Direct compounding method of metal lithium electrode and inorganic solid electrolyte ceramic diaphragm

An inorganic solid, ceramic separator technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve lithium dendrite short circuit and solid/solid interface instability, increase the difficulty of popularization and application, increase the difficulty of battery technology and Manufacturing cost and other issues, to achieve the effect of solving poor stability and solving large interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

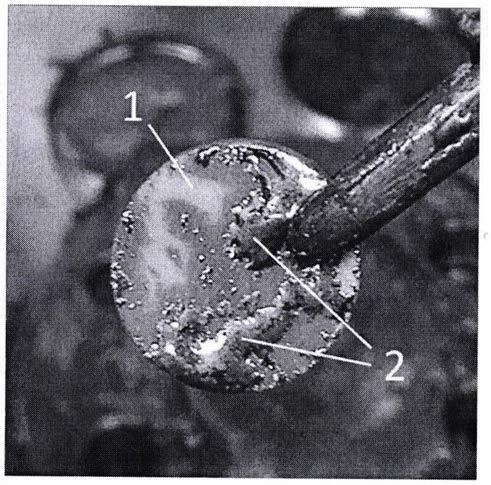

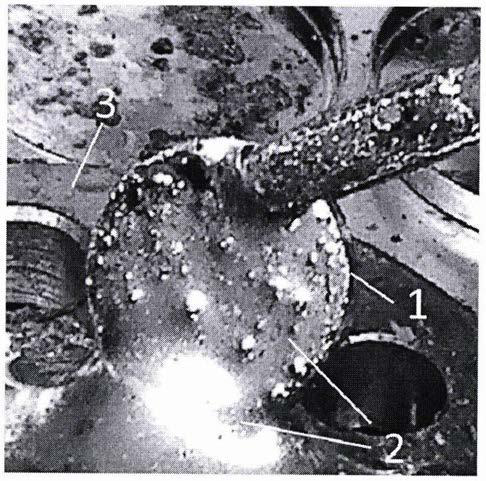

[0025] A 0.50 mol Nb-doped LLZO inorganic solid electrolyte ceramic separator (1) prepared by a self-compacting method, see (Journal of the European Ceramic Society, 38:5454-5462) for the specific preparation process. First, in the air, use 500, 1000, and 3000 mesh diamond grinding discs for grinding and polishing successively, remove the surface layer of the ceramic diaphragm 1 and make the two surfaces smooth, and obtain a ceramic diaphragm 1 with a thickness of about 1 mm and a diameter of about 1.2 cm. Diaphragm 1 looks like figure 1As shown; immediately after polishing, the ceramic diaphragm 1 was transferred to an argon-protected glove box; then, under the protection of Ar gas in the glove box, the ceramic diaphragm 1 and the molten lithium pool 3 were respectively placed on a central temperature-controlled heating platform, and Raise the temperature from room temperature to 280°C at a rate of about 10°C / min; add a metal lithium sheet at the bottom of the lithium melting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com