Patents

Literature

49 results about "Electrochemical engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrochemical engineering is the branch of chemical engineering dealing with the technological applications of electrochemical phenomena, such as electrosynthesis of chemicals, electrowinning and refining of metals, flow batteries and fuel cells, surface modification by electrodeposition, electrochemical separations and corrosion. This discipline is an overlap between electrochemistry and chemical engineering.

Metallic structures incorporating bioactive materials and methods for creating the same

InactiveUS20060115512A1Reduce riskEconomical and scaleableStentsSurgeryInsertion stentMedical device

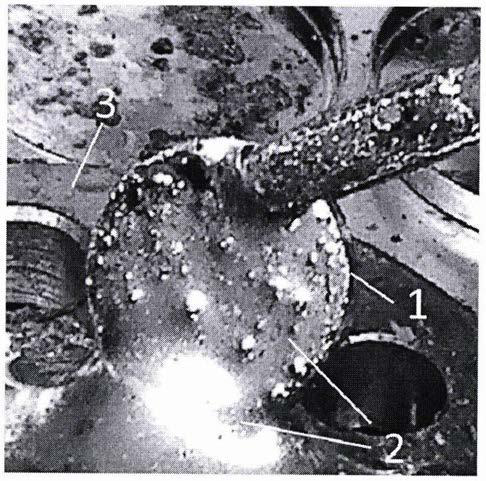

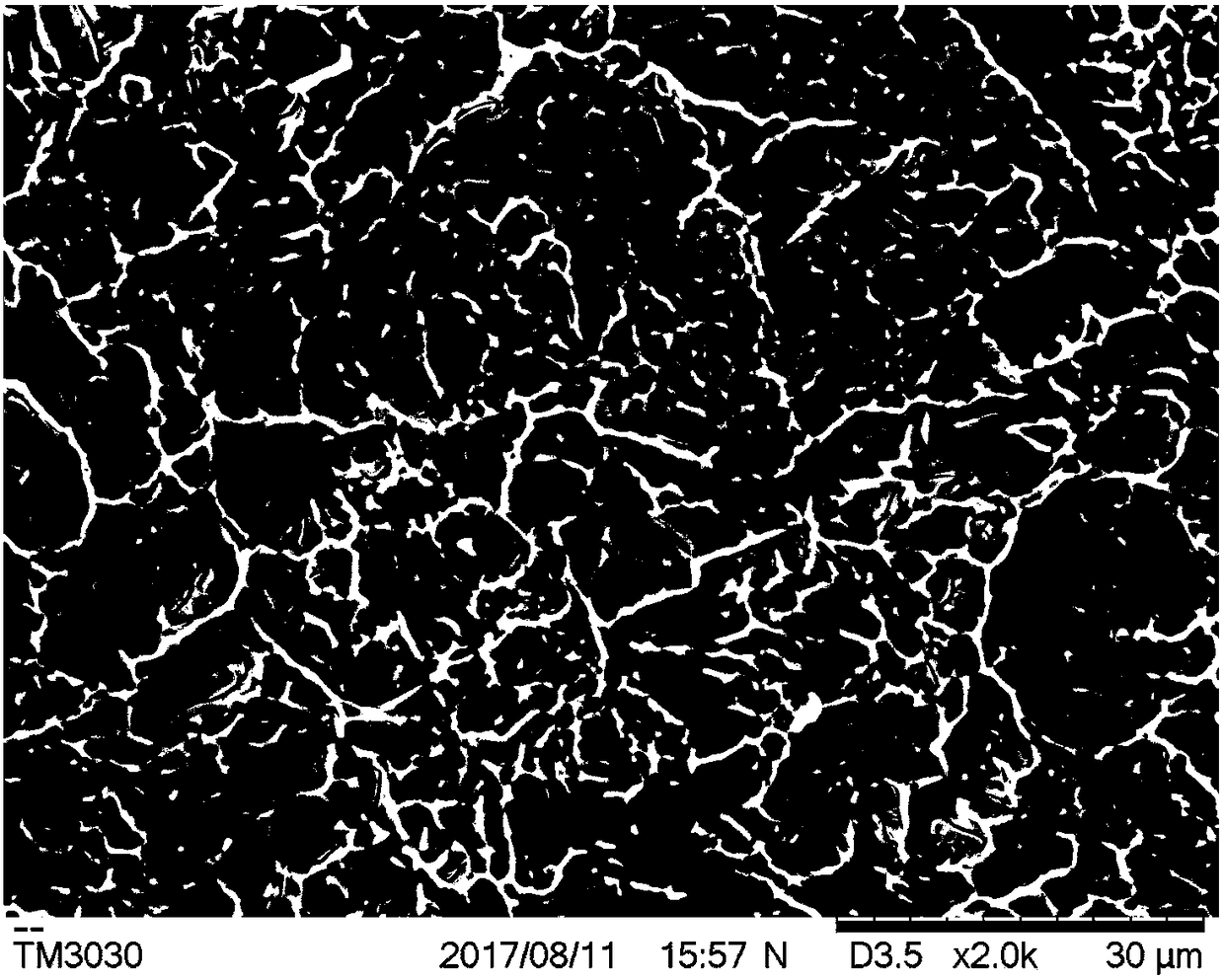

Disclosed herein are methods to create medical devices and implantable medical devices with an electrochemically engineered porous surface that contains one or more bioactive materials to form bioactive composite structures. The bioactive composite structures are prepared using electrochemical codeposition methods to create metallic layers with pores that can be loaded with bioactive materials. In one use, the implantable medical devices of the present invention include stents with bioactive composite structure coatings.

Owner:MEDLOGICS DEVICE CORP

Nanocrystal metal oxide composite electrode and method for preparing same

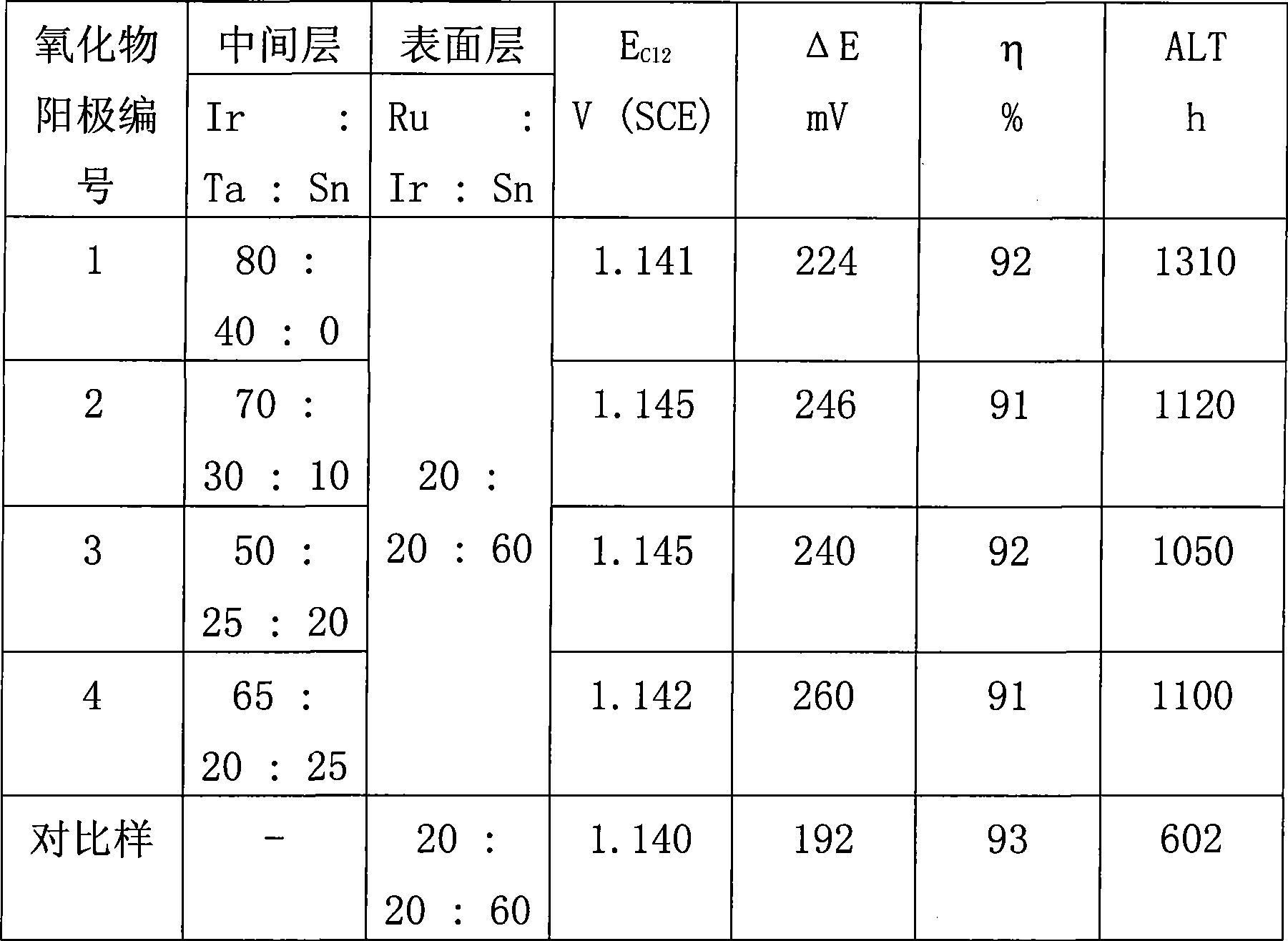

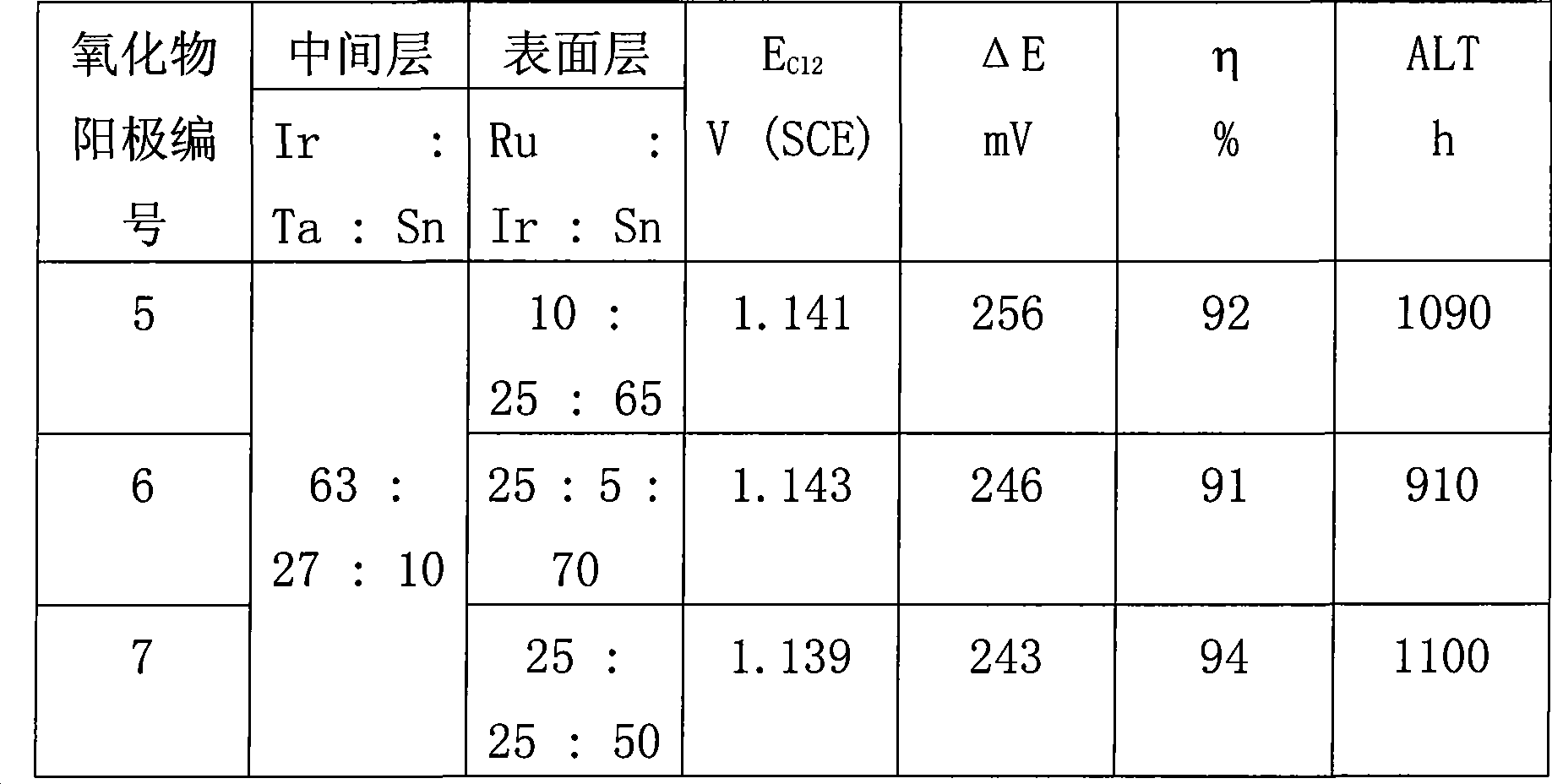

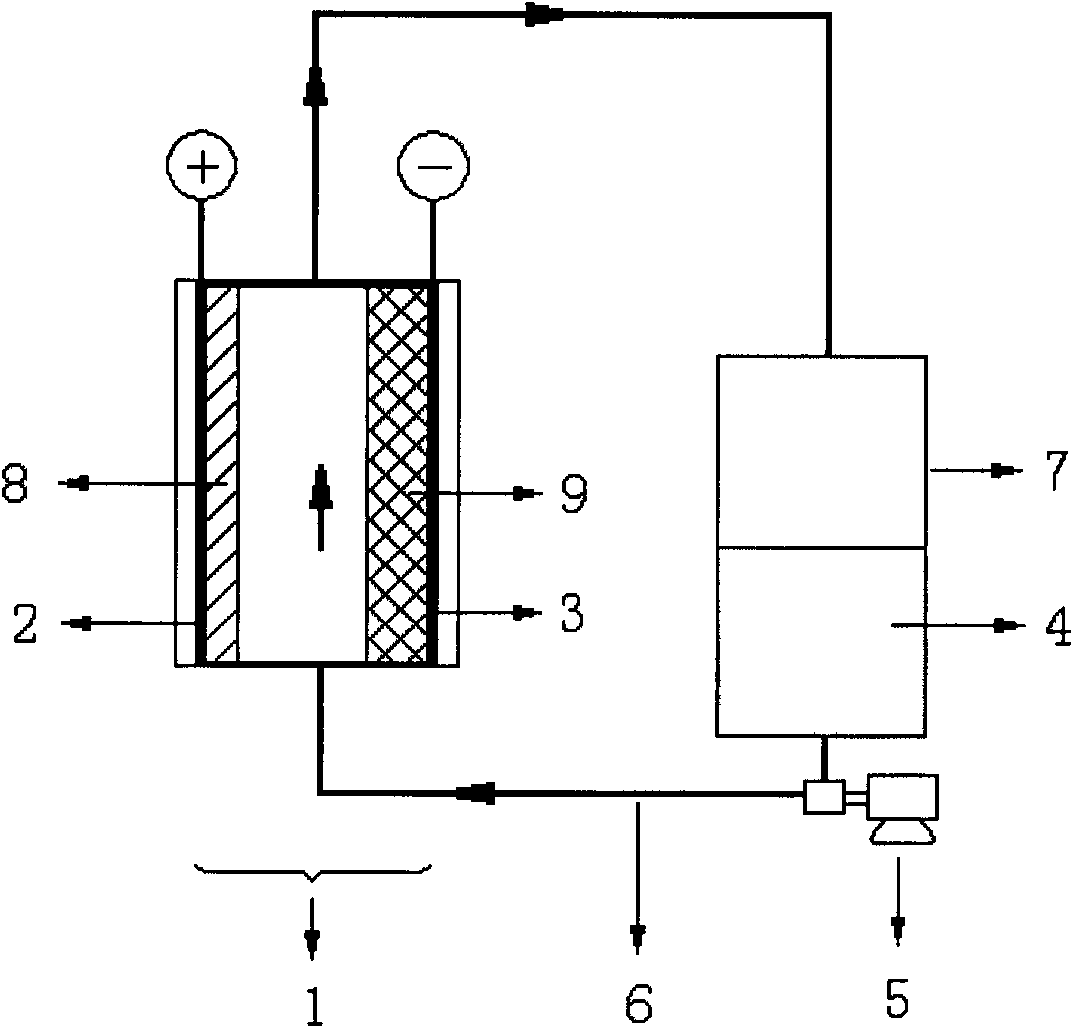

The invention relates to a nanocrystal metal oxide composite electrode and a method for preparing the same. The electrode is suitable for a seawater electrolysis device for preventing the contamination of sea creature and used for electrolytic production of sodium hypochlorite, cathode protection and other electrochemical engineering; a main structure of the electrode comprises a substrate, an anticorrosive antipassivated middle layer and a surface activity layer, wherein the substrate is metal titanium; the purity of the metal titanium is over 99 percent; the middle layer is iridium-tantalum or iridium-tantalum-tin oxide; the surface activity layer is ruthenium-iridium-tin metal oxide; a process for preparing the electrode adopts a sol-gel method and comprises three process steps of the pretreatment of the substrate, the preparation of the anticorrosive antipassivated middle layer and the preparation of the surface activity layer; and the electrode has the characteristics of even compositions, difficulty for burning loss, fine crystal grains, simple preparation process, controllable process and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Titanium-based oxide acid resistant anode and preparation method thereof

InactiveCN102268689AStrong acid resistanceSolution to short lifeSurface reaction electrolytic coatingSolid state diffusion coatingFiberElectrolysis

The invention provides a titanium-based oxide acid resistant anode and a preparation method thereof, and specifically to an electrode catalyst used in the process of electrolysis and a preparation method thereof, belonging to the technical field of electrochemical engineering. The invention is characterized in that: the titanium-based oxide acid resistant anode is especially applicable to electrolysis with oxygen evolution and organic electrolysis and has a long life in a sulfuric acid solution; the anode comprises an electrode matrix, an intermediate transition layer and an active coating; the preparation method for the anode comprises the steps of preparing Ti / Tio2NT by electrochemical anodization in ionic liquid and forming Ti / TiO2NT / C+N+B by co-cementation of B, C and N under the catalytic cementation of rare earth at first or preparing Ti / C+N+B through surface alloying of titanium matrix and forming Ti / C+N+B / TiO2NT through anodization heat treatment at first, applying the graphite fiber loaded intermediate transition layer of Sn, Sb, rare earth and like next, and preparing the PbO2 or MnO2 active coating at last. The titanium-based oxide acid resistant anode prepared through the preparation method provided in the invention has a service life more than 160 hours.

Owner:TAIYUAN UNIV OF TECH

Preparation method of oxide solid electrolyte diaphragm

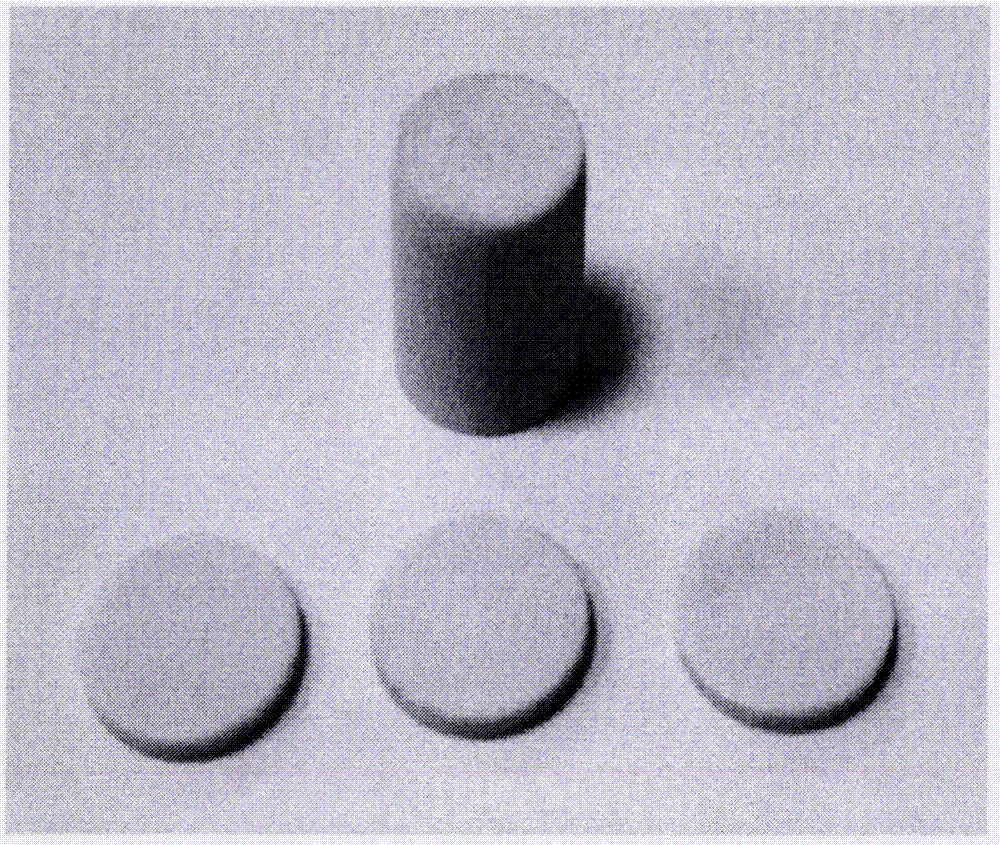

ActiveCN106384801AAvoid easily deformable problemsReduced Chances of ContaminationFinal product manufactureCell component detailsLithium hydroxideMechanical energy

The invention relates to a preparation method of an oxide solid electrolyte diaphragm, belonging to the fields of electro chemical engineering and ceramic industry. The method comprises the following steps: by using lithium carbonate or lithium hydroxide as a lithium source, putting previously prepared solid electrolyte powder in a crucible, and directly sintering at high temperature to obtain a compact block; and carrying out cutting and sanding on the block to obtain the solid electrolyte diaphragm sheet. The method avoids the complex mold preforming process in the conventional method; and the mechanical energy is converted into the surface free energy of the powder granules by ball milling, the excessive low-melting-point lithium salt is molten at high temperature to generate the liquid phase which is covered on the powder particle surfaces, and the powder automatic aggregates under the action of surface tension, so that the surface free energy is lowered, thereby forming the compact solid electrolyte block. The method has the advantages of simple technique, smooth and compact finished product and the like, can easily implement large-scale production, and is especially suitable for preparing oxide solid electrolyte diaphragms in the solid secondary battery.

Owner:NO 63971 TROOPS PLA

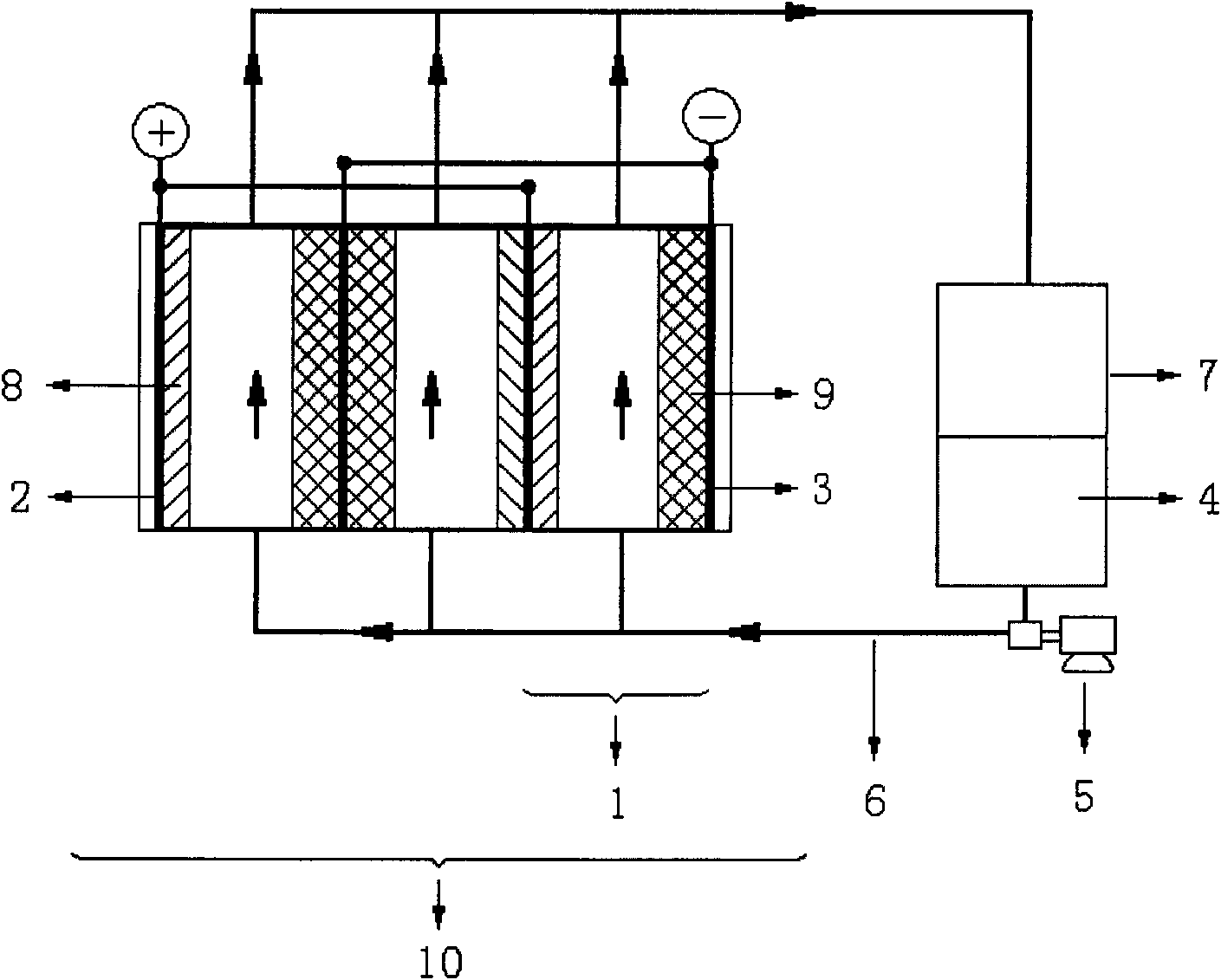

All-lead liquid flow battery

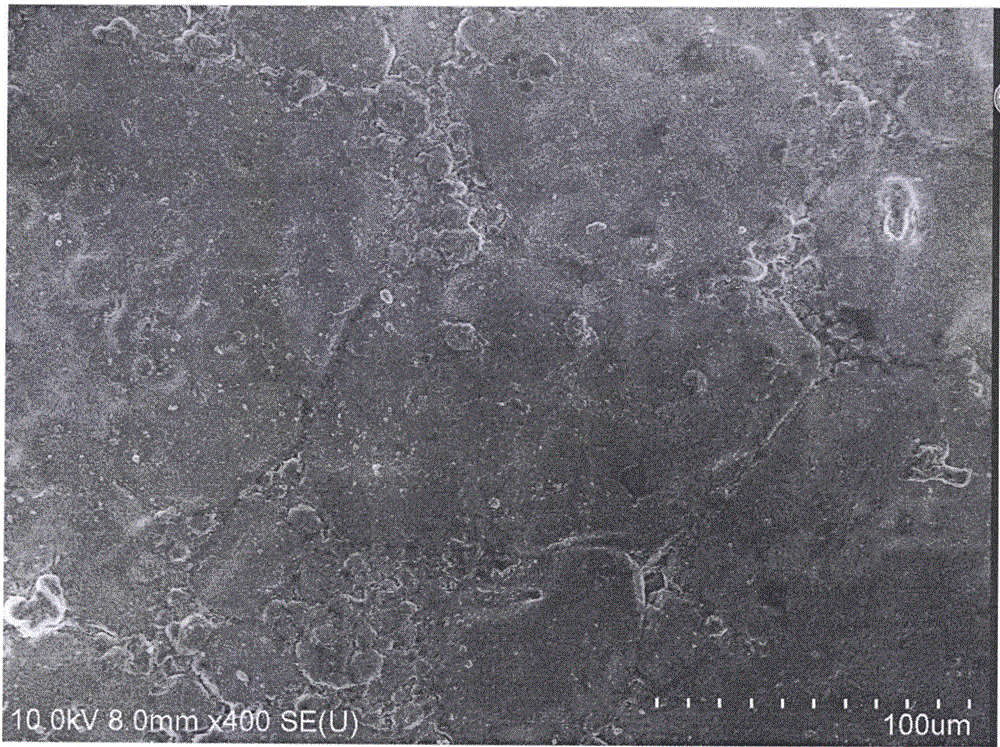

InactiveCN102723518AIncrease transfer speedReduce concentration polarizationRegenerative fuel cellsCollectors/separatorsLead dioxideEngineering

The invention belongs to the electrochemical engineering and industrial fields, particularly to a lead liquid flow battery. The single battery cell consists of a deposition-type lead dioxide anode, a deposition-type lead dioxide cathode and an electrolyte containing soluble lead salt. A galvanic pile can be formed by a plurality of battery cells being connected serially or in parallel. The electrolyte of the galvanic pile is stored in a storage tank and the electrolyte pushed by a liquid pump keeps flowing between the storage tank and the pile pipes in the process of charging and discharging. The lead in the electrolyte is deposited on current collectors of the positive electrode and the negative electrode to become the lead dioxide and metallic lead when the battery is charged. And the lead dioxide and metallic lead dissolve in the electrolyte to become lead ions when the battery is discharged. The liquid flow battery is characterized by simple manufacture, low cost and long cycle life.

Owner:NO 63971 TROOPS PLA

Acid-fast anode

The invention relates to an acid-proof anode which belongs to the electrochemical engineering technical field and in particular relates to electrode catalyst which is used in the electrolysis process and a method for preparing the electrode catalyst. The acid-proof anode is characterized in that the acid-proof anode is composed of a titanium substrate, an interlayer of solid solution and an activated layer, the anode is the acid-proof anode which co-diffuses one or two or three of B, C and N to the titanium substrate under the condition of rare-earth catalysis, simultaneously, the invention provides anode material which has long service life, good electro-catalytic activity, good wear resistance and good corrosion resistance in sulfuric acid solution, and the anode material is in particular suitable in electrolysis production which has oxygen evolution and organic electrolysis process.

Owner:TAIYUAN UNIV OF TECH

Niobium carbide and tantalum carbide electrode preparation method

InactiveCN103482625AReduce stepsSimple processCarbon compoundsLead-acid accumulator electrodesEpoxyElectrolysis

The invention belongs to the field of electrochemistry engineering and industry, and particularly to a niobium carbide and tantalum carbide electrode preparation method, wherein a plate, a sheet, foil or a wire of metal niobium or tantalum is adopted, and is subjected to a reaction with carbon, carbon monoxide, an epoxy resin and the like in the protection of gas with a temperature of 600-1200 DEG C so as to obtain a compact niobium carbide and tantalum carbide layer on the outer surface of niobium and tantalum, wherein the internal is the metals such as niobium and tantalum, and the obtained material has the advantages of flexibility, strength and the like of the metal, has the electric conduction niobium carbide and tantalum carbide layer adopted as the strong corrosion resistance layer, and can be used as a dimensionally stable anode used in sulfuric acid, hydrochloric acid, chlor-alkali electrolysis and other electrolytes. The preparation method has advantages of less operation steps, simple process and stable quality, and is especially suitable for preparation of redox flow batteries, secondary batteries, and electrolysis industry electrodes.

Owner:NO 63971 TROOPS PLA

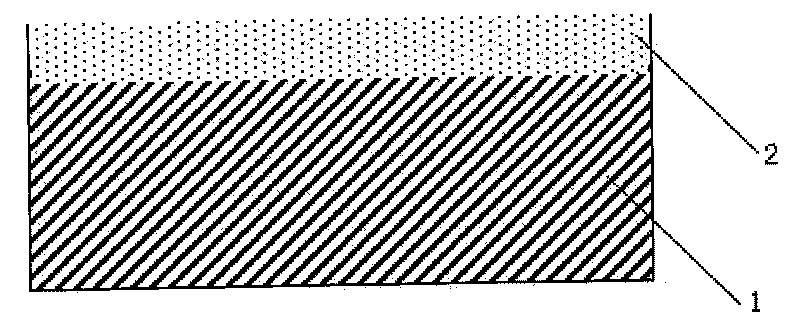

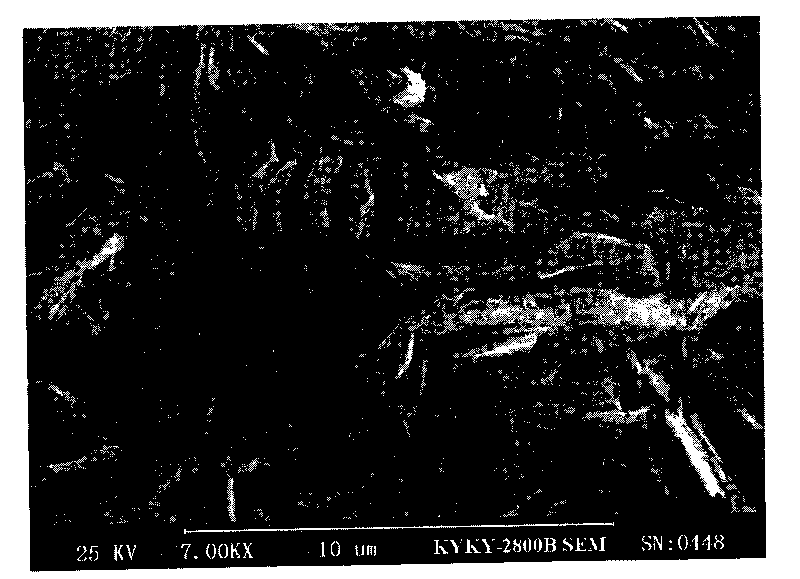

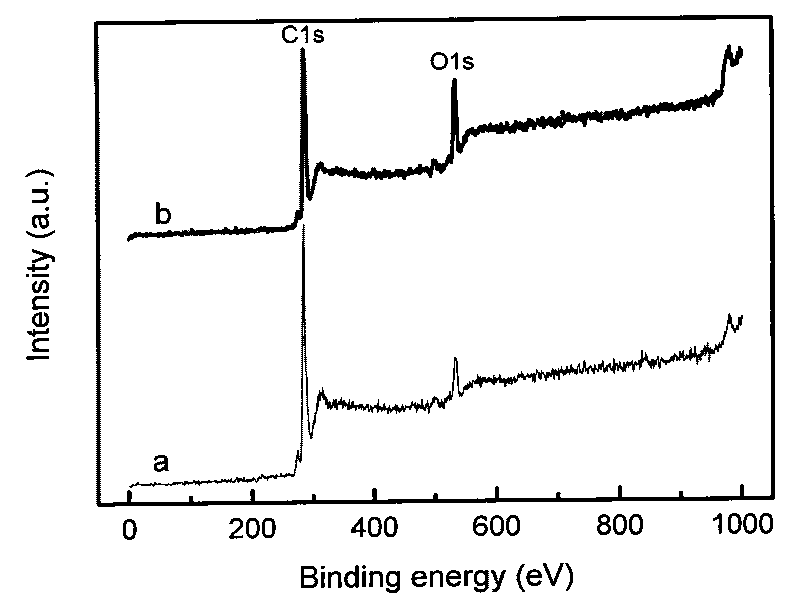

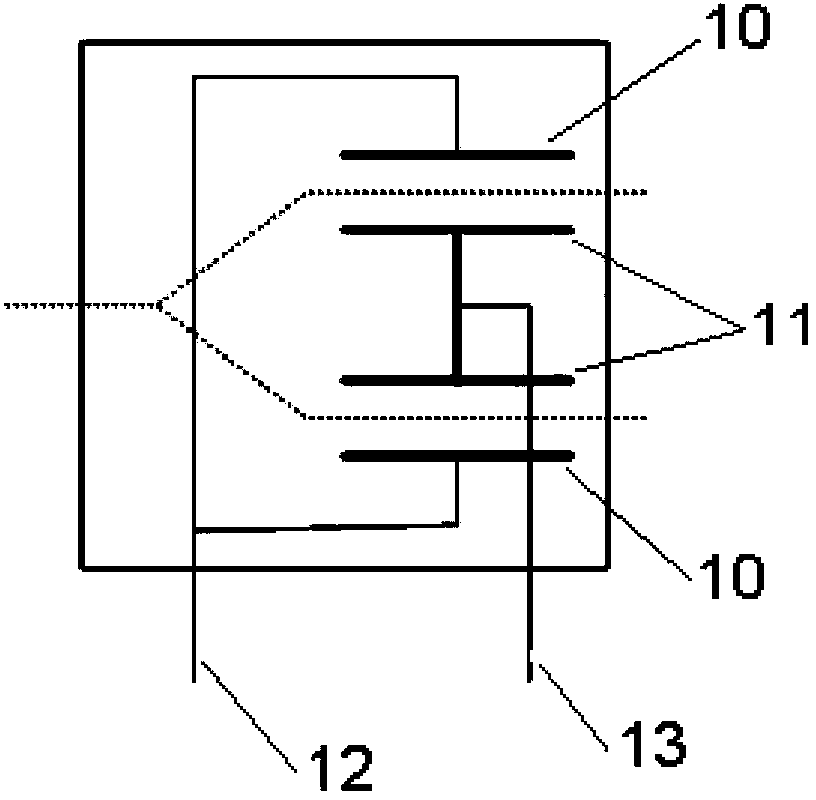

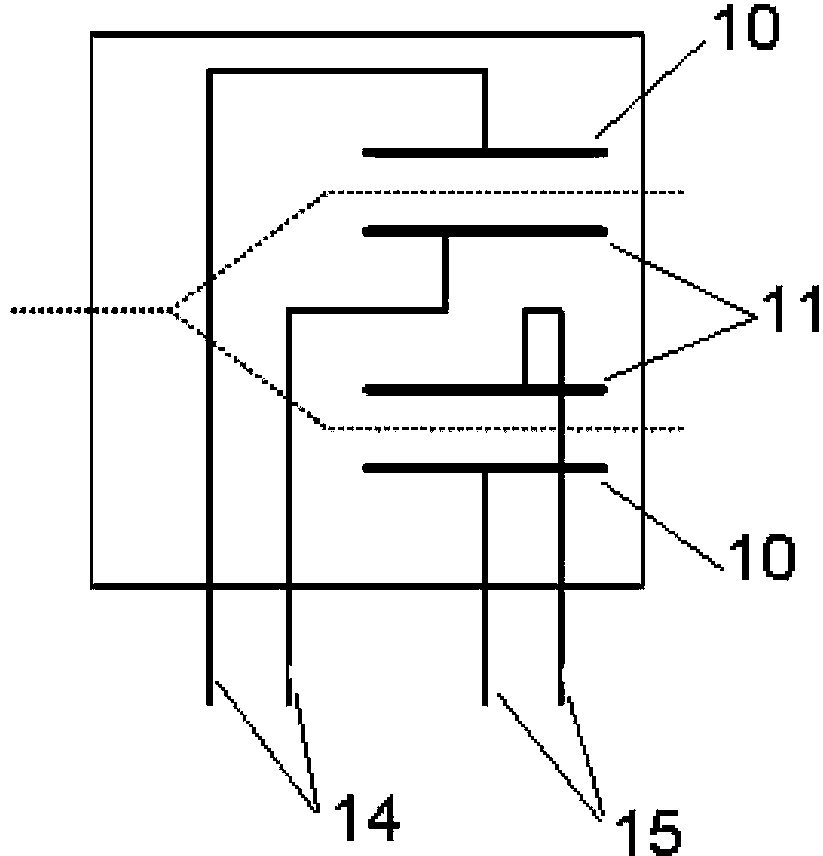

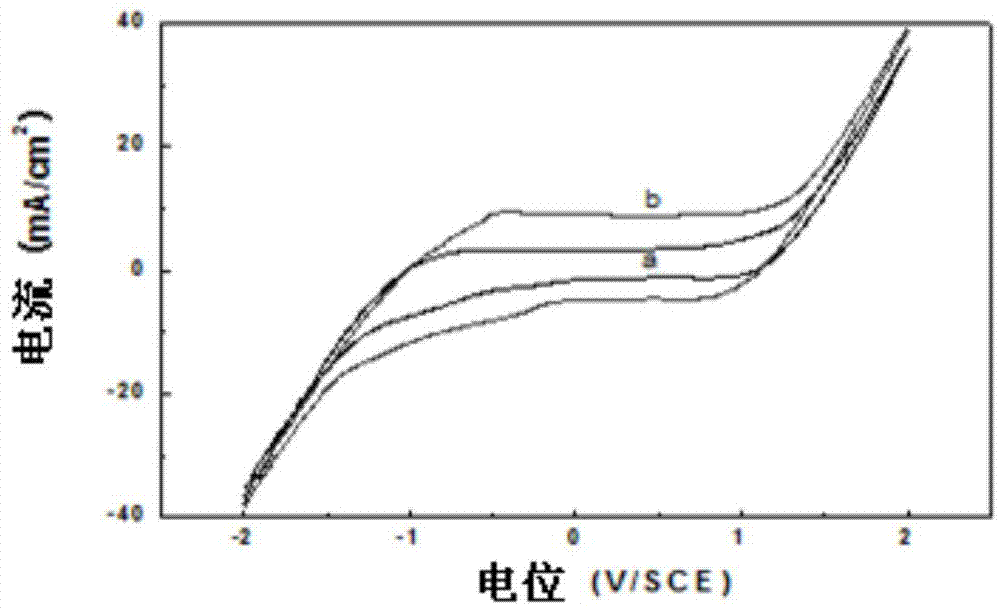

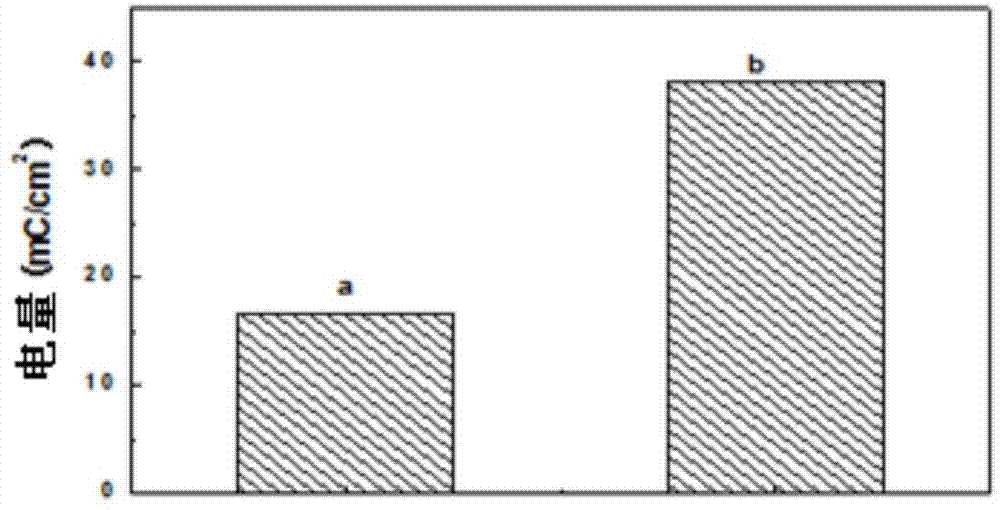

Electrochemically modified graphite electrode

InactiveCN101697323AHigh energyImprove stabilityElectrolytic capacitorsHybrid capacitor electrodesWater basedHigh energy

The invention discloses an electrochemically modified graphite electrode, which consists of a graphite body and an active layer, wherein the active layer is attached to the surface of the graphite body. The electrochemically modified graphite electrode is characterized in that: the active layer (2) is a product directly obtained in a way that the graphite body (1) is subjected to circular treatment between electrochemical oxidation and electrochemical reduction in water-based electrolyte solution with ionic conductivity. The electrochemically modified graphite electrode is used as an electrode material of an electrochemical capacitor, has high energy, high power density and high-speed charge and discharge performances, also has the advantages of high electric conductivity, low material cost, high stability, long service life, simple manufacture, low production cost and the like. In addition, the electrochemically modified graphite electrode of the invention can be widely applied to applicable electrochemical engineering and serves as the electrode material.

Owner:OCEAN UNIV OF CHINA

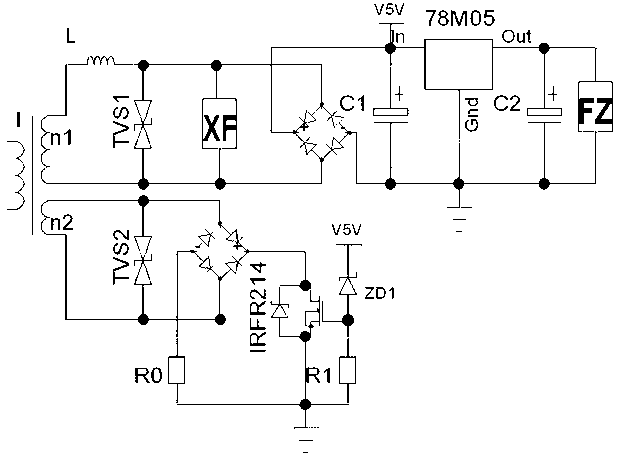

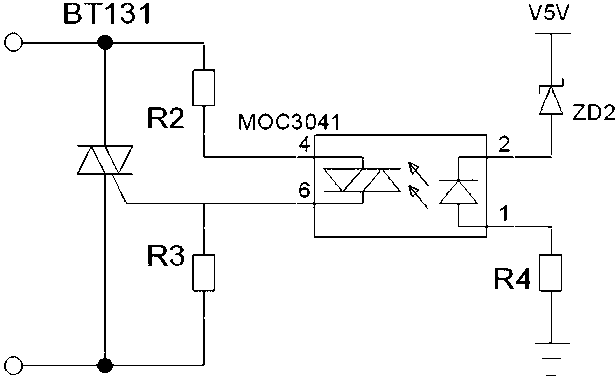

Non-contact self-powered power supply for overhead high voltage line

InactiveCN103227515AStable supplyExtended working hoursElectromagnetic wave systemCircuit arrangementsEngineeringHigh pressure

The invention discloses a non-contact self-powered power supply for an overhead high voltage line, belongs to the technical field of electrochemical engineering, and relates to an induced electricity taking device for an overhead high voltage power transmission line. The non-contact self-powered power supply comprises an opening and closing annular iron core mounted on the high voltage power transmission line, a power coil and a control coil wound on the annular iron core, a power circuit module, a leakage circuit module and a control circuit module. The power coil and the power circuit module induce to obtain electric energy from the high voltage line, and the control coil, the control circuit module and the leakage circuit module have shunt and current limiting effects. The self-powered power supply can work safely and provide stable power output all the time when the current of the high voltage power transmission line is changed in a wide range.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Acid resistant anode, and preparation method

This invention relates to a method for preparing acid-resistant anode. The acid-resistant anode is composed of Ti as the matrix, SnO2 + Sb2O4 + graphite fibers as the intermediate buffer layer, and PbO2 or MnO2 as the active layer. The method adds highly conductive and acid-resistant graphite fibers into the intermediate buffer layer, thus the adhesiveness between the active layer and the intermediate buffer layer is improved, and the anode has high conductivity and service life in strong acid solution. The acid-resistant anode has such advantages as high acid resistance, long service life, high catalytic activity and wide applications.

Owner:TAIYUAN UNIV OF TECH

Method for manufacturing acid resistant anode

The invention relates to a method for preparing an acid-proof anode which belongs to the electrochemical engineering technical field and in particular relates to electrode catalyst which is used in an electrolysis process and a method for preparing the electrode catalyst. The acid-proof anode is characterized in that the acid-proof anode is composed of a titanium substrate, an interlayer of solid solution and an activated layer, the anode is the acid-proof anode which co-diffuses one, two or three of B, C and N to the titanium substrate under the condition of rare-earth catalysis, simultaneously, the invention provides anode material which has long service life, good electro-catalytic activity, good wear resistance and good corrosion resistance in sulfuric acid solution, and the anode material is in particular suitable in electrolysis production which has oxygen evolution and organic electrolysis process.

Owner:TAIYUAN UNIV OF TECH

Direct compounding method of metal lithium electrode and inorganic solid electrolyte ceramic diaphragm

ActiveCN111370627AReduce surface tensionHigh melting temperatureFinal product manufactureCell component detailsMetallic lithiumElectrical battery

The invention relates to a direct compounding method of a metal lithium electrode and an inorganic solid electrolyte ceramic diaphragm, and belongs to the field of electrochemical engineering and ceramic industry. According to the method, the surface tension of the lithium liquid is reduced by increasing the melting temperature; through a friction mode, meanwhile, an oxide layer on the surface ofthe lithium liquid and air pits formed in the micro surface of the ceramic diaphragm due to unevenness are destroyed. Fresh lithium liquid makes direct contact with the ceramic diaphragm body and theninfiltrates and spreads, and the problems that in a conventional method, the lithium liquid is difficult to infiltrate on the surface of the ceramic diaphragm, the solid / solid interface contact resistance of the metal lithium electrode and the inorganic solid electrolyte ceramic diaphragm is large, and the stability is poor are solved. According to the method, the direct compounding of the metallithium electrode and the inorganic solid electrolyte ceramic diaphragm is realized without depositing a transition infiltration layer on the surface of the ceramic diaphragm in advance in manners ofatomic deposition and the like, the process flow is simple, and the method is particularly suitable for a solid-state battery system taking metal lithium as a negative electrode and taking oxide inorganic solid electrolyte ceramic as a diaphragm.

Owner:中国人民解放军军事科学院防化研究院

Preparation method of lithium lanthanum niobium oxygen solid electrolyte diaphragm

InactiveCN106898821AIncrease success rateSimple methodFinal product manufactureElectrolyte accumulators manufactureNiobiumLithium hydroxide

The invention relates to a preparation method of a lithium lanthanum niobium oxygen solid electrolyte diaphragm, and belongs to the field of electrochemical engineering and ceramic industry. The method comprises the following steps that lithium carbonate, acetic acid and lithium hydroxide are taken as lithium sources, the mixed material powder is sintered in advance to form lithium lanthanum niobium oxygen solid electrolyte powder, then a powder body is placed in a crucible, is compacted by vibration, and is then directly sintered at high temperature to obtain a compact block body; and the block body is cut and grinded to obtain a lithium lanthanum niobium oxygen solid electrolyte diaphragm sheet. The method avoids the complicated mold tableting process in the traditional method, does no need a high-tension apparatus, and does not need the addition of a sintering assistant either; and the powder body is aggregated to form the compact block body by utilizing the surface tension of a liquid phase generated through melting of the lithium salt at high temperature. The preparation method has the advantages of simple process, smoothness and compactness of a product, easy large-scale production and the like, and is particularly suitable for the preparation of the lithium lanthanum niobium oxygen solid electrolyte diaphragm in a solid state battery.

Owner:NO 63971 TROOPS PLA

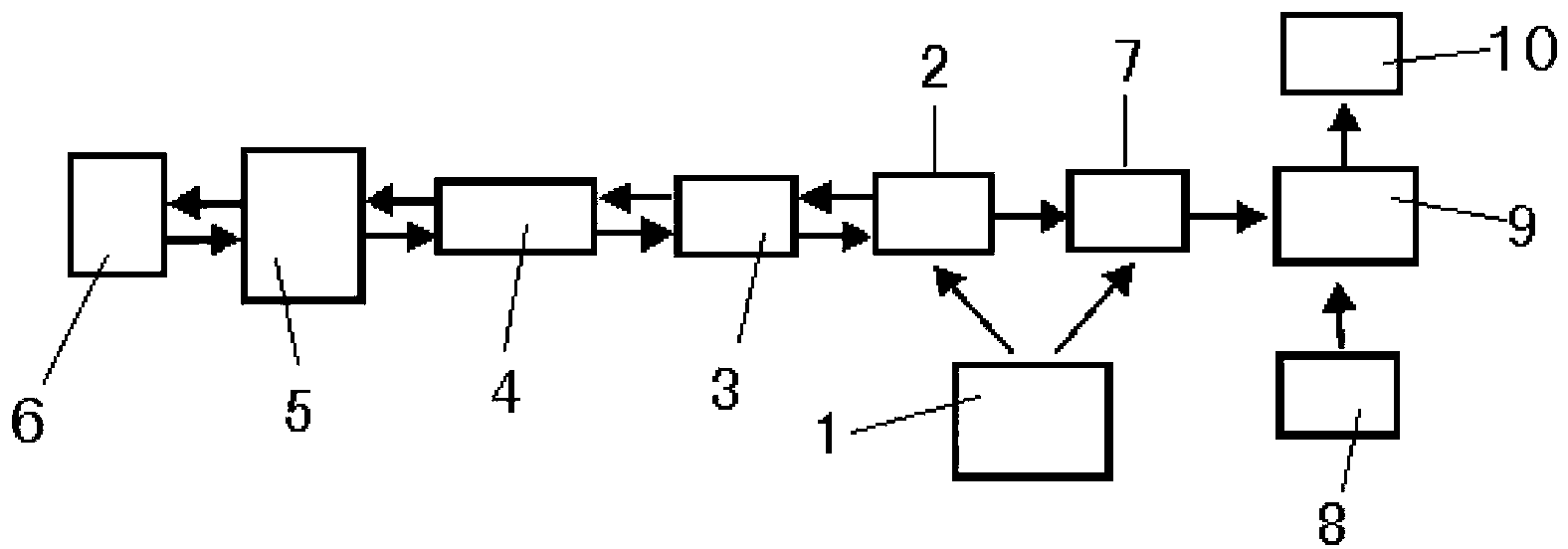

On-site verification apparatus for optical fiber current sensor

ActiveCN103616651ASolve the lock-up problemReduce latch-upMeasurement using digital techniquesWavelength filterCurrent sensor

The invention relates to an on-site verification apparatus for an optical fiber current sensor, a usage method of the on-site verification apparatus and application of the on-site verification apparatus. The on-site verification apparatus for the optical fiber current sensor includes an optical fiber current detection sensing module and an optical fiber current detection processing and display module. The optical fiber current detection sensing module is composed of a light source, a linear polariscope, a polarization separator, a modulator, a transmission optical fiber, a 1 / 4 wavelength filter, an optical fiber sensing head, a reflector and a photoelectric detector. Proceeding from installation and debugging of the optical fiber current detection sensing module, the optical fiber current sensor on-site verification apparatus has reasonable control steps, is easy to operate, and can carry out efficient, economic and accurate error detection and quantity transmission on a DC heavy current sensor working on site for a long time; the optical fiber current sensor on-site verification apparatus is suitable for detecting and verifying a current detection sensor working on site for a long time in fields of electrolytic aluminum, electrolytic copper, electric smelting, electroplate and other electrochemical engineering; the on-site verification apparatus for the optical fiber current sensor is good in safety performance, large in measuring dynamic scope, high in frequency response degree, small in size and light in weight; and by adopting the on-site verification apparatus for the optical fiber current sensor, the measuring precision of a current detection apparatus can be raised, and needs of safety and stabilization of a power supply system are met.

Owner:XUNDI SCI & TECH HUBEI PROV

Lead liquid flow battery electrolyte

The invention relates to the electrochemical engineering and industrial fields, particularly to a lead liquid flow battery electrolyte comprising the basic components of fluoboric acid and an aqueous solution of soluble divalent lead. The concentration of fluorboric acid is 0.5-3 mole per liter and the concentration of divalent lead is 0.2-1.5 mole per liter. Some cations such as cadmium, manganese, cobalt, etc, can be added as cation additives, and some anions such as sulfate radical, chlorate radical, perchlorate radical, etc, can be added as anion additives. The rate of disposition and dissolution of lead dioxide and mental lead is very high in the fluorboric acid aqueous solution of the lead fluoborate. The electrode overpotential can be reduced and the rate of electrodes can be improved by adding cation and annion additives in the electrolyte. The electrolyte can be directly used as a liquid flow battery with deposition type lead dioxide as an anode, having advantages of high conductivity, long cycle life, low cost and stable quality.

Owner:NO 63971 TROOPS PLA

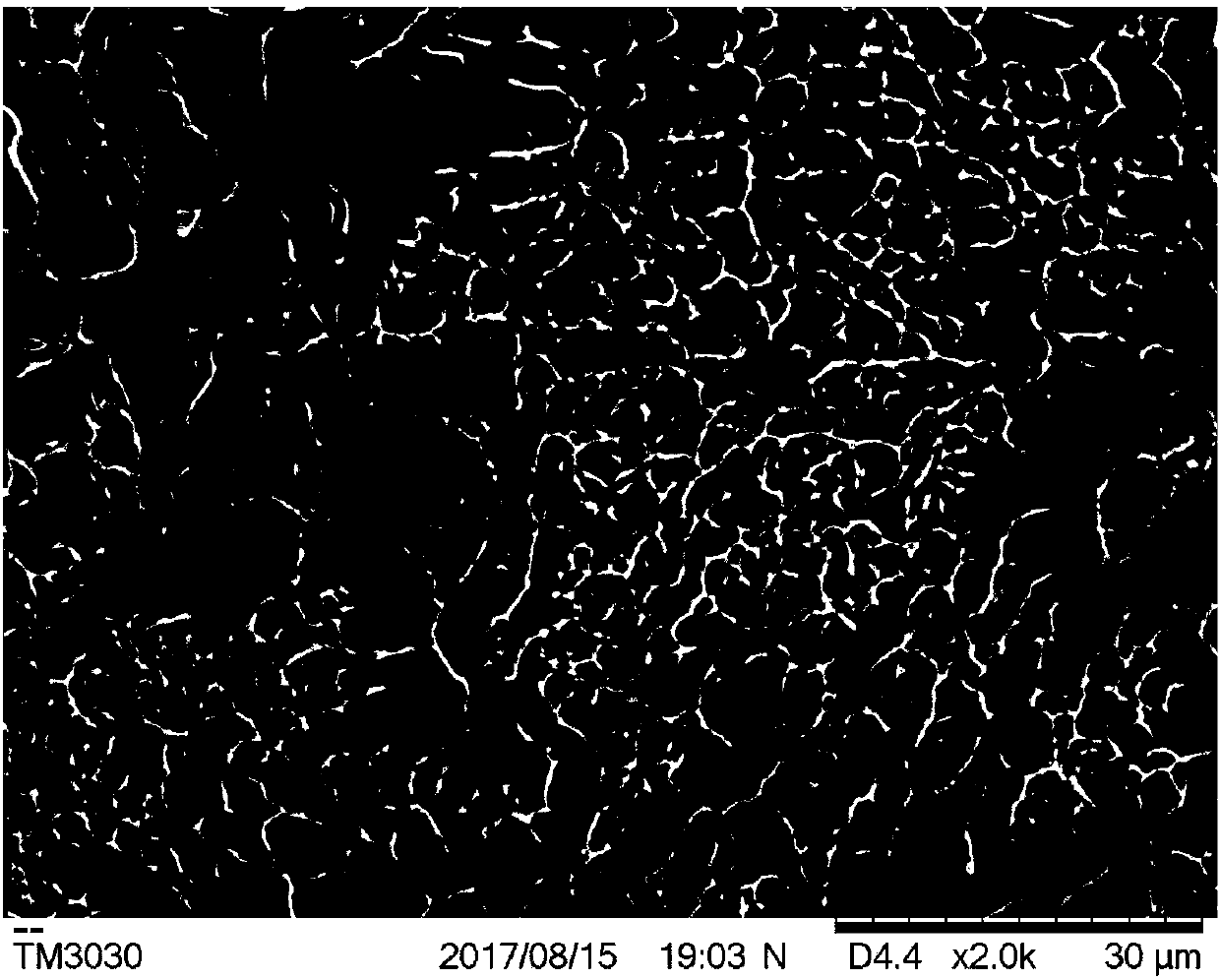

Preparation method of metal oxide coating anode

ActiveCN104846357AHigh catalytic activityImprove efficiencySolid/suspension decomposition chemical coatingPlasma jetElectrolysis

The invention belongs to the technical field of electrochemistry, and relates to a preparation method of a metal oxide coating anode. The anode prepared under the assistance of normal pressure plasma is suitable for degrading seawater sewage by electrolysis, preventing marine organisms from damage, implementing cathode protection and other electrochemical engineering occasions. The preparation method comprises the steps of substrate pretreatment, coating solution preparation and coating anode preparation. The method specifically comprises the following steps: adjusting a plasma discharge current and a jet gun motion speed to set values, jetting the prepared coating solution on the pretreated substrate surface in a coverage mode, drying the substrate in a drying box to form a coating on the substrate surface, and oxidizing the coating surface by plasma jet discharge; and repeating the jetting, drying and plasma oxidization steps 6-8 times, and sintering the substrate in a sintering furnace, thereby completing the coating anode preparation. The method has the advantages of simple preparation technique, reliable principle, low energy consumption and high efficiency. The prepared anode has the advantages of favorable stability, long service life and environment friendliness.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

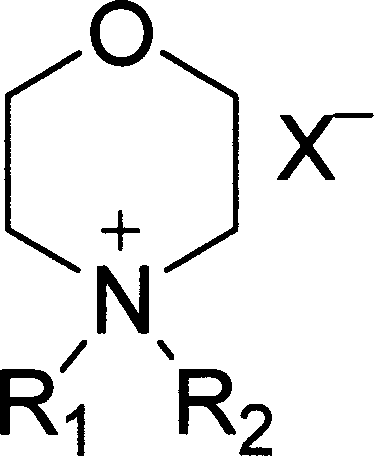

Compound containing morpholine cation radical and its synthesis process and use

InactiveCN1986534AThe synthetic route is simpleHigh yieldOrganic chemistryChemical reactionMorpholine

The present invention relates to compound containing morpholine cation radical and its synthesis and use. The compound of the present invention is one excellent green solvent with dissolving capacity higher than organic solvent, has low production cost, simple synthesis path and high yield, and is suitable for industrial production. The compound of the present invention is used as ionic liquid and may be used as gas absorbent and liquid extractant in separation engineering, as reaction medium and catalyst in chemical reaction, as electrolyte in electrochemical engineering, etc.

Owner:WUHAN UNIV

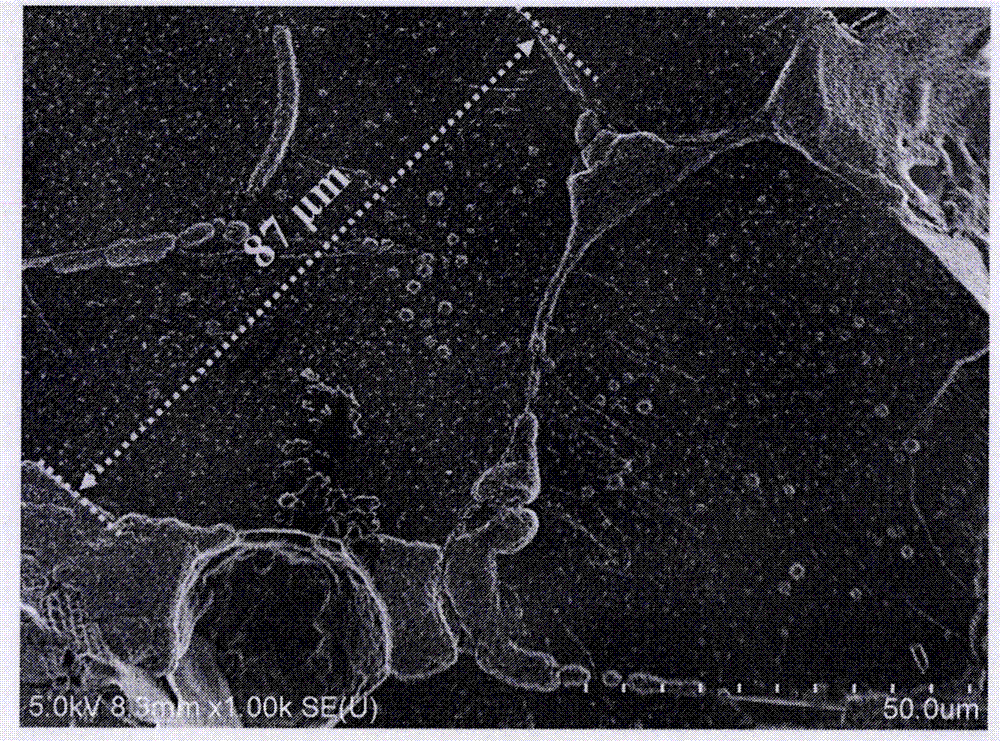

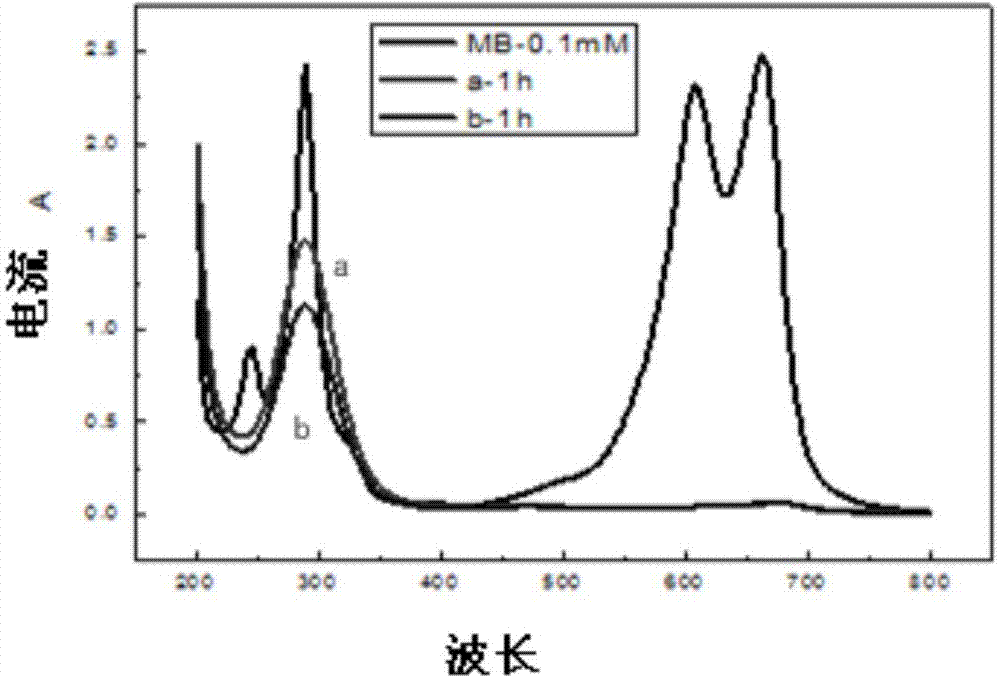

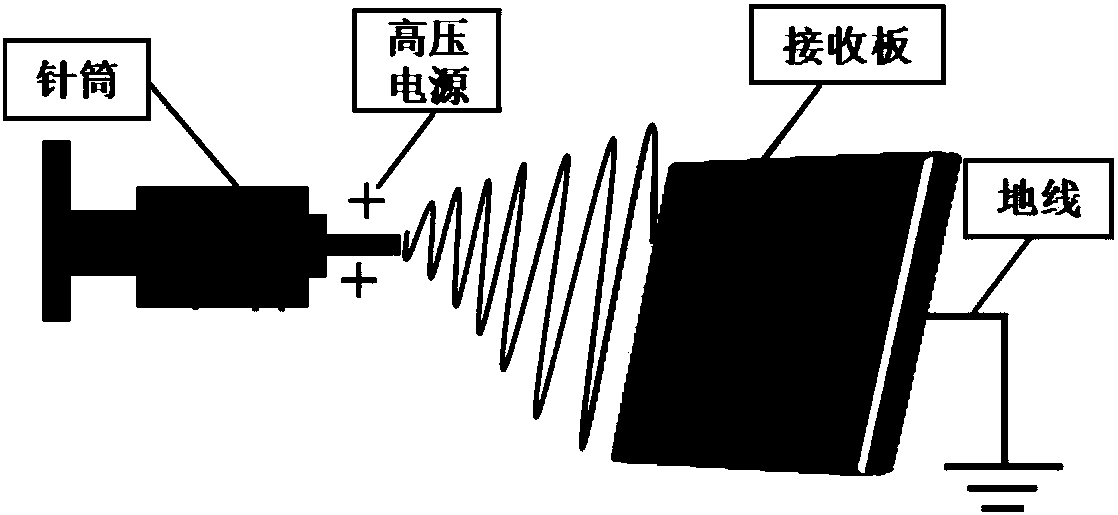

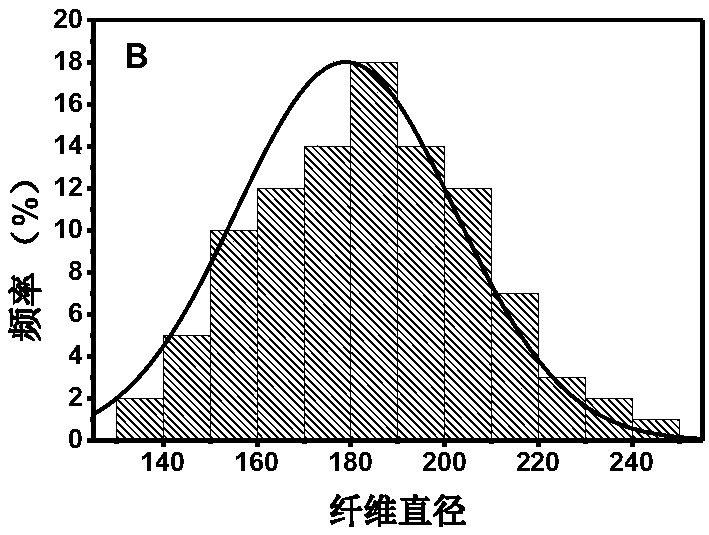

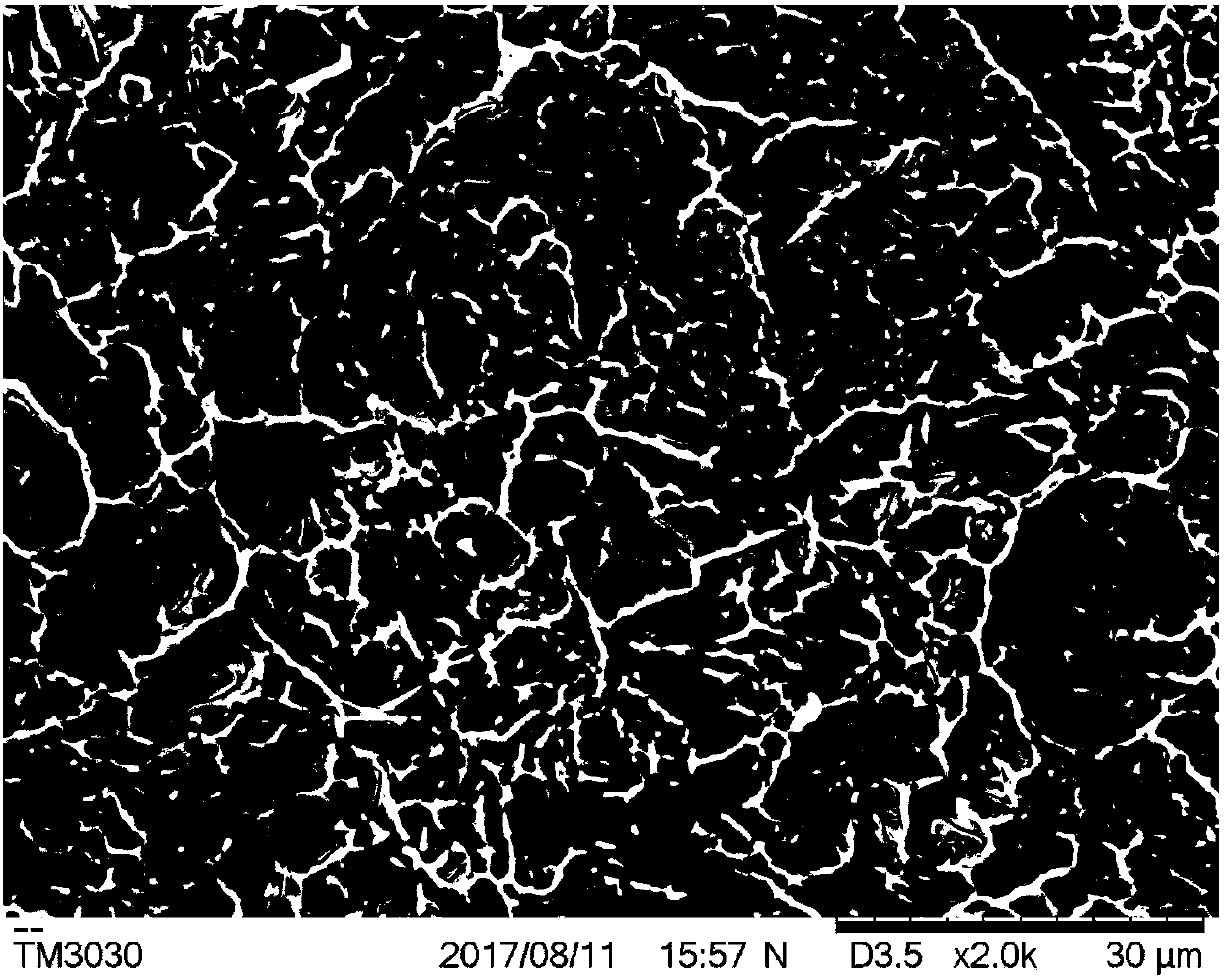

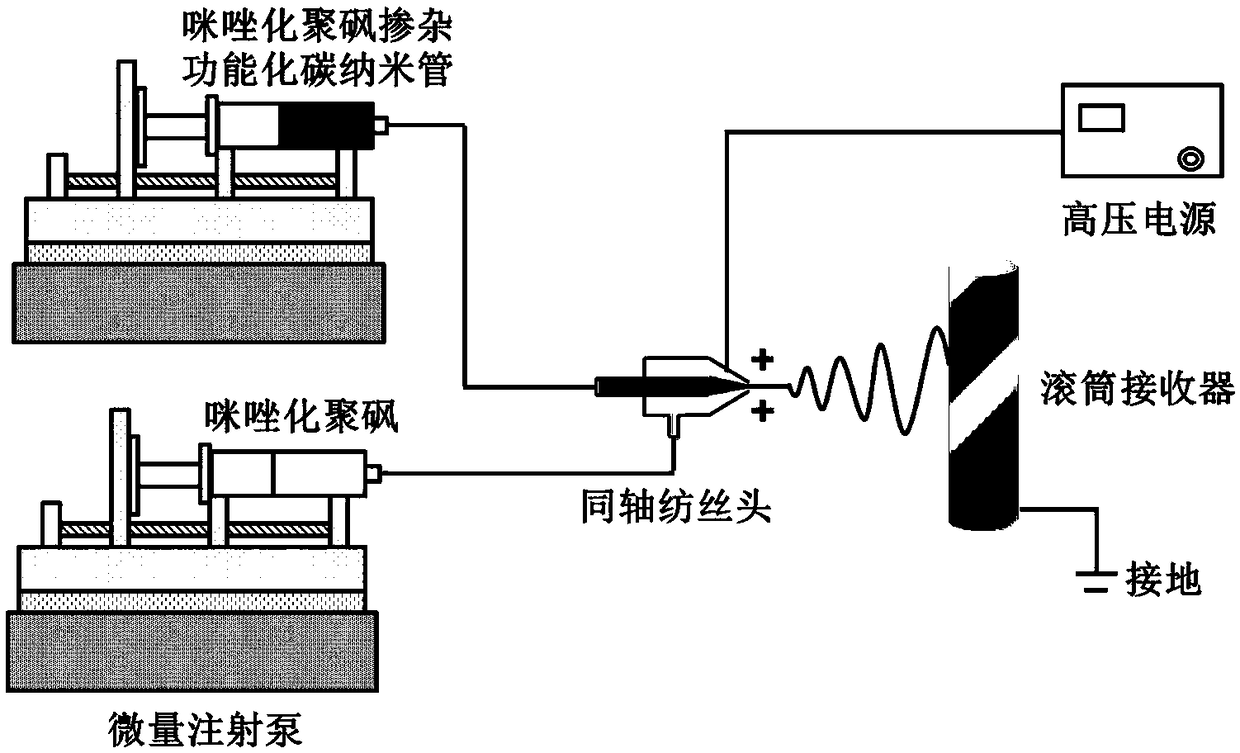

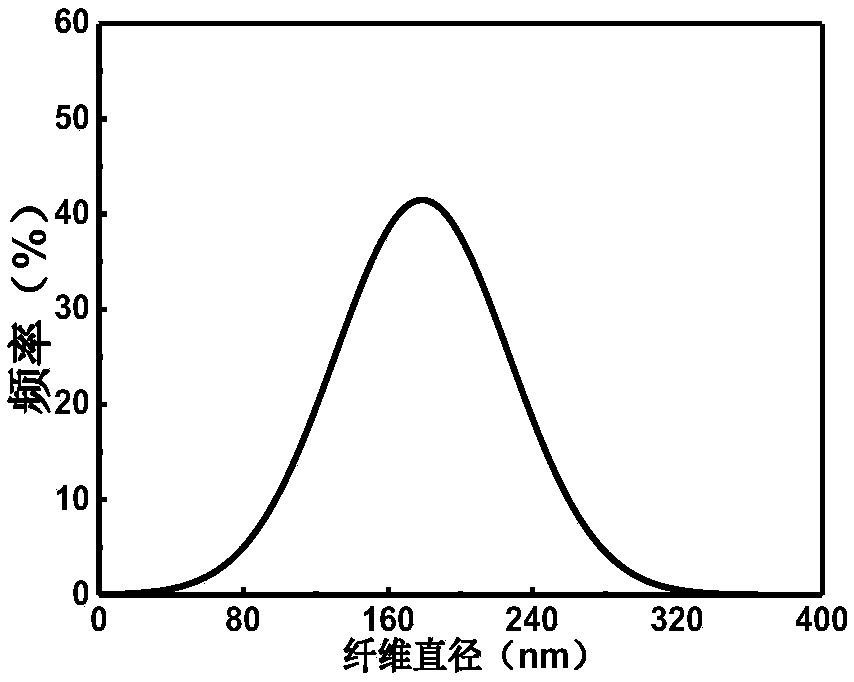

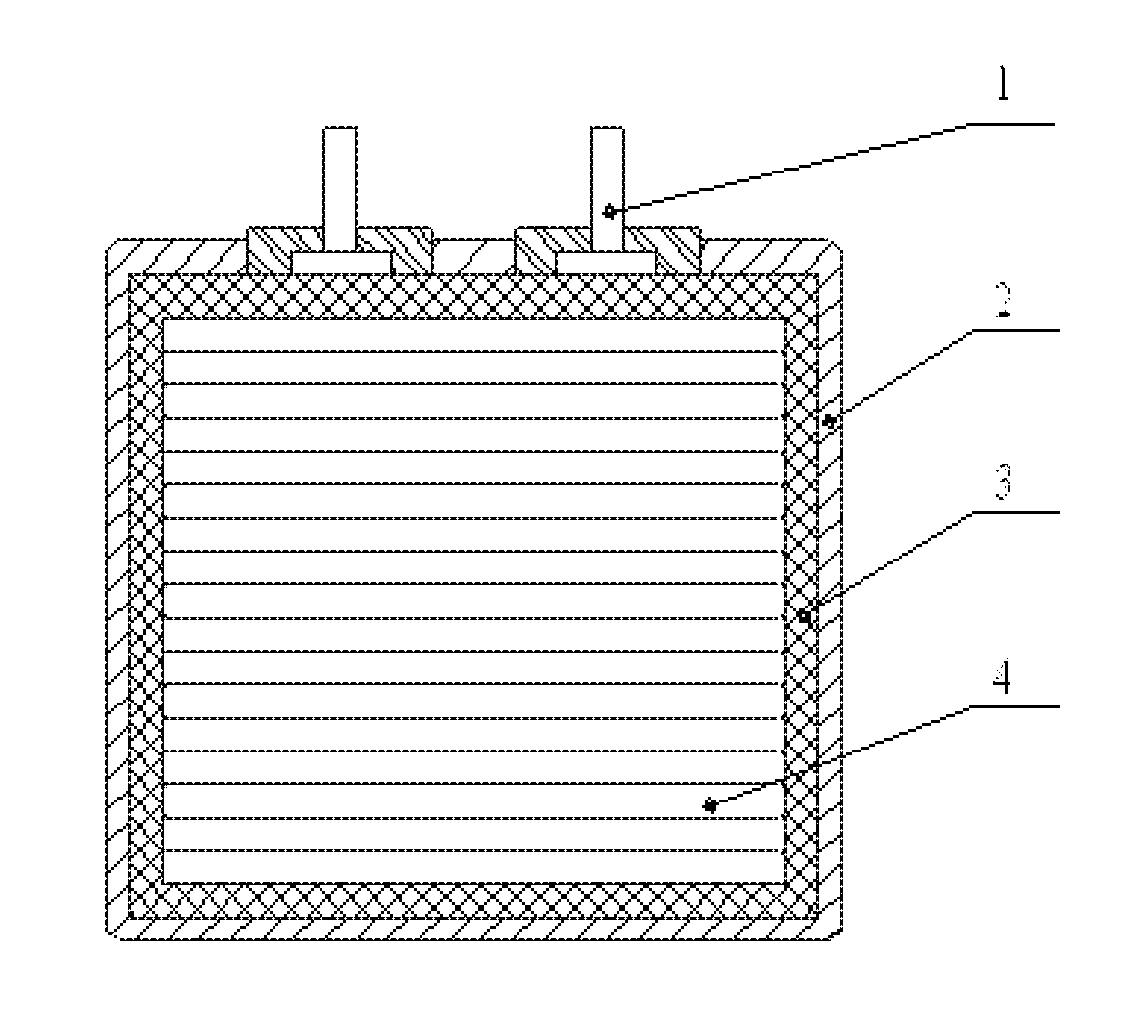

Method for preparing ion conductivity membrane for flow battery through electrostatic spinning

ActiveCN108598520AHigh mechanical strengthIncreased swelling resistanceShrinkingNanotechnologySwelling capacityCarbon nanotube

The invention belongs to the technical field of electrochemical engineering and relates to a method for preparing an ion conductivity membrane for a flow battery through electrostatic spinning. In a high-voltage electric field, a carbon nanotube-doped non-fluorinated cation exchange polymer is dispersed into a spinning solution of an N,N-dimethyl formamide or N,N-dimethyl acetamide solvent; the spinning solution forms electrospun nanofiber on a receiving plate through the electrostatic force traction of a spinning nozzle to obtain the electrospun nanofiber with a three-dimensional network structure; and then solvent steam bath, hot pressing and protonation are carried out to prepare a compact membrane with ionic conductivity for the flow battery. Ions are conducted along the axial direction of the fiber to form a long-range ordered conducting channel; penetration of vanadium ions through a hydrophilic channel is significantly reduced through excellent ion barrier property of a carbon nanotube; and the electrospun membrane has relatively high mechanical strength and swelling resistance through fibration, therefore, the membrane disclosed by the invention obtains relatively high charge-discharge property of an all-vanadium flow battery.

Owner:DALIAN UNIV OF TECH

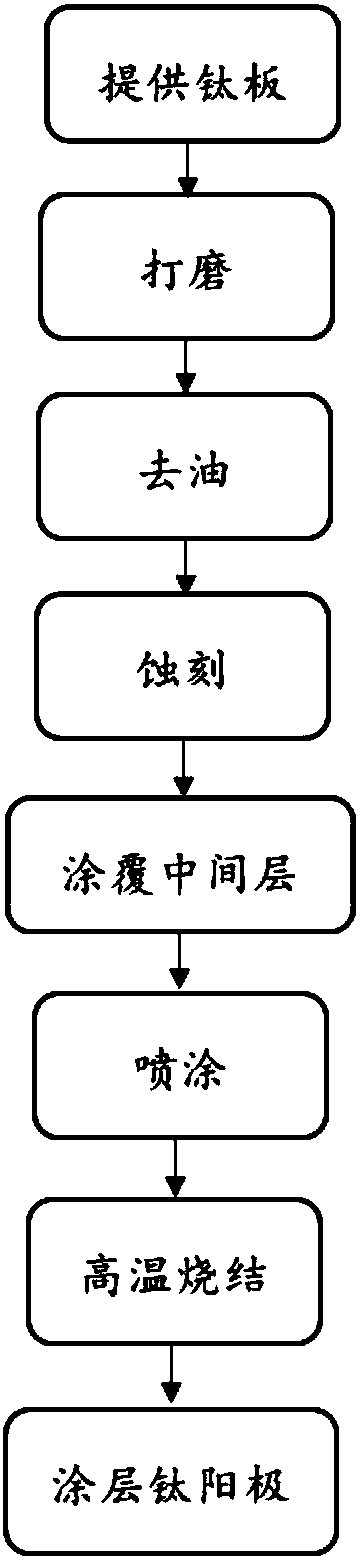

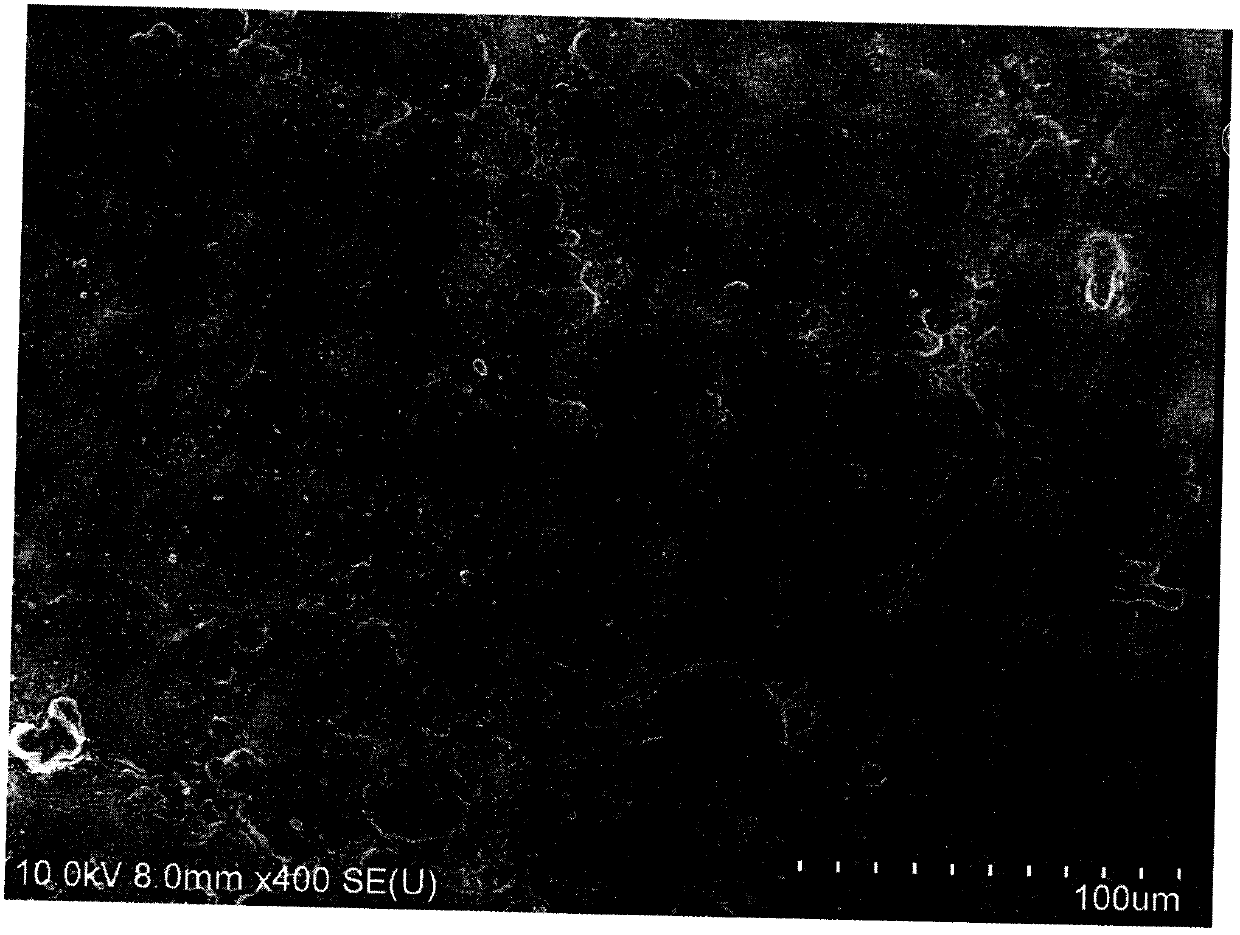

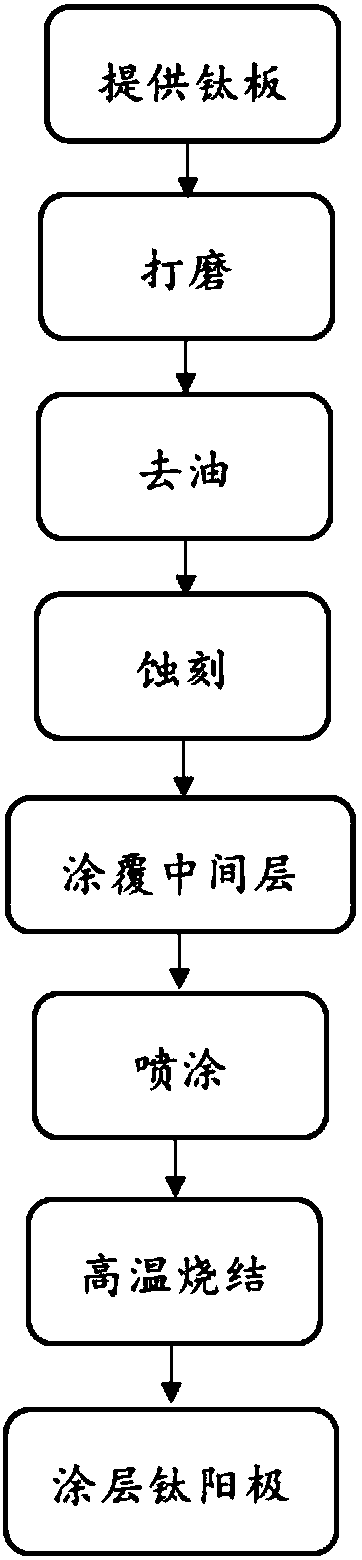

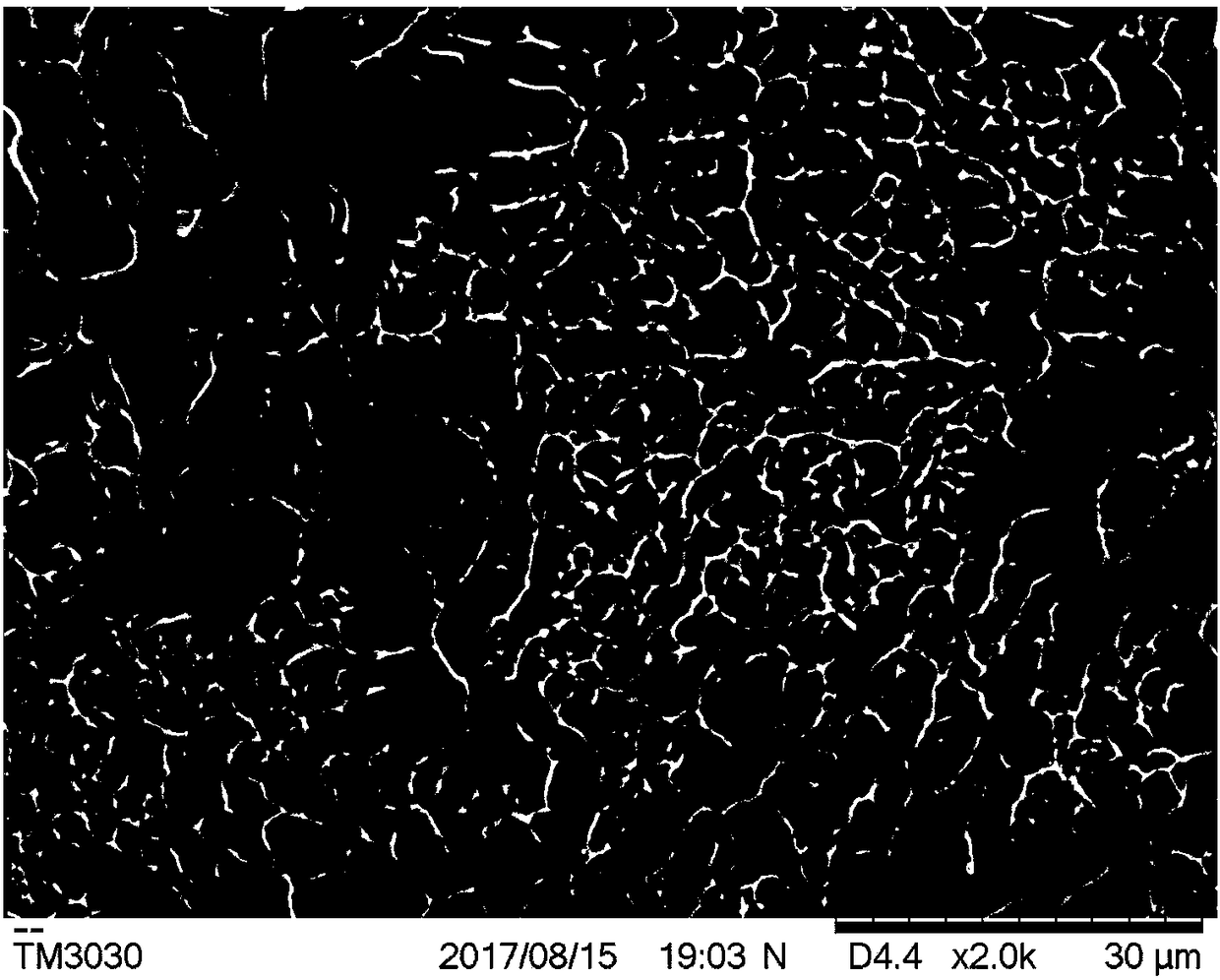

Coated titanium anode and spraying pyrolysis preparation method thereof

ActiveCN107779847AOvercome the technical flaw of short lifespanLow costLiquid/solution decomposition chemical coatingSlurryMaterials science

The invention belongs to the field of preparing electrodes for electrochemical engineering, and more specifically, relates to a coated titanium anode and a spraying pyrolysis preparation method thereof. The method includes following steps: (1), coating the surface of a titanium plate after being pretreated with an antioxidation layer; (2), controlling temperature of the titanium plate to 250-300 DEG C, and atomizing and spraying electrode preparation raw material slurry onto the surface of the antioxidation layer of the titanium plate; (3), sintering the titanium plate at high temperature to obtain the coated titanium anode. The coated titanium anode is prepared by combining spraying technology with step-by-step thermal treatment, so that the technical defect of short service life of electrodes caused by the fact that coatings are prone to dry-cracking when being baked at high temperature in a brush-coating method in the prior art is overcome ingeniously; quick and accurate preparationof the coated titanium anode is realized, preparation cost is low, and product quality is controllable. On the premise that performance is ensured, coating amount of precious metal is lowered greatly, cost of the coated titanium plate is lowered remarkably, and expansion and parity of applying the coated titanium anode are facilitated.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION +1

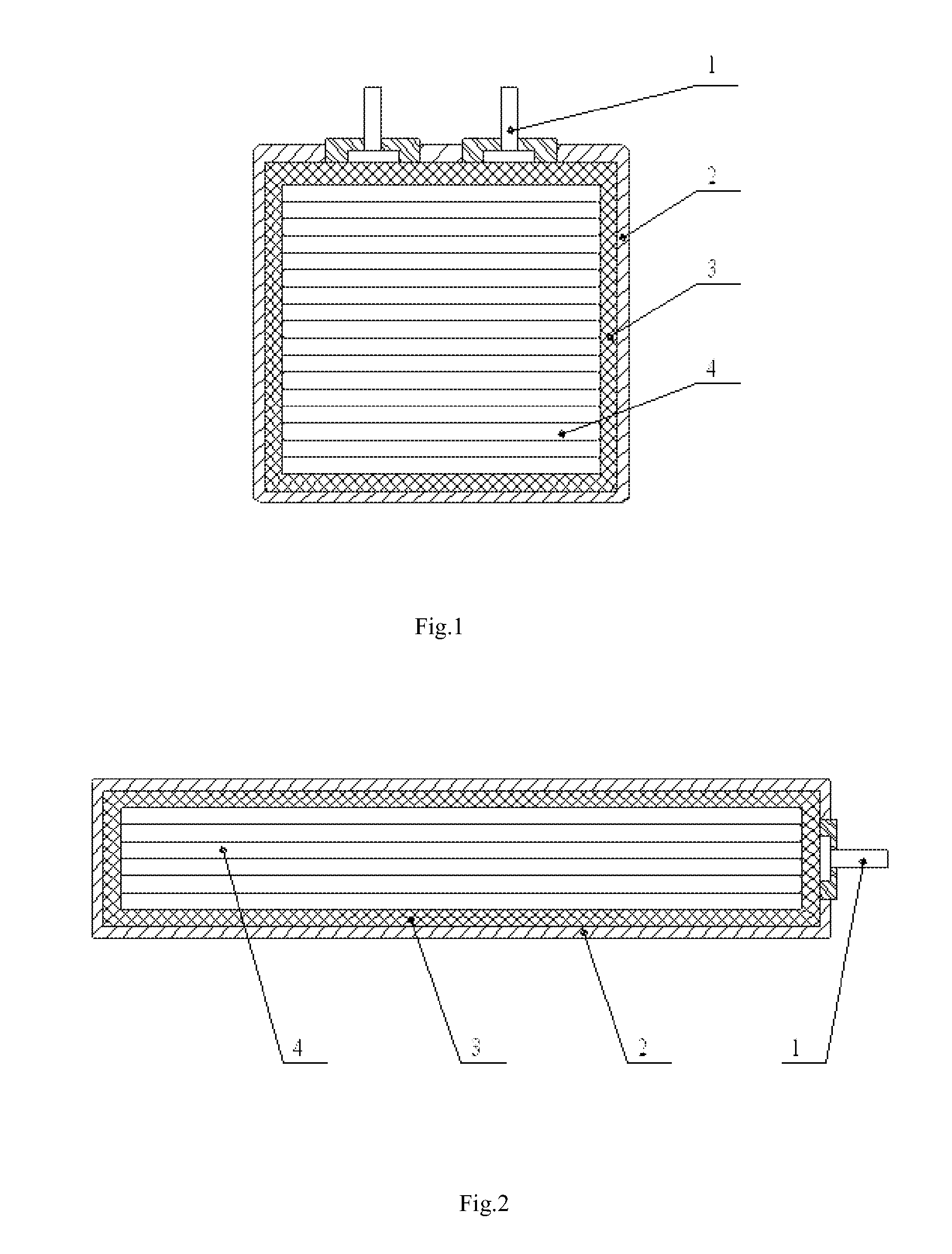

Solid-state chemical current source and a method for increasing a discharge power

InactiveUS20080268332A1Prolong high power discharge timeReduce heat lossDeferred-action cellsSmall-sized cells cases/jacketsElectrical conductorThermodynamics

The invention relates to a solid-state chemical current source and to a method for increasing a discharge power thereof. The inventive current source can be used in electrochemical engineering, in particular for primary and secondary solid-state chemical power sources, which are based on solid ion conductors and exhibit a high discharge power and for a method for increasing the said discharge power. The solid-state chemical current source comprises a body provided with current leading-out wires and solid-state galvanic cells which are arranged therein, are connected to the current leading-out wires, are based on solid ion conductors and perform the function of heating elements. A heat insulation for reducing heat losses of the heated galvanic cells is arranged inside and\or outside the body. The inventive method for increasing the discharge power of the solid-state chemical current source by heating it consists in using the heat produced by the electric current flowing through the galvanic cells and in maintaining the hot state of the said galvanic cells during the discharge. The said invention makes it possible to obtain a solid-state chemical current source exhibiting a high discharge power, a low self-discharge (about 1-3% per year), a long-term power storage and to increase energy characteristics in such a way that they are equal to or greater than 600 Watt-hour / dm3.

Owner:THE POTANIN INST

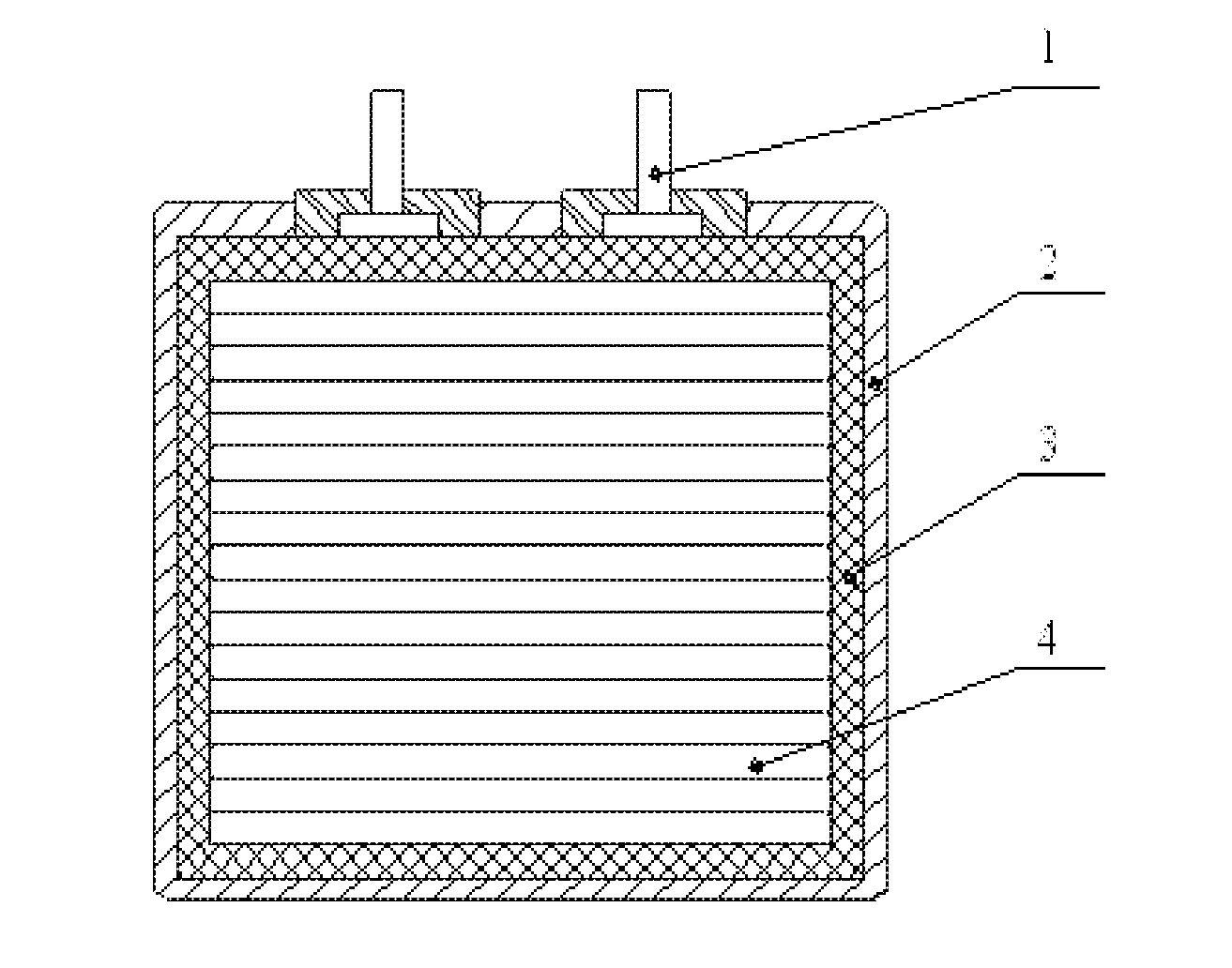

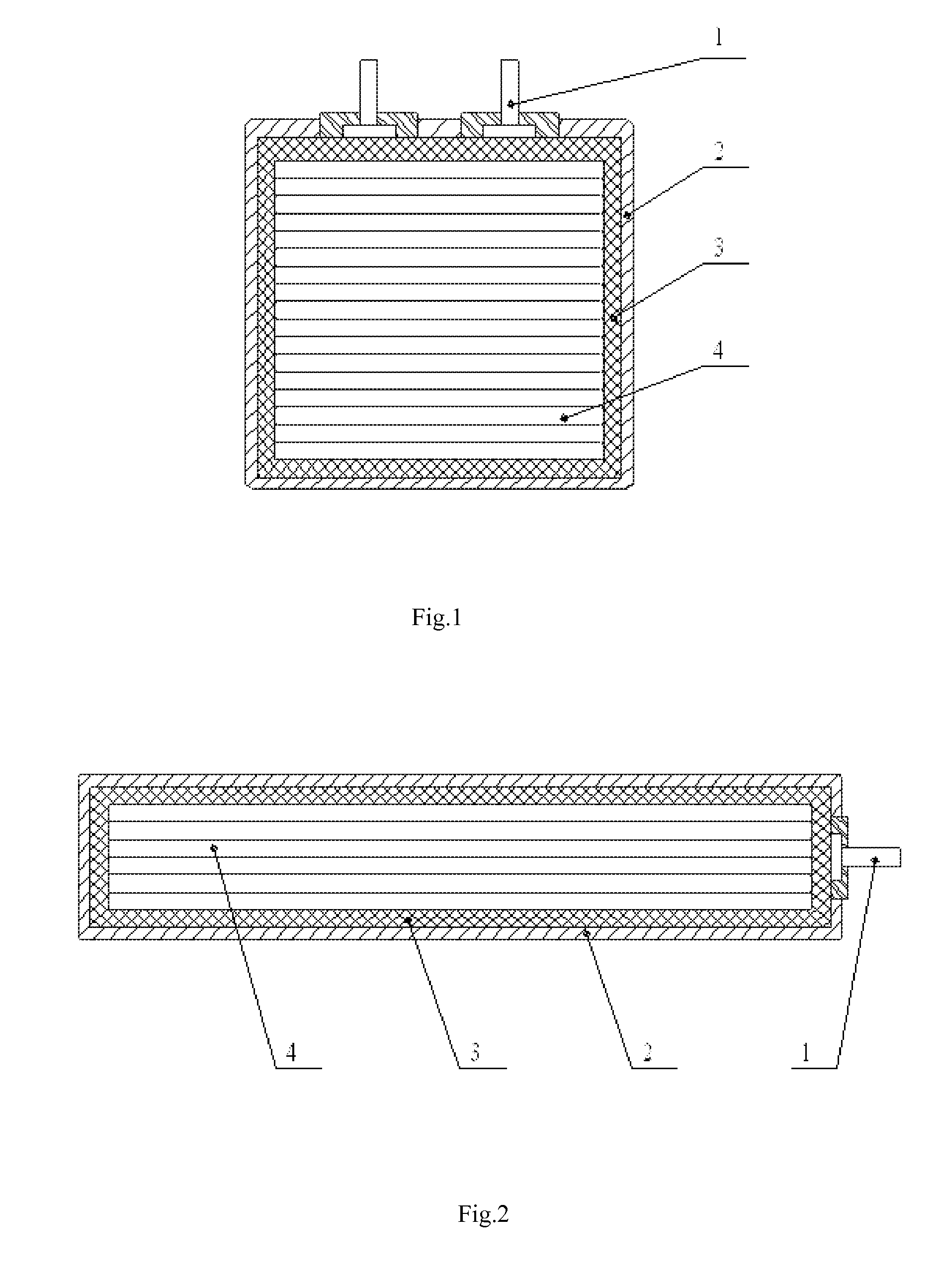

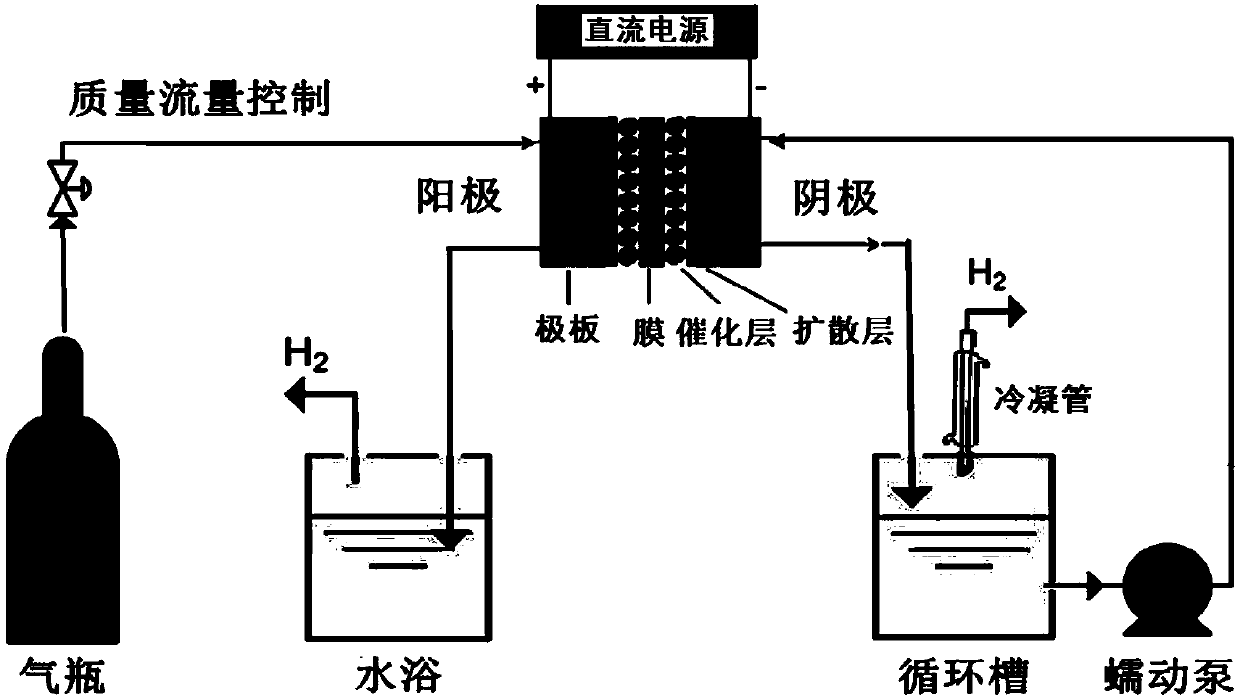

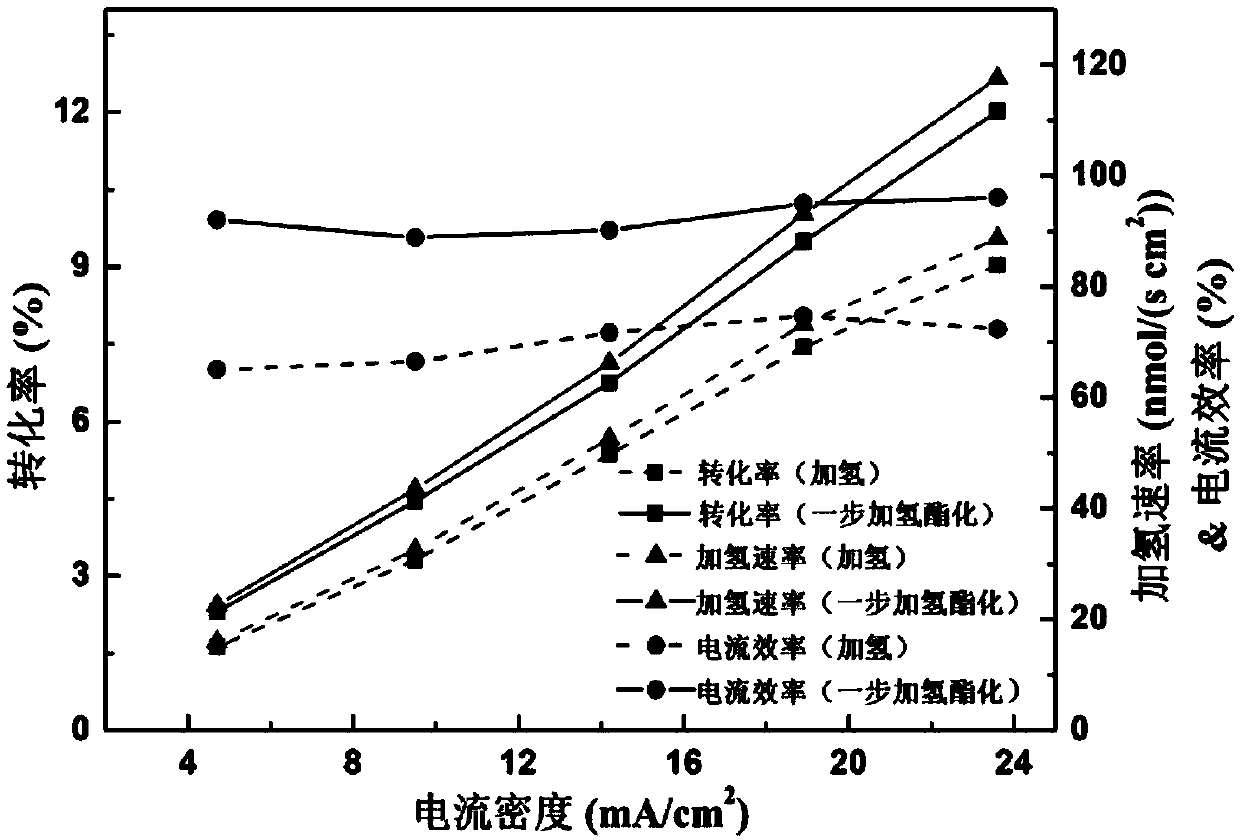

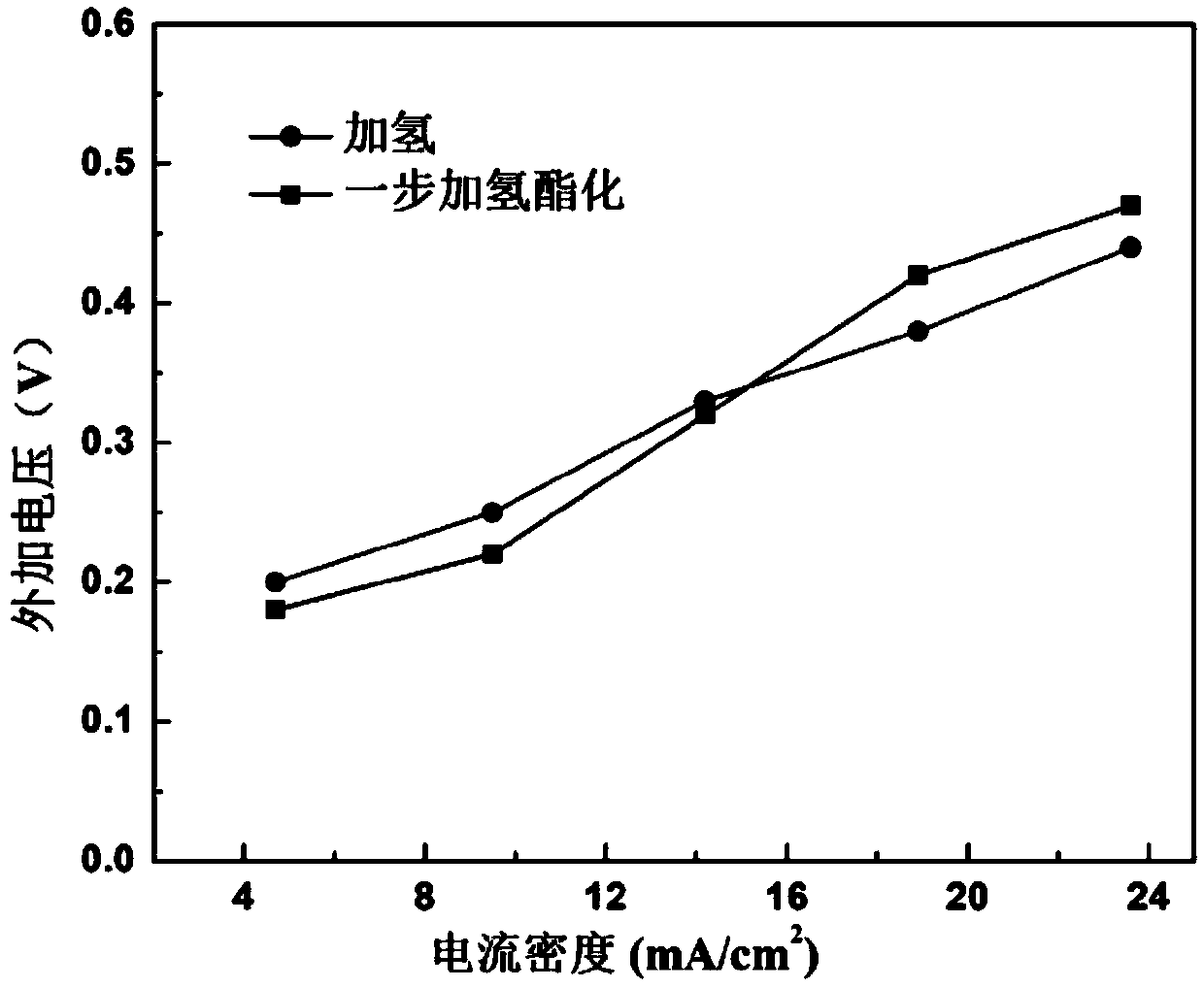

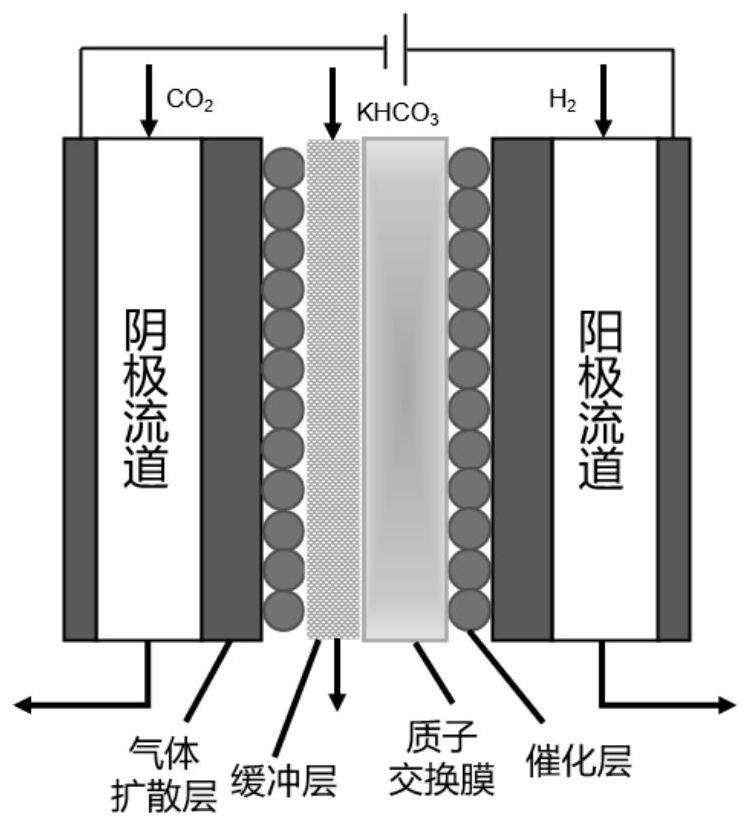

Method of one-step hydrogenation esterification between ketone and carboxylic acid in electrochemical hydrogen pump reactor

ActiveCN108677210ALarge specific surface areaLarge reaction interfaceElectrolysis componentsOrganic chemistryAlcoholHydrogenation reaction

The invention belongs to the technical field of electrochemical engineering, and relates to a method of one-step hydrogenation esterification between ketone and carboxylic acid in an electrochemical hydrogen pump reactor. In an electrochemical hydrogen pump reactor, when electrical power is applied, an electrochemical window with extremely low hydrogen is utilized to dissociate hydrogen in the anode, then hydrogen is delivered to the catalysis layer of the cathode to generate in-situ adsorption hydrogen, in-situ adsorption hydrogen and ketone in the cathode circulation liquid carry out hydrogenation reactions directly, the generated alcohols further carry out esterification reactions with carboxylic acids in the cathode circulation liquid; hydrogenation and esterification are carried out in one reactor under a normal pressure, and a synergistic effect is generated.

Owner:DALIAN UNIV OF TECH

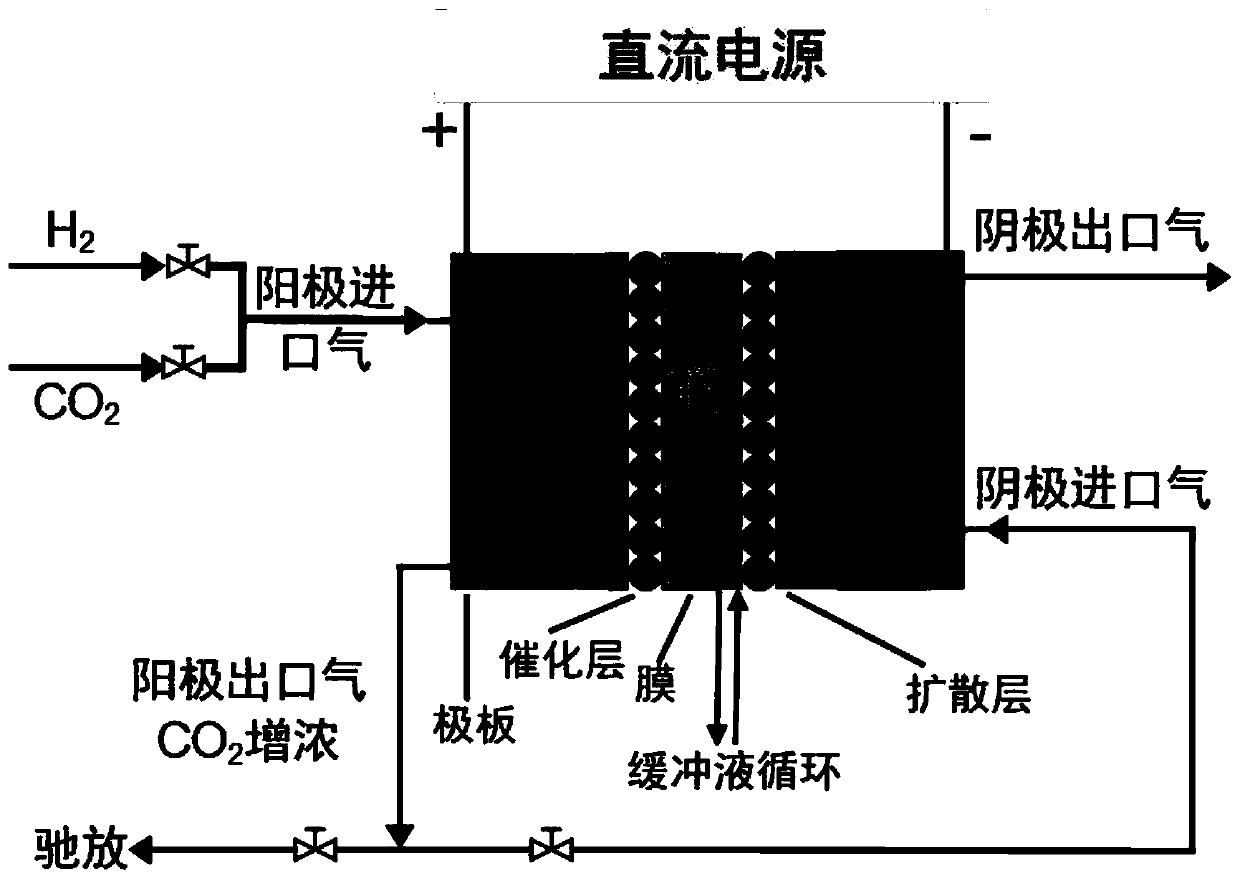

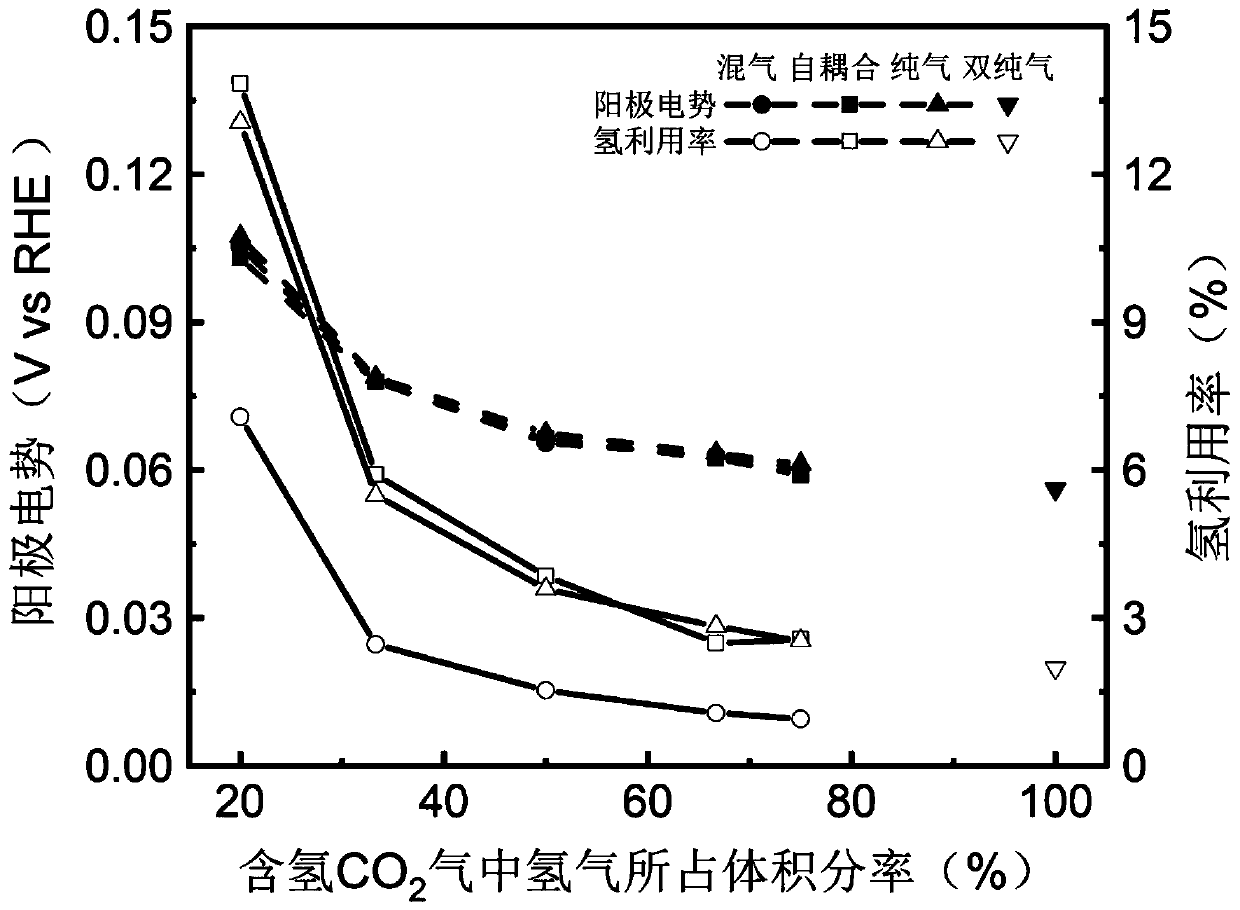

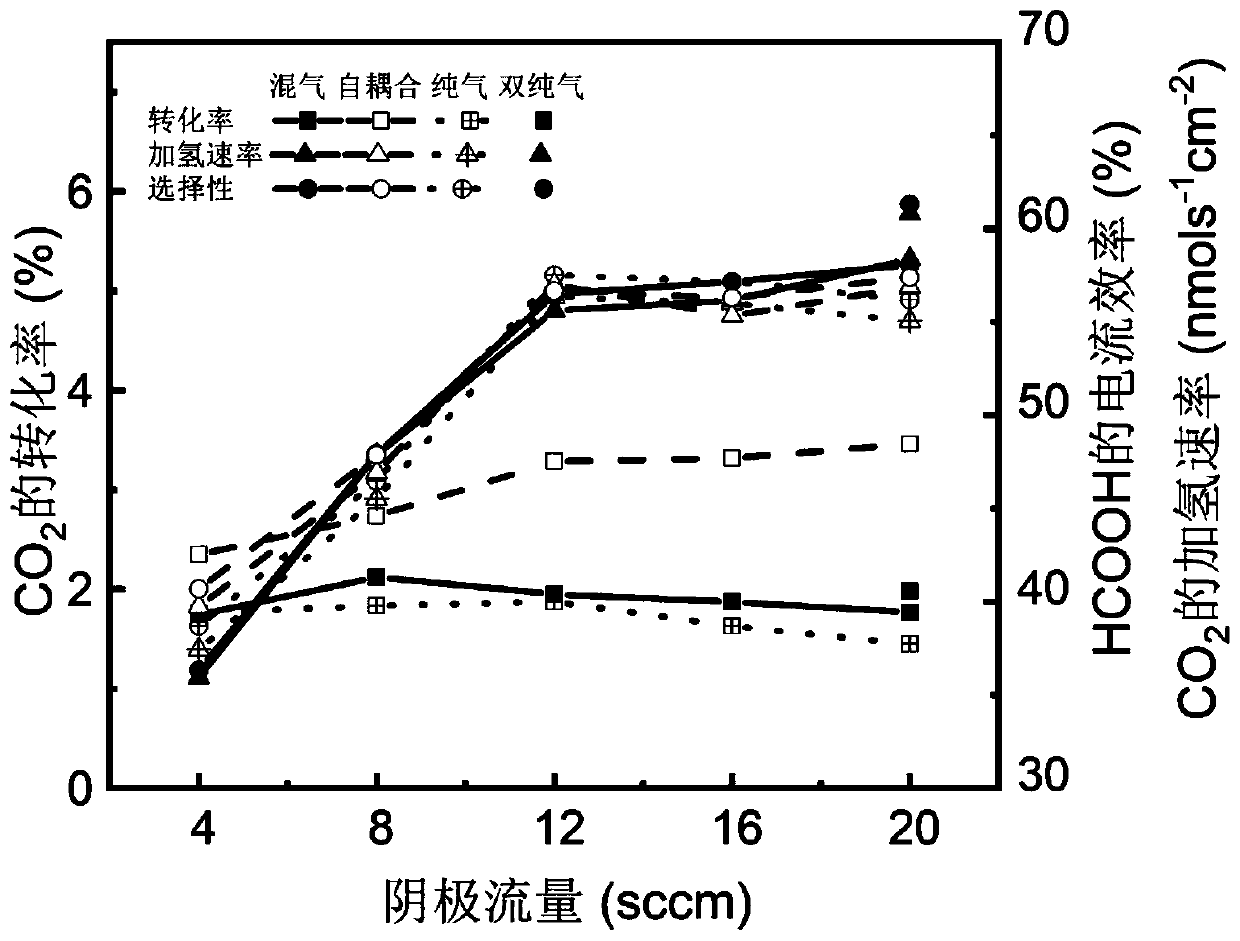

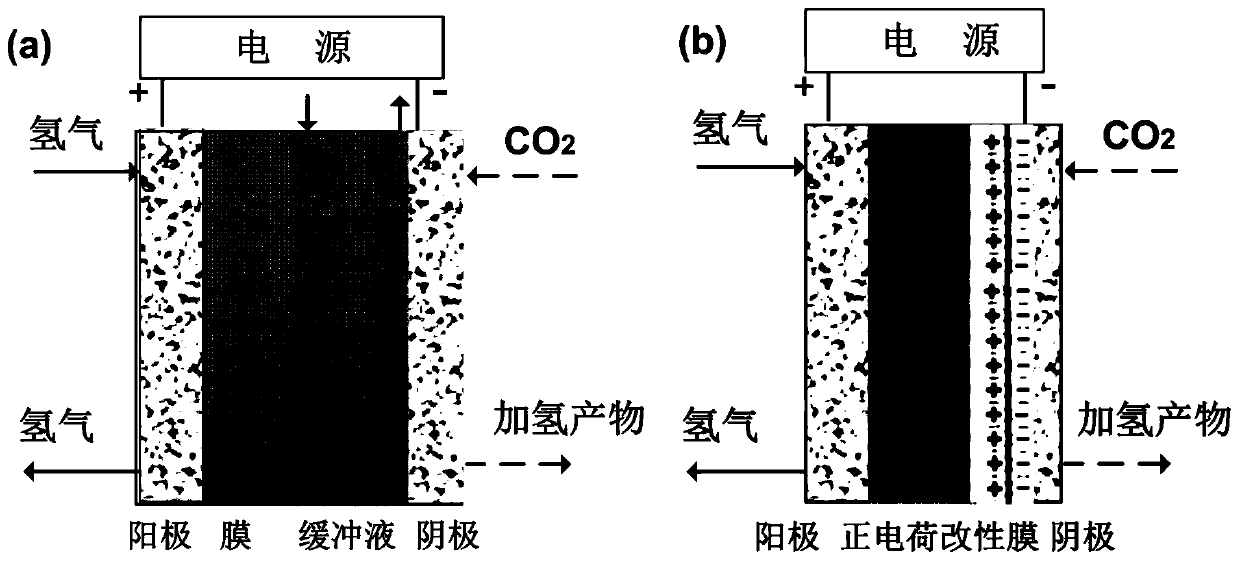

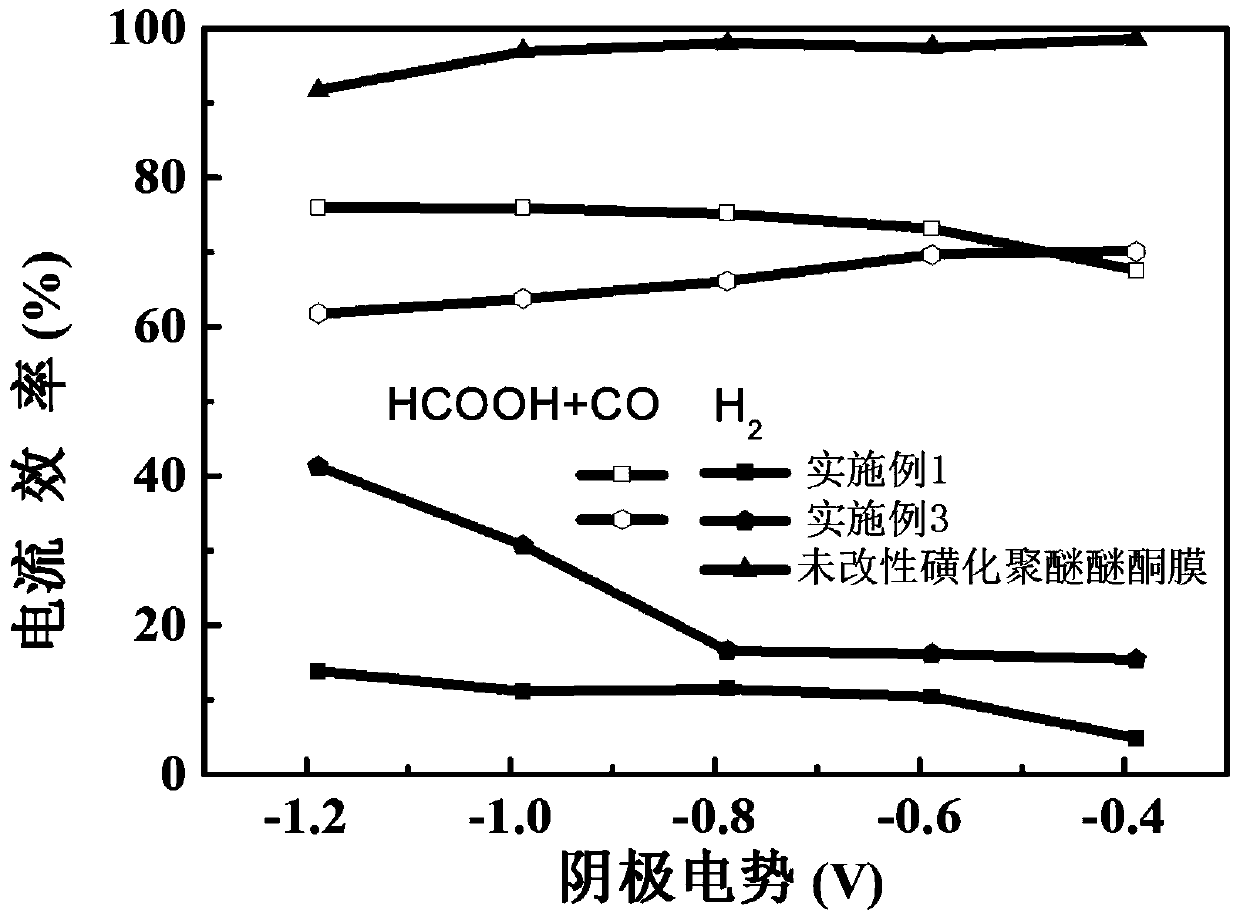

H2/CO2 separation and CO2 hydrogenation self-coupling method

ActiveCN111101146AIncrease profitHigh selectivityElectrolysis componentsOrganic chemistryIn situ adsorptionElectrochemical window

The invention belongs to the technical field of electrochemical engineering, and relates to a H2 / CO2 separation and CO2 hydrogenation self-coupling method. In an electrochemical hydrogen pump, H2 / CO2mixed gas is fed from an anode, anode outlet gas is introduced into a cathode to serve as a raw material, and cathode CO2 hydrogenation is achieved. When electric energy is externally added at normaltemperature and normal pressure, high selectivity and controllable dissociation of the hydrogen at the anode are realized by utilizing an extremely low electrochemical window of hydrogen, and generated hydrogen protons are transferred to a cathode catalyst layer to generate in-situ adsorption hydrogen to participate in cathode CO2 hydrogenation. CO2 in the anode outlet mixed gas is enriched through hydrogen transmembrane transmission and is directly used as cathode feed, so that cathode CO2 catalytic hydrogenation is realized. According to the invention, hydrogen separation and CO2 hydrogenation of the same strand of H2 / CO2 feed gas are synchronously carried out in the same reactor, and synergistic interaction is realized, so that the process and the device are simplified, and the utilization rate of the H2 / CO2 feed gas is improved.

Owner:DALIAN UNIV OF TECH

Method for preparing carbon nanotube reinforced anion exchange membrane through coaxial electrostatic spinning

The invention belongs to the technical field of electrochemical engineering, and relates to a method for preparing a carbon nanotube reinforced anion exchange membrane through coaxial electrostatic spinning. Functionalized carbon nanotubes are fixed to the inside of nanofiber by using coaxial electrostatic spinning, and the dense membrane with three-dimensional network morphology is prepared through solvent steam bath, hot pressing and hydroxyl ion exchange. The functionalized carbon nanotubes are fixed to the inside of the nanofiber and are oriented in the axial direction of the nanofiber, and an imidazole functional group on the surface promotes aggregation of ion clusters in the membrane. Therefore, compatibility of organic / inorganic components is effectively enhanced, the doping amountof the carbon nanotubes is improved, and the hydroxyl ion conductivity, mechanical strength and water-resistant swelling resistance of the membrane are remarkably improved.

Owner:DALIAN UNIV OF TECH

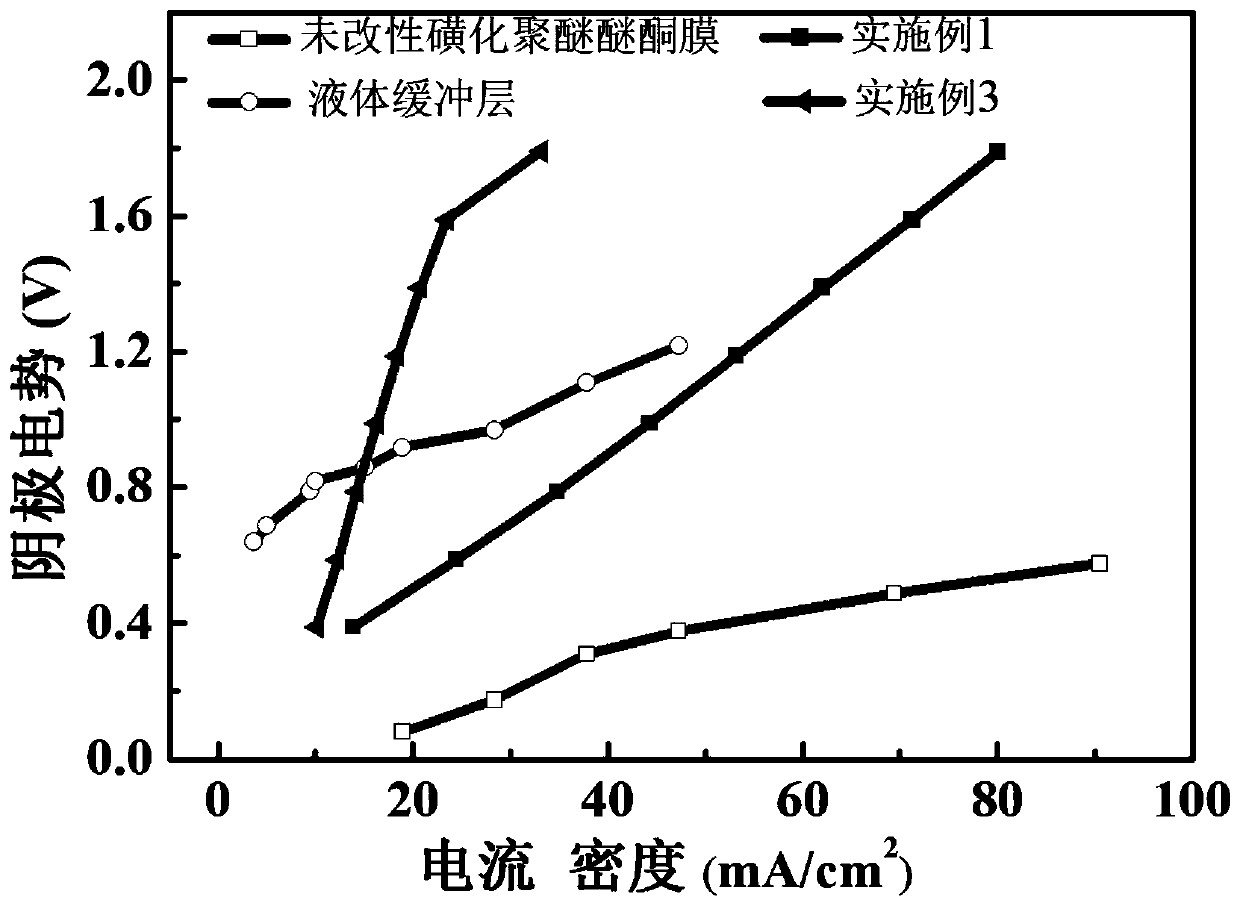

Method for controlling cathode potential in electrochemical hydrogen pump CO2 hydrogenation reactor by film method

ActiveCN110311161AHigh cathodic potentialAvoid liquid environmentFuel cellsHydrogenation reactionProton

The invention belongs to the technical field of electrochemical engineering and relates to a method for controlling the cathode potential in an electrochemical hydrogen pump CO2 hydrogenation reactorby a film method. The method is characterized in that a positive charge-modified proton exchange film is utilized in place of a liquid buffer layer, when electric energy is applied to the electrochemical hydrogen pump CO2 hydrogenation reactor, hydrogen protons generated by anode hydrogen dissociation pass through the positive charge-modified proton exchange film, and in-situ adsorbed hydrogen generated at a cathode undergoes hydrogenation reaction with CO2; positive charges are introduced into the proton exchange film through ion displacement or layer-by-layer self-assembling, the positive charges in the film migrate and accumulate toward the cathode under the action of an electric field to form a double electrode layer with the cathode, the cathode potential of CO2 hydrogenation is regulated, and CO2 hydrogenation reaction is promoted. The method is advantaged in that the modified film is utilized in place of the liquid buffer layer, the liquid phase environment can be avoided, interface problems are eliminated, the higher cathode potential can be achieved, moreover, the Donnan repulsion effect of the positive charges to the hydrogen protons is utilized, the hydrogen evolution reaction is stably inhibited for a long time, and relatively high CO2 hydrogenation efficiency is achieved.

Owner:DALIAN UNIV OF TECH

Solid-state chemical current source and a method for increasing a discharge power

InactiveUS20120119706A1Reduce heat lossSimplification of the current source structureBatteries circuit arrangementsSmall-sized cells cases/jacketsElectrical conductorGalvanic cell

A solid-state chemical current source and a method for increasing a discharge power thereof are disclosed. The current source can be used in electrochemical engineering, in particular for primary and secondary solid-state chemical power sources. The solid-state chemical current source comprises a body provided with current leading-out wires and solid-state galvanic cells which are arranged therein, are connected to the current leading-out wires, are based on solid ion conductors and perform the function of heating elements. A heat insulation for reducing heat losses of the heated galvanic cells is arranged inside and\or outside the body. The inventive method for increasing the discharge power of the solid-state chemical current source by heating it consists in using the heat produced by the electric current flowing through the galvanic cells and in maintaining the hot state of the said galvanic cells during the discharge.

Owner:THE POTANIN INST

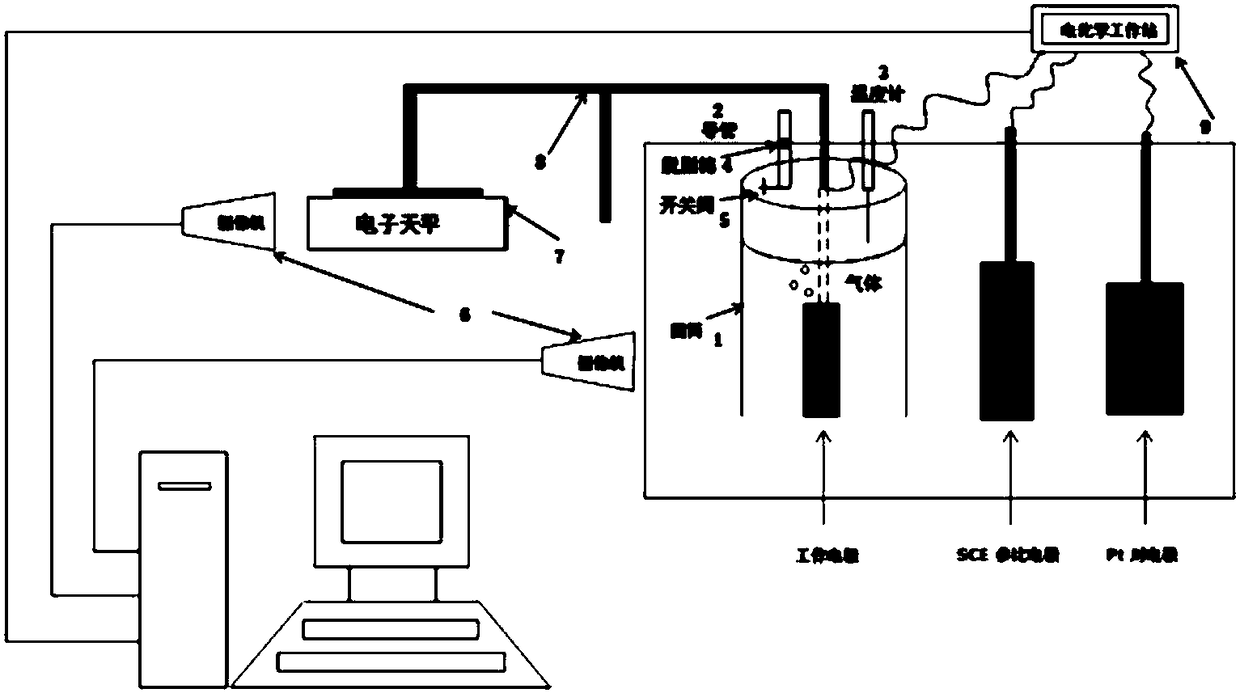

Method and device for real-time synchronous tracking of hydrogen evolution amount and electrochemical testing

ActiveCN109142209AAccurately calculate the amountRealize synchronous monitoringWeather/light/corrosion resistanceHydrogenMonitoring system

The invention belongs to the field of electrochemistry, particularly relates to a method and device for real-time synchronous tracking of hydrogen evolution amount and electrochemical testing, and provides a method for synchronous tracking of hydrogen evolution amount and electrochemical testing and a device used in the method. The method can achieve real-time tracking. Firstly, two cameras are added on the basis of generating hydrogen through measuring electrode reaction, real-time camera shooting recording is carried out on the hydrogen evolution amount and the corrosion situation of the electrode surface, and a relationship between potential current change and the hydrogen evolution amount can be obtained at any time in an experiment by combing an electrochemical on-line monitoring system.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

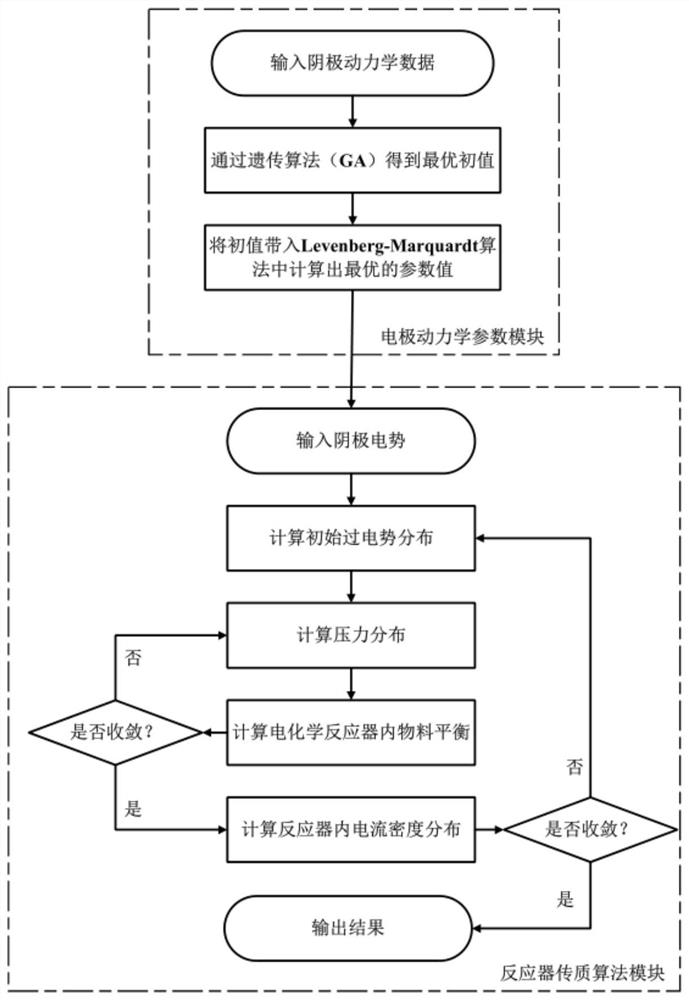

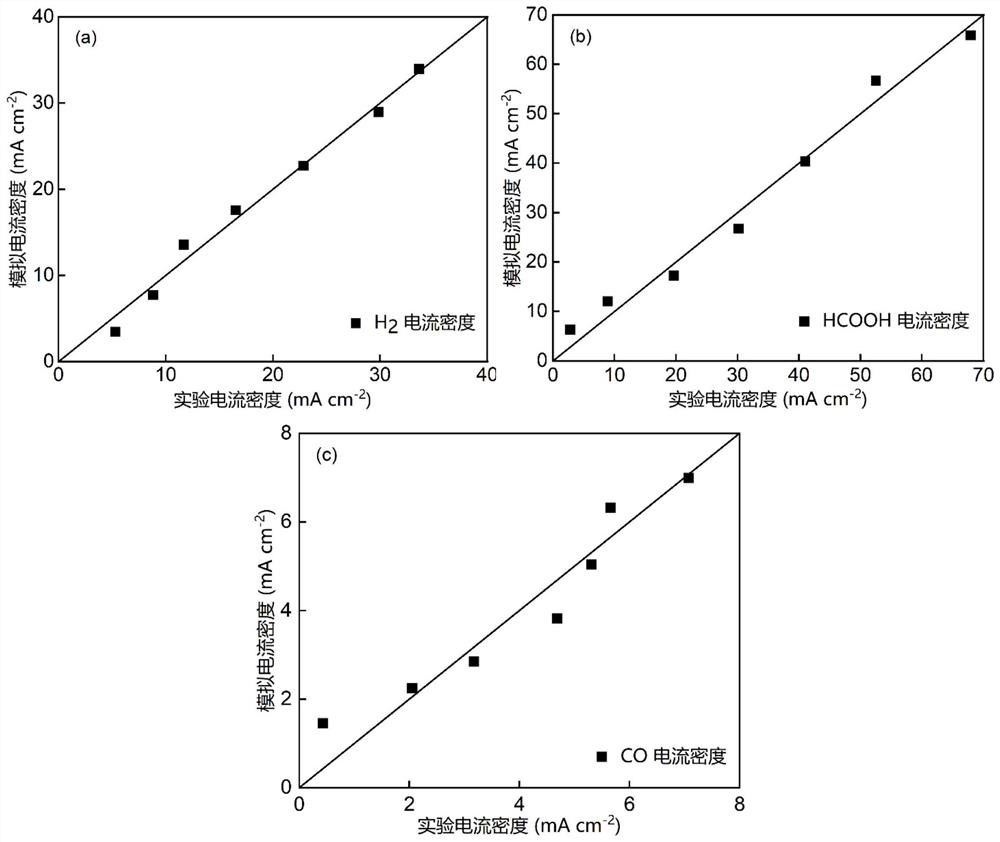

Modeling method for kinetic mass transfer model of CO2 electrochemical hydrogenation reactor

PendingCN112687348ASimple and accurate simulationEasy to integrateGenetic modelsComputational theoretical chemistryMATLABSide reaction

The invention relates to a modeling method for a kinetic mass transfer model of a CO2 electrochemical hydrogenation reactor, and belongs to the technical field of electrochemical engineering. The method comprises the following steps: S1, establishing an electrode kinetic model for generating formic acid, CO and a cathode hydrogen evolution side reaction through CO2 electro-catalysis; S2, optimizing and solving model parameters of electrode dynamics, wherein an optimized objective function is a minimum value of residual sum of squares of current densities of formic acid, carbon monoxide and hydrogen calculated by the model and an experimental result; S3, using a nonlinear optimization function in MATLAB for solving the model parameters; and S4, establishing a mass transfer coupling electrode kinetic model for the CO2 electrochemical hydrogenation reactor, discretizing a control equation of the gas mass transfer model by adopting a finite difference method, and realizing coupling calculation of cathode dynamics and a mass transfer equation by calculating overpotential distribution of each product of the cathode. The method is good in universality and has guiding significance for design of similar reactors.

Owner:DALIAN UNIV OF TECH

A kind of preparation method of niobium carbide and tantalum carbide electrode

InactiveCN103482625BReduce stepsSimple processCarbon compoundsLead-acid accumulator electrodesEpoxyElectrolysis

The invention belongs to the field of electrochemistry engineering and industry, and particularly to a niobium carbide and tantalum carbide electrode preparation method, wherein a plate, a sheet, foil or a wire of metal niobium or tantalum is adopted, and is subjected to a reaction with carbon, carbon monoxide, an epoxy resin and the like in the protection of gas with a temperature of 600-1200 DEG C so as to obtain a compact niobium carbide and tantalum carbide layer on the outer surface of niobium and tantalum, wherein the internal is the metals such as niobium and tantalum, and the obtained material has the advantages of flexibility, strength and the like of the metal, has the electric conduction niobium carbide and tantalum carbide layer adopted as the strong corrosion resistance layer, and can be used as a dimensionally stable anode used in sulfuric acid, hydrochloric acid, chlor-alkali electrolysis and other electrolytes. The preparation method has advantages of less operation steps, simple process and stable quality, and is especially suitable for preparation of redox flow batteries, secondary batteries, and electrolysis industry electrodes.

Owner:NO 63971 TROOPS PLA

A kind of preparation method of oxide solid electrolyte diaphragm

ActiveCN106384801BAvoid easily deformable problemsReduced Chances of ContaminationFinal product manufactureCell component detailsFree energiesFluid phase

The invention relates to a preparation method of an oxide solid electrolyte membrane, belonging to the fields of electrochemical engineering and ceramic industry. In this method, lithium carbonate or lithium hydroxide is used as a lithium source, the pre-prepared solid electrolyte powder is placed in a crucible, and directly sintered at high temperature to obtain a dense block; the block is cut and polished to obtain a solid electrolyte diaphragm Flakes. This method avoids the complicated mold pressing process in the conventional method. First, the mechanical energy is converted into the surface free energy of the powder particles through ball milling, and then the excessive low melting point lithium salt is melted at high temperature to form a liquid phase covering the surface of the powder particles. , Under the action of surface tension, the powder is automatically agglomerated, the surface free energy is reduced, and a dense solid electrolyte block is formed. The method has the advantages of simple process, smooth and dense finished product, easy scale-up, etc., and is especially suitable for the preparation of oxide solid electrolyte diaphragms in solid-state secondary batteries.

Owner:NO 63971 TROOPS PLA

A kind of coated titanium anode and its spraying pyrolysis preparation method

ActiveCN107779847BOvercome the technical flaw of short lifespanLow costLiquid/solution decomposition chemical coatingSpray pyrolysisSlurry

The invention belongs to the field of preparing electrodes for electrochemical engineering, and more specifically, relates to a coated titanium anode and a spraying pyrolysis preparation method thereof. The method includes following steps: (1), coating the surface of a titanium plate after being pretreated with an antioxidation layer; (2), controlling temperature of the titanium plate to 250-300 DEG C, and atomizing and spraying electrode preparation raw material slurry onto the surface of the antioxidation layer of the titanium plate; (3), sintering the titanium plate at high temperature to obtain the coated titanium anode. The coated titanium anode is prepared by combining spraying technology with step-by-step thermal treatment, so that the technical defect of short service life of electrodes caused by the fact that coatings are prone to dry-cracking when being baked at high temperature in a brush-coating method in the prior art is overcome ingeniously; quick and accurate preparationof the coated titanium anode is realized, preparation cost is low, and product quality is controllable. On the premise that performance is ensured, coating amount of precious metal is lowered greatly, cost of the coated titanium plate is lowered remarkably, and expansion and parity of applying the coated titanium anode are facilitated.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com