Motor control device and electric power steering device

A motor control and motor technology, which is applied in the field of electric power steering devices, can solve the problems of a larger occupied area of a substrate, a complicated circuit pattern, an increase in the size of the substrate, etc., and achieve the effect of suppressing torque fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

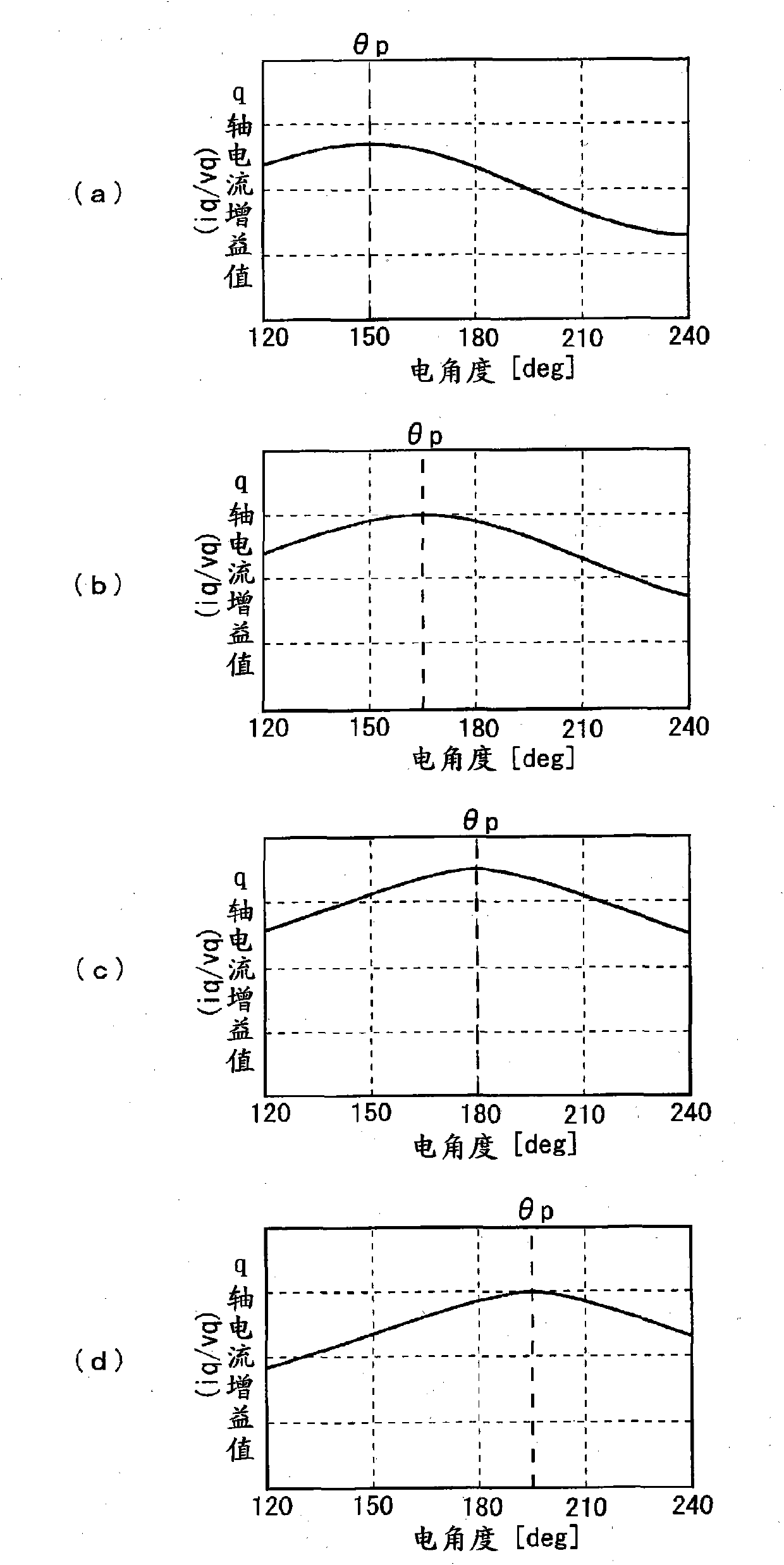

[0115] figure 2 It is a block diagram showing the configuration of the motor control device according to the first embodiment of the present invention. figure 2 The shown motor control device is configured using an ECU 10 and drives a brushless motor 1 having three-phase windings (not shown) of u-phase, v-phase, and w-phase. The ECU 10 includes a phase compensator 11 , a microcomputer 20 , a 3-phase / PWM (Pulse Width Modulation, pulse width modulation) modulator 12 , a motor drive circuit 13 , and a current sensor 14 .

[0116] The steering torque T output from the torque sensor 3 , the vehicle speed S output from the vehicle speed sensor 4 , and the rotational position P output from the position detection sensor 5 are input to the ECU 10 . The phase compensator 11 performs phase compensation for the steering torque T. The microcomputer 20 functions as a control unit for obtaining a voltage command value used for driving the brushless motor 1 . Details of the functions of ...

no. 2 approach

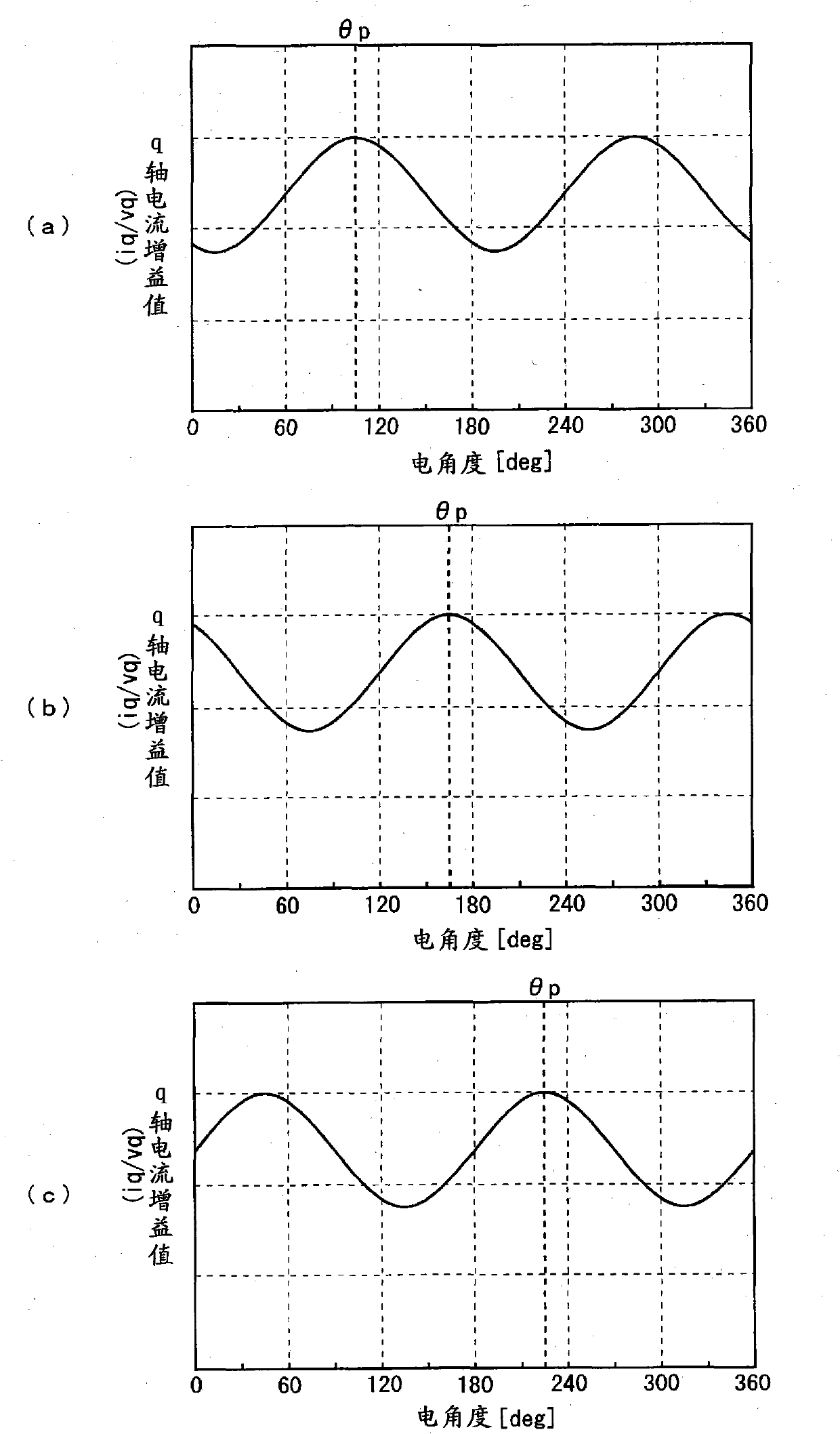

[0196] Figure 8 It is a block diagram showing the configuration of a motor control device according to a second embodiment of the present invention. In the motor control device of the present embodiment, the microcomputer 20 and the current sensor 14 are replaced with the microcomputer 30 and the current sensor 15 in the motor control device of the first embodiment. This motor control device performs feedback control when the current sensor 15 is operating normally, and performs open-loop control when the current sensor 15 fails.

[0197] One current sensor 15 is provided on each of the paths through which the three-phase drive currents supplied to the brushless motor 1 flow, and detects the three-phase drive currents. The current values of the three phases detected by the current sensor 15 (hereinafter referred to as u-phase current detection value i u , V-phase current detection value i v And w-phase current detection value i w ) is input to the microcomputer 30.

[...

no. 3 approach

[0222] refer to Figure 9 to Figure 11 Next, a motor control device according to a third embodiment of the present invention will be described.

[0223] Among them, the main difference between the third embodiment and the first embodiment is as follows: Instead of the data acquisition unit 41, the correction coefficient determination unit 42, and the correction execution unit 43 of the first embodiment, the phase current calculation unit 141 is implemented by a microcomputer. , the storage unit 142 , the phase resistance calculation unit 143 and the functions of the correction unit 144 . In the following description, the same reference numerals are assigned to the same configurations as those of the first embodiment, and description thereof will be omitted.

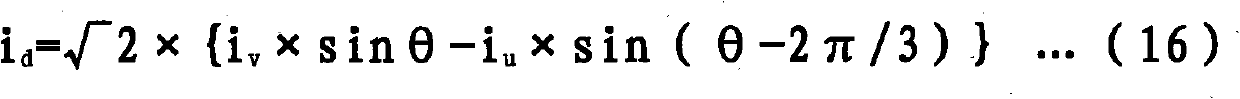

[0224] In the present embodiment, the current sensor 14 and the phase current calculation unit 41 described later are configured to detect the current I of the u-phase, v-phase, and w-phase of the brushless motor 1 . u ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com