Nanocrystal metal oxide composite electrode and method for preparing same

A composite electrode and oxide technology, which is applied in the field of electrochemistry, can solve the problems affecting the performance of oxide anodes, the actual composition is difficult to control, and the grain size is large, so as to achieve good matching and synergy, improve reaction selectivity, and excellent The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

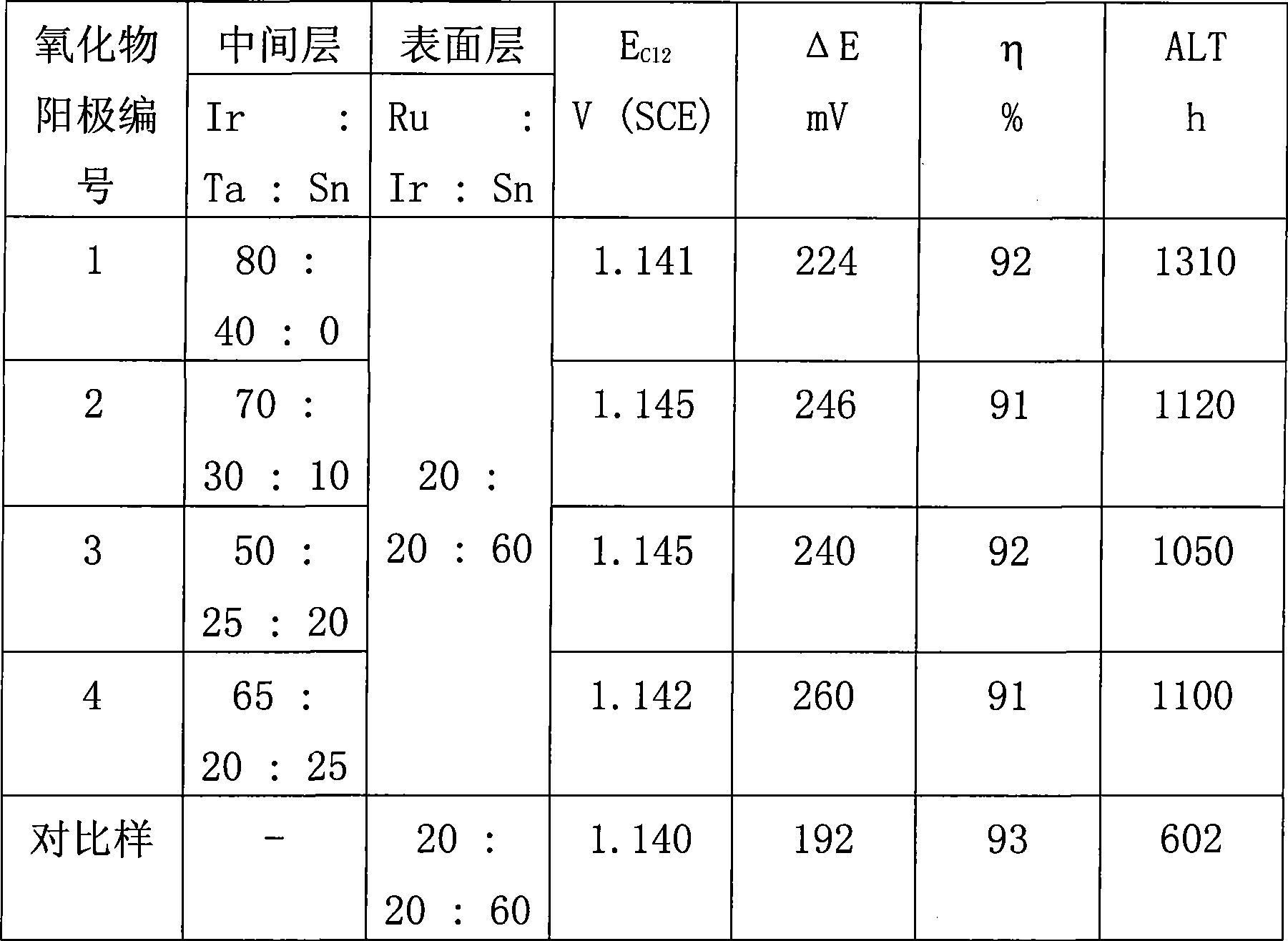

[0012] Example 1: One of the preparation schemes of nanocrystalline metal oxide composite electrodes.

[0013] (1) Matrix pretreatment: The TA2 industrial pure titanium plate test piece with a mass percentage of more than 99% with a size of 200mm × 100mm × 1.5mm is used as the electrode matrix, and the surface of the sandblasted titanium plate test piece is rinsed with water. , and etched in oxalic acid solution with a temperature of 90° C. and a concentration of 10% by weight for 2 hours to obtain a uniform rough surface, and immersed the test piece in ethanol for use. (2), preparation of intermediate layer: first mix citric acid and ethylene glycol, and the molar ratio of the two is 1:5; then chloroiridic acid, tantalum pentachloride and stannous chloride are molar ratio Ir:Ta : Sn is (55 ~ 70): (10 ~ 30): (0 ~ 25) (see Table 1 for details, forming 4 kinds of products with different proportions), add it to the mixed solution of citric acid and ethylene glycol, adjust the sol...

Embodiment 2

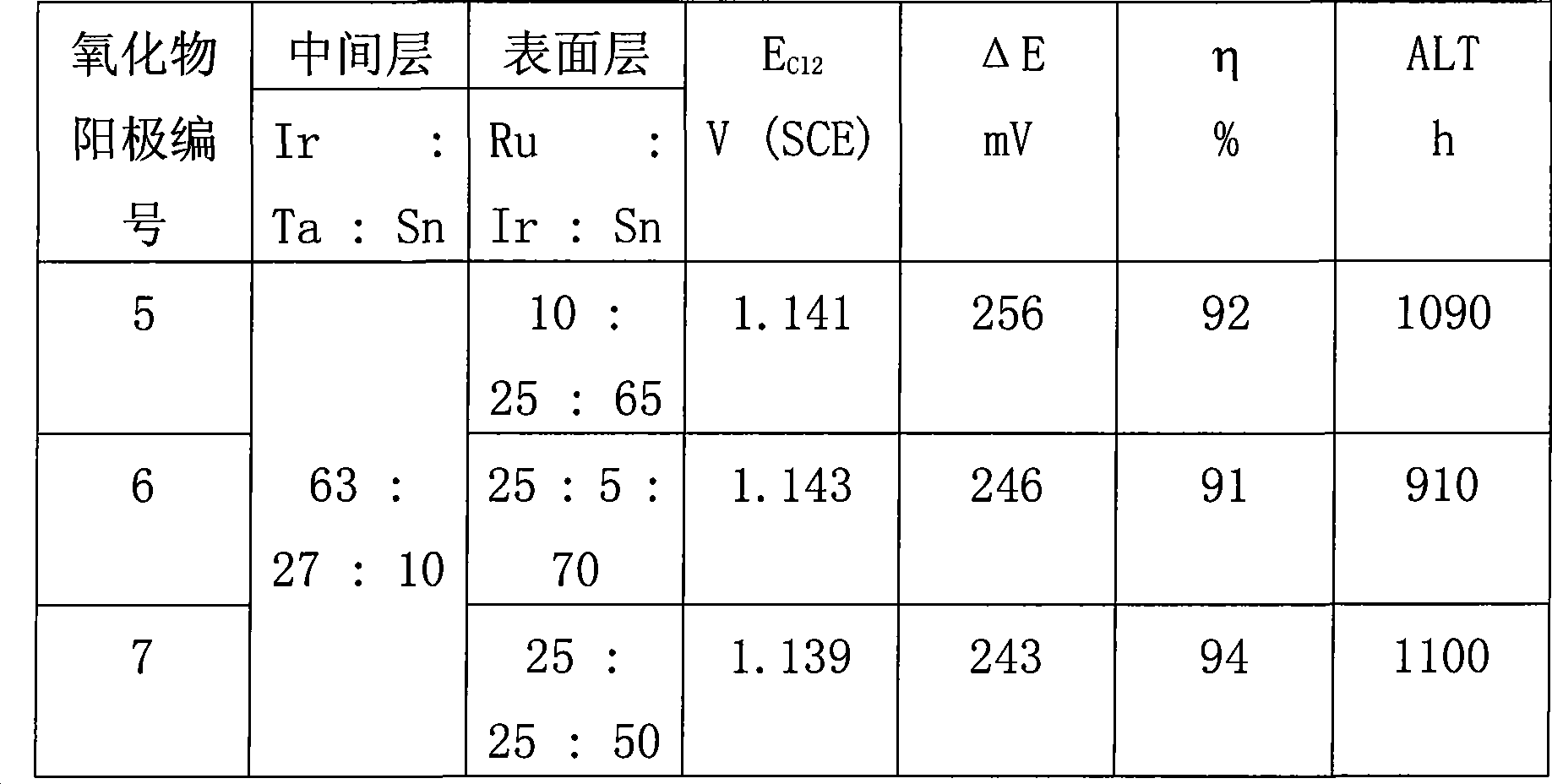

[0015] Example 2: The second preparation scheme of the nanocrystalline metal oxide composite electrode.

[0016] (1) The size of the substrate sample and the pretreatment method are the same as those in Example 1. (2), the preparation of the intermediate layer: first mix citric acid and ethylene glycol, and the molar ratio of the two is 1:5; The molar ratio of 63:27:10 was added to the mixed solution of citric acid and ethylene glycol, and the solvent was adjusted so that the molar concentration of the metal in the solution was 0.35mol / L; stirred at 60 °C for 8 hours, and then left for 3 hours to obtain a mixture containing Colloidal solution A mixed with metal ions; colloidal solution A was painted on the pretreated titanium substrate test piece, dried with an infrared lamp, and then thermally oxidized at 500 ° C for 15 minutes, repeating the above process of painting, drying, and thermal oxidation. The iridium content of the intermediate layer is 3.5g / m 2 . (3), preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com