Direct-current brushless motor control method

A brushless DC, motor technology, applied in the direction of torque ripple control, starting devices, etc., can solve the problems of large torque ripple, many sensors, complex parameter adjustment, etc., achieve rapid shutdown and reverse rotation, and reduce torque ripple , The effect of suppressing torque ripple during commutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

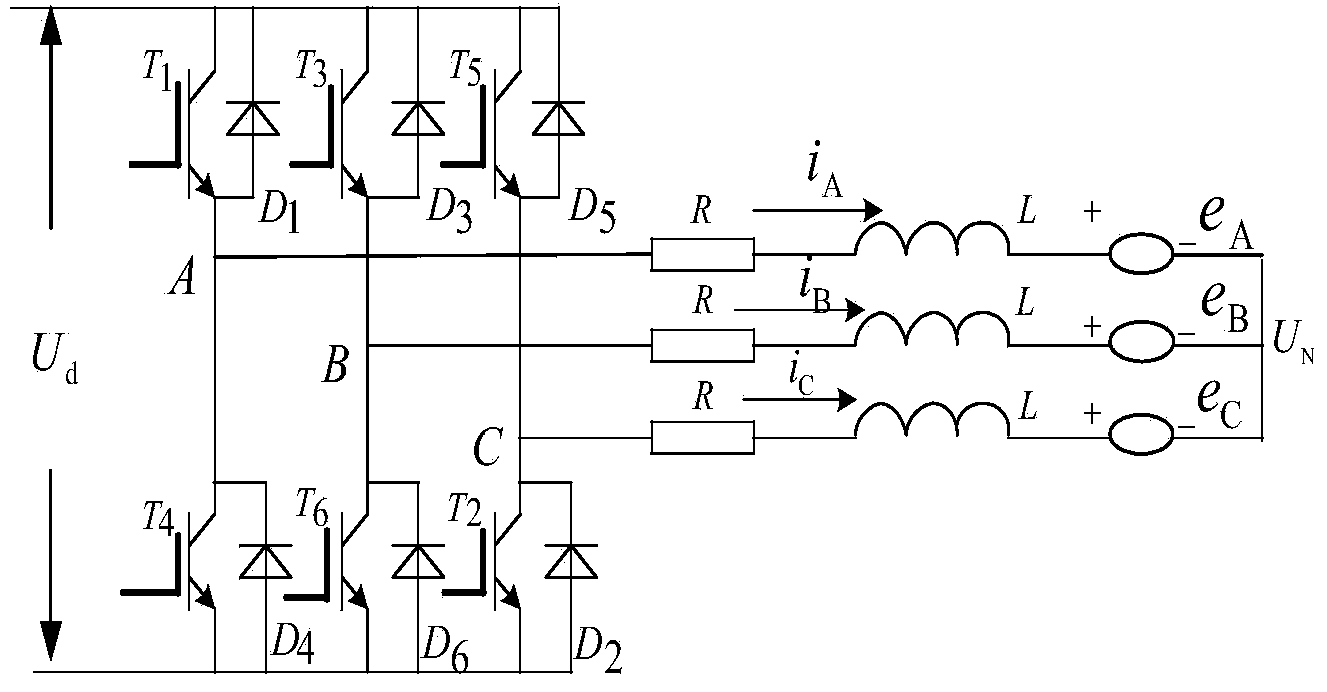

[0035] Such as figure 1 As shown, the core of the DC brushless motor control system is the inverter. The whole circuit is powered by DC, and the inverter, the core device of the control system, is generally controlled by six power transistors (T1~T6), of which the upper bridge arms are T1, T3, T5, and the lower bridge arms are T2, T4, T6. The inverter is a switch that controls the flow of current to the motor coils. The core of the inverter is the control strategy, which generates a pulse width modulation signal to control the frequency of switching on and off of the transistor and the time of forward and reverse rotation.

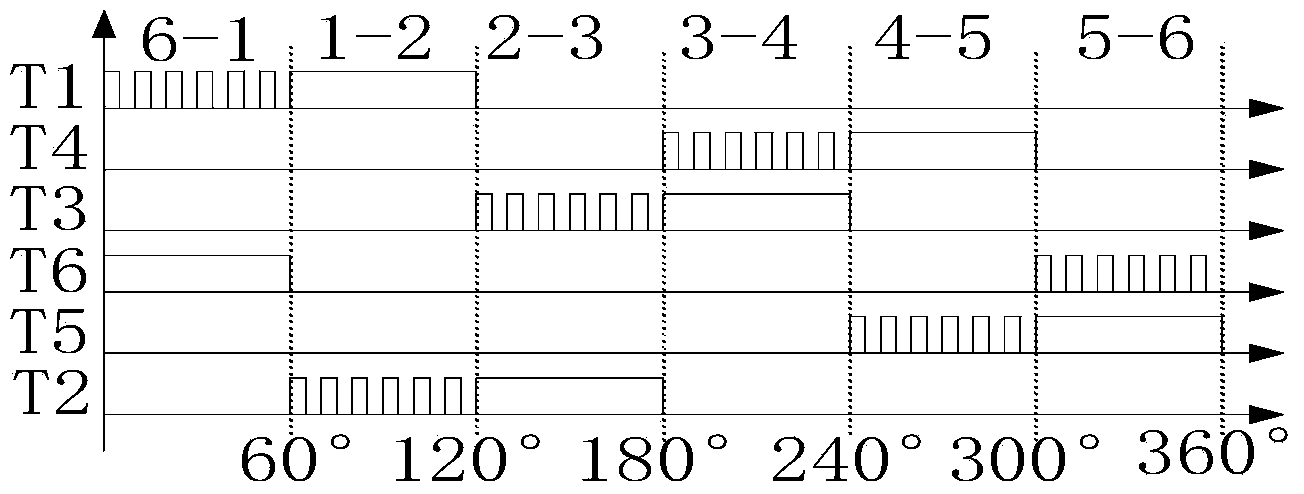

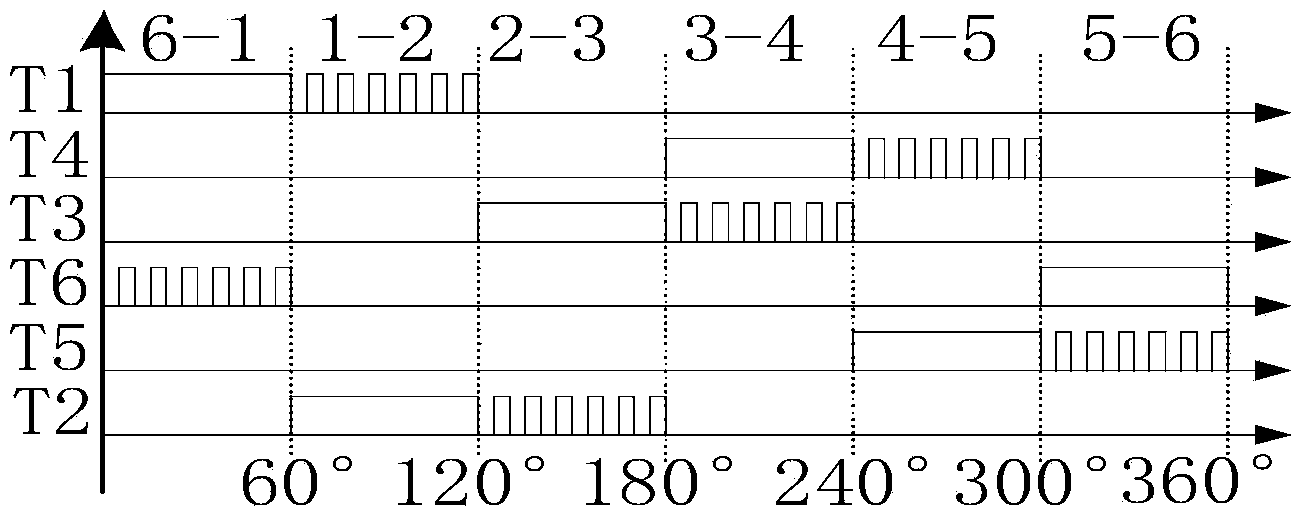

[0036] At present, there are generally five main modulation methods of brushless DC motors, namely PWM-ON type, ON-PWM type, H_PWM-L_ON type, H_ON-L_PWM type, and H_PWM-L_PWM type. Such as Figure 2-6 .

[0037] ⑴PWM-ON type: I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com