Direct torque brushless DC servo control system and its working method

A control system, DC servo technology, applied in the control system, vector control system, excitation or armature current control and other directions, can solve the problem of affecting the torque control effect, the switching frequency is not fixed, the filtering is unfavorable, etc., to solve the torque Pulsation, fast response, good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

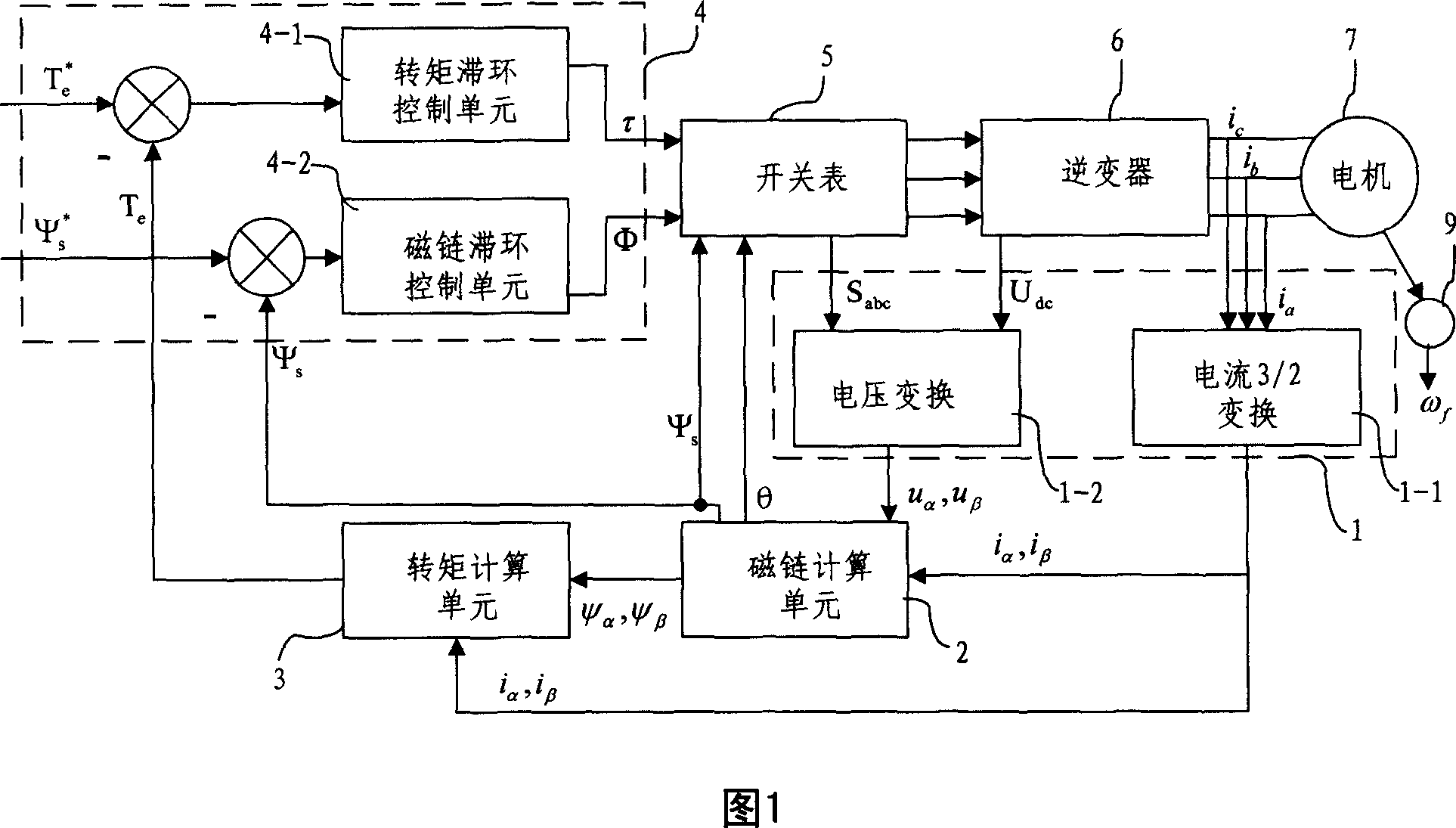

[0035] See Fig. 1 and Fig. 5, the direct torque brushless DC servo control system of the present embodiment comprises: inverter 6, data signal processor DSP 8, speed measuring encoder 9, power drive circuit 10, signal processing circuit 11 and rectifier filter circuit 12.

[0036] The 220V alternating current is connected to the power supply terminal of the inverter 6 through the output terminal of the rectification filter circuit 12 ; the control output terminal of the inverter 6 is connected to the power supply terminal of the motor 7 . The digital signal processor 8 has a PWM control output end, and the power drive circuit 10 is connected in series with the control signal input end of the inverter unit 6; the digital signal processor 8 has an ADC analog-to-digital conversion input end; the signal processing circuit 11 includes a current sensor 13. The ADC analog-to-digital conversion input terminal of the digital signal processor 8 detects the current signal and voltage sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com