Sealed electric-motor and sealed pump

A technology of electric motors and sealed pumps, which is applied in the direction of electric components, machines/engines, liquid fuel engines, etc., can solve the problems of installation error, torque performance difference, increase assembly adjustment process, motor performance degradation, etc., and achieve stable output performance , The installation error is small, the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, the hermetic motor and hermetic pump of the present invention will be described with reference to the drawings.

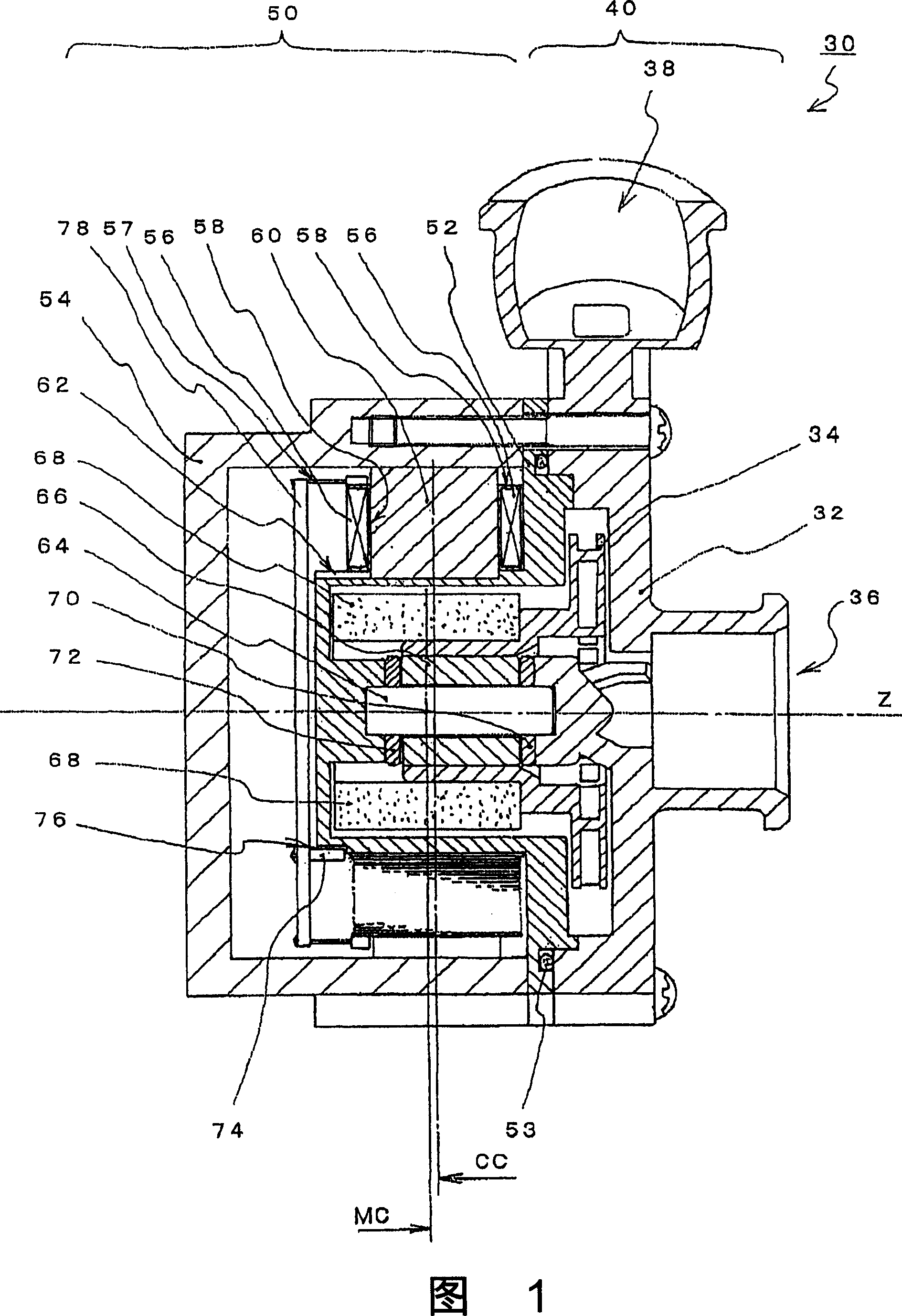

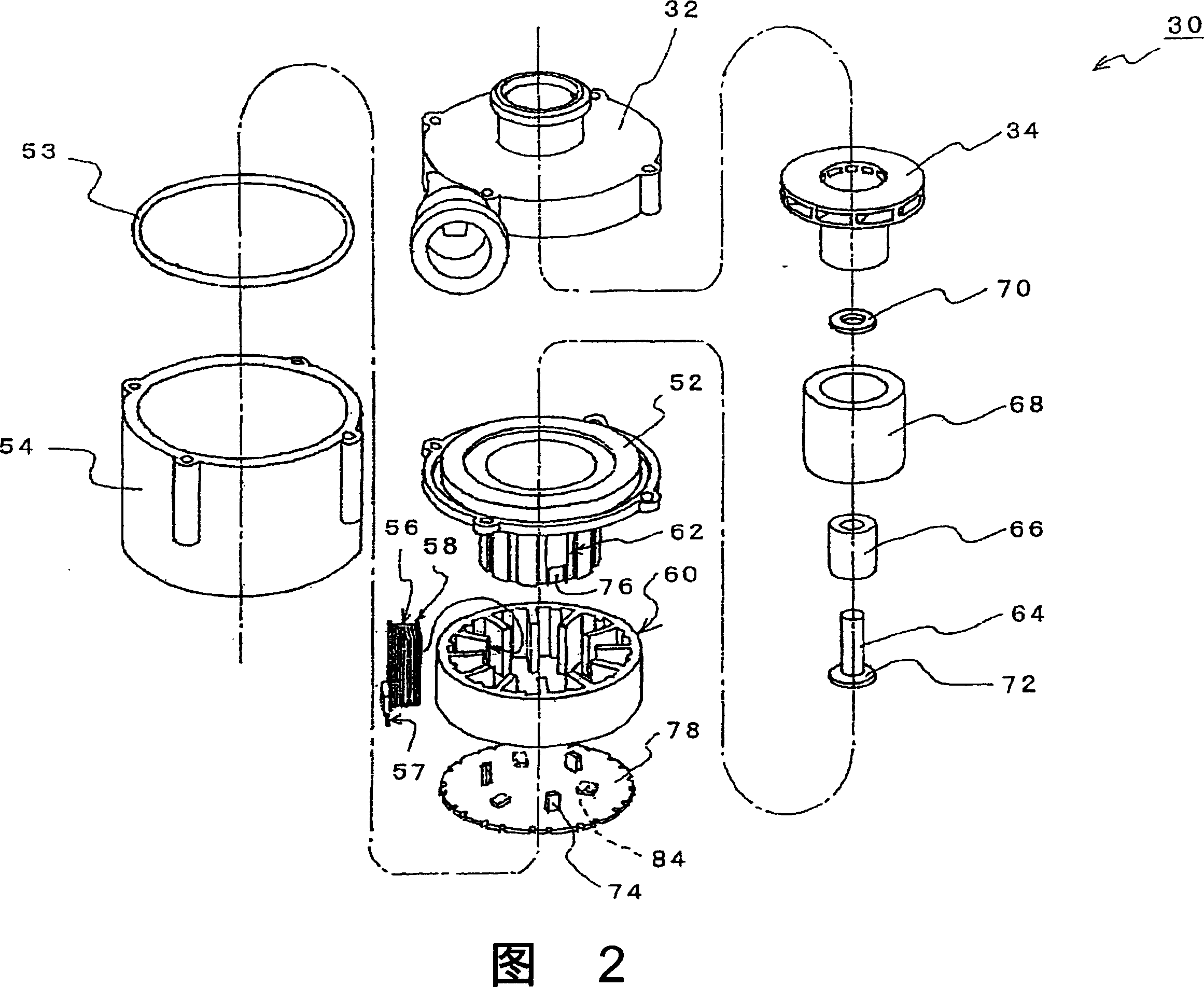

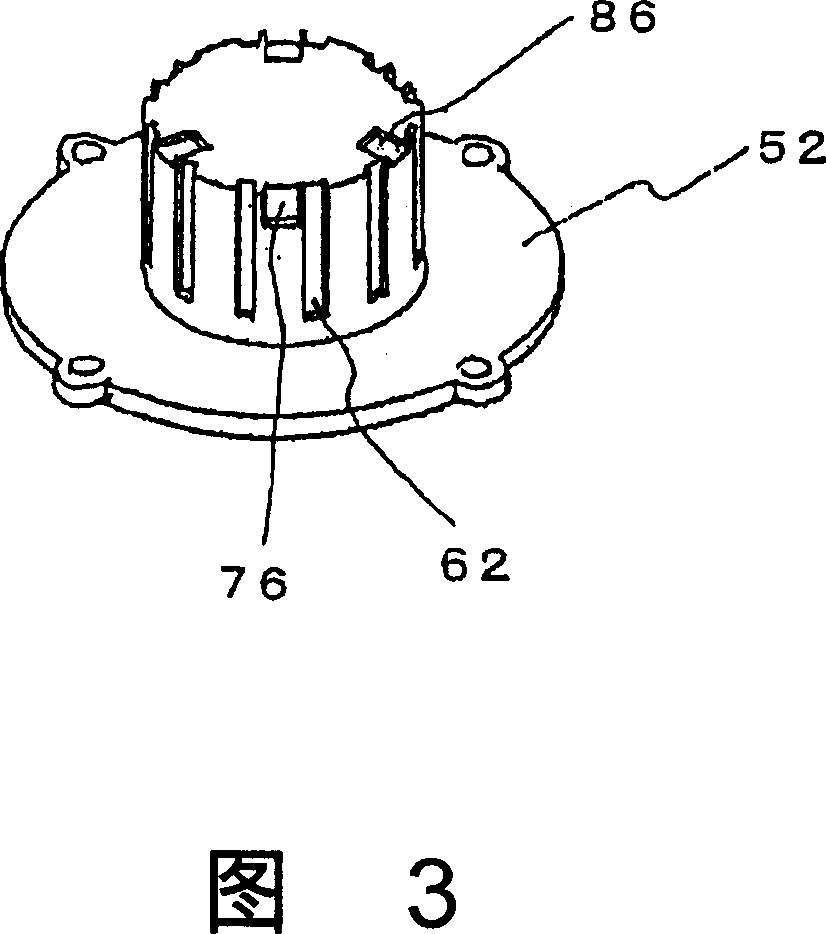

[0041] FIG. 1 is a cross-sectional view showing an example of a hermetic pump 30 using a hermetic motor 50 according to the present invention. The upper half above the center line Z in FIG. 1 is a section where the stator core 60 is located, and the lower half below the center line Z in FIG. 1 is a section where the magnetic sensor 74 is located. In addition, FIG. 2 is a perspective view showing a state in which the sealed pump 30 shown in FIG. 1 is disassembled into parts. FIG. 3 is a perspective view of the can body 52 viewed from the bottom side.

[0042] As shown in Figures 1 and 2, the sealed pump 30 of the present invention includes a sealed motor 50 and a pump portion 40, wherein the sealed motor 50 has a stator core 60, a rotor magnet 68 and a tank body 52, and the tank body 52 combines the stator iron The core 60 is sealed away from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com