Preparation method of metal oxide coating anode

A technology of oxide coating and anode, which is applied in the field of electrochemistry, can solve the problems of changing the living environment of marine organisms and the adverse effects of the marine environment, and achieve the effects of long service life, environmental friendliness and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

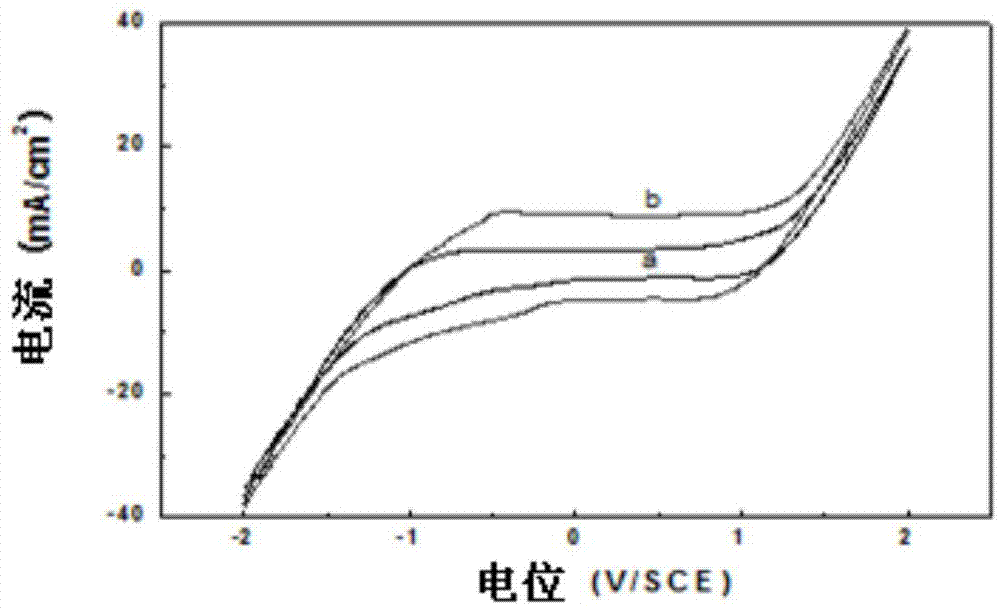

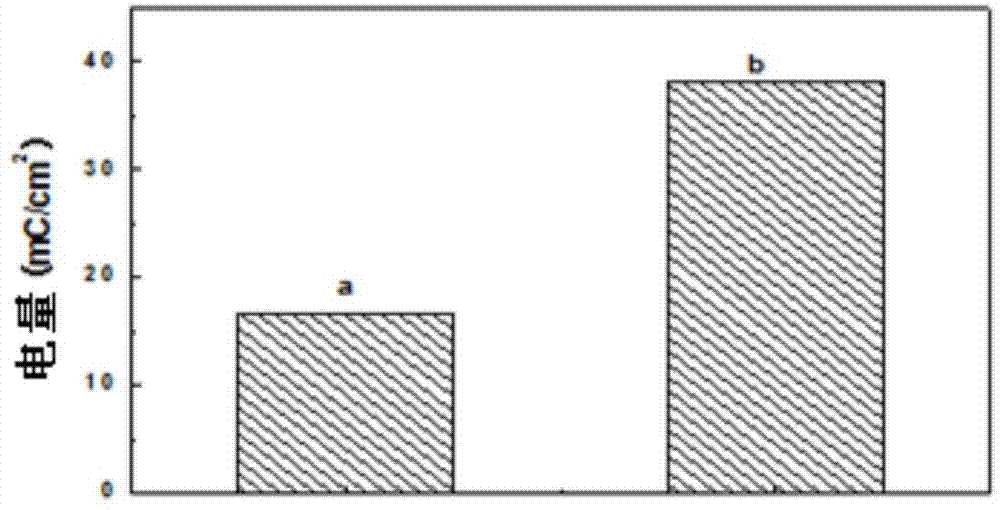

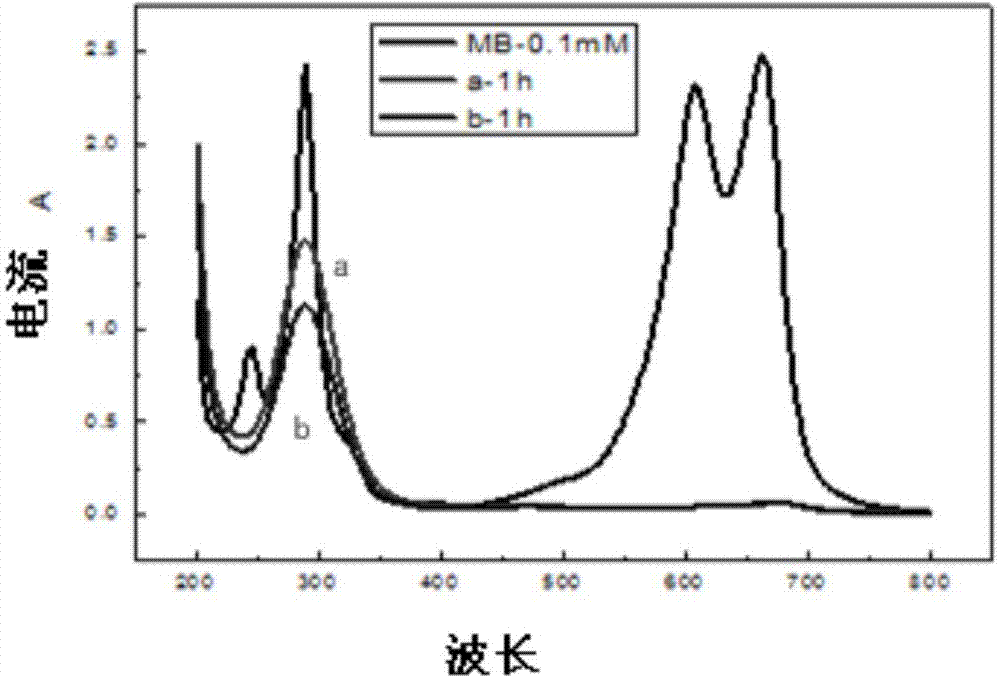

[0017] The preparation method of the metal oxide coated anode involved in this embodiment includes three steps of substrate pretreatment, coating liquid preparation and coating anode preparation:

[0018] (1) Substrate pretreatment: select TA2 industrial pure titanium plate with a length, width and thickness of 140mm×110mm×3mm and a purity of 99% as the substrate material, and use corundum with a particle size of 120 μm to sandblast the titanium plate substrate and rinse it with distilled water to remove it Sand grains and metal shavings remaining on the surface of the substrate, put the titanium plate substrate into an acetone solution for degreasing, place it in an oxalic acid aqueous solution with a concentration of 10% by mass and a temperature of 90°C for 1 hour, and wait for the surface of the substrate to When the roughness Ra is 3.5 μm, take it out, clean it ultrasonically with distilled water, and then clean it with industrial alcohol for 2-3 times. After drying the su...

Embodiment 2

[0025] The preparation method of the metal oxide coated anode involved in this embodiment includes three steps of substrate pretreatment, coating liquid preparation and coating anode preparation:

[0026] (1) Substrate pretreatment: select TA2 industrial pure titanium plate of 140mm×110mm×3mm as the substrate material, use corundum with a particle size of 120 μm to sandblast the titanium plate substrate and rinse with distilled water to remove the sand particles and metal remaining on the substrate surface Chips, put the titanium plate substrate into acetone solution (concentration parameter) to remove oil, then place it in an oxalic acid aqueous solution with a concentration of 10% by mass and a temperature of 100°C for acid etching for 1 hour, until the surface roughness Ra of the substrate is 1.5 μm Take it out and clean it ultrasonically with distilled water, and then clean it with industrial alcohol for 2-3 times. After drying the substrate, immerse it in an anhydrous alco...

Embodiment 3

[0030] The preparation method of the metal oxide coated anode involved in this embodiment includes three steps of substrate pretreatment, coating liquid preparation and coating anode preparation:

[0031] (1) Substrate pretreatment: select TA2 industrial pure titanium plate of 140mm×110mm×3mm as the substrate material, use corundum with a particle size of 120 μm to sandblast the titanium plate substrate and rinse with distilled water to remove the sand particles and metal remaining on the substrate surface Chips, put the titanium plate substrate into acetone solution (concentration parameter) to remove oil, then place it in an oxalic acid aqueous solution with a concentration of 10% by mass and a temperature of 92°C for acid etching for 1 hour, until the surface roughness Ra of the substrate is 2 μm Take it out and ultrasonically clean it with distilled water, and then clean it with industrial alcohol for 2-3 times. After drying the substrate, immerse it in an anhydrous alcohol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com