Coated titanium anode and spraying pyrolysis preparation method thereof

A technology of spraying pyrolysis and titanium anode, which is applied in the direction of coating, metal material coating process, liquid chemical plating, etc., to achieve the effects of easy industrialization, high dehydration efficiency, rapid and accurate preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

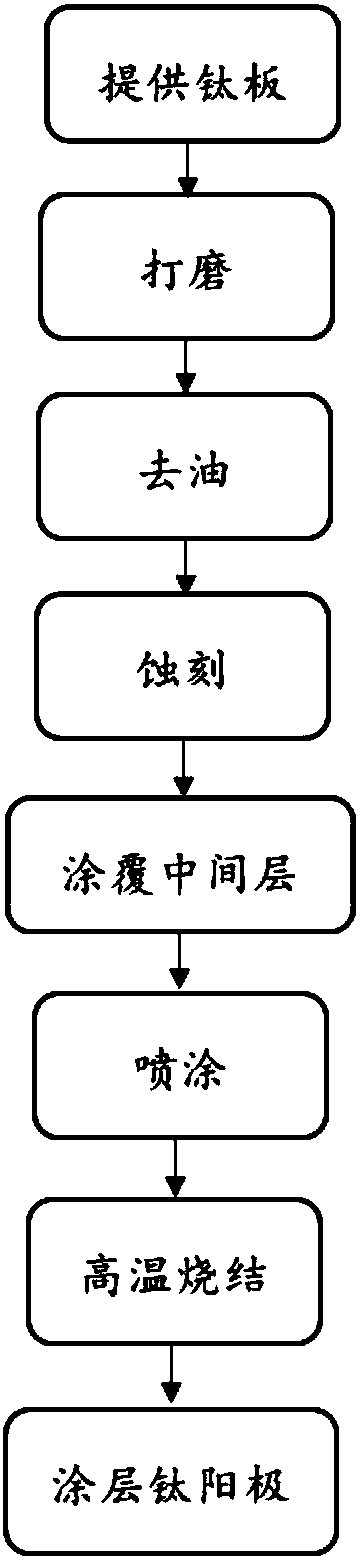

[0043] The invention provides a coating titanium anode spray pyrolysis preparation method, comprising the following steps:

[0044] (1) Pretreatments such as grinding, degreasing and etching are carried out to the titanium plate. The grinding operation is to use sandpaper to polish until metallic luster appears; the degreasing operation is to use lye to wash the titanium plate for 2 to 3 times; The titanium plate is put into acid and boiled for 1-5 hours. The titanium oxide layer on the surface of the pretreated titanium plate is polished off, and the oil stains are cleaned off by degreasing operations. Etching can increase the surface roughness of the titanium plate and enhance the adhesion of the coating.

[0045](2) Coating an anti-oxidation layer, also known as an intermediate layer, on the surface of the pretreated titanium plate. The anti-oxidation layer can be a dense thin film of conductive metal oxide, and its function is to prevent the oxidation of the titanium plat...

Embodiment 1

[0057] In this embodiment, the coating titanium anode spray pyrolysis preparation method mainly includes the following steps:

[0058] Step 1, provide titanium plate, and undergo pretreatment such as grinding, degreasing and etching. Specifically, a 1cm×2cm titanium plate is provided, polished with 240# alumina water-grinding paper until a metallic luster appears, then rinsed three times with lye containing sodium carbonate, rinsed with deionized water, and then boiled in 10wt.% oxalic acid Etch for 2 hours.

[0059] Step 2: Coating an intermediate layer, namely an anti-oxidation layer, on the surface of the titanium plate. Specifically, one side of the titanium plate was spin-coated or brush-coated with a layer of conductive glass film ATO with a thickness of 0.5 μm, and baked in an oven at 400° C. for 10 minutes.

[0060] Step 3, the titanium plate is kept at a set temperature during spraying. Specifically, the titanium plate was kept at 250° C. during spraying.

[0061]...

Embodiment 2

[0073] In this embodiment, the coating titanium anode spray pyrolysis preparation method mainly includes the following steps:

[0074] Step 1, provide titanium plate, and undergo pretreatment such as grinding, degreasing and etching. Specifically, a 1cm×2cm titanium plate is provided, polished with 240# alumina water-grinding paper until a metallic luster appears, then rinsed three times with lye containing sodium carbonate, rinsed with deionized water, and then boiled in 10wt.% oxalic acid Etch for 2 hours.

[0075] Step 2: Coating an intermediate layer, namely an anti-oxidation layer, on the surface of the titanium plate. Specifically, one side of the titanium plate was spin-coated or brush-coated with a layer of conductive glass film ATO with a thickness of 0.2 μm, and baked in an oven at 400° C. for 10 minutes.

[0076] Step 3, the titanium plate is kept at a set temperature during spraying. Specifically, the titanium plate was kept at 275°C while spraying.

[0077] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com