Brushless DC electric motor

A technology of DC motors and circuit boards, applied in the direction of generators/motors, electric components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

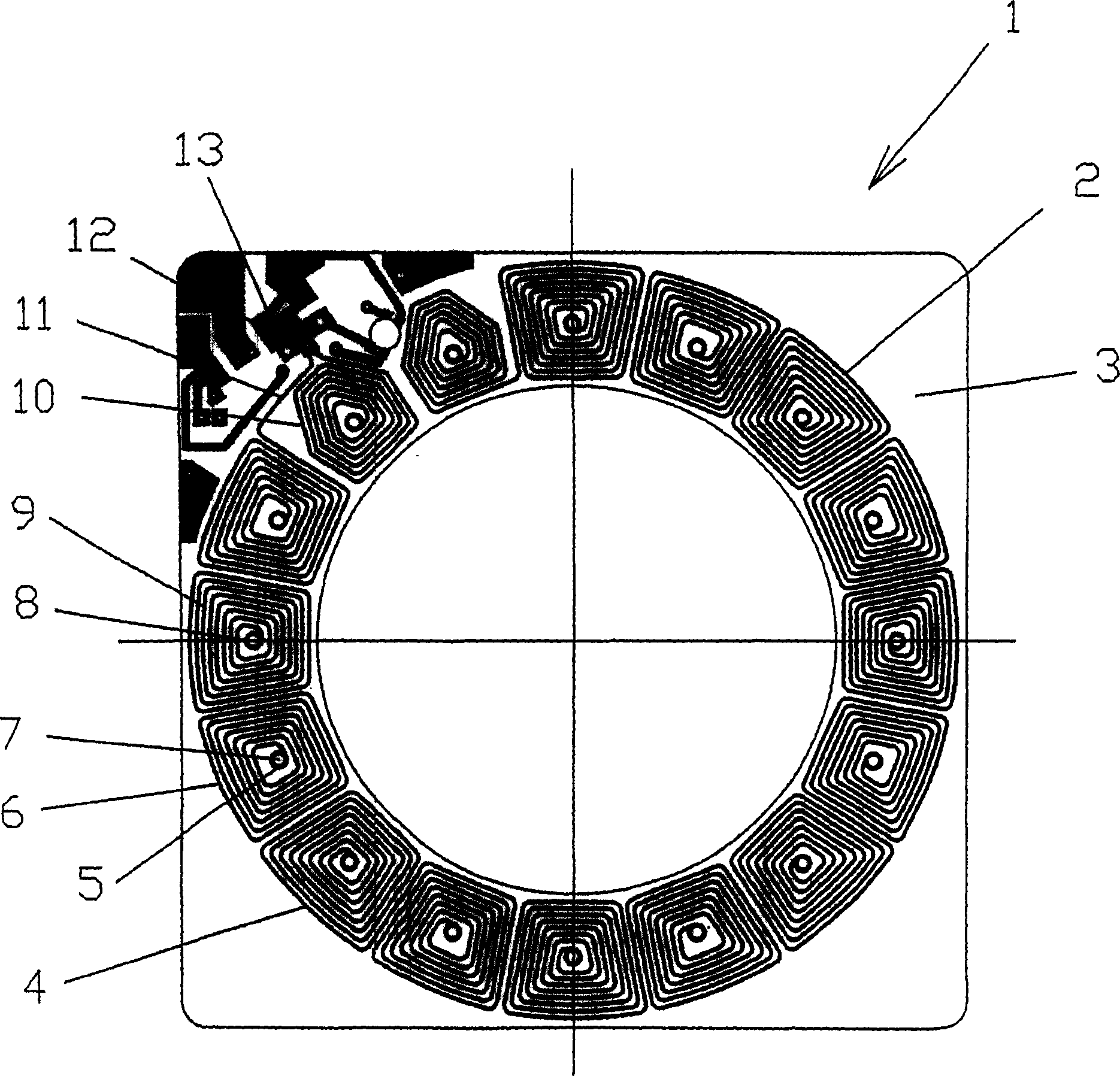

[0017] Described below is a new type of brushless DC motor using a stator coil of a printed circuit board. In our description below we will refer to this printed circuit board as a stator board or a circuit board. Magnetic rotors are made of permanent magnetic material and may be part of a single unit or a series of units with identical poles. This whole or unit will be referred to hereinafter as the rotor disk or the rotor / impeller. The simple instructions below are divided into six sections: Stator Plate, Rotor, Motor Description, Combined Motor / Blower, Motor Controller, and Operating Instructions.

[0018] Stator plate

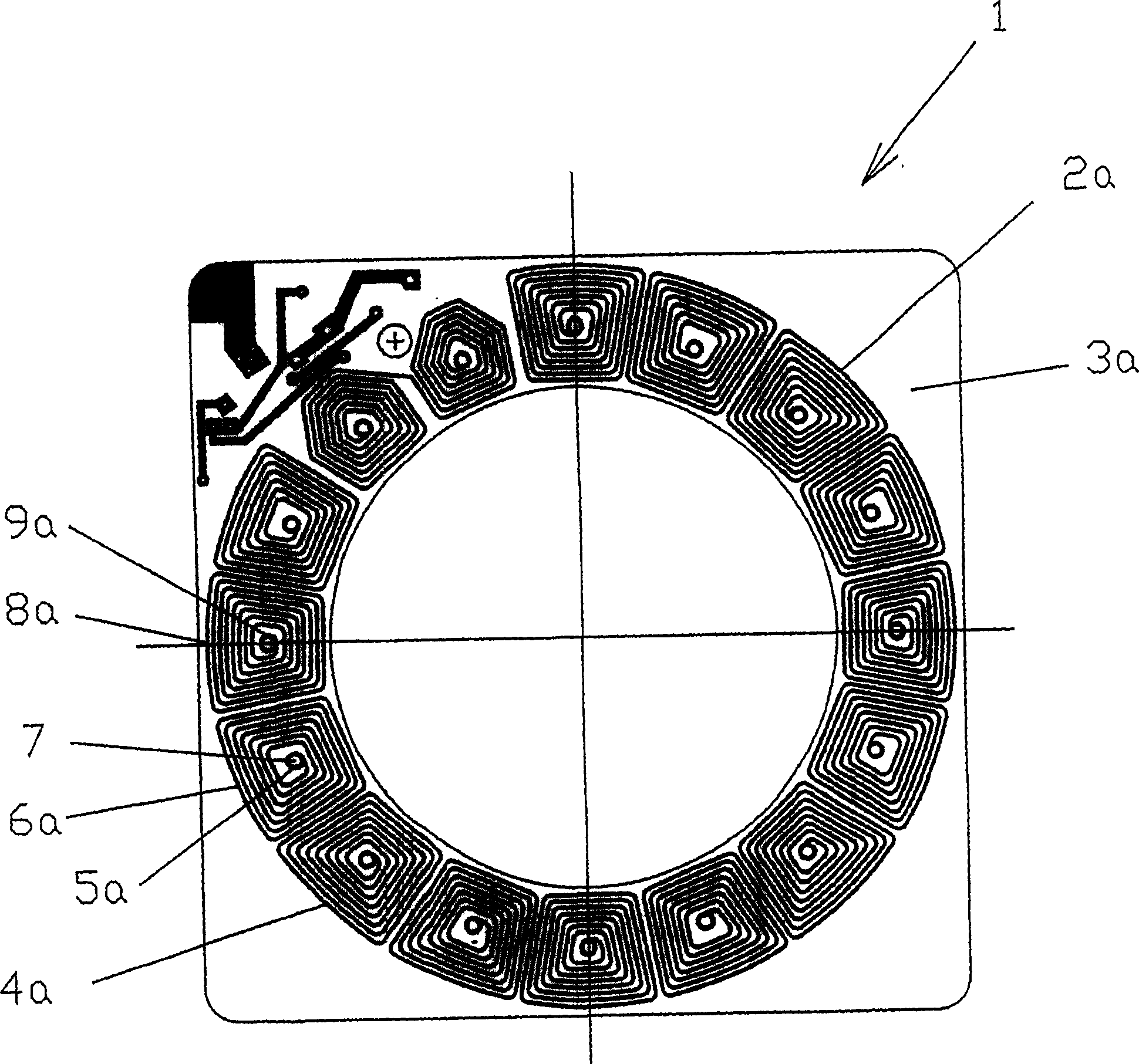

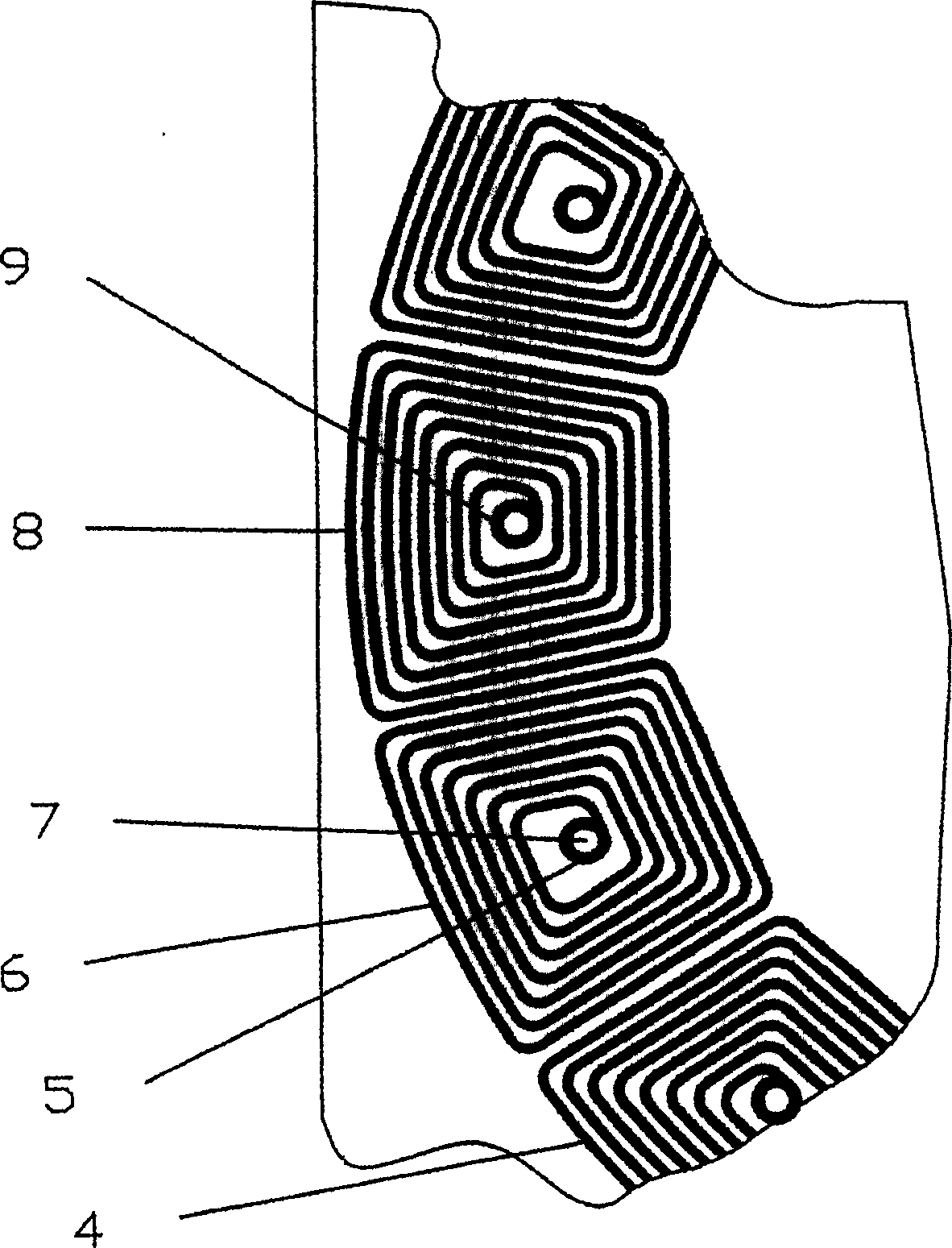

[0019] The stator plate described here is designed for use with an H-bridge controller. Figure 1A It is the front side of the stator plate 1, including the coil 2 located on the circumference of the stator plate on the circuit board substrate 3, which is etched from metal, usually copper. Figure 1B is the rear side (perspective) of the stator plate 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com