Preparation method of lithium lanthanum niobium oxygen solid electrolyte diaphragm

A solid electrolyte and diaphragm technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolyte immobilization/gelation, etc., can solve the problems of easy contamination of samples, complex and cumbersome process, time-consuming and labor-intensive, etc. The method is simple and successful The effect of high rate and low grain boundary resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

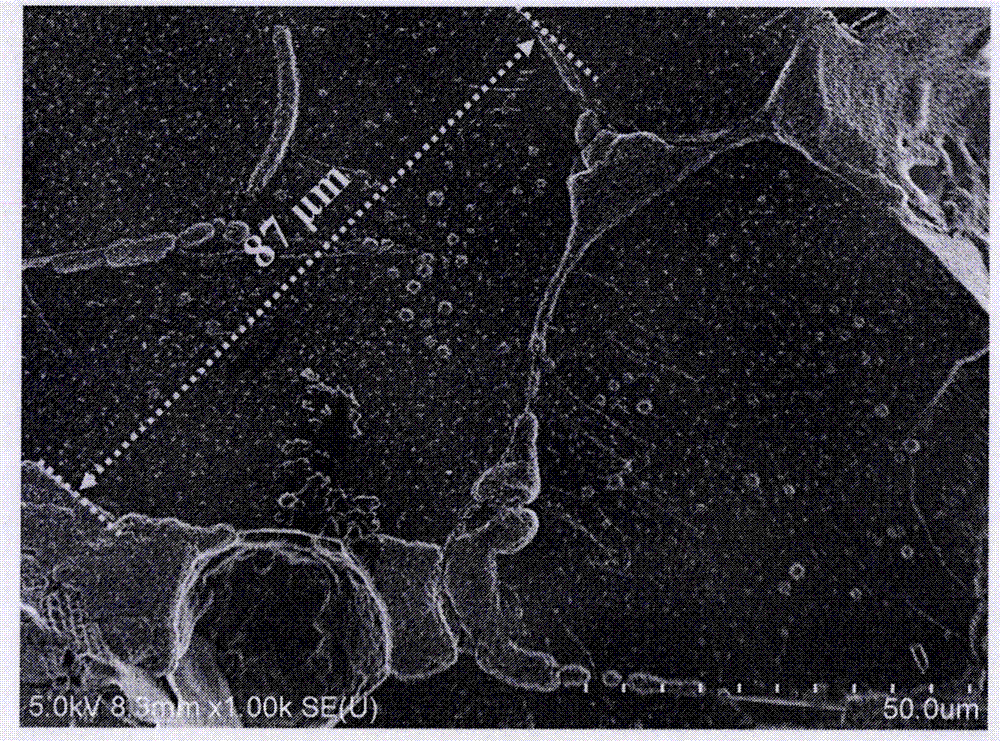

[0014] Lithium carbonate (Li 2 CO 3 , excess 15%) 14.6031g, lanthanum oxide (La 2 o 3 ) 23.2793g and niobium oxide (Nb 2 o 5 ) 10.0966g, put it in a ball mill jar, add 20ml of absolute ethanol, the ball mill speed is 400 rpm, and ball mill for 10h; the obtained slurry is dried at 80°C for 10h, and ground to obtain the primary oxide material; the primary material is placed in a control In the corundum crucible in the heating furnace, the temperature is rapidly raised to 1150°C and kept for 10 hours; the primary material after high temperature treatment is directly crushed and mixed evenly by grinding, ball milling, etc., and sieved with a 100-mesh sieve to obtain lithium lanthanum niobium oxide powder , the average particle size is about 12 microns measured by a Malvern laser particle size analyzer; the obtained powder is placed in a cylindrical corundum crucible, placed in a temperature-controlled furnace, and sintered in air at a high temperature of 1150 ° C for 10 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com