Liquid level control system

A liquid level control and liquid level technology, applied in liquid level control, control/regulation system, non-electric variable control and other directions, can solve problems such as waste, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

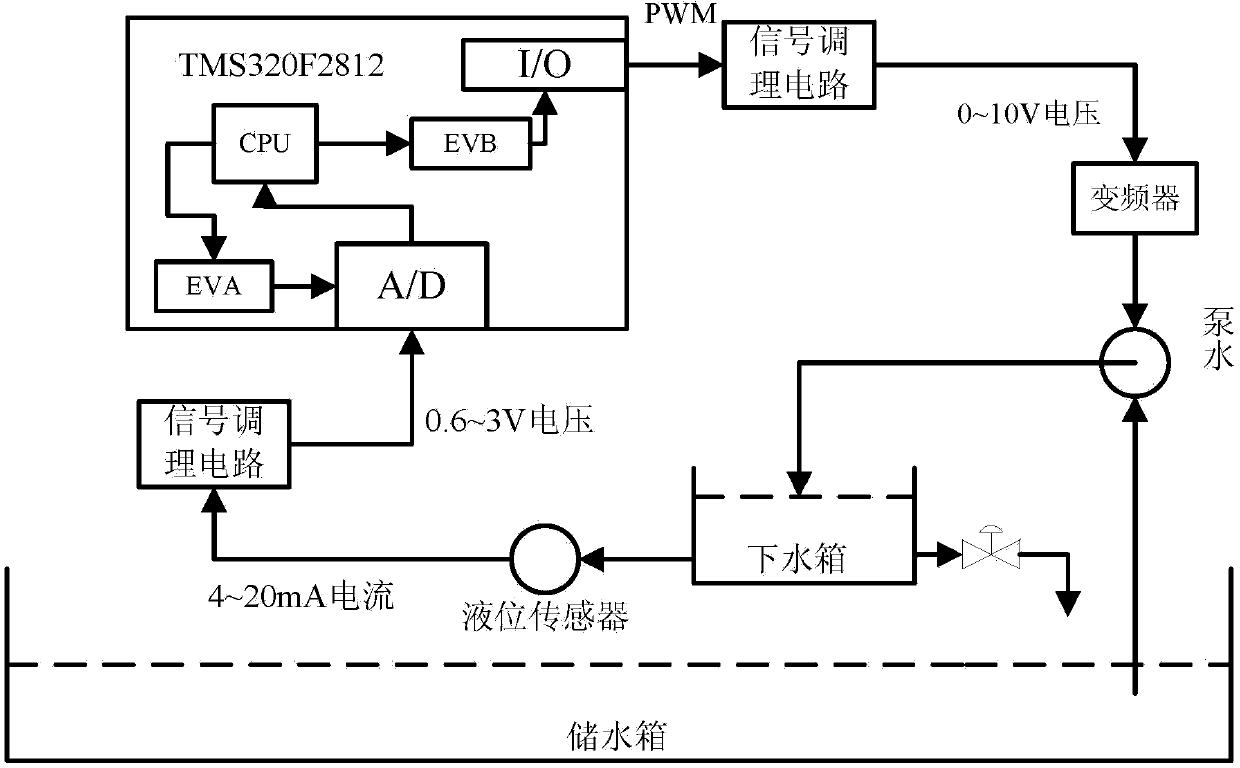

[0015] Such as figure 1 As shown in , the liquid level sensor in the water tank collects liquid level signals, processes the collected liquid level signals, and obtains signals that can be received by the ADC module. After AD conversion, digital filtering is performed to filter out high-frequency interference, and then Carry out scale transformation and convert to digital quantity of water level. The DSP calculates the size of the error control amount between the collected water pressure value and the set water pressure value, and sends it to the PID control module. After the PID operation, it outputs the corresponding PWM wave, and then performs corresponding signal processing and converts it into The frequency converter can receive the analog voltage signal, change its output frequency, and then change the speed of the water pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com