Method of one-step hydrogenation esterification between ketone and carboxylic acid in electrochemical hydrogen pump reactor

An electrochemical and reactor technology, applied in the field of electrochemical engineering, to achieve the effect of improving the uniformity of dispersion, increasing the reaction interface, increasing the reaction rate and conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

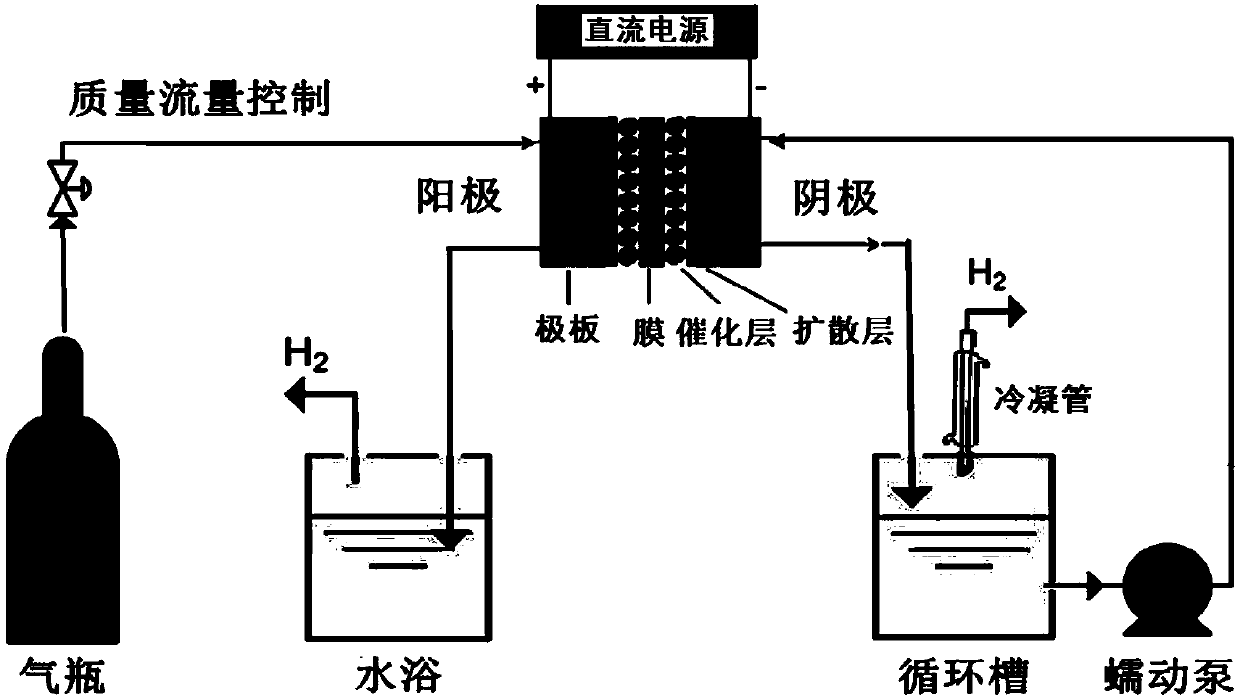

Method used

Image

Examples

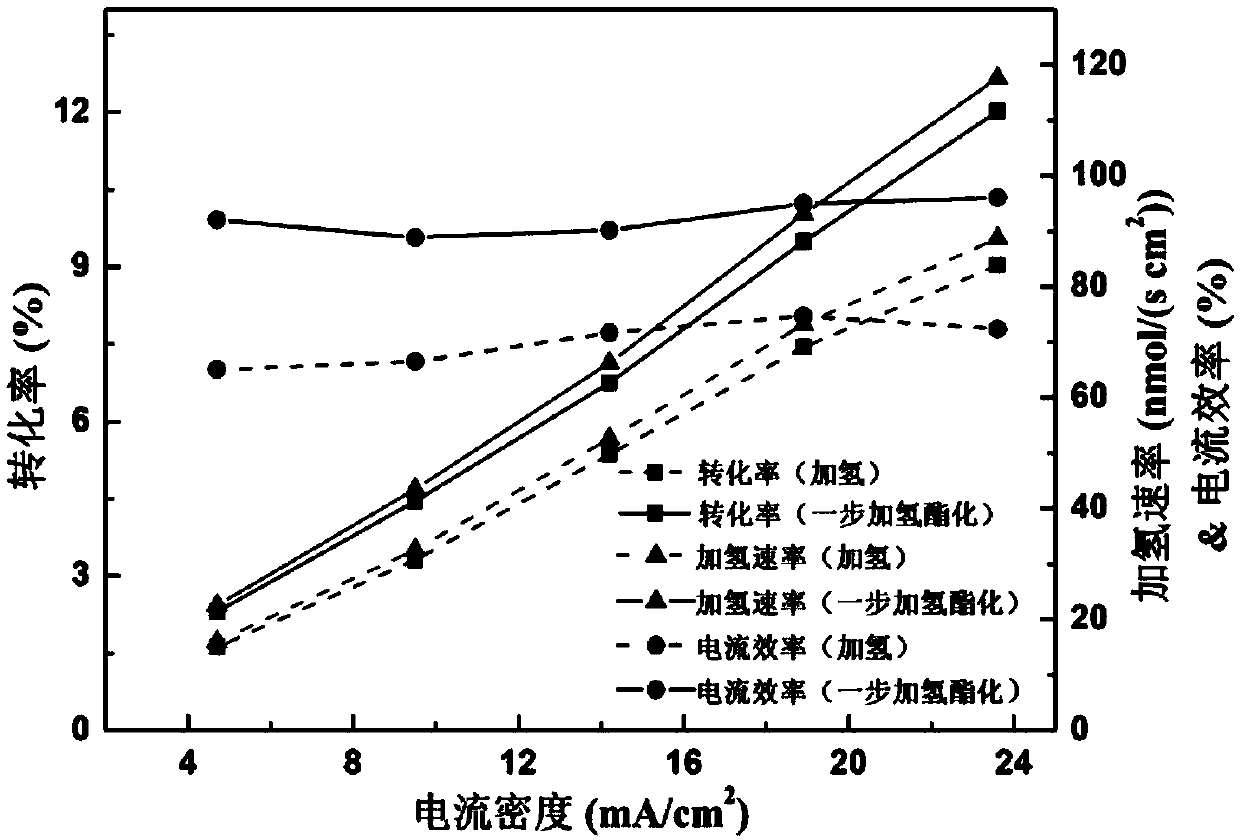

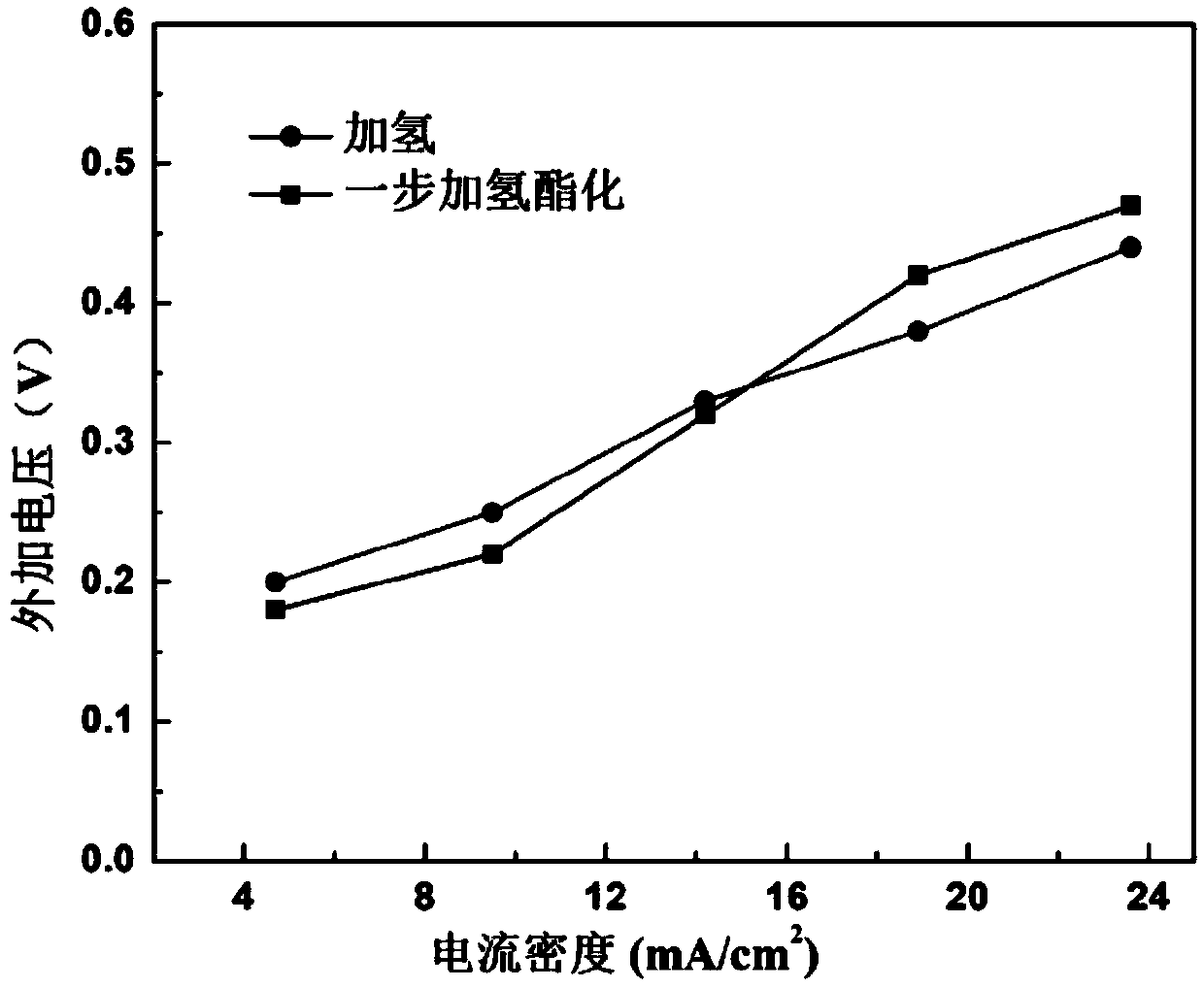

Embodiment 1

[0026] In the electrochemical hydrogen pump reactor, the anode hydrogen is fed, and the feed amount is 20sccm; the cathode ethyl ketone and acetic acid mixture is fed, the feed liquid temperature is 40°C, the circulation flow rate is 10ml / min, and the pH value is 1.8, wherein The volume ratio of butanone to acetic acid is 1:1. When the electrochemical hydrogen pump reactor with a constant current of 18.9mA / cm 2 , After operating at 40°C for 3 hours, the reactor voltage was 0.47V, the reaction rate of hydrogenation of butanone to butanol was 117.6mmol / (cm s), and the current efficiency was 96.1%. Compared with only hydrogenation of butanone at the cathode, the conversion rate of butanone is increased by about 25%, and the hydrogenation rate and current efficiency are increased by about 30%. The conversion rate of butanol and acetic acid to generate sec-butyl acetate is 85.6%, which is about 1.09 times that when the alkyd esterification reaction is simply carried out at the cat...

Embodiment 2

[0028] In the electrochemical hydrogen pump reactor, the anode hydrogen is fed, and the feed amount is 10 sccm; the cathode butanone and acetic acid mixture is fed, the feed liquid temperature is 60 ° C, the circulation flow rate is 20 mL / min, and the pH value is 1.0, where The volume ratio of butanone to acetic acid is 1:1. When the electrochemical hydrogen pump reactor with a constant current of 18.9mA / cm 2 , After operating at 60°C for 3 hours, the reactor voltage was 0.55V, the reaction rate of hydrogenation of butanone to butanol was 82.9mmol / (cm s), and the current efficiency was 83.6%. Compared with only hydrogenation of butanone at the cathode, the conversion rate of butanone is increased by about 20%, and the hydrogenation rate and current efficiency are increased by about 30%. The conversion rate of butanol and acetic acid to generate sec-butyl acetate is 82.3%.

Embodiment 3

[0030]In the electrochemical hydrogen pump reactor, the anode hydrogen is fed, and the feed amount is 25 sccm; the cathode butanone and acetic acid mixture is fed, the temperature of the feed liquid is 40°C, the circulation flow rate is 30mL / min, and the pH value is 3.0, where The volume ratio of butanone to acetic acid is 1:1. When the electrochemical hydrogen pump reactor with a constant current of 18.9mA / cm 2 , After running at 40°C for 10 hours, the reactor voltage is 0.66V, the reaction rate of hydrogenation of butanone to butanol is 51.3mmol / (cm s), the current efficiency is 52.4%, and the reaction rate of butanol and acetic acid to generate sec-butyl acetate The conversion rate was 75.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com