Patents

Literature

192results about How to "Avoid process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for FS-IGBT device

InactiveCN102800591AImprove performanceIntegrity guaranteedSemiconductor/solid-state device manufacturingPower semiconductor deviceImpurity

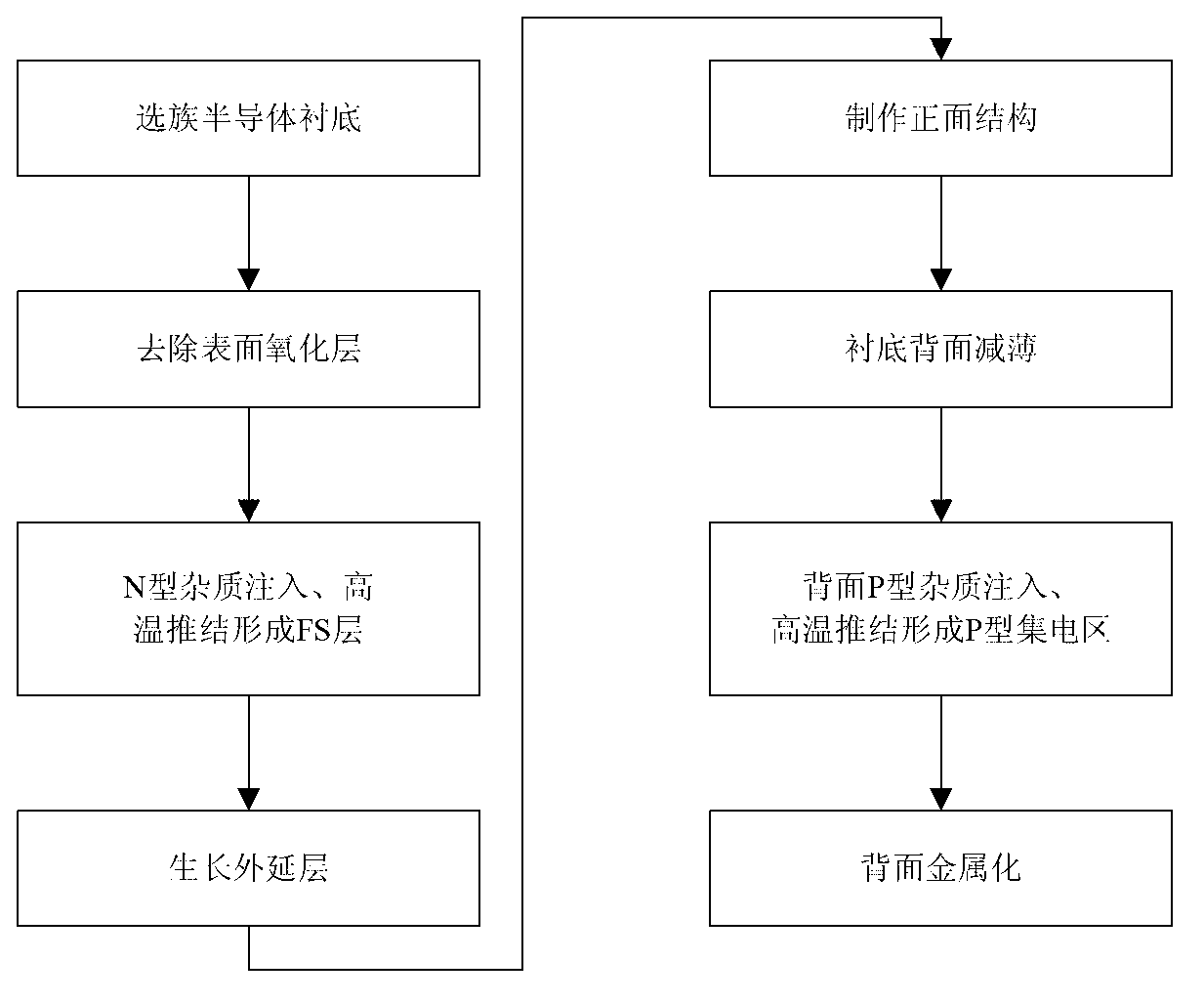

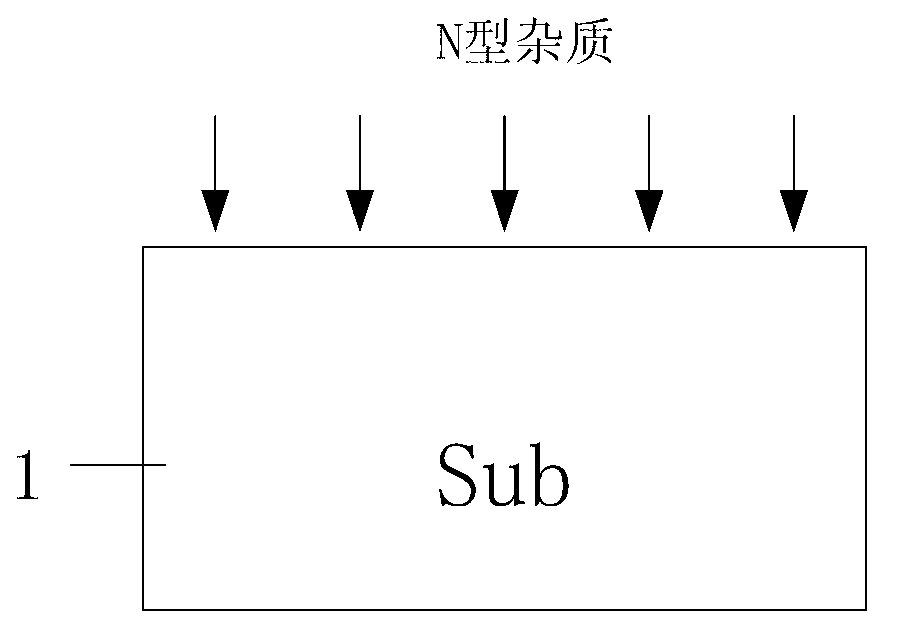

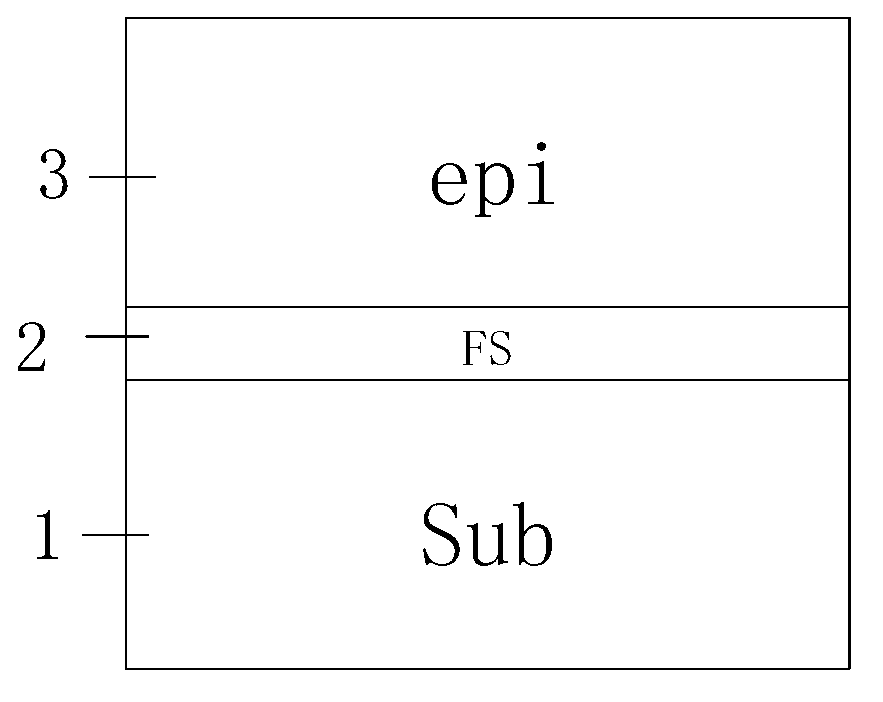

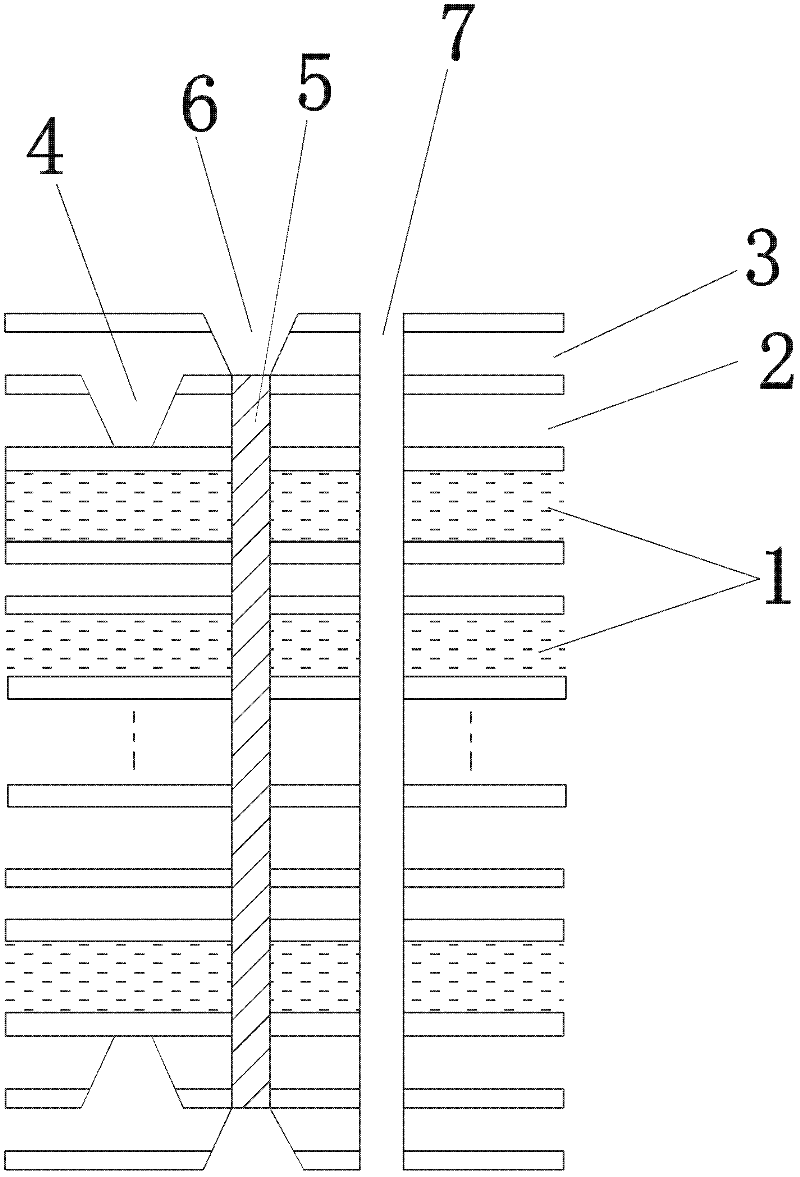

A preparation method for an FS-IGBT (Field Stop-Insulated-Gate Bipolar Transistor) device belongs to the technical field of power semiconductor devices. In the preparation method, N-type impurity injection is performed on a substrate to form a field stop layer, then an epitaxial layer is generated, a front patterning is manufactured, then the back part is thinned, injection and annealing for a P-type collector region on the back part are performed, a manner of metalization on the back part is adopted to manufacture a field stop transistor, and impurities in the field stop layer can be activated fully. In addition, the preparation method can lead in an N-type transition region between the field stop layer and the P-type collector region by controlling thermal budget and back thinning positions, and the performance of the device can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

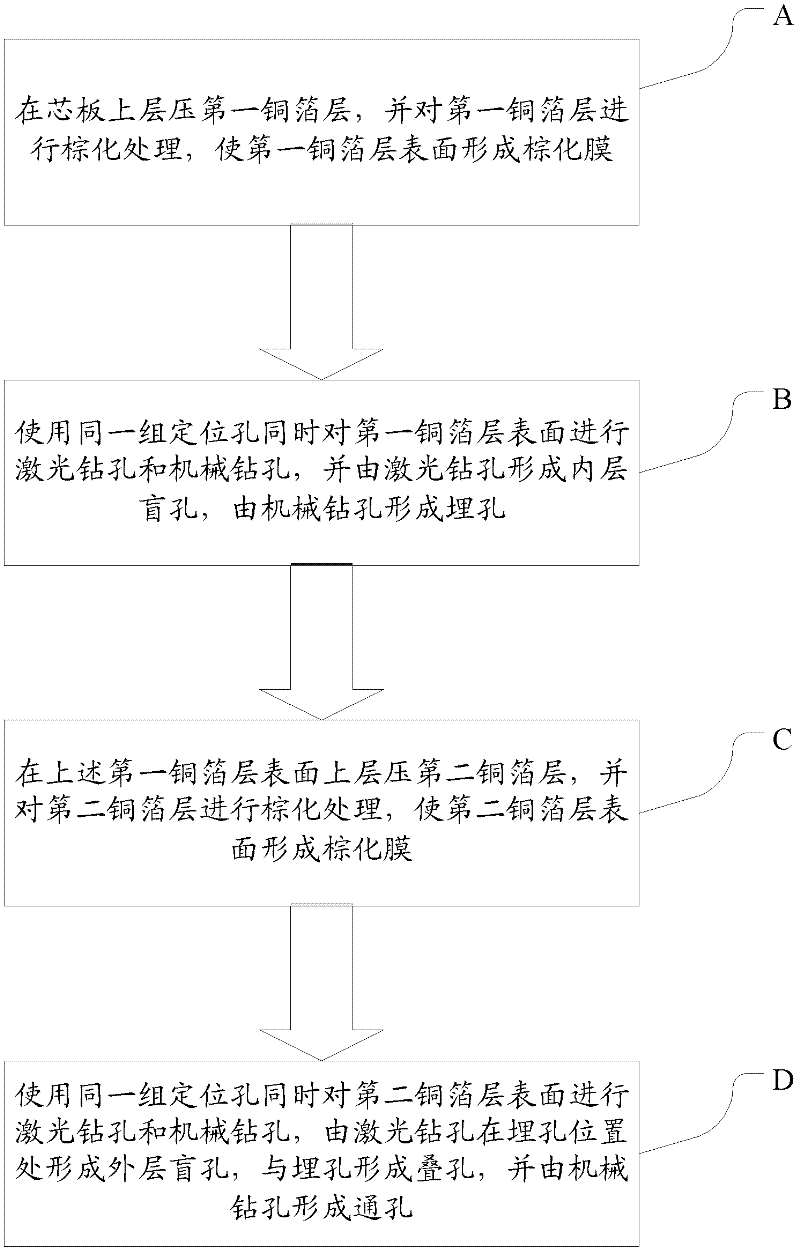

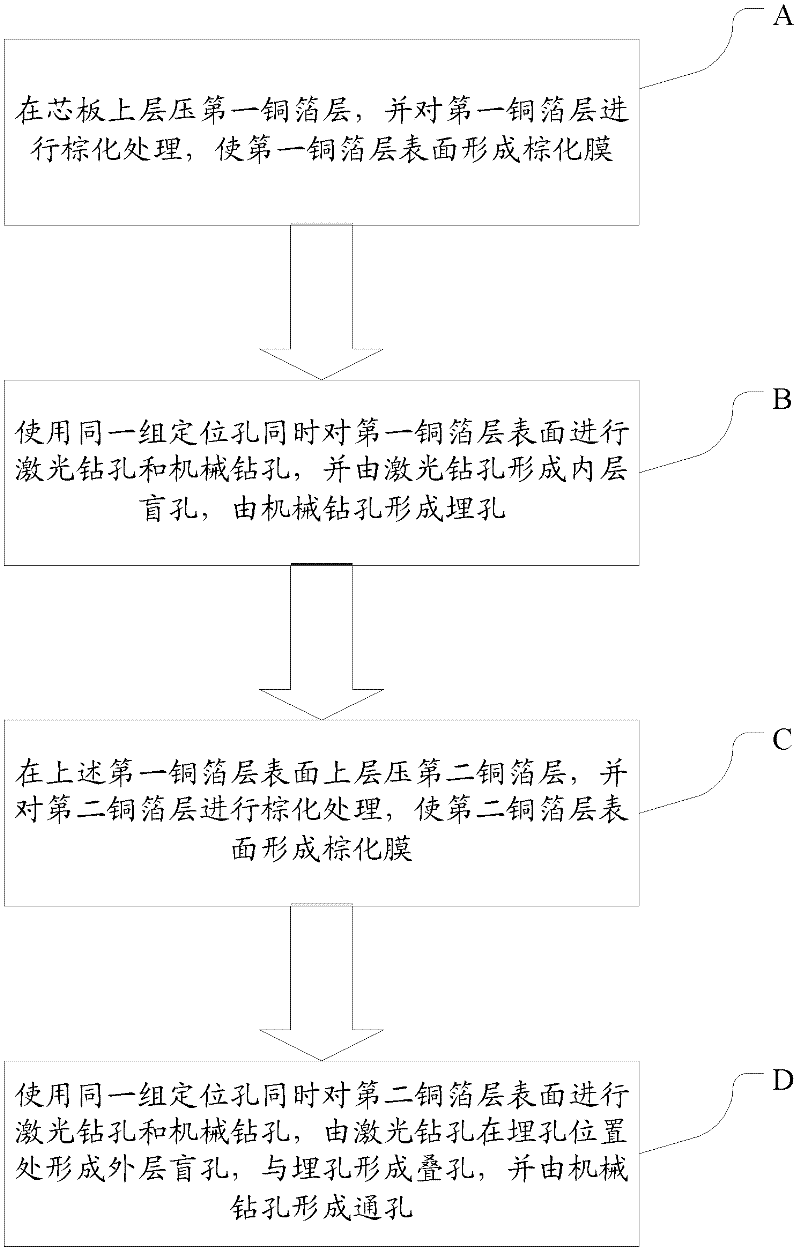

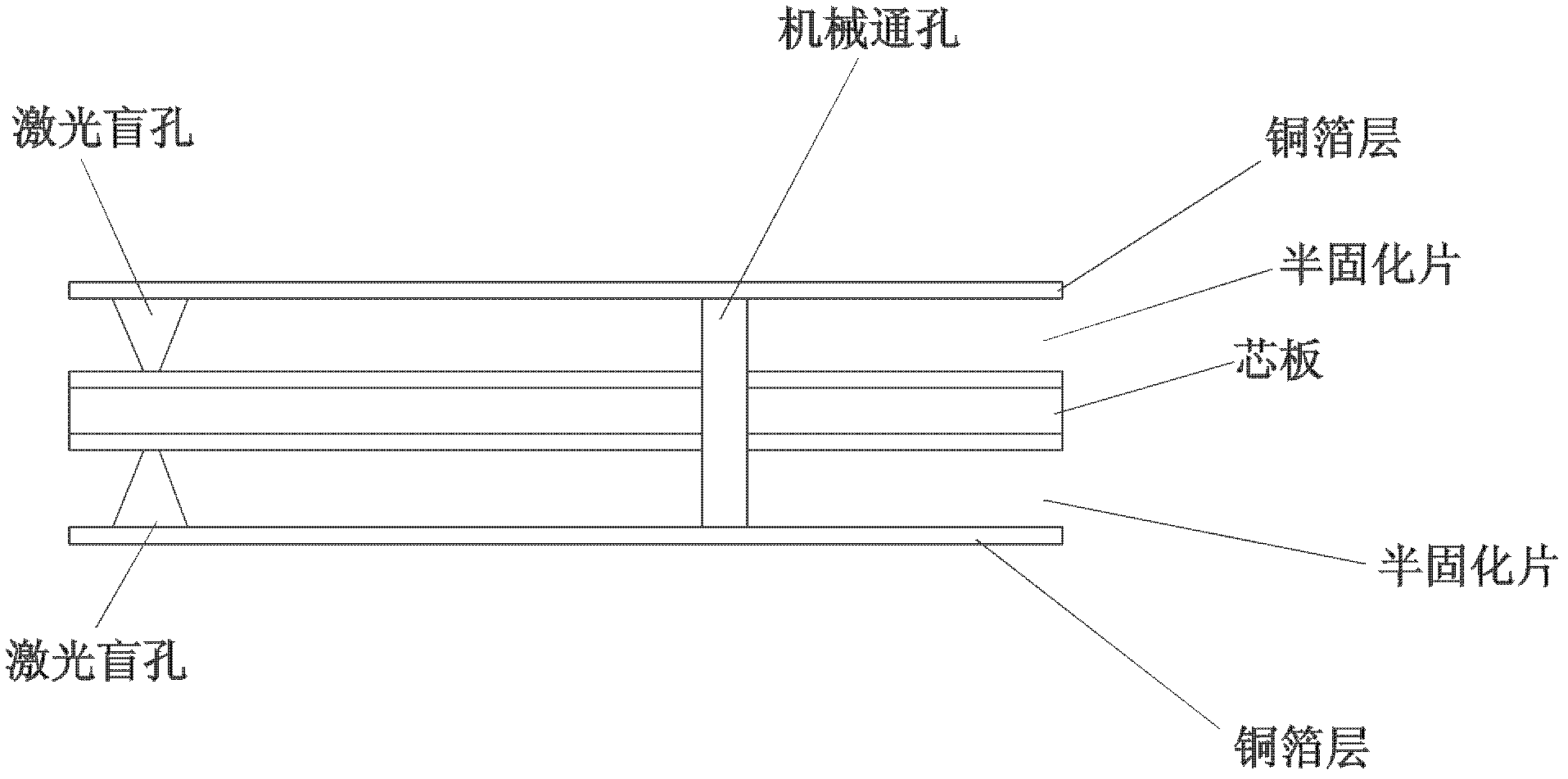

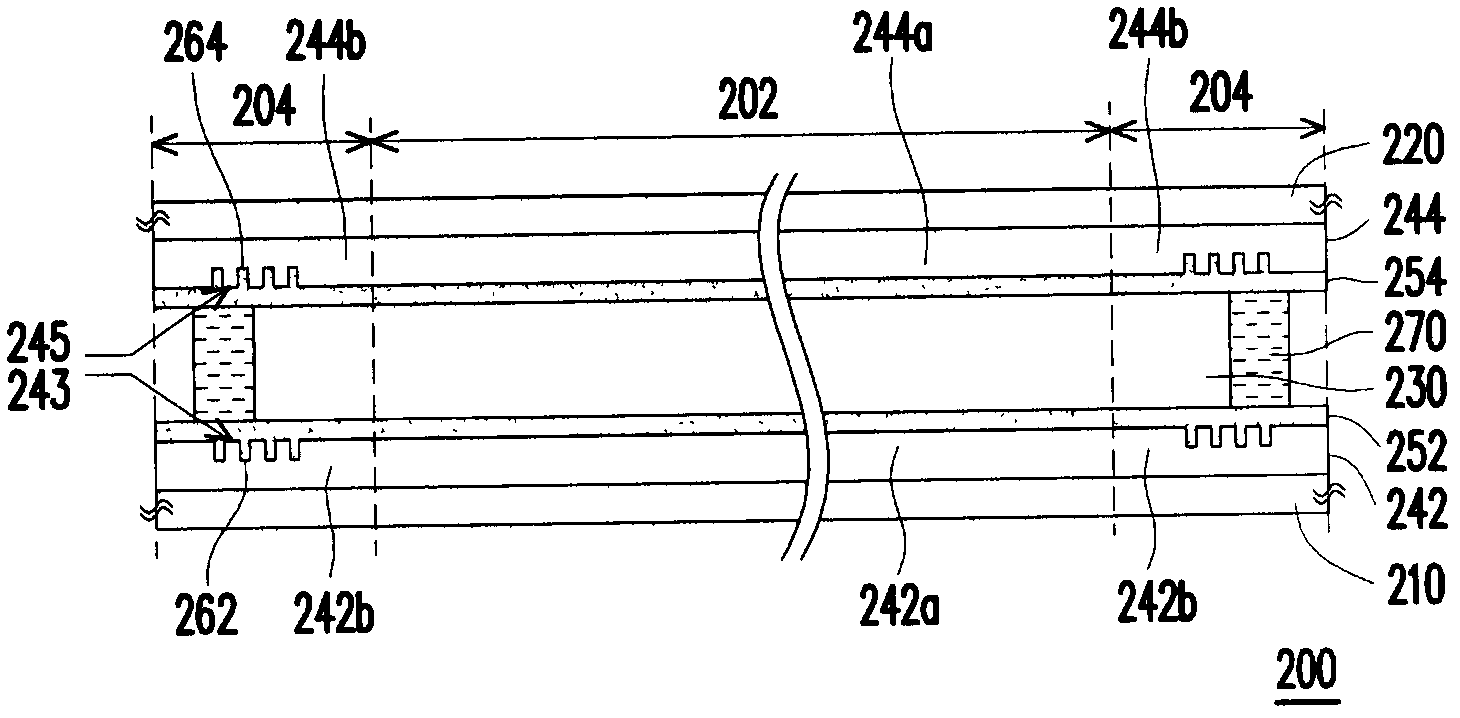

Production method of multi-stage HDI plate

ActiveCN102523704AGood dimensional stabilityAvoid processPrinted circuit aspectsMultilayer circuit manufactureCopper foilElectroplating

The invention discloses a production method of a multi-stage HDI plate. The method comprises the following steps: A. laminating a first copper foil layer on a core plate, carrying out multiband to the first copper foil layer so as to form a brown film on a surface of the first copper foil layer; B. using a same group of location holes to simultaneously carry out laser drilling and mechanical drilling to the surface of the first copper foil layer, forming an internal-layer blind hole through the laser drilling and forming a buried hole through the mechanical drilling; C. laminating a second copper foil layer on the surface of the first copper foil layer, carrying out the multiband to the second copper foil layer so as to form the brown film on the surface of the second copper foil layer; D. using the same group of location holes to simultaneously carry out the laser drilling and the mechanical drilling to the surface of the second copper foil layer, forming an outer-layer blind hole on the position of the buried hole through the laser drilling, forming a folded hole with the buried hole and forming a through hole through the mechanical drilling. At present, the blind hole and the buried hole are drilled separated so that the through hole and the blind hole are not matched with each other. According to the method of the invention, the above problem can be solved; processes of internal layer copper deposition, padpower, an internal layer plating hole graph, porefilling electroplating, film stripping, abrasive-belt grinding plate and the like can be reduced; a production period can be substantially shortened and production cost can be saved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

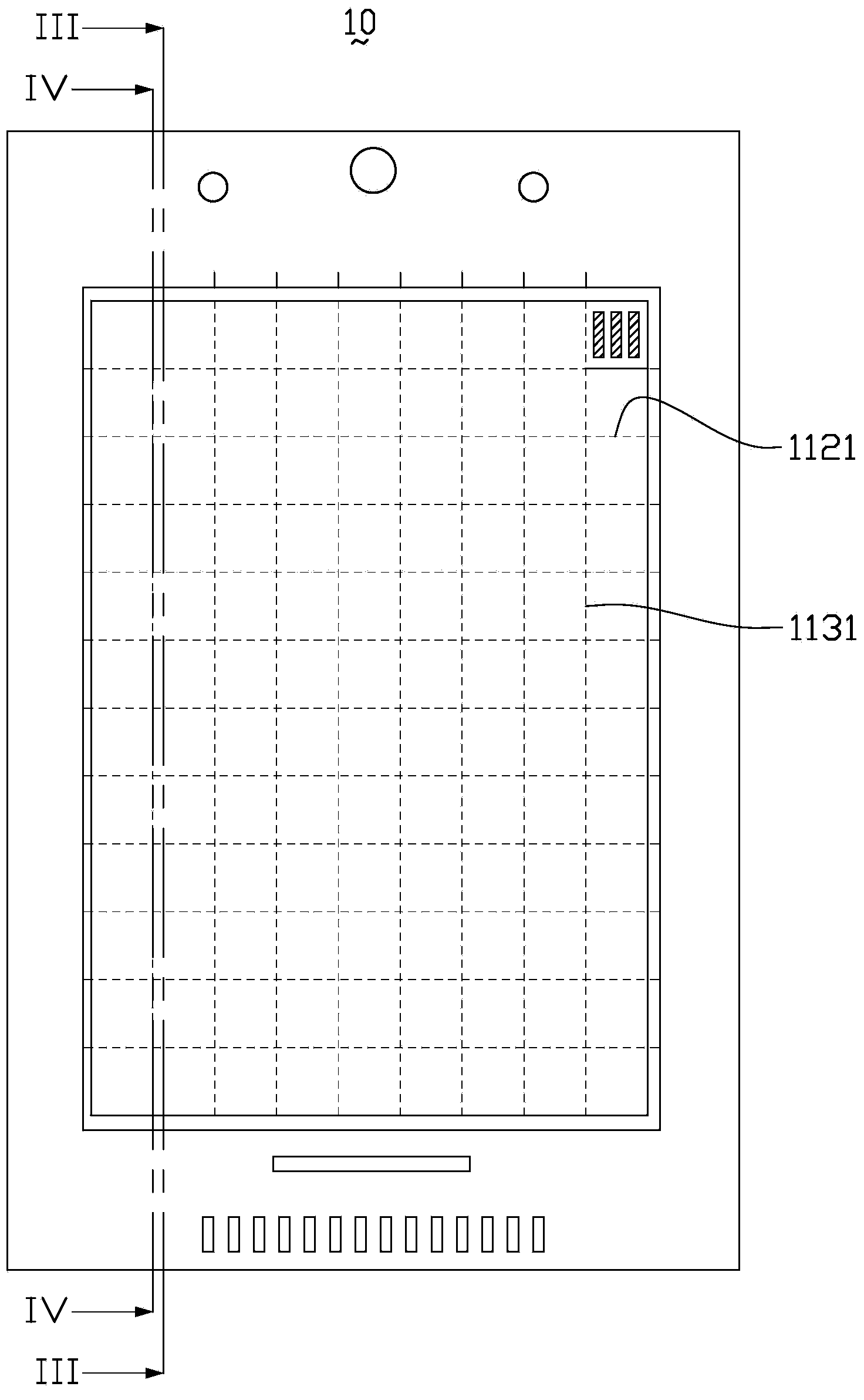

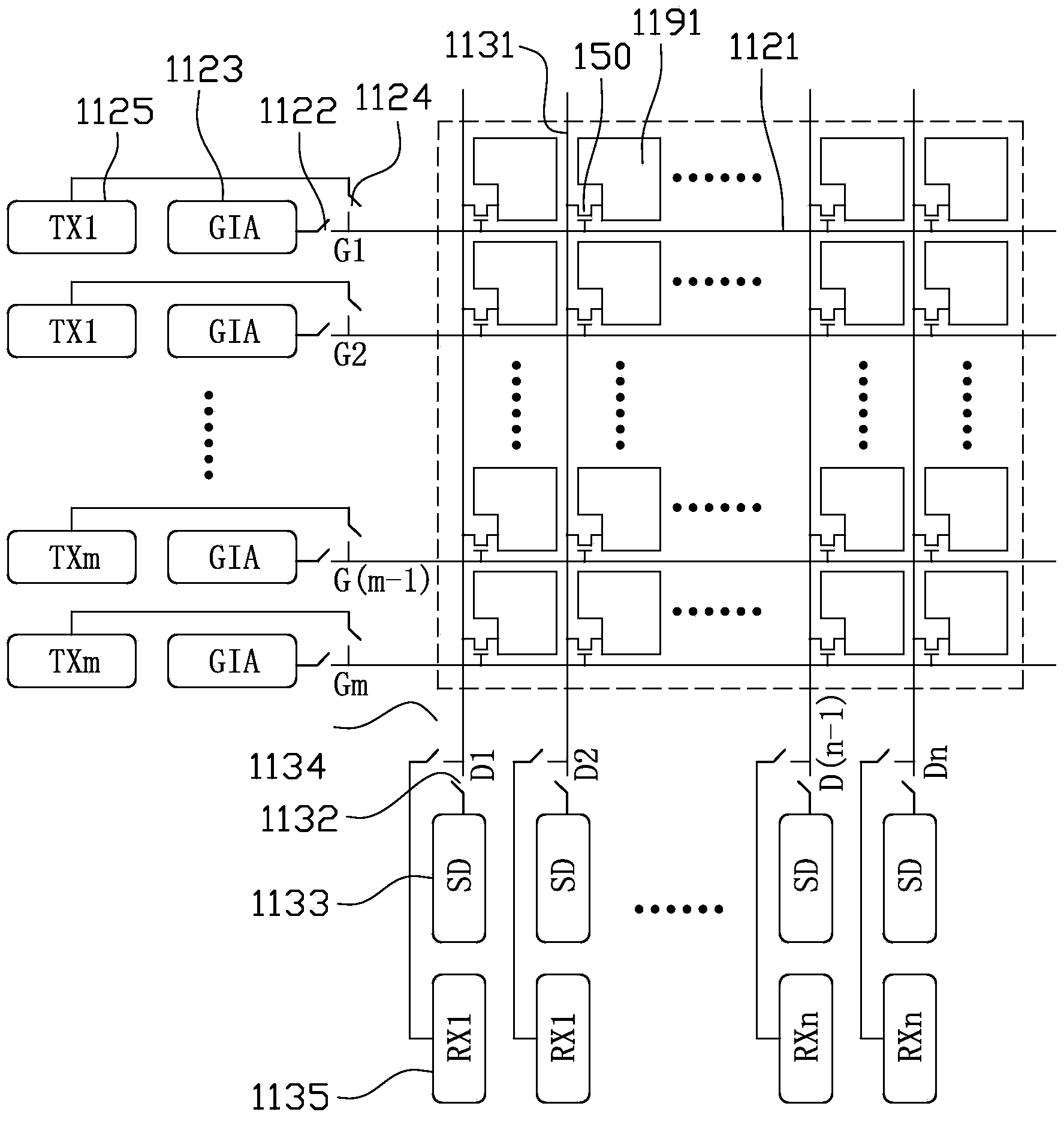

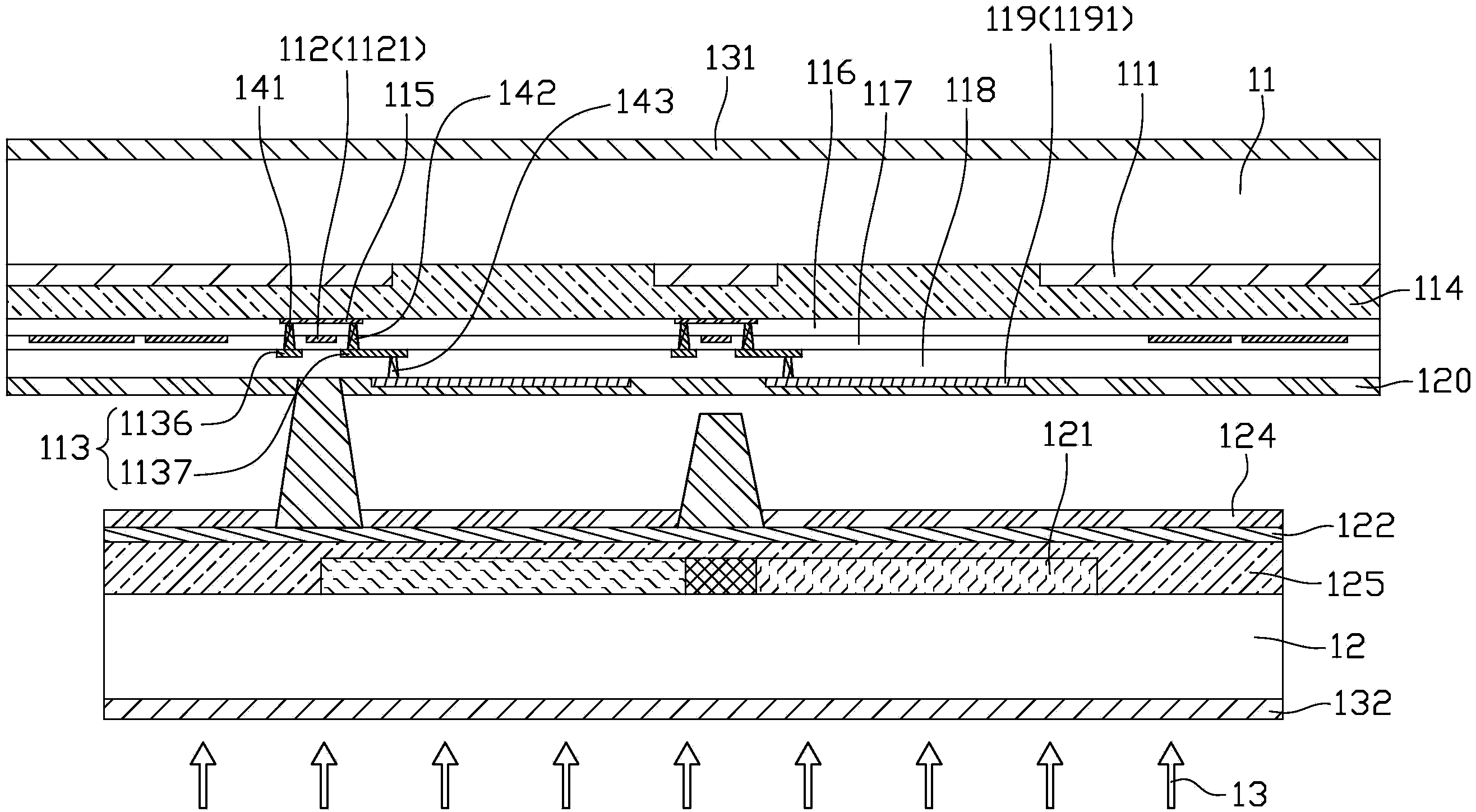

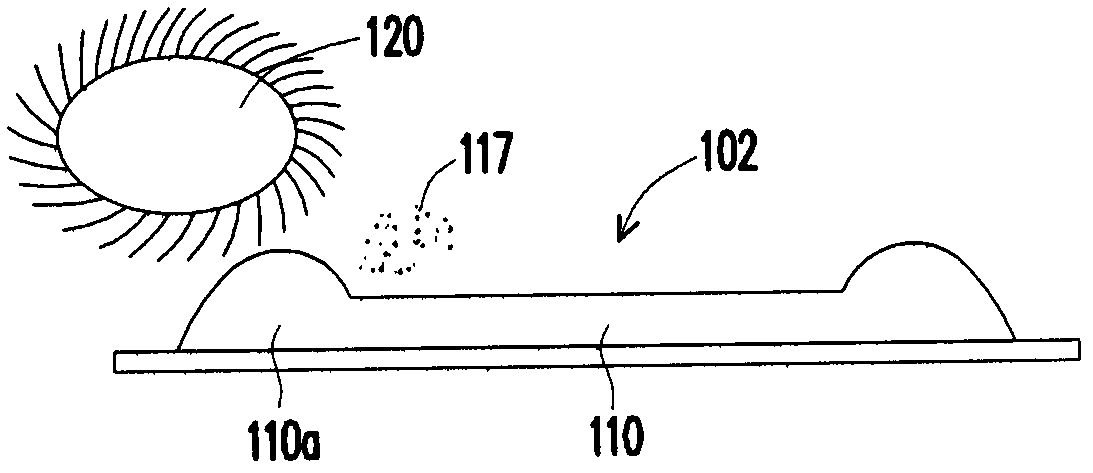

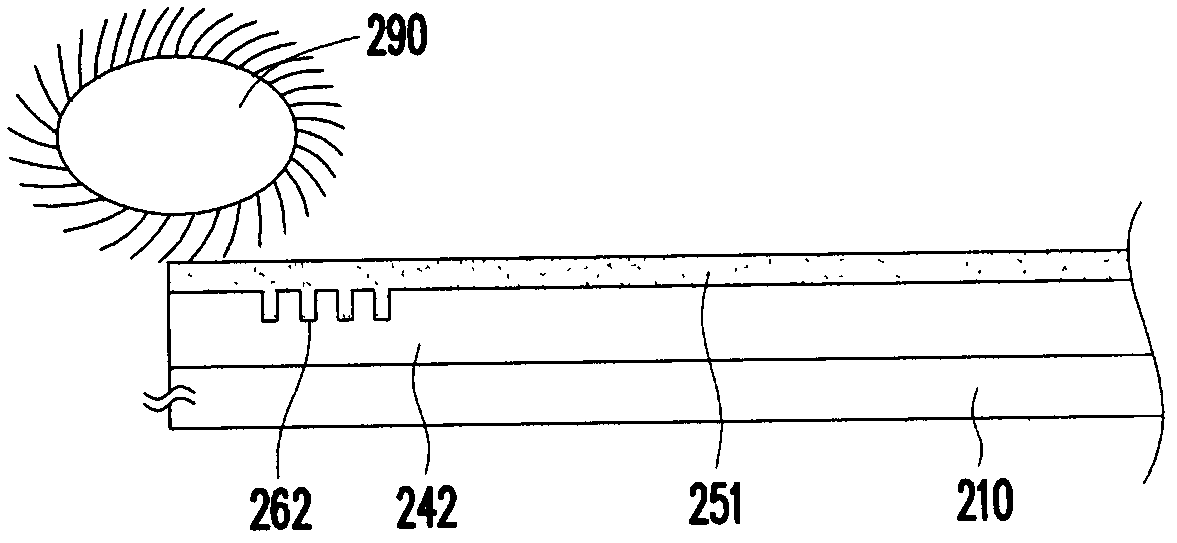

Touch display panel and touch display device

ActiveCN104020595AFull lamination process savesAvoid processNon-linear opticsInput/output processes for data processingTouch SensesOxide thin-film transistor

A touch display panel comprises a first substrate and a second substrate opposite to the first substrate, wherein the first substrate is located above the second substrate to enable he first substrate to be located on one side close to a user, grid lines and data lines are formed on one side of the first substrate close to the second substrate and intersected to form multiple pixel units arranged in a matrix mode, a pixel electrode and an oxide thin-film transistor are arranged in each pixel unit, the pixel electrodes are connected with the grid lines and data lines through the oxide thin-film transistors, at least one portion of the grid lines concurrently serves as one of touch driving lines and touch sensing lines, at least one portion of the data lines concurrently serves as the other one of the touch driving lines and the touch sensing line, the grid lines and the data lines receive image scanning signals and data signals at an image display stage for image display and receives touch driving signals and output touch sensing signals at a touch detection stage for touch detection.

Owner:KUSN INFOVISION OPTOELECTRONICS

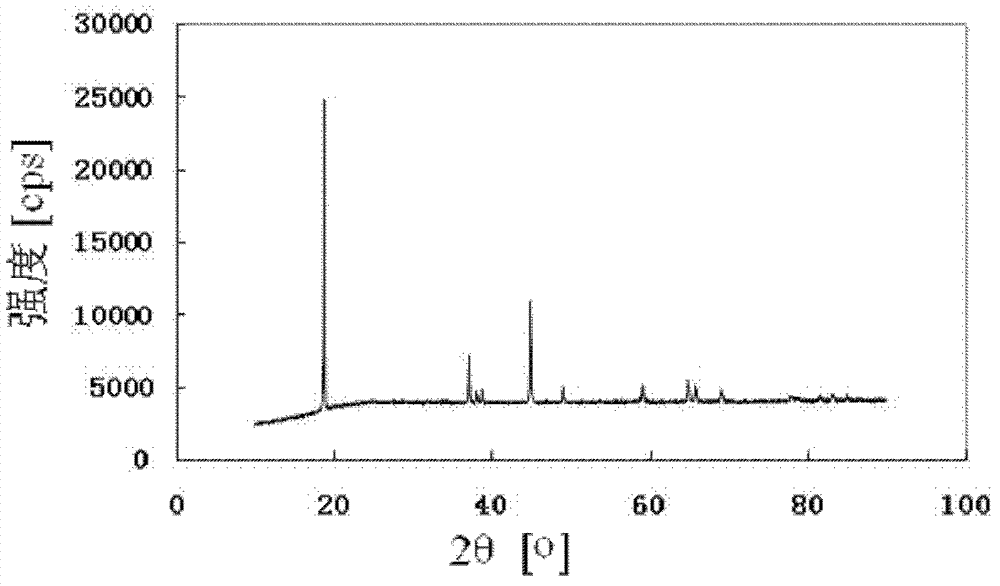

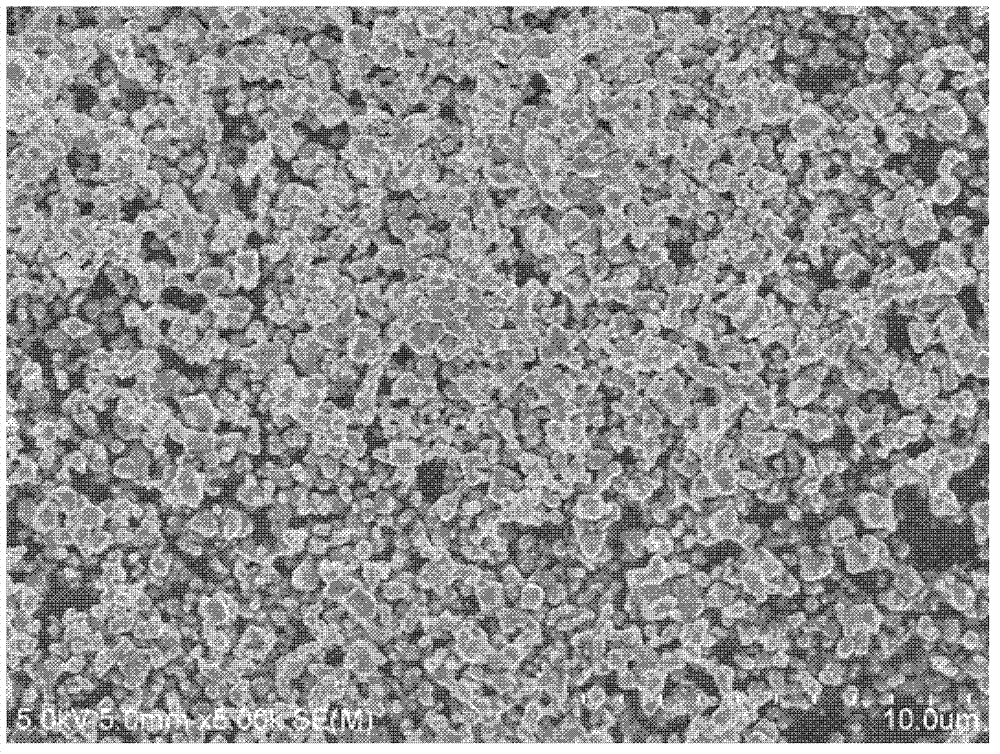

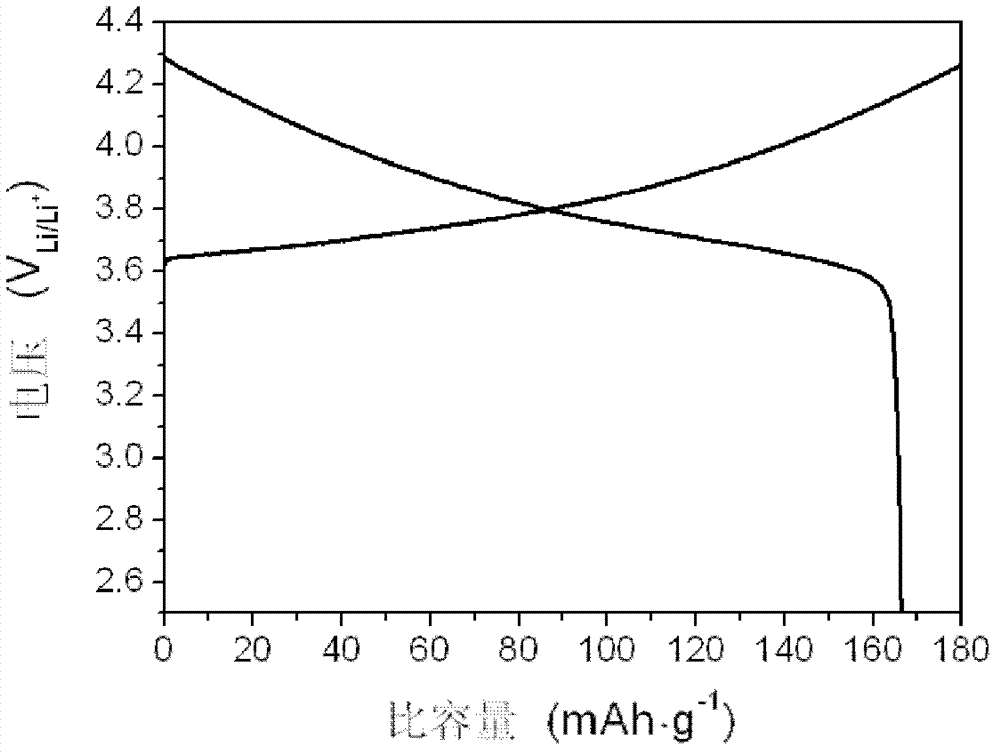

Nickel-based positive electrode material, and preparation method thereof and battery

ActiveCN103094576AIncrease capacityImprove structural stabilityCell electrodesSecondary cellsMetallurgySlurry

The invention relates to a nickel-based positive electrode material, and a preparation method thereof and a battery. The composition of the nickel-based positive electrode material is LiaNibCocMndMeM'fO2-g / 2Fg (M is at least one selected from Ti, Zr, Al, Fe, Cr, Si, and Cu; M' is at least one selected from Mg, Ca, Sr, Ba, and W; a is no smaller than 0.95 and no greater than 1.2; b is no smaller than 0.2 and no greater than 0.9; c is no smaller than 0 and no greater than 0.4; d is no smaller than 0 and no greater than 0.4; e+f is greater than 0.05and no greater than 0.2; and g is greater than 0.02 and no greater than 0. 1). Anions and cations are used in co-doping. With a synergistic effect, nickel-based positive electrode material capacity, structural stability and circulation performance are greatly improved. The preparation method at least comprises the 4 steps that: (1) corresponding raw materials are weighed according to the molar ratio consistent with LiaNibCocMndMeM'fO2-g / 2Fg; (2) the raw materials are subjected to wet grinding; (3) slurry obtained by grinding is dried; and (4) the dried material is subjected to solid-phase synthesis under a temperature of 500-1100 DEG C. With the process, the raw materials can be more uniformly dispersed, and the obtained product has the advantages of high capacity and good circulation performance. The process is simple, and has the advantages of low cost and suitability for large-scale industrialized productions. With the process, problems such as complicated process and acid and alkali pollution of a wet chemical precursor preparation method are avoided. The invention also relates to a battery with the material as an active substance.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

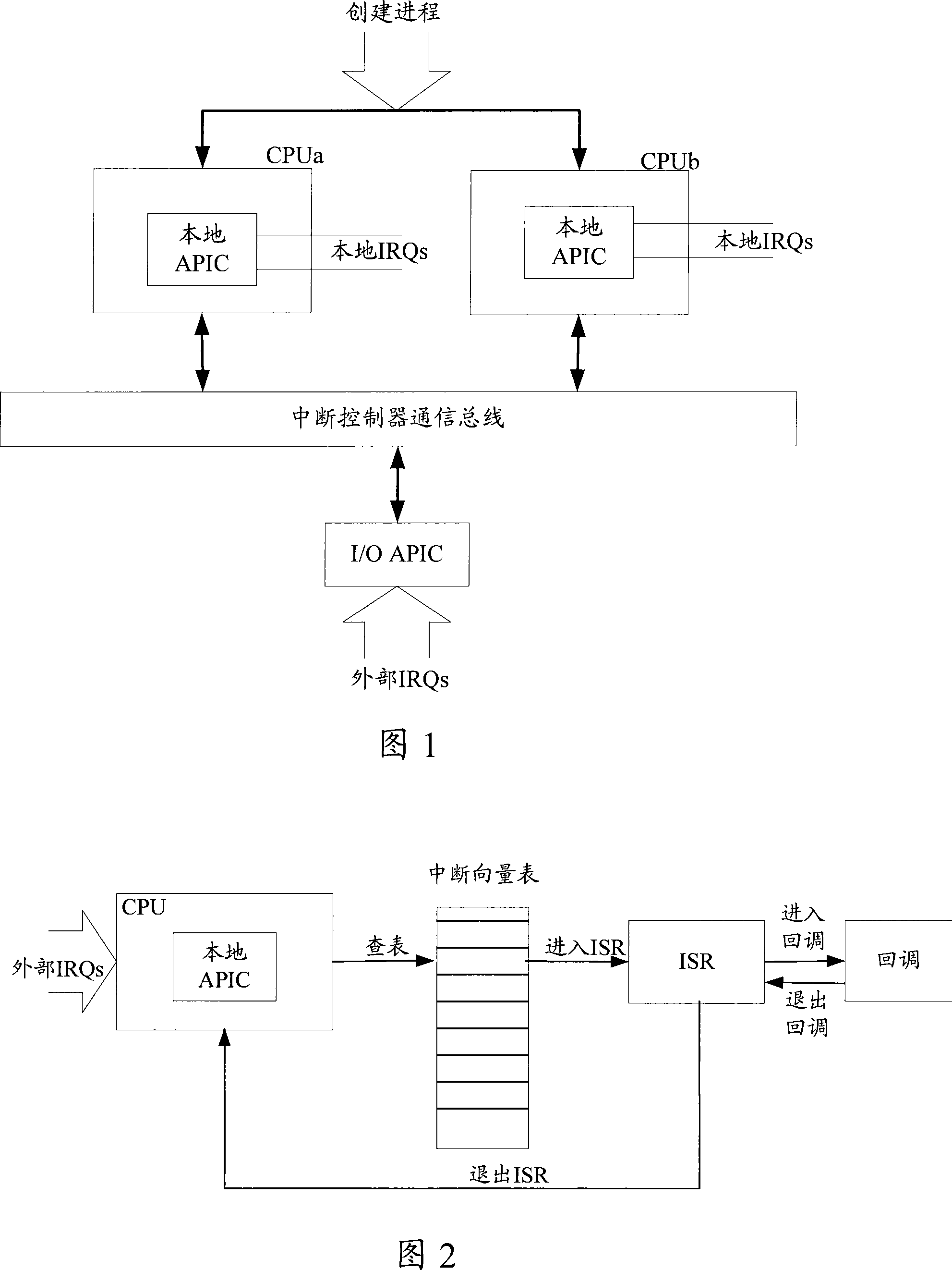

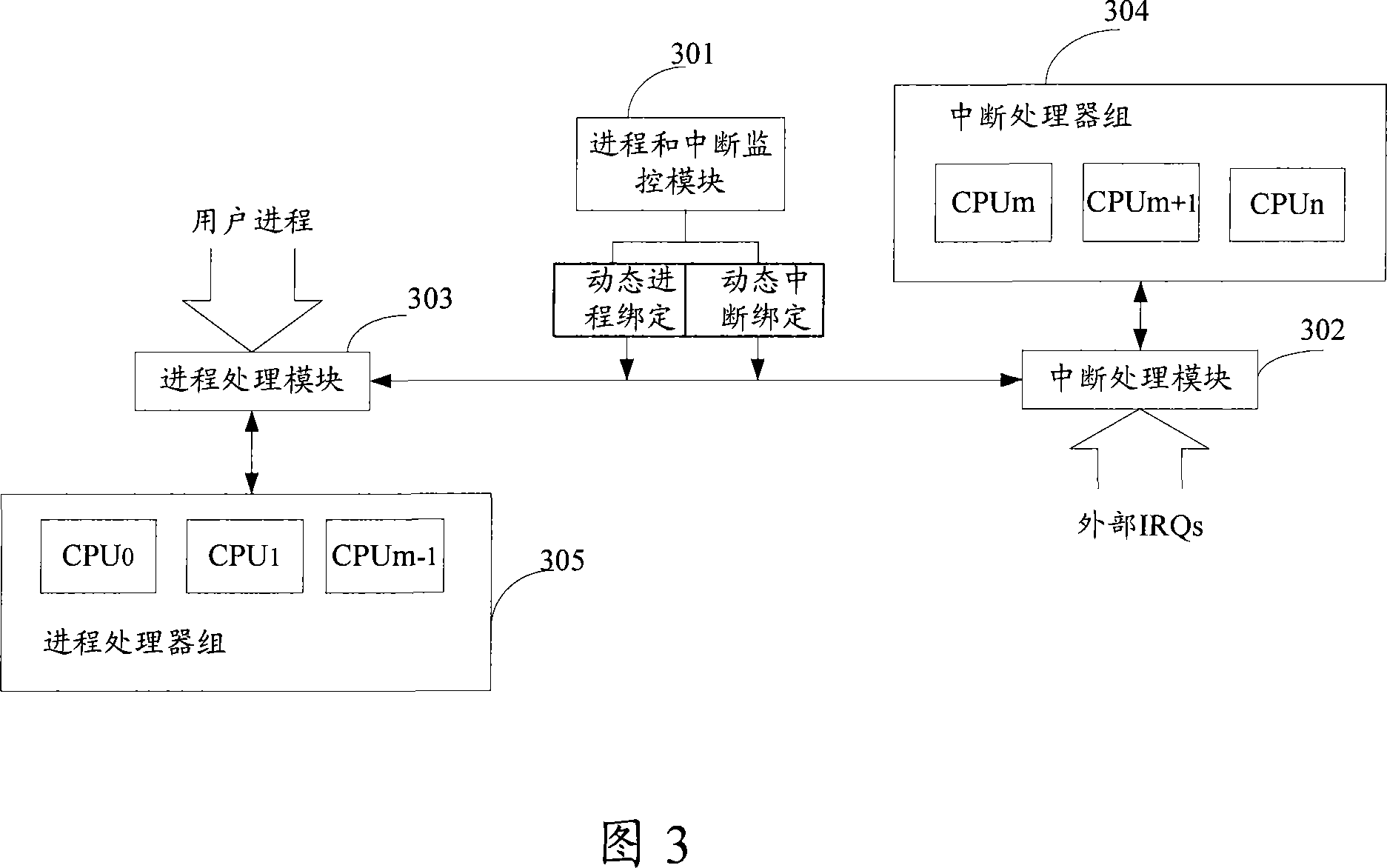

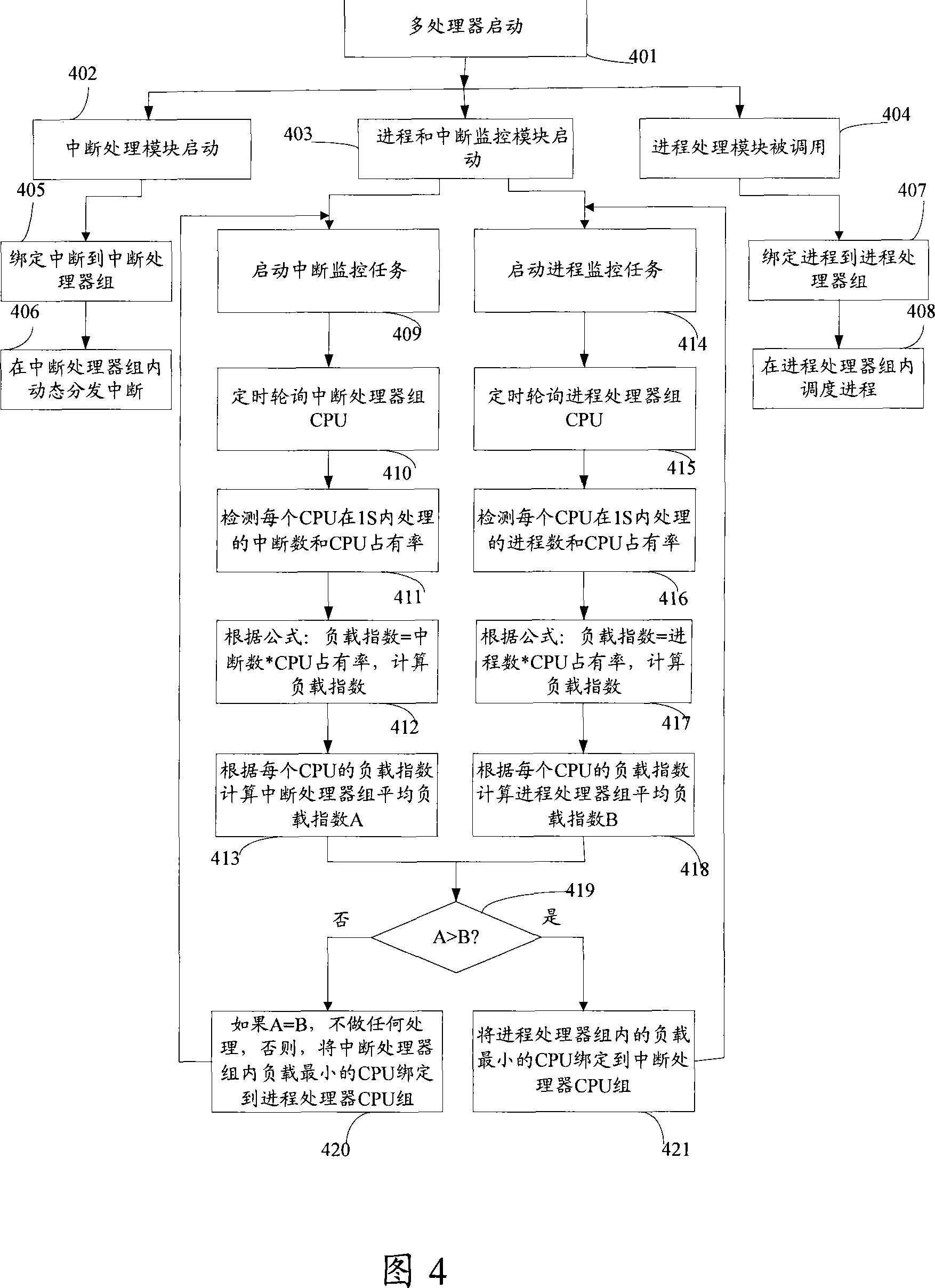

Process and interrupt processing method and device for symmetrical multiprocessing system

InactiveCN101246438AEnsure real-time requirementsTimely responseProgram initiation/switchingEmbedded systemSymmetric multiprocessing

The invention discloses a disposal for process and interruption in a SMP system. The method adapts separation interrupt handling and process handling on processor grade, processes specially the interruption by using one or a group processors, furthermore, monitors the process and the interruption handling, and dynamic adjusts the number of processors in two group processors according to the load index of the process and the interruption handling. The invention also discloses a handling device for process and interruption in a SMP system. The device comprises interrupted handling module, a process processing module, a process and interruption monitor module. The device ensures the process handling and interruption handling mutual noninterference to improve the hit rate of cache and to ensure the stabilizing ability and actual time character of the system.

Owner:ZTE CORP

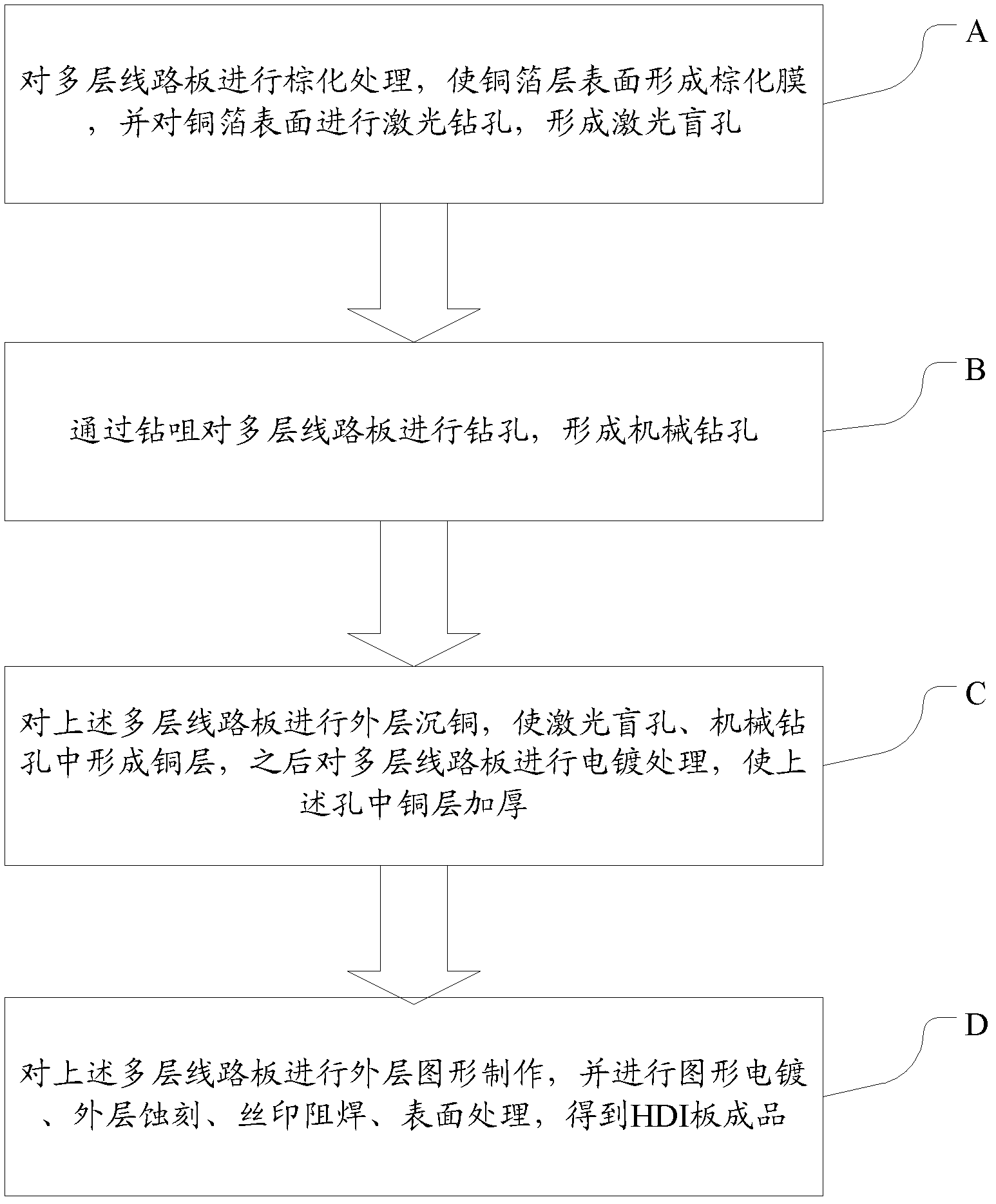

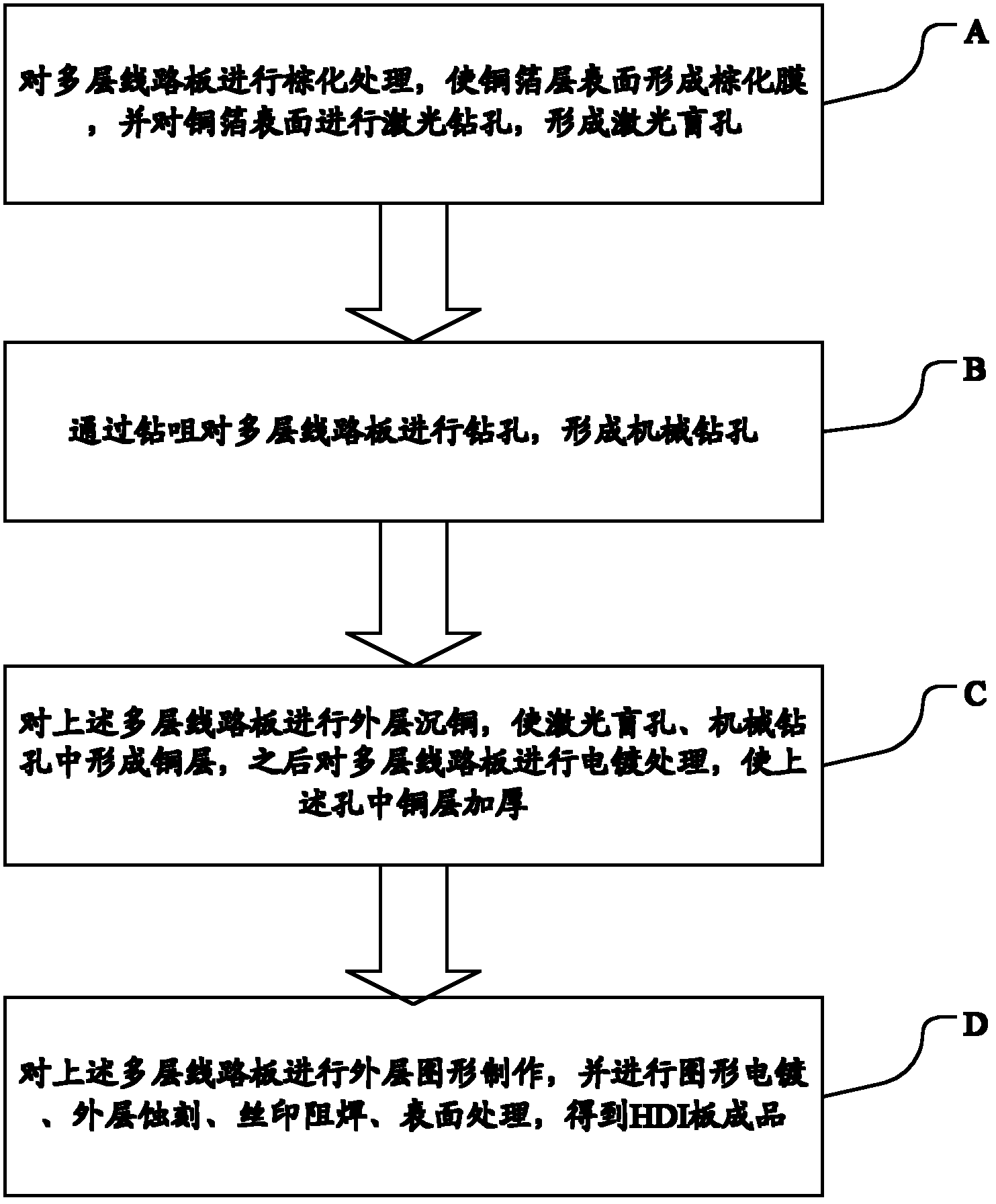

Manufacturing process of HDI (High Density Interconnection) board

InactiveCN102427685AGood dimensional stabilityAvoid processMultilayer circuit manufactureEtchingHigh density

The invention relates to a manufacturing process of an HDI (High Density Interconnection) board. The manufacturing process comprises the following steps of: A, carrying out browning treatment on a multilayer circuit board so that a browned film is formed on the surface of a copper foil layer, and carrying out laser hole drilling on the surface of the copper foil to form laser blind holes; B, carrying out hole drilling on the multilayer circuit board through a drill bit to form mechanical drill holes; C, carrying out outer-layer copper precipitation on the multilayer circuit board so that copper layers are formed in the laser blind holes and the mechanical drill holes, and carrying out electroplating treatment on the multilayer circuit board, so that the copper coppers in the laser blind holes and the mechanical drill holes are thickened; and D, carrying out outer-layer pattern making on the multilayer circuit board, and carrying out pattern electroplating, outer-layer etching, silk-screen mask soldering and surface treatment to obtain the HDI board as a finished product. Compared with the prior art, the manufacturing process disclosed by the invention has the advantages of avoiding processes, such as outer-layer copper precipitation, board electroplating, outer-layer pattern hole-electroplating, porefilling electroplating, mold stripping, board grinding with an abrasive belt and the like which are adopted after laser hole drilling, greatly shortening production cycle and reducing production cost; meanwhile, according to the manufacturing process disclosed by the invention, because the process of grinding the board with the abrasive belt is not required, size stability of the circuit board is relatively better, and the circuit board cannot deform.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Display panel and method of manufacturing the same

Owner:AU OPTRONICS CORP

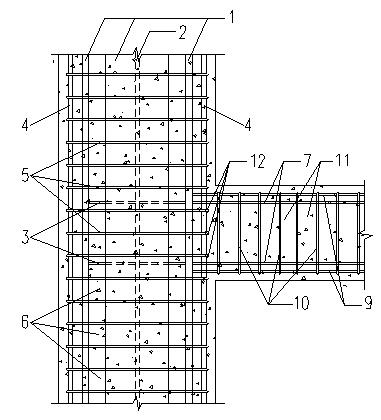

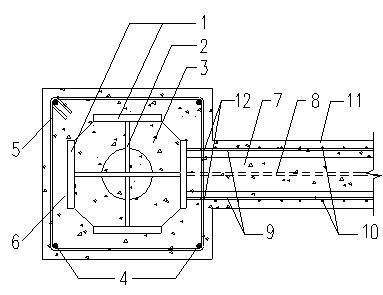

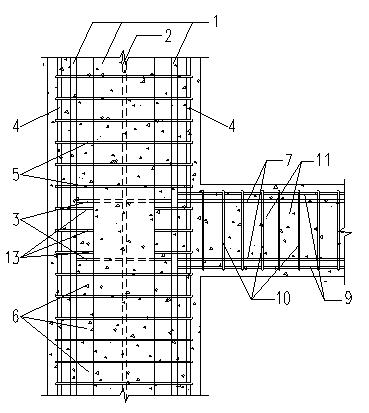

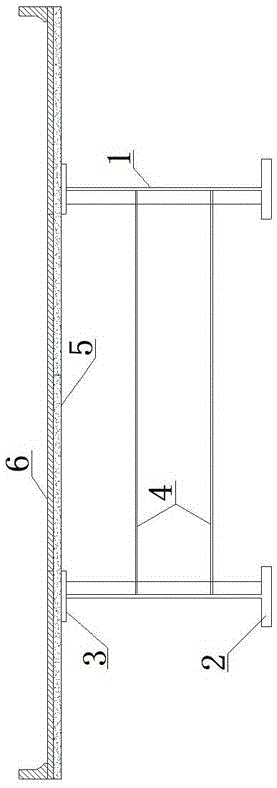

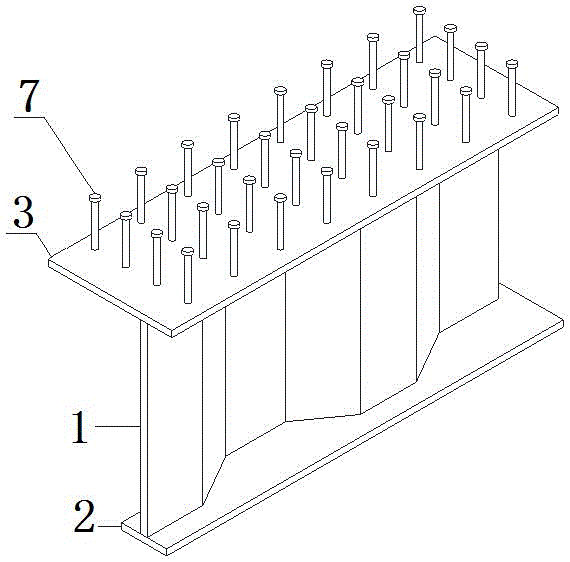

Hooped steel reinforced concrete beam-column joint of core area U-shaped column

ActiveCN102433938AShorten the construction periodReduce construction costsBuilding constructionsReinforced concreteRebar

The invention provides a hooped steel reinforced concrete beam-column joint of a core area U-shaped column, which relates to the field of constructional engineering. The hooped steel reinforced concrete beam-column joint of the core area U-shaped column comprises a column type steel flange plate, a column type steel web plate, a column horizontal stiffened steel plate, a column longitudinal bar, a column hoop, a column U-shaped hoop and a column concrete as well as a beam type steel flange plate, a beam type steel web plate, a beam longitudinal bar, a beam hoop and beam concrete; the beam-column joint core area is steel reinforced concrete structure building or structure of the U-shaped hoop. In the joint core area, the original closed hoop is replaced with the U-shaped hoop which is suitable for the structural forms at the beam-column joints of high-rise and super high-rise buildings. According to the invention, a column hoop through hole which is formed on the beam type steel web plate due to the need of enabling the column hoop to penetrate through the beam type steel web plate in the common steel reinforced concrete beam-column joint is avoided; one procedure is reduced in the member manufacturing process; the trouble of first penetrating through the reinforcing steel bar for making the hoop and then carrying out bending molding and segmental welding on the reinforcing steel bar during construction is prevented; and the beam-column joint can be manufactured in advance so that the construction period is shortened and the construction costs are saved.

Owner:中国建筑东北设计研究院有限公司

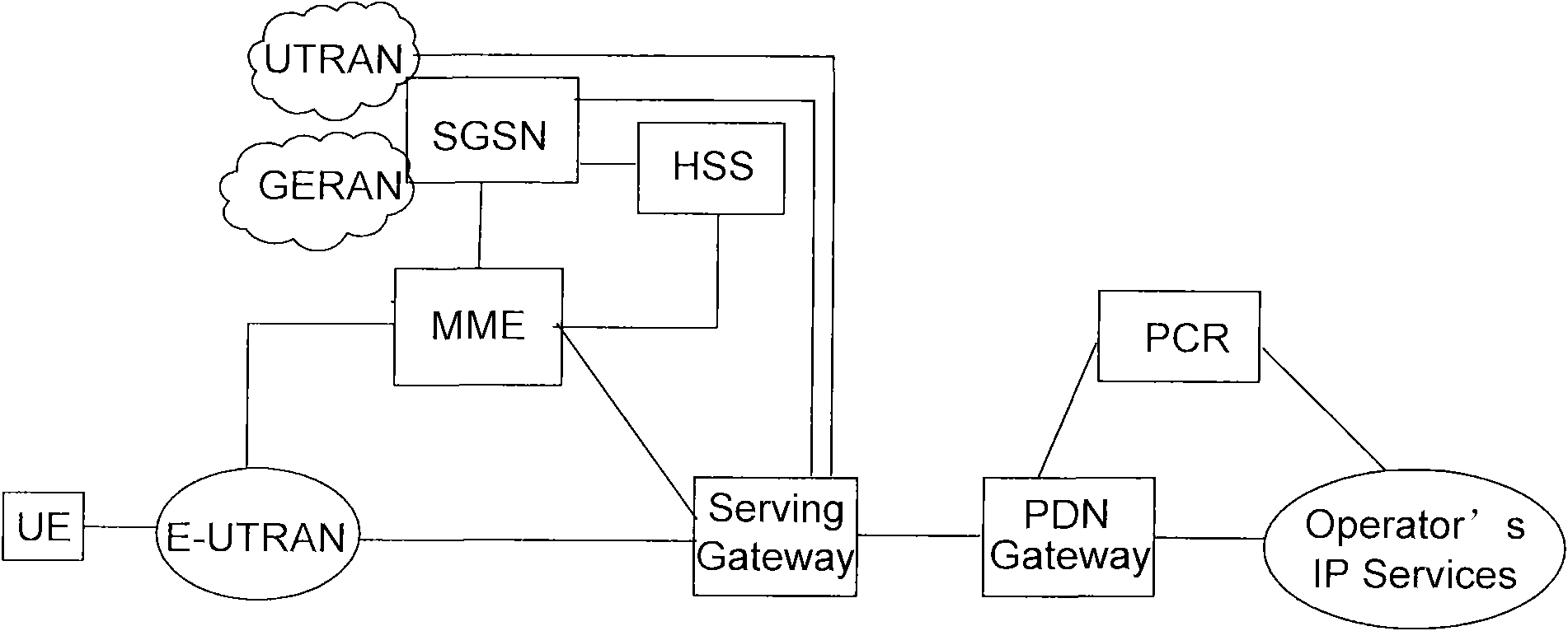

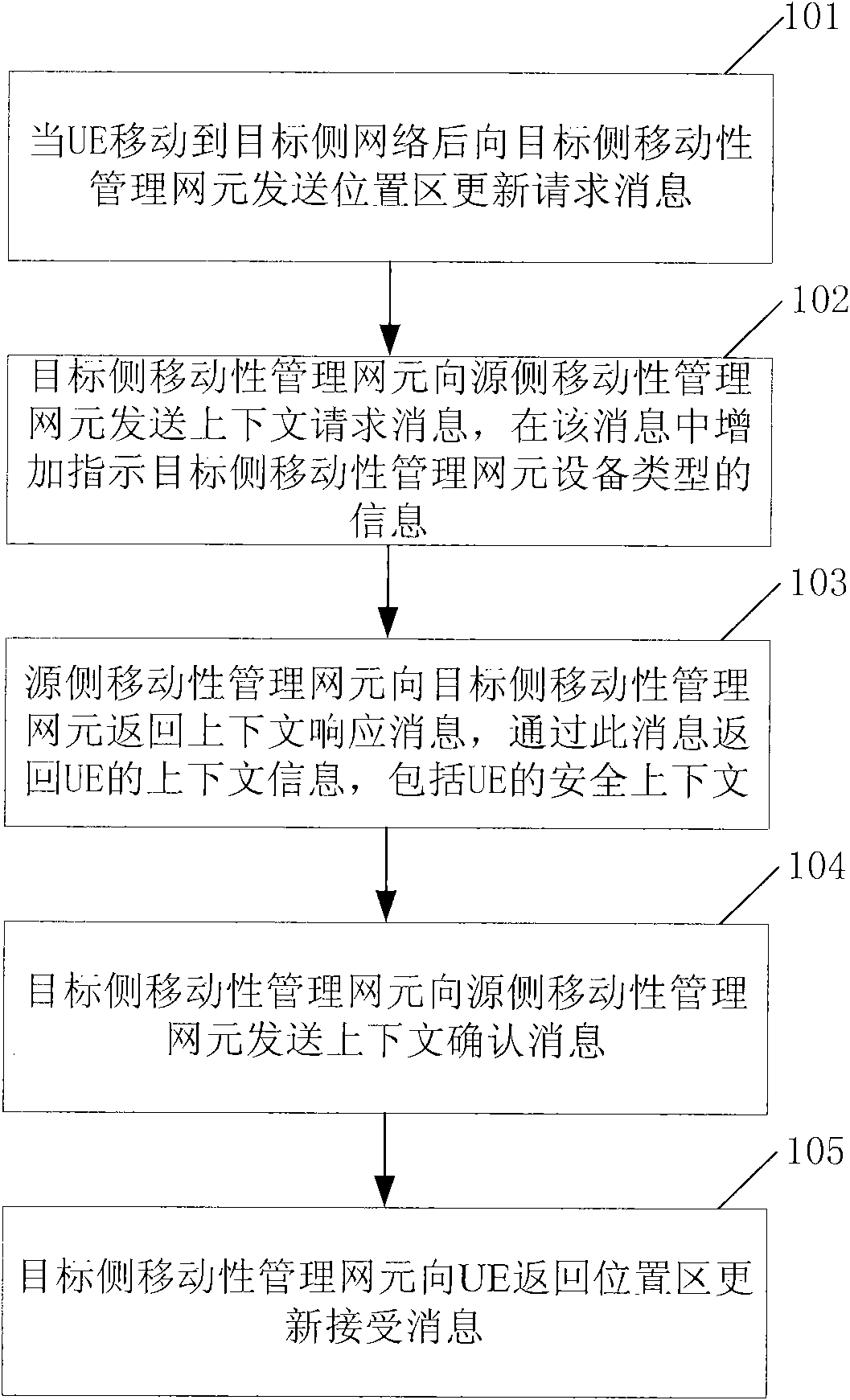

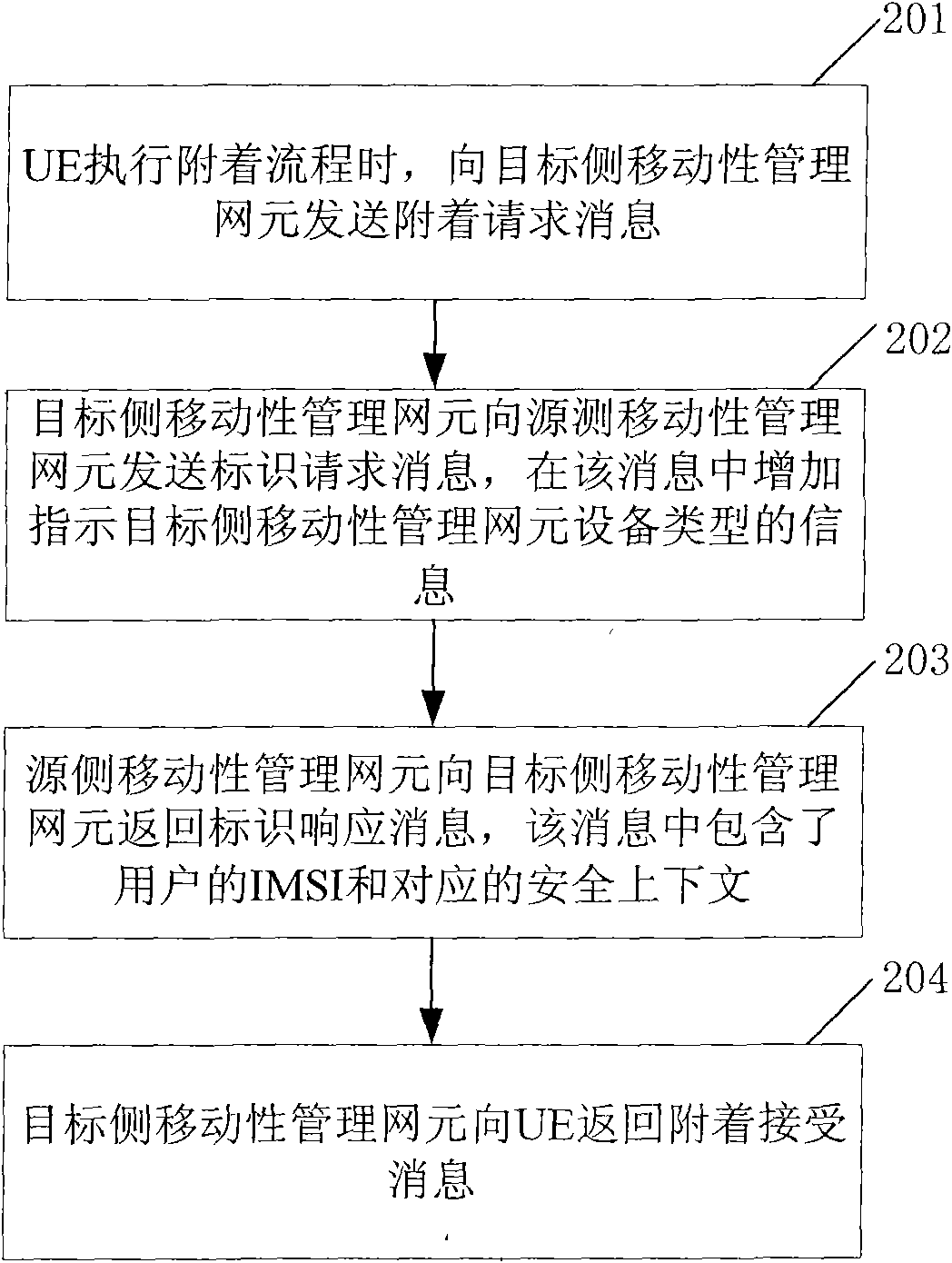

Method for providing security context, mobile management network element and mobile communication system

ActiveCN101594608AAvoid processReduce interaction loadSecurity arrangementNetwork data managementMobile communication systemsMobility management

The invention provides a method for providing security context, a mobile management network element and a mobile communication system, belonging to the field of communications.The method comprises the following steps: receiving request messages carrying instruction information, which is transmitted by the mobile management network element at the target side; transmitting user facility security context corresponding to the instruction information to the mobile management network element at the target side.In the embodiment of the invention, as the request messages transmitted from the mobile management network element at the target side to the mobile management network element at the source side carries the instruction information, so that the mobile management network element at the source side can transmit the security context corresponding to the instruction information to the mobile management network element at the target side according to the instruction information in the request messages, thus avoiding the process where the mobile management network element at the target side interacts with HSS to obtain the security context, reducing interaction load with the HSS.

Owner:HUAWEI TECH CO LTD

Simplified industrial method for recovering silicon carbide from mortar generated in cutting process of silicon wafers

InactiveCN101875492AAvoid difficult sortingEasy to operateSemiconductor/solid-state device manufacturingLubricant compositionSolid componentDiluent

The invention relates to a simplified industrial method for recovering silicon carbide from mortar generated in cutting process of silicon wafers. The method comprises the steps of: 1. adding diluent in the cutting mortar for reducing system viscosity; 2. carrying out primary separation on the mortar subjected to viscosity reduction by using a precise filter A, and setting and controlling filtering precision according to the requirement of silicon material wire-electrode cutting on the particle size distribution of a silicon carbide abrasive to obtain a solid component S1; 3. carrying out alkali wash, acid wash and rinse on the solid component S1, drying a wet material to directly obtain high-quality silicon carbide which meets the requirement of the silicon material wire-electrode cutting; 4. carrying out secondary separation on the mortar fluid subjected to the primary separation by using a precise filter B, and controlling the filtering precision to ensure that smallest passing particles which can be retained are below 2mu m so as to obtain a solid substance S2, and then separating clear liquid; and 5. carrying out alkali wash, acid wash and rinse on the solid component S2 obtained after secondary separation, drying a wet material to collect and obtain silicon carbide micropowder which has smaller particle size and can be used in other industrial occasions.

Owner:JIANGSU JIAYU RESOURCE UTILIZATION

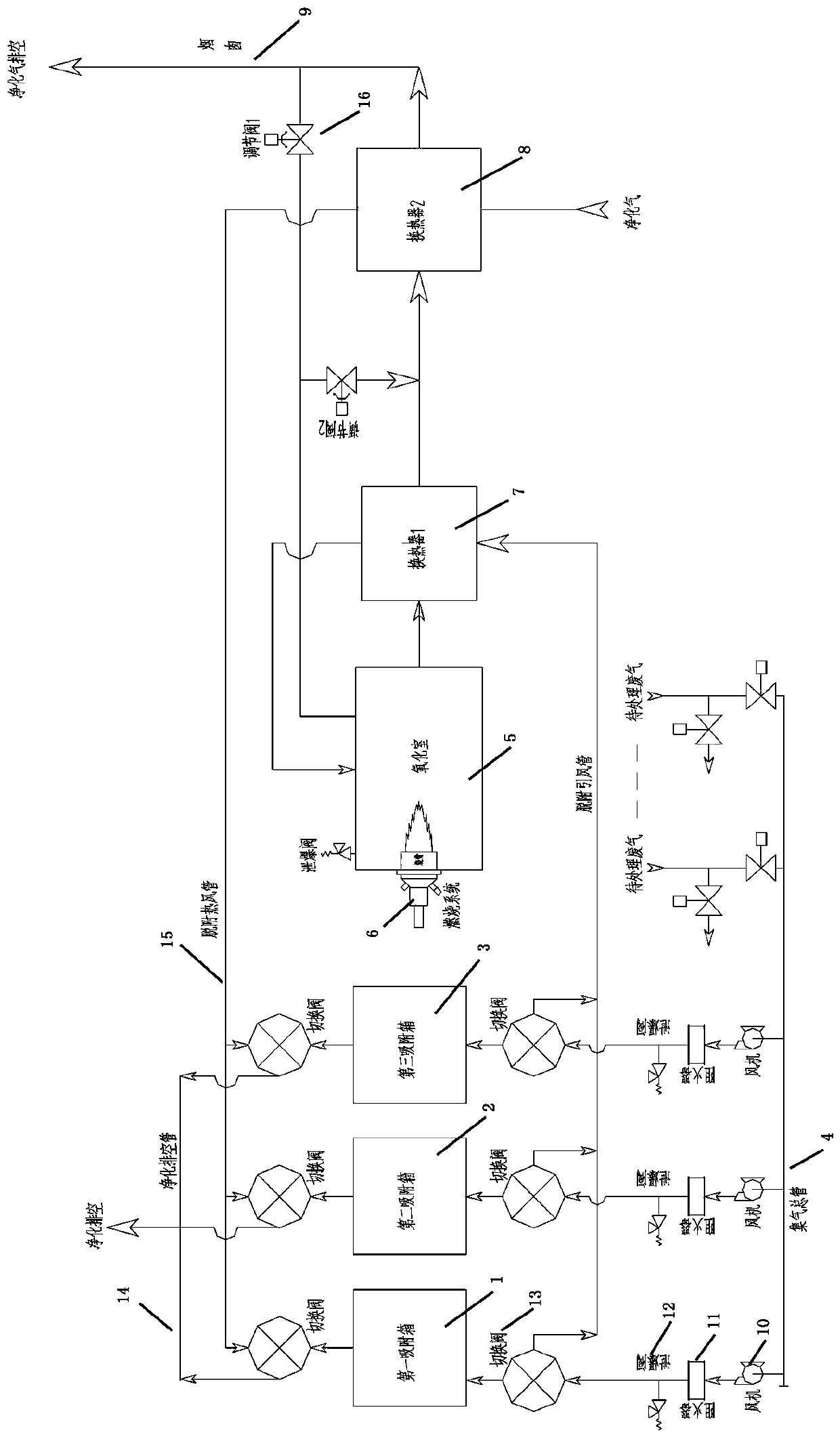

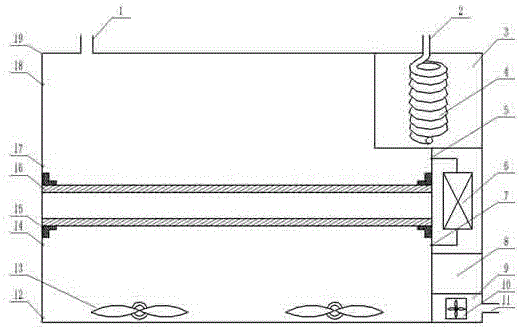

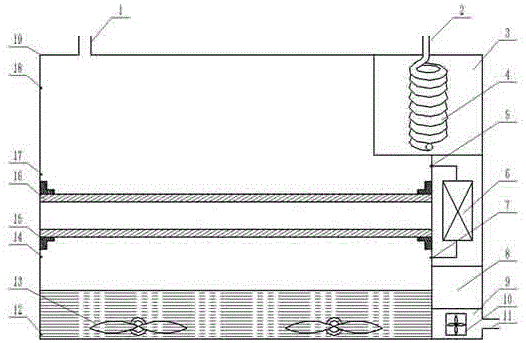

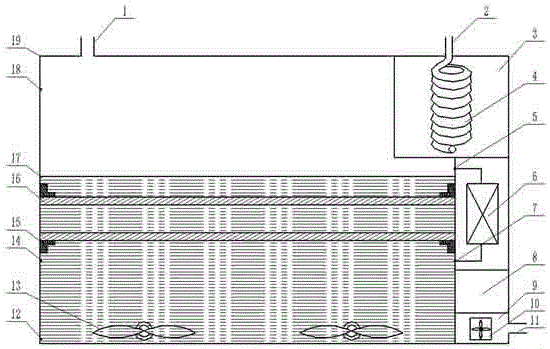

Treatment equipment for VOCs (Volatile Organic Chemicals) technological waste gas of packaging and printing industry

InactiveCN107774093AAvoid processGuaranteed safe operationGas treatmentDispersed particle separationOrganic chemicalsThermal energy

The invention belongs to the technical field of air pollution prevention and control equipment, and relates to treatment equipment for VOCs process waste gas in the packaging and printing industry. The exhaust gas containing VOCS enters the adsorption device from the gas collection main pipe, and the treated exhaust gas is discharged through the purification and exhaust pipe; when the adsorption reaches saturation, the system enters the desorption cycle, and the adsorbed VOCs are desorbed by hot air, and desorbed to obtain concentrated VOCs The gas is sent to the first heat exchanger for preheating through the desorption air duct, and then transferred to the oxidation chamber for oxidation. Part of the evacuated purified gas is heated by the second heat exchanger and transferred to the adsorption box for desorption through the second heat exchanger and the desorption hot air pipe, so that the saturated adsorbent can be desorbed and regenerated. The combustion system is installed on the left facade of the oxidation chamber to provide heat for the oxidation chamber. The invention effectively solves the problem of adsorption and reuse of process waste gas discharged from ovens of gravure printing machines and composite machines with large air volume and low VOCs exhaust concentration.

Owner:广东汕樟轻工股份有限公司

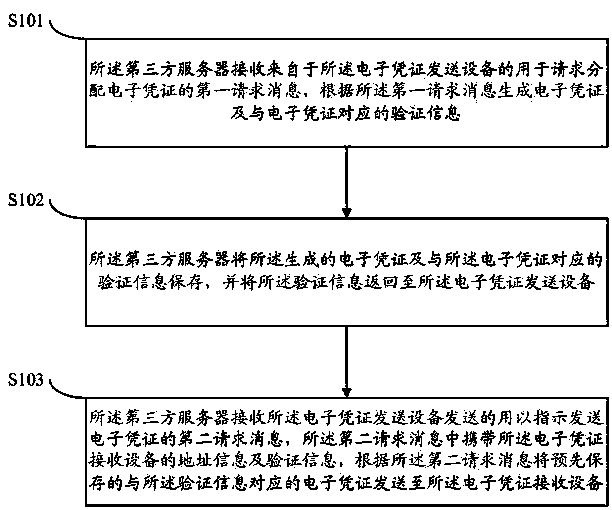

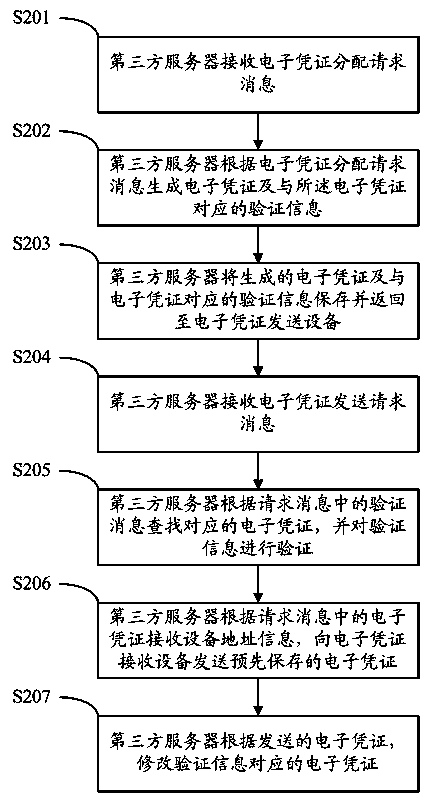

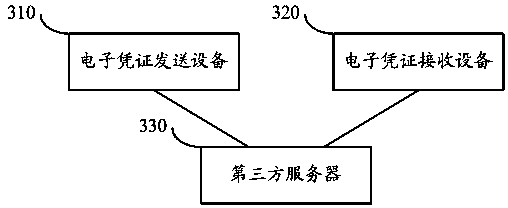

Electronic certificate sending method

ActiveCN103812837AAvoid processUser identity/authority verificationPersonally identifiable information

The invention discloses an electronic certificate sending method. According to the electronic certificate sending method, an electronic certificate having verification information is firstly distributed to an electronic certificate sending user and is further stored, after a request of the electronic certificate sending user is received subsequently, an electronic certificate corresponding to the verification information in the request is directly sent to an electronic certificate receiving user specified in the request, so a problem that the electronic certificate receiving user can not acquire personal identity information of the electronic certificate sending user while receiving the electronic certificate in a process of sending the electronic certificate through verifying personal identity information is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

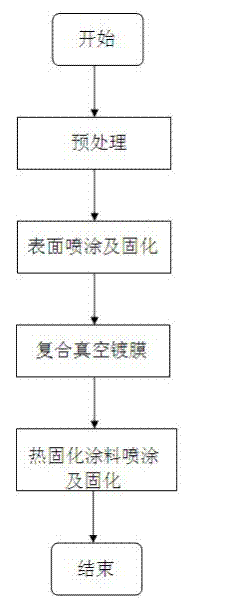

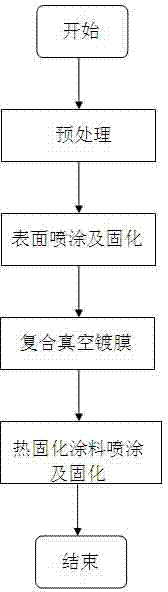

Composite vacuum plating method

ActiveCN102383101AHigh densityStrong metal feelingVacuum evaporation coatingSputtering coatingSputteringPre treatment

The invention discloses a composite vacuum plating method and belongs to the technical field of surface treatment. The method comprises steps of surface pretreatment of a base material, surface spraying and solidification, vacuum plating, spraying of thermocuring paint and solidification. The vacuum plating comprises nickel plating through magnetron sputtering, nickel-chromium plating through combination of magnetron sputtering and chrome plating through ion plating and cathode arc ion. The invention omits an onerous furbisher process, simplifies technical flow, increases production efficiency and mitigates labor intensity of workers; secondly, a mixed film plating technology of magnetron sputtering and ion plating is employed that the obtained product film has high film density and strong metal feel; thirdly, preparations of a metal layer and a metal mixed coating are carried out in a same vacuum furnace, so as to facilitate operation, guarantee good bond of the film and enhance product quality.

Owner:HUZHOU BIAOLI ENERGY SAVING TECH CO LTD

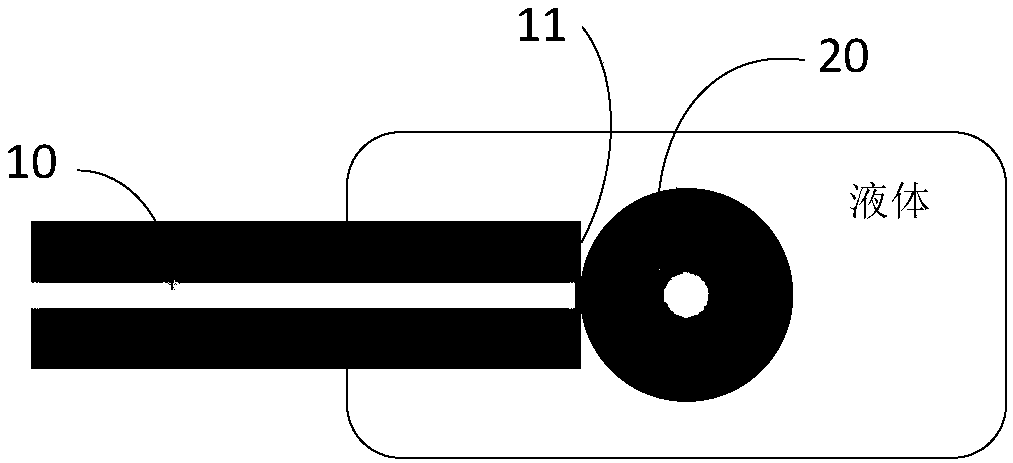

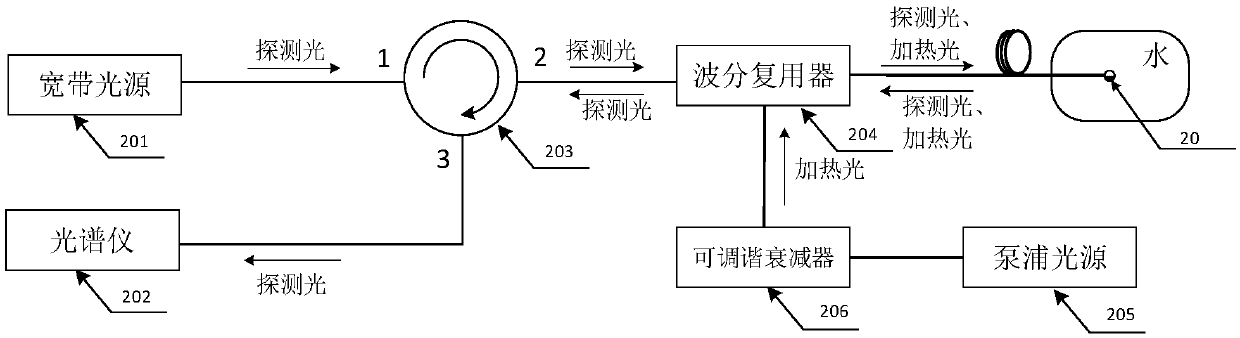

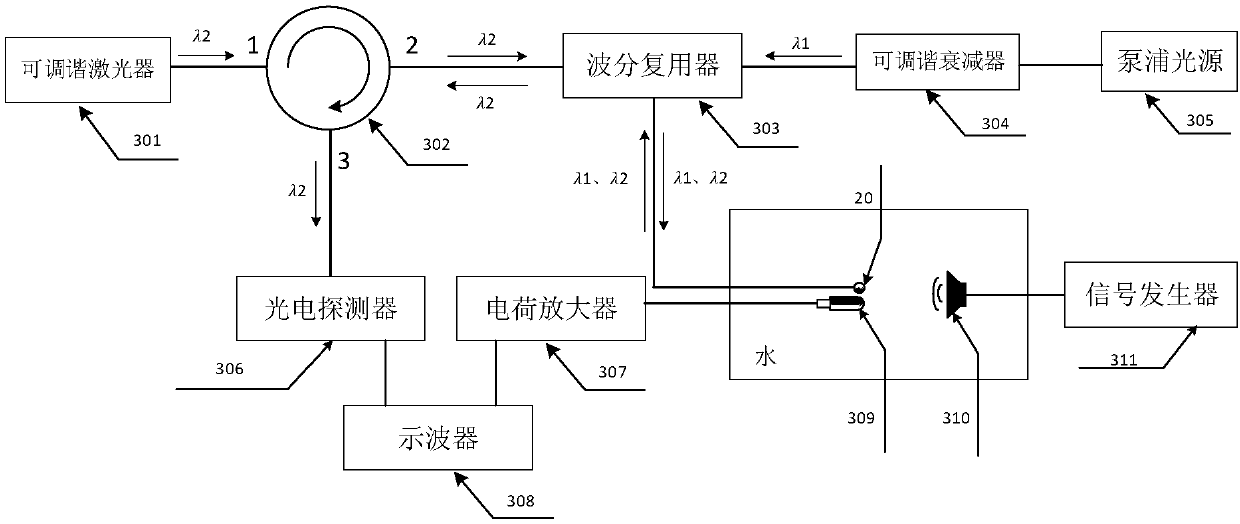

Air micro-cavity type fiber hydrophone, manufacturing method of the same, and signal detection method

ActiveCN107817043AEasy to makeAvoid processSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansFrequency bandEngineering

The invention discloses an air micro-cavity type fiber hydrophone, a manufacturing method of the same, and a signal detection method. The air micro-cavity type fiber hydrophone is formed by a fiber and an air micro-cavity at the end surface of the fiber, wherein the air micro-cavity can be used as a compressible Fabry-Perot cavity for sensing the micro-cavity length or reflected light interferencespectrum change caused by the external pressure so as to realize measurement of sound wave and ultrasonic wave. The manufacturing method of the air micro-cavity type fiber hydrophone is simple, and optically heats the fiber end surface coated with luminous absorption material to realize water vaporization on the fiber end surface and form an air micro-cavity on the fiber end surface, thus avoiding the complicated process, such as fiber Fabry-Perot cavity structure manufacturing and pressure sensitive film welding. Besides, the manufacturing method of the air micro-cavity type fiber hydrophonerealizes accurate on-line control of the cavity length by adjusting the heating laser power, can overcome the problem that a traditional manufacturing method is not enough in the repeatability of device structural parameters, can realize dynamic tuning of the measurement range and the working frequency band on single sensor, and can improve applicability of the sensor.

Owner:JINAN UNIVERSITY

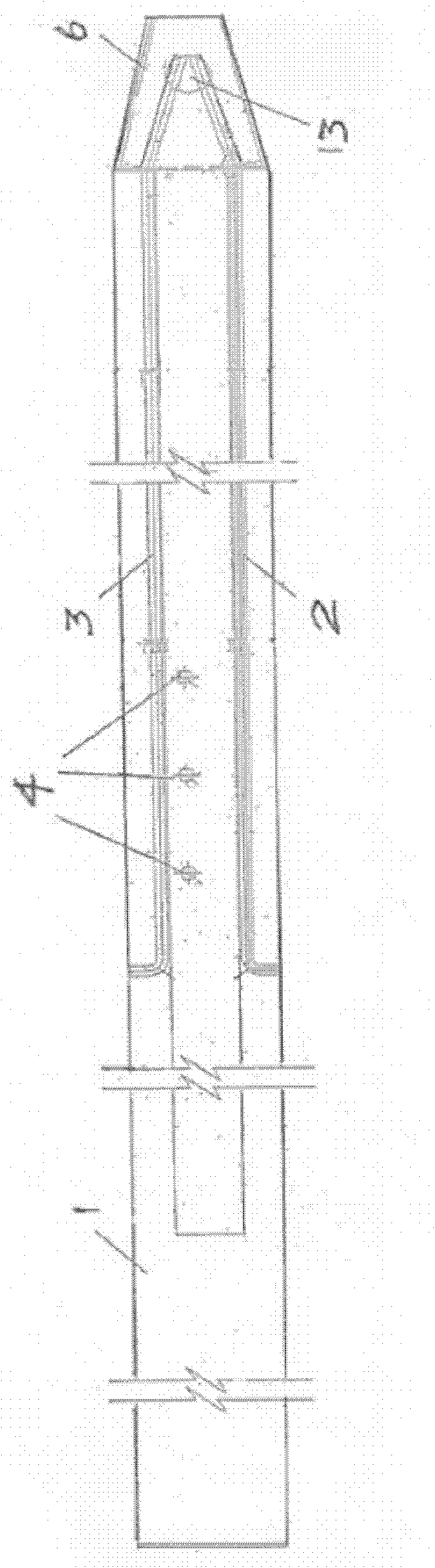

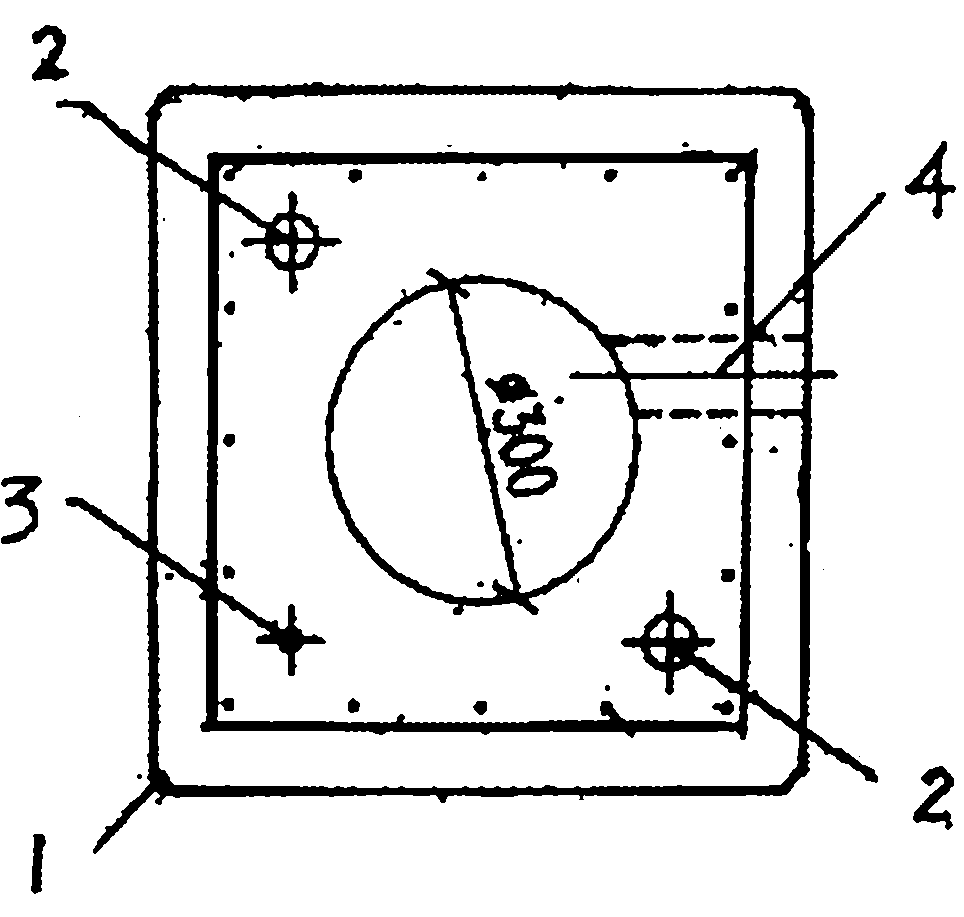

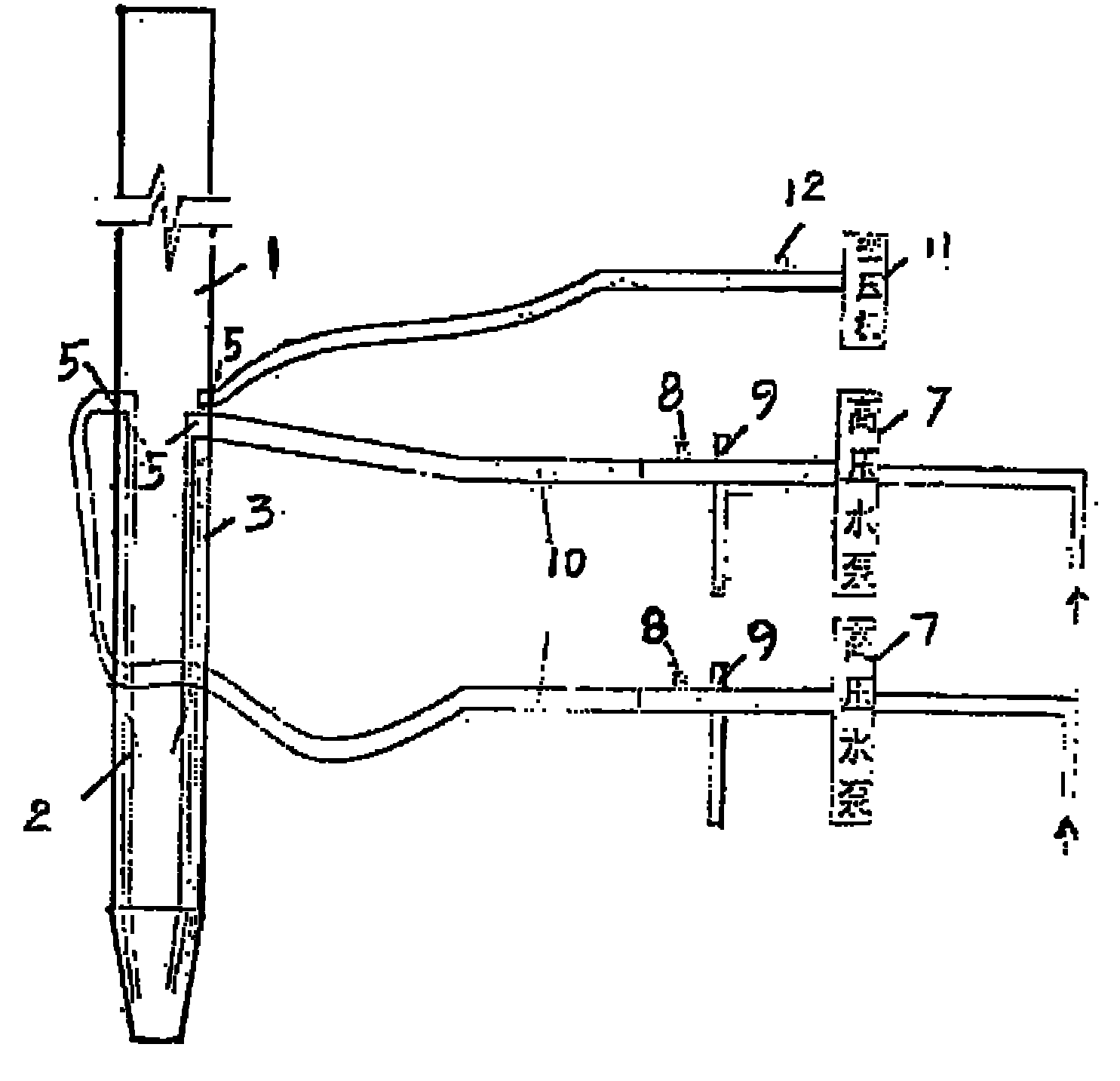

Water-flushing sinking-assisting system and construction technical method thereof

ActiveCN102182186AShorten the effective lengthGuaranteed bearing capacityBulkheads/pilesEffective lengthSlurry

The invention relates to a water-flushing sinking-assisting system. Two water jet pipes and an air pipe are preembedded in a pile body of a precast pile, water inlet ends of the two water jet pipes are connected to a quick joint and then connected to a double-table water pump, and a side wall of the pile body is provided with three outer drainage holes communicated with a pile core; a pile tip isa funnel shaped steel pile tip welded by a steel plate; and the two water jet pipes at the pile tip flush water directly along the pile axial line direction. The invention has the advantages that because the three outer drainage holes with the diameter of 70mm, reserved at the pile body, are communicated with the pile core, the effective length of an inner drainage slurry channel is reduced so asto drain away water and sand; because a water pipe and the air pipe are preembedded in concretes, the pipes are unnecessary to pull out, an internal thread bend elbow of 90 DEG is adopted at a water inlet end and an air inlet end so as to connect the quick joint; and because the quick joint is utilized, the assembly and disassembly are quick, the steps of assembling and disassembling the water pipe and the air pipe are effectively avoided, the operation is simple, the cost is lower, and the pile-sinking efficiency is improved.

Owner:CCCC FIRST HARBOR ENG +1

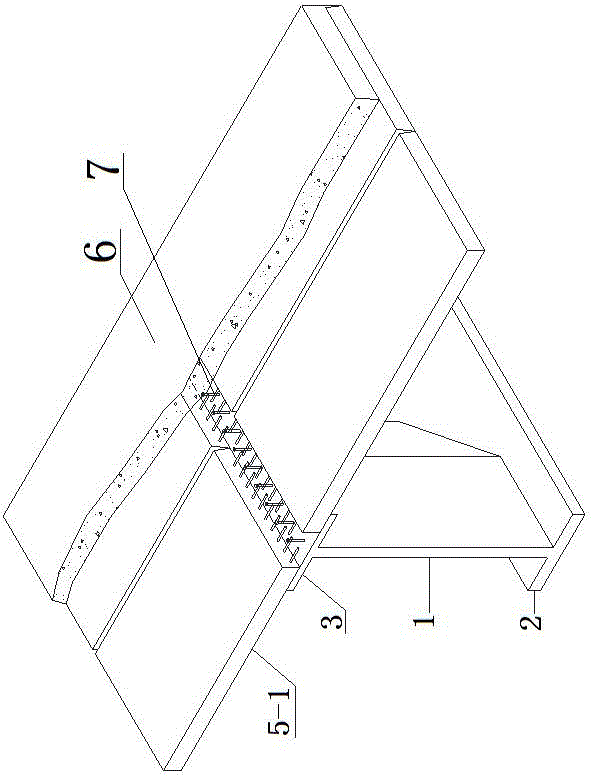

Corrugated steel web few-main-beam structure

InactiveCN105133486AReduce the amount of concreteReduce the weight of the main beamBridge structural detailsBridge deckBox girder

The invention discloses a corrugated steel web few-main-beam structure which comprises a plurality of corrugated steel web main beams, a concrete prefabricated plate arranged on corrugated steel webs, and a bridge deck pavement layer is laid on the concrete prefabricated plate. According to the corrugated steel web few-main-beam structure, a corrugated steel web combined structure is adopted, the use efficiency of steel and concrete materials is fully developed, the use amount of concrete is reduced, the dead load of the main beams is reduced, energy conservation and environmental friendliness are achieved, and the economic performance is good. Structural key parts of the corrugated steel web main beams and a concrete bridge deck slab are factorized, the concrete bridge deck slab is prefabricated in a factory and can reduce the additional stress caused by shrinkage and creep of the concrete, the product quality is easily ensured, and compared with a cast-in-place mode, the process of demounting and mounting a formwork is omitted, the wet work amount on the field is reduced, the construction period is shortened, and the construction progress is shortened. The smooth passing of the road can be achieved under a bridge in the construction process of the bridge, fast construction can be achieved, the influences on the existing traffic are small, and the social benefits are good. A basis is provided for factory standardized and prefabricated production and field assembly building of a 30 m-50 m corrugated steel web PC box girder bridge, and the application fields are expanded.

Owner:HENAN DAJIAN BRIDGE STEEL STRUCTURE

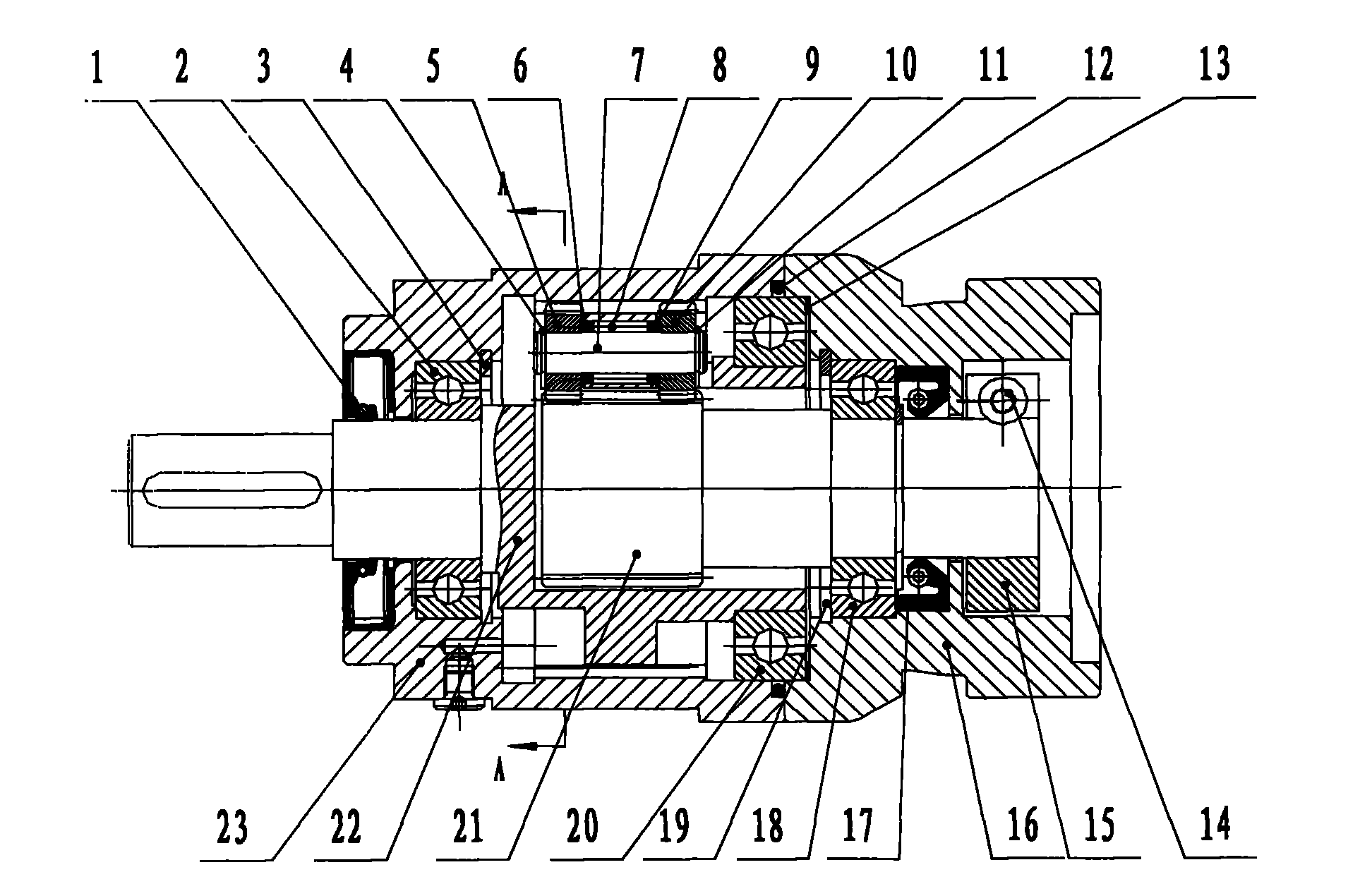

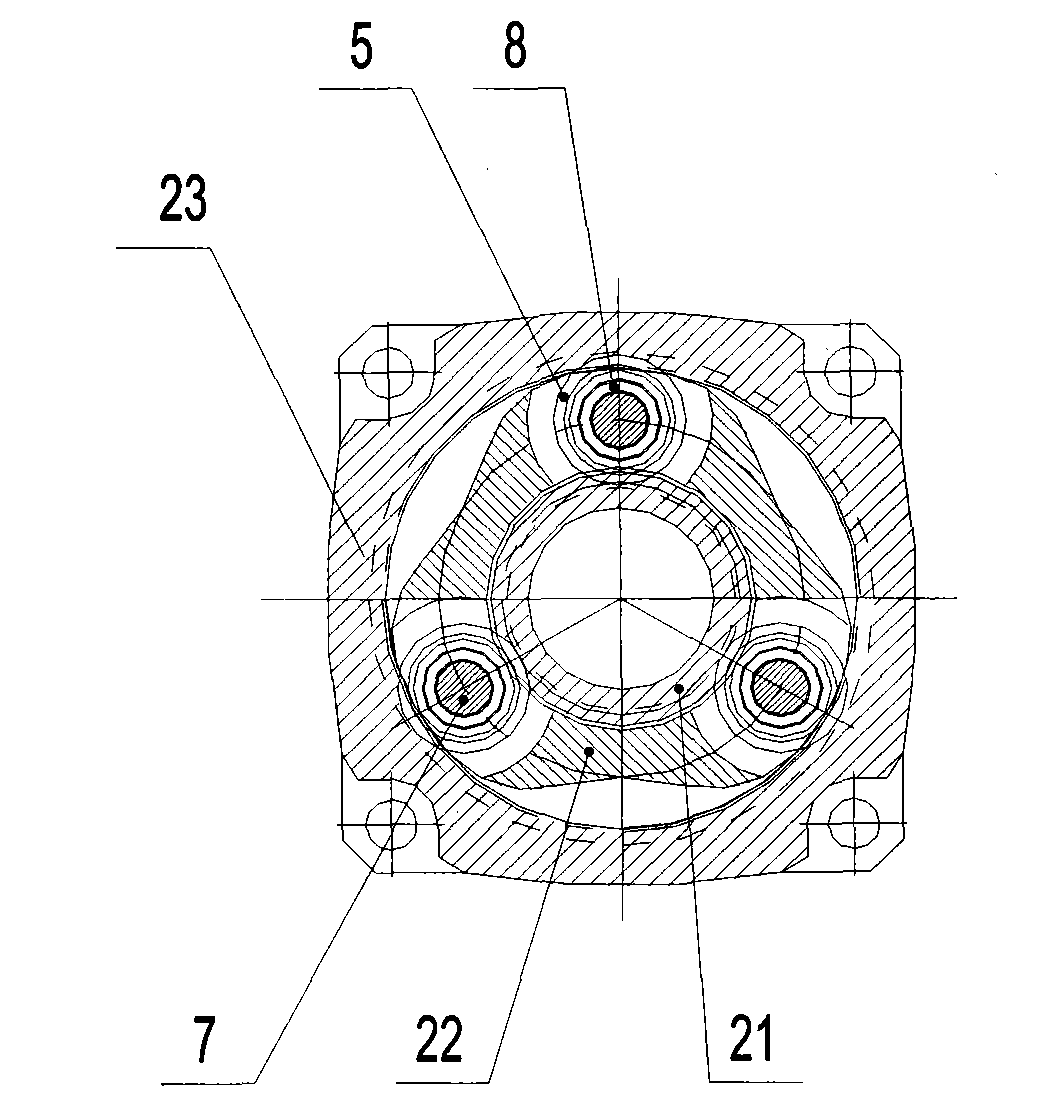

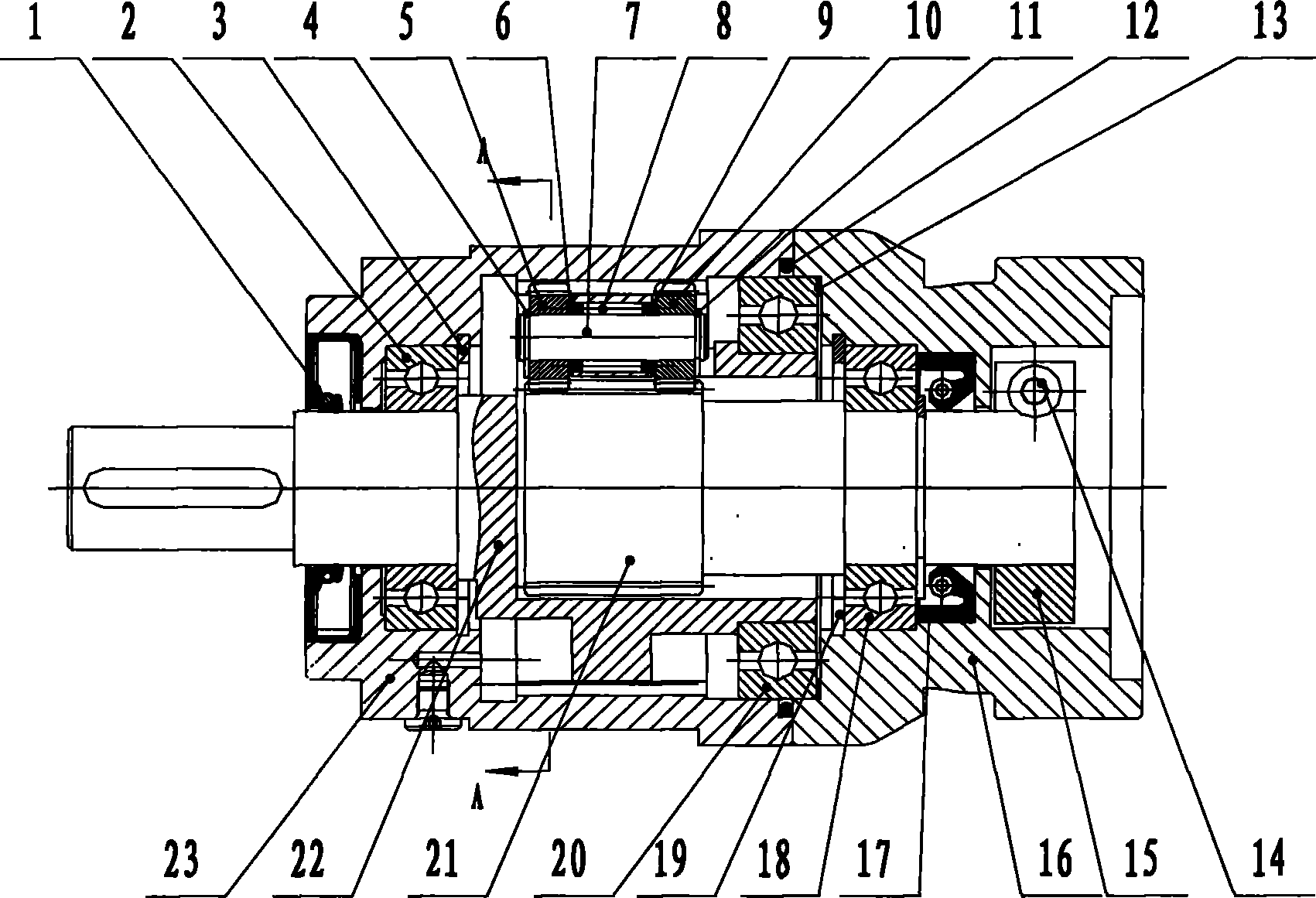

Planet gear speed reducer

InactiveCN102588517AImproved meshing propertiesAchieving Backlash CompensationGear lubrication/coolingToothed gearingsNeedle roller bearingEngineering

The invention provides a novel planet gear speed reducer, which can maintain that the plant gear speed reducer operates at high precision under the lower processing precision of the planet gear and is compact in structure. The novel planet gear speed reducer comprises a gear transmission part and a shell part; wherein the shell part comprises a tail end shell and a planet internal-gear shell; the gear transmission part comprises a plurality of planet gear sets, a sun gear shaft and a planet wheel bracket shaft body; each planet gear set is two planet gears arranged at both ends of the planet gear shaft in parallel; the planet gear shaft is arranged on the planet wheel bracket shaft body; and a needle roller bearing is arranged between the planet gear shaft and the planet wheel bracket shaft body, so that the planet wheel shaft can rotate relatively between the planet gear bracket shaft bodies. According to the novel planet gear speed reducer, the manufacturing cost of the planet gear speed reducer is effectively reduced, and the high precision is realized.

Owner:赵强 +1

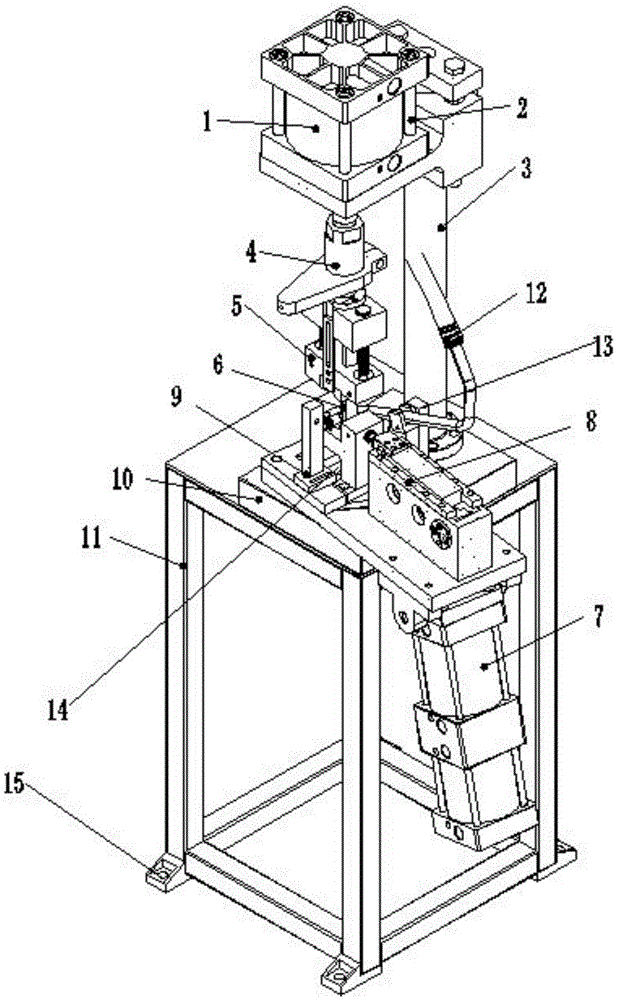

Gas extraction pipeline continuous and automatic drainage and deslagging device

InactiveCN106837407AGuaranteed continuityIncrease moisture contentMining devicesDrainageContinuous/uninterruptedInterference resistance

The invention belongs to the field of gas extraction and relates to a gas extraction pipeline continuous and automatic drainage and deslagging device. The gas extraction pipeline continuous and automatic drainage and deslagging device is composed of a main device tank, a water tank, a gas extraction inlet, a gas negative-pressure extraction port, a condensing system, a pressure regulating system, a control system, a drainage and deslagging system, a water level monitoring system, a water and slag mixer, a pressure monitoring system, a separating plate guide groove and a separating plate, wherein the water tank is arranged inside the main device tank and separated into an upper tank body and a lower tank body by the separating plate; the condensing system can condense steam inside gas and collecting water into the water tank; the water level monitoring system and the pressure monitoring system are connected with a control system so that the control system can control opening and closing of the separating plate as well as pressure regulation of the pressure regulating system; water and slag can be uniformly mixed by the water and slag mixer and then drained via the drainage and deslagging system. The gas extraction pipeline continuous and automatic drainage and deslagging device is stable in system operation, high in interference resistance, convenient to arrange, full in automation and capable of saving manual operation and achieving continuous and efficiency operation.

Owner:HENAN POLYTECHNIC UNIV

Fusion neuron model, neural network structure, training method, reasoning method, storage medium and equipment

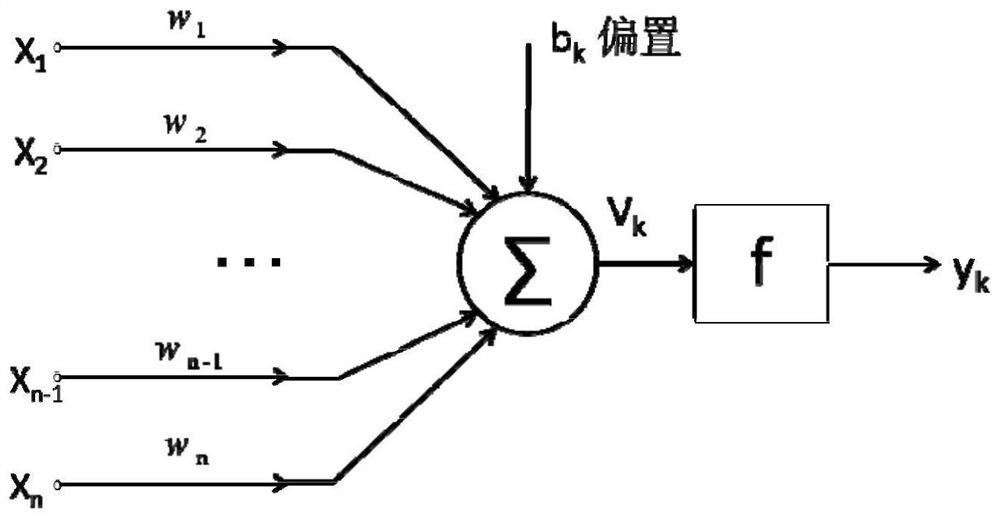

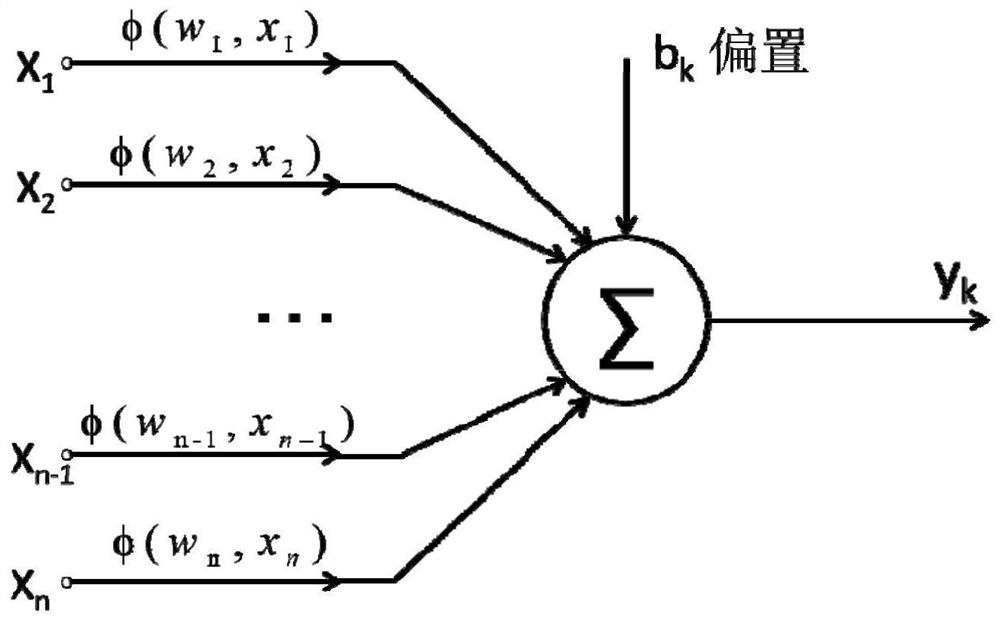

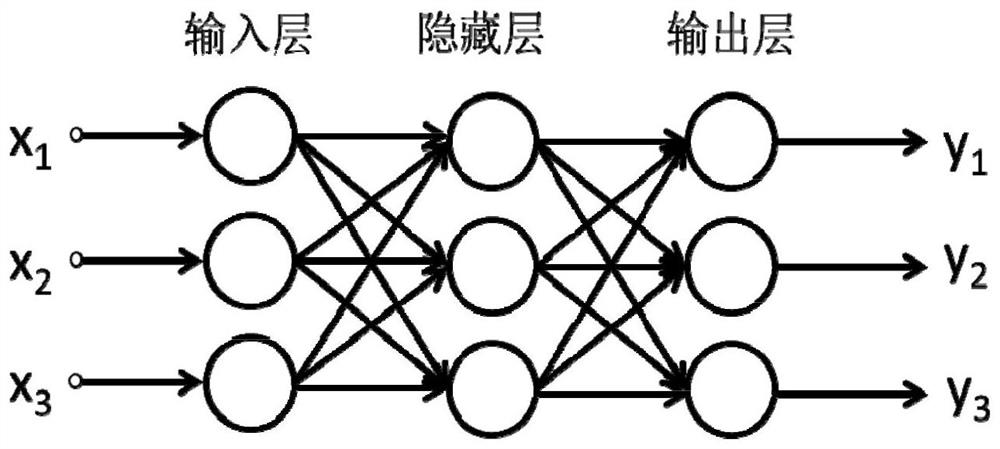

PendingCN112529166AIncreased computing speed and the ability toImprove computing efficiencyNeural architecturesPhysical realisationNeural net architectureMachine learning

The invention relates to an artificial neuron and a neural network, in particular to a fusion neuron model, a neural network structure, an inference method and a training method of the neural networkstructure, a computer readable storage medium and computer equipment. Each synaptic connection weight of the fusion neuron model is any continuous derivable nonlinear function, and linear-to-nonlinearmapping is realized on the synaptic weight. The neural network structure forms a hierarchical structure by taking a fusion neuron model as a basic composition unit, and the reasoning method comprisesthe following steps: substituting input data into a connected nonlinear weight function, calculating a connection weighting result, and summing all weighting results of neurons, and directly transmitting the weighted results to a next-stage neuron; carrying out forward transmission in sequence to finally obtain an identification result. According to the training method, parameters of a neuron model are optimized through a back propagation algorithm and a gradient descent algorithm; and the computer readable storage medium and the computer equipment can realize specific steps of the reasoningmethod and the training method.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI +1

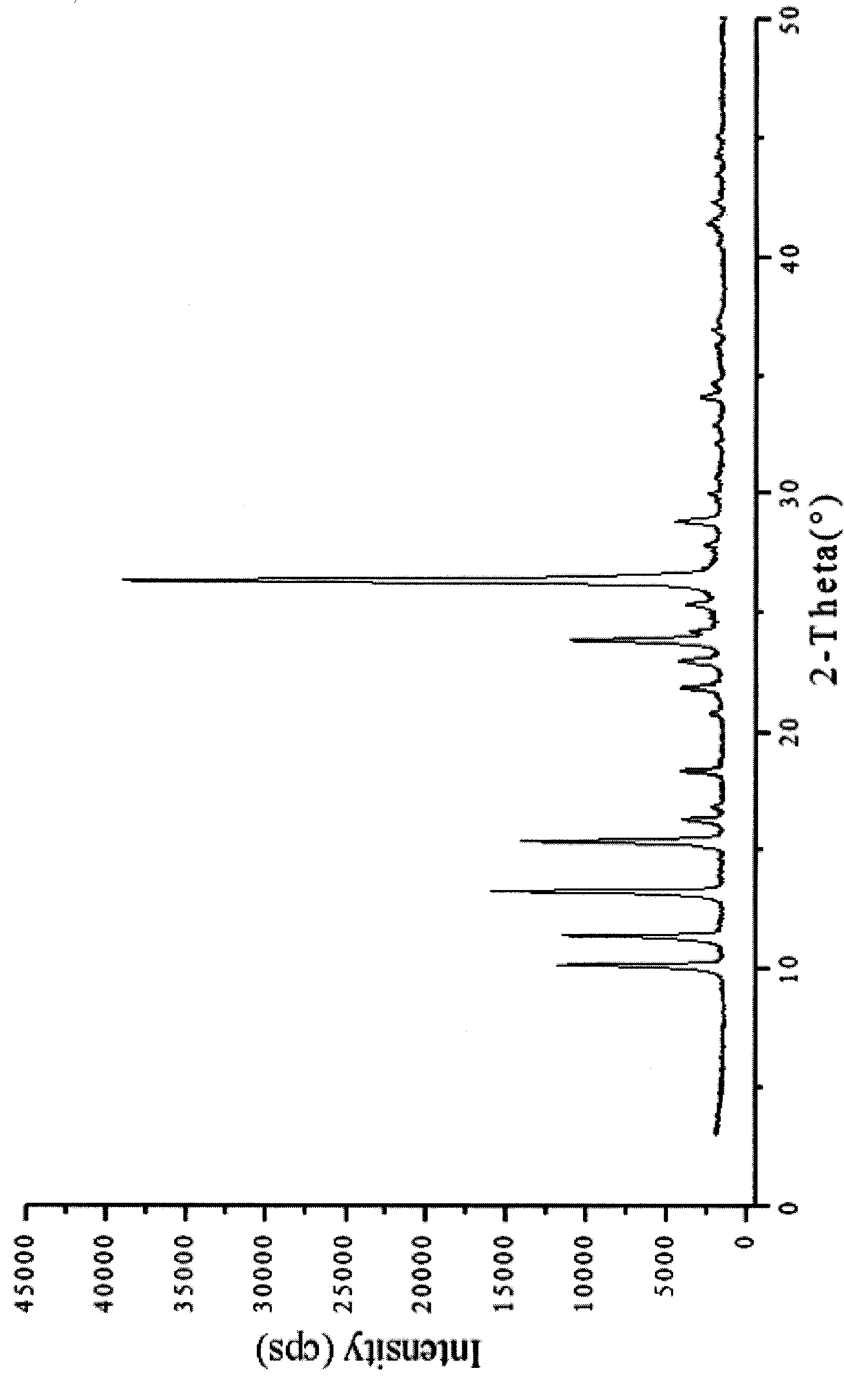

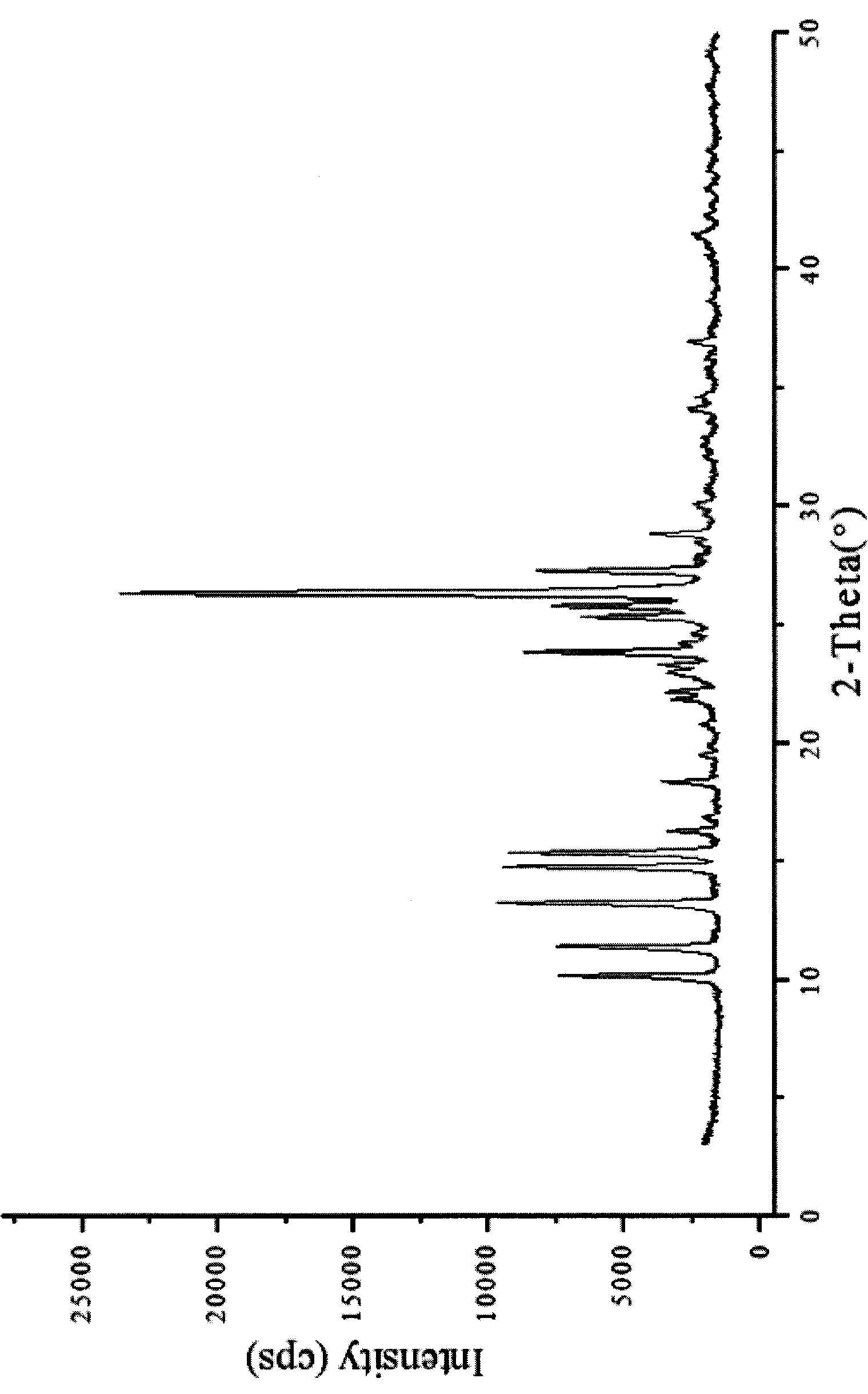

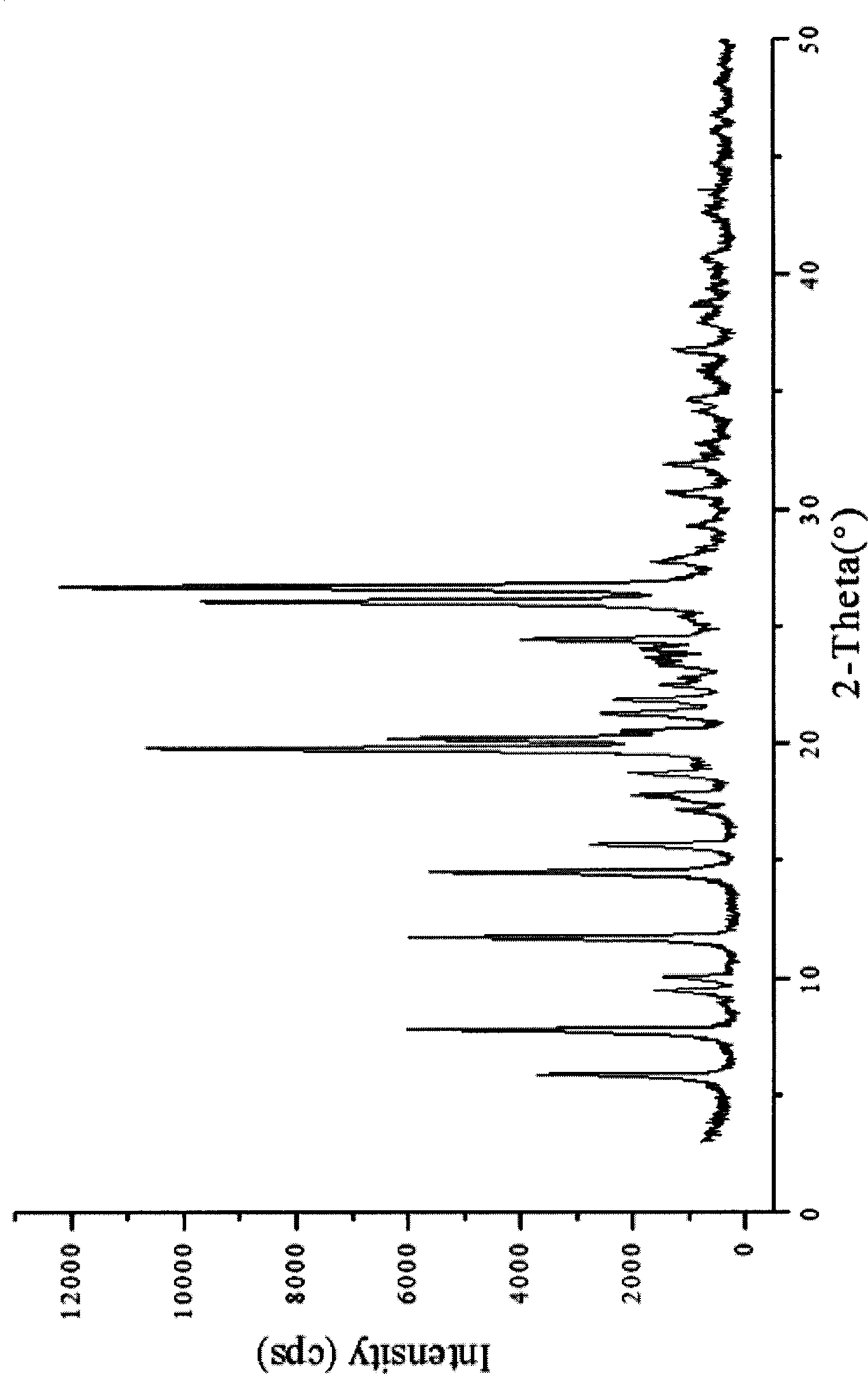

Baicalein-nicotinamide eutectic crystal

The invention relates to a eutectic crystal formed from baicalein and nicotinamide. An XRPD (X Ray Powder Diffraction) pattern of the baicalein-nicotinamide eutectic crystal disclosed by the invention has characteristic peaks at 5.83 degrees, 7.71 degrees, 11.70 degrees, 14.44 degrees, 15.70 degrees, 19.81 degrees, 20.19 degrees, 26.05 degrees and 26.56 degrees, a DSC (Differential Scanning Calorimetry) diagram of the baicalein-nicotinamide eutectic crystal has a strong endothermic peak at 165.65 DEG C, and an infrared spectroscopy of the baicalein-nicotinamide eutectic crystal has characteristic wave numbers at 3444.98cm<-1>, 3338.89cm<-1>, 3180.72cm<-1>, 1641.48cm<-1> and 1386.86cm<-1>; the measurement results of the XRPD pattern, the DSC diagram and the infrared spectroscopy of the baicalein-nicotinamide eutectic crystal are all different from the related measurement results of baicalein and physical mixtures of baicalein and nicotinamide, which indicates that the crystal is a novel crystal form completely different from that of baicalein and physical mixtures of baicalein and nicotinamide.The baicalein-nicotinamide eutectic crystal is prepared by a grinding method which is simple and convenient in flow, free of pollution, low in cost and high in yield.

Owner:CHINA PHARM UNIV

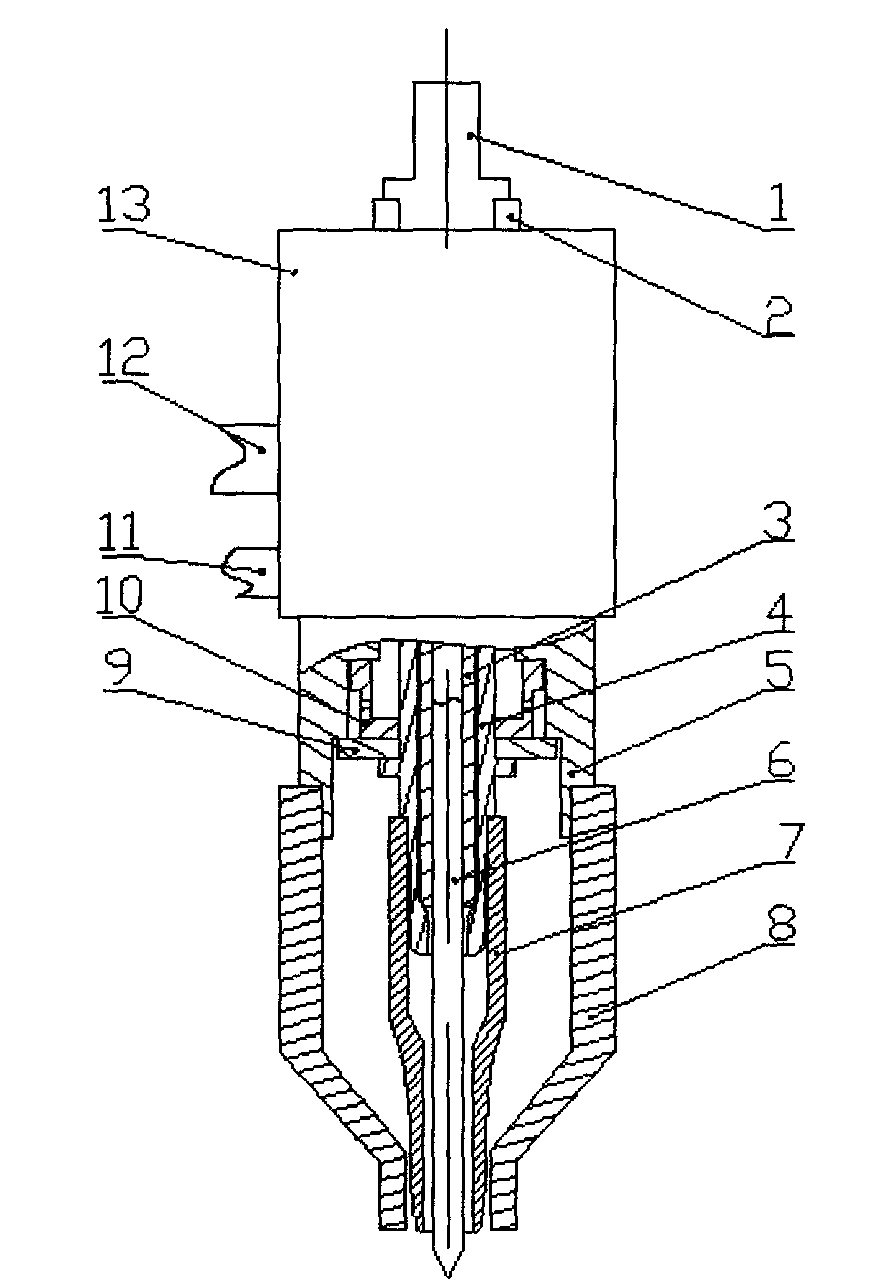

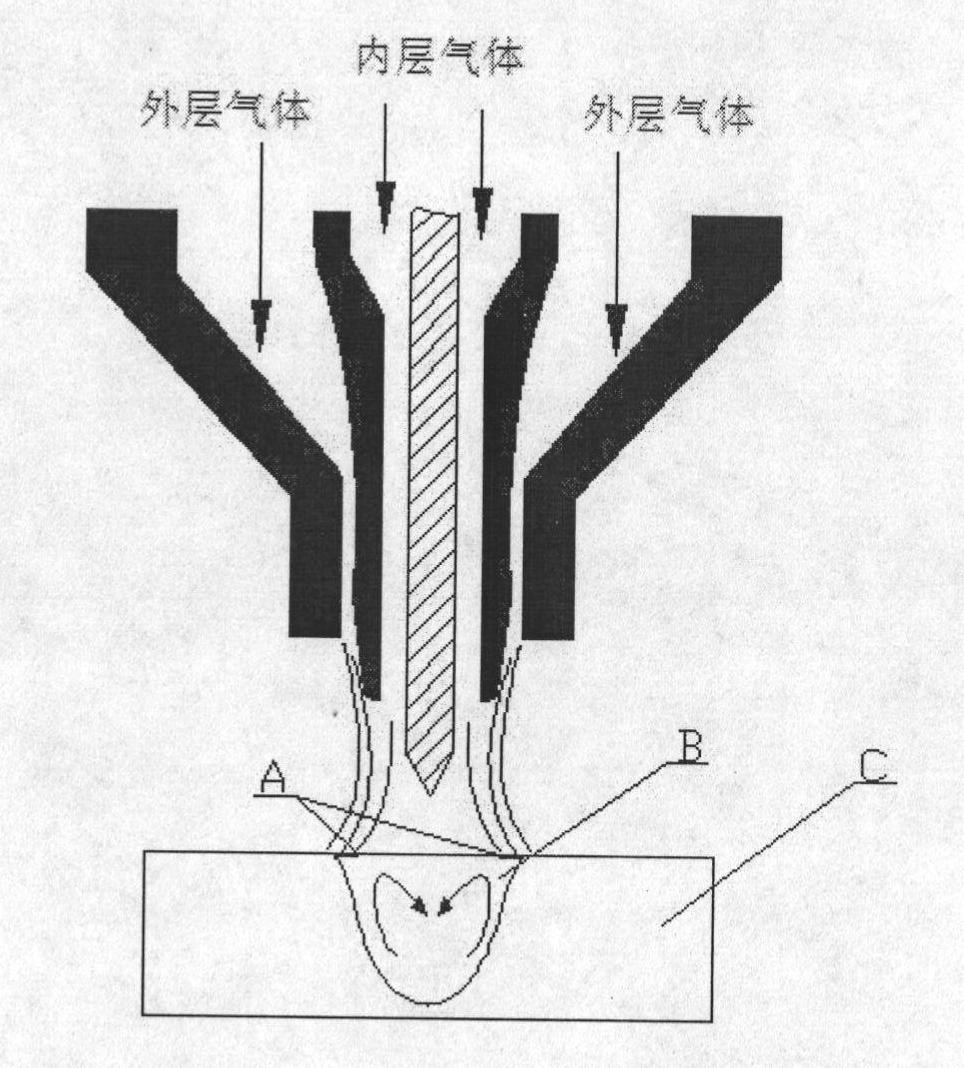

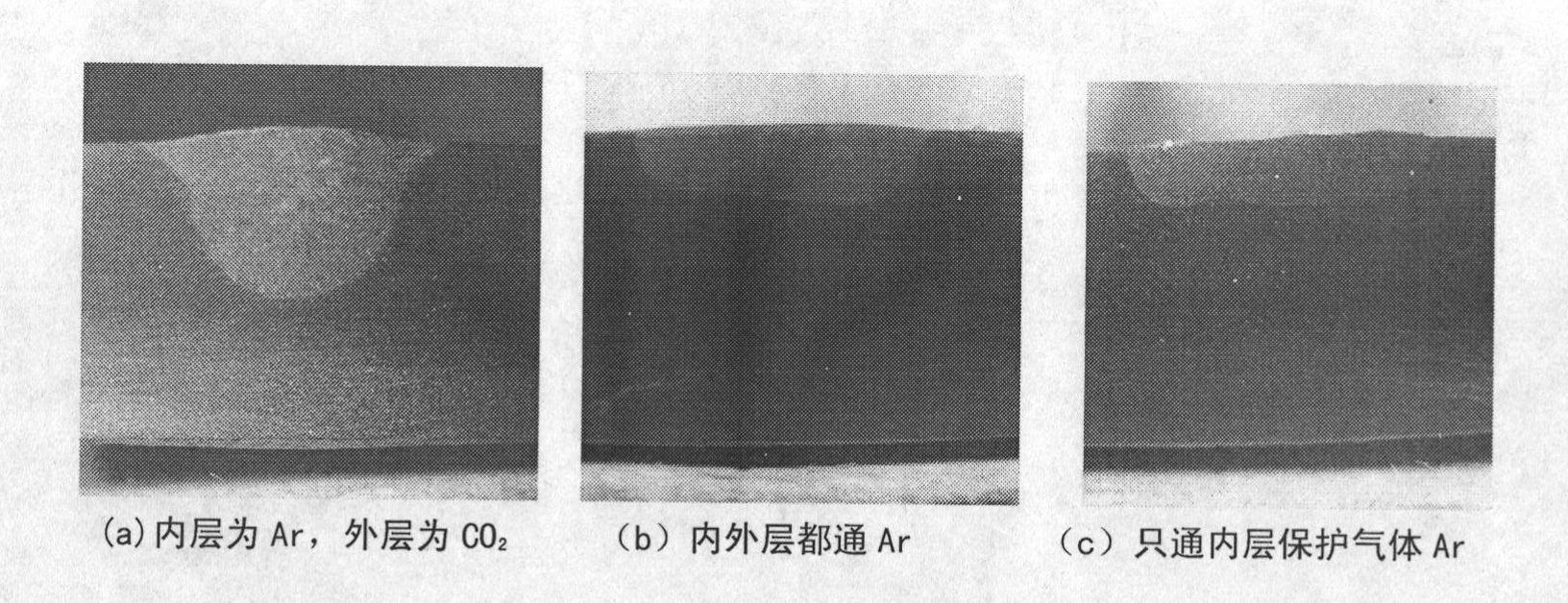

Gas molten pool coupling active welding method

InactiveCN102151957AAvoid processImprove welding efficiencyArc welding apparatusMelting tankEngineering

The invention discloses a gas molten pool coupling active welding method and belongs to the field of active welding. An inner layer of gas and an outer layer of gas which are different are adopted during the welding process; the inner layer of gas relates to inert gas (Ar or He); and the outer layer of gas relates toN2+O2 mixed gas or N2+CO2 mixed gas. The outer layer of gas penetrates voltaic arcs and then is decomposed to generate element O and element N, and is coupled a the molten pool, thereby changing the floating state of metal in the molten pool and leading the metal to flow from the surface of the molten pool to the bottom part of the molten pool so as to realize the purpose of increasing the molten depth and simultaneously improving the impact toughness of welding seams. The intake volume of element O or element N can be coarsely adjusted by adjusting the flow of the outer layer of gas or the mixture ratio of the mixed gases, and can be finely adjusted by adjusting the coupling area (namely the coupling volume) between the outer layer of gas and the metal of the molten pool, thereby playing the role of precisely controlling the forming and quality of the welding seams.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

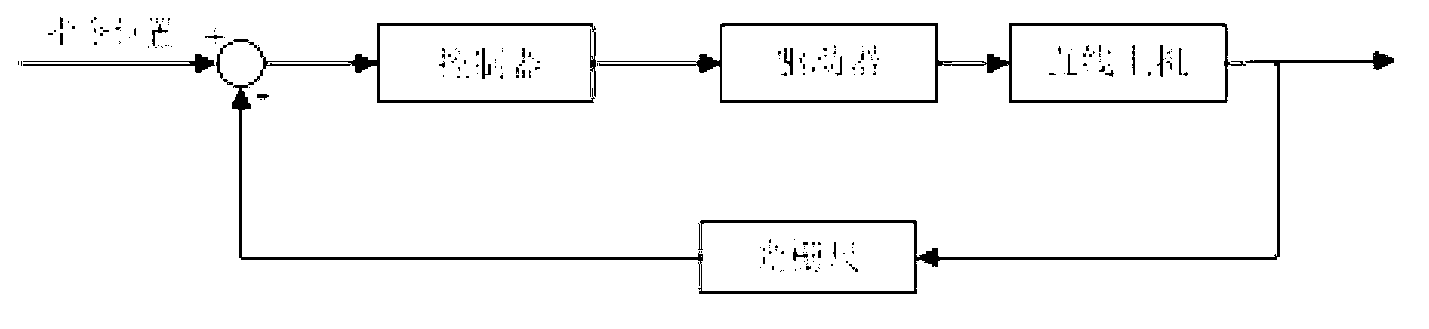

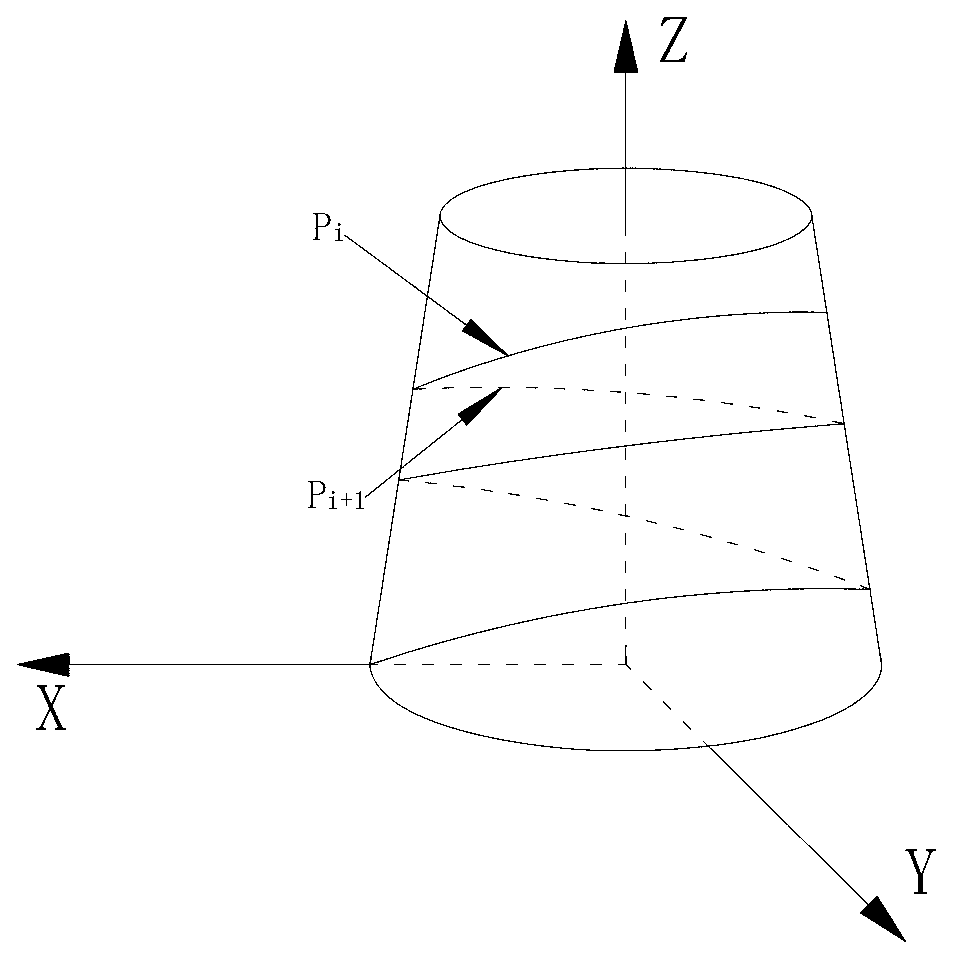

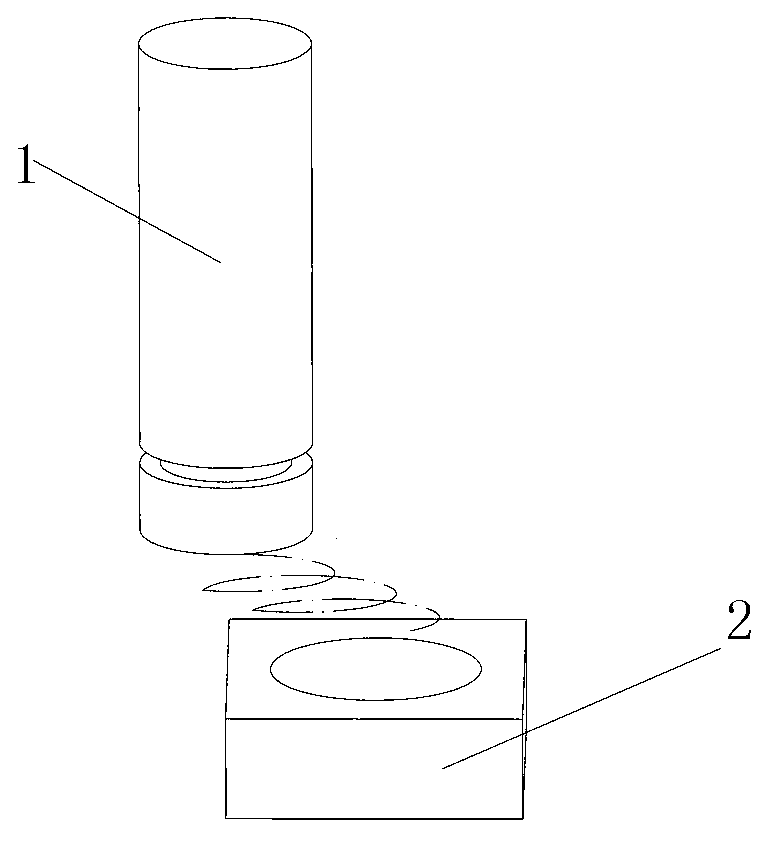

Three-dimensional cone interpolation method for electric sparkle forming processing

InactiveCN103056460AAvoid interferenceRealize 3D reversible interpolationNumerical controlEngineering

The invention discloses a processing method for a numerical control machine tool of an electric sparkle forming machine. When an X axis and a Y axis shake, a processing electrode of a Z axis feeds or rolls back with certain speed in the vertical direction to replace traditional interpolation, namely the Z axis firstly moves to the given circle center position, and then the X axis and the Y axis move along a horizontal track. Therefore, due to the three-dimensional shaking feeding or rolling back during processing, discharging of processing scraps can be facilitated, and processing accuracy is further improved.

Owner:ZHEJIANG UNIV +1

Novel air conditioner pipeline perforating device

InactiveCN105618858AAvoid processShorten production hoursLarge fixed membersPunchingDrilling machines

The invention discloses a novel air conditioner pipeline perforating device which comprises a cutting assembly, a punching assembly, a support assembly and a perforating tool, wherein the cutting assembly comprises a clamping cylinder, a cylinder seat, a support shaft, a connecting shaft sleeve, a clamping seat and a tool bit assembly; the clamping cylinder is fixed on the support shaft by the cylinder seat and connects the clamping seat with the tool bit assembly by the connecting shaft sleeve; the other end of the support shaft is fixed with the support assembly for connection; the punching assembly comprises a top punching cylinder and a punching device; the punching device is fixed on the support assembly; and a blade on the tool bit assembly and a tool bit at the front end of the punching device both align with the pipeline perforating tool. The novel air conditioner pipeline perforating device avoids the procedures of chamfering and blowing-out of aluminium skimmings, caused by use of conventional drilling machines for perforating, and production hours are saved and quality risk is reduced.

Owner:HEFEI JIANGHUAI AUTOMOBILE PIPE

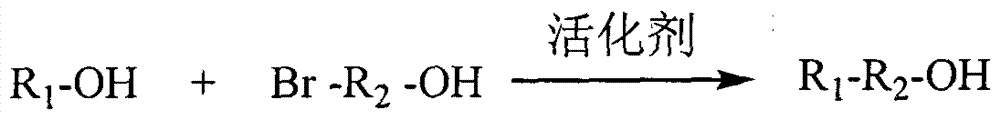

Multifunctional synergistic pharmaceutical composition based on adriamycin and construction method of multifunctional synergistic pharmaceutical composition

ActiveCN107952082ASmall particle sizeReduced stabilityHydroxy compound active ingredientsPeptide/protein ingredientsMicro environmentTumor cells

The invention relates to a multifunctional synergistic pharmaceutical composition based on adriamycin. According to the pharmaceutical composition, natural hydrophobic small molecules having a conjugated structure are covalently coupled with a polysaccharide skeleton to form an anti-angiogenesis drug, the anti-angiogenesis drug is physically mixed with the conjugated structure-modifying mitochondria damage peptide derivative and adriamycin, and the pharmaceutical composition of a nano size is assembled by virtue of various supramolecular driving forces. The pharmaceutical composition has the advantages of simultaneously regulating a tumor micro environment and tumor cells, reversing the anti-apoptosis characteristics of tumor cells, and maximizing the antitumor effect of the adriamycin. Inaddition, the multifunctional synergistic pharmaceutical composition has the advantages of the adriamycin such as high load, high stability and high targeting. The multifunctional synergistic pharmaceutical composition based on the adriamycin is compatible with corresponding medicinal auxiliary materials to prepare antitumoar drug preparations for injection, oral administration or external use. The multifunctional synergistic pharmaceutical composition is prepared by virtue of a multi-component supramolecular combination construction, so that the operation is simple, and the industrialized production is easy to realize.

Owner:CHINA PHARM UNIV

Manufacturing method of circuit board

InactiveCN108055784AAvoid thickness (tin thickness) deviationIncrease productivityConductive pattern reinforcementElectroless nickelCopper plating

The invention discloses a manufacturing method of a circuit board. According to the method, a positive process is adopted to manufacture an inner-layer circuit and / or an outer-layer circuit. The positive process includes the following steps that: a circuit pattern is formed on a circuit board through a film coating procedure, an exposure procedure and a developing procedure sequentially; copper isplated at the circuit pattern on the circuit board, so that an electroplated copper layer can be formed; electroless nickel treatment is performed, so that a nickel layer can be formed on the surfaceof the electroplated copper layer; and film removal and etching treatment are performed sequentially, the circuit is formed on the circuit board through etching. According to the manufacturing methodof the invention, conventional tin plating performed after copper plating is replaced by the electroless nickel treatment, so that the nickel layer with uniform thickness can be deposited through theelectroless nickel treatment after the copper is plated onto the outer-layer circuit pattern, and therefore, the deviation of protective layer thickness (tin thickness) caused by special pattern distribution can be completely avoided, and the problem of the film clamping of electrolytic tinning during circuit electroplating which is performed on the pattern can be solved, the scrap rate of the circuit board can be decreased, the cost production of the circuit board can be decreased, and the quality of the circuit board can be improved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH +1

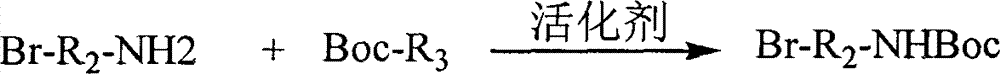

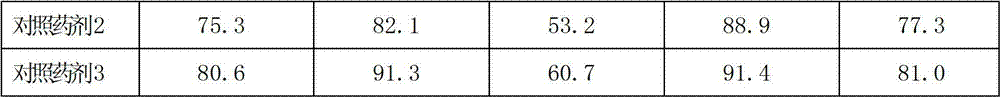

Paraquat water dispersible granules and preparation method thereof

ActiveCN102726398AChange the traditional dosage formIncrease the difficultyBiocideAnimal repellantsGas solidWater dispersible

The invention discloses paraquat water dispersible granules and a preparation method thereof. The paraquat water dispersible granules comprise 70-95% by mass of paraquat positive ions, preferably 80-95% by mass of paraquat positive ions. The preparation method of the paraquat water dispersible granules comprises the following steps of: mixing paraquat probe drug, dispersible wetting agent, filling agent, binding agent and other auxiliaries, and mixing mixture with water to obtain suspension or aqueous solution; and carrying out spray drying, pelleting and gas-solid separation on the suspension or aqueous solution, and packaging, so as to obtain the paraquat water dispersible granule product. According to the invention, paraquat is made into high-content water dispersible granules, and packaging cost and transportation cost can be effectively reduced, thus environmental protection performance and safety of each link from production to application are improved, and the paraquat water dispersible granules has obvious control effect on weeds compared with the conventional paraquat water aqua.

Owner:NANJING GAOZHENG AGROCHEM

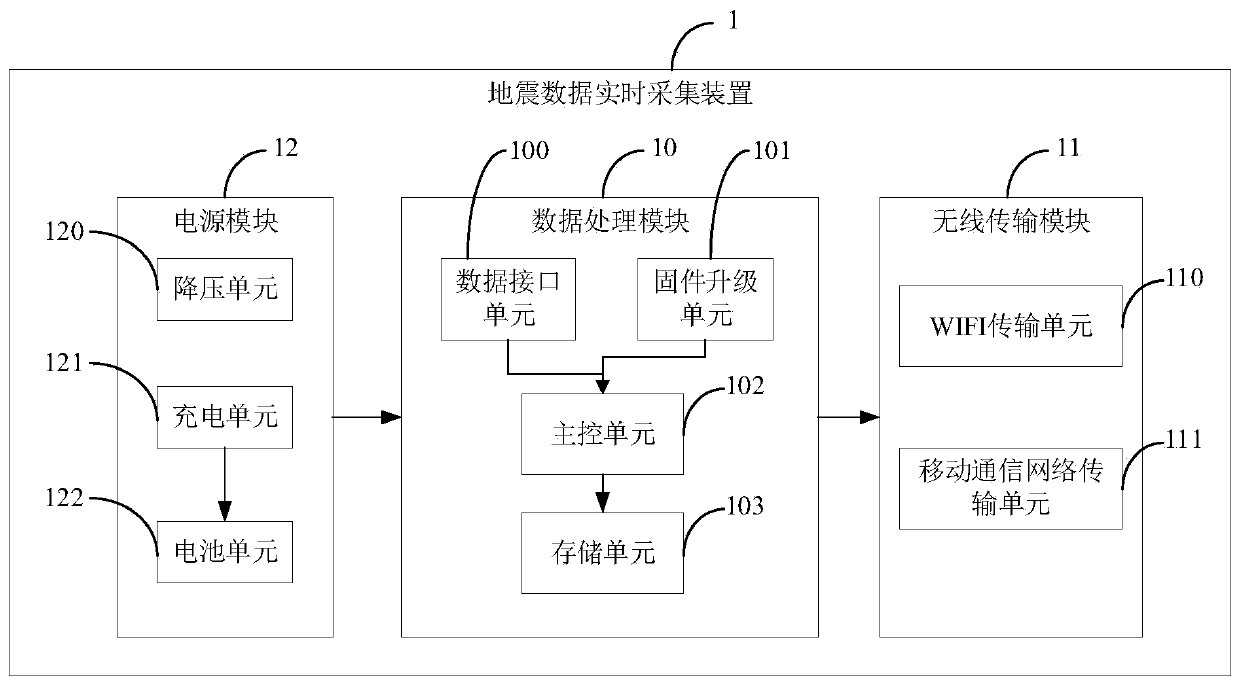

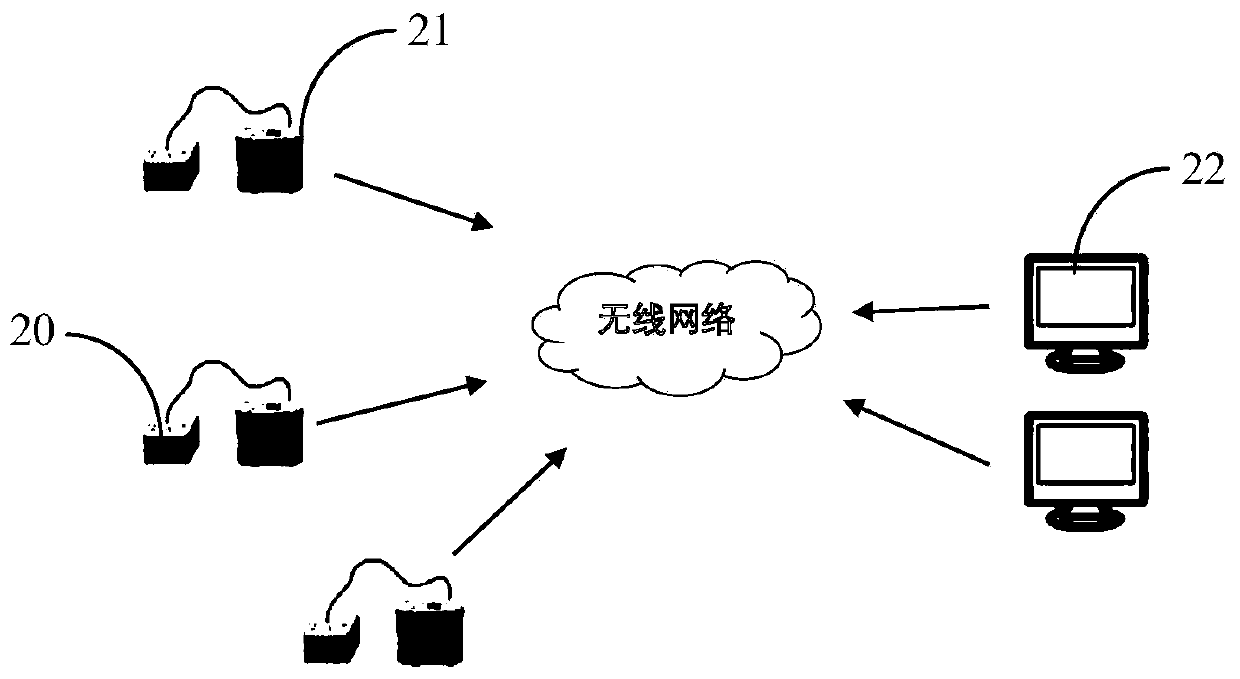

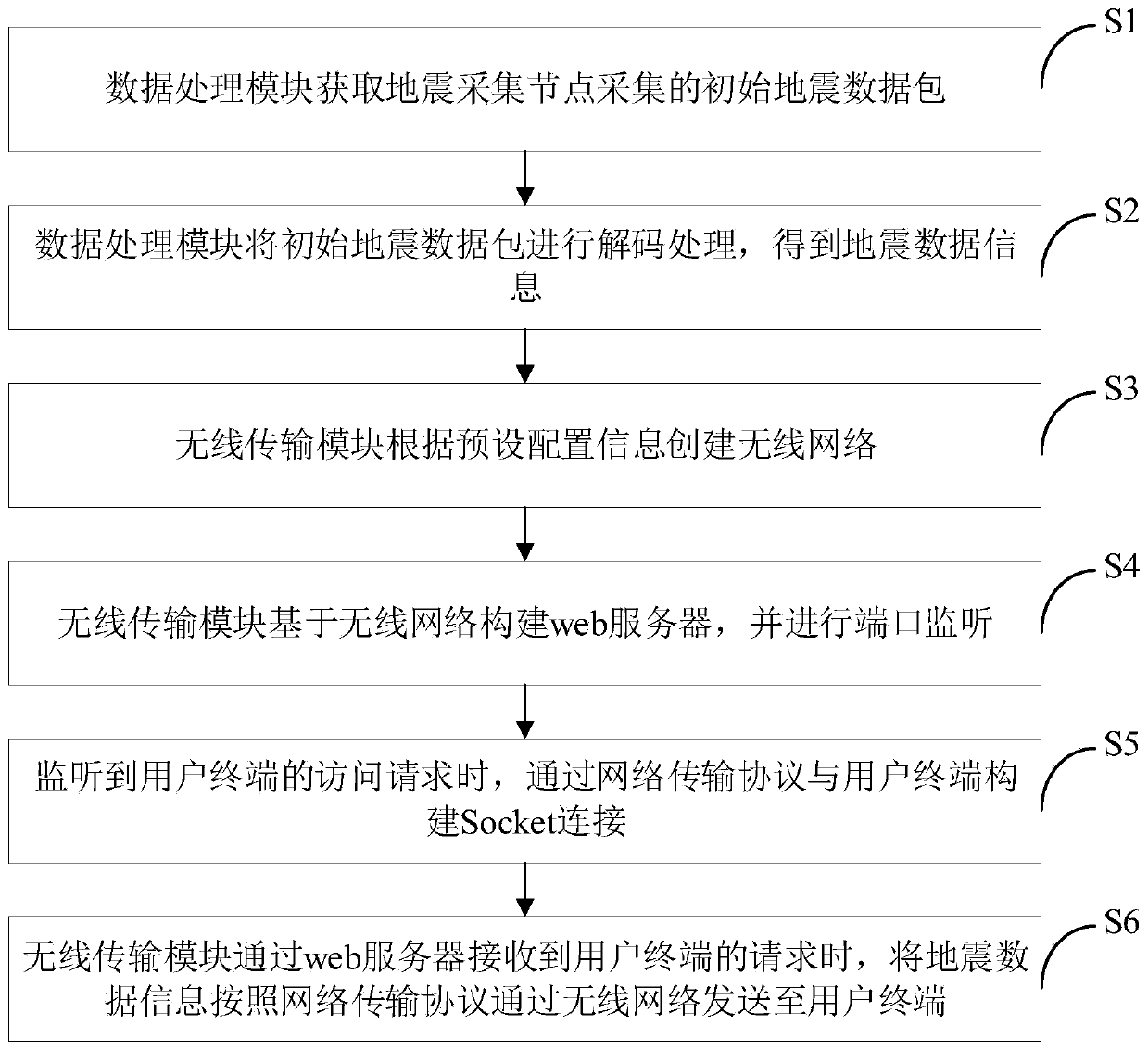

Seismic data real-time acquisition device, system and method

InactiveCN111123353ARealize data processing functionIncrease redundancySeismic signal transmissionSeismic signal recordingData packWireless transmission

The invention discloses a seismic data real-time acquisition device, system and method. The device comprises a data processing module for acquiring an initial seismic data packet from a preset seismicacquisition node, carrying out decoding and processing of the initial seismic data packet according to preset configuration information to obtain seismic data information, and storing the seismic data information and a wireless transmission module being electrically connected with the data processing module; a wireless network based on an HTTP protocol is established between a web server and a user terminal, and then seismic data information obtained through processing of the data processing module is sent to the user terminal through the wireless network. With the mode, the seismic data canbe transmitted to the user terminal in real time through the wireless network while original seismograph hardware facilities are not changed; and the data can be obtained without waiting for all the collected data to be finished, so that the requirement for obtaining the seismic signal collected data in the specific time period in time in engineering investigation is met.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Composite zinc alloy film coating process

InactiveCN103668071AHigh densityStrong metal feelingVacuum evaporation coatingSputtering coatingZinc alloysFilm coating

The invention discloses a composite zinc alloy film coating process, and belongs to the technical field of surface treatment. The process sequentially comprises the steps of substrate surface pre-treatment, surface spraying and curing, vacuum film coating and heat-curable coating spraying and curing, wherein the vacuum film coating step comprises magnetron sputtering nickel plating, magnetron sputtering-ion plating mixed nickel-chromium plating and cathodic arc ion chromium-plating. According to the process, a heavy polishing procedure is eliminated, the process flow is simplified, the production efficiency is improved, and the labor intensity of a worker is reduced; in addition, a magnetron sputtering-ion plating mixed film coating technology is adopted, and an obtained product is high in film layer density and highly metallic; moreover, a metal layer and a metal mixed coating are prepared in the same vacuum furnace, so that the process is easy to operate, high bonding force of a film layer is ensured, and the quality of the product is improved.

Owner:WUXI HUIMING ELECTRONICS TECH

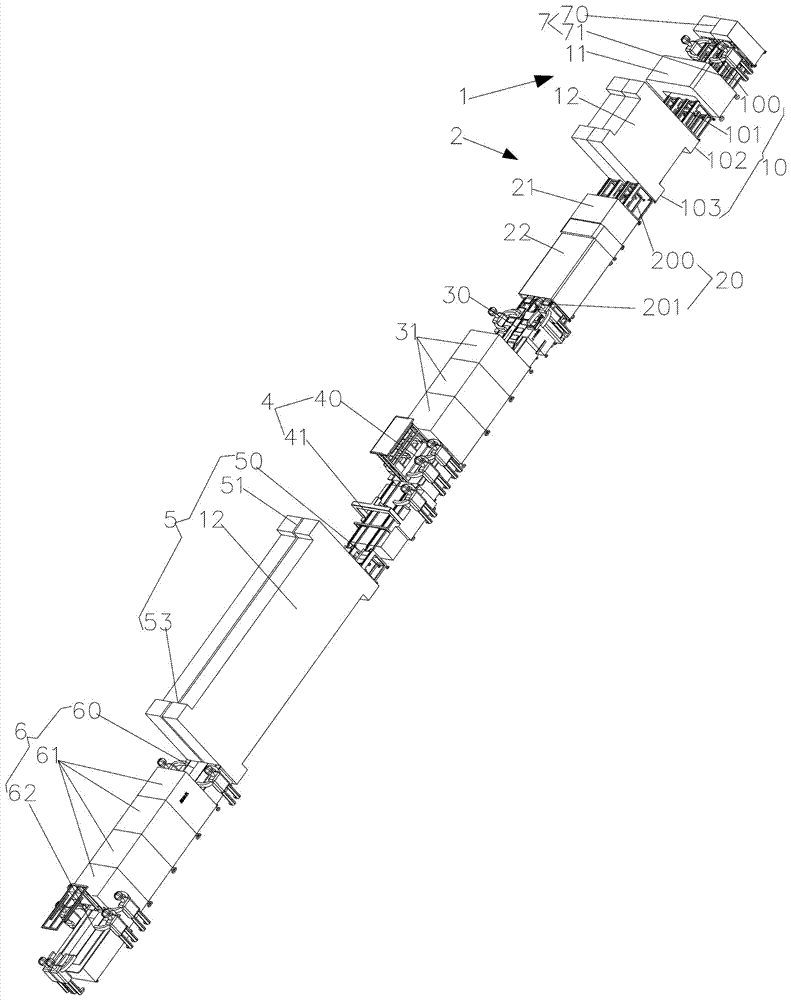

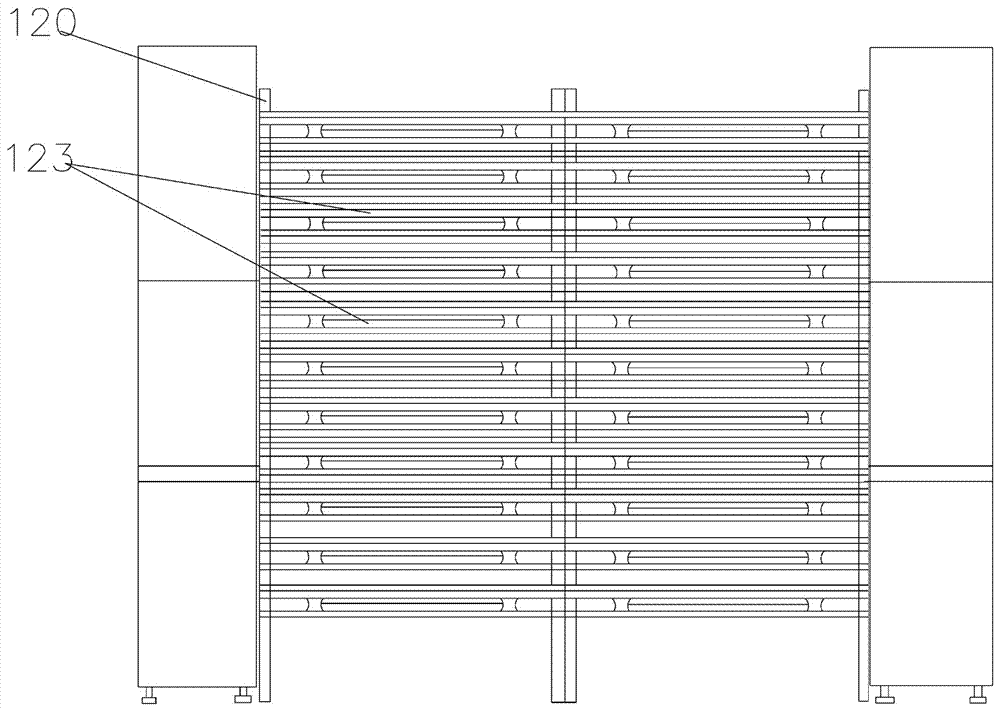

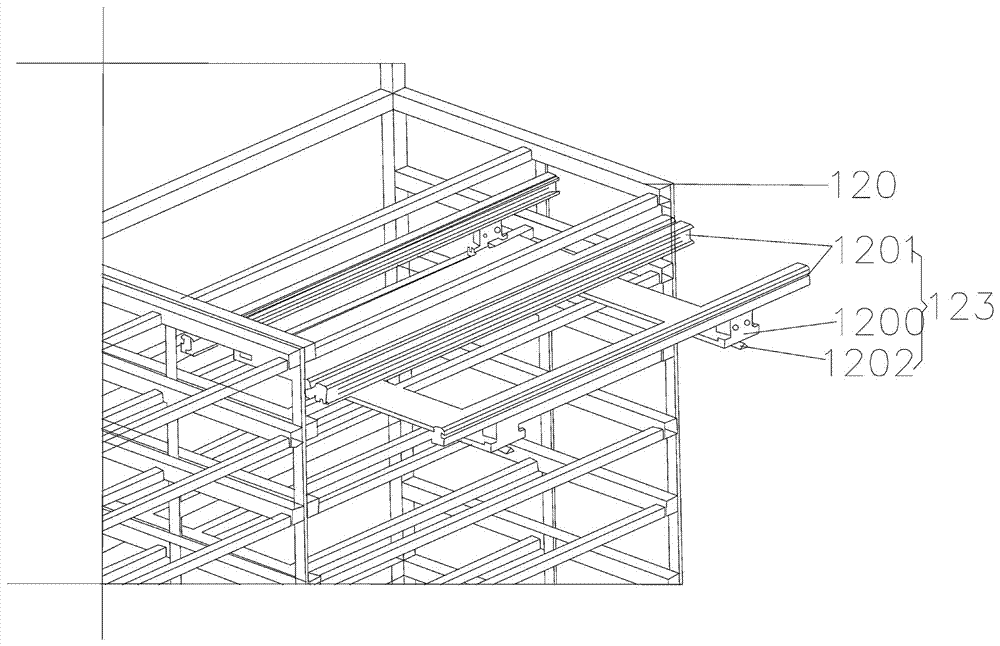

Double-rail assembly line and production technology thereof

PendingCN107016939AReduce labor intensityQuality improvementIdentification meansLacquerAssembly line

The invention provides a double-rail assembly line and a production technology thereof. According to the double-rail assembly line and the production technology thereof, past semi-automated production equipment is replaced by adopting automated mechanical production equipment, and three three-resisting lacquer spraying processes and an LED module glue filling and drying technology are integrated in one assembly line, so that human involvement is greatly reduced, the labor intensity of operators is reduced, the production cost is lowered, and the production efficiency and the product quality are improved. The assembly line comprises an LED circuit board three-resisting lacquer spraying unit and an LED module glue filling unit which are connected with each other; the LED circuit board three-resisting lacquer spraying unit comprises a three-resisting lacquer dotting module, a three-resisting lacquer spraying module and a bottom shell screw locking module which are in connection in sequence; the LED module glue filling unit comprises a glue filling module, a drying module and a mask screw locking module; the bottom shell screw locking module is connected with the glue filling module.

Owner:FUJIAN QIANGLI PHOTOELECTRICITY

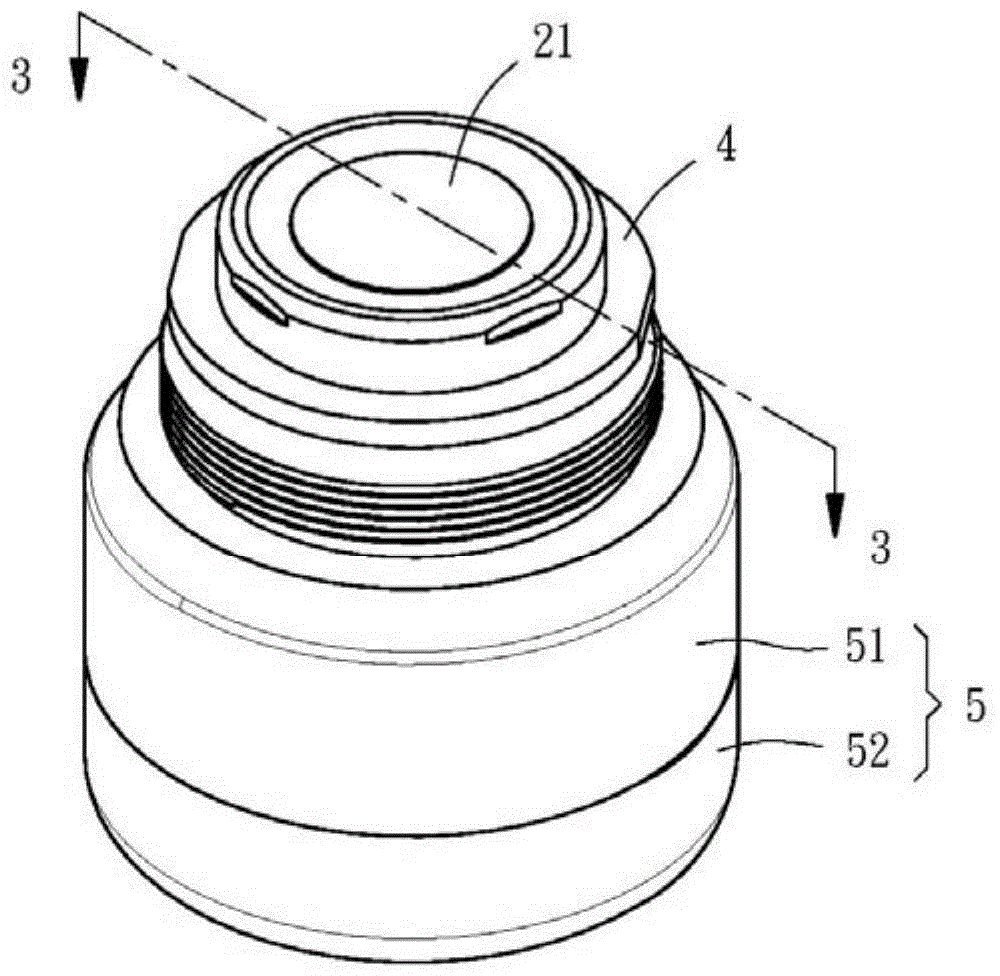

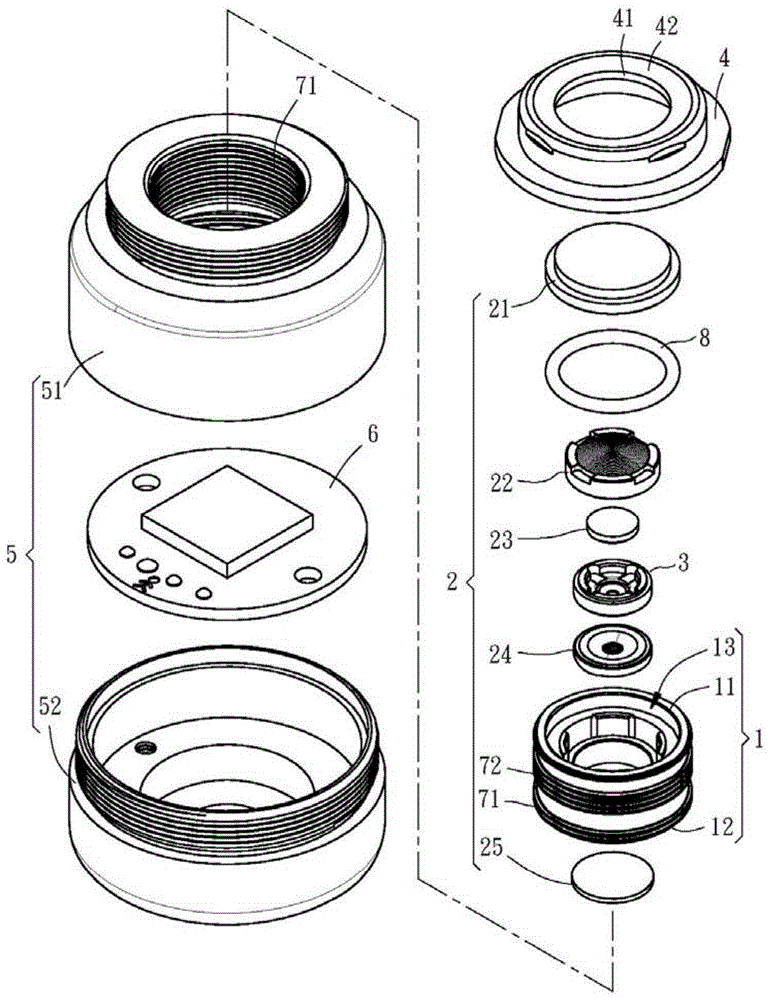

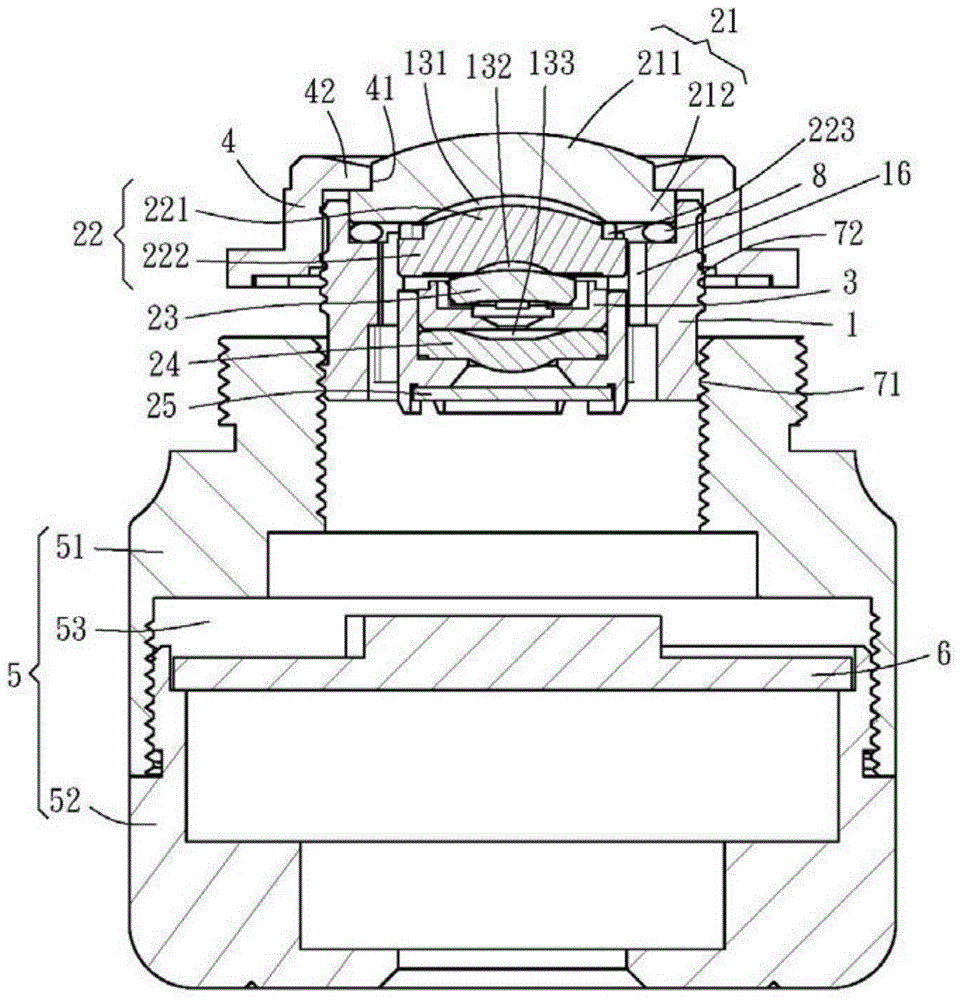

Dewing rapid dissipating lens module

A dewing rapid dissipating lens module of the present invention comprises a lens cone, a lens group, a limiting member and a module base. A plurality of ventilation grooves are arranged in the lens cone, the module base is equipped with an accommodating chamber, and the lens group is equipped with at least two lenses, wherein one lens is equipped with a plurality of air discharge ducts at the periphery, and the air discharge ducts are distributed annularly and at intervals. The limiting member limits the lens group to be positioned at the lens cone, and the limiting member, one lens and the module base enclose the two ends of the lens cone separately to form an enclosed system in which the other lenses of the lens group are enclosed. A light path space is formed between the two lenses, so that the air discharge ducts are communicated with each other via the light path space, and the ventilation grooves are communicated with the air discharge ducts and the accommodating chamber, and accordingly, the accommodating chamber, the light path space, the air discharge ducts and the ventilation grooves jointly form an internal circulation channel for moisture dissipation.

Owner:H P B OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com