Hooped steel reinforced concrete beam-column joint of core area U-shaped column

A technology of beam-column joints and concrete, which is applied in the direction of architecture and building construction, can solve the problems of component fabrication and construction inconvenience, and achieve the effect of saving construction period and reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

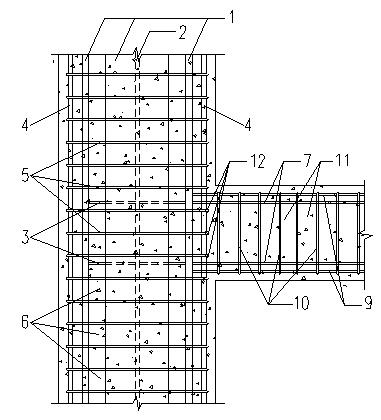

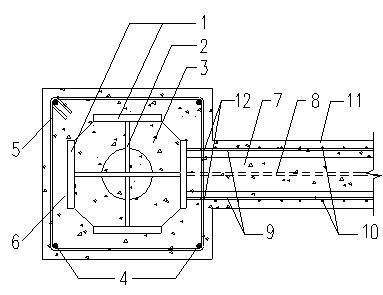

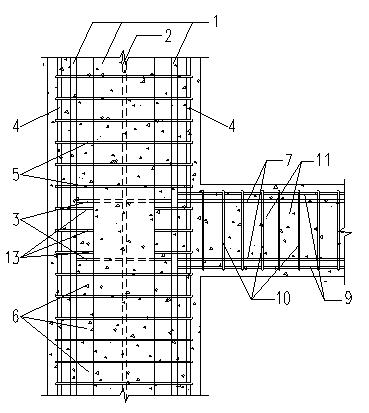

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] The invention solves the problem of inconvenience caused to component manufacture and construction by opening holes on the web plate of the shaped steel beam in order to allow the column stirrup to pass through the traditional shaped steel concrete beam-column joint. The steel concrete beam-column joint with U-shaped column stirrups in the core area is a special form of the beam-column joint of the steel concrete structure. The core area of the joint uses U-shaped stirrups 13 instead of the original closed stirrups 5, see attached image 3 -4. At the same time, there is no need to open column stirrup through holes 12 on the beam-shaped steel web, and it is suitable as a structural form of beam-column joints of high-rise and super high-rise buildings.

[0019] The present invention as image 3 As shown in -4, it consists of column-shaped steel flange plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com