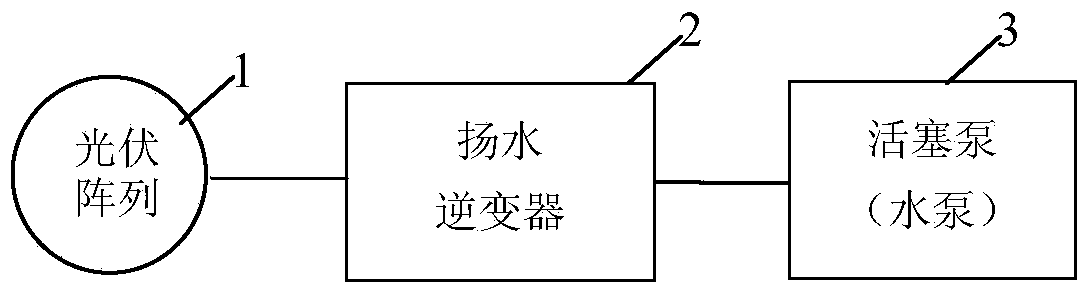

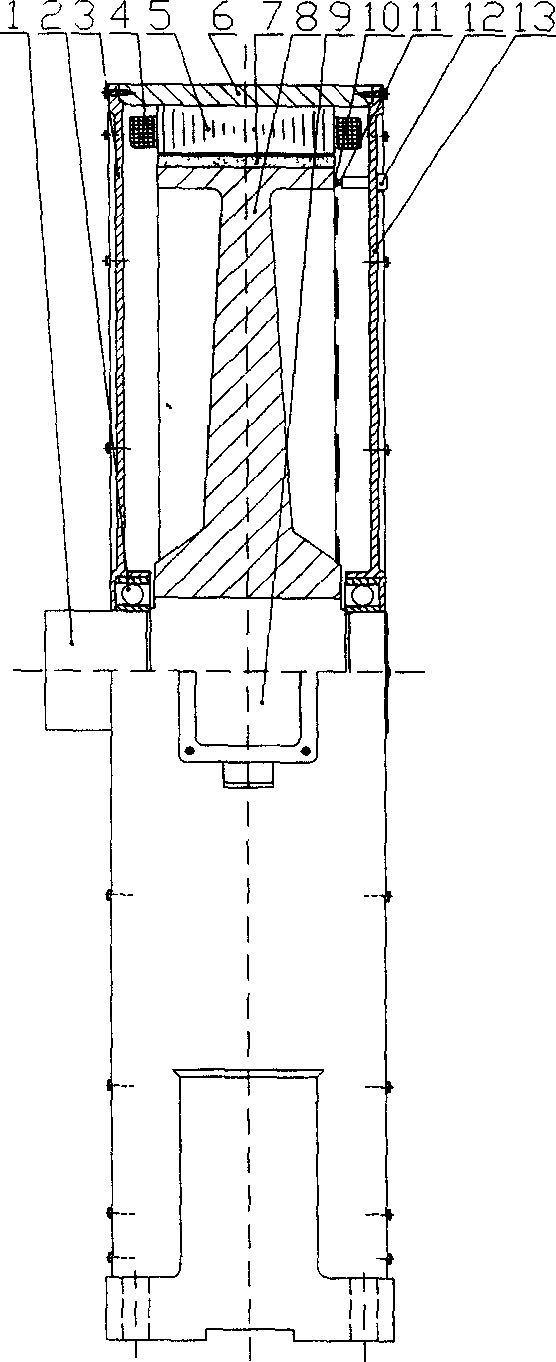

Sensor-less three-stage type starting method for deep well piston pump and application thereof

InactiveCN103762913AImprove startup success rateIncrease success rateElectronic commutatorsStarter arrangementsBrushless motorsEngineering

The invention discloses a sensor-less three-stage type starting method for a deep well piston pump. The piston pump is driven by a direct-current brushless motor, and the starting method includes the following steps that S1, the current position of a rotor is determined based on short-time pulse detection and positioning, and an inverter is controlled according to a controlling strategy corresponding to the position; S2, the step S1 is repeated until revolving speed reaches a first threshold value; S3, the reversing moment is determined based on a pulse width modulation stator current slope, and at the reversing moment, a control strategy of a next sector is used for controlling the inverter; S4, the step S3 is repeated until the revolving speed reaches a second threshold value which is larger than the first threshold value; S5, the reversing moment is determined based on back electromotive force zero passing point detection, and at the reversing moment, a control strategy of a next sector is used for controlling the inverter. The starting method can be used for a high-lift photovoltaic water pumping system and can improve the success rate of starting the system.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV +1

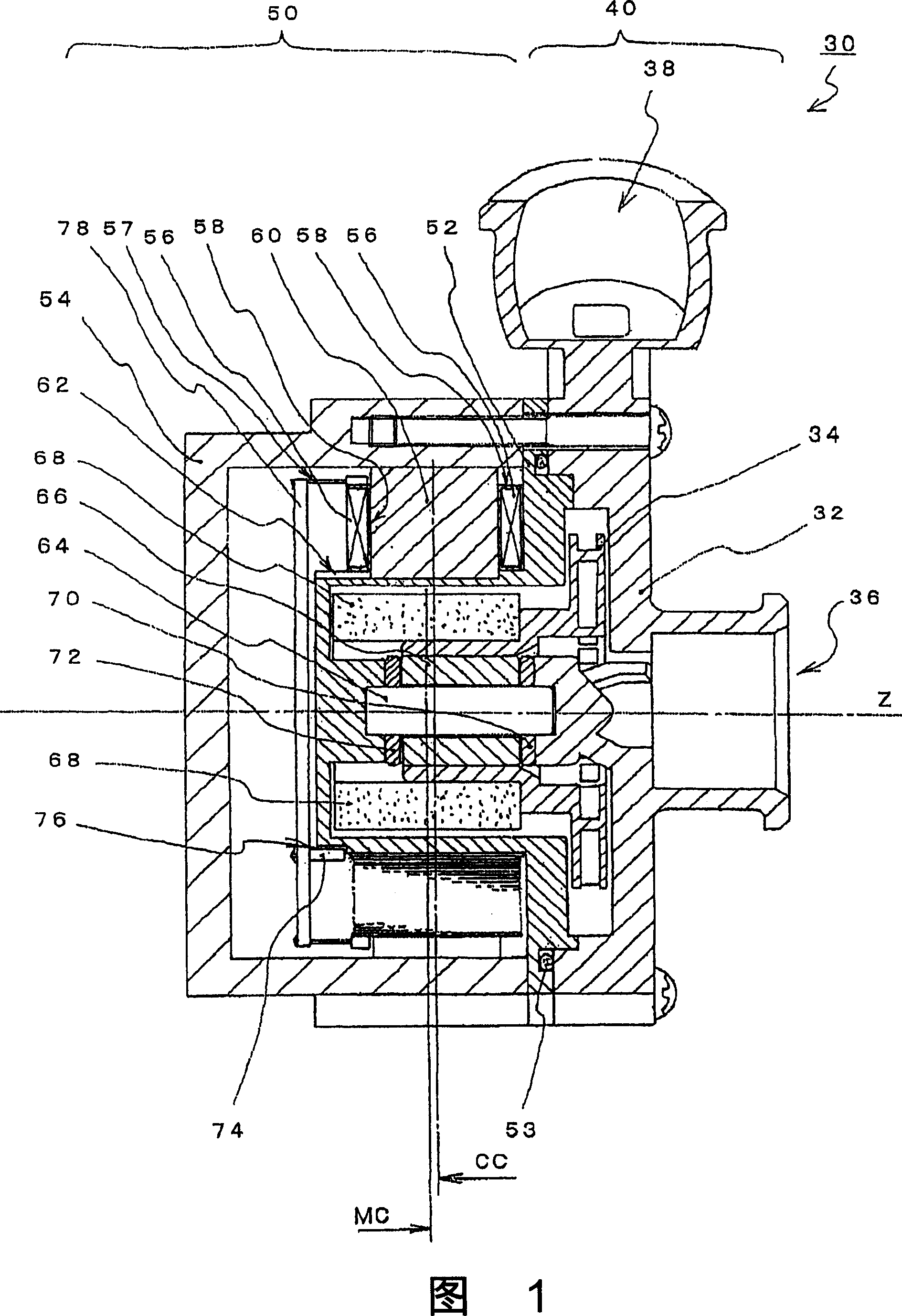

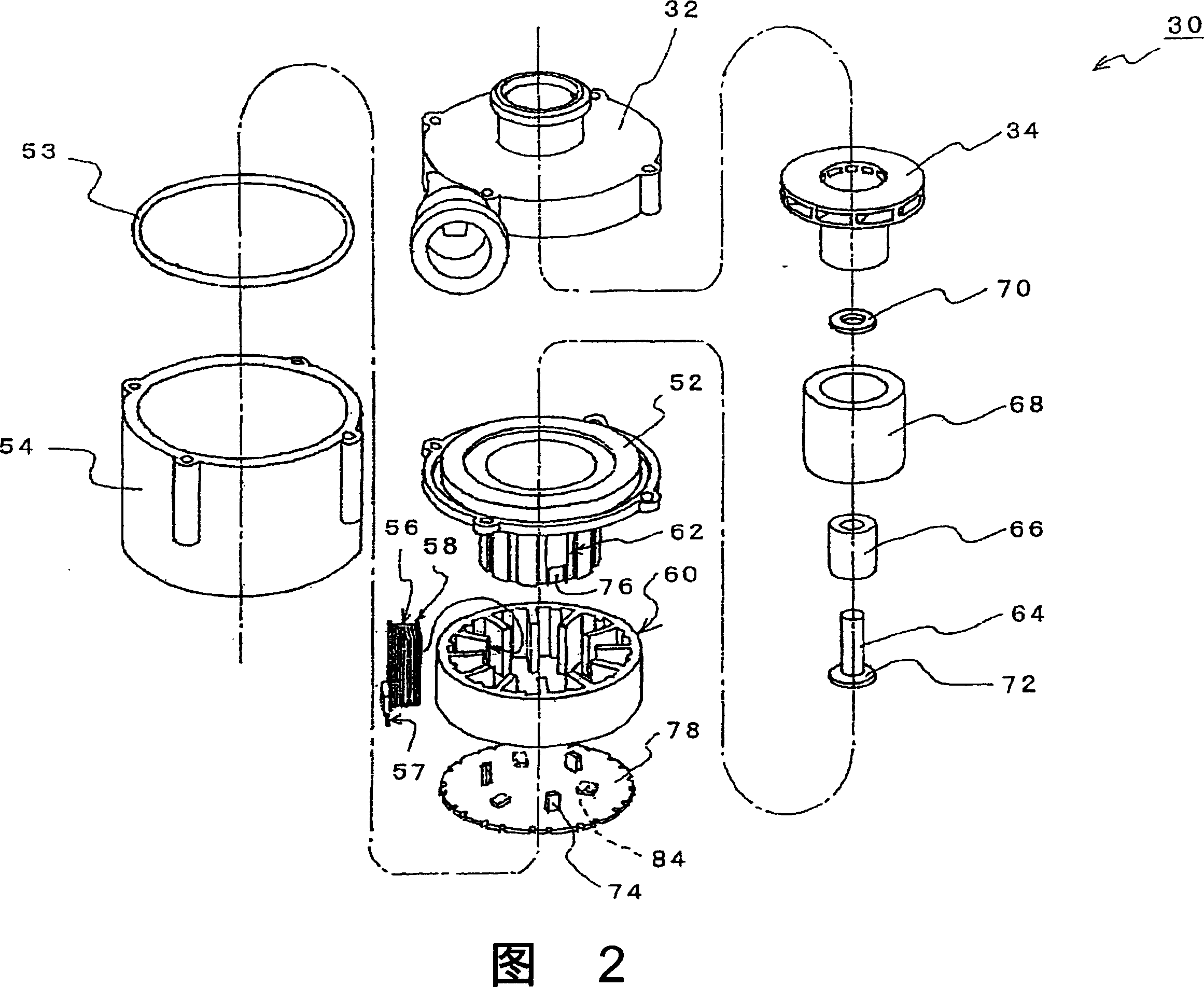

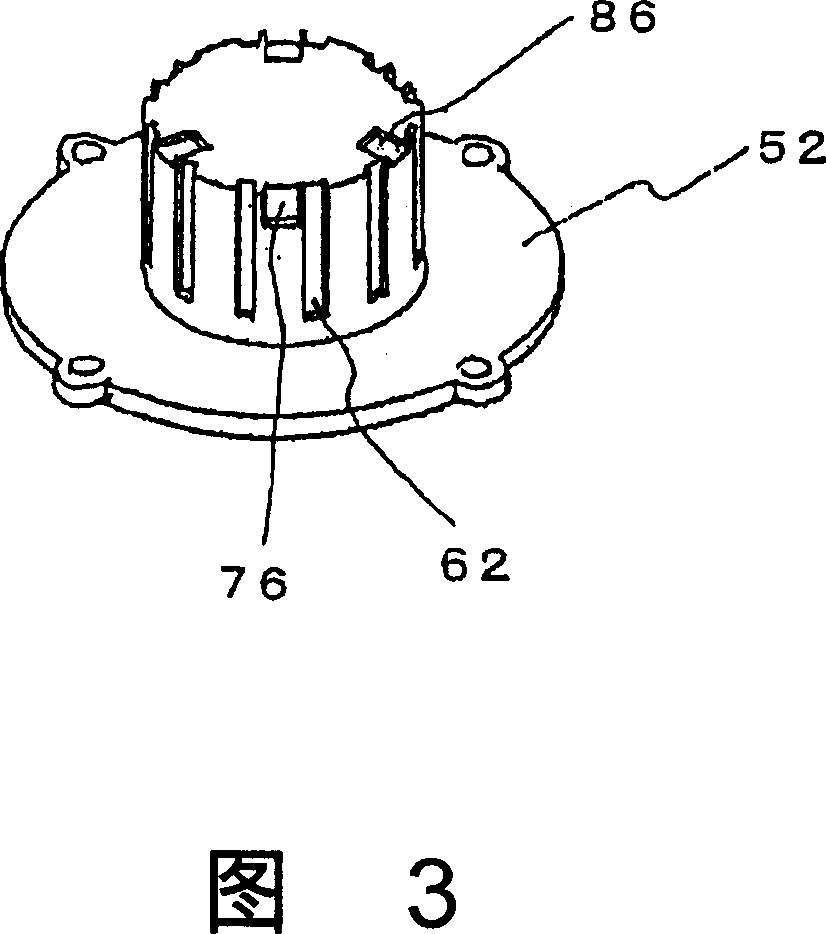

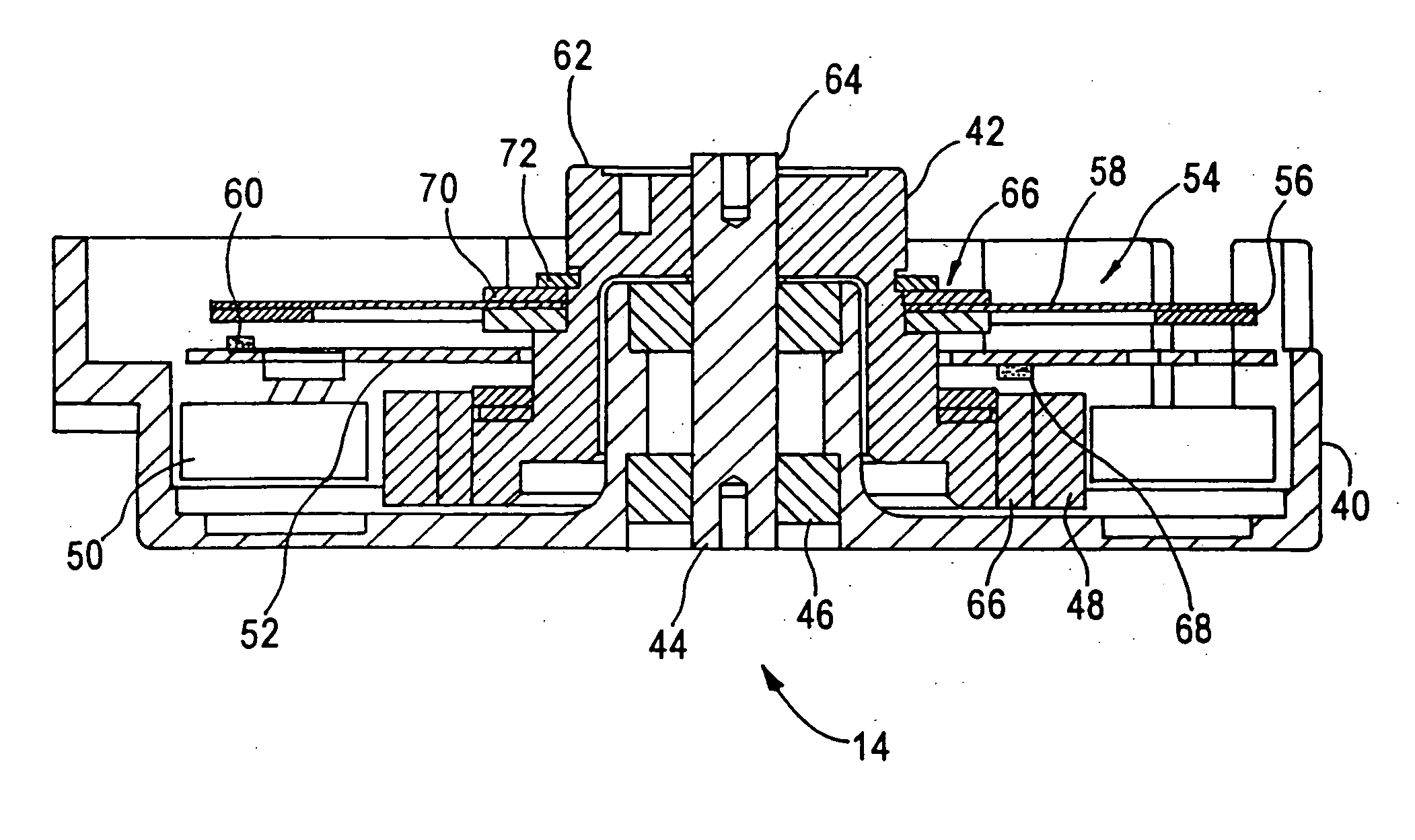

Sealed electric-motor and sealed pump

InactiveCN1941569AReduced imbalance in output characteristicsEasy to installPump componentsStructural associationBrushless motorsRotor magnets

The present invention provides an inexpensive canned motor which is efficient as a motor and is little in dispersion of performance. In this canned motor (50) which has a can (52) for isolating and sealing the stator core (60) of a DC brushless motor from a rotor magnet (68), the can (52) has a core positioning part (62) which positions the stator core (60) in the rotational direction of the rotor magnet (68) and a sensor positioning part (76) which positions the magnetic sensor (74) for detecting the magnetic pole of the rotor magnet (68), in the rotational direction of the rotor magnet (68). It is to be desired that the above core positioning part (62) should be recessed. Moreover, it is to be desired that the above sensor positioning part (76) should be recessed in parallel with the rotating shaft of the rotor magnet (68), or recessed in parallel with a sensor board for mounting a magnetic sensor (74).

Owner:SANKYO SEIKI MFG CO LTD

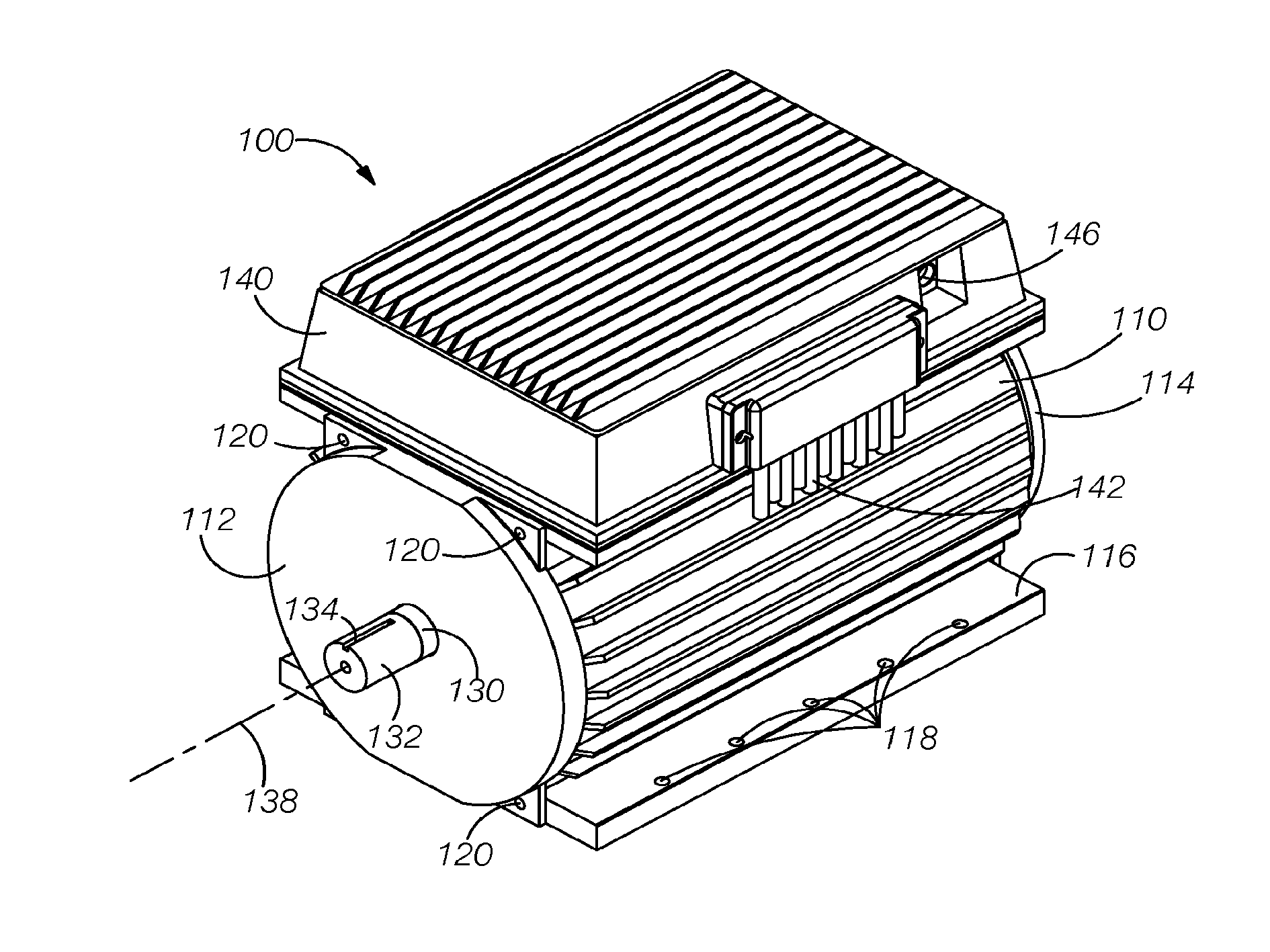

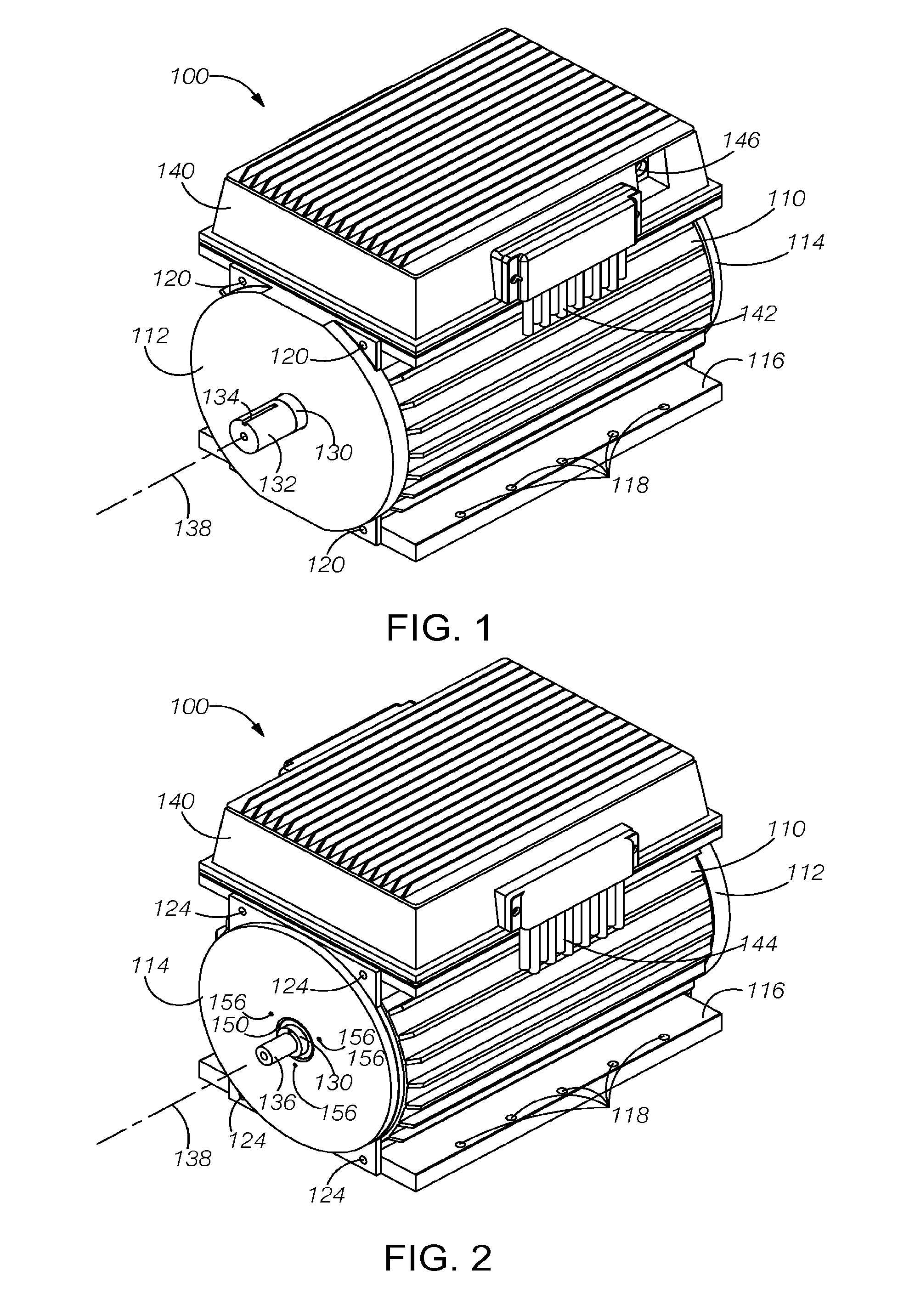

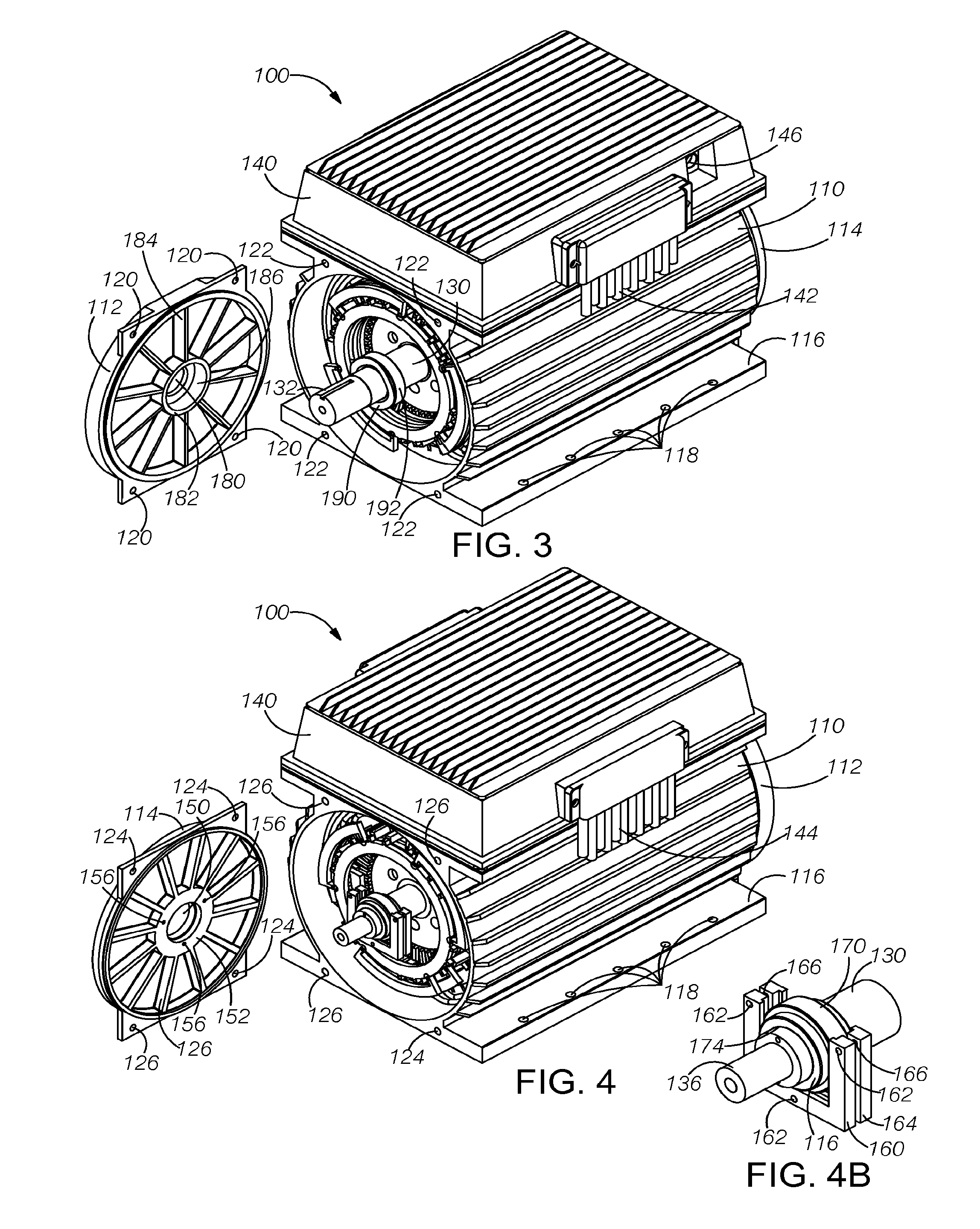

Systems and devices for performing powered threading operations

ActiveUS20120039679A1Turning machine accessoriesThread cutting machinesOperator interfaceBrushless DC electric motor

A device and associated system for threading, cutting, and reaming pipe ends are described. The device and system utilizes a brushless DC electric motor. The devices also include on-board electronics and operator interface(s) to provide sophisticated control and information as to the various operations. Also described are methods of operating the devices and several different modes for performing various operations.

Owner:EMERSON ELECTRIC CO

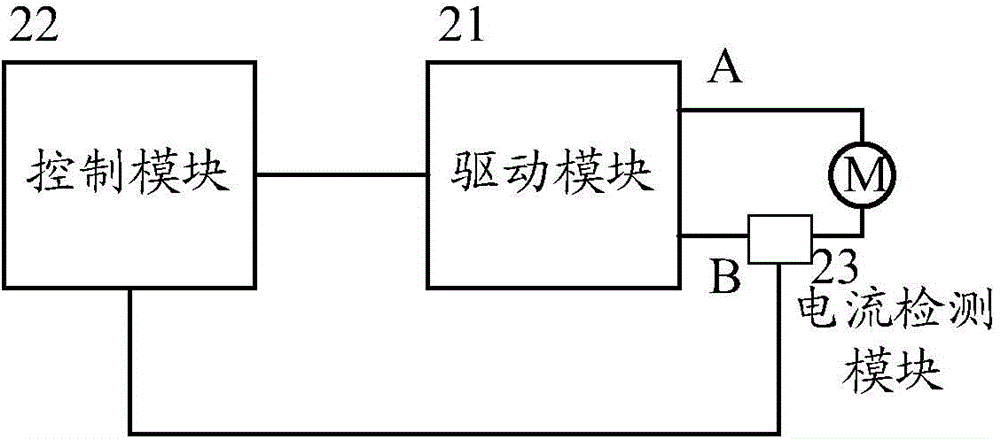

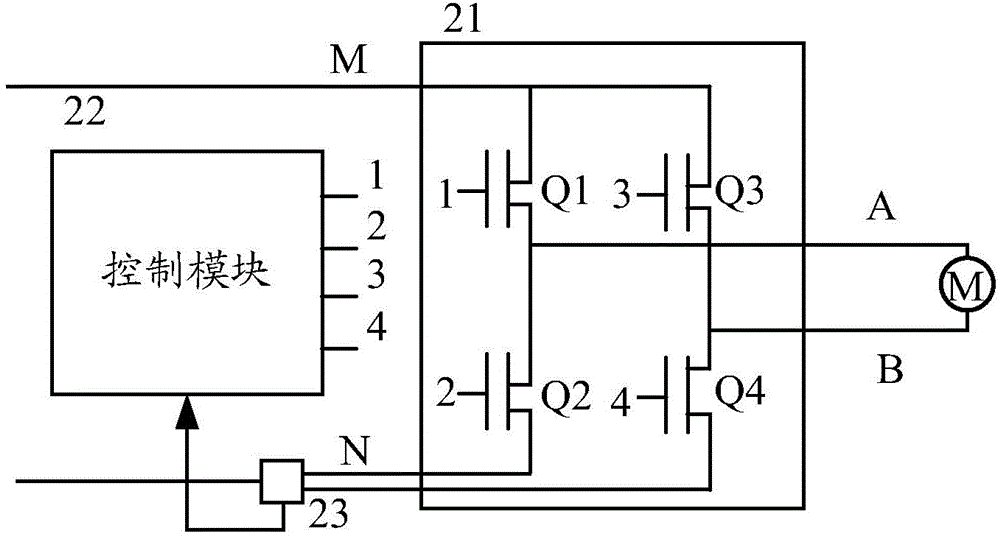

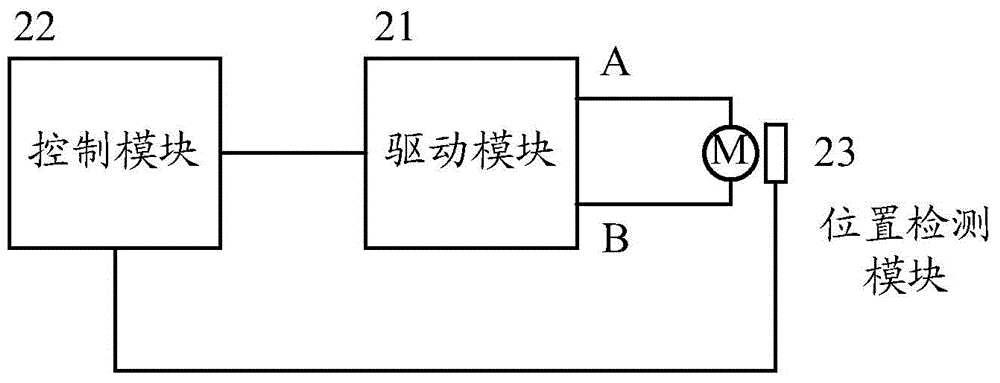

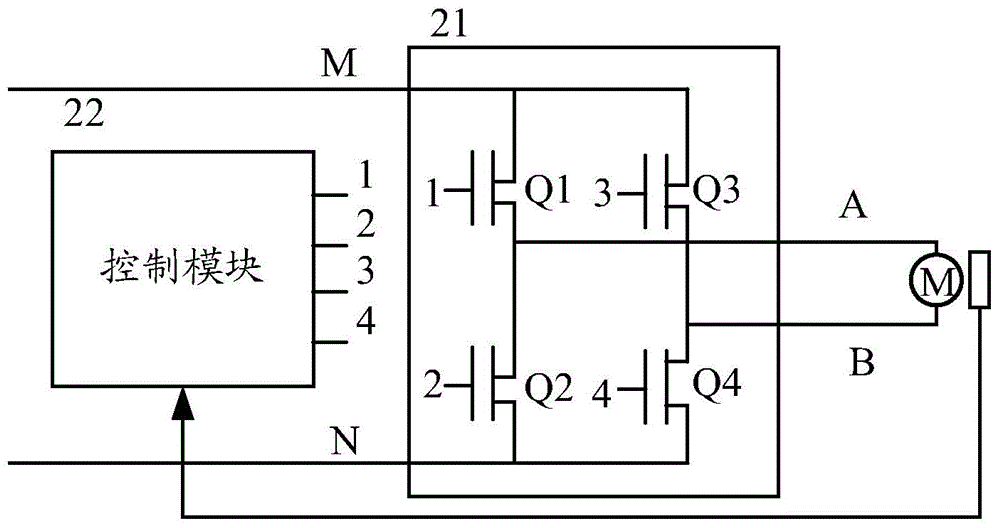

DC brushless motor system for drainage motor, and DC brushless motor control method and control apparatus for drainage motor

ActiveCN104980067AReduce target RPMReduce half-water, half-air noiseSingle motor speed/torque controlBrushless motorsPower flow

A control method and control device of a direct current brushless motor for a drain pump, and direct current brushless motor system for the drain pump, the control method of the direct current brushless motor for the drain pump comprising: detecting the current flowing through the stator winding of the direct current brushless motor; comparing the current value of the current with a first critical current value; when the current value of the current is lower than the first critical current value, determining that the drain pump is in a half-water half-air operation state, and setting the target rotation speed of the direct current brushless motor as a first predetermined rotation speed, the first predetermined rotation speed being lower than the rated rotation speed of the direct current brushless motor. The half-water half-air state of the drain pump is identified according to the current flowing through the stator winding of the direct current brushless motor, and half-water half-air noise is reduced by reducing the target rotation speed of the direct current brushless motor in the half-water half-air state.

Owner:CHANGZHOU LEILI MOTOR SCI & TECH

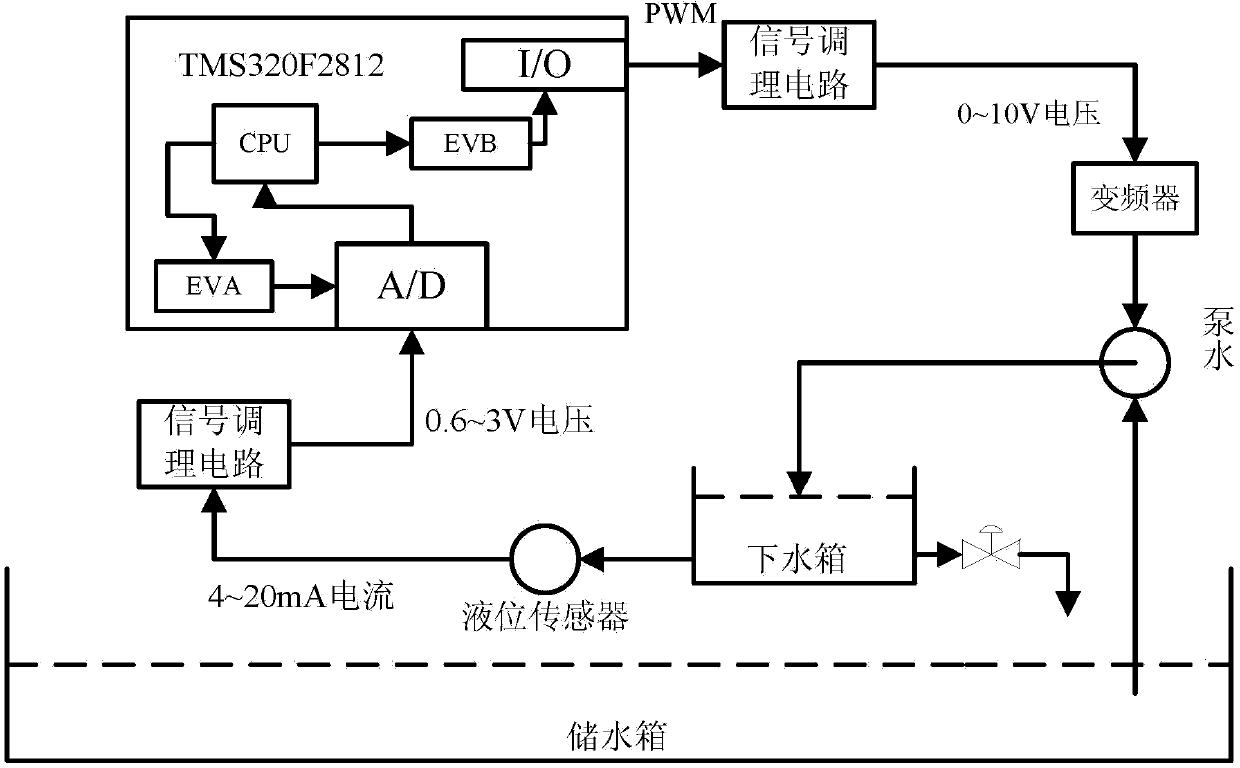

Liquid level control system

InactiveCN103869839AReduce labor intensityImprove work efficiencyLevel controlBrushless motorsClosed loop

Provided is a liquid level control system. A closed-loop system composed of a controller, a pressure sensor, an A / D converter, a control output, an MM420 frequency converter, and a water pump driven by a direct-current brushless motor is used as the control core of the liquid level control system. The liquid level control system further comprises a photoelectric coupling circuit, an I / V conversion circuit, a voltage matching circuit, a filter circuit and the like. In order to realize constant-liquid-level water supply, first, water pressure information of a water tank is periodically acquired through a liquid pressure sensor arranged in the water tank, the water pressure information is converted into a standard signal within an amplitude range, and the standard signal is input to a DSP for AD conversion, filtering and scale transform so as to convert the pressure information into a digital pressure Hf. The DSP compares the actual pressure value of the water tank with a set pressure value to form a deviation control quantity, and an output PWM waveform signal is controlled according to the law of a PID control algorithm. The output frequency of the MM420 frequency converter is changed by changing the duty ratio of the PWM waveform signal so as to change the speed of the water pump, change the pumping rate of the water tank and maintain the stability of the water level of the water tank.

Owner:南京恒誉名翔科技有限公司

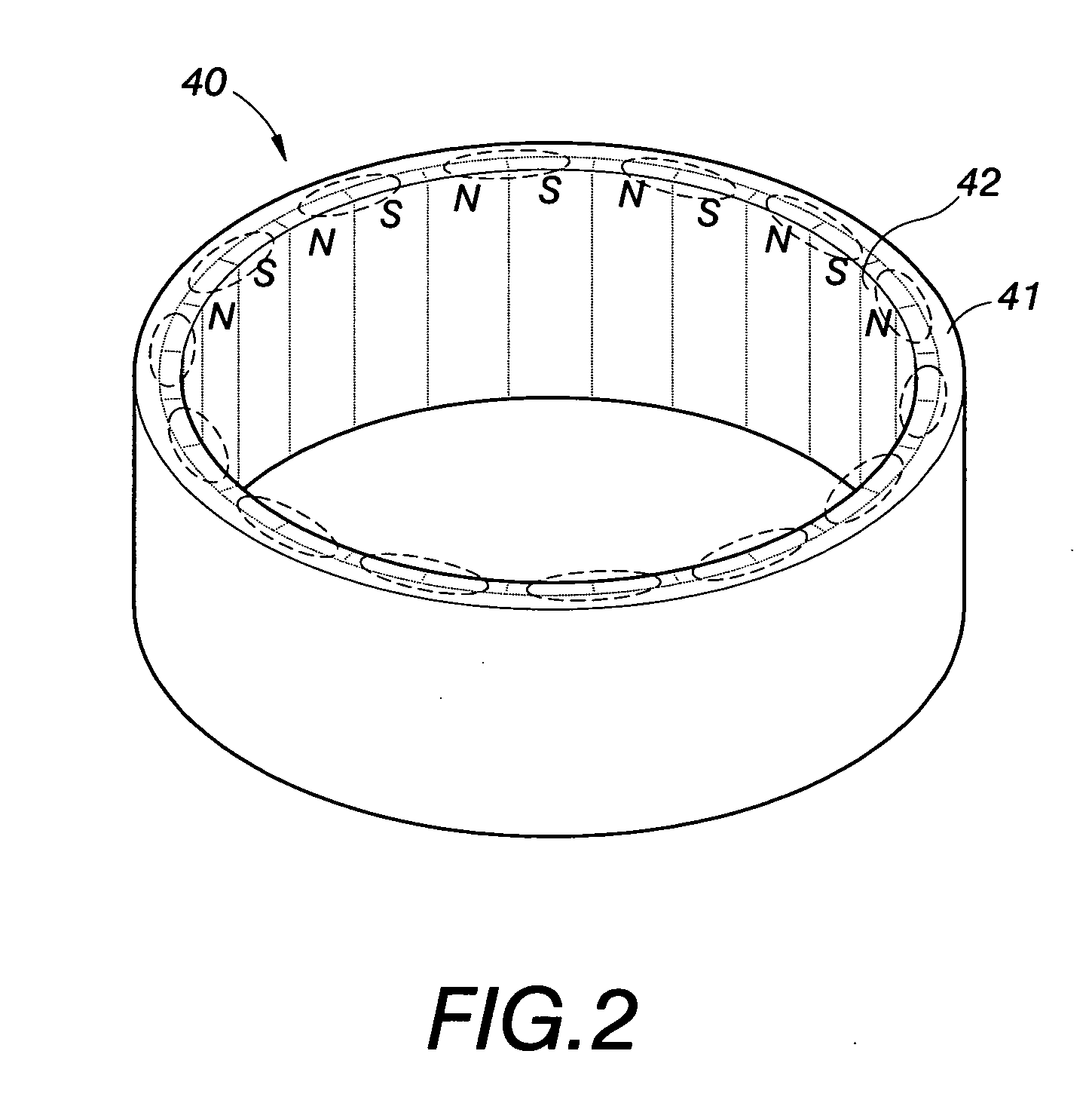

DC brush-free motor and fan rotated by outer rotor having annular ferrite magnet with alignment on its inner periphery

InactiveUS20070090710A1Achieve effectShorten magnetic loopPiezoelectric/electrostriction/magnetostriction machinesMagnetic circuitBrushless motorsMagnetic energy

A DC brush-free motor or fan rotated by an outer rotor having an annular ferrite magnet with grain alignment on its inner periphery, the main body of the motor or fan is composed of a base, a stator and an outer rotor surrounding the stator; the outer rotor includes a rotating disk and the annular ferrite magnet fixed on an inner periphery of the rotating disk, the annular ferrite magnet is a multipolar anisotropic permanent magnet, the main body of the annular magnet is divided into a magnetic conductive outer layer which is not magnetic and a magnetic inner layer, fluxes of the inner layer turn back when they pass the outer layer to thereby shorten the magnetic loops, and to increase magnetic force and the effect of magnetic energy accumulation. When the motor runs, the outer rotor drives a rotating axle (on the base) extended out of a housing to put out power and to be a power output axle of the motor. As to the fan, the outer rotor is provided on its outer portion with fan blades, an effect of air blowing can be achieved by rotating the fan blades.

Owner:SUPER ELECTRONICS

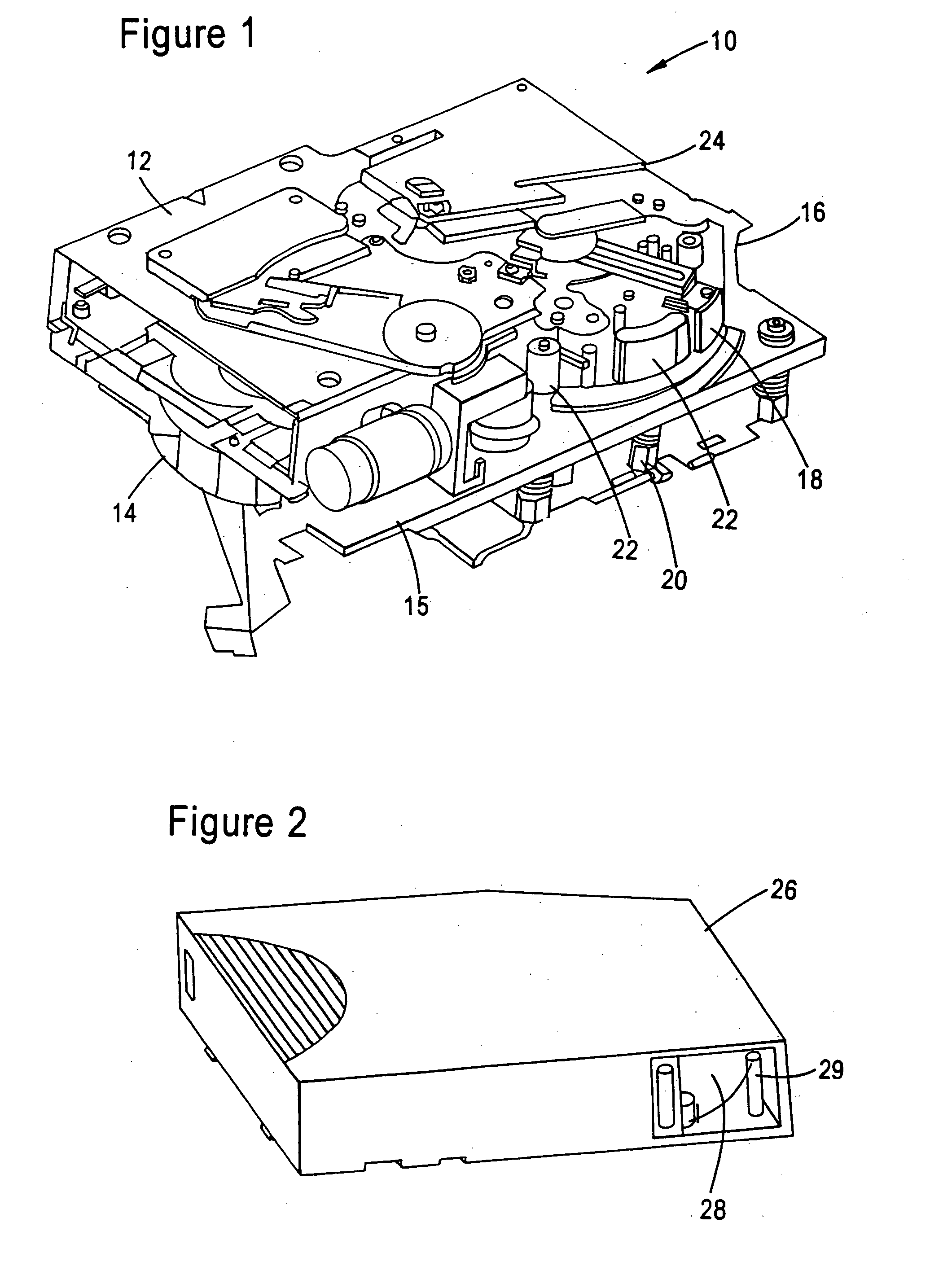

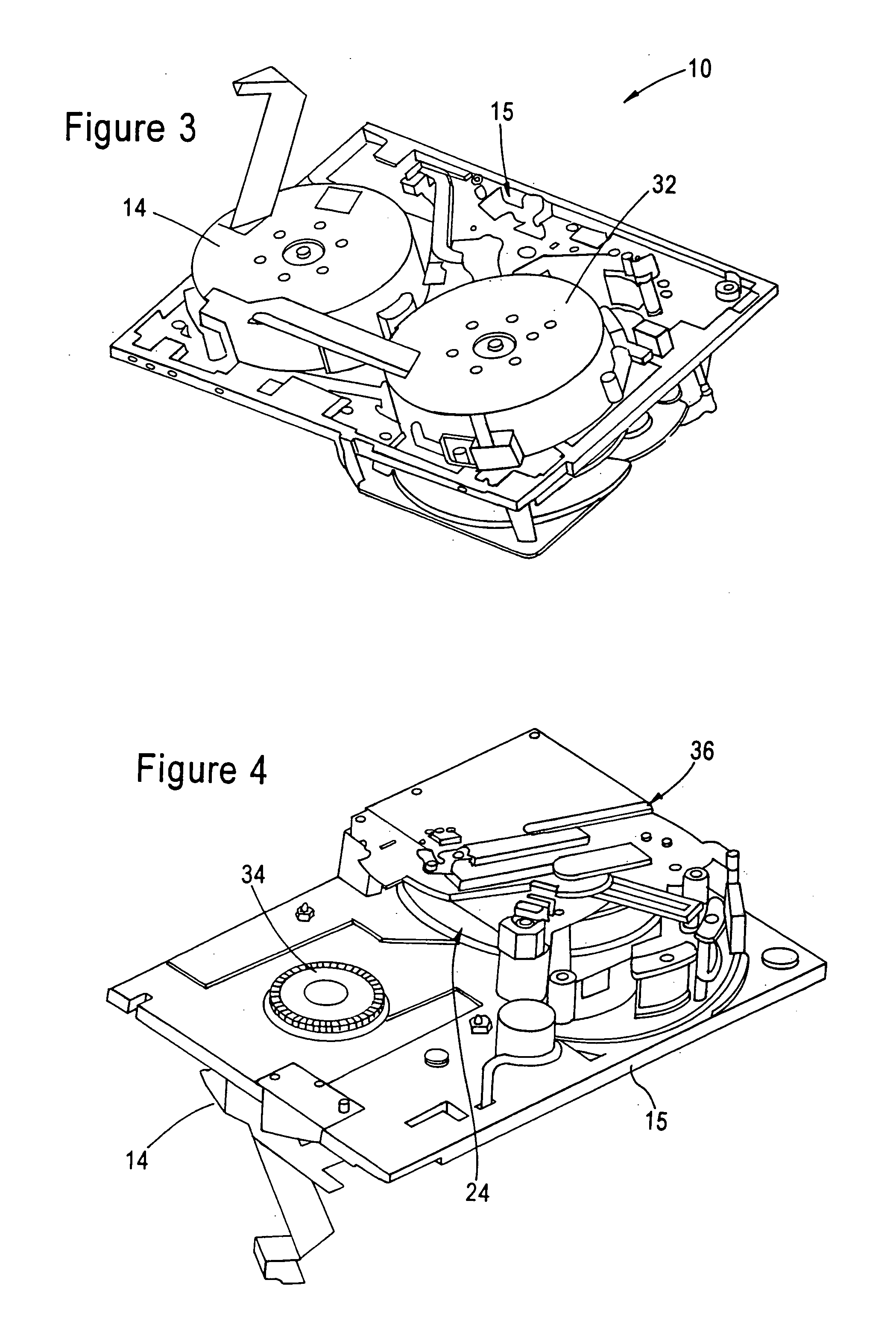

Motor/encoder assembly for tape drives

InactiveUS20060033388A1Compact designCurrent is limitedAssociation with control/drive circuitsMechanical energy handlingBrushless motorsEngineering

A magnetic / encoder assembly has a compact design and combines the features of motor, encoder and chuck locating feature within a single motor housing. The motor / encoder includes a DC brushless motor with an inner magnetic rotor. The motor windings and the commutation electronics are mounted towards the bottom side of a printed circuit board. The rotor of the motor is extended above the surface of the printed circuit board. The extended rotor provides a precision seat for the magnetic wheel with multiple poles. The top surface of the printed circuit board mounts the sensor for the encoder. The extension of the rotor provides the precision mounting surface of the cartridge driving chuck.

Owner:QUANTUM CORP

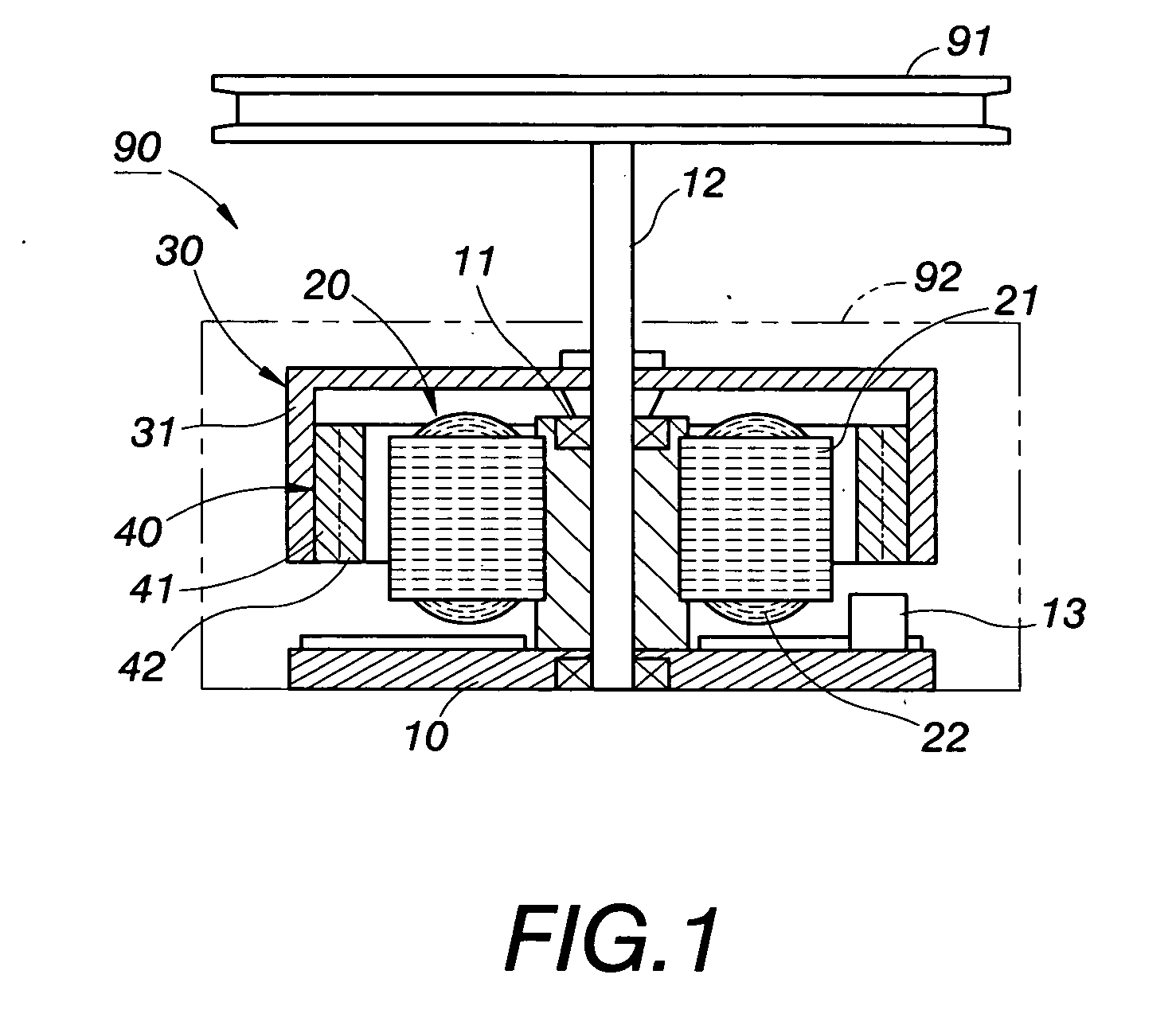

Electric motor vehicle

InactiveUS20110288707A1Useful activityAuxillary drivesDigital data processing detailsControl systemMaster controller

Various embodiments include an electric motor vehicle which does not have any active suspension components, gearbox, differential or other mechanical transmission components, in various embodiments including consists a chassis, at least one pair of integrated wheel and brushless DC electric motor assemblies mounted on the chassis with conventional suspension components including springs and dampers. In various embodiments, a battery pack on the chassis provides power to the integrated wheel and electric motor assemblies; and a control system operates each integrated wheel and motor assembly independently of each other integrated wheel and motor assembly. Various embodiments include the control system has including a master controller connected to the battery pack, and, a separate slave controller connected to the battery pack and to each of the integrated wheel and motor assemblies, as well as the master controller.

Owner:WESTLAKE BARRY +1

Multi-phase permanent magnet brushless DC electric motor

ActiveUS8604655B1Increase volumeReduce voltageAssociation with control/drive circuitsMagnetic circuit stationary partsElectrical conductorEngineering

A multi-phase, permanent magnet brushless DC electric motor includes 24 phase windings operating at a reduced voltage so that the motor can be powered by batteries or other sources of DC voltage to enable the motor to be used safely for propelling watercraft or other vehicles where the higher voltages required for conventional high horsepower motors would not be acceptable. The motor is wound by solid conductors spaced apart by 7.5 degrees. The conductors are interconnected and electrically driven by a sequence of drive currents to provide a six-pole stator. The connections to and interconnections between the stator windings are mirrored at each end of the stator to distribute the connections and interconnections between the two ends of the motor. A corresponding six-pole rotor using permanent magnets secured to a hollow rotor core is caused to rotate by the fields generated by the stator.

Owner:FERRAN ROBERT J

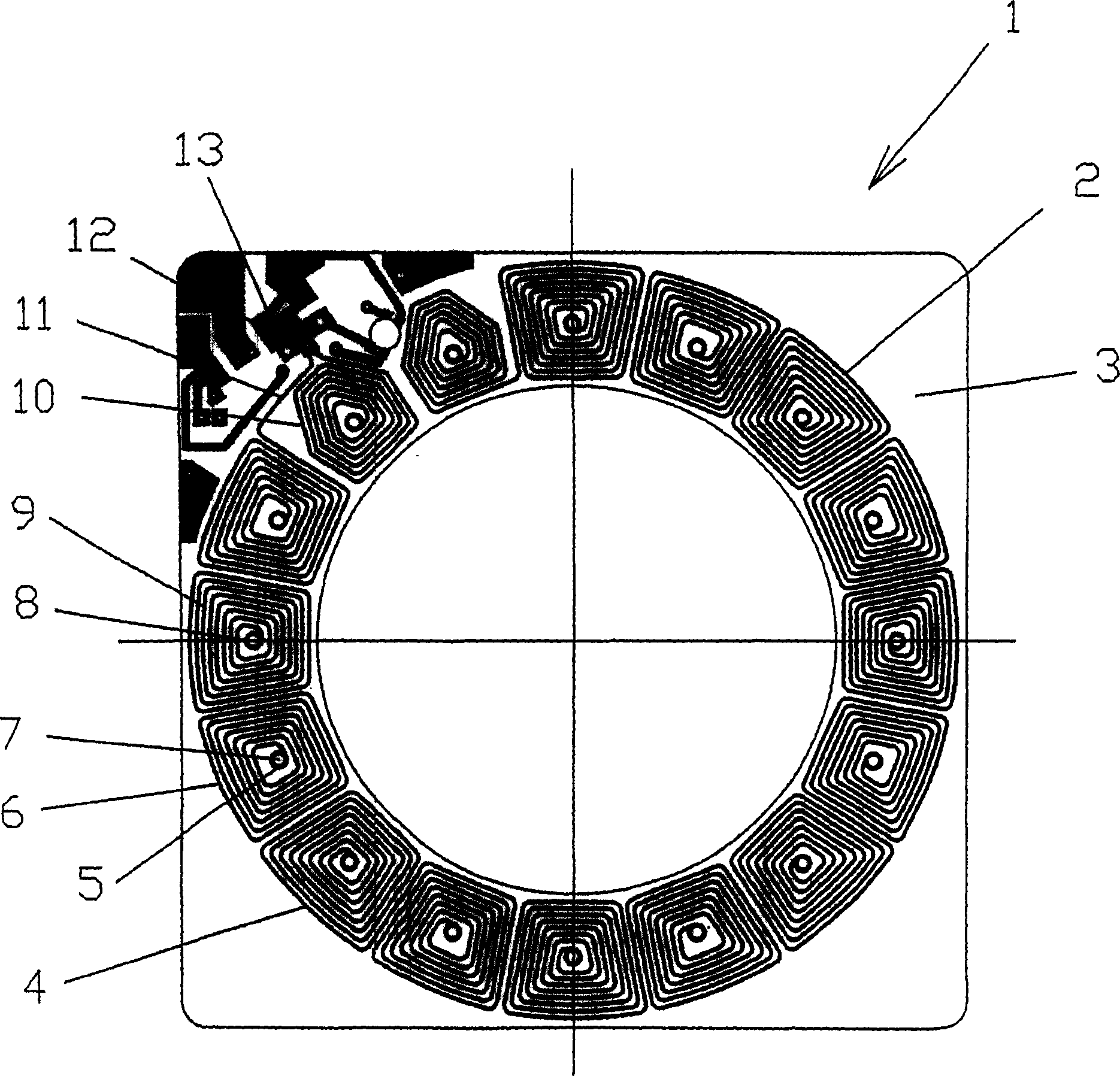

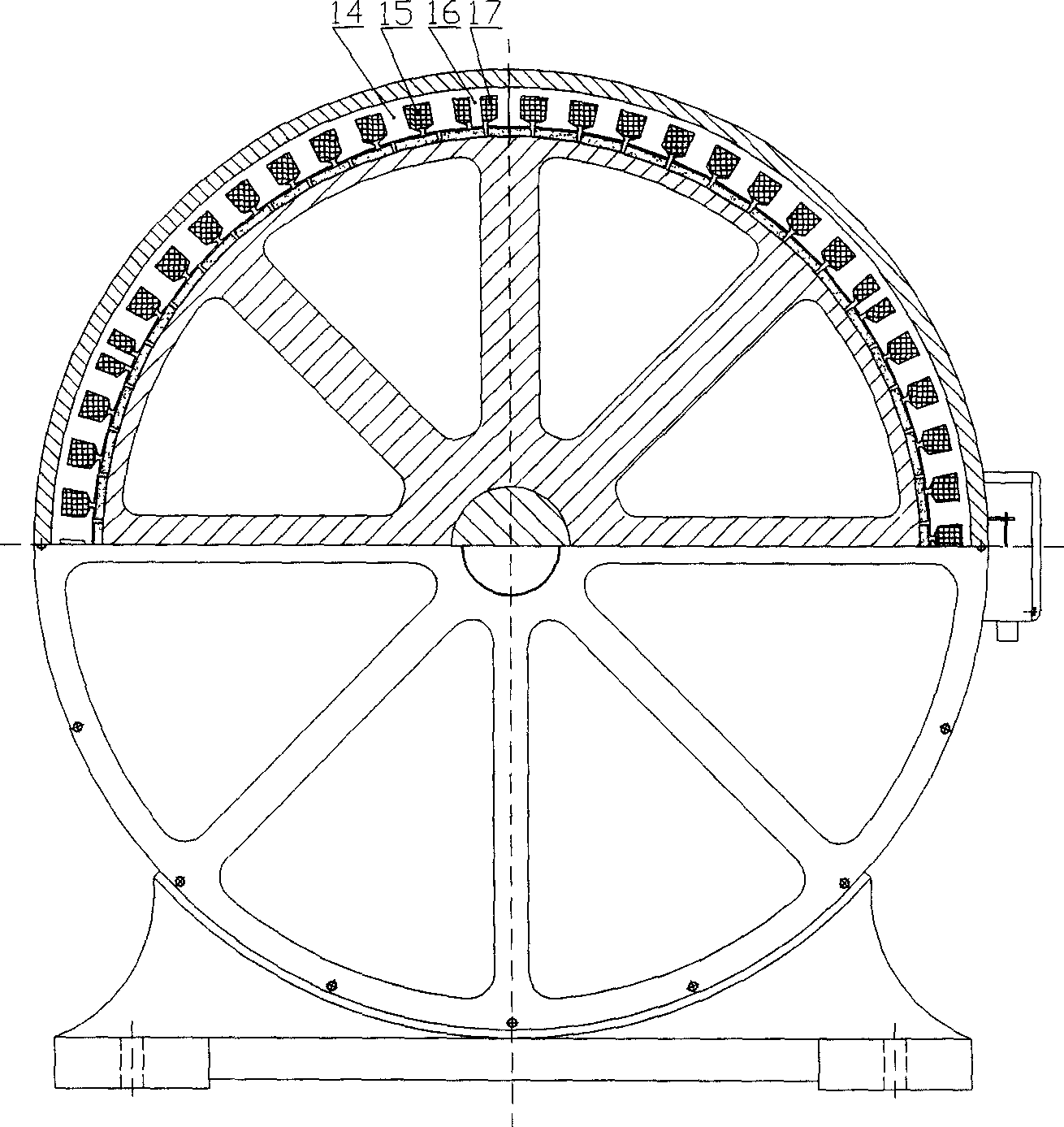

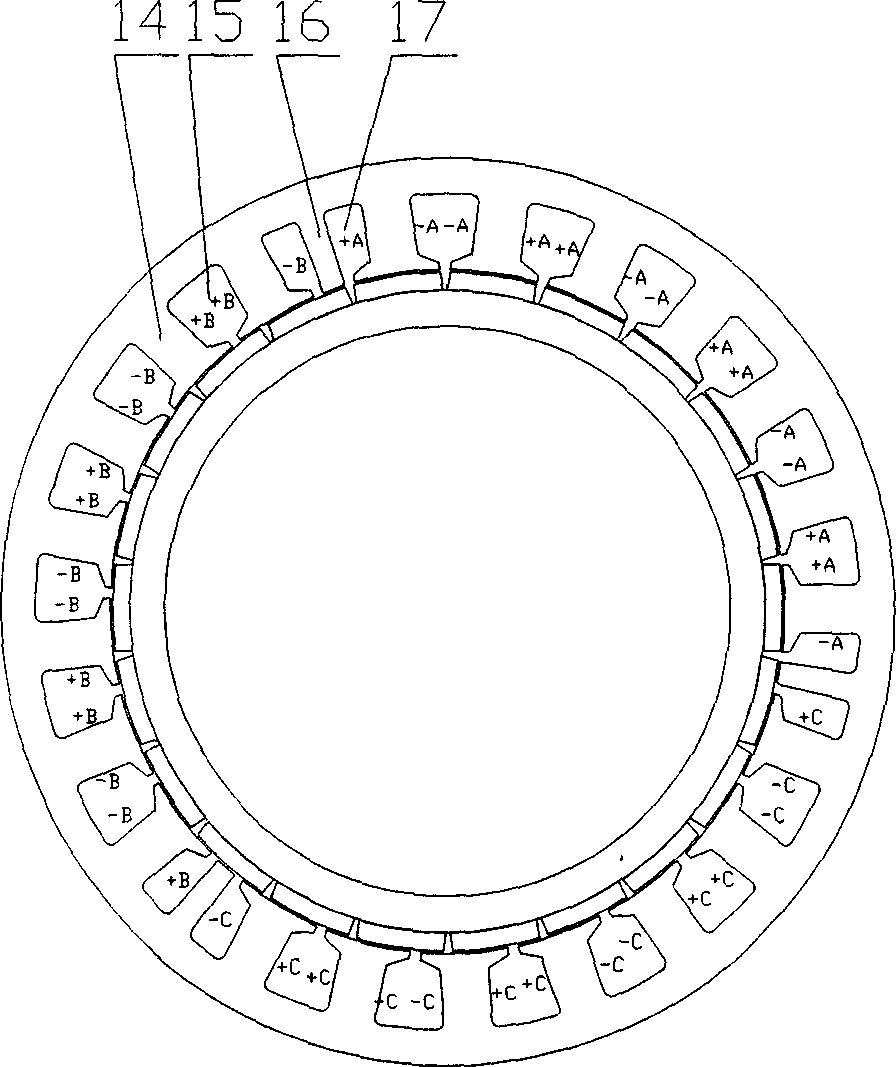

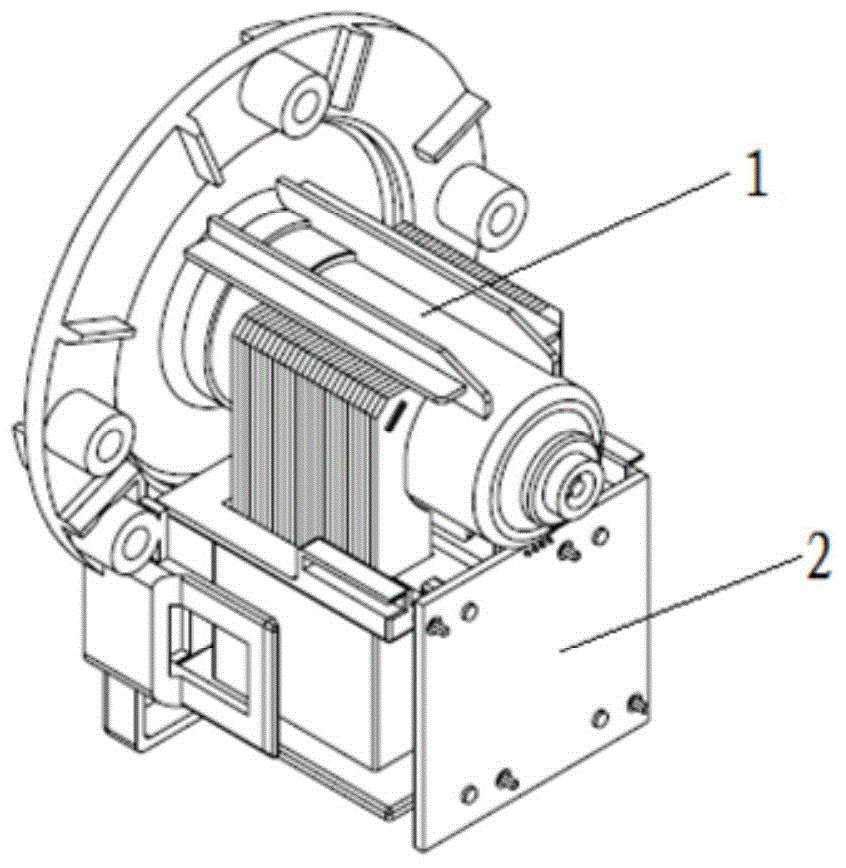

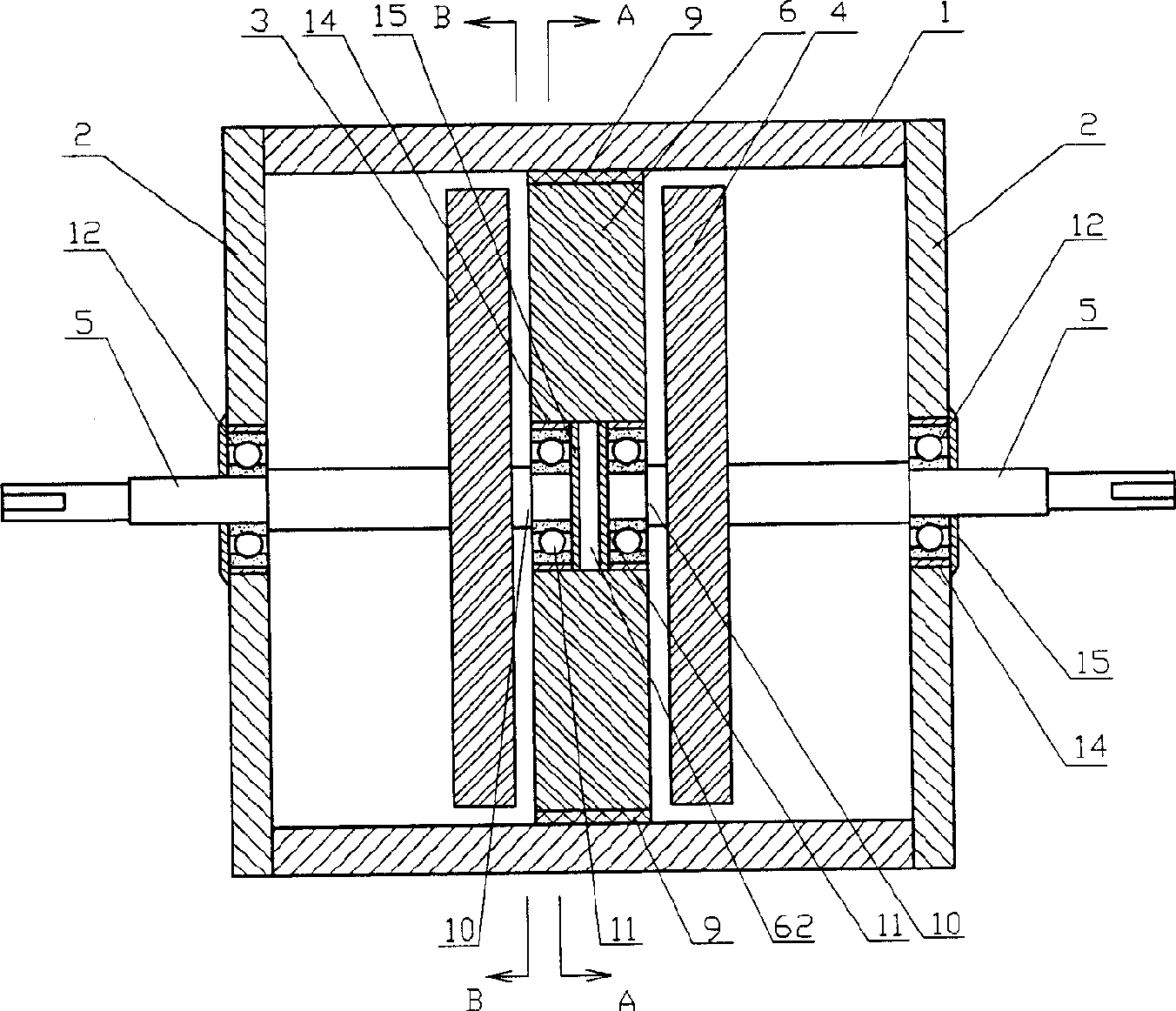

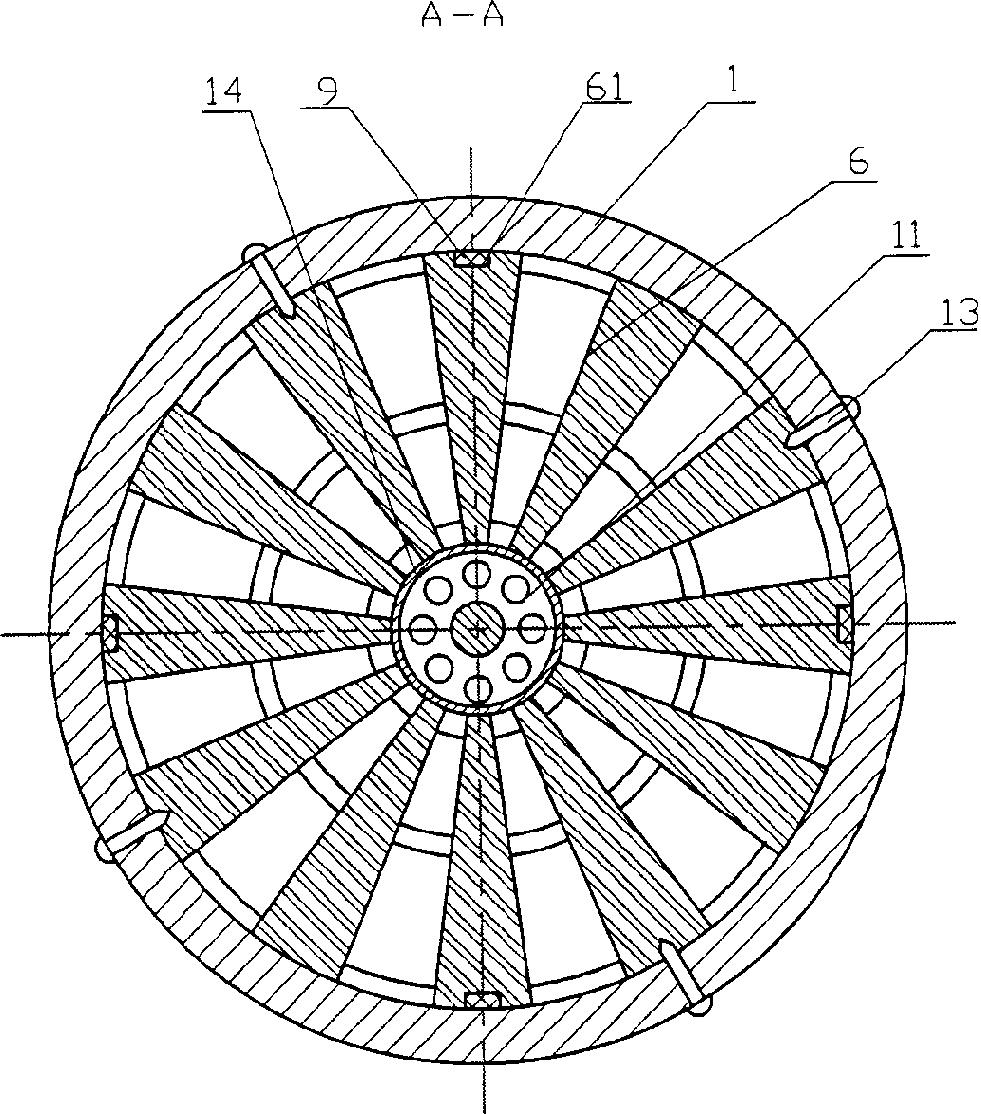

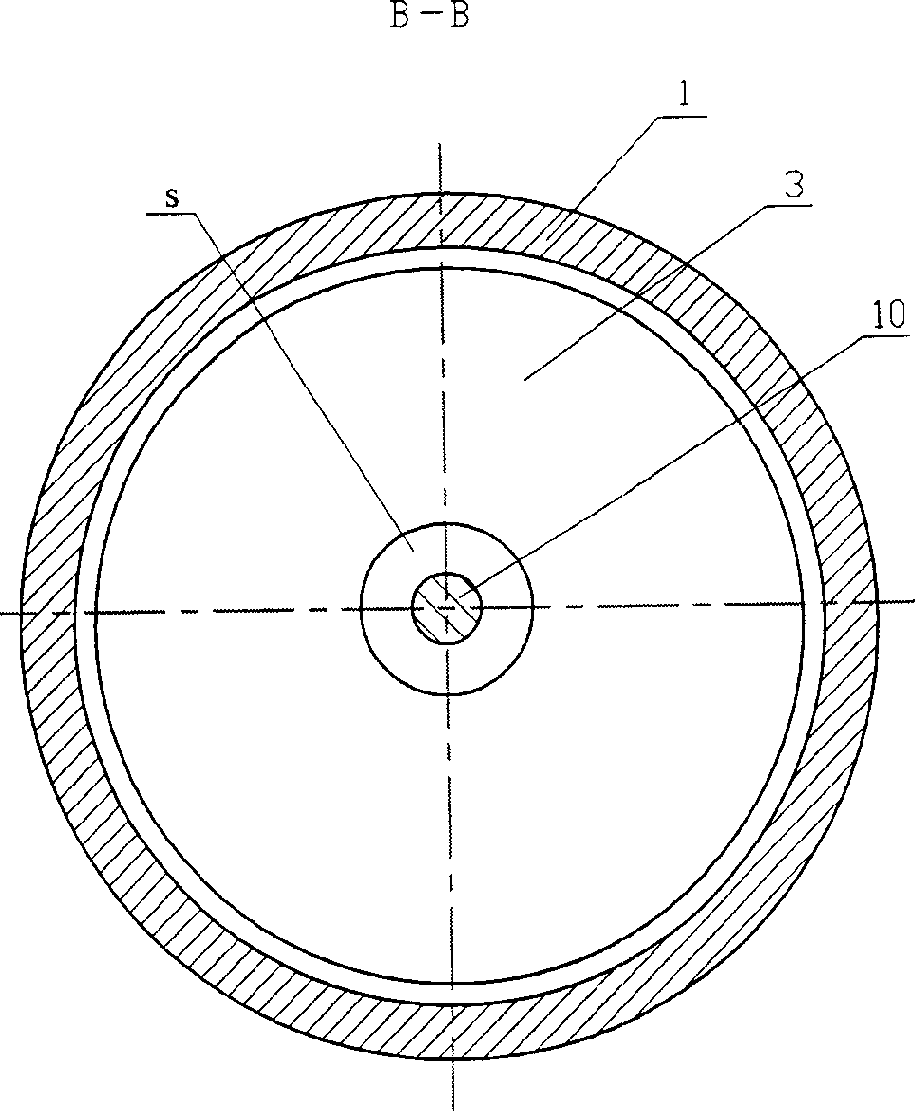

Modularized stator structure low-speed DC brushless motor

InactiveCN1862928AImprove efficiencySimple winding processMagnetic circuit rotating partsMagnetic circuit stationary partsBrushless motorsLow speed

The invention discloses the blocking stator structure low speed direct current brushless motor. It divides evenly the inner diameter circle of the stator iron core into the K1 fan section group, the A, B, C three phases of each fan section group accounts for the same superficial one fan section respectively, the stator iron core of each fan section are mounted with K2 canine tooth, the tooth distance between the border canine tooth is one polar distance, the stator iron core between the said border two fan sections are mounted with one the small slot respectively, one small tooth is mounted between the said two small slots, the settling distance collecting loop are coiled on each canine tooth, the poles of the electric machine of the invention can be designed largely, the ends of the electric machine stator winding don't fold each other, the ends are shorter, the winding modulus is one, the process of the coiling is easy, and the stator iron core of the electric machine can depress the permanent magnet guiding humorous wave torque availably without the flume, the efficiency of the electric machine is high.

Owner:TIANJIN UNIV

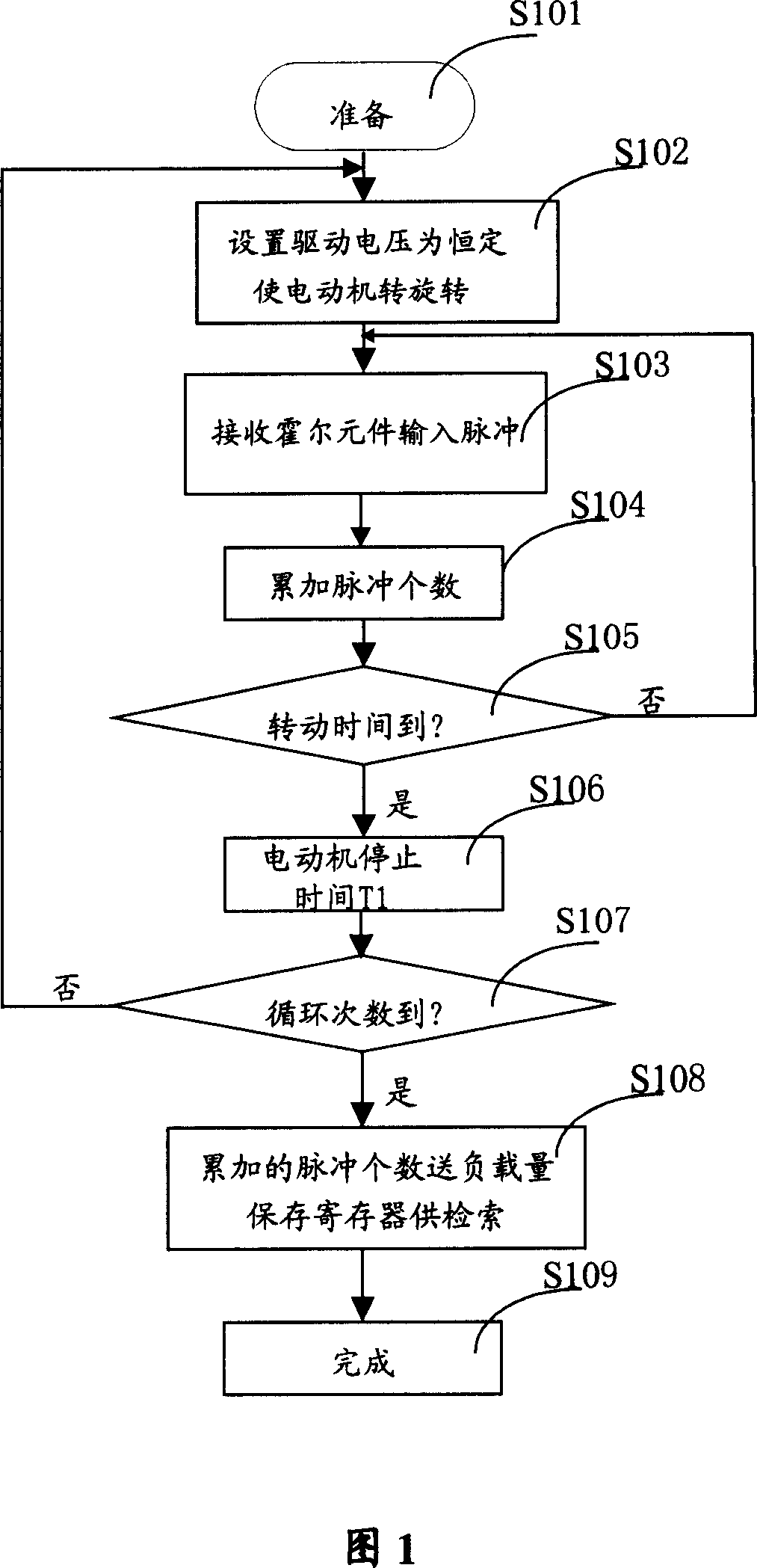

Electric motor load judgment method

ActiveCN1928579ANo additional costReduce complexityControl devices for washing apparatusTextiles and paperBrushless motorsHall element

The disclosed load decision method for dc brushless motor and ac motor with speed feedback loop comprises: 1) setting constant drive voltage to rotate the motor; 2) receiving the input pulse from Hall element of the dc brushless motor or pulse signal from speed feedback of ac motor; 3) accumulating pulse number in one period; 4) deciding load according to pulse number. Wherein, it is better to turn back to step 1) after 3), and repeats steps 1)-3) for some times. This invention is convenient and well precise.

Owner:HAIER GRP CORP +1

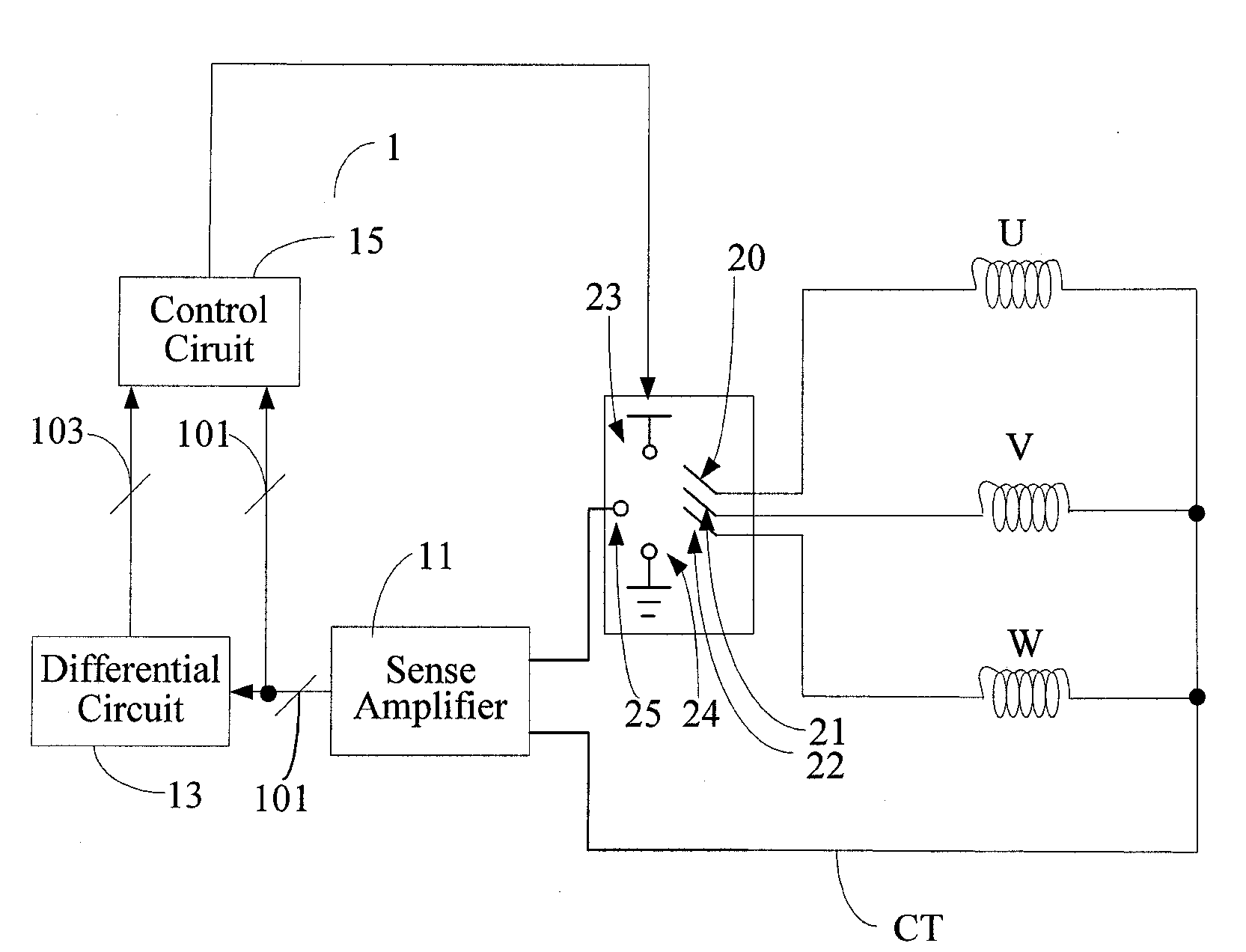

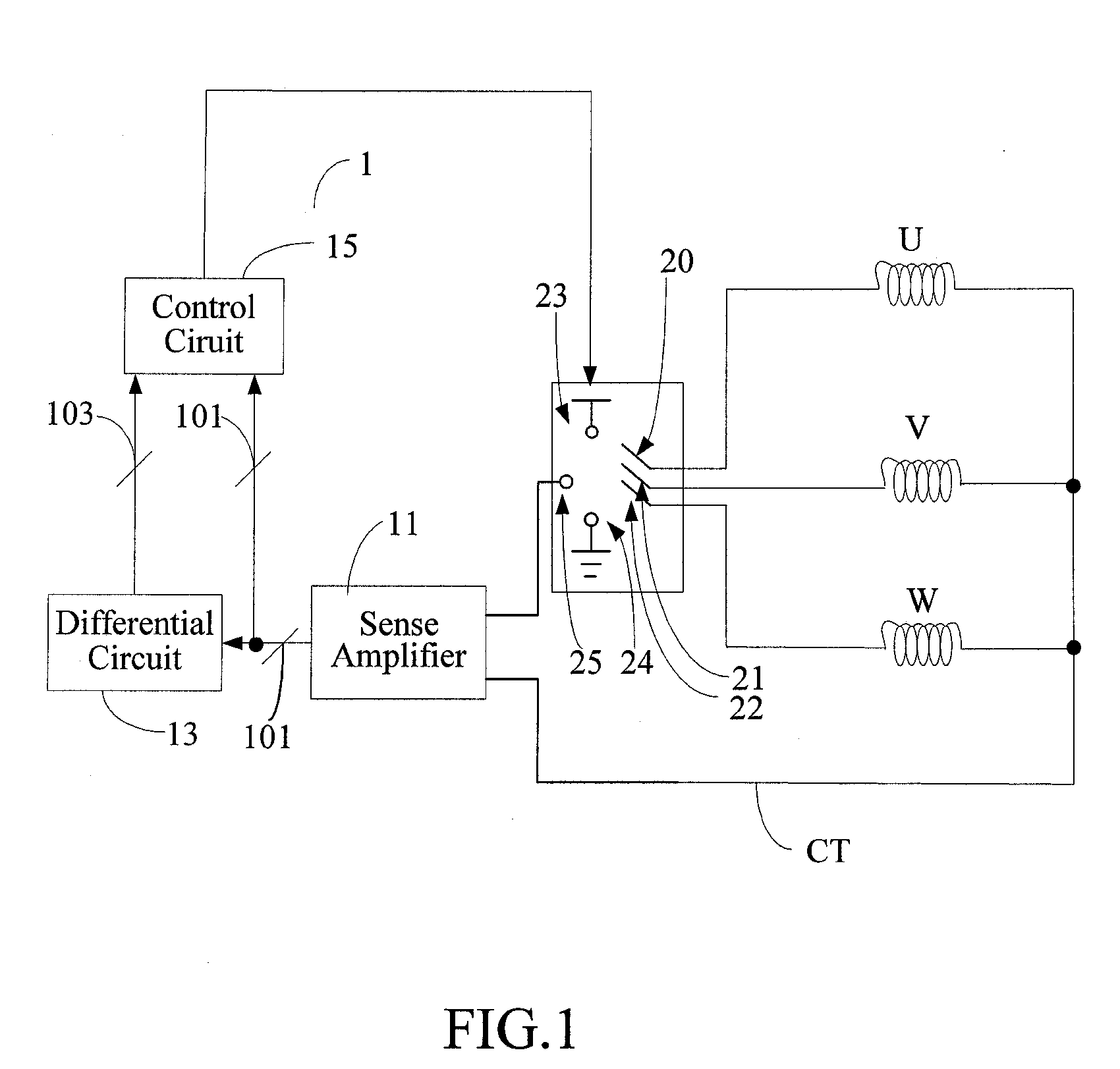

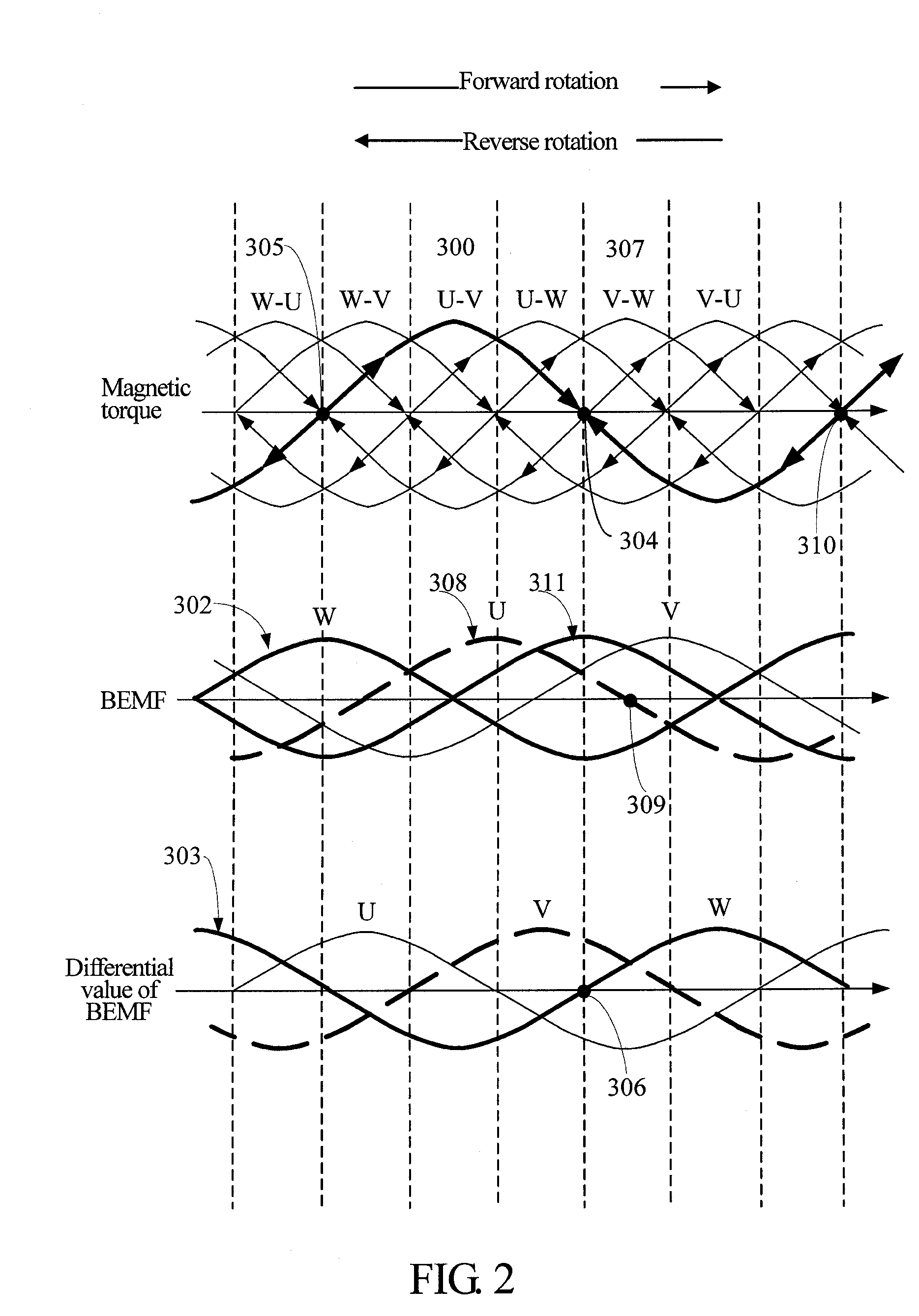

Control Apparatus for Starting a Direct Current Brushless Motor and Method Thereof

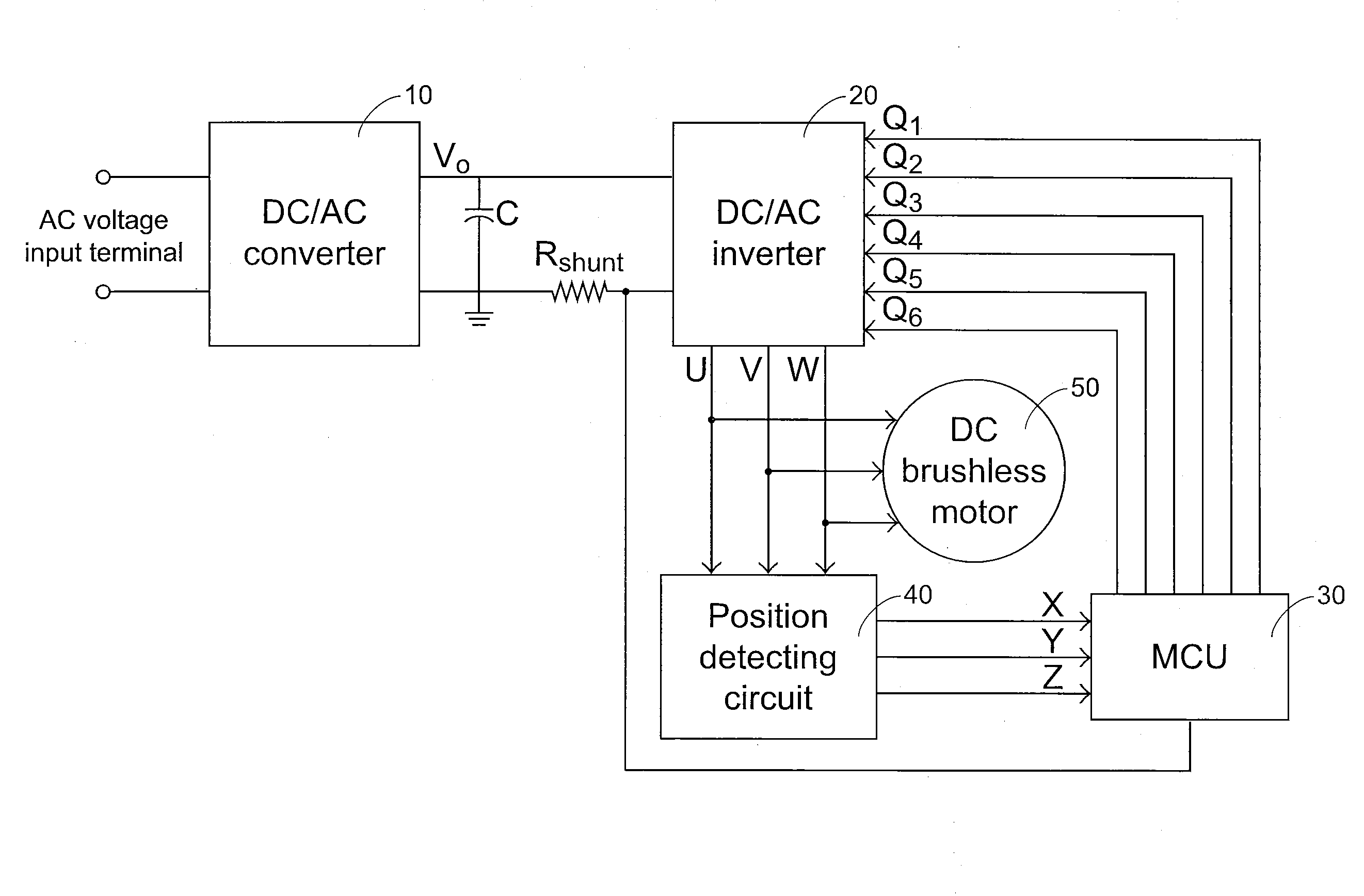

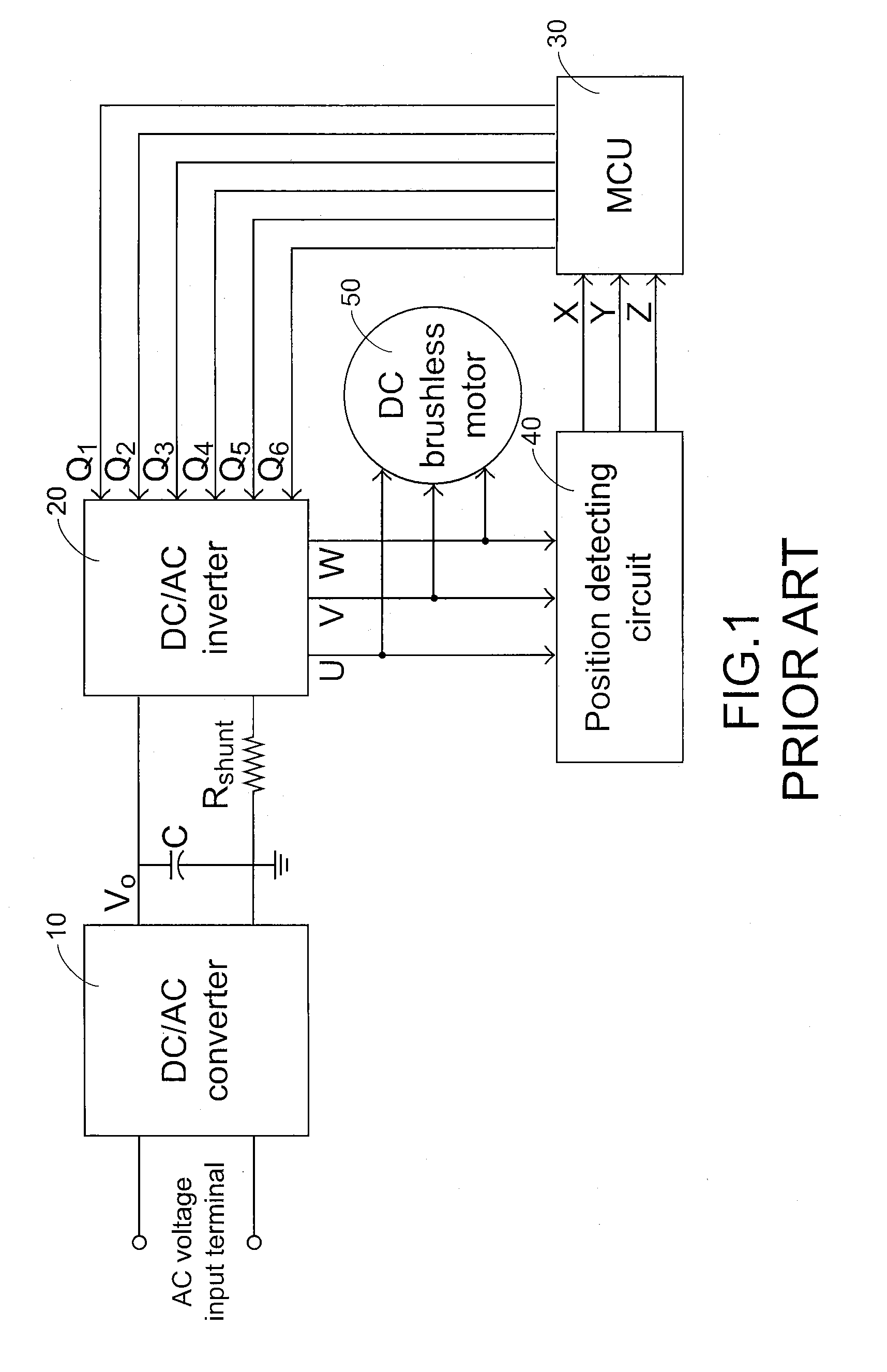

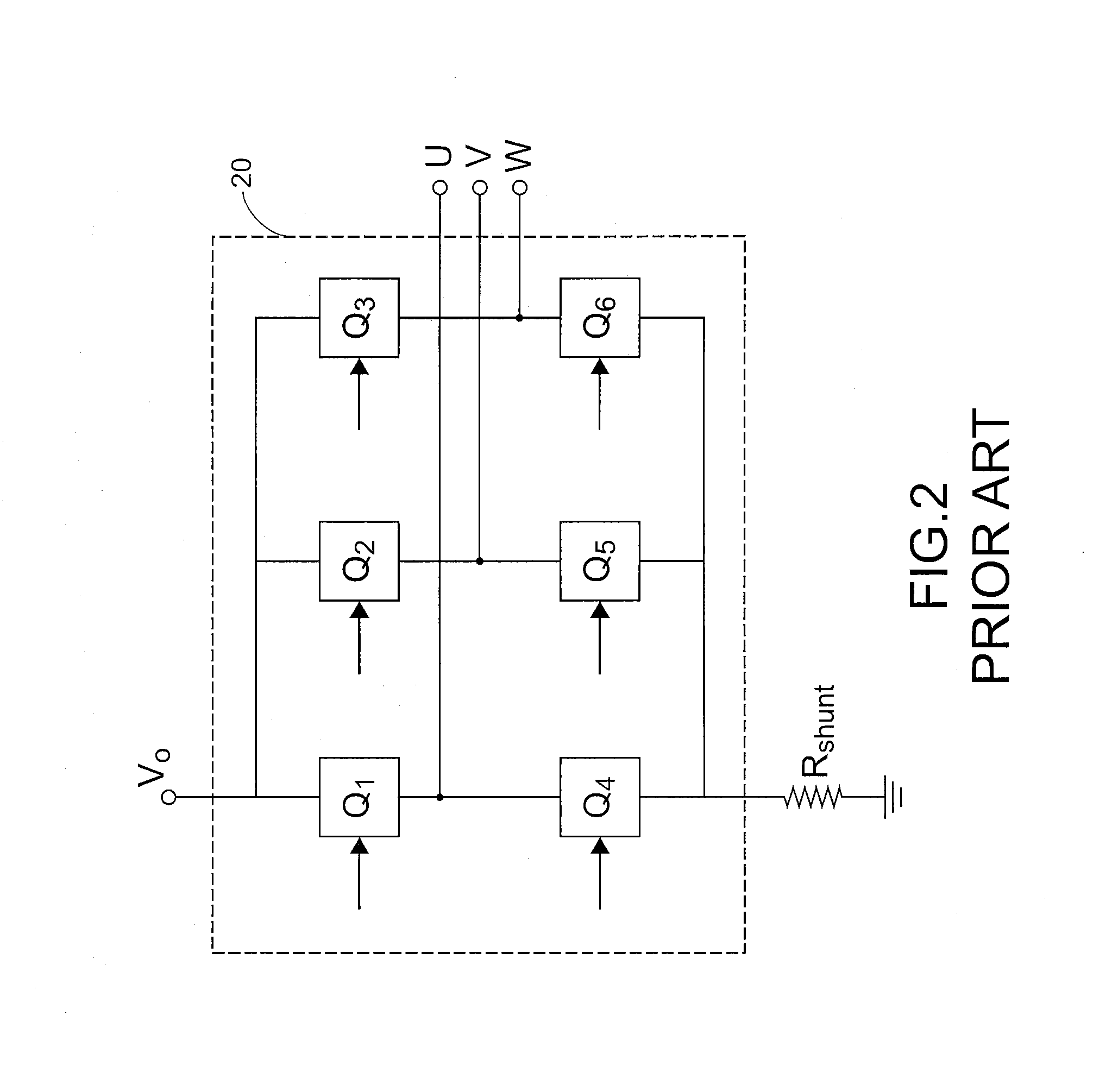

ActiveUS20090179603A1Motor/generator/converter stoppersAC motor controlBrushless motorsAudio power amplifier

An apparatus for starting a direct current brushless motor and a method thereof are provided. The direct current brushless motor comprises a plurality of windings. The control apparatus comprises a sense amplifier, a differential circuit, and a control circuit. The sense amplifier is configured to detect a first back electromotive force of a non-electrified first winding. The differential circuit is configured to calculate a differential value of the first back electromotive force. The control circuit is configured to provide a current to two of the windings and to switch the current to another two of the windings to start the direct current brushless motor.

Owner:ADVANCED ANALOG TECH INC

DC brushless motor system for drainage motor, and DC brushless motor control method and control apparatus for drainage motor

ActiveCN104980066AReduce target RPMReduce half-water, half-air noiseSingle motor speed/torque controlDynamo-electric machinesBrushless motorsVoltage pulse

A control method and control device of a direct current brushless motor for a drain pump, and direct current brushless motor system for the drain pump, the control method comprising: when the rotation speed of a direct current brushless motor reaches a first predetermined rotation speed, comparing the duty ratio of a voltage pulse supplying power for the stator winding of the direct current brushless motor with a first critical duty ratio; and when the duty ratio of the voltage pulse is lower than the first critical duty ratio, determining that the drain pump is in a half-water half-air operation state, and setting the target rotation speed of the direct current brushless motor as a second predetermined rotation speed, the second predetermined rotation speed being lower than the first predetermined rotation speed. The half-water half-air state of the drain pump is identified according to the duty ratio of the voltage pulse supplying power for the stator winding, and half-water half-air noise is reduced by reducing the target rotation speed of the direct current brushless motor in the half-water half-air state.

Owner:CHANGZHOU LEILI MOTOR SCI & TECH

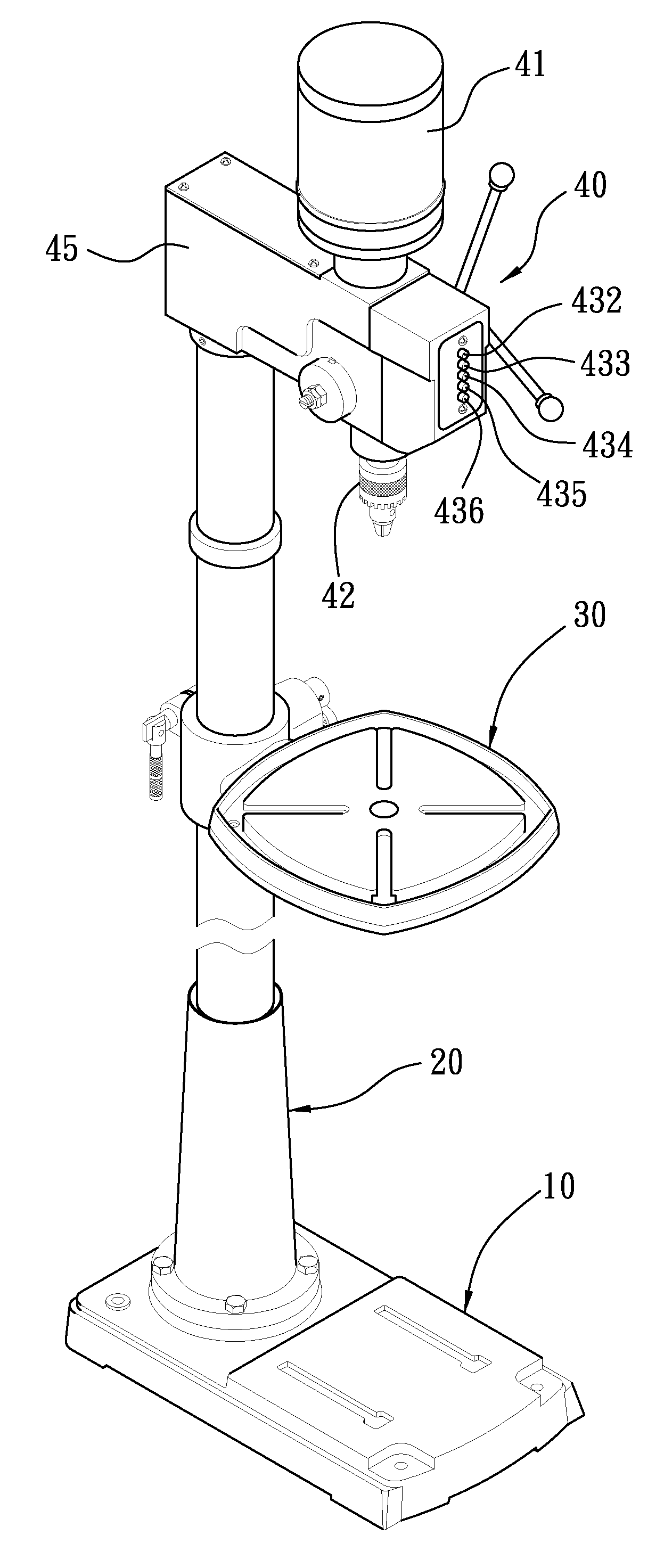

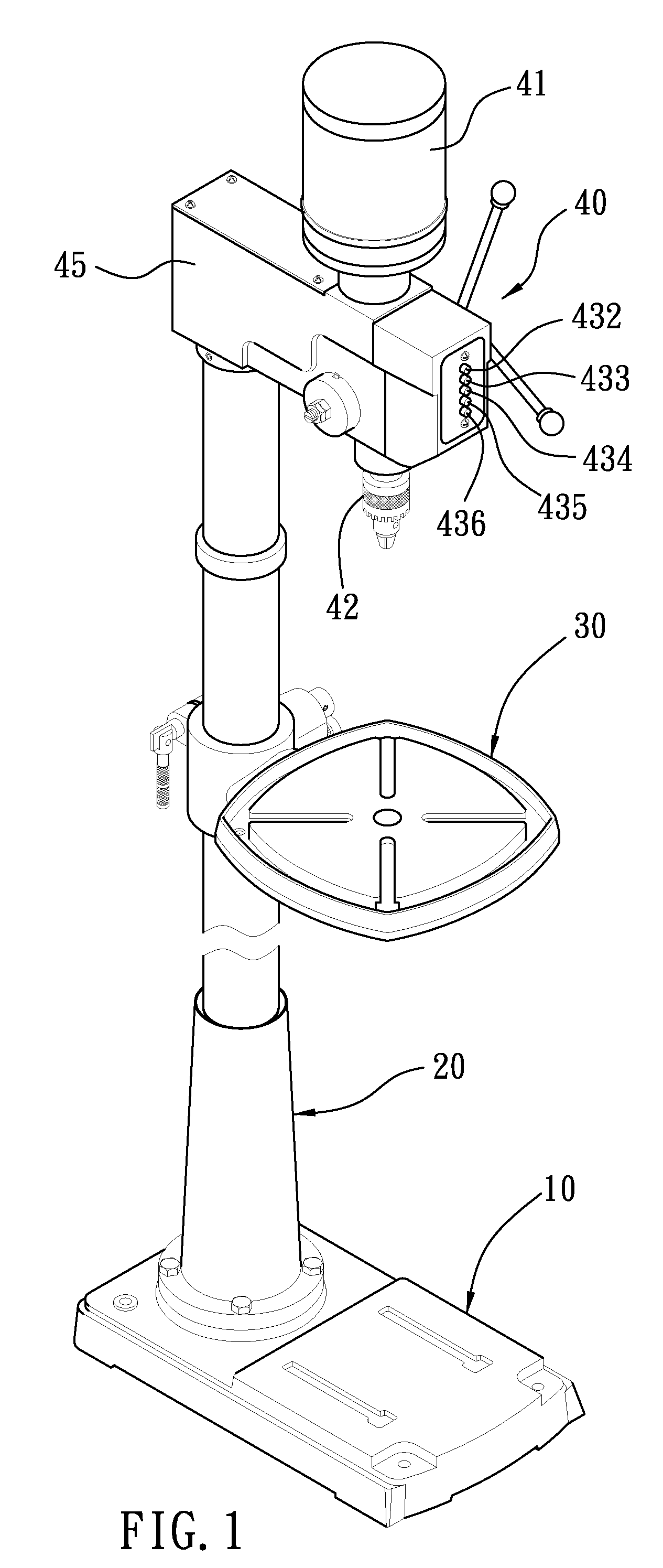

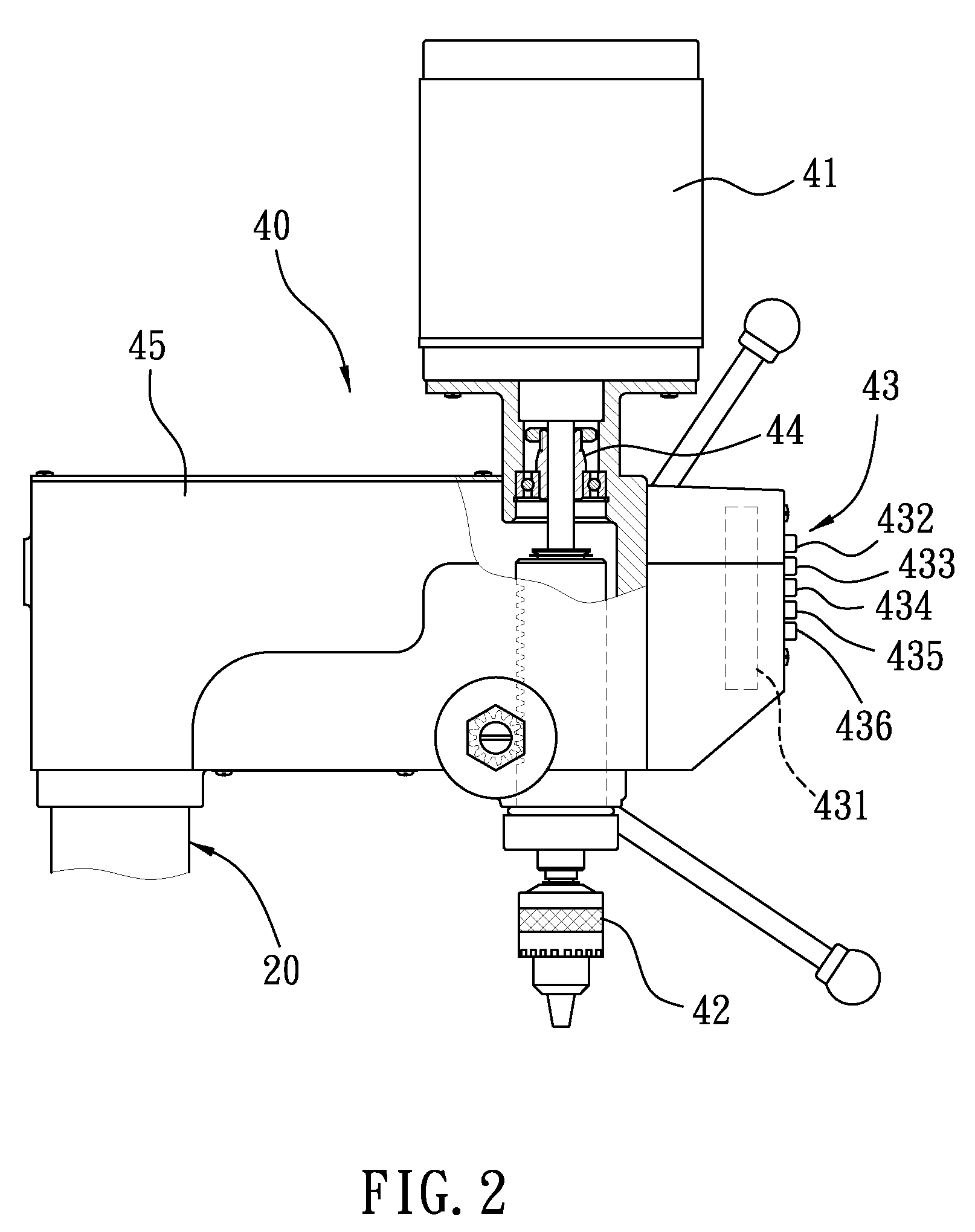

Drilling Machine

InactiveUS20100028095A1Carried conveniently and shiftedDrilling/boring measurement devicesThread cutting machinesBrushless motorsAlternating current

A drilling machine includes a base located on a horizontal surface, a post provided on the base, a worktable movably connected to the post and a drilling unit provided on the post. The drilling unit includes a direct-current brushless motor, a drill and a transmission. The direct-current brushless motor is provided on the post. The drill is operatively connected to the direct-current brushless motor. The transmission includes a circuit board and gear-related buttons operable to instruct the circuit board to convert an alternating current into various direct currents to cause the motor and, therefore, the drill to rotate at various rotational rates.

Owner:SHUN BAO ENTERPRISE

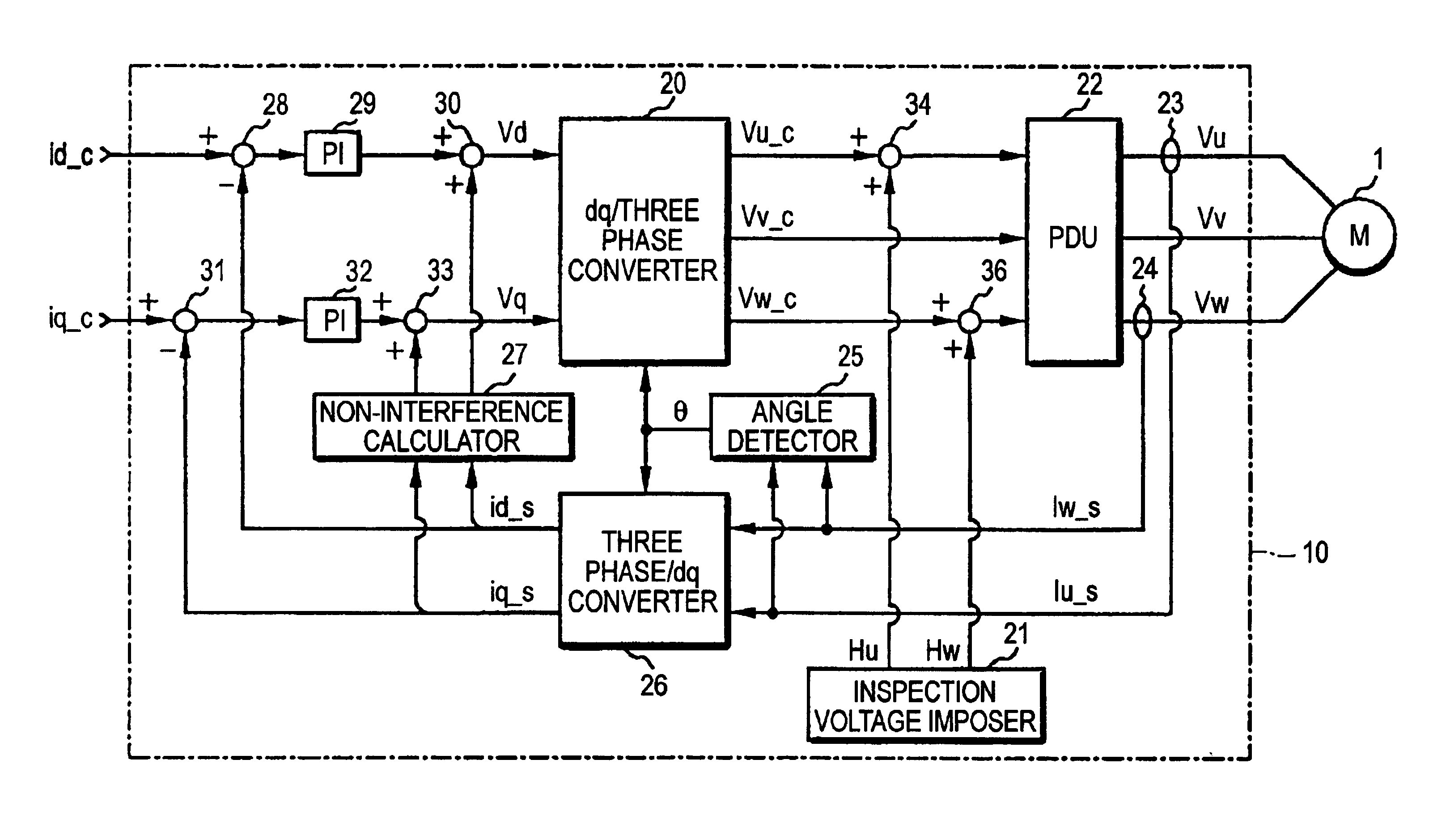

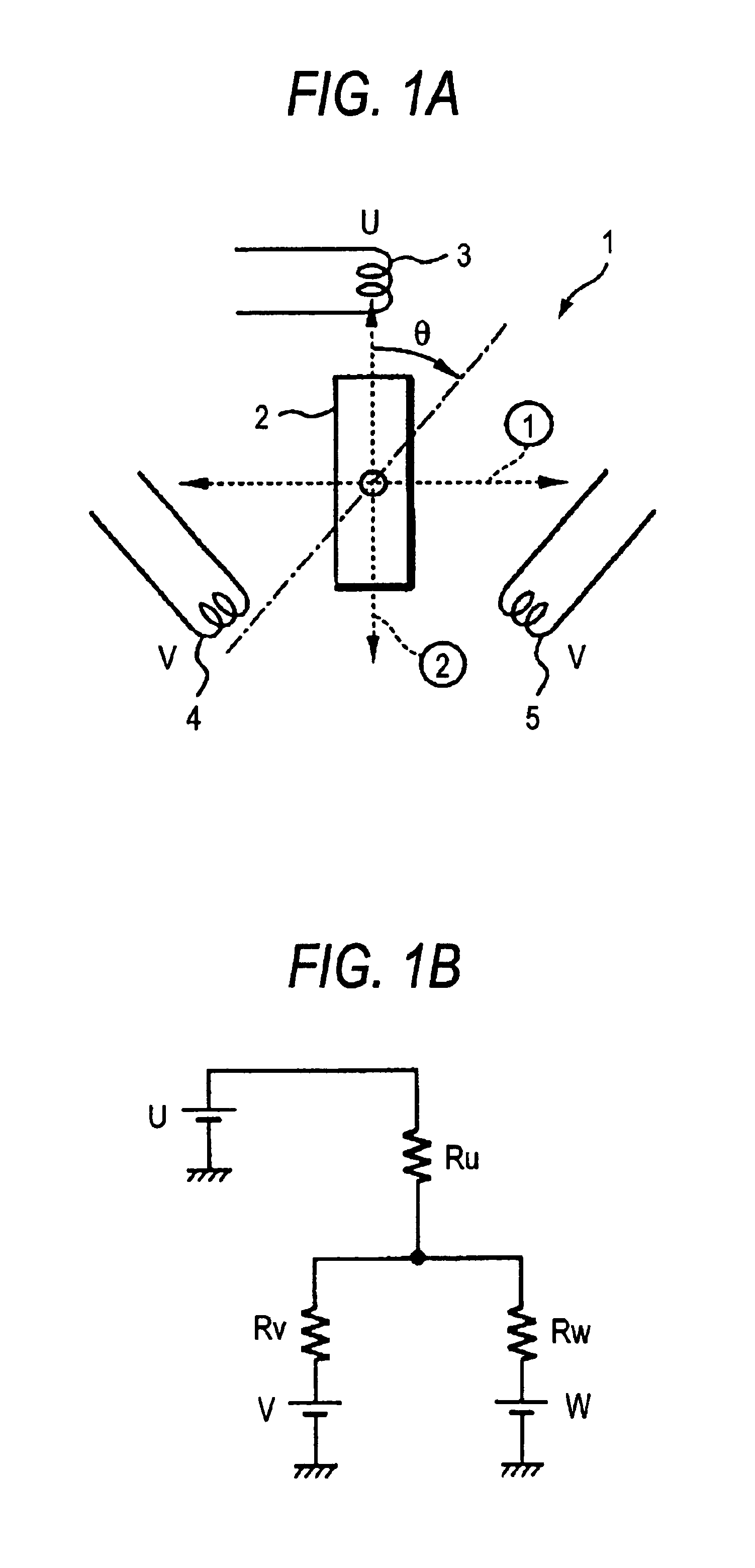

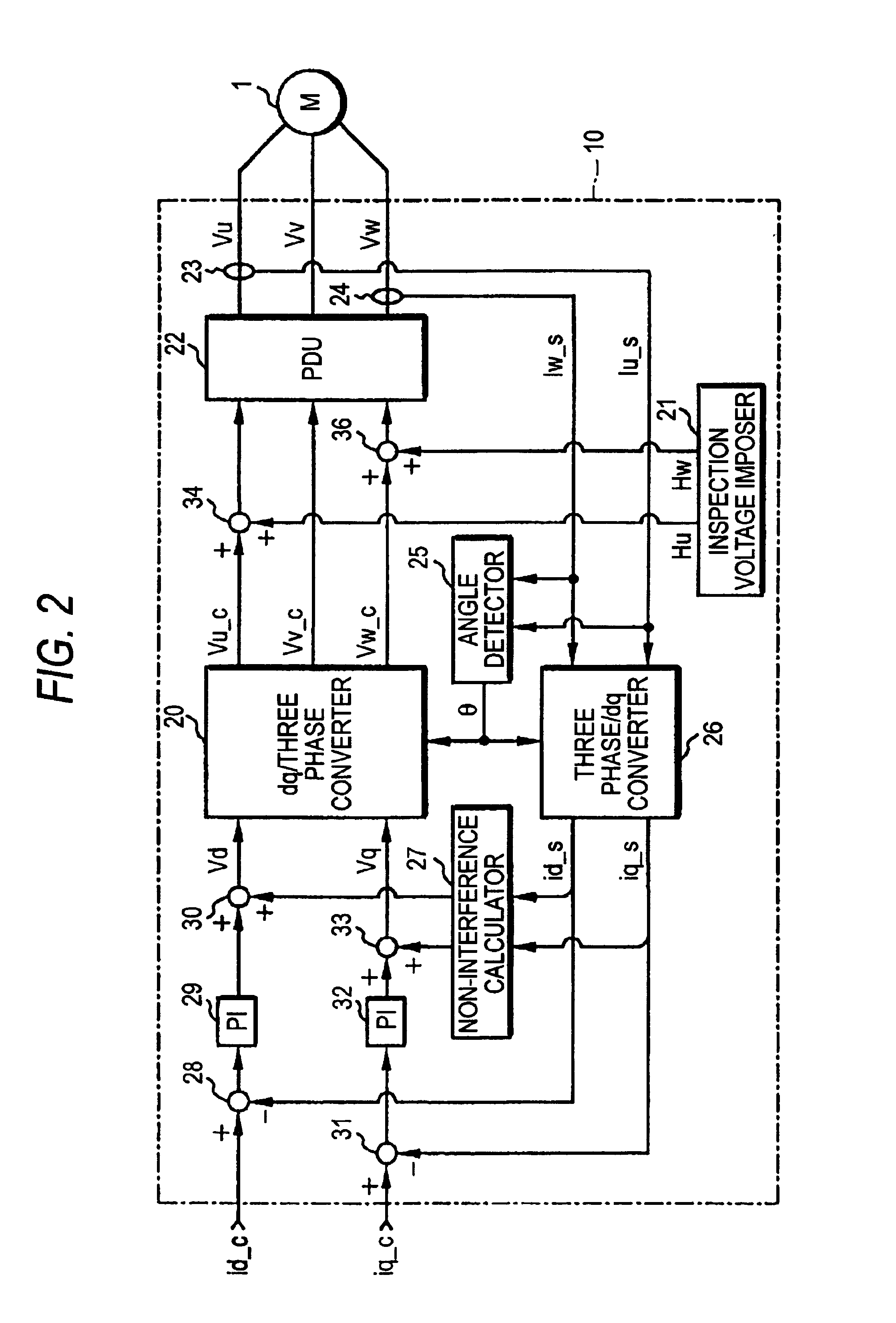

Rotor angle detecting apparatus for DC brushless motor

InactiveUS6909290B2Reduce generationNoise is generatedVector control systemsSingle motor speed/torque controlBrushless motorsRotor angle

An inspection voltage imposer generates an inspection voltage by multiplying fundamental voltage string data in which a certain voltage output pattern where an average of output voltage levels in one period becomes 0 is set by data of a modulation signal whose value varies every period and impose the inspection voltage on a drive voltage of a motor. When the inspection voltage is imposed on the drive voltage of the motor, an angle detector detects the rotor angle of the motor based on the fundamental voltage string data, a variation of an inspection current and the data of the modulation signal in respective control cycles.

Owner:HONDA MOTOR CO LTD

Disk birotor dual veer DC brushless motor

InactiveCN1801587AContinuous and smooth operationReduce manufacturing costMagnetic circuit rotating partsBrushless motorsManufacturing cost reduction

The invention discloses a disc dual-rotor dual-rotation direction dc brushless motor, which comprises: a base, an end cap on two ends of base, a stator with a disc stator core fixed between rotors and a disc stator winding sector-shaped coiled on core, two rotors with inner surface as N and S-pole permanent magnets and arranged vertically in base, and output shaft with one end fixed on outer surface of rotor ad another end extended out the cap. Wherein, the two side surfaces of stator core are opposite to the inner surfaces of rotor; the stator core has same current direction as winding coil on same side while the current direction of two windings opposite. This invention has simple structure, runs reliably, and can reduce cost and energy consumption.

Owner:曾琼东

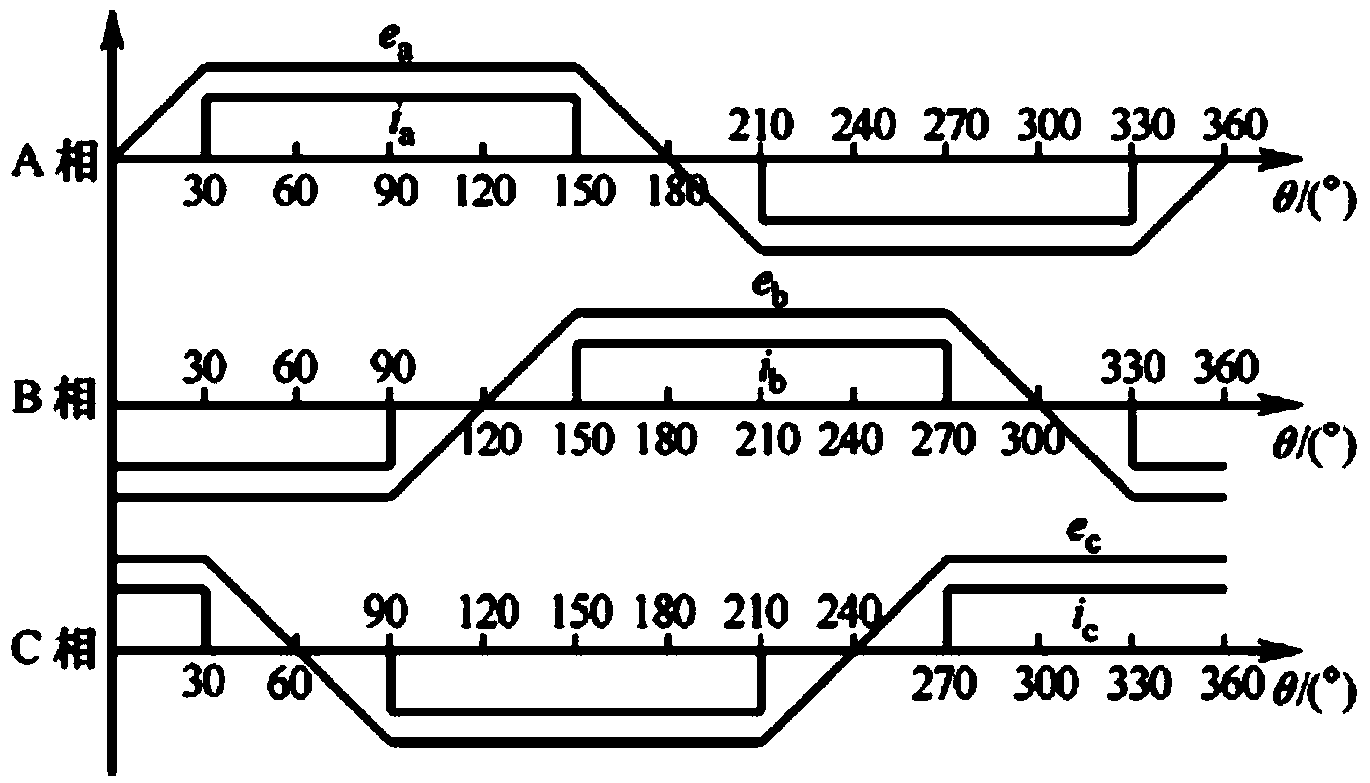

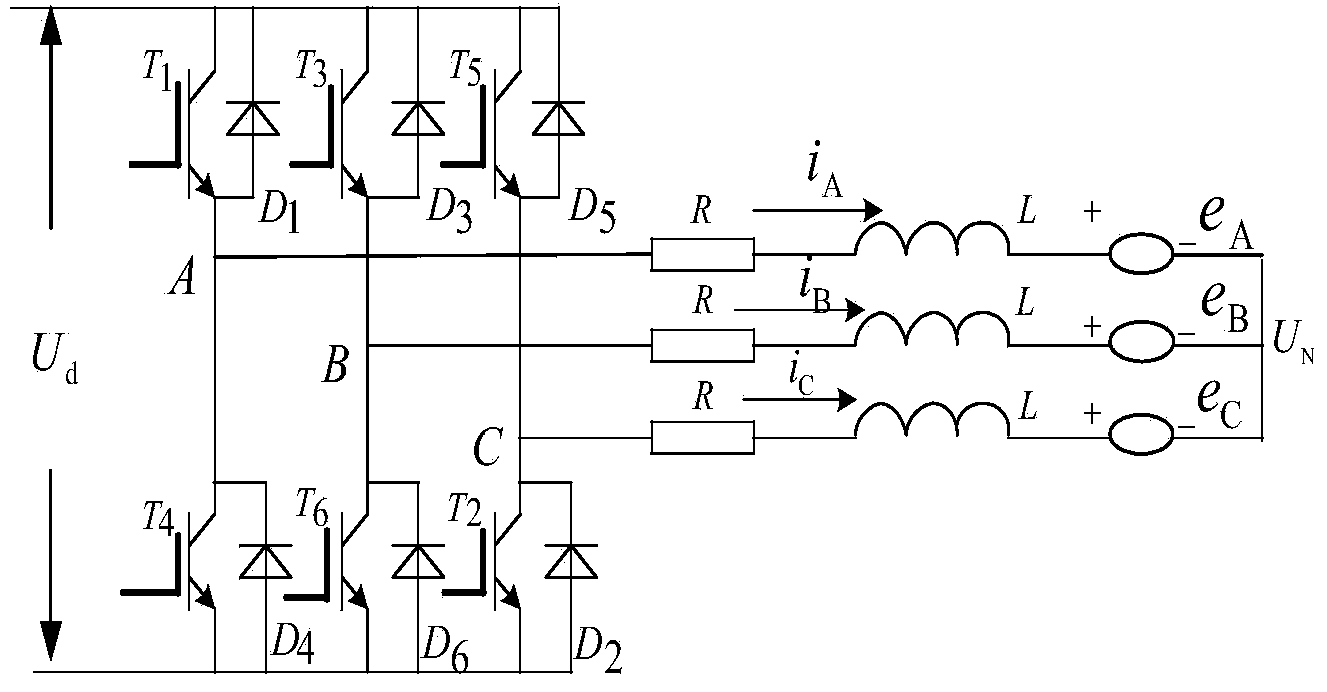

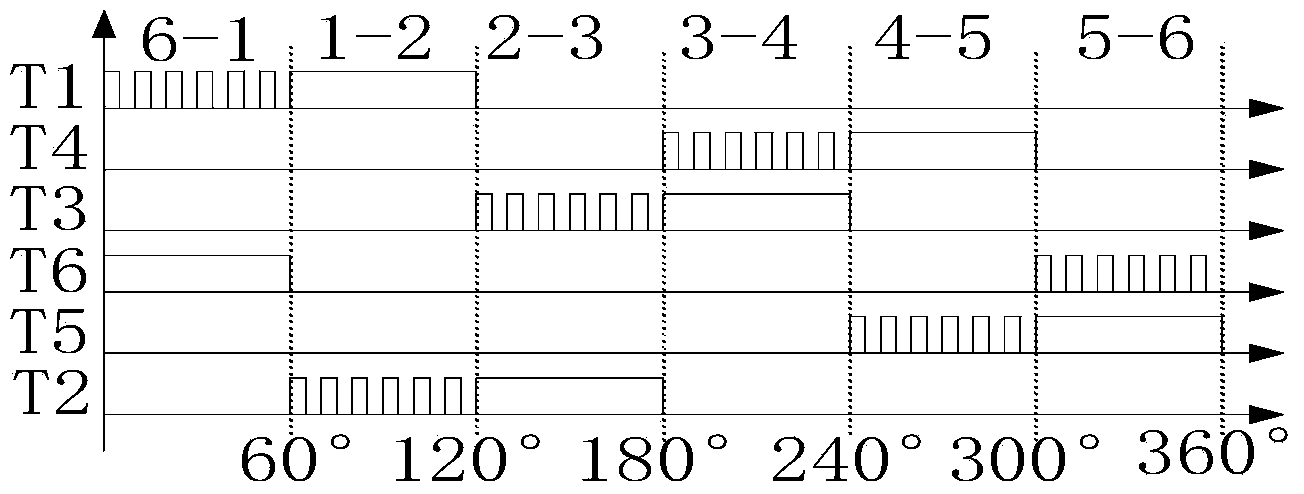

Direct-current brushless motor control method

InactiveCN103986377ASuppression of torque rippleEasy to FeedbackTorque ripple controlStarter arrangementsBrushless motorsControl system

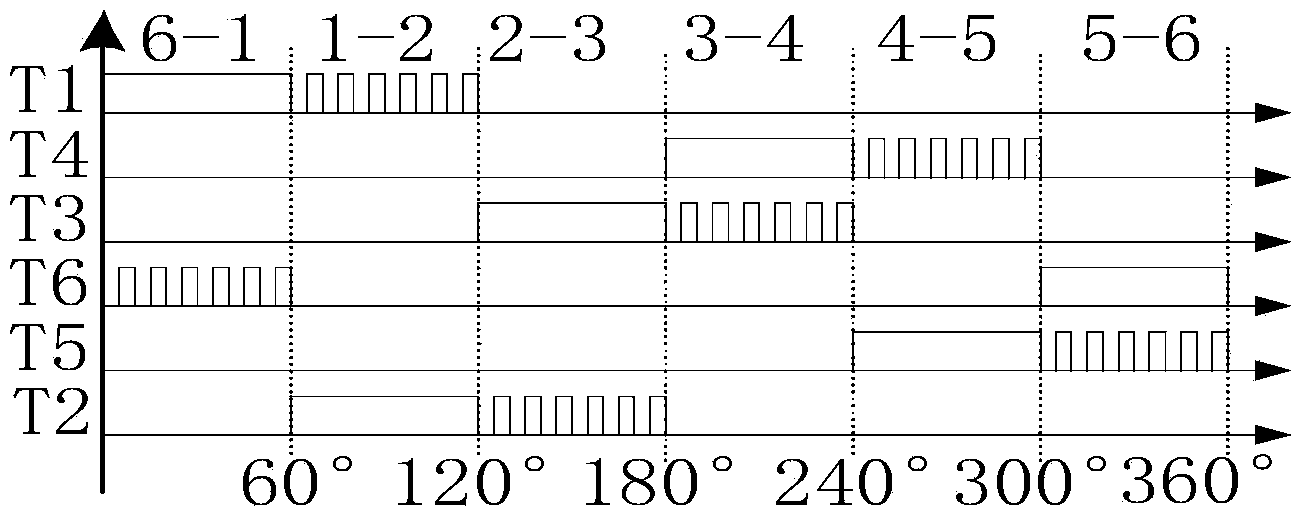

The invention discloses a direct-current brushless motor control method. An adopted control system is characterized in that an upper switching tube and a lower switching tube on a bridge arm in one phase are controlled to be turned on in a complementary mode in an on interval of 120 degrees for a three-phase inverter and lower bridge arms of the other two phases are alternately constantly turned on for 60 degrees, namely in the interval of 0-60 degrees, T1 and T4 are turned on in the complementary mode, and T6 is turned on constantly; in the interval of 60-120 degrees, T1 and T4 are turned on in the complementary mode, and T2 is constantly turned on; in the interval of 120-180 degrees, T3 and T6 are turned on in the complementary mode, and T2 is constantly turned on; in the interval of 180-240 degrees, T3 and T6 are turned on in the complementary mode, and T4 is constantly turned on; in the interval of 240-300 degrees, T2 and T5 are turned on in the complementary mode, and T4 is constantly turned on; in the interval of 300-360 degrees, T2 and T5 are turned on in the complementary mode, and T6 is constantly turned on.

Owner:STATE GRID CORP OF CHINA +1

Torque compensation method and system for DC brushless motor

InactiveUS20080075439A1Increase the pulse widthReducing pulse widthTorque ripple controlSynchronous motors startersBrushless motorsAverage current

A torque compensation method and system for a DC brushless motor. When the DC brushless motor coupled with an asymmetric load is rotating, the difference between an instant current and an average current of a shunt resister is an index of adjusting control signals within an absolute rotor position for the purpose of approaching the corresponding instant current to the average current.

Owner:SUNPLUS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com